Temperature control device of electric cooker

A technology for temperature control devices and rice cookers, applied in heating devices, temperature control, non-electric variable control, etc., can solve problems such as enlarged faults, short service life, and shortened service life of electric cookers, so as to avoid man-made damage , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

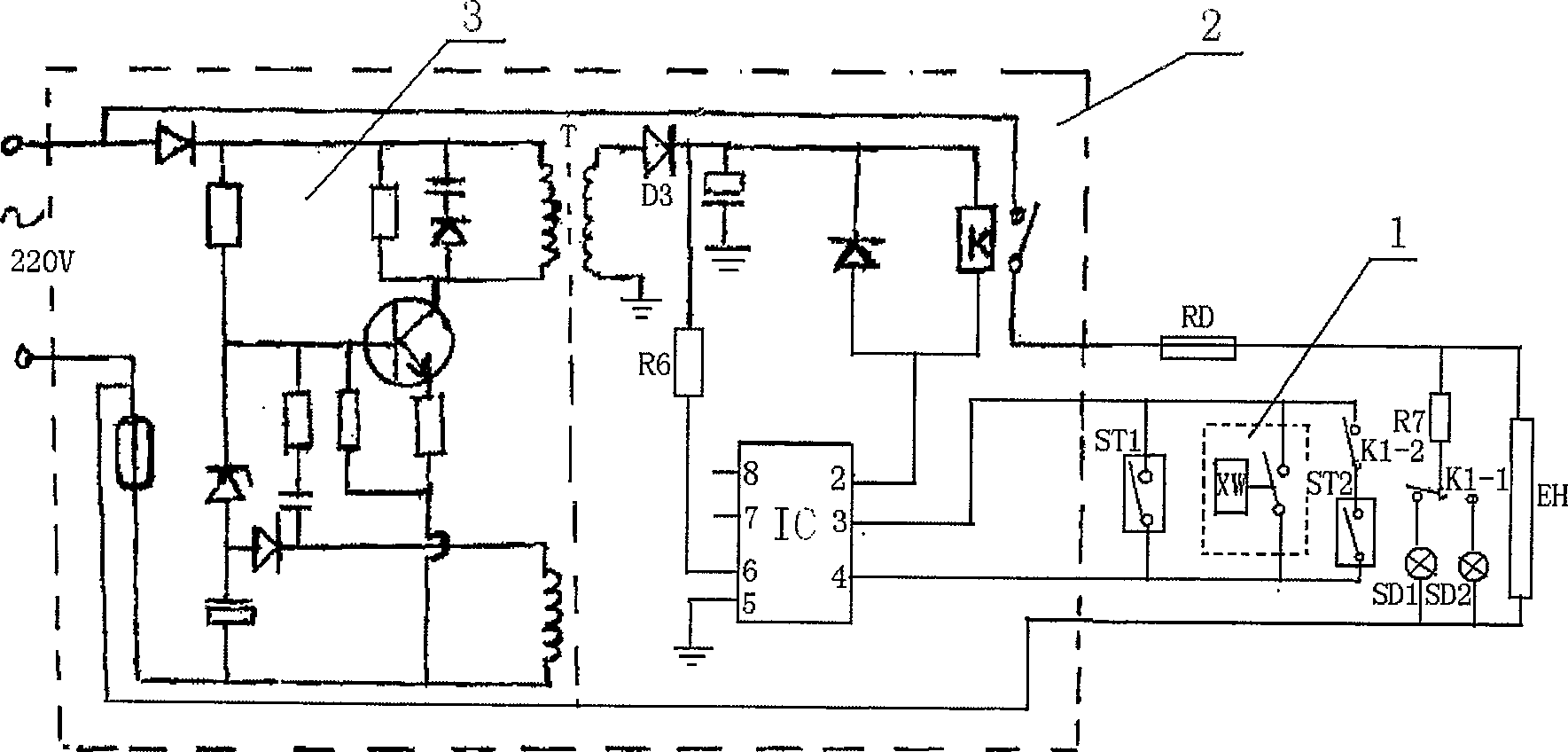

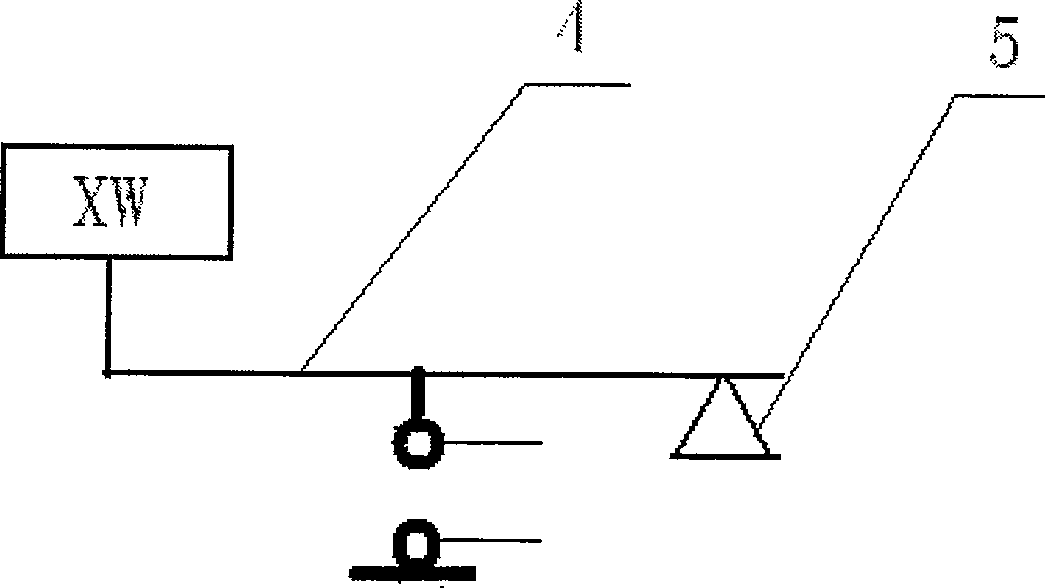

[0031] Such as figure 1 , figure 2 As shown, a temperature control device for an electric rice cooker includes, a power supply, a magnetic control switch 1 located in the pot, a heat preservation device connected in parallel with a group of contacts K-2 of the cooking and heat preservation switch K1 and the magnetic control switch 1 The device ST2 and the electric heating plate EH are located on the shell of the electric rice cooker and are provided with a controller 2 connected with the electric heating plate EH and the magnetic control switch 1 . Described controller 2 also can be located at the plug place of electric cooker power line. The controller 2 includes a power supply circuit 3, a transformer T, an integrated circuit IC, and a relay K. The power supply is connected to the primary phase of the transformer T through the power supply circuit 3. One end of the secondary side of the transformer T is grounded, and the other end is respectively connected to the relay thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com