Detection method of impurities in lithium hexafluorophosphate

A lithium hexafluorophosphate and detection method technology, applied in the field of chemical analysis, can solve the problems of few qualitative and quantitative reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The present embodiment detects lithium hexafluorophosphate impurity qualitative and quantitative method, comprises the following steps:

[0051] (1) deuterated solvent pretreatment;

[0052] In a nitrogen-filled glove box, the deuterated acetonitrile was dehydrated by molecular sieves to within 10 μg / g (the moisture content was tested by a Karl Fischer moisture meter).

[0053] (2) Calibration

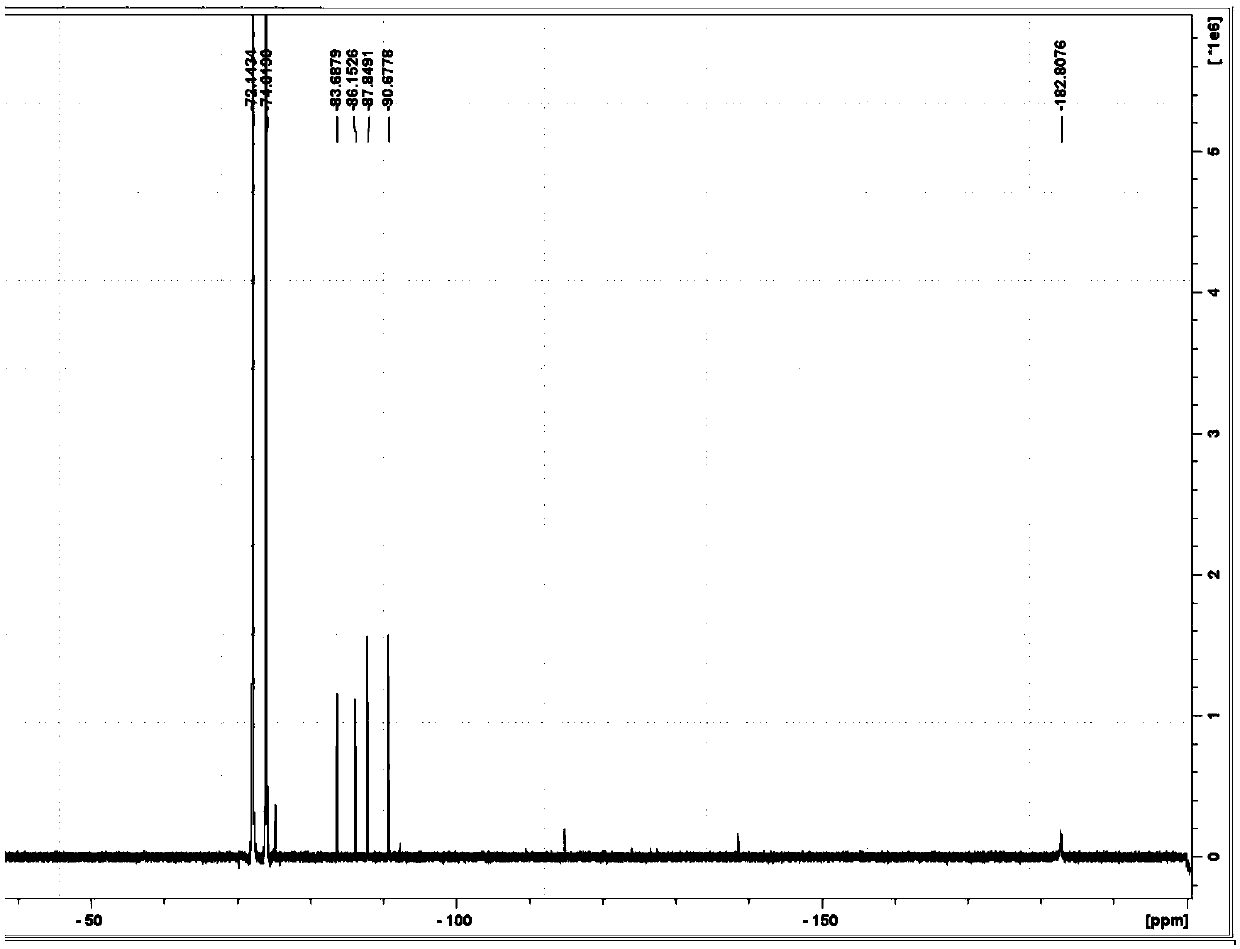

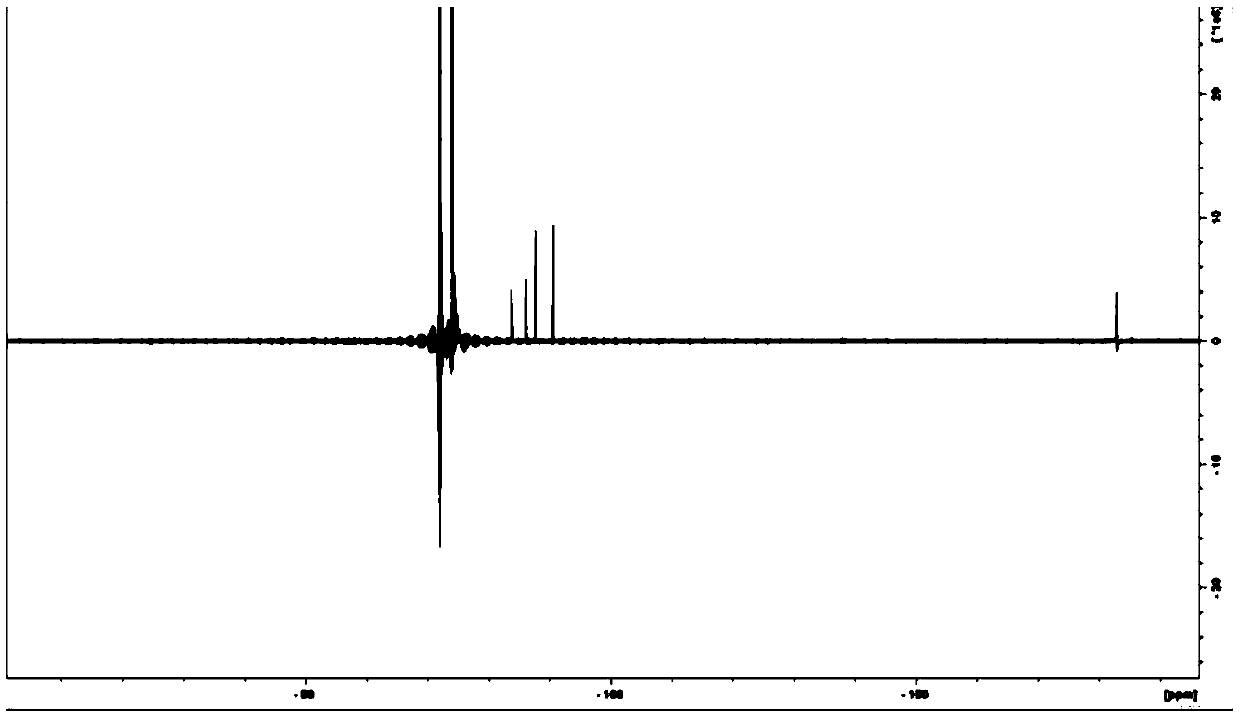

[0054] A coaxial NMR tube is used, and a deuterated acetonitrile solution of hexafluorobenzene and a deuterated acetonitrile solution of lithium hexafluorophosphate with a concentration of 200 μg / g are respectively added to the inner and outer tubes for fluorine spectrum detection; figure 1 shown.

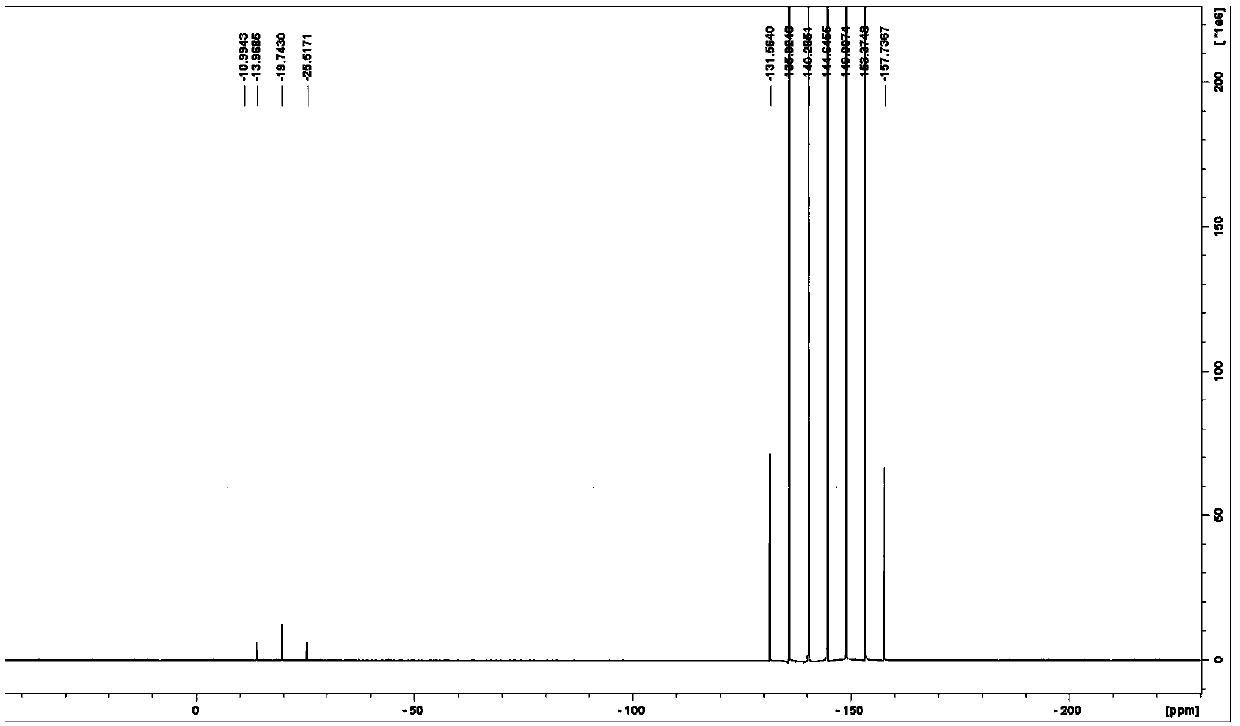

[0055] The deuterated acetonitrile solution of phosphoric acid and the deuterated acetonitrile solution of lithium hexafluorophosphate with a concentration of 1000 μg / g were respectively added into the inner and outer tubes for phosphorus spectrum detection; figure 2 shown.

[0...

Embodiment 2

[0079] The present embodiment detects lithium hexafluorophosphate impurity qualitative and quantitative method, comprises the following steps:

[0080] (1) deuterated solvent pretreatment;

[0081] In a nitrogen-filled glove box, the deuterated acetone was refluxed with calcium hydride to remove water to within 10 μg / g (the moisture content was tested by a Karl Fischer moisture meter).

[0082] (2) Calibration

[0083] A coaxial nuclear magnetic tube is used, and a deuterated acetone solution of hexafluorobenzene and a deuterated acetone solution of lithium hexafluorophosphate with a concentration of 200 μg / g are respectively added to the inner and outer tubes for fluorine spectrum detection;

[0084] The deuterated acetone solution of phosphoric acid and the deuterated acetone solution of lithium hexafluorophosphate with a concentration of 1000 μg / g were respectively added to the inner and outer tubes for phosphorus spectrum detection;

[0085] (3) Lithium hexafluorophospha...

Embodiment 3

[0089] The present embodiment detects lithium hexafluorophosphate impurity qualitative and quantitative method, comprises the following steps:

[0090] (1) deuterated solvent pretreatment;

[0091] In a nitrogen-filled glove box, the deuterated dimethyl sulfoxide was dehydrated by molecular sieves to within 10 μg / g (the moisture content was tested by a Karl Fischer moisture meter).

[0092] (2) Calibration

[0093] A coaxial NMR tube is used, and a deuterated dimethyl sulfoxide solution of hexafluorobenzene and a deuterated dimethyl sulfoxide solution of lithium hexafluorophosphate are added to the inner and outer tubes with a concentration of 200 μg / g, respectively, for fluorine spectrum detection;

[0094] A coaxial nuclear magnetic tube is used, and a deuterated dimethyl sulfoxide solution of phosphoric acid and a deuterated dimethyl sulfoxide solution of lithium hexafluorophosphate are added to the inner and outer tubes with a concentration of 1000 μg / g, respectively, for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com