Preparation method of oxidized ore collecting agent and application thereof

A technology of collector and oxidized ore, which is applied in the direction of solid separation and flotation, can solve the problems of poor sorting effect of flotation collectors, and achieve strong selective collection ability, good stability and dispersion, The effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

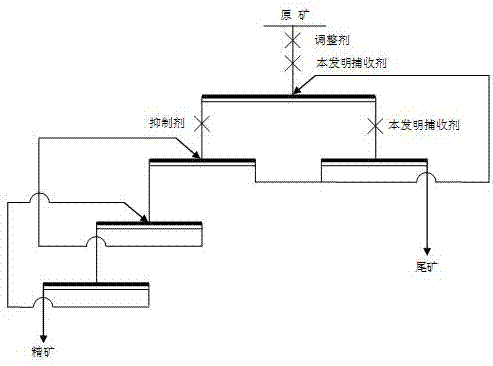

[0022] Raw ore WO of a tungsten mine in Henan 3 The grade is 0.10%, and more than 94% of the tungsten exists in the form of scheelite, and the content of carbonate minerals such as calcite in gangue minerals is relatively high. The oxidized ore collector of the present invention is used to carry out a flotation closed-circuit test on the ore.

[0023] After adding conditioner and said collector 100~300g / t in raw ore, carry out rough separation to obtain rough separation foam product and product in rough separation tank; add inhibitor water glass to rough separation foam product, carry out three times of separation , to obtain the final scheelite concentrate product; add 50-150 g / t of the collector to the product in the roughing tank, and perform roughing to obtain the tailings product. Selected middlings and sweeping middlings are returned in sequence.

[0024] Table 1 shows the comparison test results of the scheelite flotation carried out by the collector of the present in...

Embodiment 2

[0028] Raw ore WO of a tungsten mine in Hunan 3 The grade is 0.32%. Tungsten mainly occurs in scheelite, and the content of carbonate minerals such as calcite in gangue minerals is very high. The oxidized ore collector of the present invention is used to carry out a flotation closed-circuit test on the ore.

[0029] After adding conditioner and said collector 100~300g / t in raw ore, carry out rough separation to obtain rough separation foam product and product in rough separation tank; add inhibitor water glass to rough separation foam product, carry out three times of separation , to obtain the final scheelite concentrate product; add 50-150 g / t of the collector to the product in the roughing tank, and perform sweeping to obtain the tailings product. Selected middlings and sweeping middlings are returned in sequence.

[0030] Table 2 shows the comparison test results of scheelite flotation with the collector of the present invention and the collector on site.

[0031] ...

Embodiment 3

[0034] Raw ore WO of a tungsten mine in Henan 3 The grade is 0.26%, and more than 80% of the tungsten exists in the form of scheelite, and the content of carbonate minerals such as calcite in gangue minerals is relatively high. The oxidized ore collector of the present invention is used to carry out a flotation closed-circuit test on the ore, and the flotation temperature is 10°C.

[0035] After adding conditioner and 100~300g / t of the collector to the raw ore, roughing is carried out to obtain the roughing foam product and the product in the roughing tank; the inhibitor water glass is added to the roughing foam product for three times of beneficiation , to obtain the final scheelite concentrate product; add 50-150 g / t of the collector to the product in the roughing tank, and perform sweeping to obtain the tailings product. Selected middlings and sweeping middlings are returned in sequence.

[0036] Table 3 shows the comparison test results of scheelite flotation with the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com