Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101 results about "Hexachlorobenzene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

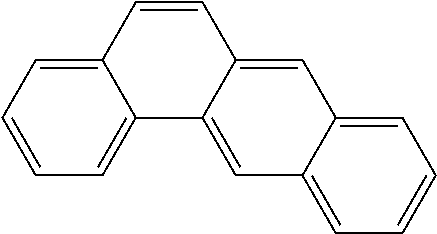

Hexachlorobenzene, or perchlorobenzene, is an organochloride with the molecular formula C₆Cl₆. It is a fungicide formerly used as a seed treatment, especially on wheat to control the fungal disease bunt. It has been banned globally under the Stockholm Convention on Persistent Organic Pollutants.

Preparation of graphene

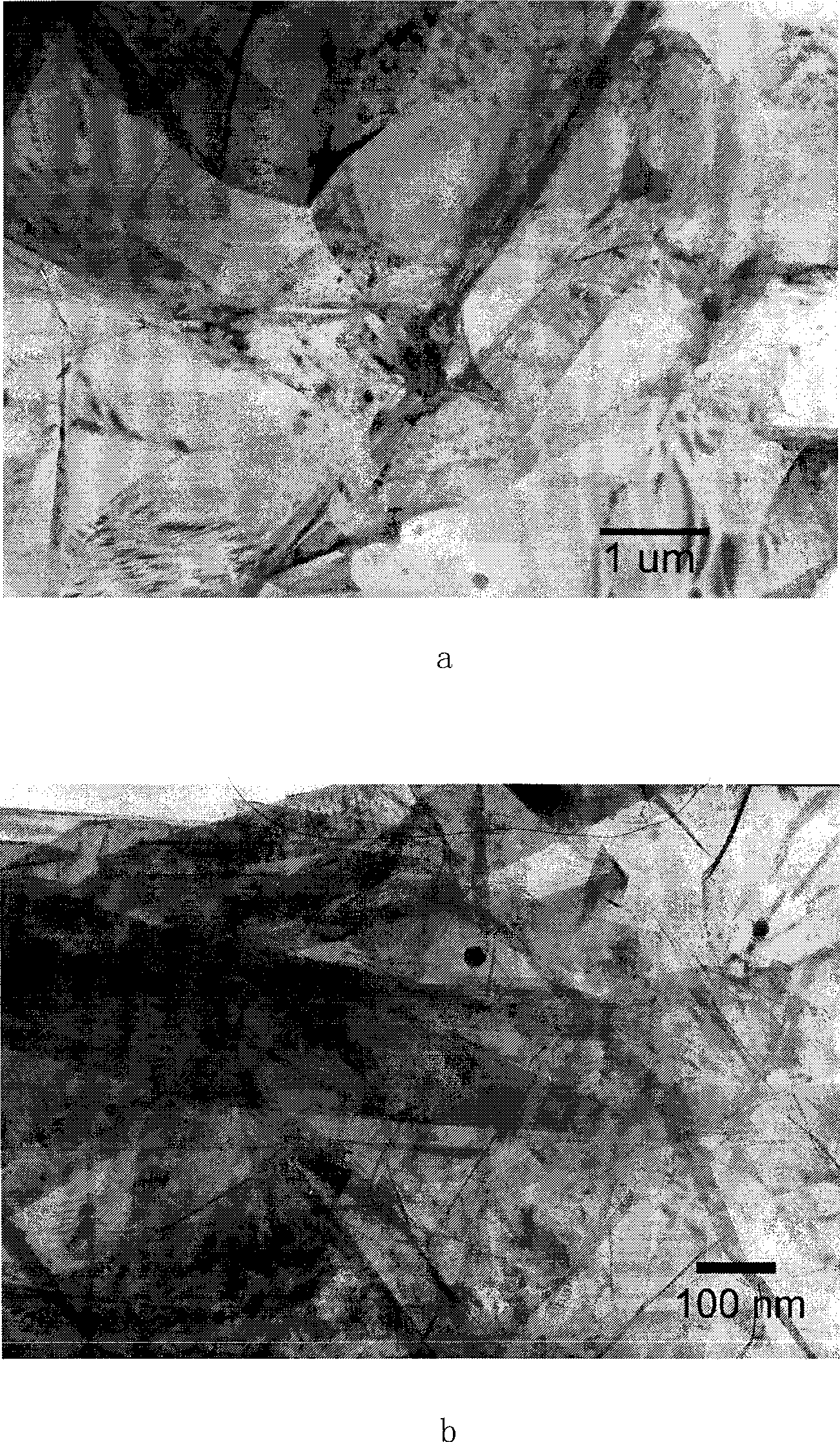

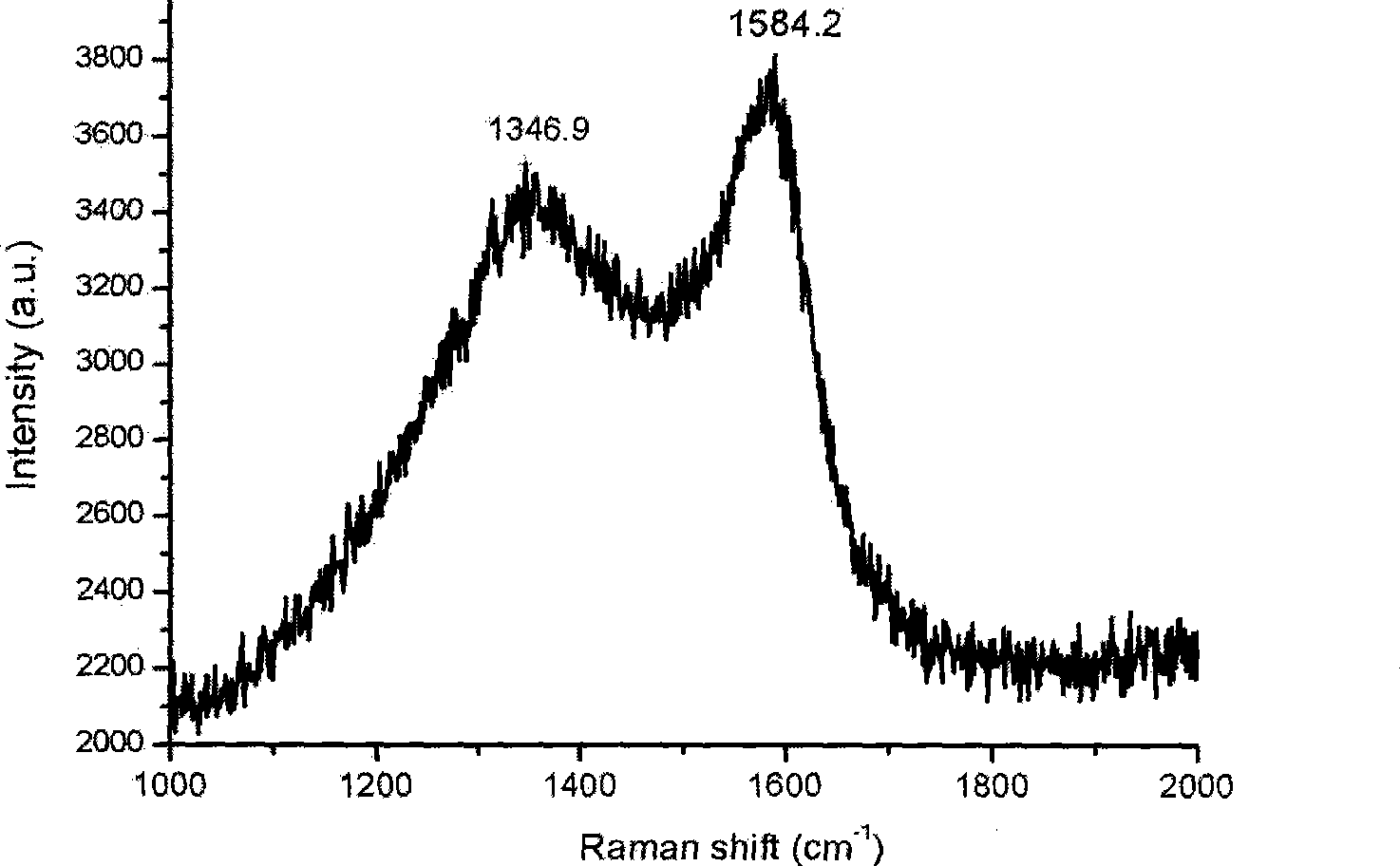

The invention discloses a method for preparing graphene, which belongs to the technical field of chemical synthesis. The method is characterized in that sodium metal and halogenated hydrocarbon are taken as raw materials to react in a solvent in inert atmosphere so as to prepare the grapheme; reaction temperature is preferably between 120 and 400 DEG C, and is more preferably between 160 and 360 DEG C; the molar ratio of the sodium metal to the halogenated hydrocarbon is preferably between 1:1 and 100:1, wherein the halogenated hydrocarbon can be added before reaction or during the reaction; and the halogenated hydrocarbon is preferably halogenated C1-4 aliphatic hydrocarbon and halogenated benzene, such as tetrachloroethylene, hexachlorobenzene, trichloroethylene, bromobenzene, ethylenetetrabromide and the like. The method also preferably performs post-treatment on the prepared graphene so as to improve purity. The method has the advantages of simple equipment, easy operation, low cost, high yield and good product properties, can play an important role in the industrial production of graphene and related products such as lithium ion batteries and the like, and is broad in application prospects.

Owner:PEKING UNIV

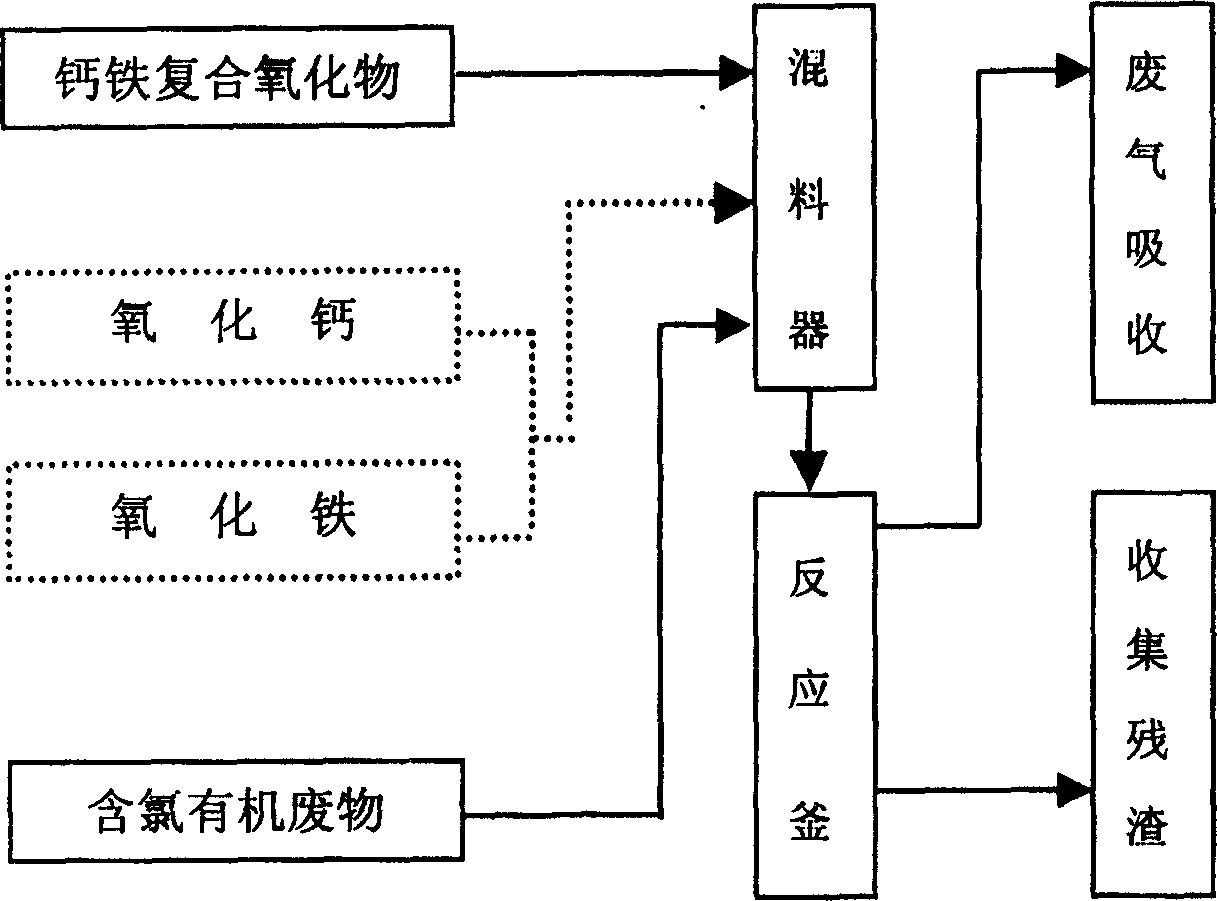

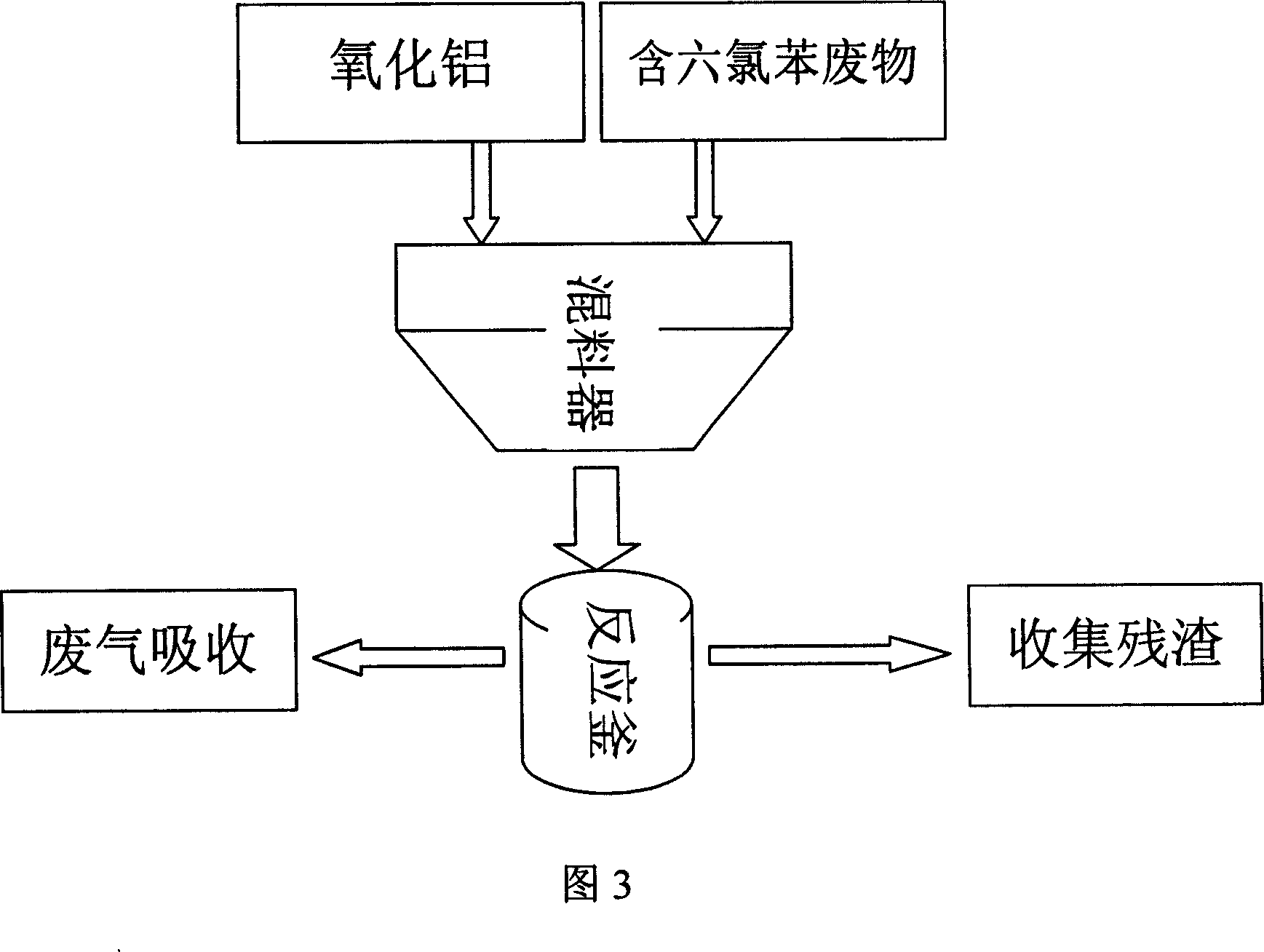

Method for dechloridizing organochloric compound

InactiveCN1539693AAchieve complete dechlorinationSolid waste disposalOrganic chemistry methodsCompound aOrganochloride

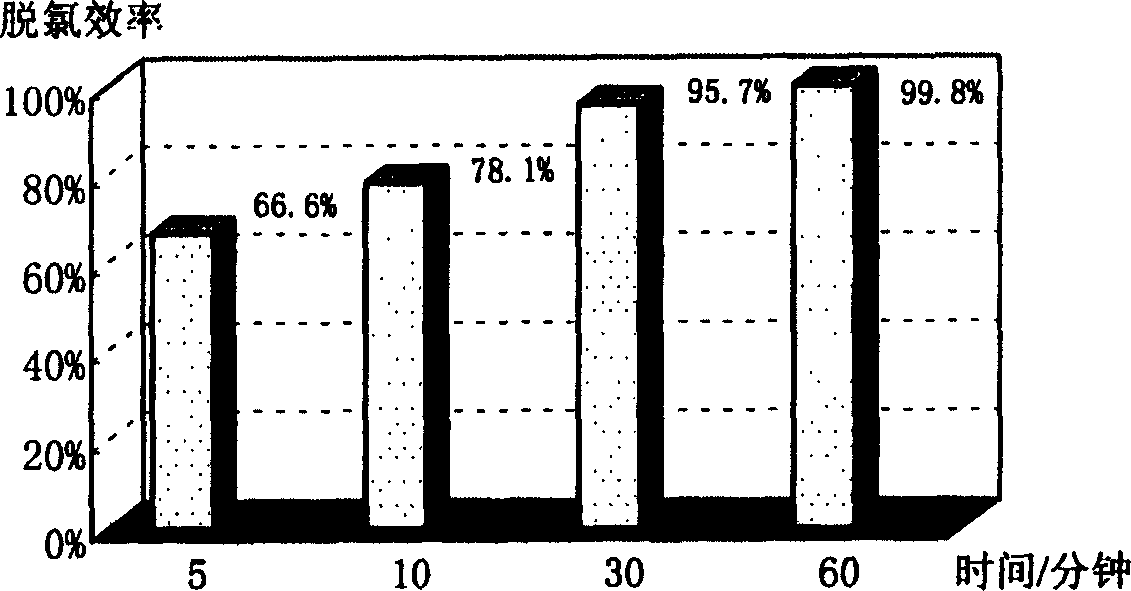

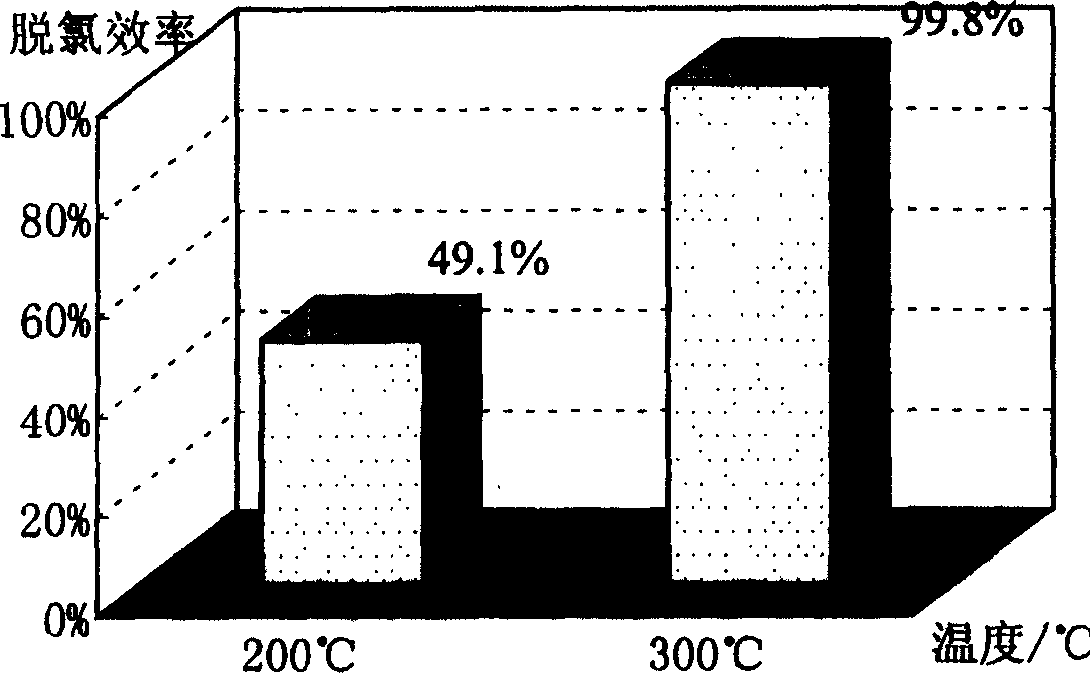

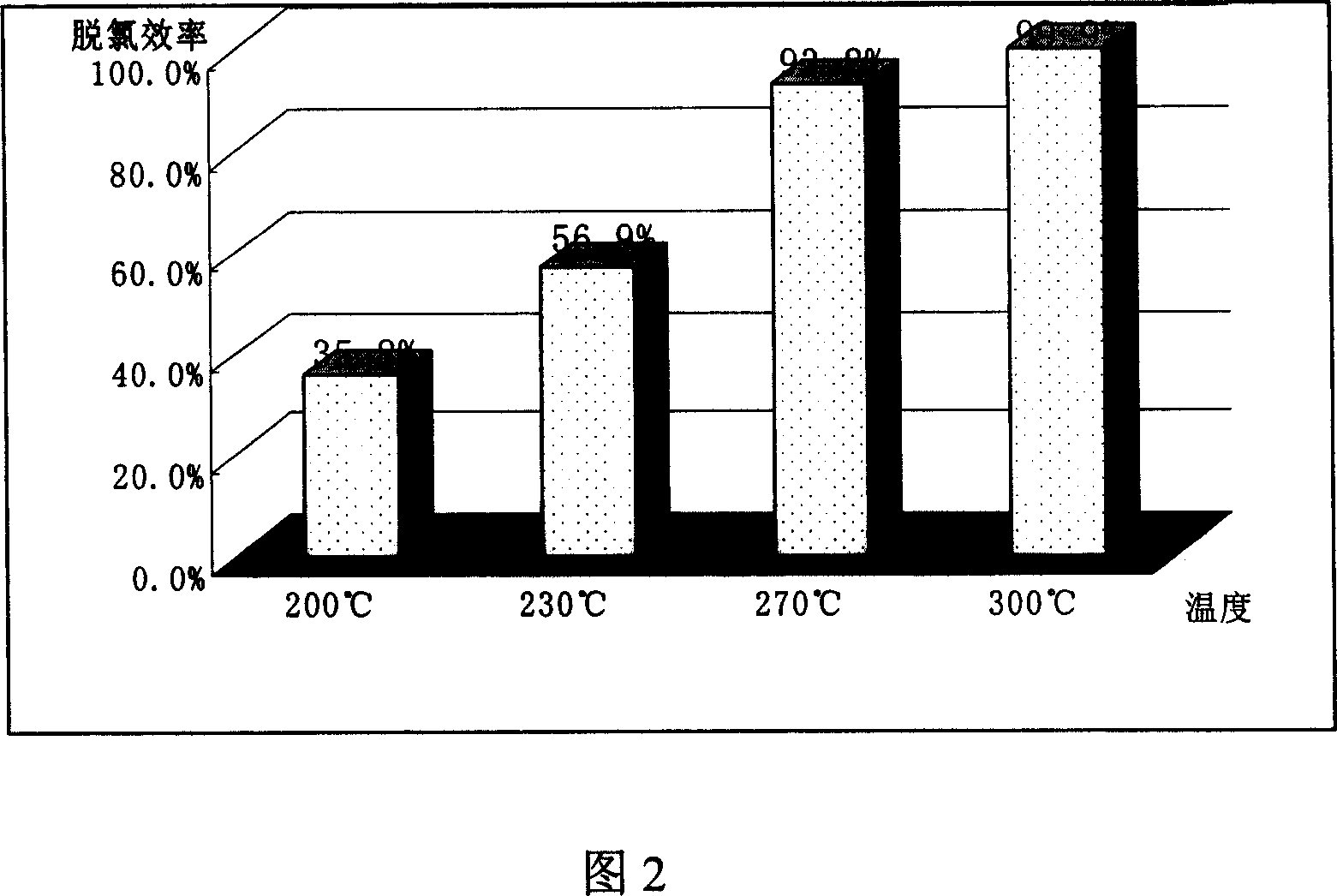

A process for dechlorinating the organic chlorine compound includes mixing the mixture of CaO and Fe2O3 or the composite oxide of Ca and Fe with said organic chlorine compound (hexachlorobenzene) in a sealed container, and reaction at temp higher than 200 deg.C

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

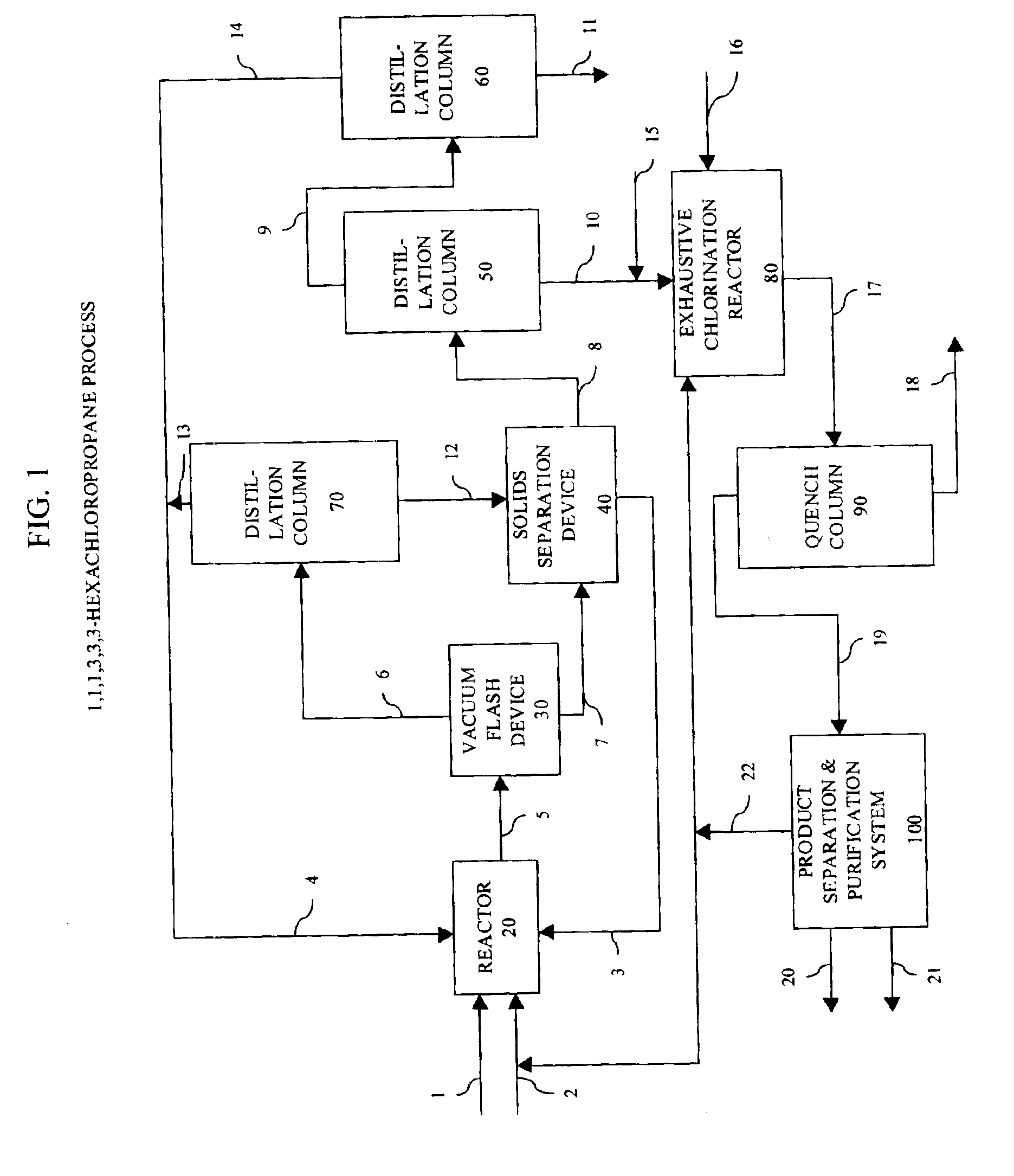

Method for reusing heavy end by-products in the manufacture of polychlorinated alkanes

ActiveUS7112709B2Efficient productionReduce the number of materialsHalogenated hydrocarbon separation/purificationPreparation by halogen additionAlkaneHexachlorobutadiene

A method for recovering much of the carbon and chlorine value in the heavy ends and other undesired by-products formed during the production of a C3 or higher polychlorinated alkane through the reaction of carbon tetrachloride with an olefine or chlorinated olefine, the improvement comprising the step of first separating the heavy ends and any other higher or lower boiling chlorohydrocarbon impurities from most of the desired product, and subjecting the separated heavy ends and impurities therewith to a high temperature exhaustive chlorination to produce carbon tetrachloride, tetrachloroethene, and minor amounts of hexachlorobutadiene and hexachlorobenzene by-products.

Owner:OCCIDENTAL CHEM CORP

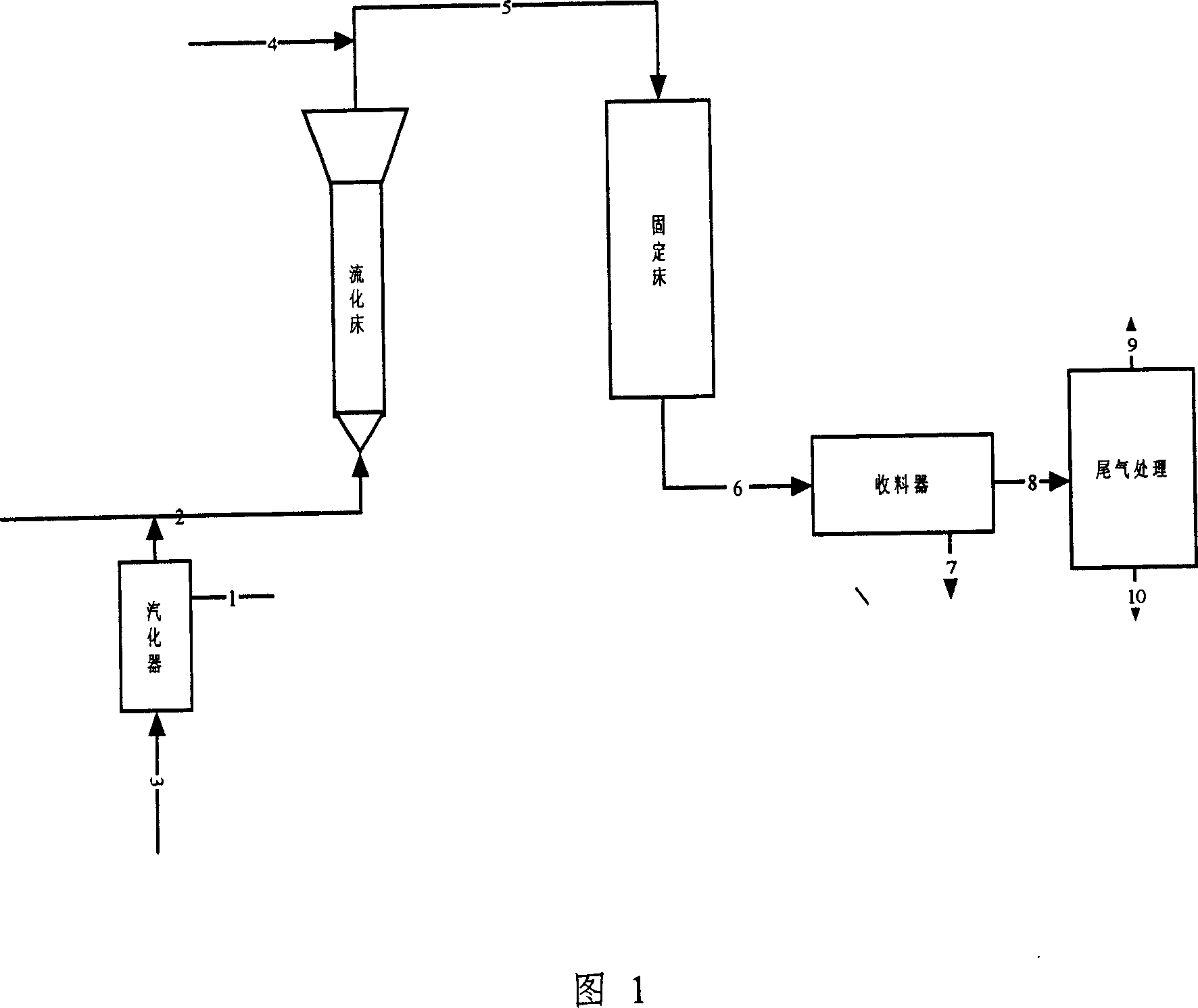

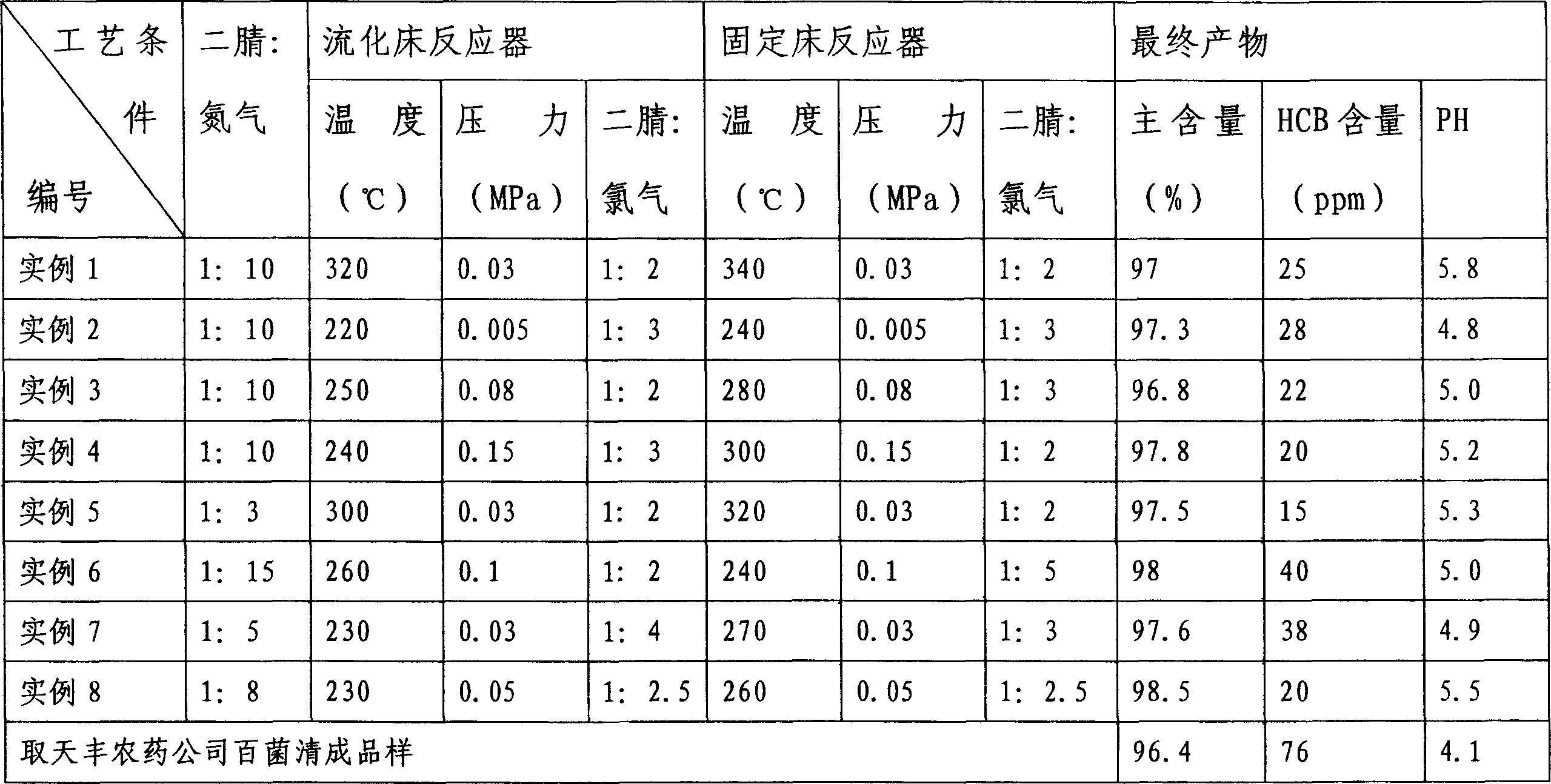

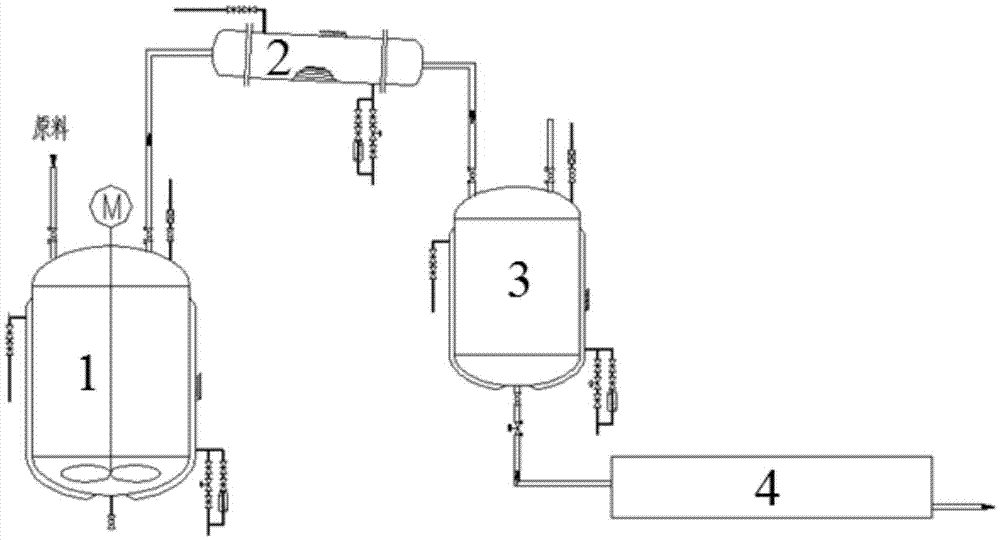

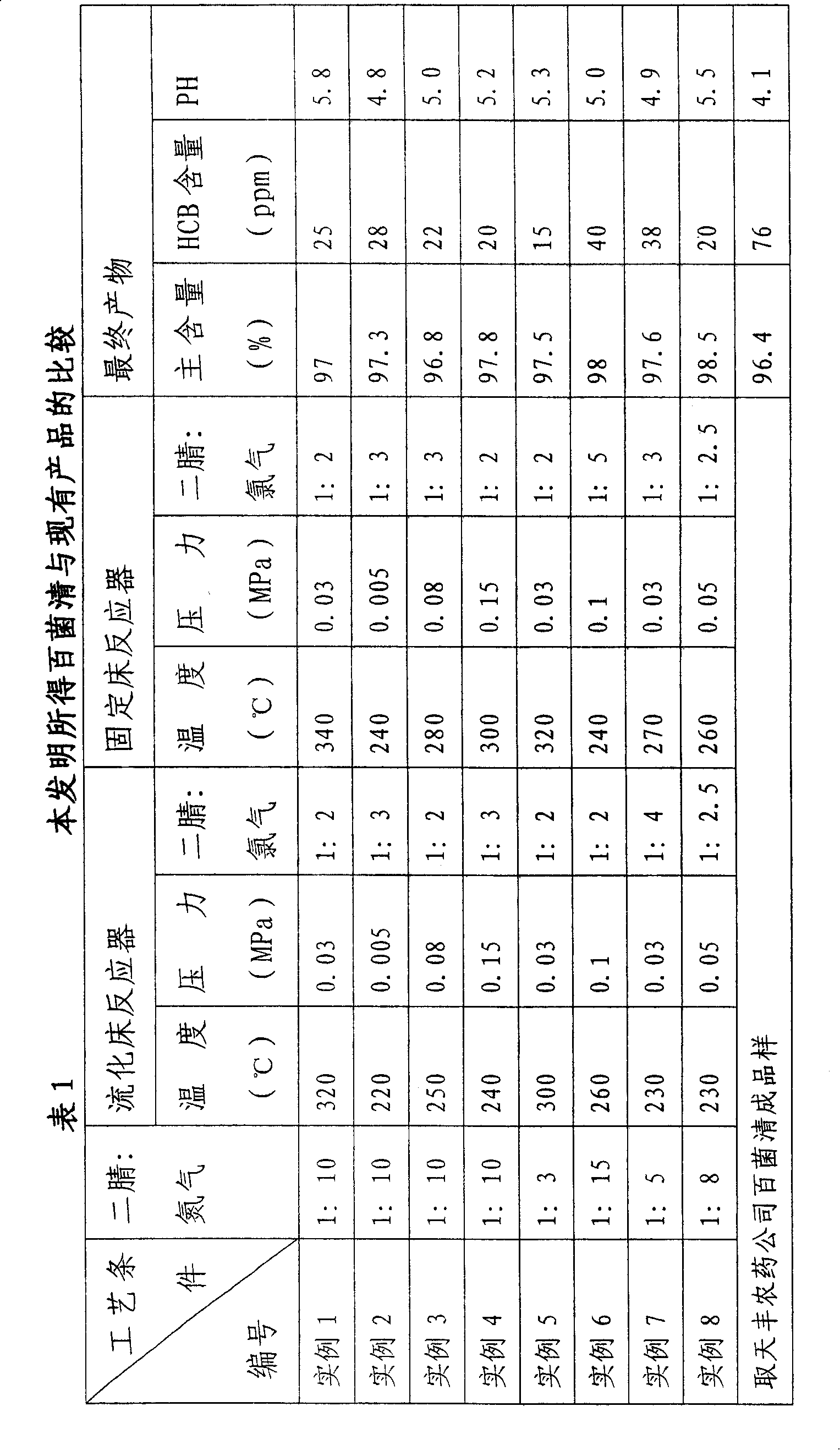

Production method of low hexachlorobenzene content chlorothalonil

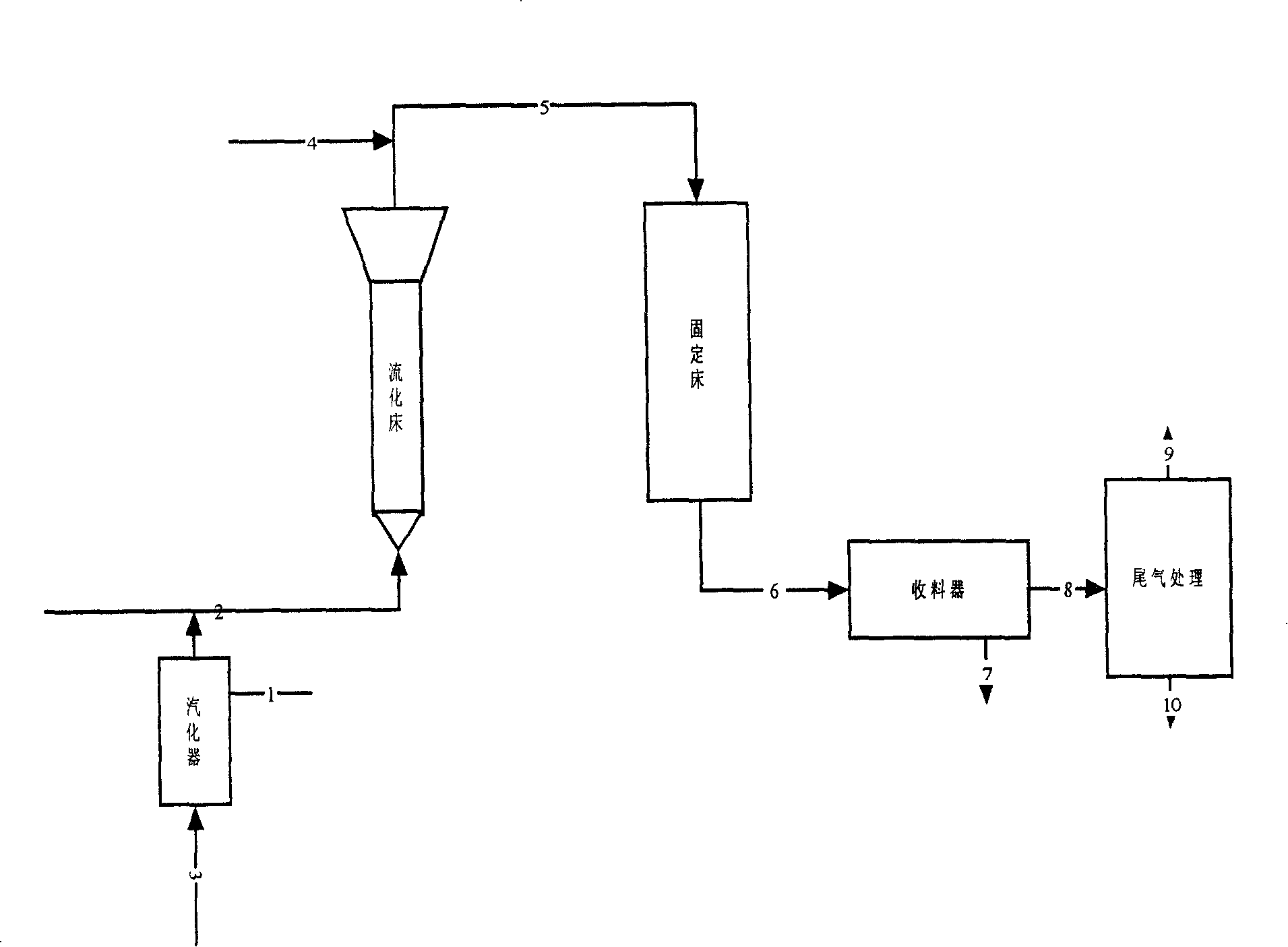

InactiveCN1948278AAdjust Reaction LoadImprove controllabilityBiocideCarboxylic acid nitrile preparationFluidized bedFixed bed

The present invention discloses a production method of chlorothalonil with low hexachlorobenzene content. Said production method includes the following steps: firstly, vapourizing m-dicyanobenzene, using nitrogen gas to carry out the vapourized m-dicyanobenzene from the vapourizer, making the vapourized m-dicyanobenzene be mixed with chlorine gas, and making them be fed into fluidized bed to make first-step reaction, making the reaction product be further mixed with chlorine gas and feeding them into fixed bed to make chlorination, condensing and collecting the outputted mixed gas so as to oblain the invented chlorothalonil product.

Owner:YUNNAN CHEM RES INST

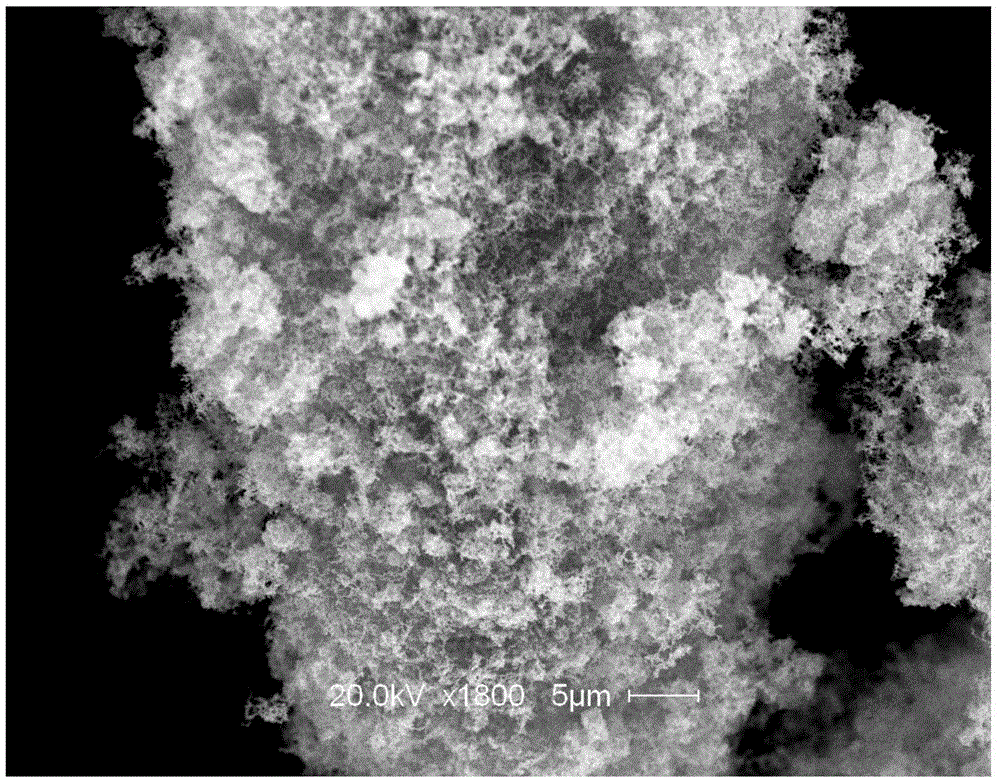

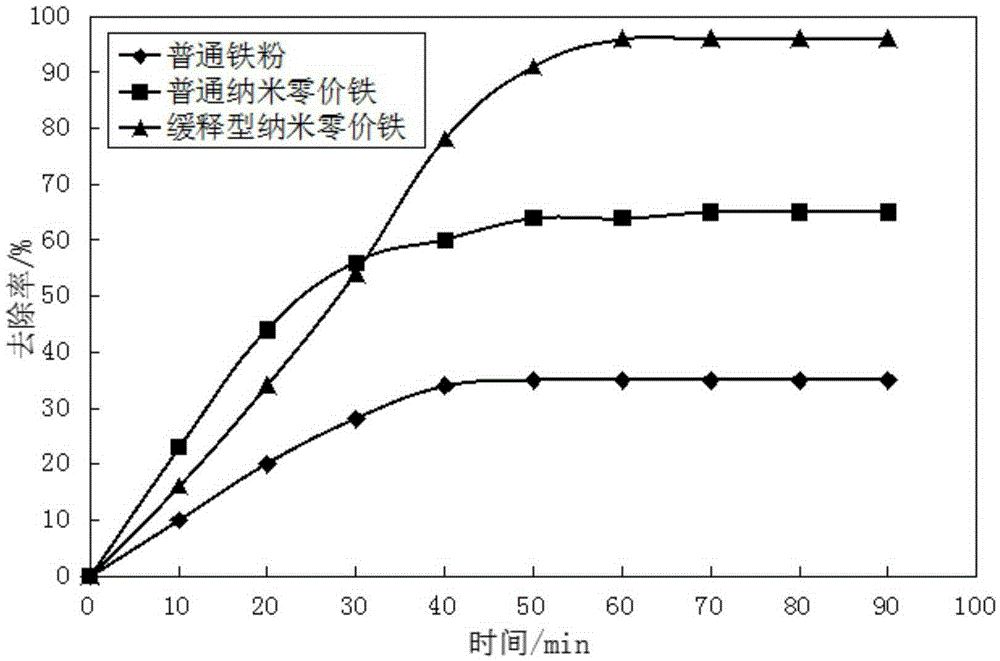

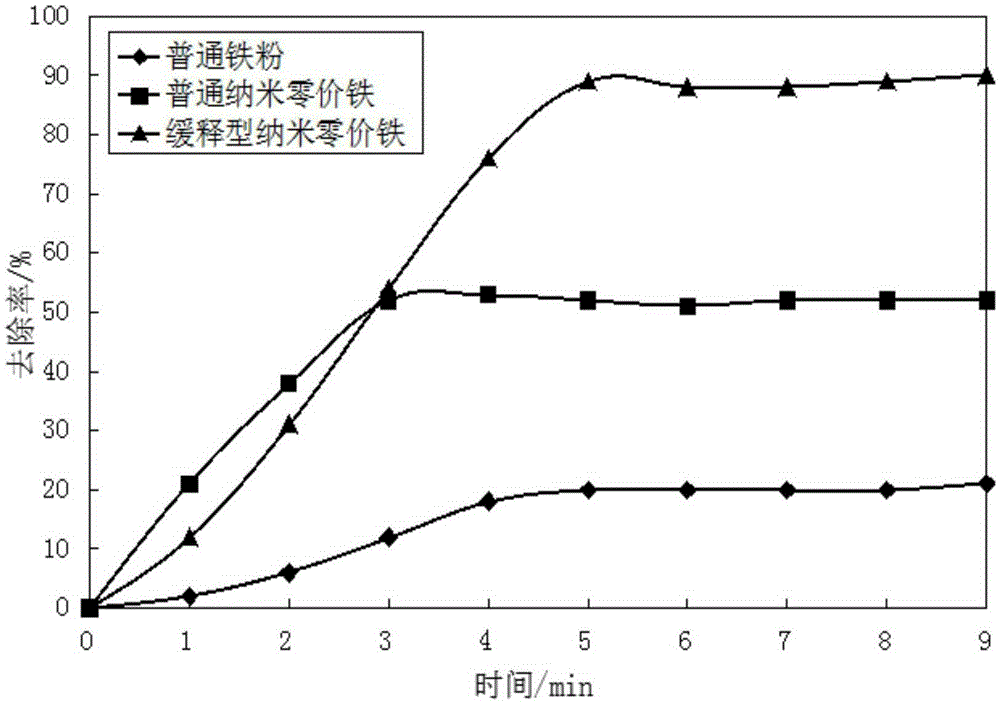

Preparation method for slow-release-type nanometer zero-valent iron particles

InactiveCN105251995AGood dispersionHigh reactivityMaterial nanotechnologyDispersityPolyaspartic acid

The invention discloses a preparation method for green slow-release-type nanometer zero-valent iron particles. The nanometer zero-valent iron particles serve as the core of a material, and the surface of the nanometer zero-valent iron particles is wrapped with polyaspartic acid (PASP). A reduction method is adopted, in a PASP aqueous solution, KBH4 or NaBH4 or other reducing agents are used for reducing Fe2+ to obtain Fe0. The preparation method is simple and free of secondary pollution. The obtained nanometer zero-valent iron particles have better dispersity and reactivity, and are higher than common iron powder by more than 174% and 148% respectively on the aspect of the effects of removing Cr6+ and hexachlorobenzene. The nanometer zero-valent iron particles have good stability in air, can be stored for a longer time, have good slow-release performance and can effectively control pollutants for a long time. Compared with common nanometer zero-valent iron, the action duration time can be improved by more than 40%, and the slow-release-type nanometer zero-valent iron particles have good market potentials.

Owner:深圳碳星水务科技有限公司 +1

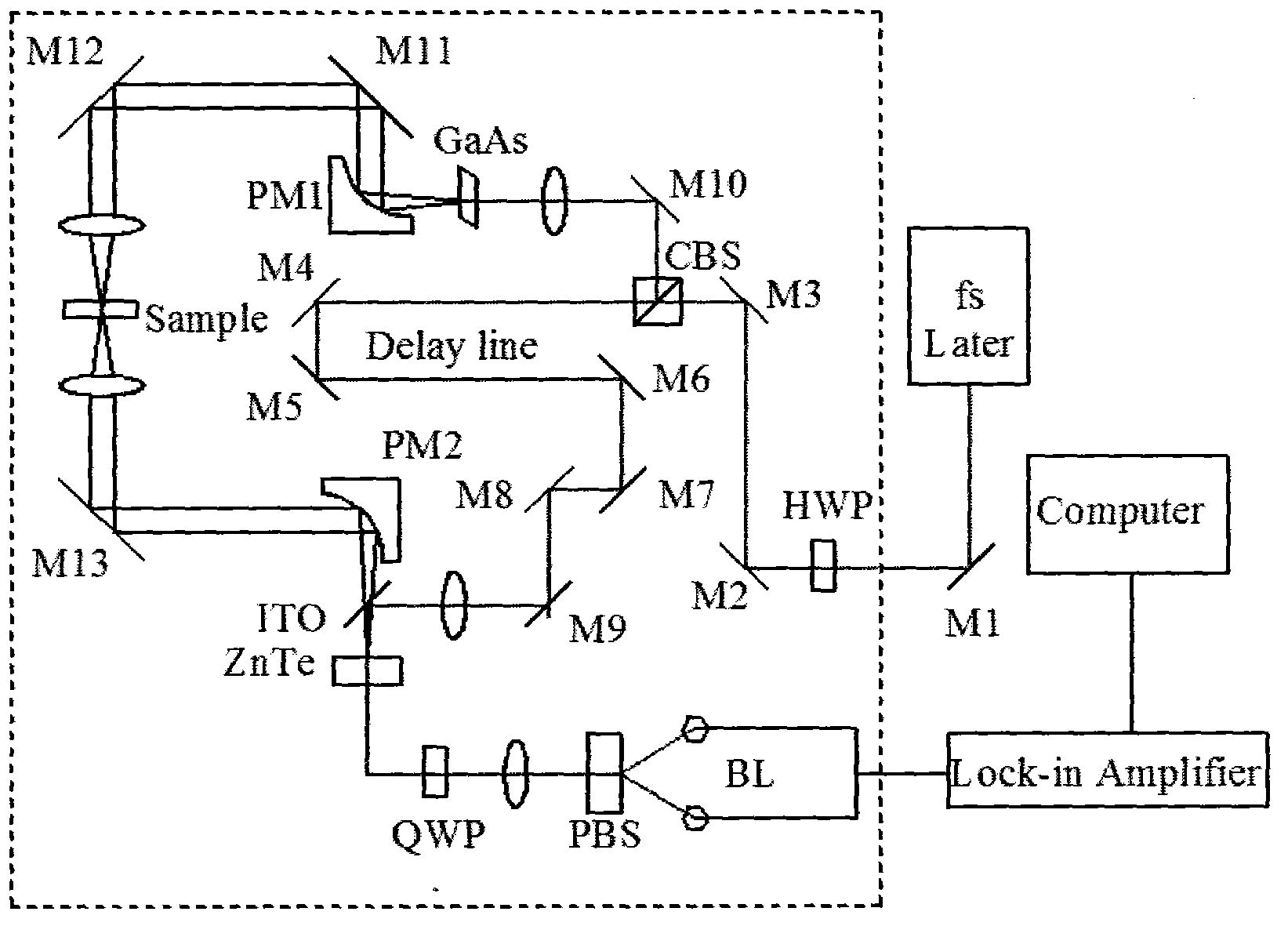

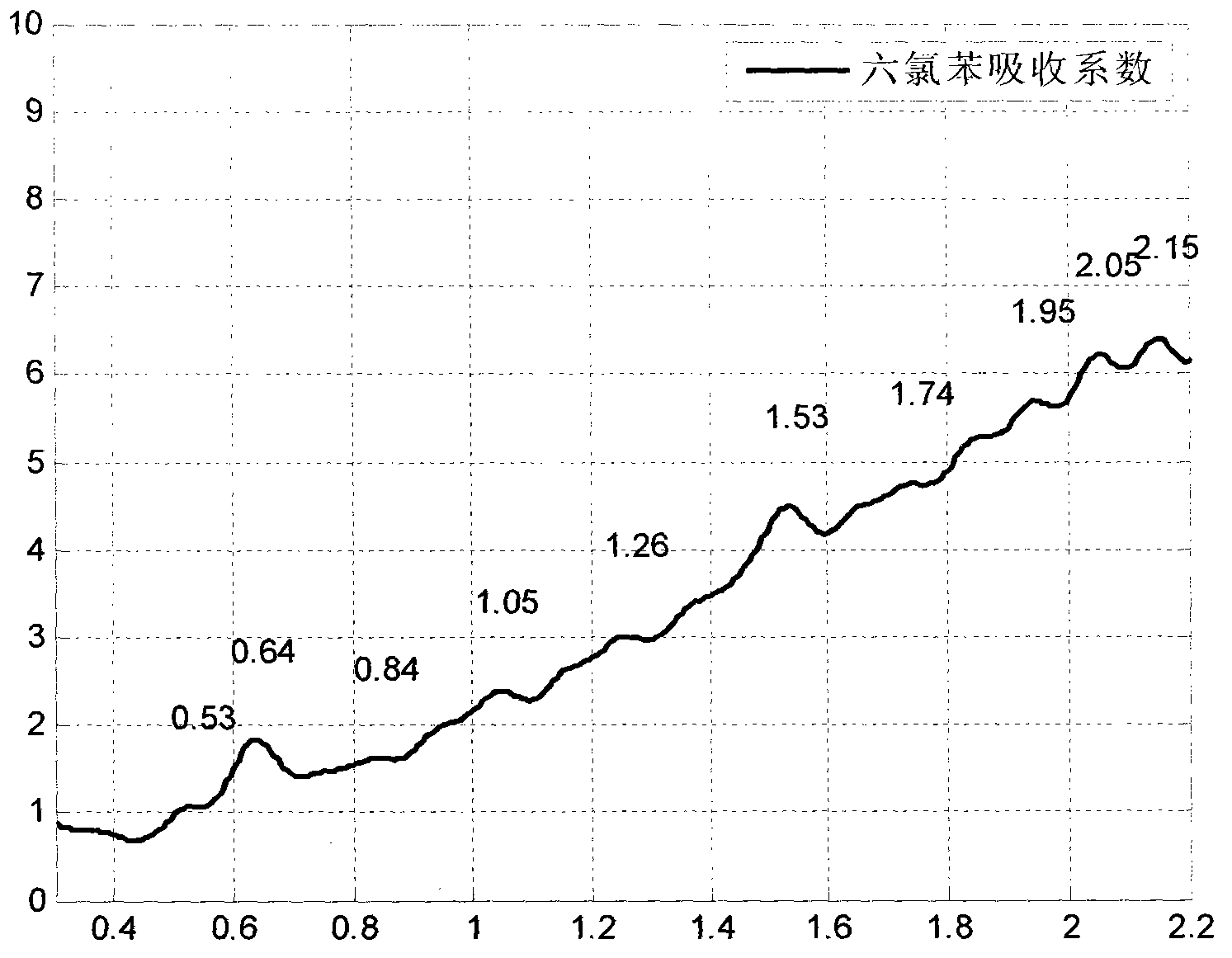

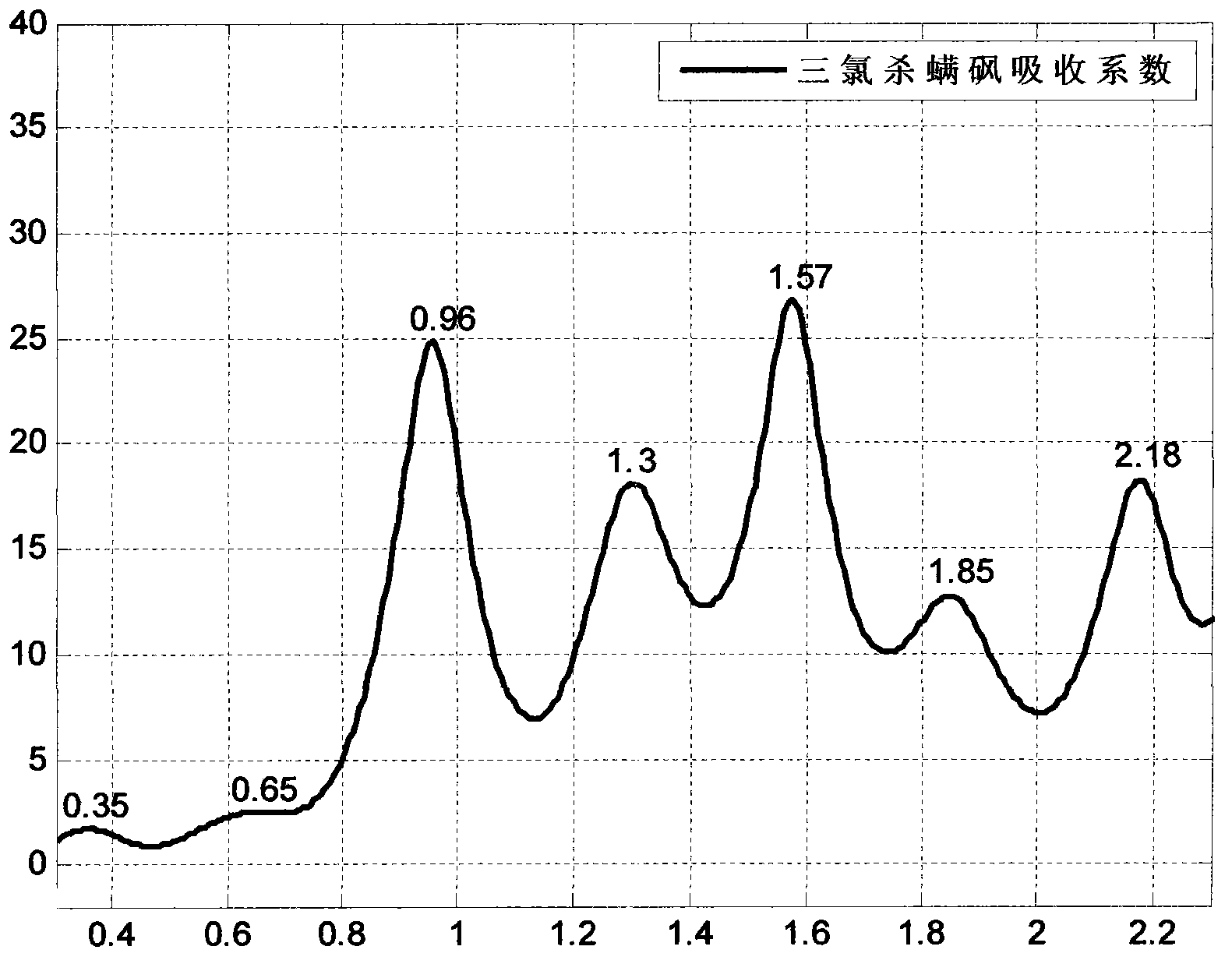

Solid pesticide identification method based on terahertz spectroscopy

InactiveCN104237143AQuick checkEasy to handleColor/spectral properties measurementsSupport vector machineTime domain

The invention discloses a solid pesticide identification method based on terahertz spectroscopy. The method comprises the following steps: (1) detecting a solid pesticide standard sample with the purity of greater than 99 percent by using a terahertz time-domain spectroscopy system, acquiring a terahertz time-domain signal of each sample, and calculating an absorption spectrum of each sample, wherein the solid pesticides refer to hexachlorobenzene, diphenylsulfon, phosmet and dipterex; (2) normalizing the absorption spectrum of each sample, wherein the influence on noise and drift is eliminated, and the absorption spectrum is used for spectral classification of each sample; and (3) identifying the terahertz absorption spectrum of each sample by utilizing a C-support vector machine (C-SVM). The method disclosed by the invention can realize rapid and nondestructive detection of pesticides and has the advantages of simple pretreatment of experimental samples, simplicity in operation, high repeatability, data processing simplicity, accurate detection result and the like.

Owner:QINGDAO UNIV OF SCI & TECH

Fireworks spraying pyrotechnic compound composition with composite effect

InactiveCN101386558AImprove performanceSuitable for industrial mass productionExplosivesComposite effectFireworks

The invention discloses a flower-spraying pyrotechnic composition with composite effects. The flower-spraying pyrotechnic composition comprises the following components in weight portion: 30 to 60 portions of potassium perchlorate, 8 to 20 portions of magnalium, 5 to 25 portions of strontium carbonate, 5 to 15 portions of polyvinyl chloride, hexachlorobenzene or chlorinated paraffin, 2 to 15 portions of phenolic resin and 10 to 20 portions of 40 to 60 mesh aluminum dross. A flower-spraying product manufactured according to the formulation of the invention can simultaneously and compositely reveal the effects of slowly burning, landing, flowering and showing red light, and is stable in performance and suitable for industrialized batch production.

Owner:王贤凤

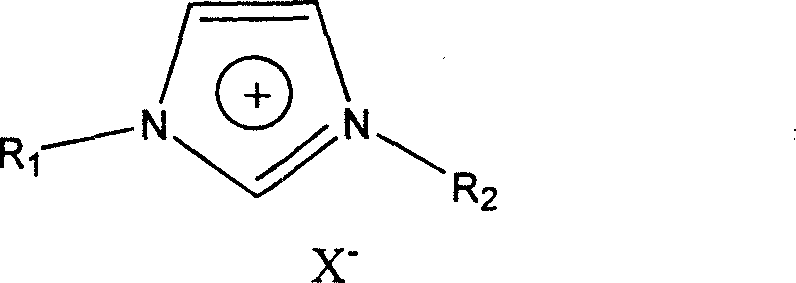

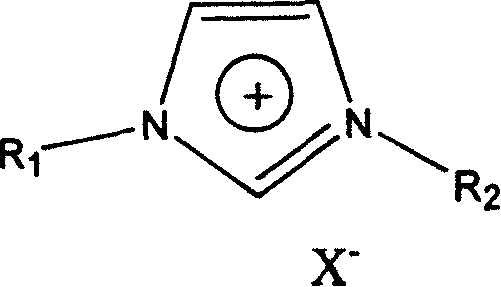

Preparation method for fluorochlorobenzene

ActiveCN101168493AMild reaction conditionsImprove conversion rateOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by halogen replacementChlorobenzeneOrganic compound

The invention relates to organic chemistry, in particular to a preparation of aromatic fluorine organic compound, which uses hexachlorobenzene as material, uses alkali metal fluoride as fluorizating agent, and uses ion liquid as medium, to be mixed, reacted, and distilled and separated in vacuum, to prepare fluoro-chlorobenzene. The inventive preparation can avoid catalyst and simplify productionprocess, with warm reaction condition, high conversion rate and yield, reduced energy consumption, reduced pollution, significant economic benefit, and large-scale industrial application. The invention can be applied in medical and chemical technical fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fireworks product

The invention relates to a fireworks product, which comprises an outer cylinder with a sealed end, and an inner cylinder arranged in the outer cylinder, wherein the sealed end of the outer cylinder is provided with a small hole for an outer igniter cord; the inside of the outer cylinder is provided with propellant powder; the inner cylinder is provided with a small hole for an inner igniter cord; the inner igniter cord is contacted with the propellant powder; and the inside of the inner cylinder is provided with propellant powder. The fireworks product contains effective powder comprising red light powder, unpacking powder, igniting powder, sounding powder and black powder, wherein the red light powder comprises 43 percent of potassium perchlorate, 30 percent of powered alloy, 20 percent of strontium carbonate, 7 percent of hexachlorobenzene and 7 percent of phenolic resin; the unpacking powder comprises 50 percent of potassium perchlorate, 30 percent of powered alloy and 20 percent of aluminum powder; the igniting powder comprises 18 percent of potassium perchlorate, 7 percent of powered alloy, 12 percent of brimstone, 47 percent of potassium nitrate and 16 percent of charcoal; the sounding powder comprises 18 percent of powered alloy, 3 percent of brimstone, 5 percent of potassium nitrate, 52 percent of minium and 22 percent of copper oxide; and the black powder comprises 7 percent of potassium perchlorate, 6 percent of powered alloy, 9 percent of brimstone, 60 percent of potassium nitrate and 18 percent of charcoal. The fireworks product can generate flowery red light when set off, and simultaneously has high safety.

Owner:王生宝

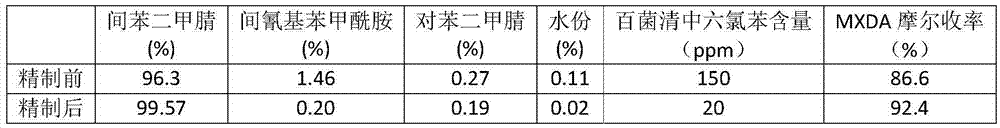

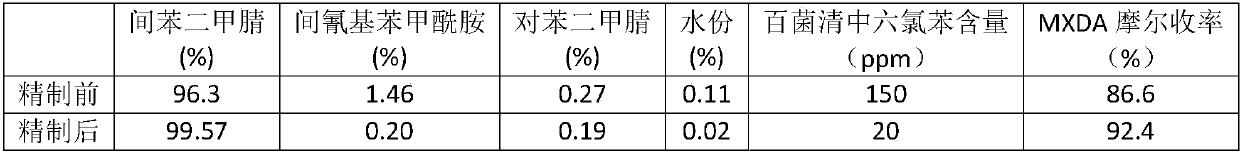

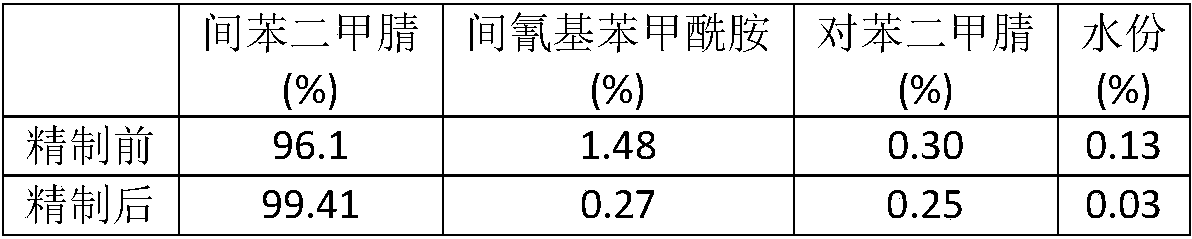

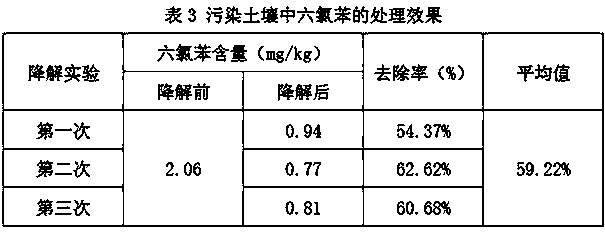

Method for refining isophthalonitrile

ActiveCN106892839AReduce contentReduce generationCarboxylic acid nitrile purification/separationDistillationPulp and paper industry

The invention relates to a method for refining isophthalonitrile. The method comprises the following steps: introducing an isophthalonitrile crude product raw material into a distillation kettle, cooling the distilled isophthalonitrile steam by a heat exchanger, introducing the isophthalonitrile into a receiving kettle, keeping the temperature, and finally, slicing by a slicer to obtain the refined isophthalonitrile finished product. Compared with the prior art, the method provided by the invention can enhance the isophthalonitrile content in the product and lower the meta-cyanobenzamide content, thereby reducing the hexachlorobenzene content in the chlorothalonil product and lowering the residue mass in the melter in the chlorothalonil production device.

Owner:SHANGHAI XIAOMING DETECTION TECH SERVICE CO LTD

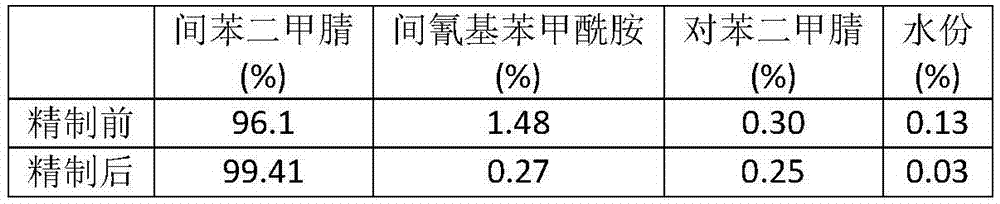

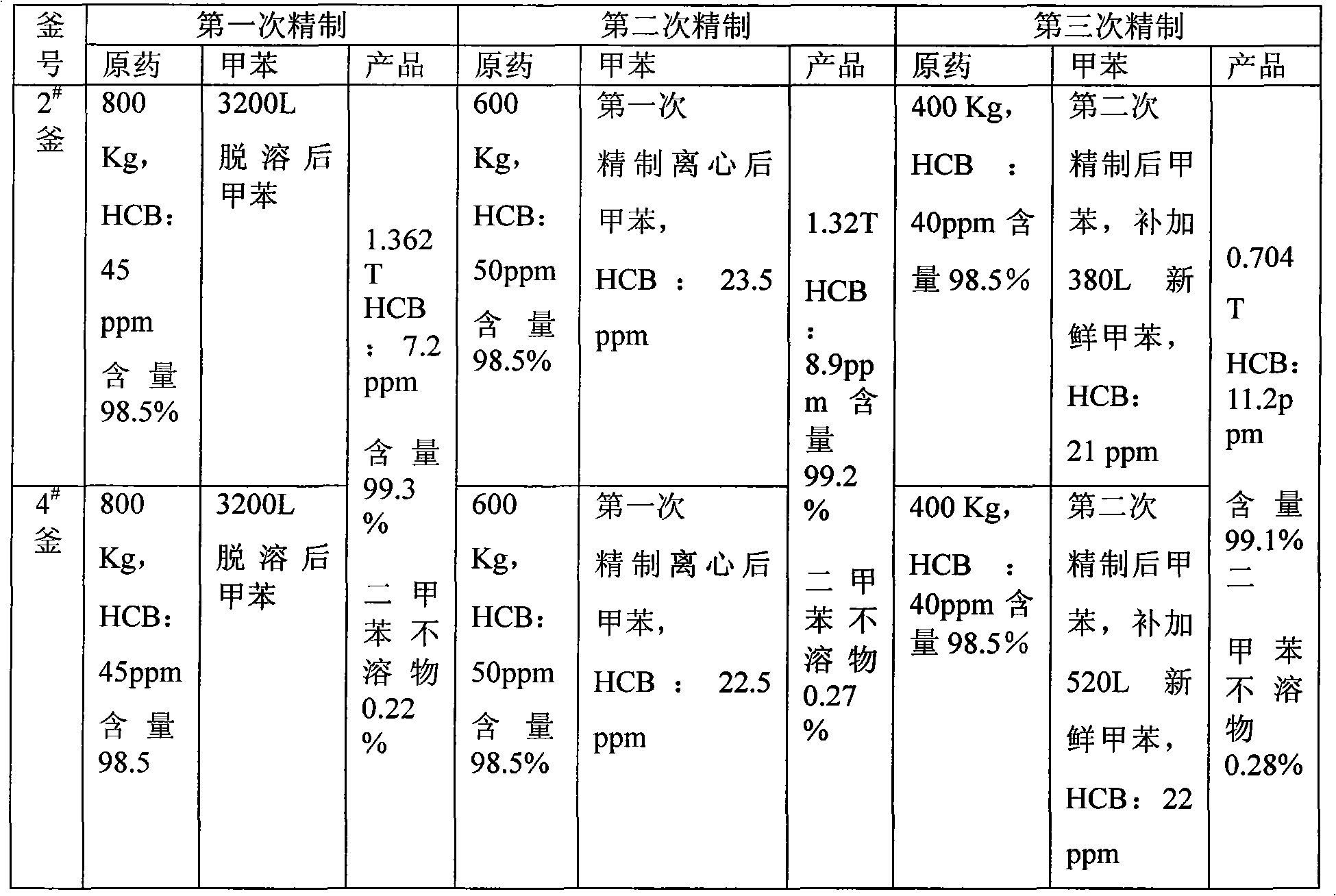

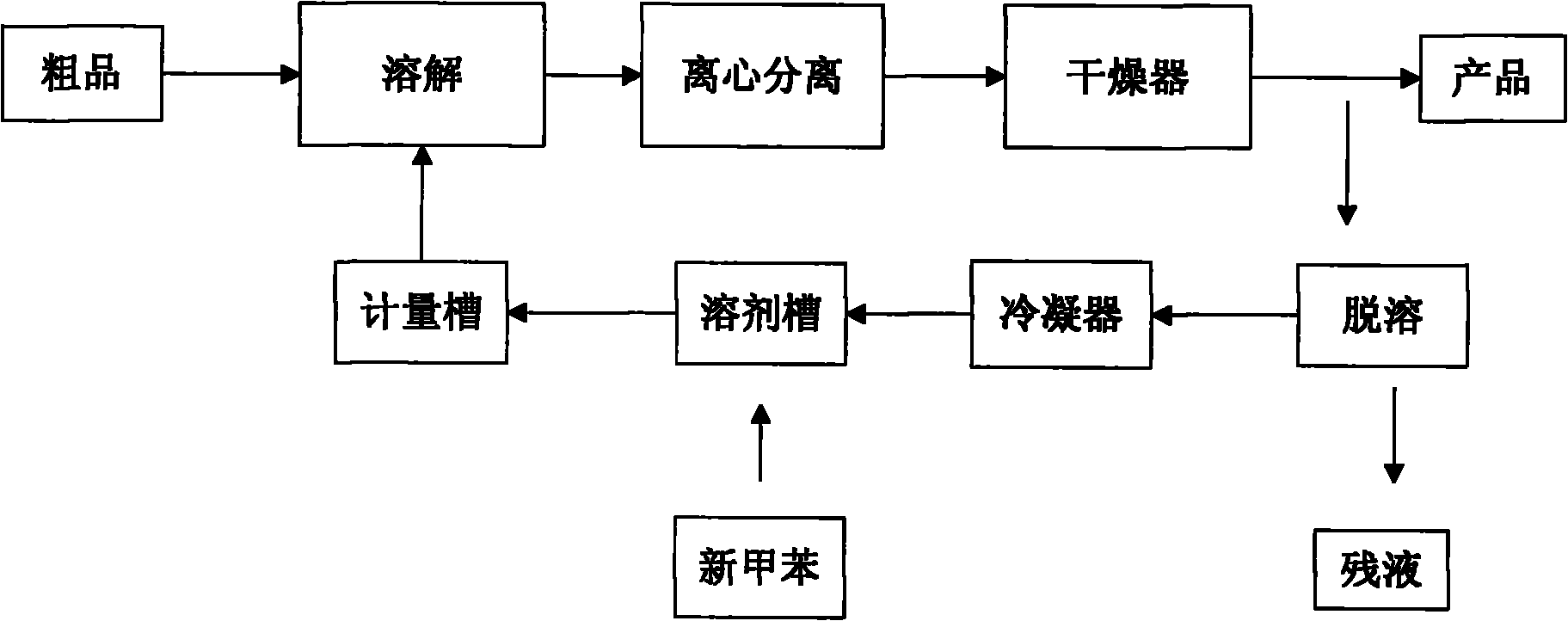

Method for purifying tetrachloroisophthalonitrile crystal

ActiveCN101962344AEasy to operateHigh purification rateBiocideFungicidesOrganic solventHazardous substance

The invention relates to a method for purifying tetrachloroisophthalonitrile crystal, which comprises the following steps of: putting a harmful substance-containing raw material tetrachloroisophthalonitrile into a dissolving kettle filled with an organic solvent, and starting a stirring device for stirring and mixing; raising the temperature in the dissolving kettle to between 85 and 90 DEG C, keeping the temperature and reacting for 1 to 1.5 hours, and reducing the temperature of the dissolving kettle to between 20 and 30 DEG C by using cooling water; and finally, separating by using a centrifugal machine, drying the obtained wet material to prepare finished tetrachloroisophthalonitrile. Compared with the prior art, the method has the advantages of simple operation, higher purification rate, high bioactivity of the obtained product, purity of more than or equal to 99 percent, yield of more than or equal to 95 percent, main impurity hexachlorobenzene content of less than or equal to 10mg / kg and dimethylbenzene undissolved substance content of less than 0.3 percent.

Owner:JIANGSU XINHE AGROCHEM

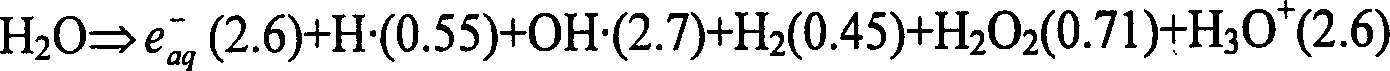

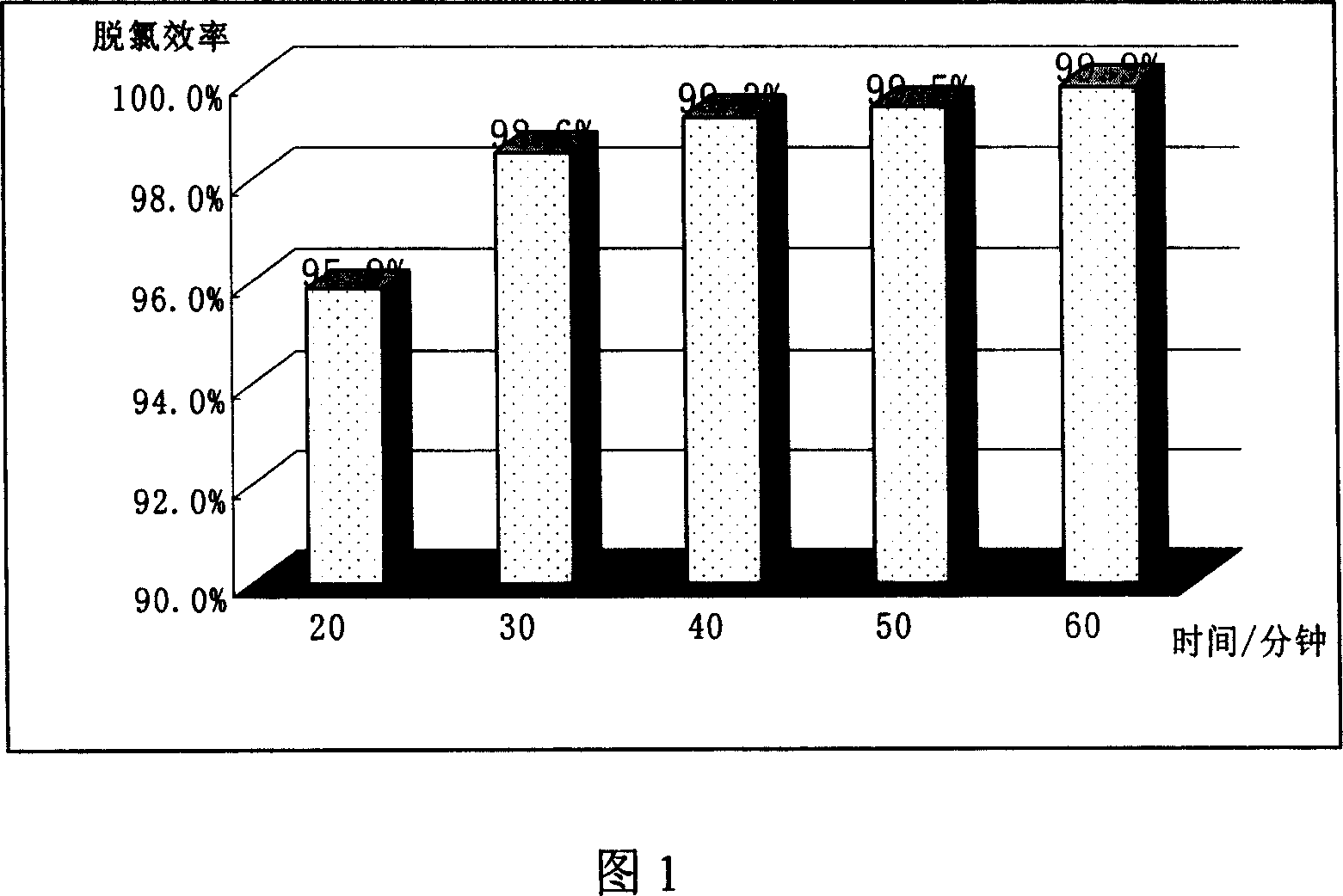

Irradiation method of degrading hexachlorobenzene in water

InactiveCN1636882AIncrease concentrationNo secondary pollutionWater/sewage treatmentGamma rayIrradiation

The irradiation method of degrading hexachlorobenzene in water is one high efficiency energy saving water treating technology. High energy electron beam or gamma ray radiated during the decay of radioactive atom is utilized to treat water containing hexachlorobenzene for degrading hexachlorobenzene.

Owner:NANJING UNIV

Preparation method for catalyst for degrading hexachlorobenzene

ActiveCN103977795AHigh selectivityHigh yieldHydrocarbon from halogen organic compoundsChemical recyclingBenzeneActive component

The invention discloses a preparation method for a catalyst for degrading hexachlorobenzene. The catalyst comprises the following components by weight percent: an Al2O3 carrier, 0.05-3 percent of an active component loaded on the Al2O3 carrier and 0.01-2.5 percent of an accessory ingredient, wherein the active component is Pt, Pd, Ag, Ru or Rh; the accessory ingredient is Na, K, Mg, Ba, Sn or Fe. The catalyst prepared by the preparation method can achieve the reaction that hexachlorobenzene is subjected to catalytic hydrogenation to be degraded into benzene and hydrogen chloride with high selectivity and high yield under a mild reaction condition; the mole conversion rate of hexachlorobenzene is 100 percent; the selectivity of benzene and hydrogen chloride is 100 percent; the catalyst with unit mass is high in hexachlorobenzene degrading amount; the using amount of the catalyst is small, and the service life is long; after being regenerated, the catalyst can be reused.

Owner:XIAN CATALYST NEW MATERIALS CO LTD +1

Halogenated arene degraded by aluminum oxide

InactiveCN101077847AAchieve complete dechlorinationOrganic decompositionPolychlorinated biphenylHexachlorobenzene

The present invention provides method of degrading halogenated arene with Al2O3 as dehalogenating agent. Hexachlorobenzene and dehalogenating agent Al2O3 in the amount of 5-100 times of hexachlorobenzene weight are mixed inside some container and reacted at 200-500 deg.c for 0.5-1.5 hr, so as to degrade hexachlorobenzene. The present invention has low cost, simple apparatus, short reaction period, low power consumption and other advantages, and can degrade halogenated arene in relatively low temperature. The method of the present invention is also suitable for degrading other halogenated arene, such as polychlorinated biphenyl, polybrominated biphenyl, BHC and DDT.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

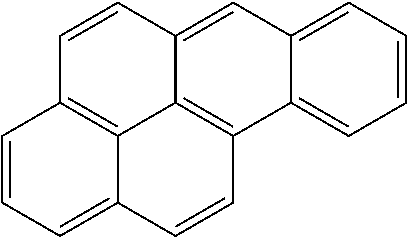

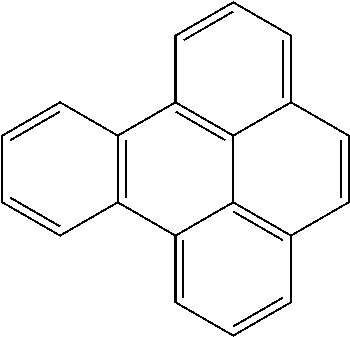

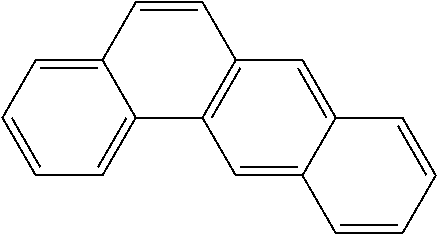

Extraction of harmful compounds from materials containing such harmful compounds

A composition and method for extracting, recovering, removing, and / or reducing at least one harmful compound selected from a harmful polycyclic aromatic hydrocarbon (PAH), bisphenol A (BPA), a harmful phthalate, a harmful polychlorinated biphenyl (PCB), a harmful dioxin, a harmful hexachlorobenzene, or a harmful organotin from a harmful compound-containing material using harmful compound-extracting composition comprising a turpentine fluid.

Owner:GREEN SOURCE ENERGY

Production method of low hexachlorobenzene content chlorothalonil

InactiveCN100404500CAdjust Reaction LoadImprove controllabilityBiocideCarboxylic acid nitrile preparationFluidized bedFixed bed

The present invention discloses a production method of chlorothalonil with low hexachlorobenzene content. Said production method includes the following steps: firstly, vapourizing m-dicyanobenzene, using nitrogen gas to carry out the vapourized m-dicyanobenzene from the vapourizer, making the vapourized m-dicyanobenzene be mixed with chlorine gas, and making them be fed into fluidized bed to make first-step reaction, making the reaction product be further mixed with chlorine gas and feeding them into fixed bed to make chlorination, condensing and collecting the outputted mixed gas so as to oblain the invented chlorothalonil product.

Owner:YUNNAN CHEM RES INST

Computer coolant

InactiveCN104087264AImprove securityGood value for moneyHeat-exchange elementsBenzoic acidMetallic materials

The invention discloses a computer coolant which is prepared from the following raw materials: 50-55 parts of glycerol, 40-45 parts of methanol, 32-35 parts of ethanol, 10-15 parts of phosphoric acid, 3-5 parts of aether, 2-3 parts of acetic acid, 3-4 parts of acetone, 3-4 parts of salicylic acid, 1-3 parts of oleic acid, 2-4 parts of n-octanoic acid, 3-5 parts of heptylic acid, 1-2 parts of isopelargonic acid, 3-4 parts of glycollic acid, 3-4 parts of phenol, 2-5 parts of benzoic acid, 3-4 parts of m-phthalic acid, 3-5 parts of trimethylolpropane, 2-5 parts of benzimidazole, 1-2 parts of hexachlorobenzene, 2-3 parts of polyether defoamer, 8-10 parts of silicon oil and 180-220 parts of deionized water. The computer coolant has the advantages of environmental protection, high safety and high cost performance, can effectively protect the metal materials of the computer cooling system, has higher compatibility for rubber and other sealing elements, prevents the dirt from generation, enhances the heat transfer capability of the cooling system, can prevent the computer cooling system from corrosion, avoids leakage, is harmless and pollution-free, and ensures the safe operation of the computer system.

Owner:张慧玲

Method for treating volatile aryl chloride pollutant and catalyst

InactiveCN109157977ACatalytic degradationSuppress generationGas treatmentMolecular sieve catalystsArylHydrogen

The invention relates to the technical field of pollutant treatment and in particular relates to a method for treating volatile aryl chloride pollutants and a catalyst. The volatile aryl chloride pollutants and steam are dissociated on the surface of the catalyst and are further reacted, and then multi-chloro organic byproducts, even long-lasting organic pollutants such as hexachlorobenzene, polychlorinated biphenyl and dioxin, can be effectively inhibited. Due to adoption of the steam in a reaction gas, a sufficient hydrogen source is provided, enrichment of chlorine substances on the surfaceof the catalyst can be inhibited, generation of harmful substances such as the multi-chloro organic byproducts in a product can be effectively inhibited, and complete catalytic degradation can be achieved for the volatile aryl chloride pollutants at a certain temperature. The method comprises the following steps: (1) providing the catalyst; (2) carrying out reaction treatment.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES

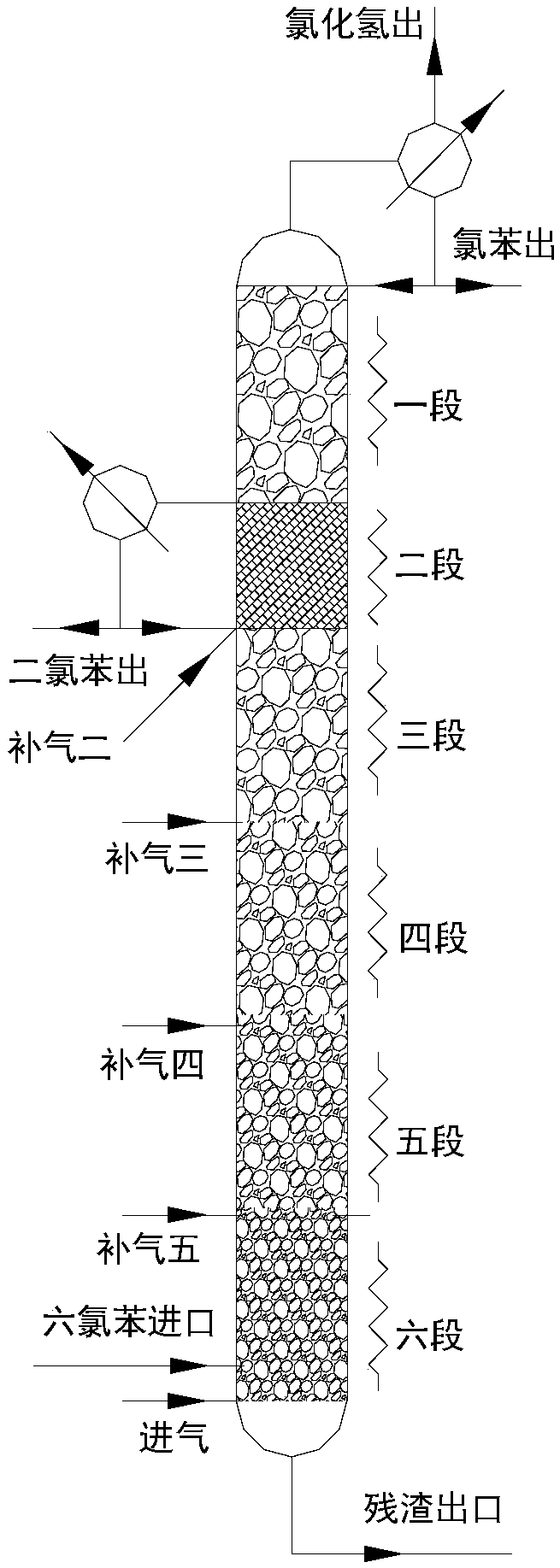

Method for producing chlorobenzene and dichlorobenzene by catalytic distillation and degradation of hexachlorobenzene

InactiveCN109485540AImprove efficiencyGood choicePreparation by dehalogenationChemical industryChlorobenzeneHydrogen

The invention discloses a method for producing chlorobenzene and dichlorobenzene by catalytic distillation and degradation of hexachlorobenzene. The method adopts a fixing bed catalytic distillation tower to gradually remove chlorine on the hexachlorobenzene in a sectional catalytic hydrogenation manner, the hexachlorobenzene and hydrogen enter from the bottom of the fixing bed catalytic distillation tower, and preform a dechlorination reaction through a catalyst bed layer. As the boiling point of the generated product is gradually reduced, the product moves upwards and exits from the top of the tower. The composition of the product at the top of the tower can be controlled by controlling the catalyst and catalytic reaction conditions, so that the purity of the obtained dichlorobenzene andchlorobenzene can reach more than 99%.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

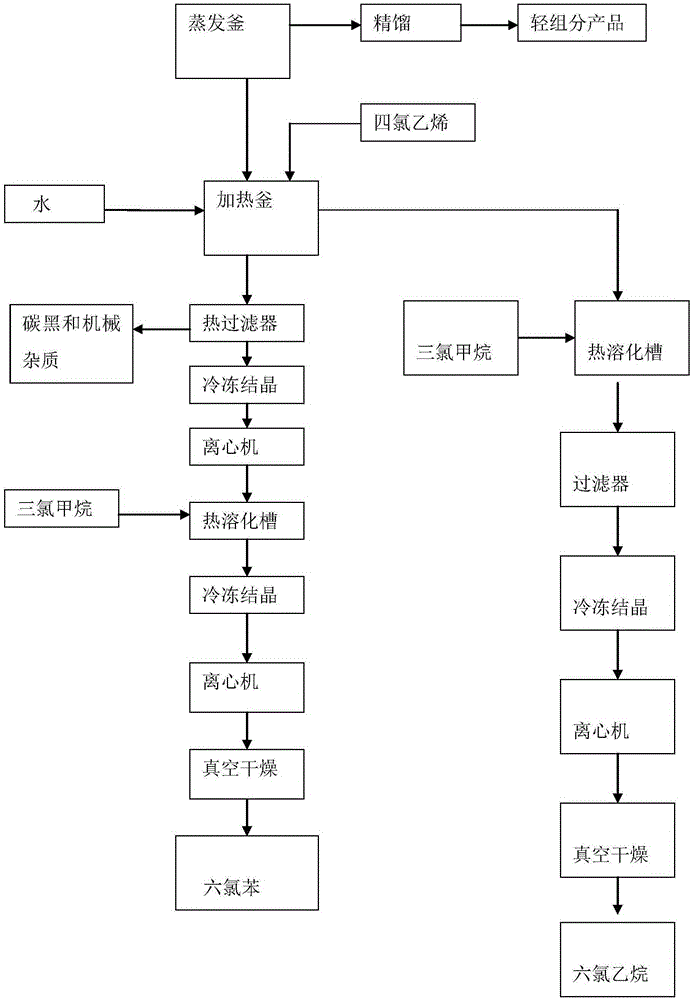

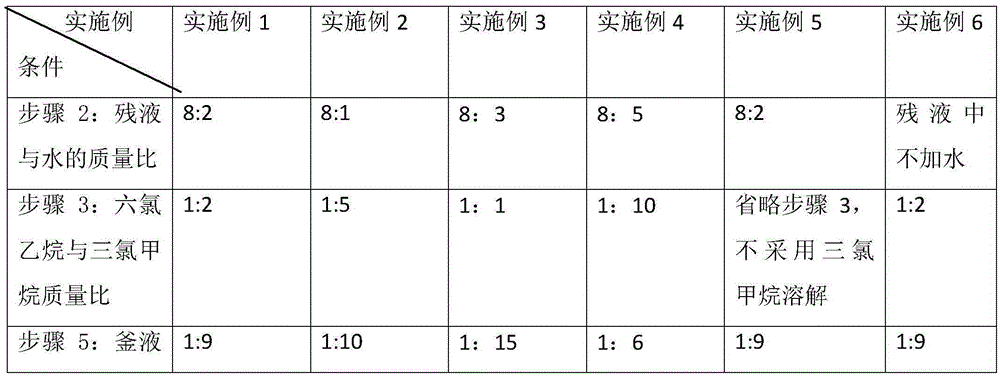

Method for separating chloride from perchloride

InactiveCN105384598AAvoid harmSave resourcesHalogenated hydrocarbon separation/purificationFiltrationCarbon Chloride

The invention discloses a method for separating chloride from perchloride. The method comprises the main following steps that 1, perchloride waste is added into an evaporator, evaporated liquid chloride is rectified, and carbon tetrachloride and tetrachloroethylene are separated out; 2, residual liquid evaporated in the first step is transferred into a sublimation kettle, water is added for heating to boiling, and meanwhile hot nitrogen is introduced in; 3, hexachloroethane sublimated in the second step is introduced into a trichloromethane dissolving tank for dissolution; 4, hot filtration is performed on the mixture obtained in the third step, the filtrate is cooled and crystallized, centrifugal separation is performed, crystals are dried to obtain a hexachloroethane product; 5, tetrachloroethylene is added into a residue in the second step to be heated and dissolved, hot filtration is performed, the filtrate is cooled and crystallized, and centrifugal separation is performed to obtain a hexachlorobenzene crude product. According to the method, hexachlorobenzene in perchloride organic risk waste is separated out, in addition, the purity of the separated hexachloroethane can be improved, and therefore the quality of the separated hexachloroethane is improved.

Owner:阳秀

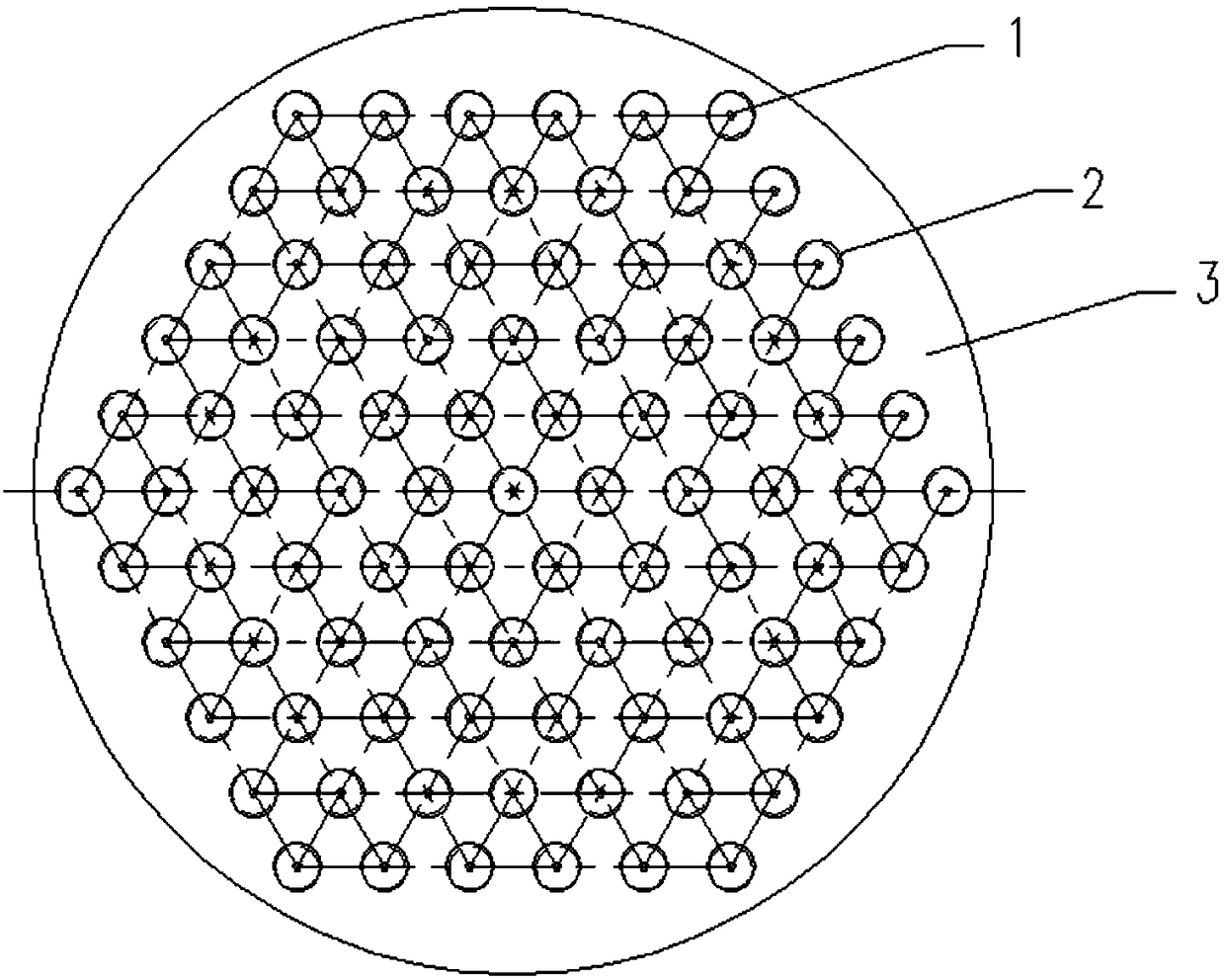

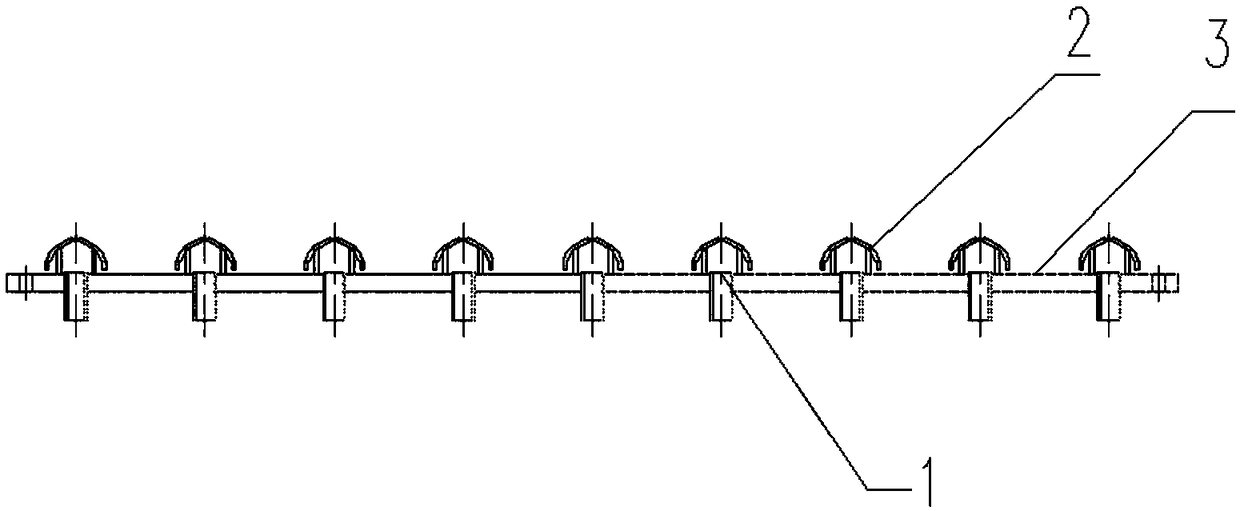

Fluidized bed distributor for chlorothalonil production

PendingCN109317060ASolve the problem of easy sintering to block the distribution plateQuality improvementCarboxylic acid nitrile preparationOrganic compound preparationEngineeringProduct gas

The invention provides a fluidized bed distributor for chlorothalonil production. The fluidized bed distributor includes a distribution plate and air caps, wherein the distribution plate is provided with a plurality of air holes, and the air caps are correspondingly arranged on the air holes. The air caps are fixedly connected to the distribution plate, and gaps are formed between the edges of theair caps and the distribution plate. The distribution plate has an opening ratio of 0.5%-5%. According to the arrangement of the air holes and the air caps in the fluidized bed distributor and the adjustment of the opening ratio, the uniform distribution of reaction gas is promoted, the fluidization state is improved, the stability of a reaction is improved, the product quality of the chlorothalonil is high, and the content of hexachlorobenzene is less than 10ppm; and meanwhile, the fluidized bed distributor effectively solves the problem that a catalyst is prone to sintering and blocking thedistribution plate, the service life of the catalyst is prolonged, and the production cost of the chlorothalonil is reduced.

Owner:JIANGSU XINHE AGROCHEM

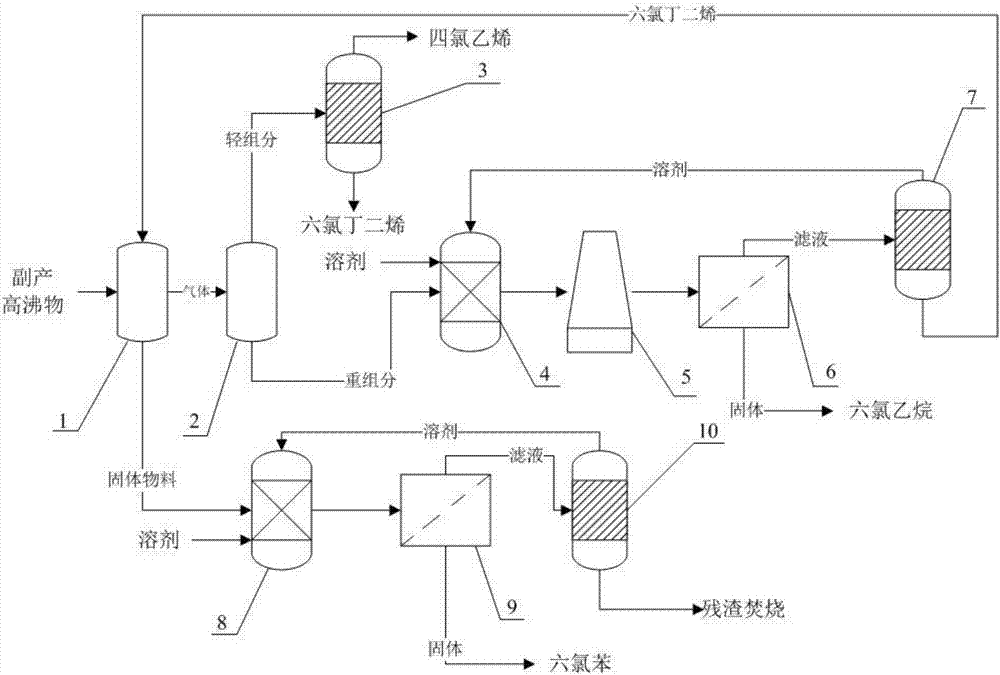

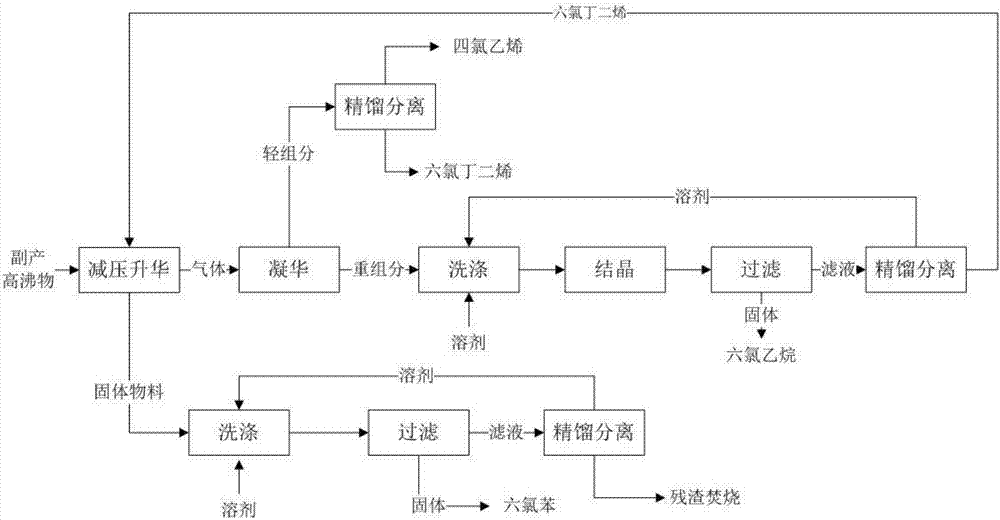

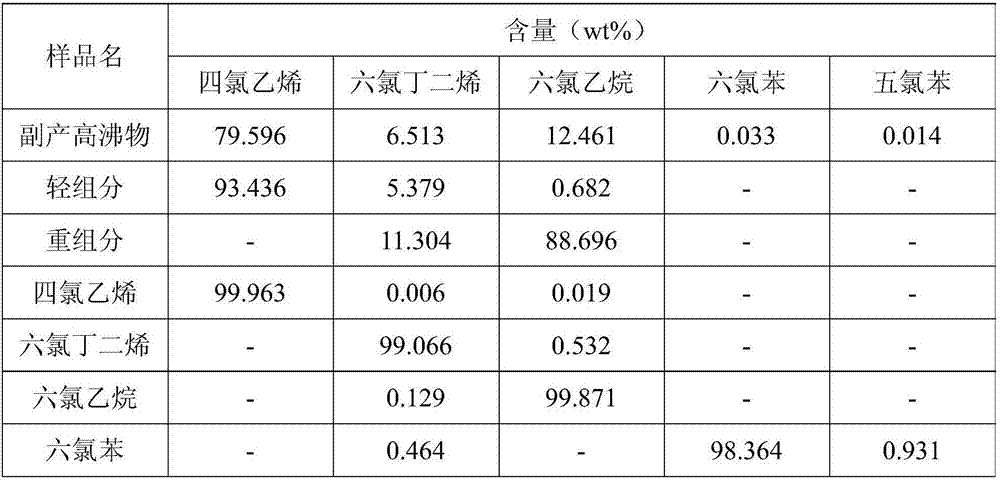

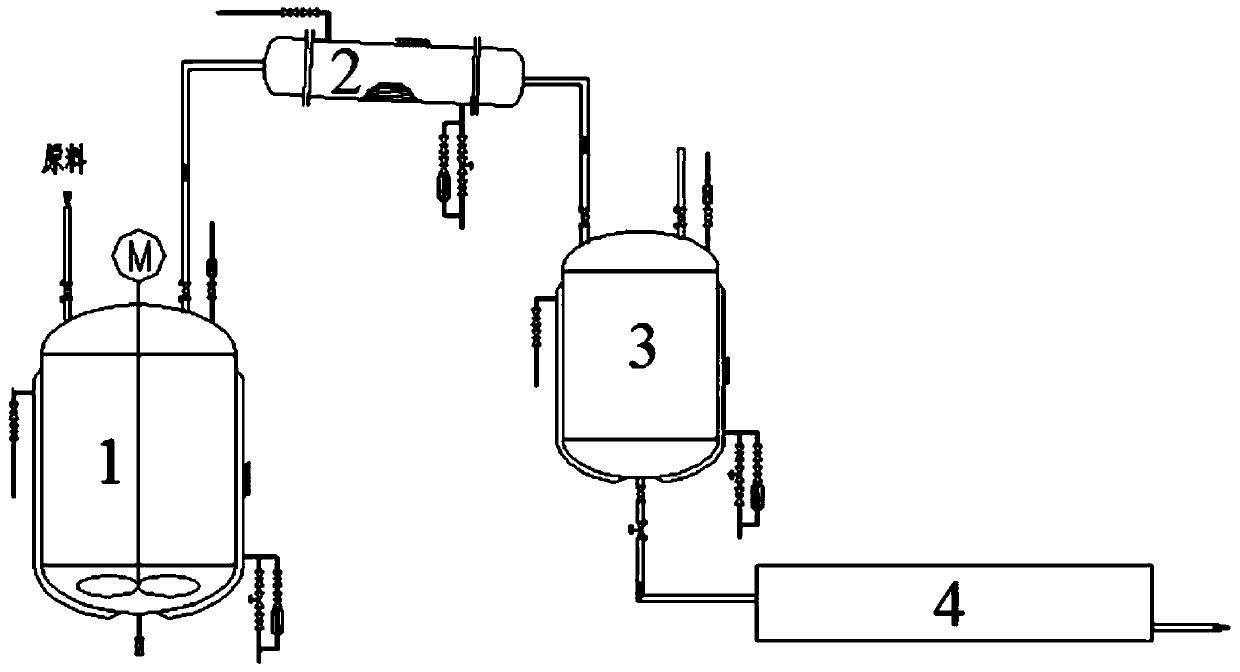

Separation system for by-product high-boiling matter in tetrachloroethylene production and separation method

InactiveCN107573210AEfficient separationLow sublimation temperatureHalogenated hydrocarbon separation/purificationSolventHexachloroethane

The invention provides a separation system for by-product high-boiling matter in tetrachloroethylene production and a separation method. The system comprises a decompression sublimation device, a desublimation device, a first rectifying tower, a hexachloroethane separation system and a hexachlorobenzene separation system, wherein a gas material outlet of the decompression sublimation device is connected with a feeding port of the desublimation device, a light-component material outlet of the desublimation device is connected with a feeding port of the first rectifying tower, a heavy-componentmaterial outlet of the desublimation device is connected with a feeding port of the hexachloroethane separation system, and a solid material outlet of the decompression sublimation device is connectedwith the hexachlorobenzene separation system. According to the method, the byproduct high-boiling matter in the tetrachloroethylene production is separated and purified one by one through processes such as decompression sublimation, washing by using a solvent, recrystallization and rectification, and high-efficiency separation of hexachloroethane, hexachlorobutadiene and hexachlorobenzene is realized; and by adopting a mode of the decompression sublimation, a sublimation temperature of the product is reduced, energy consumption of the whole technological process is effectively reduced, and production costs are greatly reduced.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Extraction of harmful compounds from materials containing such harmful compounds

A composition and method for extracting, recovering, removing, and / or reducing at least one harmful compound selected from a harmful polycyclic aromatic hydrocarbon (PAH), bisphenol A (BPA), a harmful phthalate, a harmful polychlorinated biphenyl (PCB), a harmful dioxin, a harmful hexachlorobenzene, or a harmful organotin from a harmful compound-containing material using harmful compound-extracting composition comprising a turpentine fluid.

Owner:GREEN SOURCE ENERGY

A kind of method of refining isophthalonitrile

ActiveCN106892839BReduce contentReduce generationCarboxylic acid nitrile purification/separationDistillationPulp and paper industry

The invention relates to a method for refining isophthalonitrile. The method comprises the following steps: introducing an isophthalonitrile crude product raw material into a distillation kettle, cooling the distilled isophthalonitrile steam by a heat exchanger, introducing the isophthalonitrile into a receiving kettle, keeping the temperature, and finally, slicing by a slicer to obtain the refined isophthalonitrile finished product. Compared with the prior art, the method provided by the invention can enhance the isophthalonitrile content in the product and lower the meta-cyanobenzamide content, thereby reducing the hexachlorobenzene content in the chlorothalonil product and lowering the residue mass in the melter in the chlorothalonil production device.

Owner:SHANGHAI XIAOMING DETECTION TECH SERVICE CO LTD

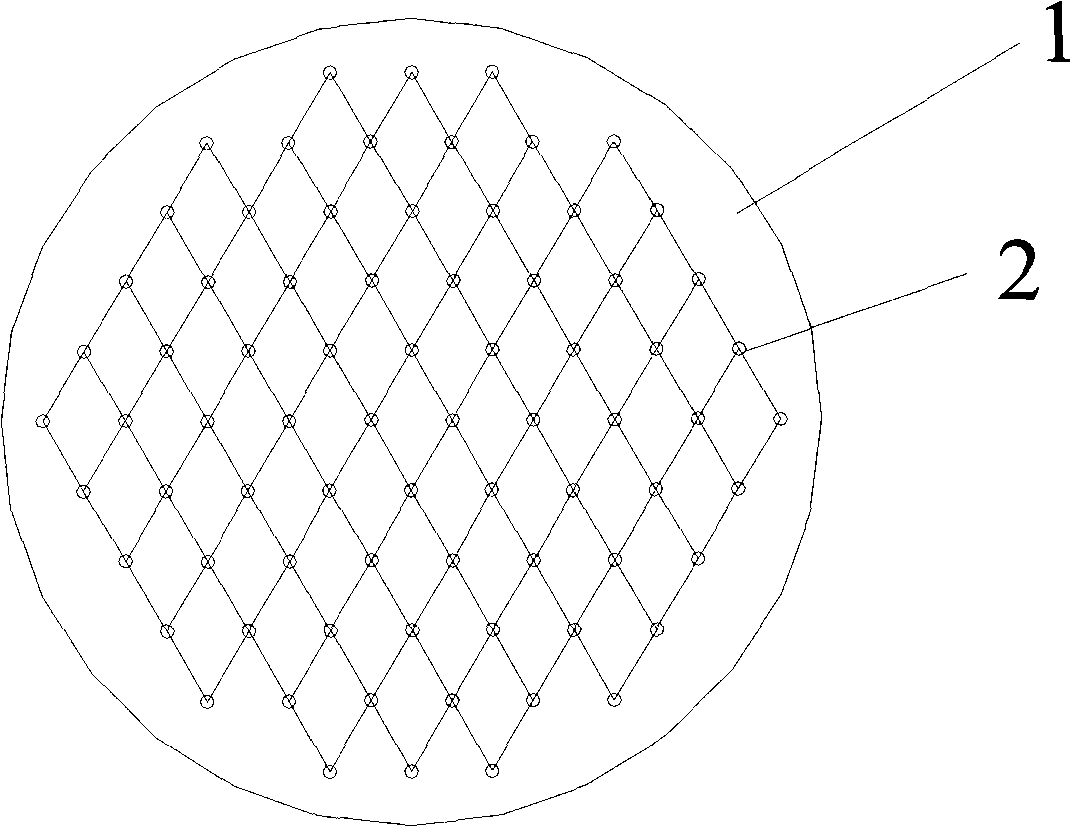

Fluidized bed distribution plate for production of tetrachloro isophthalonitrile

InactiveCN101985094AExtend the life cycleStable production pressureOrganic chemistryChemical/physical processesEngineeringAperture ratio

The invention relates to a fluidized bed distribution plate for production of tetrachloro isophthalonitrile. Pores are reserved in the central area of the round distribution plate, and are arranged in a regular triangle shape, the plate penetrating air speed is controlled to be between 0.1 and 0.2m / s, and the aperture ratio is 1.0 to 3.0 percent. Compared with the prior art, the fluidized bed distribution plate improves the fluidizing state and prolongs the life cycle of a catalyst by 3 to 5 days, only 25kg of catalyst is consumed for each ton of chlorothalonil, the phenomena of channeling, impulse and blocking can be avoided, large bubble flow can be crushed, and the merged growth of bubbles can be suppressed, so the gas-solid fluidization state can be improved, the production pressure of the chlorothalonil is stable, the content of hexachlorobenzene is lower than 40ppm, and the content of the tetrachloro isophthalonitrile product is over 98 percent.

Owner:JIANGSU XINHE AGROCHEM

Environment-friendly treatment method of hexachlorobenzene

ActiveCN104725183AEasy to separateImprove conversion ratePreparation by halogen replacementHexafluorobenzeneContinuous use

The invention discloses an environment-friendly treatment method of hexachlorobenzene. The method comprises the following steps: (1) putting hexachlorobenzene and an active potassium fluoride solution organic solvent into a single reactor; (2) performing pressure test leakage detection and nitrogen replacement on the single reactor containing a reaction solution; (3) heating the single reactor to 200-300 DEG C, boosting the pressure to 2.0-3.0MPa, and reacting for 10-15h at a reaction temperature and a reaction pressure; (4) distilling off reactants in the single reactor, condensing and then collecting the reactants; (5) performing distillation separation on hexachlorobenzene and chloropentafluorobenzene in the reactants; and (6) performing reduced pressure distillation to collect fluorochlorobenzene (byproduct) and the organic solvent in the single reactor, taking out potassium chloride residues in the single reactor, drying fluorochlorobenzene, and then adding fluorochlorobenzene into the single reactor for continuous use. The method disclosed by the invention is mild in reaction condition and relatively high in conversion rate and yield, and a practical chemical intermediate is obtained while pollution is reduced, so that the method has a broad application prospect.

Owner:JUHUA GROUP TECH CENT

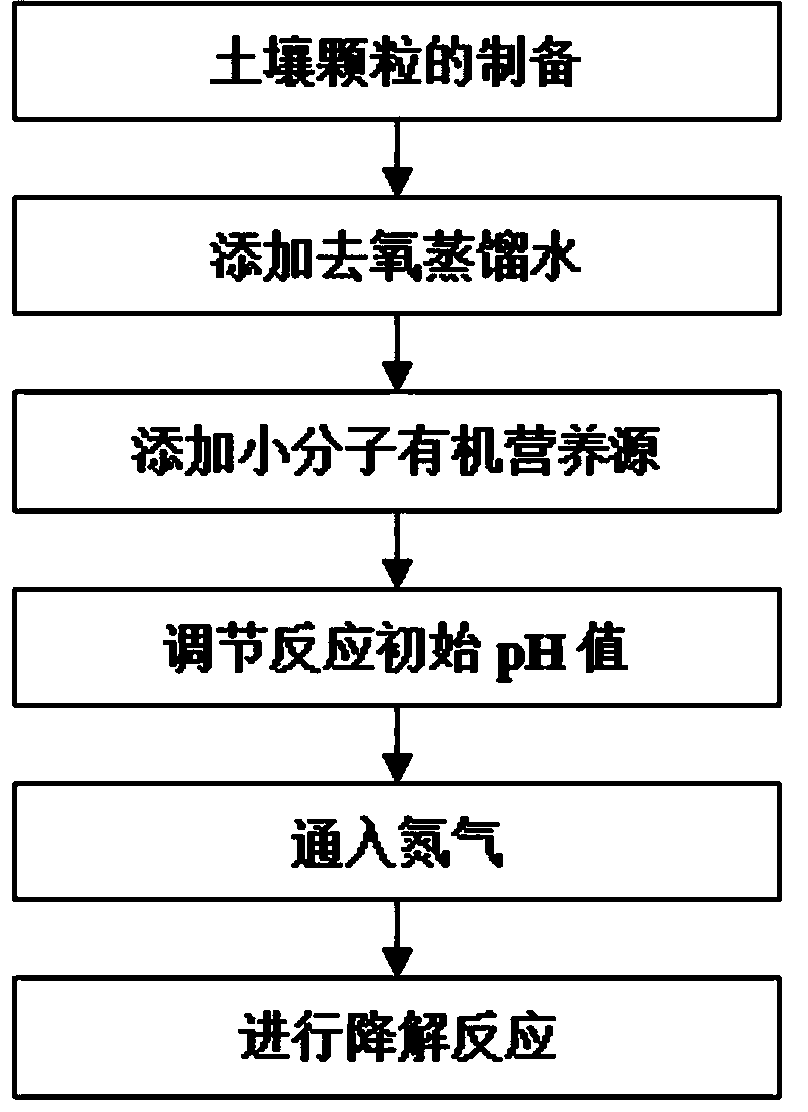

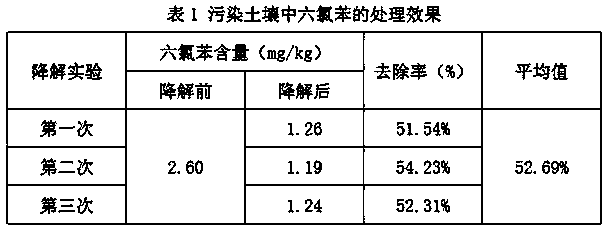

Bio-remediation method of hexachlorobenzene-contaminated soil

ActiveCN103521516ALarge specific surface areaIncrease contact areaContaminated soil reclamationDecompositionNitrogen gas

The invention discloses a bio-remediation method of hexachlorobenzene-contaminated soil, which comprises the following steps: preparing soil particles; adding deoxidized distilled water and a small-molecular organic acid nutrition source; regulating the initial pH value of the reaction system; adding nitrogen to create an oxygen-free environment; and performing an anaerobic degradation reaction by use of indigenous microorganisms in the soil, etc. According to the characteristics of strong vitality, adaptability and decomposition capacity of the indigenous microorganisms in the environment contaminated for long time, the method disclosed by the invention makes full use of the anaerobic indigenous microorganisms in the hexachlorobenzene-contaminated soil and directly performs quick remediation on the hexachlorobenzene-contaminated soil by use of the indigenous microorganisms in the soil under the condition of adding the small-molecular organic acid as a nutrition source. The method is simple and convenient to operate, the reaction conditions are mild, the operation cost is low, secondary pollution is avoided, the reaction time is short, and the engineering feasibility is high. The removal rate of hexachlorobenzene in the remediated contaminated soil is close to 60%, and thus the harm to the environment and human body caused by the hexachlorobenzene-contaminated soil is greatly reduced.

Owner:BEIJING MUNICIPAL RES INST OF ENVIRONMENT PROTECTION

Isophthalonitrile continuous rectification and purification device

PendingCN110590604AEasy to separateEfficient recyclingCarboxylic acid nitrile purification/separationBiochemical engineeringTower

The invention provides an isophthalonitrile continuous rectification and purification device which comprises a scraper evaporator and a rectification tower which are connected in sequence, can realizecontinuous and stable production and is low in operation cost. Through the device, continuous and stable purification of isophthalonitrile can be realized; the isophthalonitrile product with the purity of more than or equal to 99.83 wt% is obtained, and the content of intermediate cyanobenzamide in the product is reduced, so that the mass of residues in a melter in a chlorothalonil production device is reduced, the content of hexachlorobenzene in a downstream chlorothalonil product is reduced, and the environmental pressure is relieved.

Owner:JIANGSU XINHE AGROCHEM

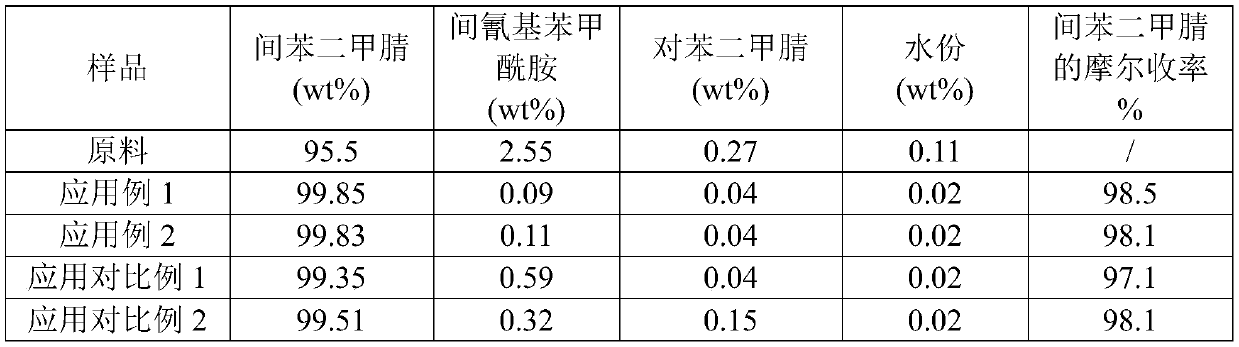

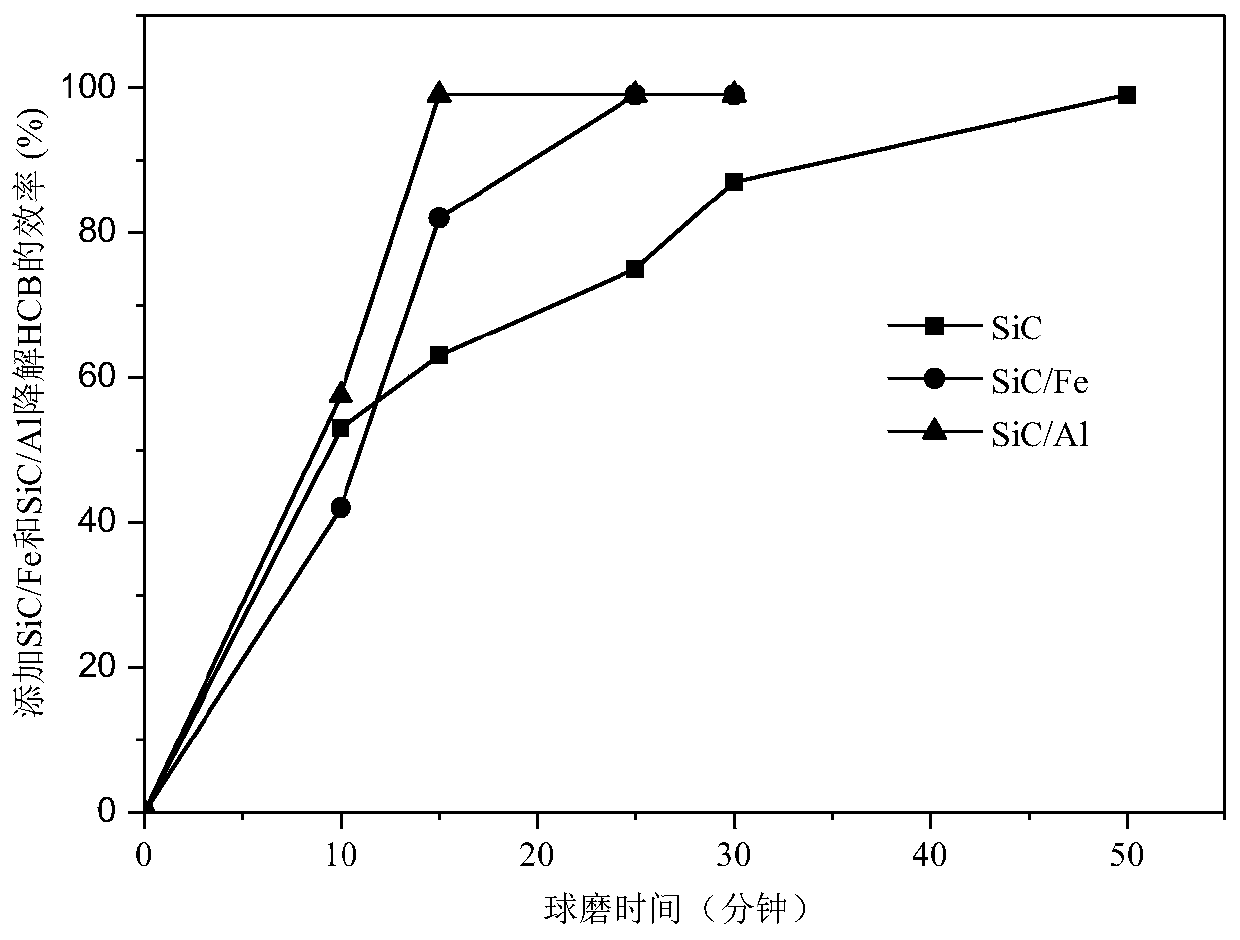

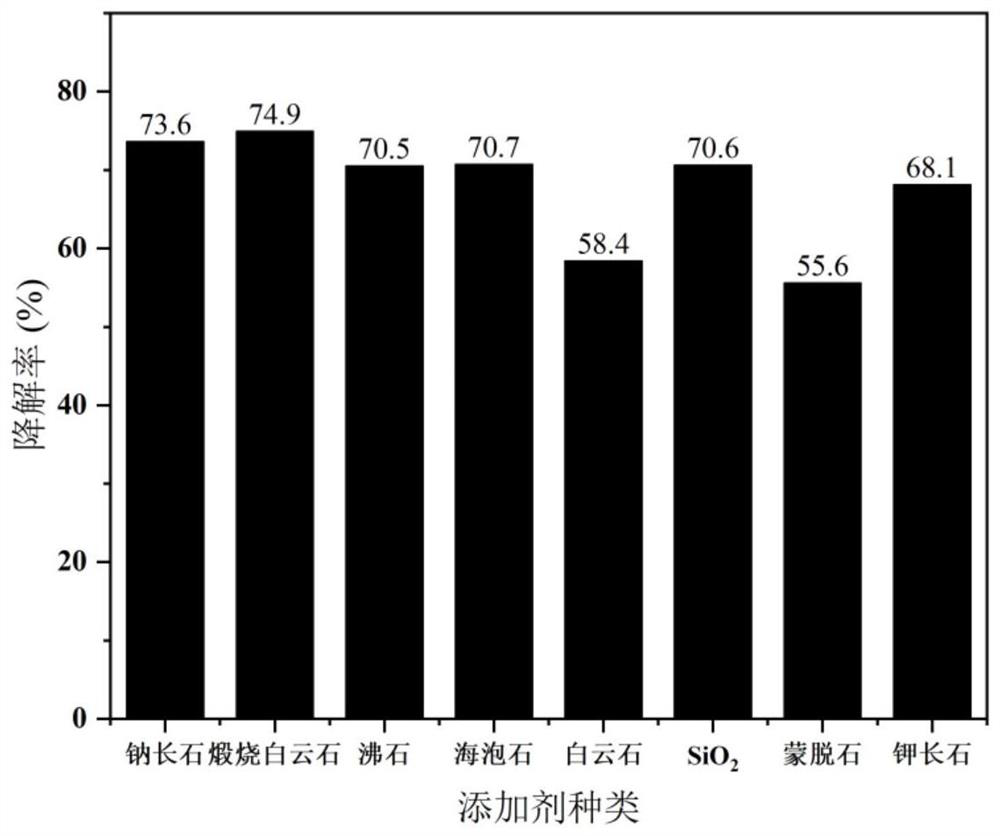

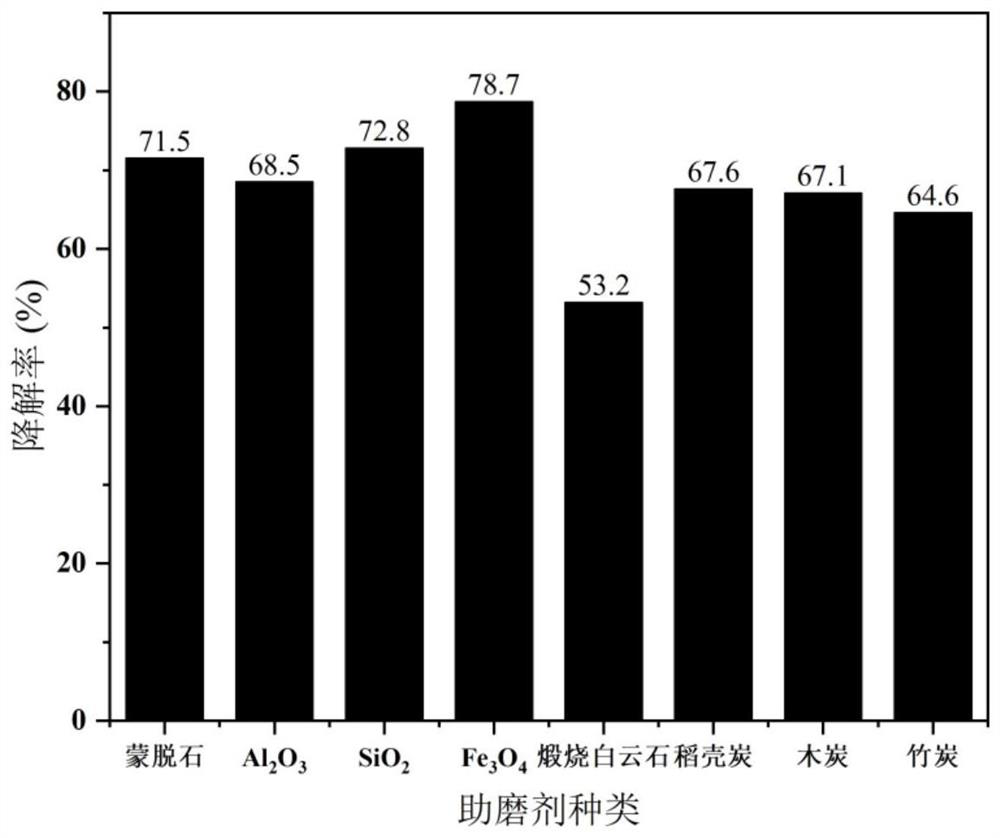

Method for mechanochemically degrading hexachlorobenzene by using silicon carbide as catalyst

InactiveCN110251877AShorten degradation timeShort degradation timePhysical/chemical process catalystsSilicon carbideHexachlorobenzene

The invention provides a method for mechanochemically degrading hexachlorobenzene by using silicon carbide as a catalyst. The silicon carbide is used as the catalyst, a degradation additive is added, and the hexachlorobenzene is degraded by a mechanochemical process. When the silicon carbide and the degradation additive are added to mechanochemically degrade the hexachlorobenzene, the degradation time of the hexachlorobenzene is greatly shortened. Experiments show that the method shortens the hexachlorobenzene degradation time to 40 min or less, and even can complete the degradation of the hexachlorobenzene only within 15 min.

Owner:SHANDONG UNIV

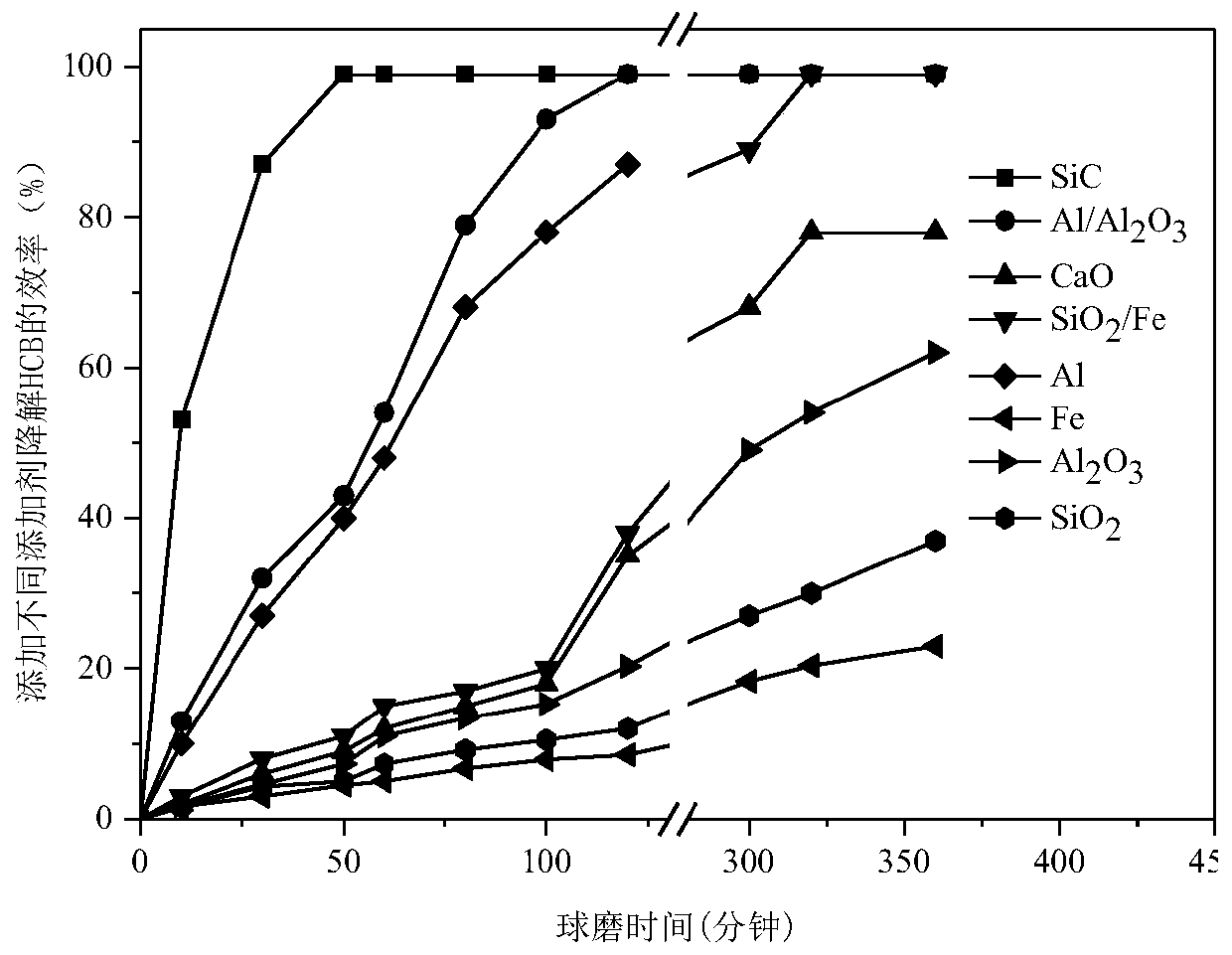

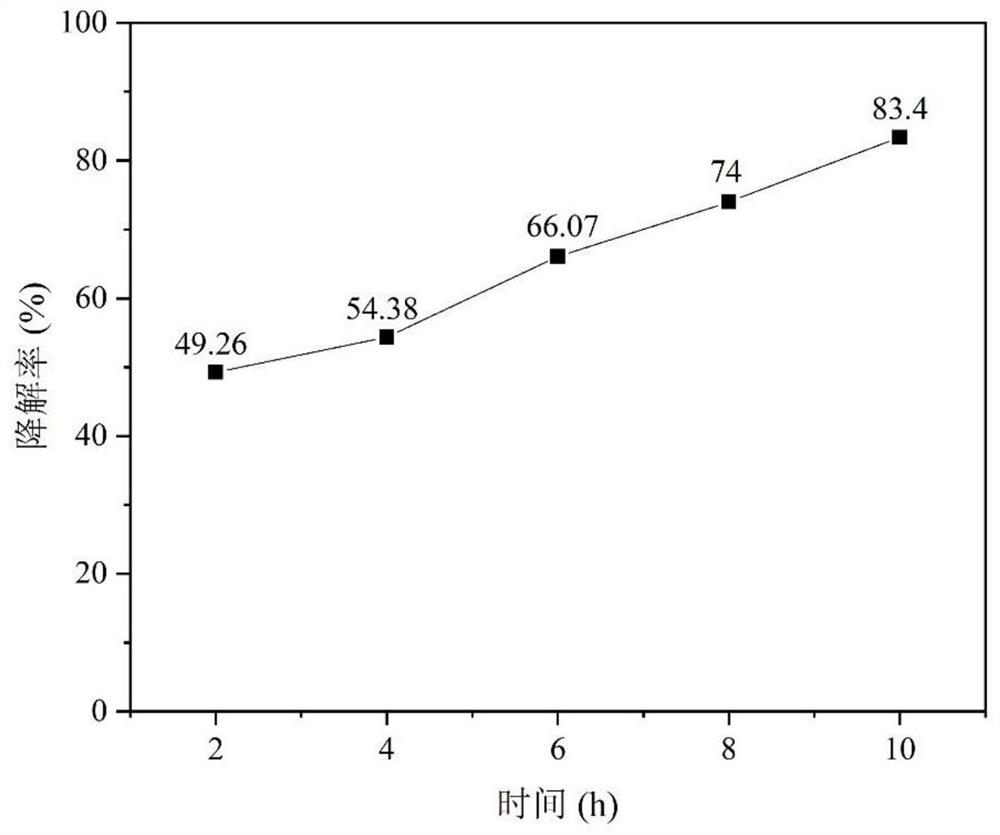

Method for repairing hexachlorobenzene contaminated soil through mechanochemistry

PendingCN112705566AImprove degradation rateGood effectContaminated soil reclamationChlorobenzeneSoil treatment

The invention belongs to the technical field of persistent organic pollutant contaminated soil treatment, and particularly relates to a method for repairing hexachlorobenzene contaminated soil through mechanochemistry. The method comprises the following steps: drying and crushing hexachlorobenzene contaminated soil, putting the crushed hexachlorobenzene contaminated soil, natural minerals and an auxiliary agent into a ball-milling tank according to a mass ratio of 5:1 to 10:1, adding milling balls according to a ball-to-material ratio of 10:1 to 30:1, fully conducting mixing for 5 min under the action of the milling balls, and carrying out a mechanochemical reaction under certain ball-milling time and rotating speed conditions. Hexachlorobenzene is finally converted into low-chlorinated benzene series and chloride ions, pollutants which are high in toxicity and easy to migrate are converted into low-toxic benzene series, and harmless treatment of the pollutants is achieved. Natural minerals are rich in reserves and have less influence on soil properties, so that the method truly realizes efficient, green and low-cost remediation of hexachlorobenzene contaminated soil, and is a mechanochemical persistent organic pollutant treatment technology with a wide application prospect.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com