Method for preparing metal material EBSD (electron backscatter diffraction) sample on basis of ultra-low temperature weak current control

A sample preparation and metal material technology, applied in the analysis of materials, material analysis using wave/particle radiation, measuring devices, etc., can solve the unfavorable application and development of EBSD technology, the ecological environment hazards of scientific research workers, and increase the input of manpower and material resources and other problems, to achieve the effect of flat and bright sample surface, good polishing effect and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

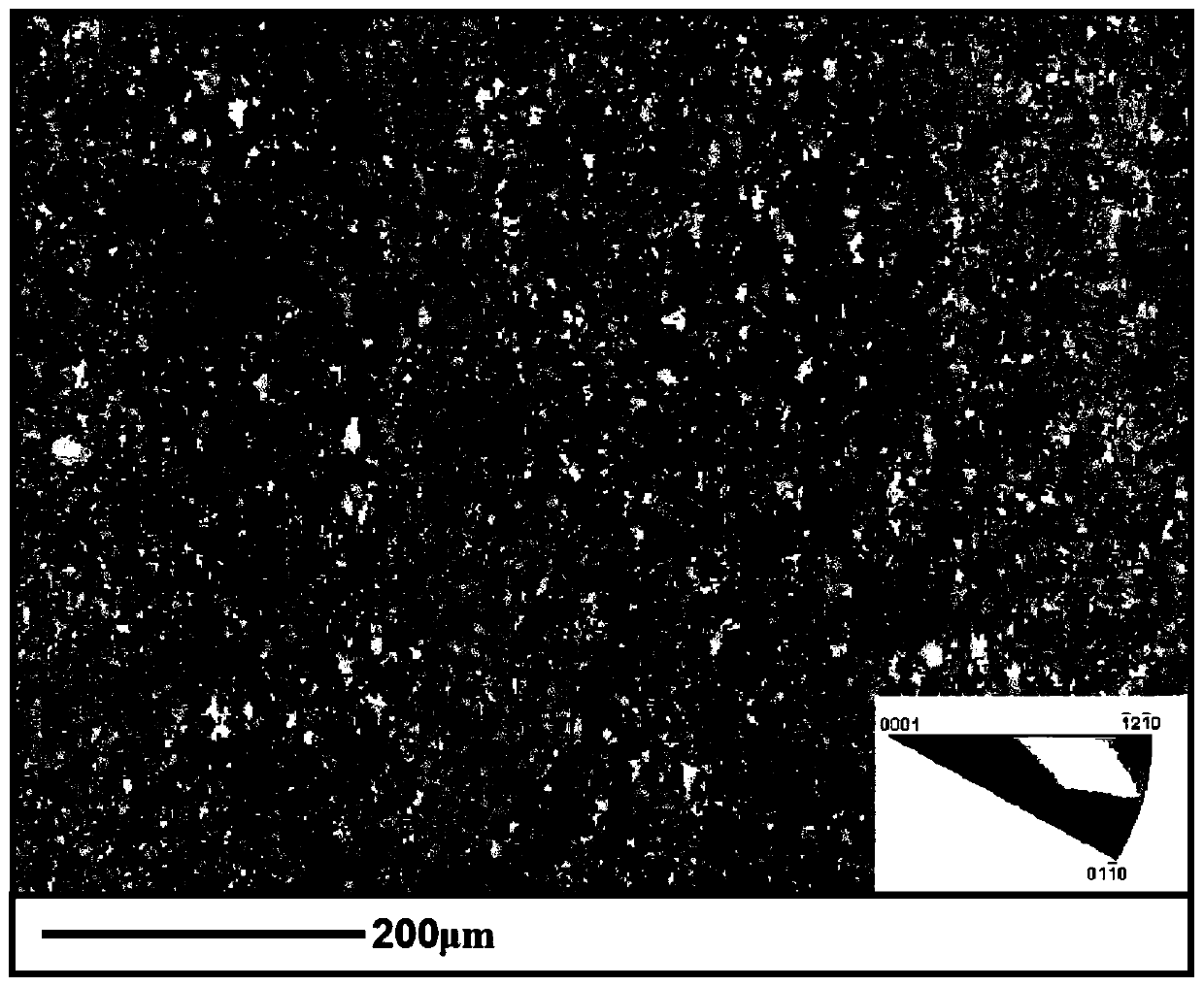

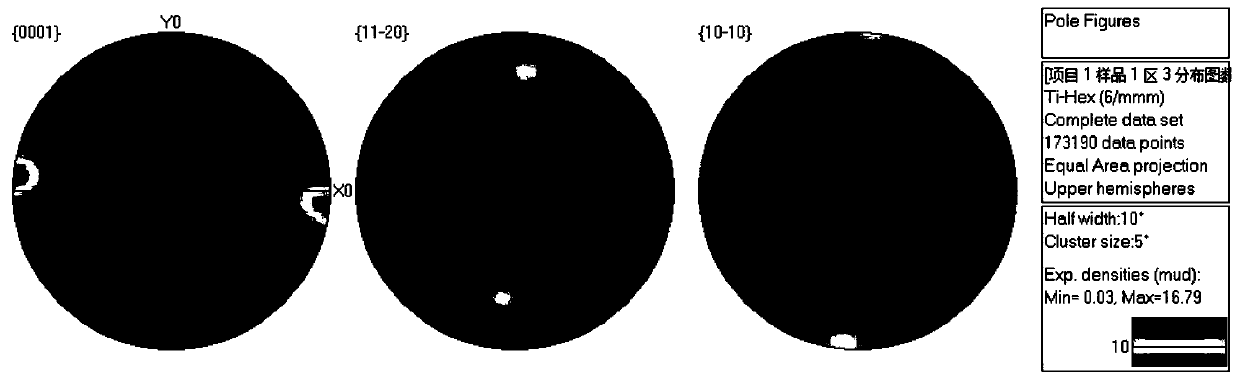

[0035] What adopted in the present embodiment is the rolled state TC4 (Ti-6Al-4V) rod, and adopts a kind of ultra-low temperature, weak current control metal material EBSD sample preparation method of the present invention, specifically comprises the following steps:

[0036] (1) Sample preparation

[0037] Cut a cylindrical EBSD sample with a wire, first clean the oil on the surface of the sample with alcohol, and use 150#, 320#, 800#, 2000# sandpaper to pre-grind the surface of the sample to remove defects such as the oxide layer on the surface of the sample, and then Metallographic treatment was carried out on the test surface, and mechanical polishing was carried out. Finally, the sample was fully washed in alcohol and dried for later use.

[0038] (2) Electropolishing test preparation

[0039] According to 10% perchloric acid and 90% absolute ethanol, 500ml of electrolyte solution was prepared, and an electrolytic polishing test platform was set up. to 60V, the specimen...

Embodiment 2

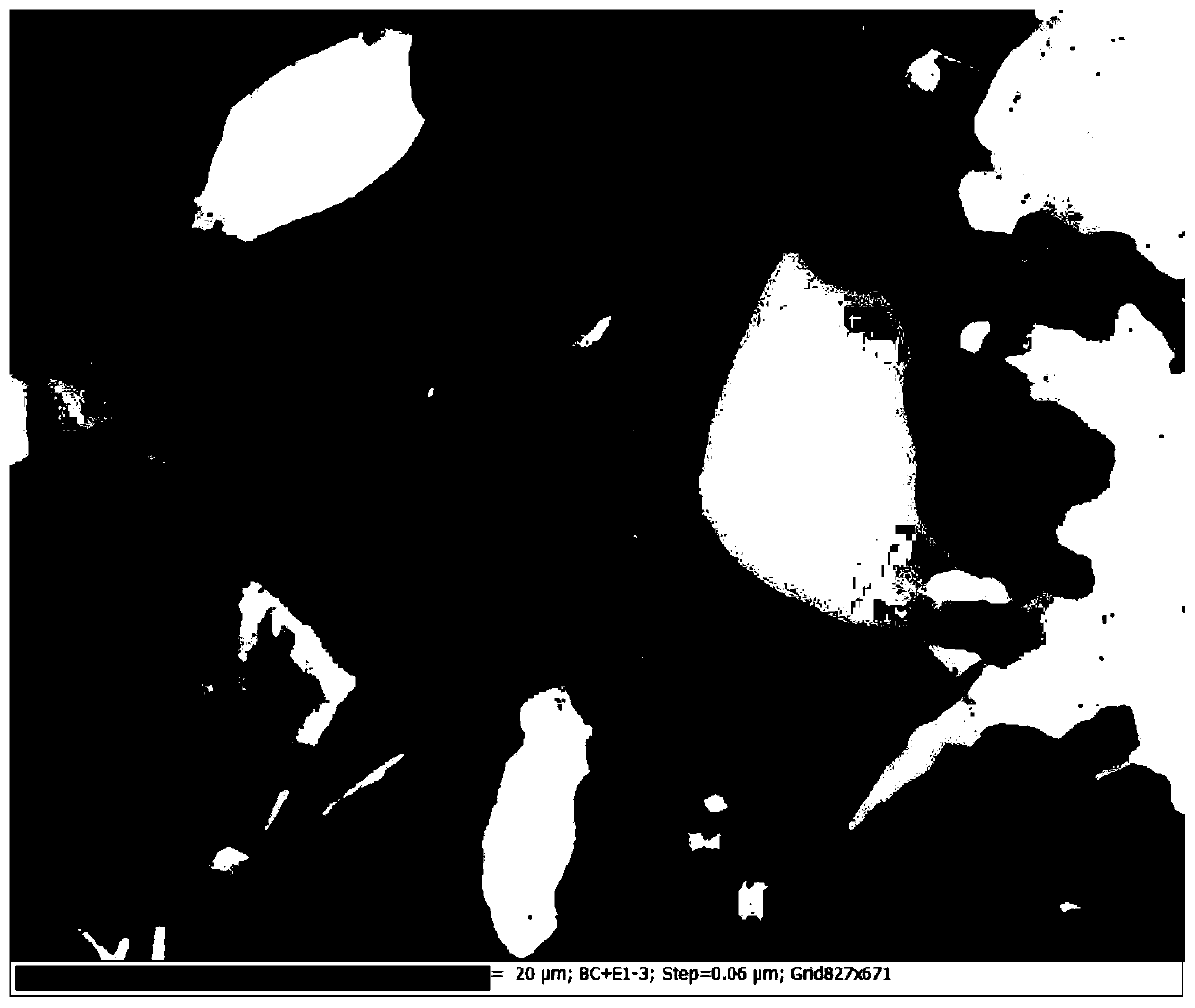

[0046] In this embodiment, the forged Zircaloy-4 alloy is used, and a sample preparation method for ultra-low temperature and weak current control metal material EBSD of the present invention is used to prepare a sample for analysis, which specifically includes the following steps:

[0047] (1) Sample preparation

[0048] A piece of EBSD sample was taken along the forging direction by wire cutting, and other steps were the same as step (1) of Example 1.

[0049] (2) Electropolishing test preparation

[0050] Prepare 500ml of electrolyte solution according to 8% perchloric acid and 92% absolute ethanol, set up an electrolytic polishing test platform, put the electrolytic polishing solution in a beaker, pour liquid nitrogen to cool the electrolytic polishing solution to about -120°C, turn on the power switch to 60V, the specimen is held in tweezers, ready for electropolishing.

[0051] (3) Electropolishing treatment and subsequent treatment

[0052] When the added liquid nitr...

Embodiment 3

[0057] Using an ultra-low temperature and weak current control metal material EBSD sample preparation method of the present invention to electropolish the rolled GH99 superalloy to prepare a sample for texture analysis, specifically includes the following steps:

[0058] (1) Sample preparation

[0059] Cut the bulk sample with a wire, and mark the sample RD, TD and ND directions. The surface of the sample is treated by pre-grinding with sandpaper to remove defects such as oil stains and oxide layers on the surface. Finally, carry out metallographic treatment on the observation surface, mechanically polish it, wash it with alcohol and blow dry it for later use.

[0060] (2) Electropolishing test preparation

[0061] According to 12% perchloric acid and 88% absolute ethanol, prepare 500ml of electrolyte solution, set up an electropolishing test platform, put the electrolytic polishing solution in a beaker, pour liquid nitrogen to cool the electrolytic polishing solution to abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com