Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44 results about "Hexafluorobenzene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

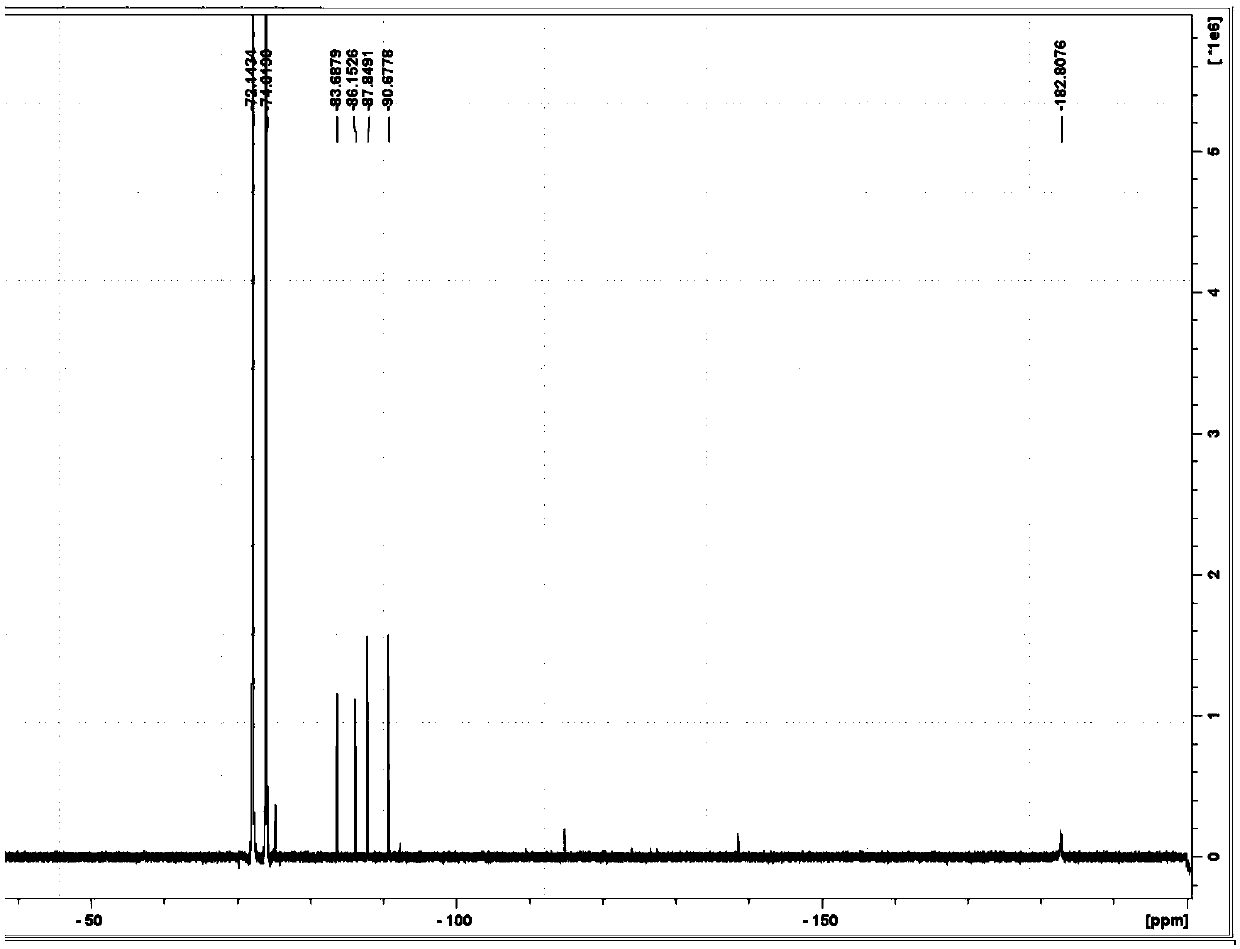

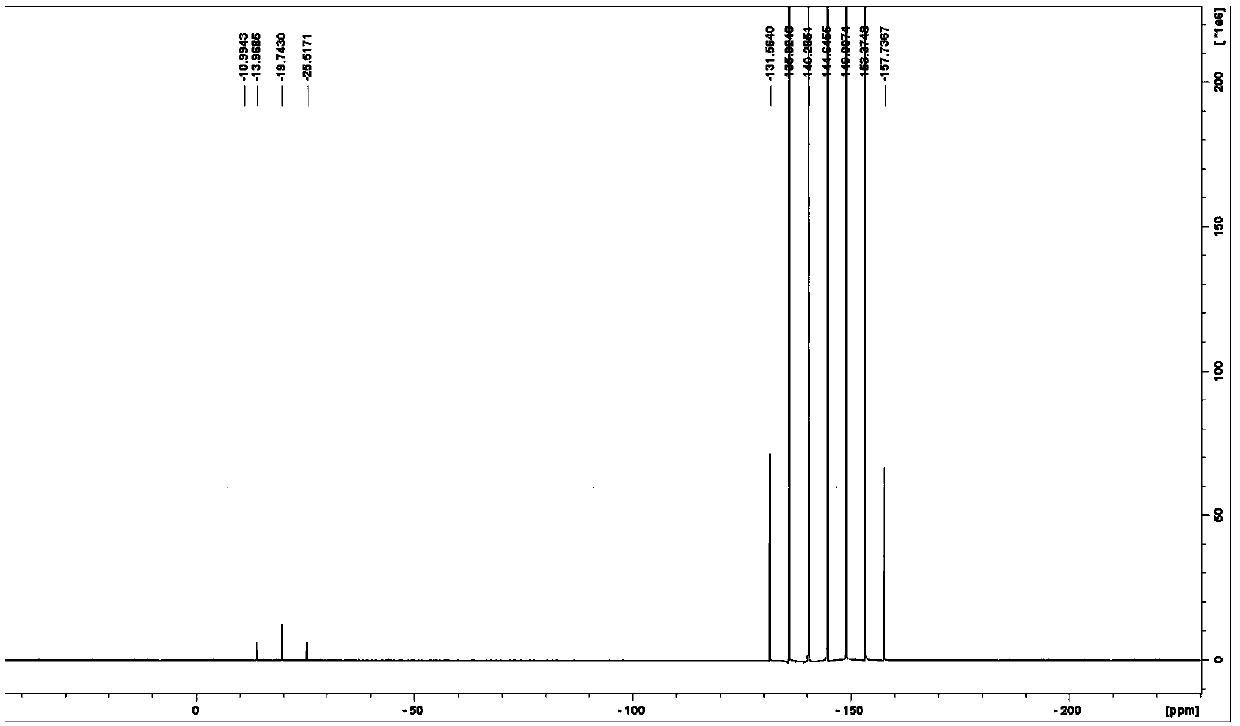

Hexafluorobenzene, HFB, C₆F₆, or perfluorobenzene is an organic, aromatic compound. In this derivative of benzene all hydrogen atoms have been replaced by fluorine atoms. The technical uses of the compound are limited, although it is recommended as a solvent in a number of photochemical reactions. In the laboratory hexafluorobenzene is used as standard in fluorine-19 NMR spectroscopy, solvent and standard in carbon-13 NMR, solvent in proton NMR, solvent when studying some parts in the Infrared and solvent in Ultraviolet–visible spectroscopy, as hexafluorobenzene itself hardly shows any absorbance in the UV region.

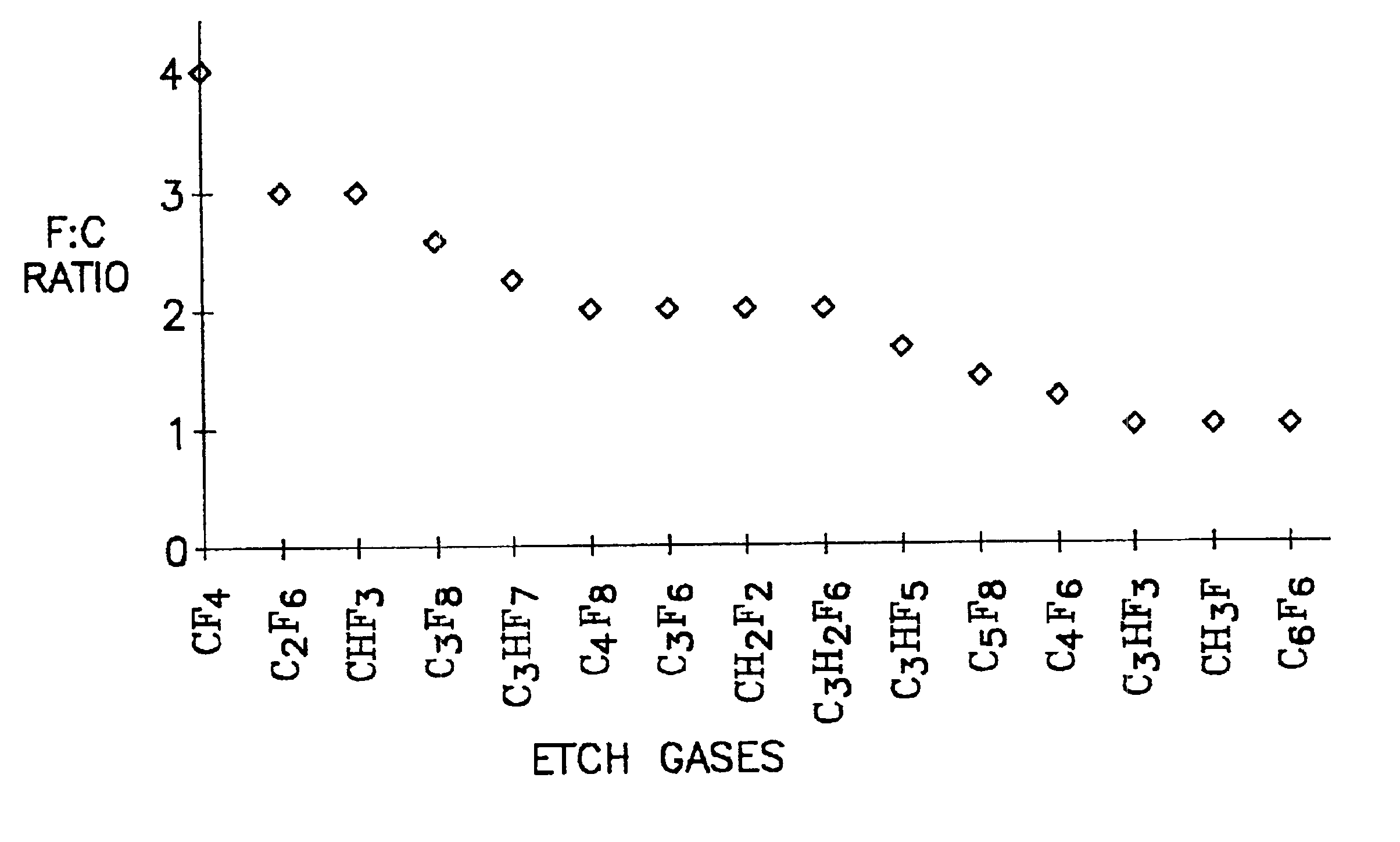

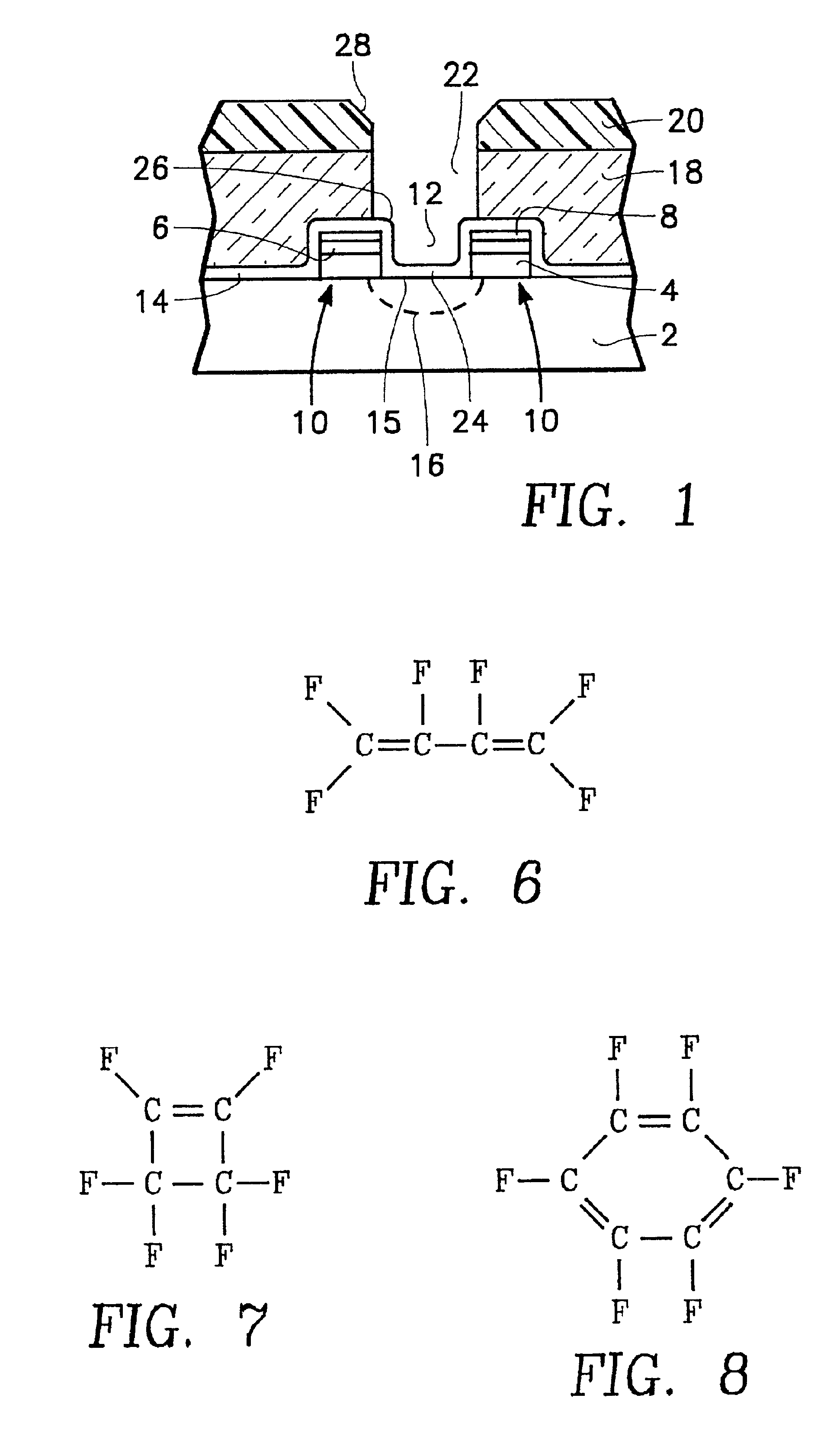

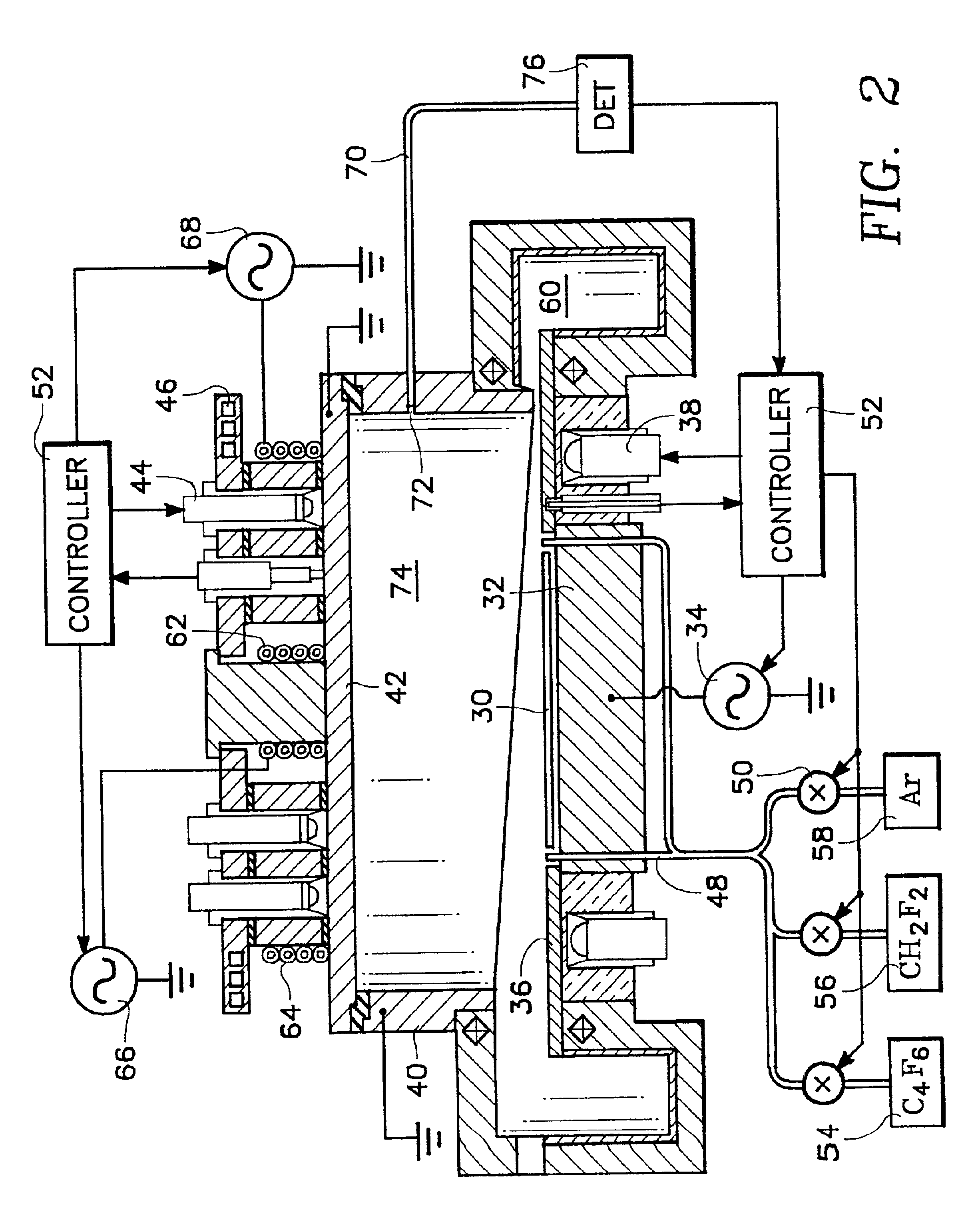

Highly selective process for etching oxide over nitride using hexafluorobutadiene

InactiveUS6849193B2High selectivityQuality improvementDecorative surface effectsSemiconductor/solid-state device manufacturingHexafluorobenzeneNoble gas

An oxide etching process, particularly useful for selectively etching oxide over a feature having a non-oxide composition, such as silicon nitride and especially when that feature has a corner that is prone to faceting during the oxide etch. The invention uses a heavy perfluorocarbon, for example, hexafluorobutadiene (C4F6) or hexafluorobenzene (C6F6). The fluorocarbon together with a substantial amount of a noble gas such as argon is excited into a high-density plasma in a reactor which inductively couples plasma source power into the chamber and RF biases the pedestal electrode supporting the wafer. A more strongly polymerizing fluorocarbon such as difluoromethane (CH2F2) is added in the over etch to protect the nitride corner. Oxygen or nitrogen may be added to counteract the polymerization. The same chemistry can be used in a magnetically enhanced reactive ion etcher (MERIE) or with a remote plasma source.

Owner:HUNG HOIMAN +4

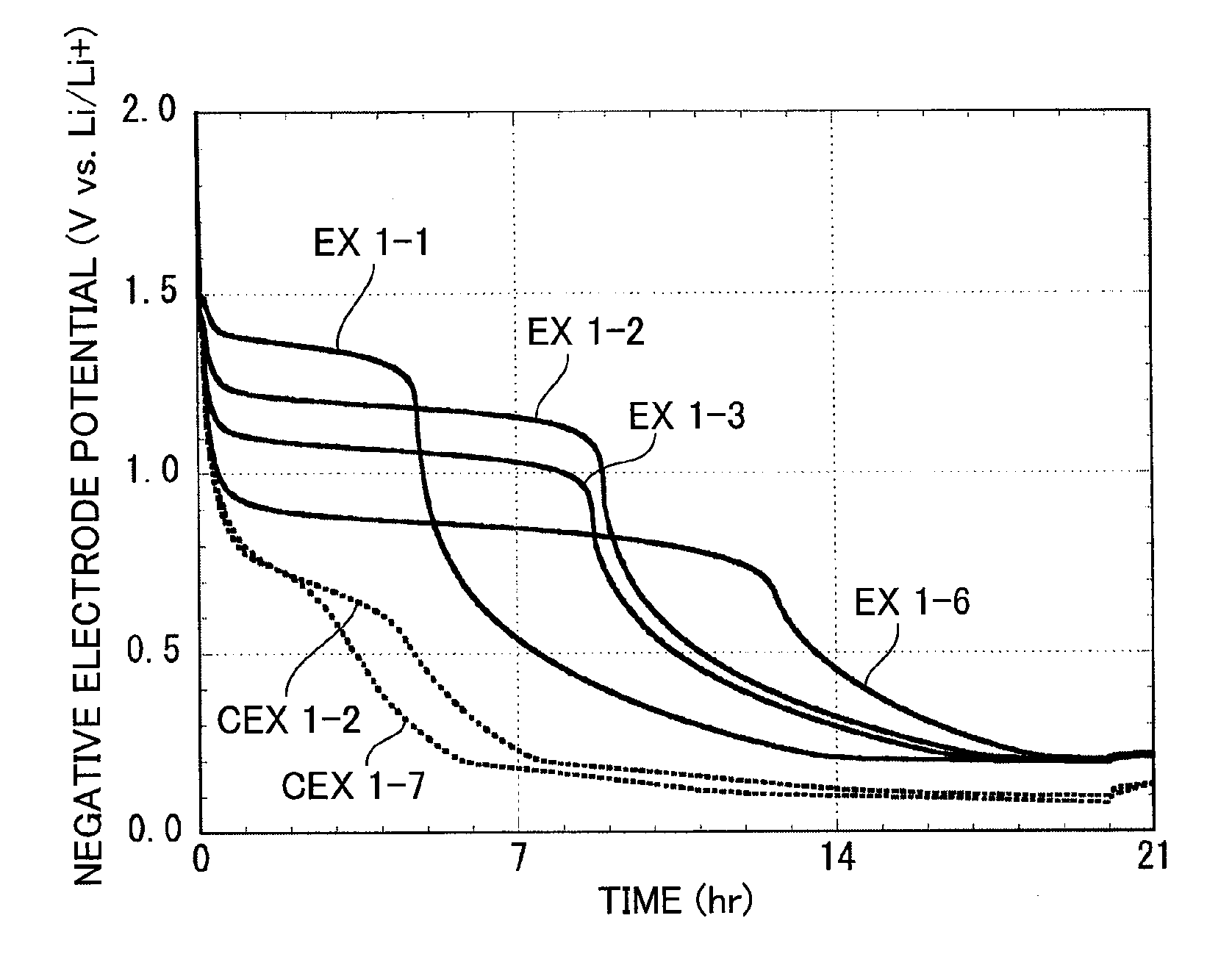

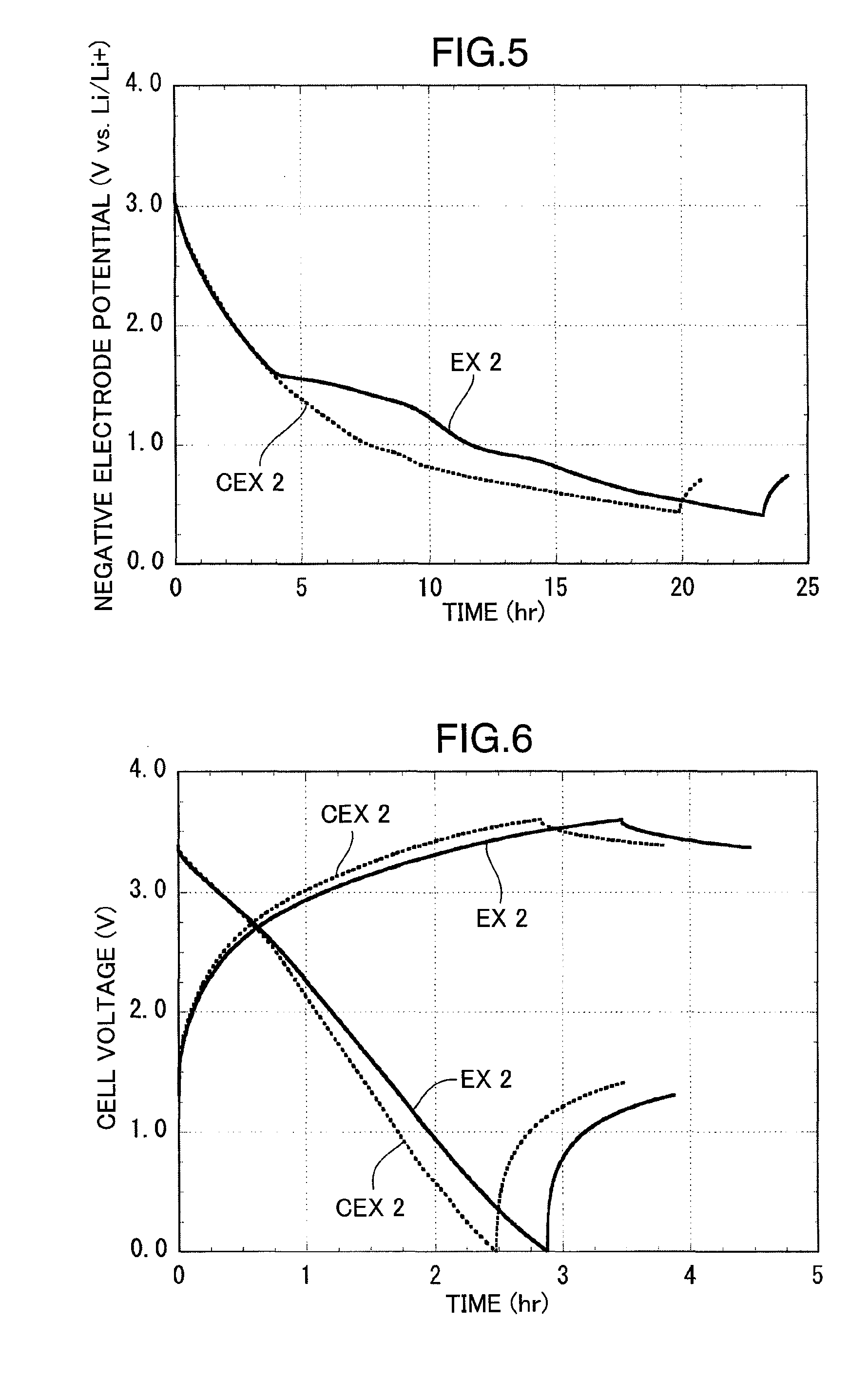

Electrochemical Energy Storage Device

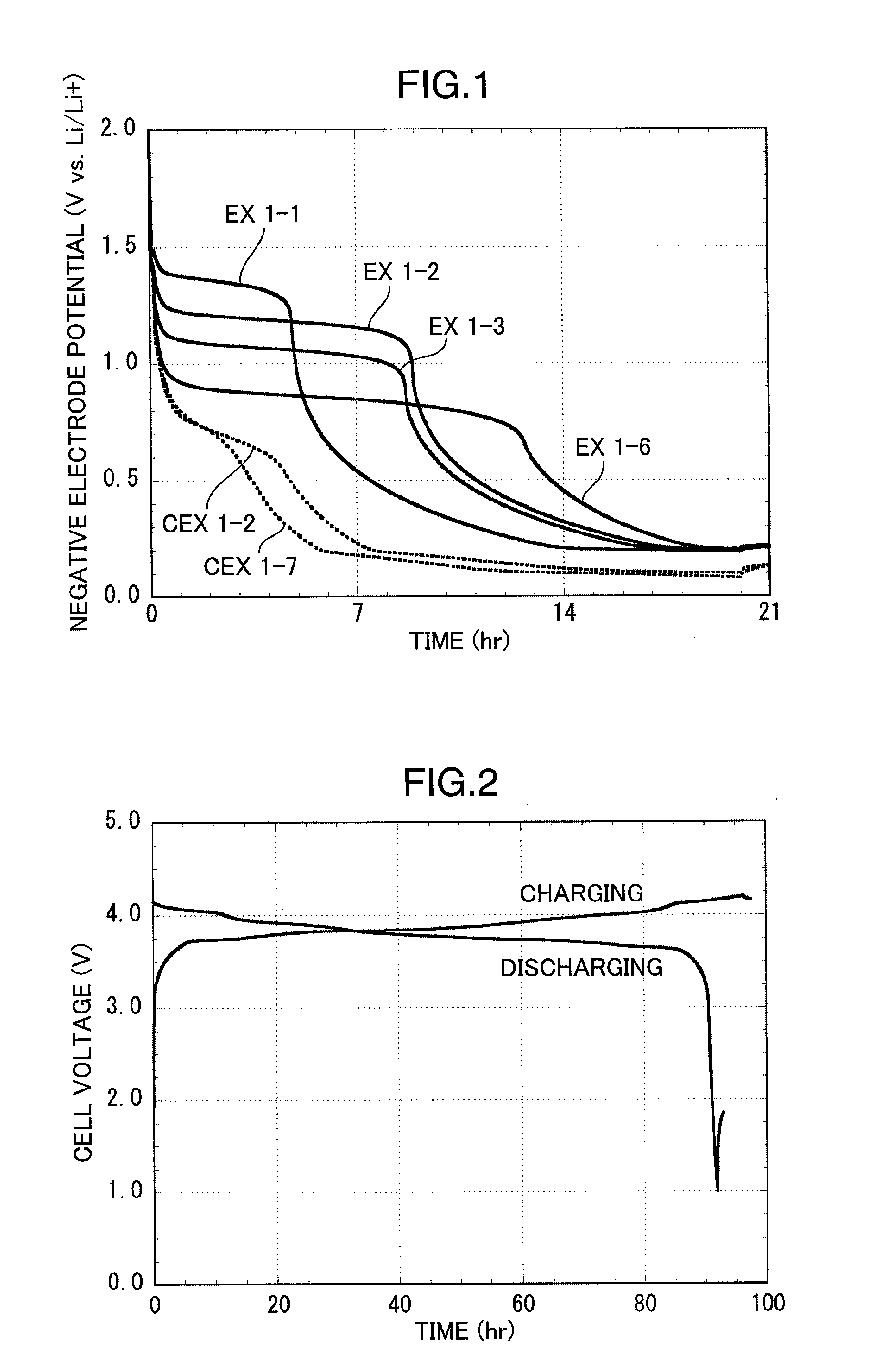

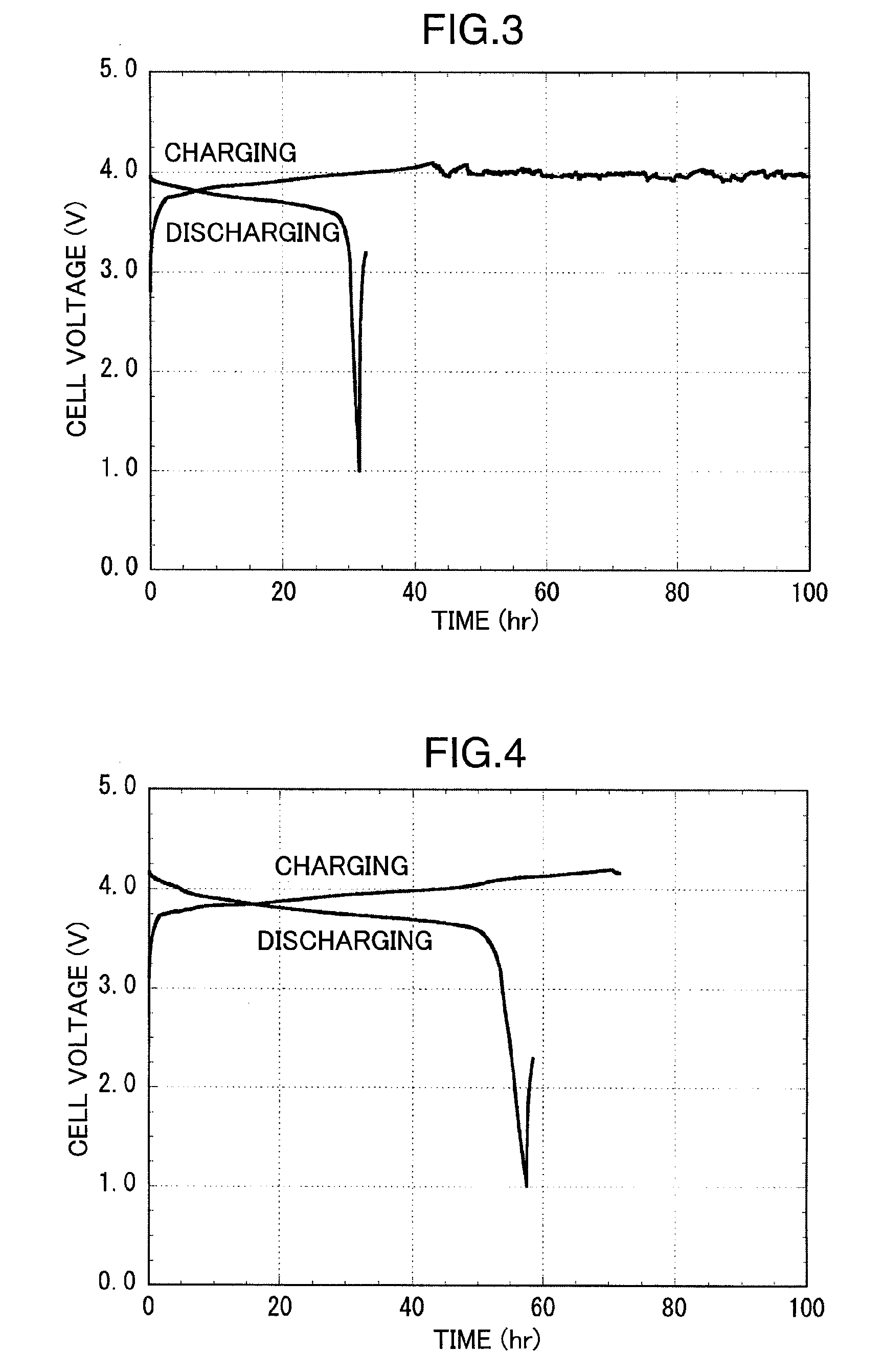

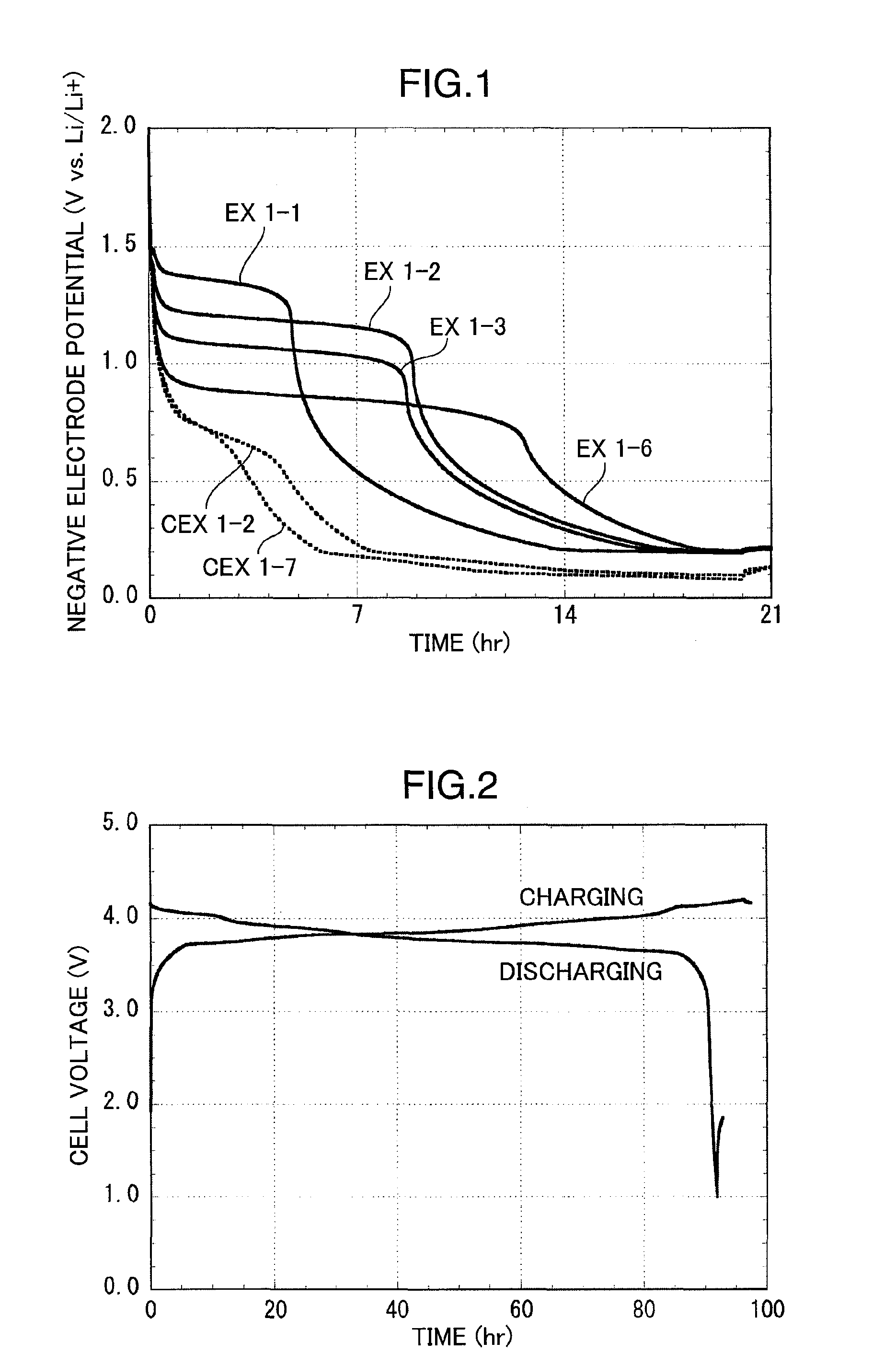

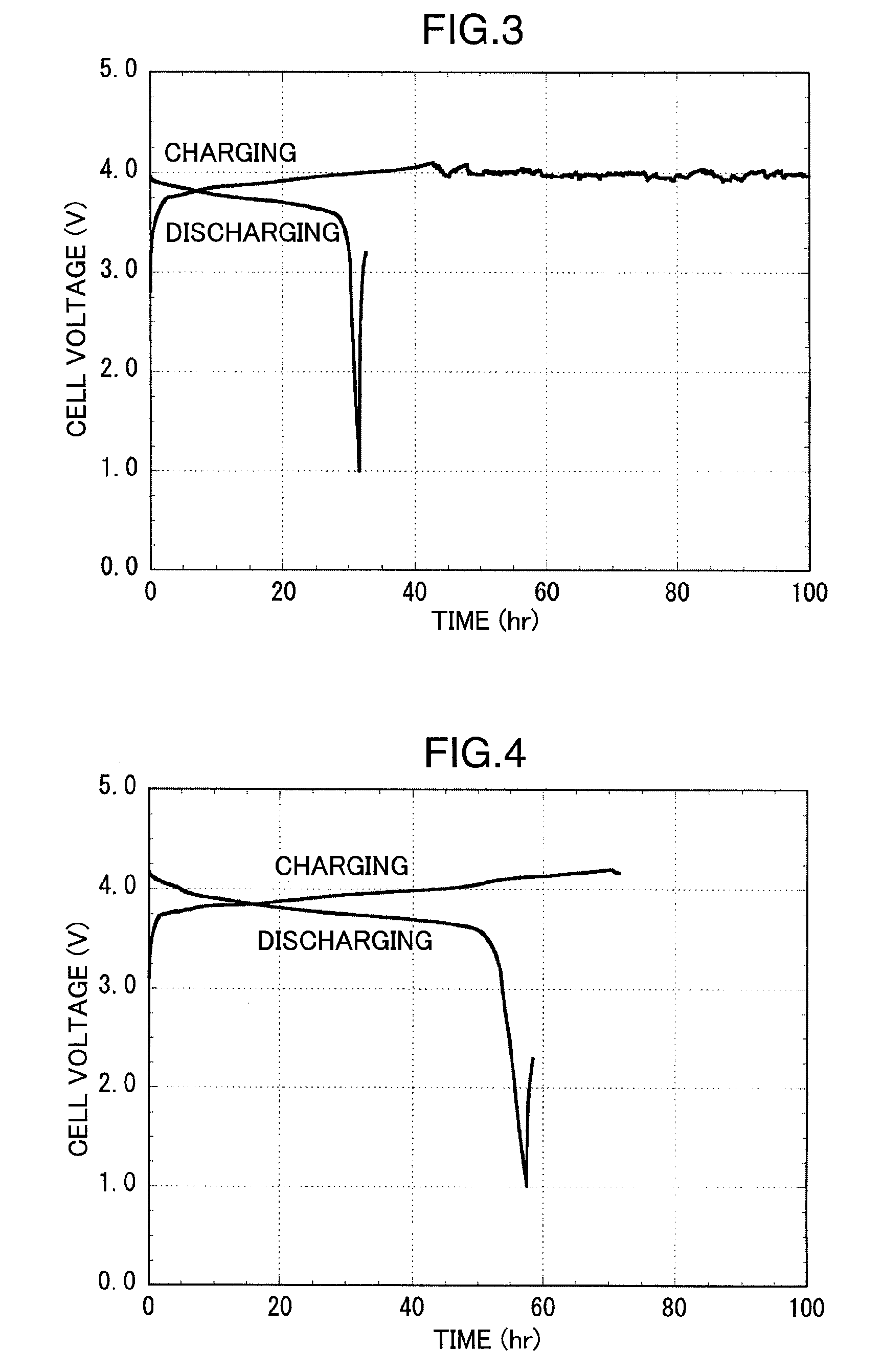

InactiveUS20090176164A1Suppress reductive decompositionImprove breathabilityHybrid capacitor electrolytesNon-aqueous electrolyte accumulatorsHexafluorobenzeneElectrode potential

An electrochemical energy storage device includes a negative electrode which contains a carbon material and has a negative electrode potential of 1.4 V or less relative to a lithium reference when being charged, and a non-aqueous electrolyte solution prepared by dissolving a lithium salt, an ammonium salt, and at least one kind of fluorinated benzene selected among hexafluorobenzene, pentafluorobenzene, 1,2,3,4-tetrafluorobenzene, 1,2,3,5-tetrafluorobenzene, 1,2,4,5-tetrafluorobenzene and 1,2,3-trifluorobenzene, in a non-aqueous solvent.

Owner:PANASONIC CORP

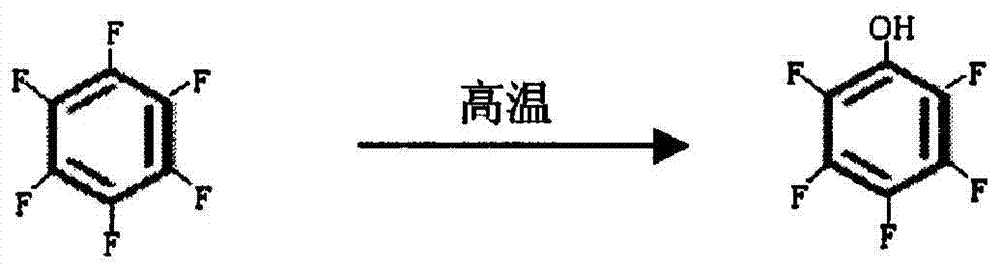

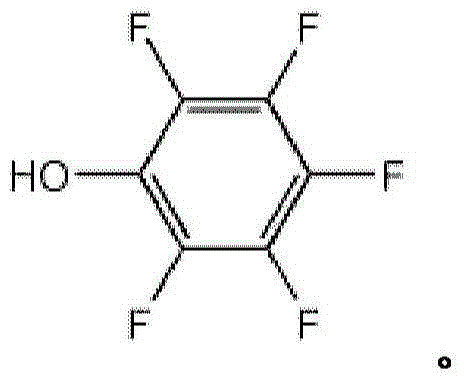

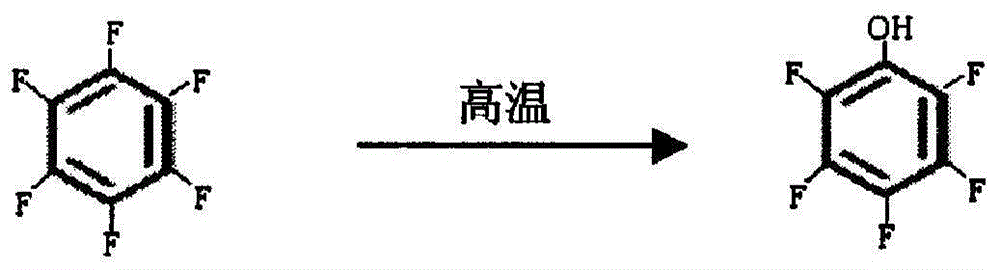

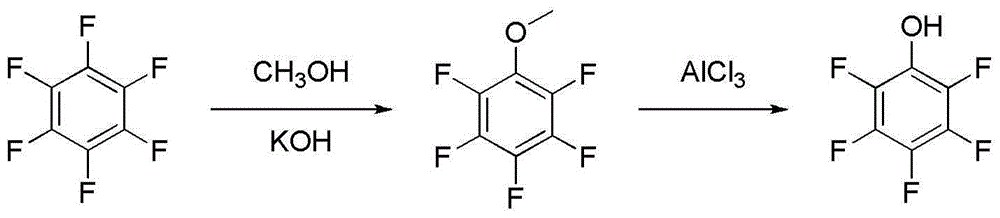

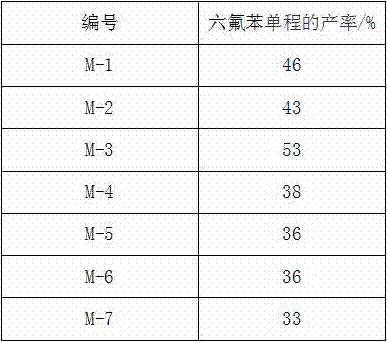

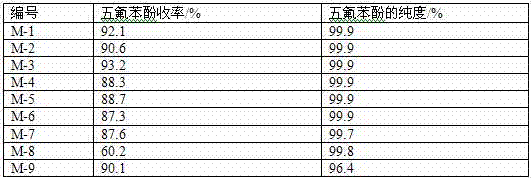

Preparation method for pentafluorophenol

ActiveCN105016983ASolve Stirring ProblemsHigh reaction yieldOrganic compound preparationEther preparationHexafluorobenzeneWastewater

The invention relates to a preparation method for pentafluorophenol. By taking hexafluorobenzene as an initial raw material, pentafluorophenol is prepared through etherification reaction and cracking reaction or by taking hexafluorobenzene as the initial raw material, pentafluorophenol is prepared by virtue of a one-step method. The preparation method provided by the invention does not need high temperature and pressurization, is less in energy consumption, and does not use expensive hydroiodic acid, so that the cost of the raw materials is low. Moreover, wastewater generated by etherification reaction is less, so that the preparation method is environmental-friendly; Cracking is carried out in a solvent, the material stirring effect is good, the reaction temperature is easy to control, and industrialization is easy to implement.

Owner:KINGCHEM LIAONING CHEMICAL CO LTD

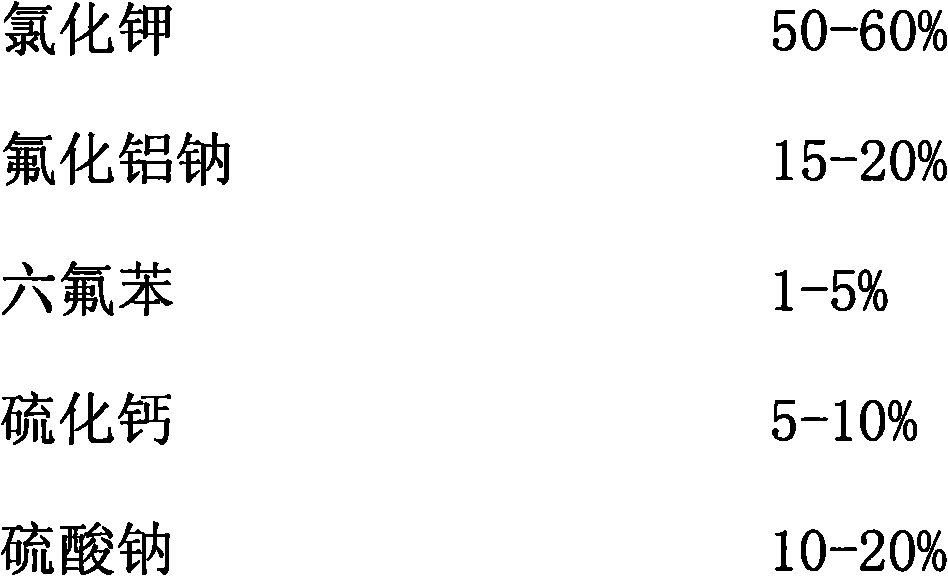

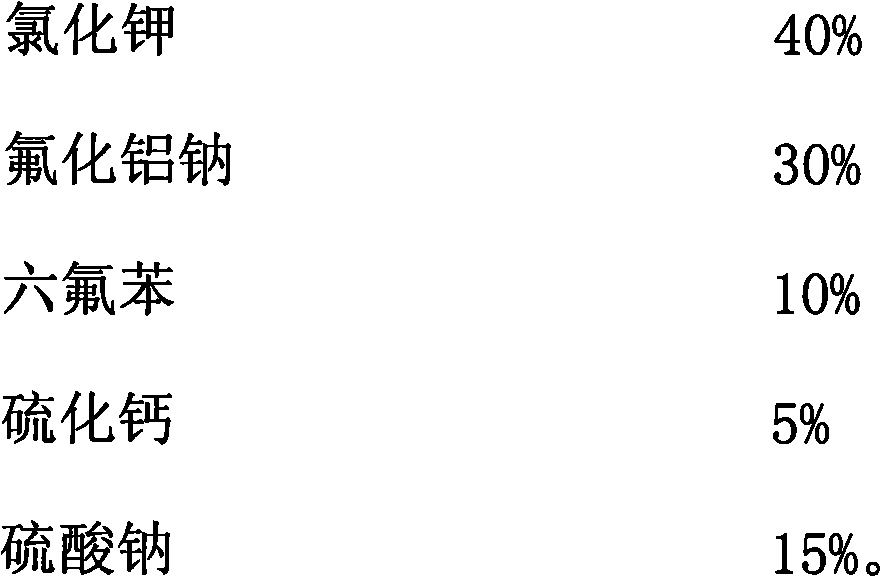

Aluminum alloy smelting refining agent

The invention relates to an aluminum alloy smelting refining agent. The aluminum alloy smelting refining agent consists of the following components by weight percent: 40-70% of potassium chloride, 15-30% of sodium aluminum fluoride, 1-10% of hexafluorobenzene, 5-15% of calcium sulphide and 5-20% of sodium sulfate. By adopting the aluminum alloy smelting refining agent, the hydrogen removing ability is enhanced, the content of hydrogen is reduced to 0.12ml / gAL, the impurity removing effect is obvious, after the refining agent is added, the refining production process is simple, and the utilization rate of the refining agent is improved.

Owner:南通市乐悦实业有限公司

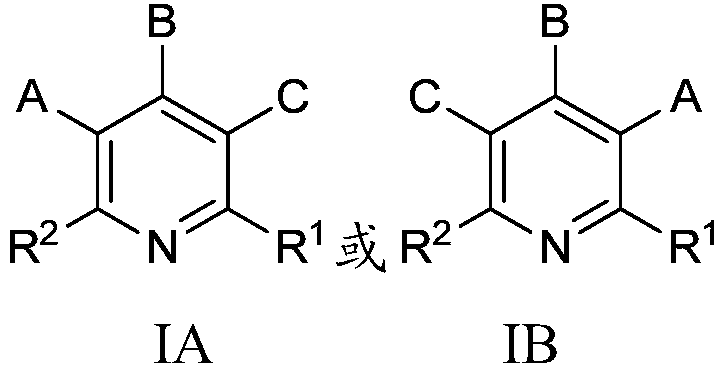

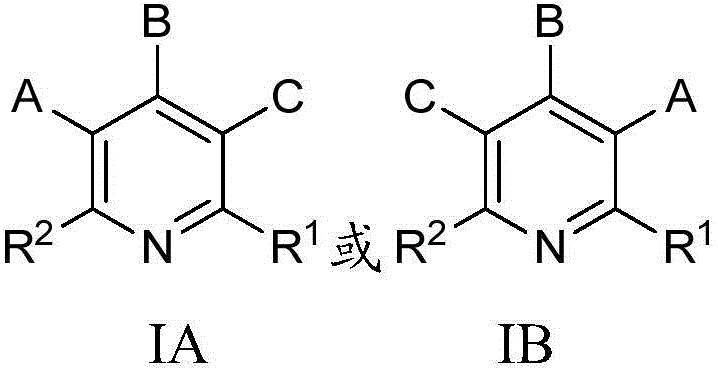

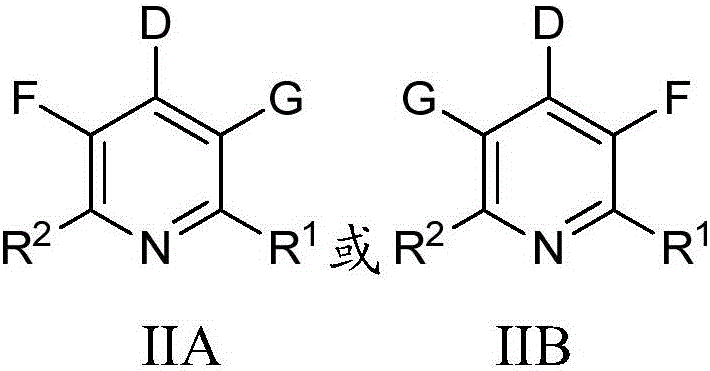

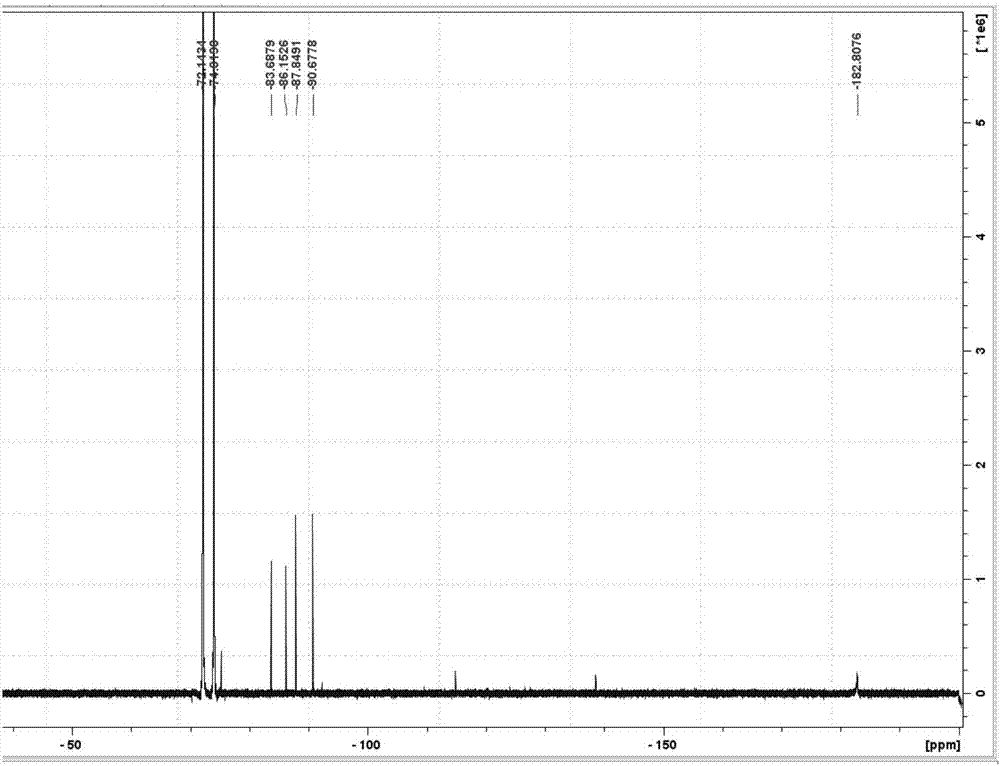

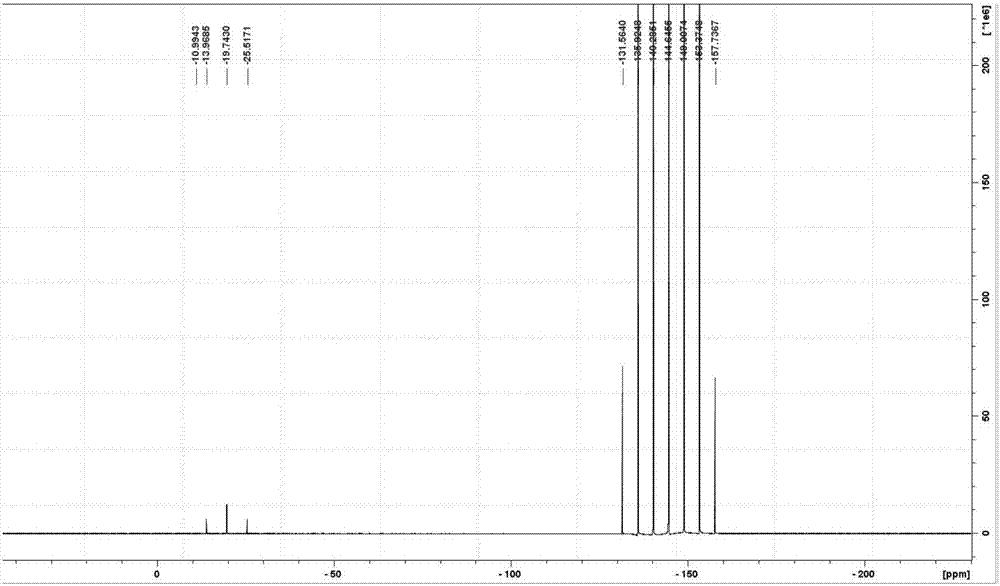

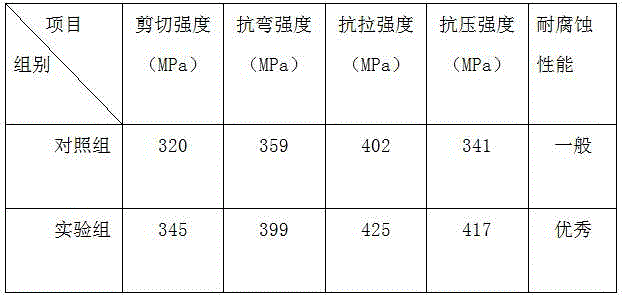

Fluorinated polyarylether compound containing column [5] arene and preparation method thereof

The invention discloses a fluorinated polyarylether compound containing column [5] arene and a preparation method thereof. According to the preparation method, a dihydroxy column [5] arene compound and excessive hexafluorobenzene react so as to prepare a para-bisfluorobenzene substituted column [5] arene derivative A, then polycondensation is performed on A, bisphenol fluorene and difluorobenzophenone, so as to obtain the polyarylether compound containing column [5] arene. The obtained polyarylether compound has excellent solubility, thermal stability, oxidization stability, mechanical property and the like, and is important engineering plastics.

Owner:FUZHOU UNIV

Aluminum alloy refining agent

The invention discloses an aluminum alloy refining agent which comprises the following raw materials in parts by mass: 20-25 parts of potassium chloride, 30-35 parts of sodium chloride, 3-5 parts of sodium carbonate, 3-6 parts of calcium fluoride, 10-15 parts of sodium sulfate, 20-25 parts of potassium nitrate, 5-10 parts of hexafluorobenzene and 1-2 parts of rare earth. The aluminum alloy refining agent can effectively remove slag inclusions in the liquid aluminum, can lower the hydrogen content in the liquid aluminum, and has obvious purifying effect on the liquid aluminum.

Owner:桑达化工(南通)有限公司

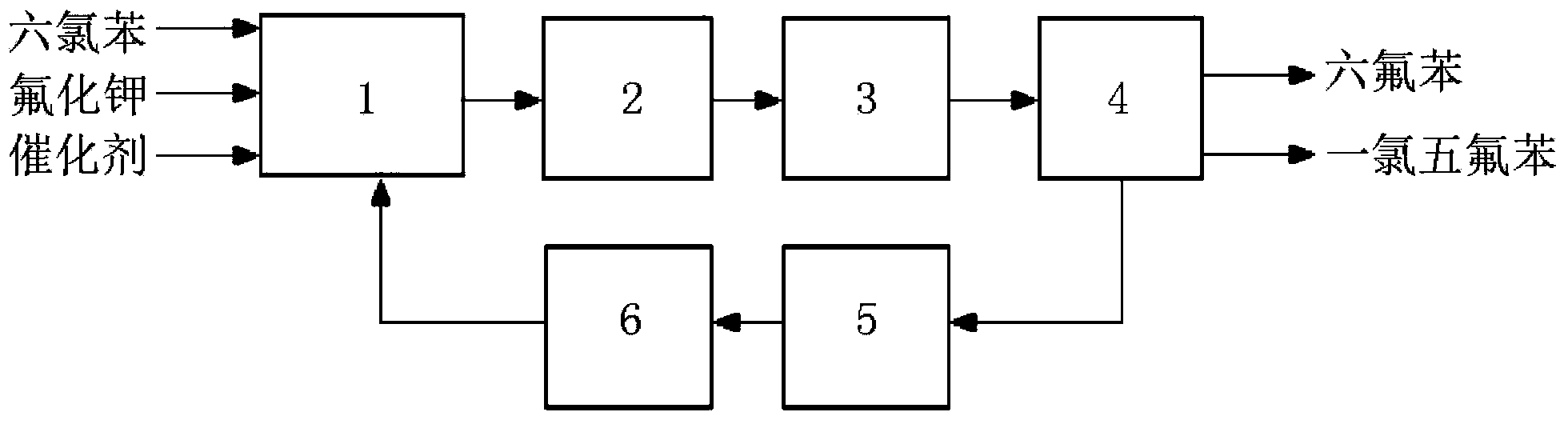

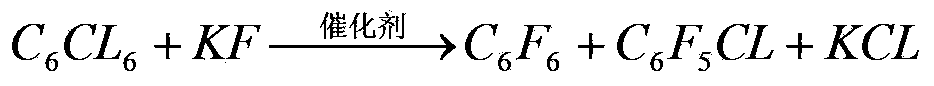

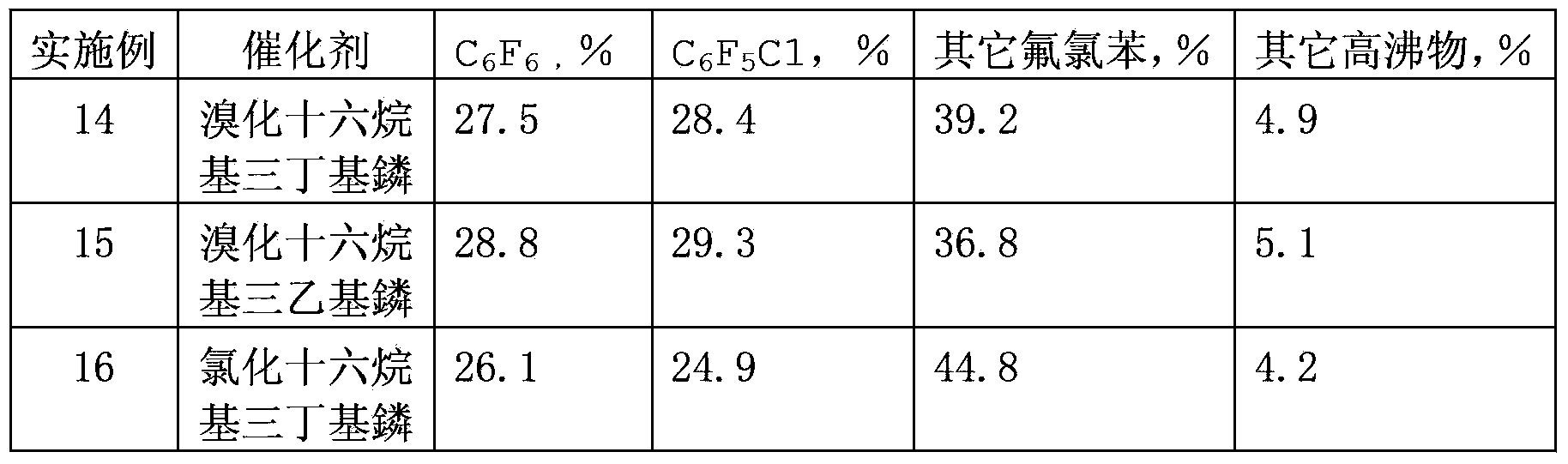

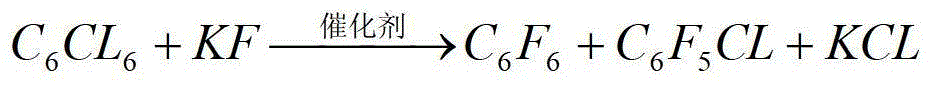

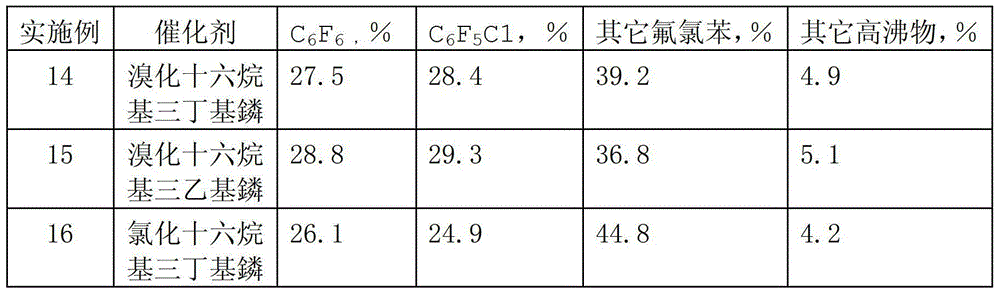

Preparation method of hexafluorobenzene and chloropentafluorobenzene

ActiveCN103360202AAvoid cokingHigh yieldPreparation by halogen replacementHexafluorobenzenePotassium fluoride

The invention discloses a preparation method of hexafluorobenzene and chloropentafluorobenzene. The preparation method of hexafluorobenzene and chloropentafluorobenzene comprises the following steps of: (1) adding raw materials including hexafluorobenzene, active potassium fluoride and a catalyst into a reactor; (2) carrying out nitrogen displacement on the reactor and adding a solvent into the reactor; (3) heating the reactor and stopping heating after a reaction completes; (4) after cooling, switching on an air valve of the reactor, evaporating a reaction product and the solvent in the reactor, and condensing and recycling the reaction product and the solvent; (5) deacidifying the reaction product and the solvent condensed and recycled in the step (4) through an acid separator; (6) separating hexafluorobenzene and chloropentafluorobenzene from the deacidified reaction product and solvent in the step (5) through a rectifying method; and (7) after the reaction product and the solvent in the reactor are completely recycled, cooling the reactor, opening a reaction kettle, and taking out residues such as potassium chloride in the reaction kettle. The preparation method of hexafluorobenzene and chloropentafluorobenzene has the characteristics of convenience for process operation, mildness in reaction, safety and controllability, simplicity in post treatment procedure, less loss and high yield.

Owner:衢州乾达科技有限公司

Electrochemical energy storage device

InactiveUS8148017B2Suppress reductive decompositionPrevent penetrationHybrid capacitor electrolytesNon-aqueous electrolyte accumulatorsElectrode potentialHexafluorobenzene

An electrochemical energy storage device includes a negative electrode which contains a carbon material and has a negative electrode potential of 1.4 V or less relative to a lithium reference when being charged, and a non-aqueous electrolyte solution prepared by dissolving a lithium salt, an ammonium salt, and at least one kind of fluorinated benzene selected among hexafluorobenzene, pentafluorobenzene, 1,2,3,4-tetrafluorobenzene, 1,2,3,5-tetrafluorobenzene, 1,2,4,5-tetrafluorobenzene and 1,2,3-trifluorobenzene, in a non-aqueous solvent.

Owner:PANASONIC CORP

Method of producing hexafluorobenzene from byproduct wastes of tetrachloroethylene

InactiveCN107098792ASmooth responseHigh yieldPreparation by halogen replacementBulk chemical productionTetrachloroethyleneHexafluorobenzene

The invention provides a method of producing hexafluorobenzene from byproduct wastes of tetrachloroethylene. The method includes the steps of: preparing an ionic liquid solvent; adding the byproduct wastes of tetrachloroethylene, dried KF, the ionic liquid solvent, and a polystyrene supporting quaternary phosphonium salt type resin catalyst into a reaction kettle; and gradually increasing the temperature of the system to perform a reaction, thus producing the products, including hexafluorobenzene and monochloropentafluorobenzene.

Owner:衢州乾达科技有限公司

Environment-friendly treatment method of hexachlorobenzene

ActiveCN104725183AEasy to separateImprove conversion ratePreparation by halogen replacementHexafluorobenzeneContinuous use

The invention discloses an environment-friendly treatment method of hexachlorobenzene. The method comprises the following steps: (1) putting hexachlorobenzene and an active potassium fluoride solution organic solvent into a single reactor; (2) performing pressure test leakage detection and nitrogen replacement on the single reactor containing a reaction solution; (3) heating the single reactor to 200-300 DEG C, boosting the pressure to 2.0-3.0MPa, and reacting for 10-15h at a reaction temperature and a reaction pressure; (4) distilling off reactants in the single reactor, condensing and then collecting the reactants; (5) performing distillation separation on hexachlorobenzene and chloropentafluorobenzene in the reactants; and (6) performing reduced pressure distillation to collect fluorochlorobenzene (byproduct) and the organic solvent in the single reactor, taking out potassium chloride residues in the single reactor, drying fluorochlorobenzene, and then adding fluorochlorobenzene into the single reactor for continuous use. The method disclosed by the invention is mild in reaction condition and relatively high in conversion rate and yield, and a practical chemical intermediate is obtained while pollution is reduced, so that the method has a broad application prospect.

Owner:JUHUA GROUP TECH CENT

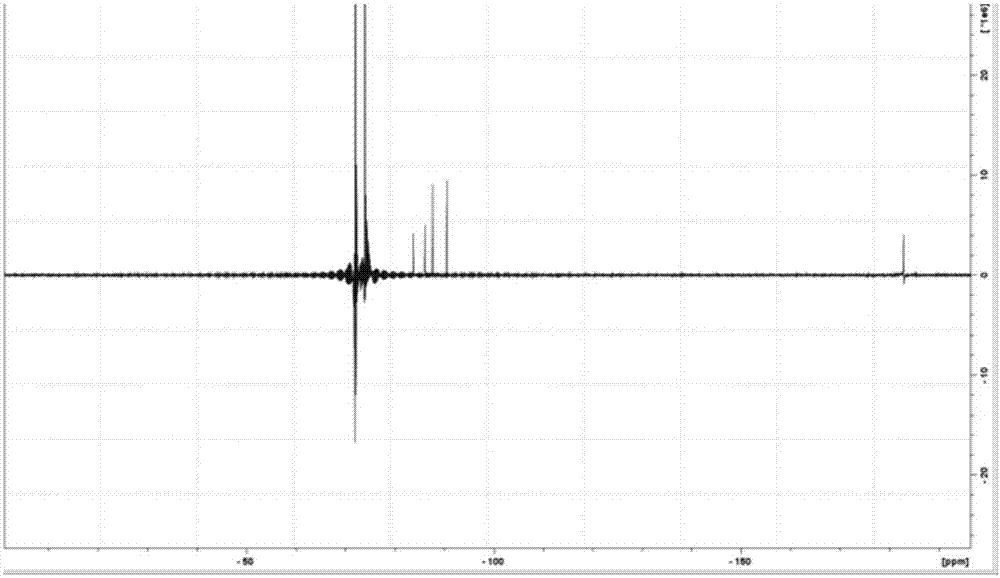

Method for detecting impurities in lithium hexafluorophosphate

ActiveCN106970103AImprove securityImprove accuracyAnalysis using nuclear magnetic resonanceHexafluorobenzenePhosphoric acid

The invention discloses a method for detecting impurities in lithium hexafluorophosphate. The method includes steps of (1), carrying out calibration, to be more specific, adding deuterated reagent solution of hexafluorobenzene and deuterated reagent solution of the lithium hexafluorophosphate into inner and outer tubes of coaxial nuclear magnetic tubes, carrying out fluorine spectrum detection, adding deuterated reagent solution of phosphoric acid and deuterated reagent solution of the lithium hexafluorophosphate into the inner and outer tubes of the coaxial nuclear magnetic tubes and carrying out phosphorus spectrum detection; (2), carrying out measurement, to be more specific, preparing to-be-detected samples with certain concentration from the lithium hexafluorophosphate and deuterated reagents and carrying out fluorine spectrum and phosphorus spectrum detection by the aid of nuclear magnetic resonators. Compared with the traditional method, the method has the advantages that the fluorine-containing and phosphorus-containing impurities in the lithium hexafluorophosphate can be qualitatively and quantitatively detected by the aid of the method, and the method is short in analysis time, easy to implement and high in sensitivity, equipment can be prevented from being damaged by fluorine-containing strong corrosive substances, and the like.

Owner:GUANGZHOU TINCI MATERIALS TECH

Pentafluorophenol preparation mehtod

ActiveCN107011126AHigh yieldSmooth responseOrganic chemistryOrganic compound preparationHexafluorobenzeneRoom temperature

The invention provides a pentafluorophenol preparation method. The pentafluorophenol preparation method is characterized by comprising the following preparation steps: adding 500-1000 parts of water, 50-100 parts of sodium hydroxide, 3-10 parts of a hydrolysis catalyst, 100 parts of hexafluorobenzene and 0.1-1 part of dodecyl secondary amine into a high pressure kettle according to parts by weight, sealing the high pressure kettle, raising the temperature to 110-150 DEG C, reacting for 3-8 hours, cooling to the room temperature, filtering, acidizing, extracting with methyl tert-butyl ether, combining an organic phase, distilling to recycle a solvent, and obtaining a crude product of 2,3,4,5,6-pentafluorophenol, adsorbing the crude product of pentafluorophenol in a crude product tank through five rectifying columns, and obtaining a purified product of pentafluorophenol.

Owner:衢州乾达科技有限公司 +1

Preparation method of pentafluorophenol

ActiveCN109369346ALow costReduce pollutionOrganic chemistryOrganic compound preparationHexafluorobenzeneOrganic matter

The invention relates to a preparation method of pentafluorophenol, and belongs to the field of chemical production technologiesprocesses. The preparation method of the pentafluorophenol is carried out according to the following technologies processes that hexafluorobenzene, strong base and water are put in a sealed container, to be prepared intothus a mixed solution is prepared, heat preservationis conducted at the temperature of 100-150 DEG C for reaction, and thus a system solution is obtained; the system solution is neutralized until the pH value is not higher than 6, then a coarse product is extracted, rectification is conducted, and the pentafluorophenol is obtained. According to the preparation method, the cost is low, organic matter and heavy metal are not adopted except for substrate, pollution is small, side reactions is are lessfewer, the reaction steps are simple, and operation is easy.

Owner:DALIAN QIKAI MEDICAL TECH

Preparation method of hexafluorobenzene

InactiveCN107827704ALess variable amountReduce energy consumptionPreparation by halogen replacementHexafluorobenzenePotassium fluoride

The invention relates to a preparation method of hexafluorobenzene, and belongs to the field of chemical production techniques. The preparation method of the hexafluorobenzene is characterized by comprising the following technologies: (1) mixing potassium fluoride with a nonprotic polar solvent, thus obtaining a mixed solution; (2) adding a reaction substrate, nitrobenzene and a phase transfer catalyst in the mixed solution, thus obtaining a reaction system, wherein the reaction substrate is chloropentafluorobenzene; (3) putting the reaction system obtained in the step (2) in a high-pressure kettle, sealing after discharging air in the high-pressure kettle, and reacting, thus obtaining a product; (4) rectifying the product after distilling, thus obtaining the hexafluorobenzene. According to the method disclosed by the invention, the energy consumption is lower, side effects are few, the reaction steps are simple, and the operation is easy; the solvent denaturation amount is less, separation and recycling are easy, and compared with other methods, and the method is greener and more environmental friendly.

Owner:DALIAN QIKAI MEDICAL TECH

Pentafluorophenol preparation method

ActiveCN107353181AReduce dosageLess side effectsOrganic chemistryOrganic compound preparationHexafluorobenzenePotassium hydroxide

The invention provides a pentafluorophenol preparation method, which comprises: using hexafluorobenzene and potassium hydroxide as raw materials, adding an appropriate amount of tetrabutylammonium hydrogen sulfate, N-sulfopropyl-3-methylpyridine triflate, N-methyl-2-[(2-methylphenoxy)acetyl]hydrazinium methylthioamide and 2,2,6,6-tetramethylpiperidine-oxynitride to a tert-butyl alcohol aqueous solution with a mass fraction of 80-85%, heating to achieve a slight boiling state, carrying out a reflux reaction for 2-3 h, adding an appropriate amount of water, distilling to recover the tert-butyl alcohol solvent, adjusting the PH value of the remaining aqueous solution by using refined hydrochloric acid to 9-10, adsorbing with a functionalized D101 macroporous adsorption resin, acidifying with refined hydrochloric acid to achieve the PH value of 1-2, layering, distilling the upper layer water phase until no oily substance exists, collecting the distilled product, combining the collected product and the lower layer oil phase, rectifying, collecting the distillate at the temperature of 142-144 DEG C, and cooling to a room temperature to obtain the colorless and transparent crystal pentafluorophenol. According to the present invention, the preparation method has advantages of simple and reasonable process, less side reactions, high reaction yield and high product purity, and can meet the quality requirements for the preparation of the high-quality liquid crystal materials and drugs.

Owner:QUZHOU UNIV

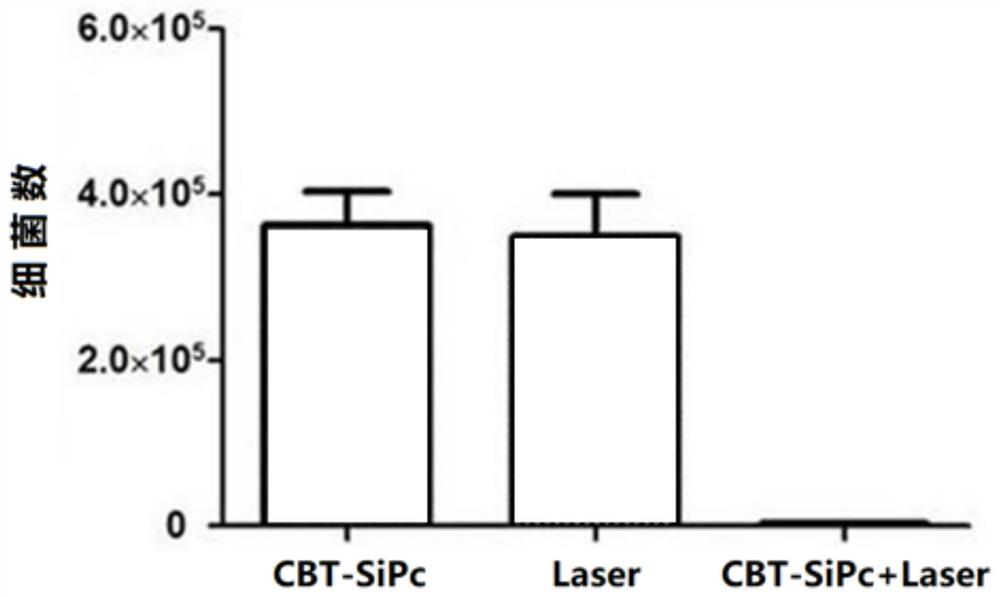

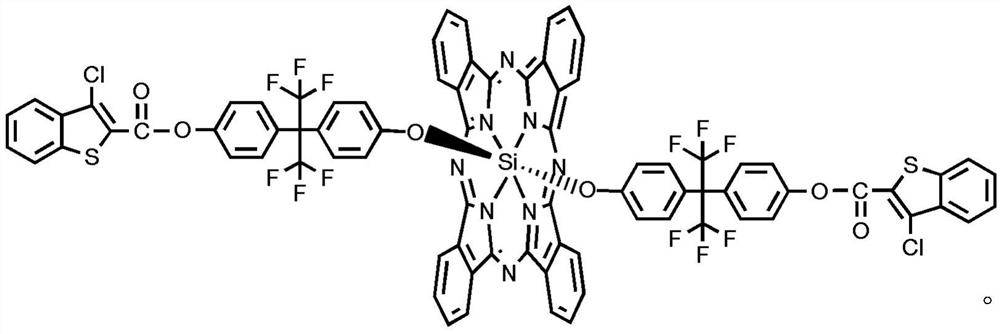

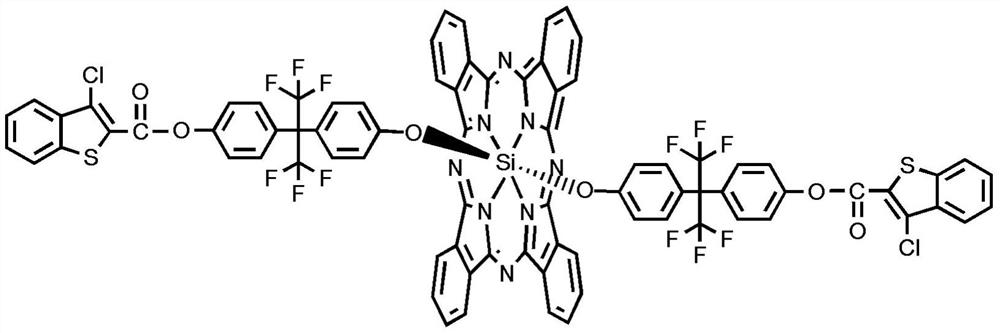

Preparation method of di-((3-chlorobenzothiophene-2-ester) hexafluorophenoxy) axially substituted silicon phthalocyanine

InactiveCN112574248AInhibition formationHigh transparencyAntibacterial agentsGroup 4/14 element organic compoundsHexafluorobenzeneAryl

The invention belongs to the field of complexes, and particularly belongs to a method for preparing di ((3-chlorobenzothiophene-2-ester) hexafluorophenoxy) axially substituted silicon phthalocyanine,and the complex is applied to photodynamic therapy of bacterial infection as a photosensitizer. The method is realized through the following steps: mixing and stirring 3-chlorobenzothiophene-2-ester hexafluorophenol (CBT-OH for short) and dichlorosilane (IV) phthalocyanine according to a ratio of 1: (0.25-4) at 140 DEG C in toluene in the presence of anhydrous K2CO3, and performing refluxing to prepare di-((3chlorobenzothiophene-2-ester) hexafluorophenoxy) axially substituted silicon phthalocyanine. According to the invention, the steric hindrance of lipophilic chlorobenzothiophene ring structure molecules with large volume can be utilized to inhibit the formation of phthalocyanine aggregates to a certain extent, inhibit the formation of aggregates and increase the permeability of bacterial cell membranes, so that the aryl thiophene axially substituted silicon phthalocyanine complex becomes a photosensitizer with application potential.

Owner:FUJIAN NORMAL UNIV

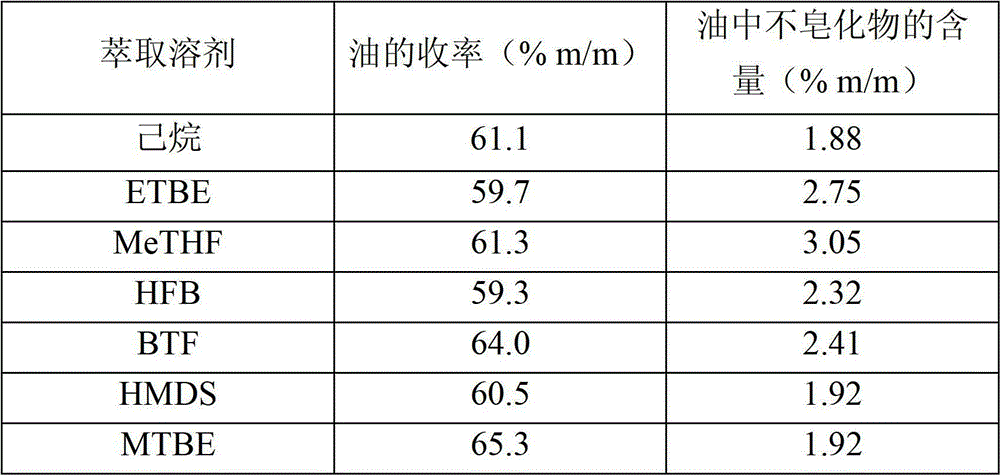

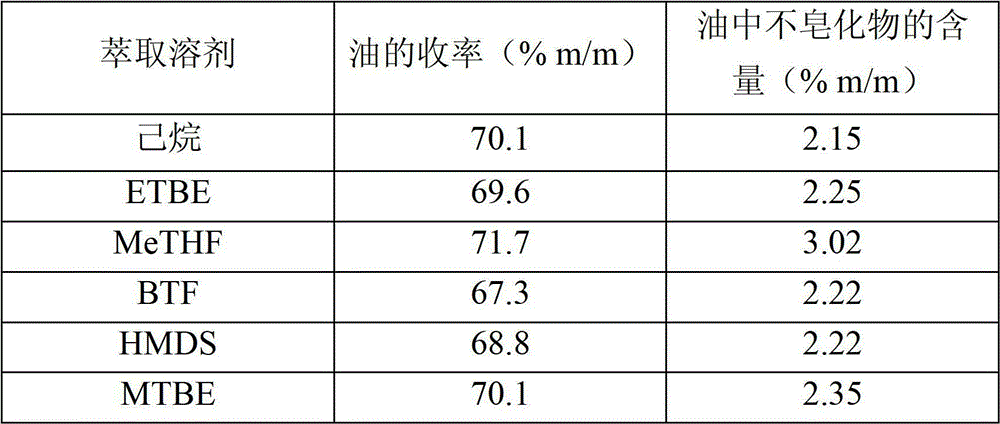

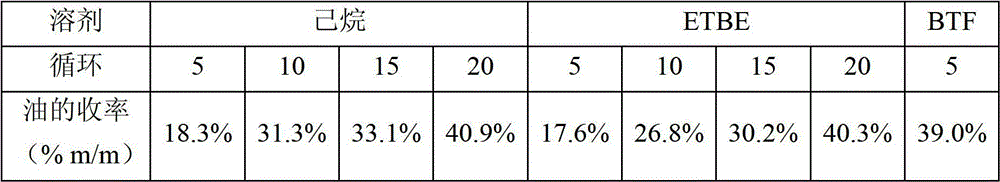

Solid/liquid extraction

InactiveCN102724887ACosmetic preparationsFatty acid esterification2-Methyl propane2-ethoxy-2-methylpropane

The invention relates to a method for the solid / liquid extraction of an oil or butter, particularly having a high unsaponifiable content, contained in at least one solid vegetable matter or a micro-organism. The method includes at least the following steps: solid / liquid extraction of at least one solid vegetable matter or a micro-organism using a first solvent system comprising a concentration of solvent selected from among fluorinated aromatic solvents, particularly trifluorotoluene (BTF) and hexafluorobenzene (BHF), tert-butyl ethers, particularly 2-ethoxy-2-methylpropane, also known as ethyl-tert-butyl-ether (ETBE), and 2-methoxy-2-methylpropane or methyl-tert-butylether (MTBE), solvents comprising at least one silicon atom, particularly hexamethyldisiloxane (HMDS) and tetramethylsilane (TMS), methyl-tetrahydrofuran (MeTHF), and mixtures thereof, representing at least 50 vol.-% in relation to the total volume of the solvent system; and, optionally, recovery of a fraction comprising the oil or butter, particularly unsaponifiable enriched. The invention also relates to an unsaponifiable fraction, oil or butter obtained using this method and to compositions containing said oil or fraction.

Owner:LAB EXPANSCIENCE

Preparation method of hexafluorobenzene

ActiveCN111116306ALow costReduced operating requirementsPreparation by halogen replacementHexafluorobenzeneChlorobenzene

A preparation method of hexafluorobenzene comprises the following steps: dehumidifying, dedusting and purifying a reactor; adding a hexachlorobenzene solid into the reactor filled with a solvent, mixing uniformly, and sealing the reactor; vacuumizing the sealed reactor for replacement, and completely discharging air in a container; cooling the reactor, controlling the temperature in the reactor tobe not more than -10 DEG C, and then stirring the solvent added with the hexachlorobenzene solid to completely dissolve the hexachlorobenzene solid; introducing fluorine gas into the reactor in a slow bubbling manner, controlling the gas inflow of the fluorine gas, controlling the temperature in the reaction container to be not more than -10 DEG C, and controlling the reaction pressure in the reaction container to be 0-1MPa; and obtaining a hexafluorobenzene mother liquor after the reaction is finished, and purifying the hexafluorobenzene mother liquor to obtain the hexafluorobenzene product.The method has the advantages of simple reaction conditions, low raw material cost, mild and easily-controlled reaction, low operation requirements and high product yield.

Owner:洛阳森蓝化工材料科技有限公司

Method for continuously preparing pentafluorophenol by micro-reactor

ActiveCN111072455AHigh reaction yieldAvoid hydrolysisOrganic chemistryOrganic compound preparationHexafluorobenzeneMicroreactor

The invention relates to a method for continuously preparing pentafluorophenol by a microreactor, which belongs to the field of chemical production processes. The method comprises the following steps:simultaneously pumping hexafluorobenzene and an inorganic alkali aqueous solution into a micro-channel reactor by using a metering pump respectively, and mixing for a hydrolysis reaction; keeping thetemperature of the reactor at 130-170 DEG C, controlling and maintaining the pressure of a pipeline at 0.5-1.0 Mpa by an outlet quantitative pressure control valve, connecting an outlet with a heat exchanger, obtaining an aqueous solution of pentafluorophenolate from the outlet of the heat exchanger, adding hydrochloric acid steam, distilling to obtain an oil layer, and rectifying and dehydratingthe oil layer to obtain pentafluorophenol. The method is simple in process, low in cost, free of amplification effect and capable of achieving continuous production.

Owner:DALIAN QIKAI MEDICAL TECH

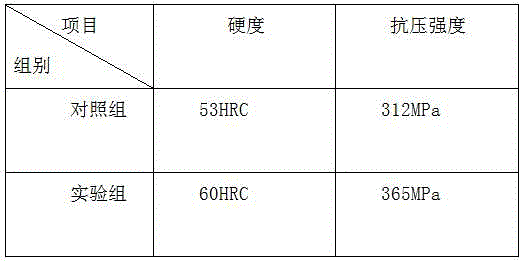

Aluminum rare earth alloy and preparation method thereof

The invention discloses an aluminum rare earth alloy. The aluminum rare earth alloy comprises, by weight, 150-152 parts of aluminum, 18-20 parts of iron, 2-4 parts of cobalt, 5-7 parts of molybdenum, 5-7 parts of zirconium, 1-3 parts of tin, 1-3 parts of iridium, 1-3 parts of terbium, 1-3 parts of dysprosium, 1-3 parts of thulium, 1-3 parts of ytterbium, 2-4 parts of potassium nitrate, 1-3 parts of sodium fluoroaluminate, 1-3 parts of hexafluorobenzene, 1-3 parts of titanium sponge and 6-8 parts of chromium sesquioxide. The aluminum rare earth alloy is high in hardness.

Owner:林海英

A kind of environmental protection processing method of hexachlorobenzene

ActiveCN104725183BEasy to separateImprove conversion ratePreparation by halogen replacementHexafluorobenzenePotassium fluoride

The invention discloses an environmentally friendly treatment method for hexachlorobenzene, which comprises the following steps: (1) putting hexachlorobenzene and an active potassium fluoride solution organic solvent into a single reactor; Perform pressure test, leak detection and nitrogen replacement in a single reactor; (3) raise the temperature of the single reactor to 200-300°C and increase the pressure to 2.0-3.0MPa; react at the reaction temperature and pressure for 10-15 hours; (4) put the The reaction product in the single reactor is steamed out and collected after condensation; (5) hexafluorobenzene and chloropentafluorobenzene of the rectification separation reaction product; (6) underpressure distillation collects the fluorochlorobenzene (by- product) and an organic solvent; then take out the potassium chloride residue in the single reactor, then re-add in the single reactor after drying the chlorofluorobenzene to continue using. The reaction condition is mild, the conversion rate and yield are high, and practical chemical intermediates can be obtained while reducing pollution, and the application prospect is broad.

Owner:JUHUA GROUP TECH CENT

A kind of preparation method of hexafluorobenzene and chloropentafluorobenzene

ActiveCN103360202BAvoid cokingHigh yieldPreparation by halogen replacementHexafluorobenzenePotassium fluoride

The invention discloses a preparation method of hexafluorobenzene and chloropentafluorobenzene. The preparation method of hexafluorobenzene and chloropentafluorobenzene comprises the following steps of: (1) adding raw materials including hexafluorobenzene, active potassium fluoride and a catalyst into a reactor; (2) carrying out nitrogen displacement on the reactor and adding a solvent into the reactor; (3) heating the reactor and stopping heating after a reaction completes; (4) after cooling, switching on an air valve of the reactor, evaporating a reaction product and the solvent in the reactor, and condensing and recycling the reaction product and the solvent; (5) deacidifying the reaction product and the solvent condensed and recycled in the step (4) through an acid separator; (6) separating hexafluorobenzene and chloropentafluorobenzene from the deacidified reaction product and solvent in the step (5) through a rectifying method; and (7) after the reaction product and the solvent in the reactor are completely recycled, cooling the reactor, opening a reaction kettle, and taking out residues such as potassium chloride in the reaction kettle. The preparation method of hexafluorobenzene and chloropentafluorobenzene has the characteristics of convenience for process operation, mildness in reaction, safety and controllability, simplicity in post treatment procedure, less loss and high yield.

Owner:衢州乾达科技有限公司

A kind of fluorine-containing polyarylether compound containing pillar [5] arene and preparation method thereof

The invention discloses a fluorinated polyarylether compound containing column [5] arene and a preparation method thereof. According to the preparation method, a dihydroxy column [5] arene compound and excessive hexafluorobenzene react so as to prepare a para-bisfluorobenzene substituted column [5] arene derivative A, then polycondensation is performed on A, bisphenol fluorene and difluorobenzophenone, so as to obtain the polyarylether compound containing column [5] arene. The obtained polyarylether compound has excellent solubility, thermal stability, oxidization stability, mechanical property and the like, and is important engineering plastics.

Owner:FUZHOU UNIV

A kind of method for preparing pentafluorophenol

ActiveCN107011126BHigh yieldSmooth responseOrganic chemistryOrganic compound preparationHexafluorobenzeneDodecane

The invention provides a pentafluorophenol preparation method. The pentafluorophenol preparation method is characterized by comprising the following preparation steps: adding 500-1000 parts of water, 50-100 parts of sodium hydroxide, 3-10 parts of a hydrolysis catalyst, 100 parts of hexafluorobenzene and 0.1-1 part of dodecyl secondary amine into a high pressure kettle according to parts by weight, sealing the high pressure kettle, raising the temperature to 110-150 DEG C, reacting for 3-8 hours, cooling to the room temperature, filtering, acidizing, extracting with methyl tert-butyl ether, combining an organic phase, distilling to recycle a solvent, and obtaining a crude product of 2,3,4,5,6-pentafluorophenol, adsorbing the crude product of pentafluorophenol in a crude product tank through five rectifying columns, and obtaining a purified product of pentafluorophenol.

Owner:衢州乾达科技有限公司 +1

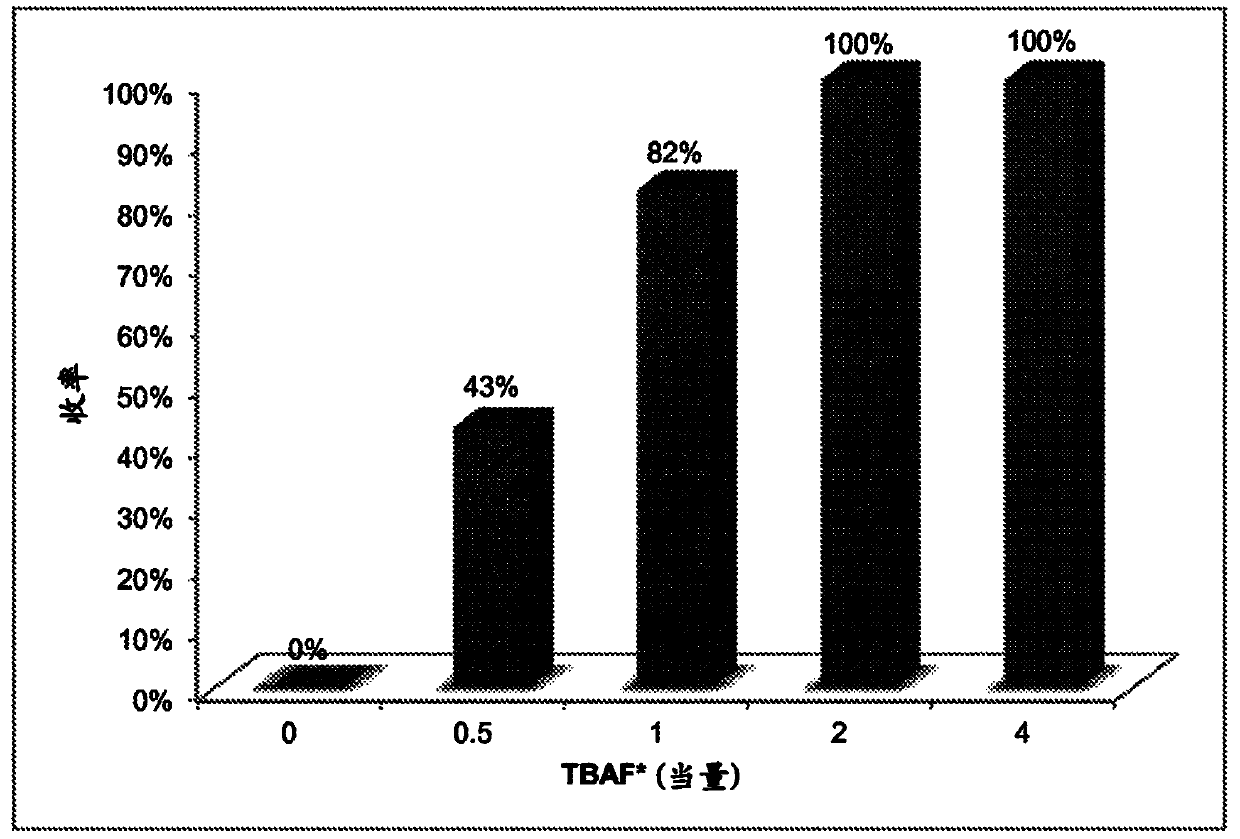

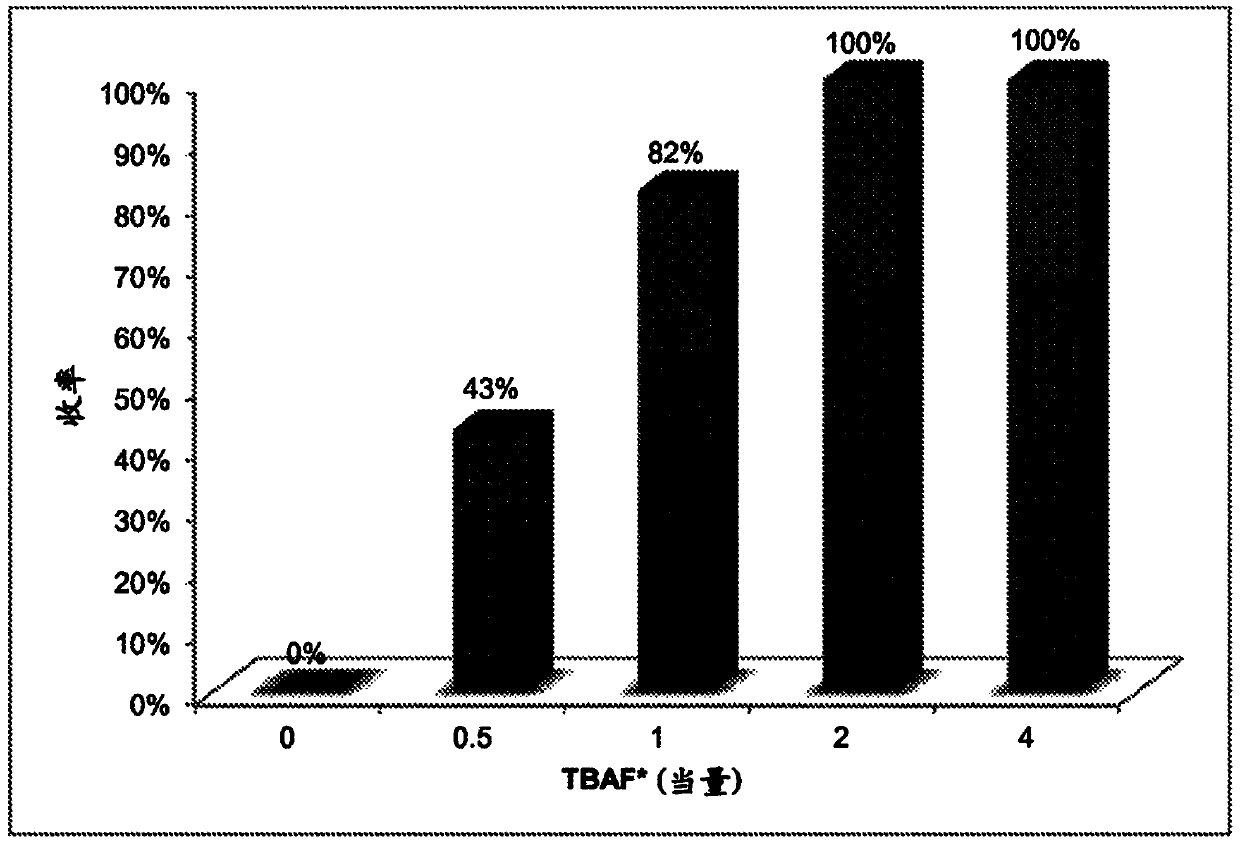

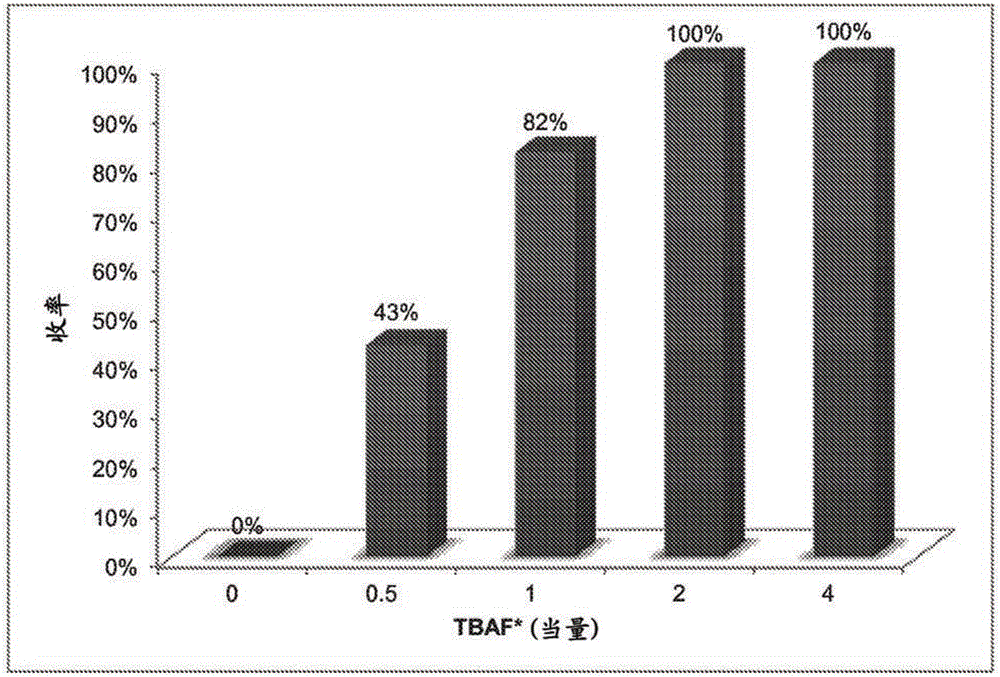

Methods of Fluorinating Compounds

A method of preparing a fluorinated aryl or heteroaryl substrate by mixing a quaternary ammonium cyanide and an aryl or heteroaryl substrate substituted with at least one chlorine, bromine, sulfonyl, or nitro group to obtain a mixture, and The mixture is mixed with hexafluorobenzene to obtain the fluorinated substrate.

Owner:DOW AGROSCIENCES LLC +1

Method for fluorinating compounds

The invention relates to a method for preparing a fluorinated aryl or heteroaryl substrate by combining a quaternary ammonium cyanide and an aryl or heteroaryl substrate substituted with at least one chloro, bromo, sulfonyl, or nitro group to thereby provide a mixture, and combining the mixture with hexafluorobenzene to thereby provide the fluorinated substrate.

Owner:DOW AGROSCIENCES LLC +1

Titanium-aluminum-chromium alloy fishhook and preparation method thereof

The invention discloses a titanium-aluminum-chromium alloy fishhook. The titanium-aluminum-chromium alloy fishhook comprises, by weight, 98-100 parts of titanium, 55-57 parts of aluminum, 48-50 parts of chromium, 4-6 parts of magnesium, 1-3 parts of terbium, 1-3 parts of dysprosium, 4-6 parts of holmium, 1-3 parts of thulium, 1-3 parts of ytterbium, 1-3 parts of lutetium, 2-4 parts of silicon, 6-8 parts of zirconium, 1-3 parts of calcium fluoride, 2-4 parts of sodium aluminum fluoride, 3-5 parts of potassium nitrate, 1-3 parts of hexafluorobenzene, 5-7 parts of molybdenum carbide, 6-8 parts of tungsten carbide and 1-3 parts of boron carbide. The hardness of the titanium-aluminum-chromium alloy fishhook is high.

Owner:林海英

A kind of preparation method of pentafluorophenol

ActiveCN107353181BReduce dosageLess side effectsOrganic chemistryOrganic compound preparationHexafluorobenzeneThio-

The invention provides a pentafluorophenol preparation method, which comprises: using hexafluorobenzene and potassium hydroxide as raw materials, adding an appropriate amount of tetrabutylammonium hydrogen sulfate, N-sulfopropyl-3-methylpyridine triflate, N-methyl-2-[(2-methylphenoxy)acetyl]hydrazinium methylthioamide and 2,2,6,6-tetramethylpiperidine-oxynitride to a tert-butyl alcohol aqueous solution with a mass fraction of 80-85%, heating to achieve a slight boiling state, carrying out a reflux reaction for 2-3 h, adding an appropriate amount of water, distilling to recover the tert-butyl alcohol solvent, adjusting the PH value of the remaining aqueous solution by using refined hydrochloric acid to 9-10, adsorbing with a functionalized D101 macroporous adsorption resin, acidifying with refined hydrochloric acid to achieve the PH value of 1-2, layering, distilling the upper layer water phase until no oily substance exists, collecting the distilled product, combining the collected product and the lower layer oil phase, rectifying, collecting the distillate at the temperature of 142-144 DEG C, and cooling to a room temperature to obtain the colorless and transparent crystal pentafluorophenol. According to the present invention, the preparation method has advantages of simple and reasonable process, less side reactions, high reaction yield and high product purity, and can meet the quality requirements for the preparation of the high-quality liquid crystal materials and drugs.

Owner:QUZHOU UNIV

Detection method of impurities in lithium hexafluorophosphate

ActiveCN106970103BImprove accuracyHigh sensitivityAnalysis using nuclear magnetic resonanceHexafluorobenzenePhosphoric acid

The invention discloses a method for detecting impurities in lithium hexafluorophosphate. The method includes steps of (1), carrying out calibration, to be more specific, adding deuterated reagent solution of hexafluorobenzene and deuterated reagent solution of the lithium hexafluorophosphate into inner and outer tubes of coaxial nuclear magnetic tubes, carrying out fluorine spectrum detection, adding deuterated reagent solution of phosphoric acid and deuterated reagent solution of the lithium hexafluorophosphate into the inner and outer tubes of the coaxial nuclear magnetic tubes and carrying out phosphorus spectrum detection; (2), carrying out measurement, to be more specific, preparing to-be-detected samples with certain concentration from the lithium hexafluorophosphate and deuterated reagents and carrying out fluorine spectrum and phosphorus spectrum detection by the aid of nuclear magnetic resonators. Compared with the traditional method, the method has the advantages that the fluorine-containing and phosphorus-containing impurities in the lithium hexafluorophosphate can be qualitatively and quantitatively detected by the aid of the method, and the method is short in analysis time, easy to implement and high in sensitivity, equipment can be prevented from being damaged by fluorine-containing strong corrosive substances, and the like.

Owner:GUANGZHOU TINCI MATERIALS TECH

A kind of preparation method of pentafluorophenol

ActiveCN105016983BSolve Stirring ProblemsHigh reaction yieldOrganic compound preparationEther preparationHexafluorobenzeneWastewater

The invention relates to a preparation method for pentafluorophenol. By taking hexafluorobenzene as an initial raw material, pentafluorophenol is prepared through etherification reaction and cracking reaction or by taking hexafluorobenzene as the initial raw material, pentafluorophenol is prepared by virtue of a one-step method. The preparation method provided by the invention does not need high temperature and pressurization, is less in energy consumption, and does not use expensive hydroiodic acid, so that the cost of the raw materials is low. Moreover, wastewater generated by etherification reaction is less, so that the preparation method is environmental-friendly; Cracking is carried out in a solvent, the material stirring effect is good, the reaction temperature is easy to control, and industrialization is easy to implement.

Owner:KINGCHEM LIAONING CHEMICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

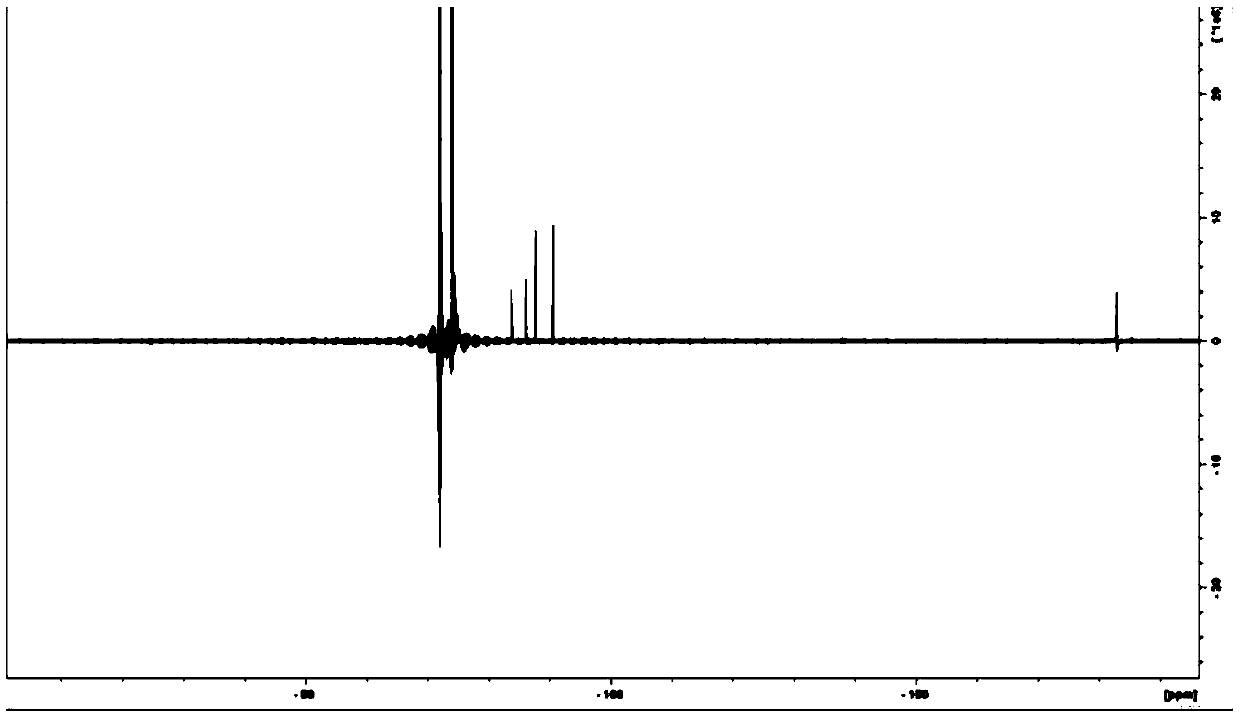

![Fluorinated polyarylether compound containing column [5] arene and preparation method thereof Fluorinated polyarylether compound containing column [5] arene and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d68ad934-2dcf-45e6-b6c0-57781a78763c/180605171701.png)

![Fluorinated polyarylether compound containing column [5] arene and preparation method thereof Fluorinated polyarylether compound containing column [5] arene and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d68ad934-2dcf-45e6-b6c0-57781a78763c/180605171704.png)

![Fluorinated polyarylether compound containing column [5] arene and preparation method thereof Fluorinated polyarylether compound containing column [5] arene and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d68ad934-2dcf-45e6-b6c0-57781a78763c/180605171707.png)

![A kind of fluorine-containing polyarylether compound containing pillar [5] arene and preparation method thereof A kind of fluorine-containing polyarylether compound containing pillar [5] arene and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/03d3aa36-e490-434b-be38-a327415ae63e/180605171701.png)

![A kind of fluorine-containing polyarylether compound containing pillar [5] arene and preparation method thereof A kind of fluorine-containing polyarylether compound containing pillar [5] arene and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/03d3aa36-e490-434b-be38-a327415ae63e/180605171704.png)

![A kind of fluorine-containing polyarylether compound containing pillar [5] arene and preparation method thereof A kind of fluorine-containing polyarylether compound containing pillar [5] arene and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/03d3aa36-e490-434b-be38-a327415ae63e/180605171707.png)