Method for using copper-containing sludge to produce copper concentrate

A technology of copper sludge and copper concentrate, applied in the field of hydrometallurgy, can solve the problems of short reaction time, high process energy consumption, and low total copper recovery rate, and achieve low total production cost, simple process flow, and copper recovery high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

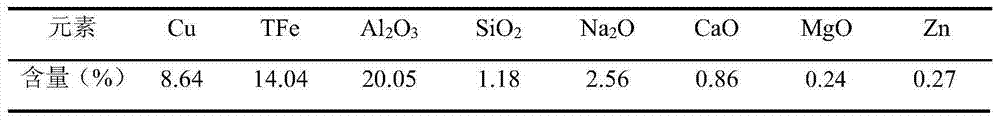

[0029] The copper-containing acid wastewater produced in the mining process of a copper sulfide mine is treated with lime neutralization process, and the copper sludge produced is mainly composed of copper hydroxide, iron hydroxide, aluminum hydroxide, carbonate In addition, there are a small amount of pyrite, limonite, quartz, alunite, dickite and trace copper sulfide. The main element analysis results of the copper sludge are shown in Table 1.

[0030] Table 1 Example 1 Copper sludge main element analysis result

[0031]

[0032] A method for producing copper concentrate from copper-containing sludge comprises the following steps in sequence.

[0033] The first step of stirring acid leaching: take 10kg of copper-containing sludge with a water content of 90.62% and send it to the stirring acid leaching system, then intermittently add concentrated sulfuric acid to the copper-containing sludge for stirring reaction, and control the concentration of the solution during the en...

Embodiment 2

[0038] The copper-containing acid wastewater produced in the production process of a wet copper extraction plant is treated with liquid alkali neutralization process, and the copper sludge produced is mainly composed of copper hydroxide, iron hydroxide, aluminum hydroxide and other substances In addition, there are a small amount of pyrite, limonite, quartz, alunite, dickite and trace copper sulfide. The main element analysis results of the copper sludge are shown in Table 2.

[0039] Table 2 Example 2 Copper sludge main element analysis results

[0040]

[0041] A method for producing copper concentrate from copper-containing sludge comprises the following steps in sequence.

[0042] The first step of stirring acid leaching: take 10kg of copper-containing sludge with a moisture content of 95.14% and send it to the stirring acid leaching system, and then intermittently add concentrated sulfuric acid to the copper-containing sludge for stirring reaction, and control the conc...

Embodiment 3

[0047] The copper-containing acid wastewater produced in the production process of a copper smelter is treated with liquid alkali neutralization process. The copper sludge produced mainly exists in the mixture of copper hydroxide, iron hydroxide and other substances. The copper sludge The main element analysis results are shown in Table 3.

[0048] Table 3 Example 3 Copper sludge main element analysis results

[0049]

[0050] A method for producing copper concentrate from copper-containing sludge comprises the following steps in sequence.

[0051] The first step of stirring acid leaching: take 10kg of copper-containing sludge with a moisture content of 94.82% and send it to the stirring acid leaching system, and then intermittently add concentrated sulfuric acid to the copper-containing sludge for stirring reaction, and control the concentration of the solution during the entire reaction process. The pH value is 2.5-2.7, and the acid leaching reaction is completed after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com