Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

92results about How to "Solve sticky" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High nickel ternary lithium ion battery anode slurry and preparation method thereof

The invention discloses a high nickel ternary lithium ion battery anode slurry and a preparation method thereof. The anode slurry comprises the following raw materials in parts by weight: 89.5 to 97.9 parts of high nickel ternary anode powder, 1 to 5 parts of conductive agent, and 1 to 5 parts of adhesive, and also comprises mixed additives accounting for 0.1 to 0.5% of the weight of all solid powder and a proper amount of solvent, wherein the mixed additives comprise dispersed additives and acidic buffering type additives, and due to the solvent, the solid content of the anode slurry is in a range of 60 to 85%. Through the mixed additive, the acid / alkali property of the surface of the high nickel ternary anode powder is improved, the dispersing force of the anode powder is enhanced, the using amount of the solvent is reduced, and the slurry production time is reduced. At the same time, the problem that the slurry becomes thick due to the change of pH value of the slurry surface after being contacted with the environment during the preparation process is solved, and the obtained anode slurry is uniform and is good in flowing property.

Owner:SHENZHEN TOPBAND

Production method of polyoxazolidone laminated board

InactiveCN101695880AImprove toughnessReduce polarityLamination ancillary operationsLaminationVitrificationEpoxy

The invention provides a production method of a polyoxazolidone laminated board, comprising the following steps: reacting diisocyanate with epoxide resin by taking imidazole compounds as catalyst for producing polyoxazolidon resin during the gradual rise of temperature; and then producing the polyoxazolidone laminated board by using the polyoxazolidon resin. The polyoxazolidone laminated board the end of which is sealed with isocyanate has better mechanical strength, favorable heat resistance and high glass transition temperature above 155 DEG C; and when in use at 180 DEG C or 200 DEG C, the mechanical property and electrical propertye of the polyoxazolidone laminated board are over 70 percent.

Owner:HUNAN HENGYUAN NEW MATERIAL TECH CO LTD

Anti-flaming anti-corrosion modified unsaturated polyester resin (UPR) glass fiber reinforced plastic grating

The invention discloses an anti-flaming anti-corrosion modified unsaturated polyester resin (UPR) glass fiber reinforced plastic grating which is prepared from, by weight, 50-150 parts of UPR, 20-60 parts of vinylite, 5-15 parts of epoxy resin, 2-5 parts of expandable graphite, 1-4 parts of aluminum hydroxide, 3-9 parts of magnesium hydrate, 2-6 parts of talcum powder, 1-4 parts of quartz powder, 2-5 parts of ceramic powder, 3-5 parts of glass fiber, 1-4 parts of benzotriazole, 1-6 parts of a BYK-W940 wetting dispersant, 2-8 parts of a BYK-W985 wetting dispersant, 1-4 parts of ammonium polyphosphate, 3-9 parts of a BYK-S6665 adding agent, 1-4 parts of a BYK-S740 adding agent, 1-5 parts of an KH-560 silane coupling agent, 2-5 parts of a curing agent and 3-6 parts of an accelerant. The anti-flaming anti-corrosion modified UPR glass fiber reinforced plastic grating has excellent anti-corrosion and anti-flaming properties.

Owner:NINGGUO CITY OF CAPE COMPOSITE MATERIAL LIMITED

Low-fluoride-silicon waterborne polyurethane emulsion and elastic film product thereof

The invention provides low-fluoride-silicon waterborne polyurethane emulsion and an elastic film product thereof, and belongs to the technical field of polyurethane and applications thereof. The low-fluoride-silicon waterborne polyurethane emulsion comprises, in weight, 15-40% of diisocyanate, 40-80% of polymer diol, 0.2-15% of polysiloxane diol, 0.4-5.0% of fluorine-containing chain extenders, 1-5% of chain extenders I, 1-10% of hydrophilic chain extenders, 0-5% of cross-linking agents and 0-10% of neutralizers. The materials are polymerized and emulsified to prepare the emulsion. According to the polyurethane emulsion prepared from the materials, the content of fluoride and silicon is low, and the elastic film product prepared from the polyurethane emulsion is high in strength, good in elasticity, surface property, water resistance and compactness, easy to release, free from toxicity and characteristic odor and not sensitized and can prevent adhesion, effectively isolate various viruses and effectively replace elastic film products such as gloves, organ bags, condoms and penetration bags prepared from natural emulsion.

Owner:四川尤博瑞新材料有限公司

Insulating cap for terminal

InactiveCN102610932ASolve the punctureSolve sheddingConnection end capsElectrical and Electronics engineeringBlind hole

The invention discloses an insulating cap for insulating a conductor terminal. The insulating cap comprises a cap body which is provided with a blind hole insulating chamber, wherein the insulating cap further comprises an elastic fixture placed at the entrance of the cap body. By using the insulating cap disclosed by the invention, the problem that an insulating tape easily causes puncturing, falling and adhering problems when being used for performing insulation at present can be solved. The insulating cap disclosed by the invention can be directly inserted into a clearance at the side of the elastic fixture and fixed into the clearance; the terminal can be quickly and conveniently insulated by the insulating cap; and the insulating cap can be repeatedly used.

Owner:马杰 +2

Resin for water-based ink as well as preparation method and application of resin

The invention provides resin for water-based ink as well as a preparation method and an application of the resin. The water-based ink is prepared from the following components in percentage by weight: 0.5-30% of pigment colorant, 0.5-10% of the resin for the water-based ink, 5-20% of wetting agent, 0.5-20% of impregnating agent, 5-15% of dissolution stabilizer and the balance of deionized water. The resin for the water-based ink is a polymer microparticle emulsion which is prepared from free radical polymerization monomers in a semi-continuous emulsion copolymerization manner by taking an alkali-soluble high-molecular polymer as an emulsifier and in the presence of a water-soluble peroxide initiator; the particle size of the polymer microparticle emulsion is 50-180nm, the acid value of the emulsion is 30-100mgKOH / g and the glass-transition temperature Tg of the emulsion is from -50 to 50 DEG C. The change of the viscosity of the resin for the water-based ink along with temperatures is low, and therefore, a nozzle cannot be blocked; the water-based ink is suitable for printing on glossy paper and common painting paper; besides, the printed materials are clear in image, good in glossiness, and excellent storage stability and scratch resistance.

Owner:CHINA BANKNOTE INK +1

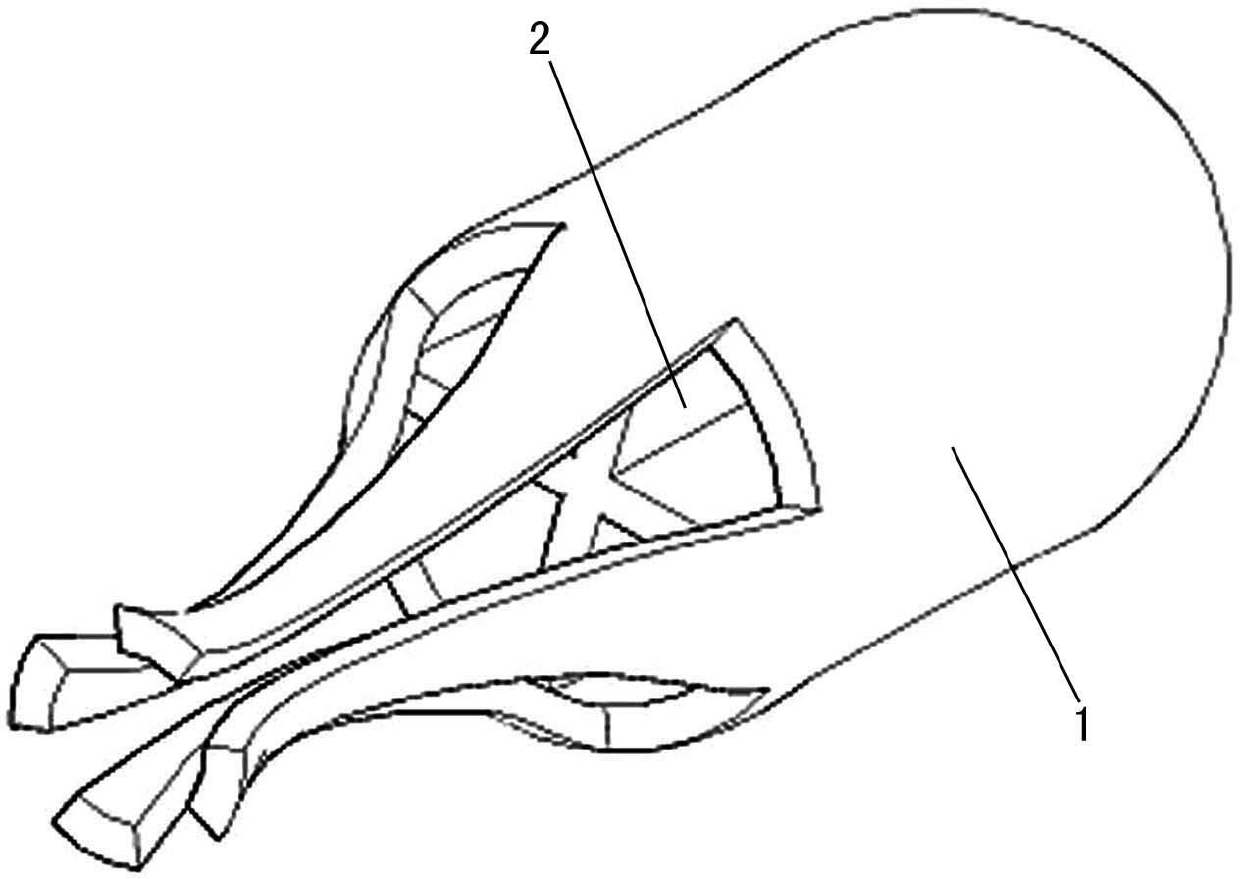

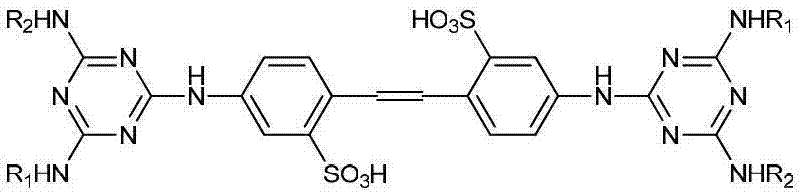

Method for synthesizing DSD (4, 4'-diaminostilbene-2, 2'-disulfonic) acid-triazine fluorescent brightening agents

ActiveCN103205134ASolve stickyIncrease profitStyryl dyesLuminescent compositionsChemical oxygen demandOrganic solvent

The invention discloses a method for synthesizing DSD (4, 4'-diaminostilbene-2, 2'-disulfonic) acid-triazine fluorescent brightening agents. A DSD acid-triazine fluorescent brightening agent reaction system is improved to a certain degree by an existing method, and on the basis of comprehensive consideration in various aspects such as the reaction cost, expanded production is carried out but only can be implemented by means of simply expanding reaction equipment. The method is characterized by comprising salifying all organic amine NH<2>R<2> and DSD acid of raw materials for tertiary condensation reaction or parts of the organic amine NH<2>R<2> and DSD acid to obtain DSD acid organic ammonium salt aqueous solution; and sequentially enabling the DSD acid organic ammonium salt aqueous solution to perform primary condensation reaction, secondary condensation reaction and tertiary condensation reaction to obtain the DSD acid-triazine fluorescent brightening agents. The method has the advantages that optional compounds or auxiliaries except for reactants are omitted in reaction procedures; the burden of desalination in an aftertreatment procedure caused by addition of extra salt in an existing method for manufacturing DSD acid-triazine fluorescent brightening agents is relieved, and the problem of foaming due to additional surfactants is solved; the COD (chemical oxygen demand) of waste liquor and the total quantity of the waste liquor are reduced; and problems of increase of cost and pollution due to organic solvents utilized in primary condensation reaction in the existing method are solved.

Owner:ZHEJIANG TRANSFAR WHYYON CHEM +1

Process for preparing alkyl alcohol ether sulphonate or alkyl phenol ether sulphonate

ActiveCN101302175AEasy to operateSimple processTransportation and packagingSulfonic acids salts preparationSolventPhenol

The invention provides a process for making alkyl alcohol ether sulfonate or alkyl phenol ether sulfonate, comprising the steps of: reacting alkyl alcohol ether or alkyl phenol ether with equal molar ratio with strong alkali or alkali metal to generate sodium salt or potassium salt of the alkyl alcohol ether or the alkyl phenol ether; adding hydroxyalkyl sulfonate and an alkaline catalyst to the sodium salt or the potassium salt of the alkyl alcohol ether or the alkyl phenol ether at a room temperature; adding solvent at the same time; reacting for 0.5 to 5 hours between 100 and 220 DEG C by means of azeotropy refluxing or evacuation, removing water which is generated by reaction, and obtaining alkyl alcohol ether sulfonate or alkyl phenol ether sulfonate. The invention has the advantages of convenient operation, simple process, easy control and low cost and so on.

Owner:中轻化工绍兴有限公司

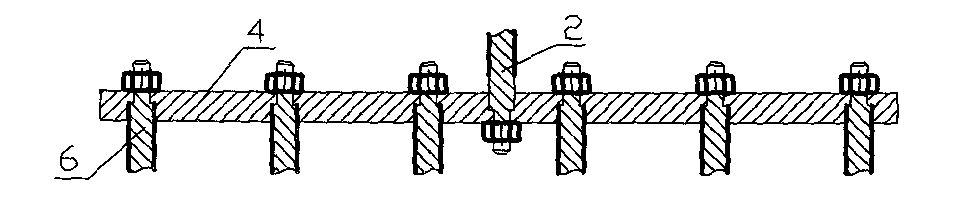

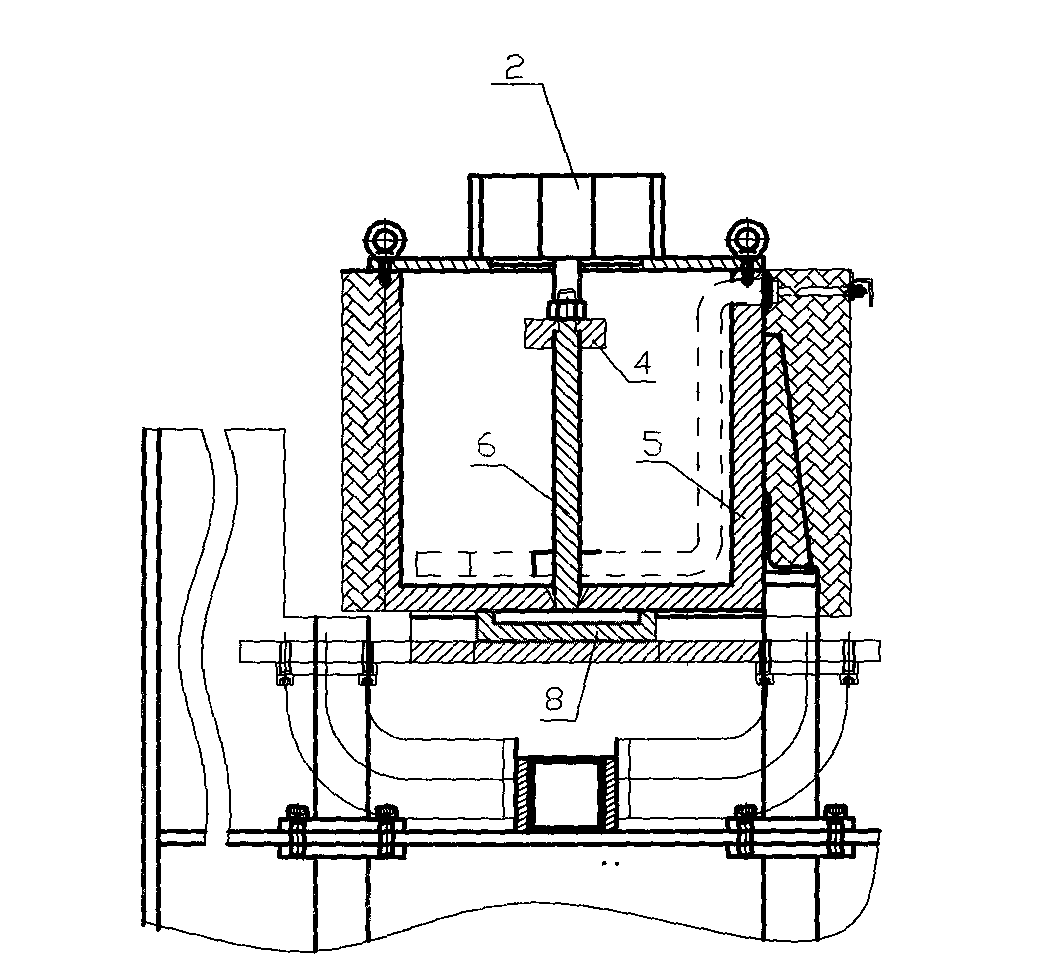

Method and special device for performing fusion welding on electrode lead plate of energy-saving environment-friendly type lead-acid battery

InactiveCN102581264AAvoid dripping accidentsReduce oxidation lossManufacturing technologyEngineering

The invention provides a method and a special device for performing fusion welding on an electrode lead plate of an energy-saving environment-friendly type lead-acid battery, relating to the manufacturing technology of lead-acid batteries. The method provided by the invention comprises the following steps: (1) heating and melting solid lead for being infused into a lead storage tank or a lead injection tank to melt the lead, and preheating a melting template; (2) shifting the melting template to tightly cling to the lead storage tank, driving plunger rods to raise through the action of a cylinder on the lead storage tank or the lead injection tank, infusing liquid lead into a rectangular groove of the melting template, and closing taper holes through the plunger rods; (3) shifting the melting template to a station for fusion welding, pushing a tooling box to lead the lower surface of the tooling box to stick on the upper surface of the melting template, and inserting a small rectangular relief block in the liquid lead inside the rectangular groove of the melting template for 2-10seconds; (4) cooling the melting template; and (5) separating a box body of the tooling box from the melting template and then taking out a product. The device provided by the invention consists of a lead melting furnace, the lead storage tank or the lead injection tank; an electric heating induction coil is fixed on the lead melting furnace; the lead storage tank is provided with an electric heating pipe, the taper holes, a cylinder piston rod and a linkage plate; and a liquid inlet pipe arranged on the side wall of the upper part of the lead storage tank is communicated with a liquid outlet pipe of the lead melting furnace. The method and the special device provided by the invention have the advantage that: little liquid lead is used so as to meet the energy-saving requirement during the process of lead injection.

Owner:FUAN GUANGYUAN ELECTROMECHANICAL

Environment-friendly aluminum profile spraying pretreatment process

PendingCN112921316AAchieve full utilizationOvercome the problem of industrial hazardous wasteMetallic material coating processesAluminium hydroxidePotassium hydroxide

The invention relates to the technical field of aluminum alloy processing, and provides an environment-friendly aluminum profile spraying pretreatment process. The process comprises the following steps of (1) washing; (2) alkali washing and oil removal, specifically, a degreasing agent is dissolved in water to be prepared into degreasing fluid, the degreasing fluid is sprayed to an aluminum profile for oil removal, and the degreasing fluid comprises, by weight, 15-20 parts of sodium hydroxide, 5-10 parts of potassium hydroxide, 1-2 parts of aluminum hydroxide, 4-6 parts of sodium gluconate, 3-5 parts of sodium nitrite and 0.1-0.3 part of sodium thiosulfate; (3) washing; (4) neutralizing; (5) washing; (6) washing with pure water; (7) chromate-free passivation; and (8) drying. The problems that a large amount of fluorine-containing and chromium-containing industrial waste residues are generated in an existing aluminum profile spraying pretreatment process, the treatment cost is high, and the environment and water resources are prone to being polluted are solved.

Owner:FUJIAN MINFA ALUMINUM

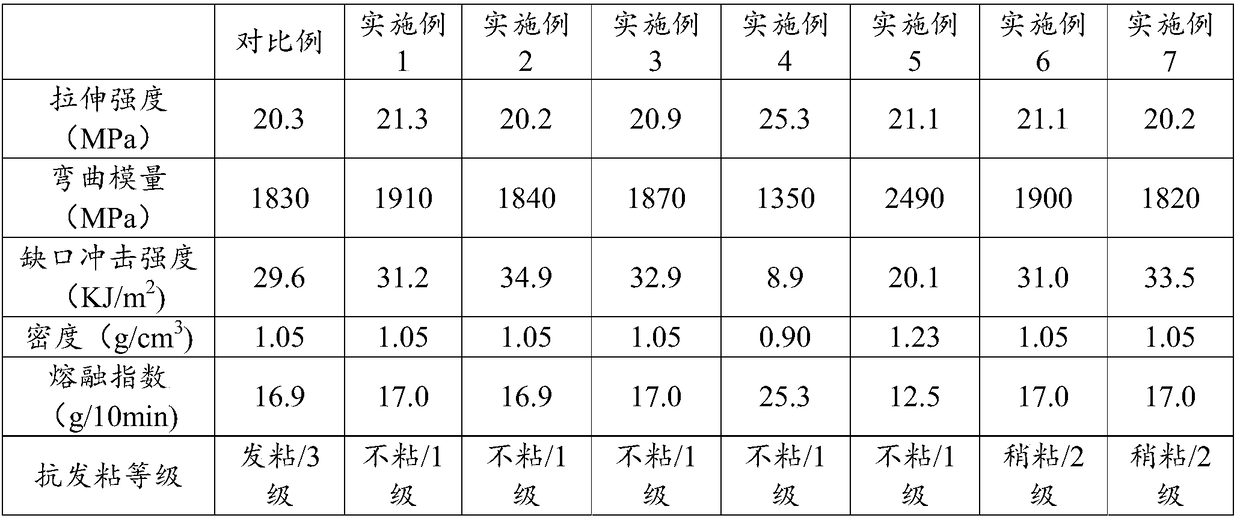

Application of nucleating agent for lowering separation viscidity of polypropylene composite material

The invention discloses application of a nucleating agent for lowering the separation viscidity of a polypropylene composite material. The invention further provides a polypropylene composite material. The polypropylene composite material is prepared from, by weight, 36-95 parts of polypropylene resin and 0.1-1 part of a nucleating agent, wherein the nucleating agent is at least one of alpha crystal type nucleating agent and a beta crystal type nucleating agent. The separation viscidity of the polypropylene material is lowered, by adding the nucleating agent, by means of the space closed effect generated after the crystallinity degree is increased, the phenomenon that auxiliaries are separated out in the using process is restrained, and the viscidity problem is solved. Meanwhile, the invention discloses a preparation method of the polypropylene composite material.

Owner:CHENGDU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

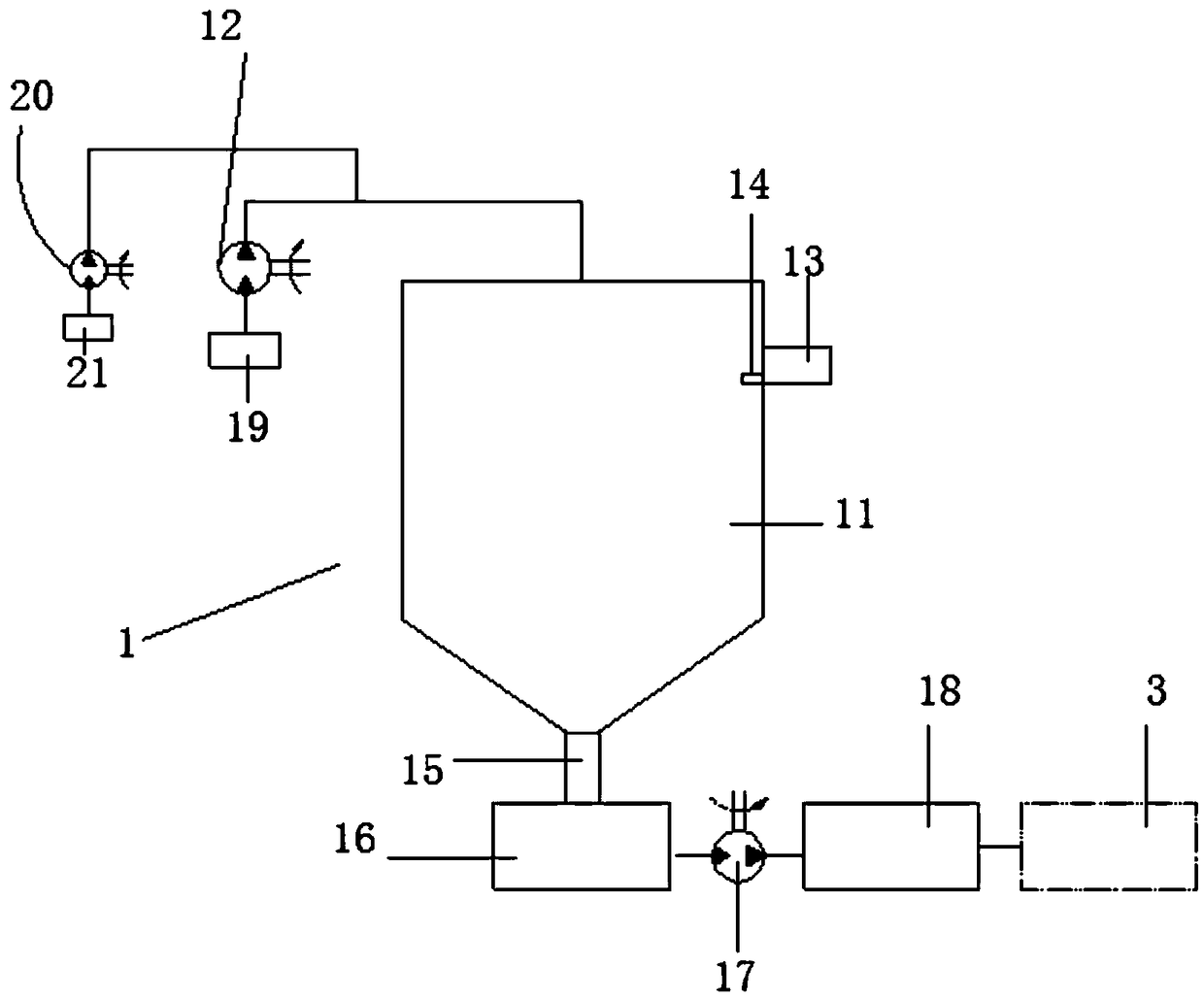

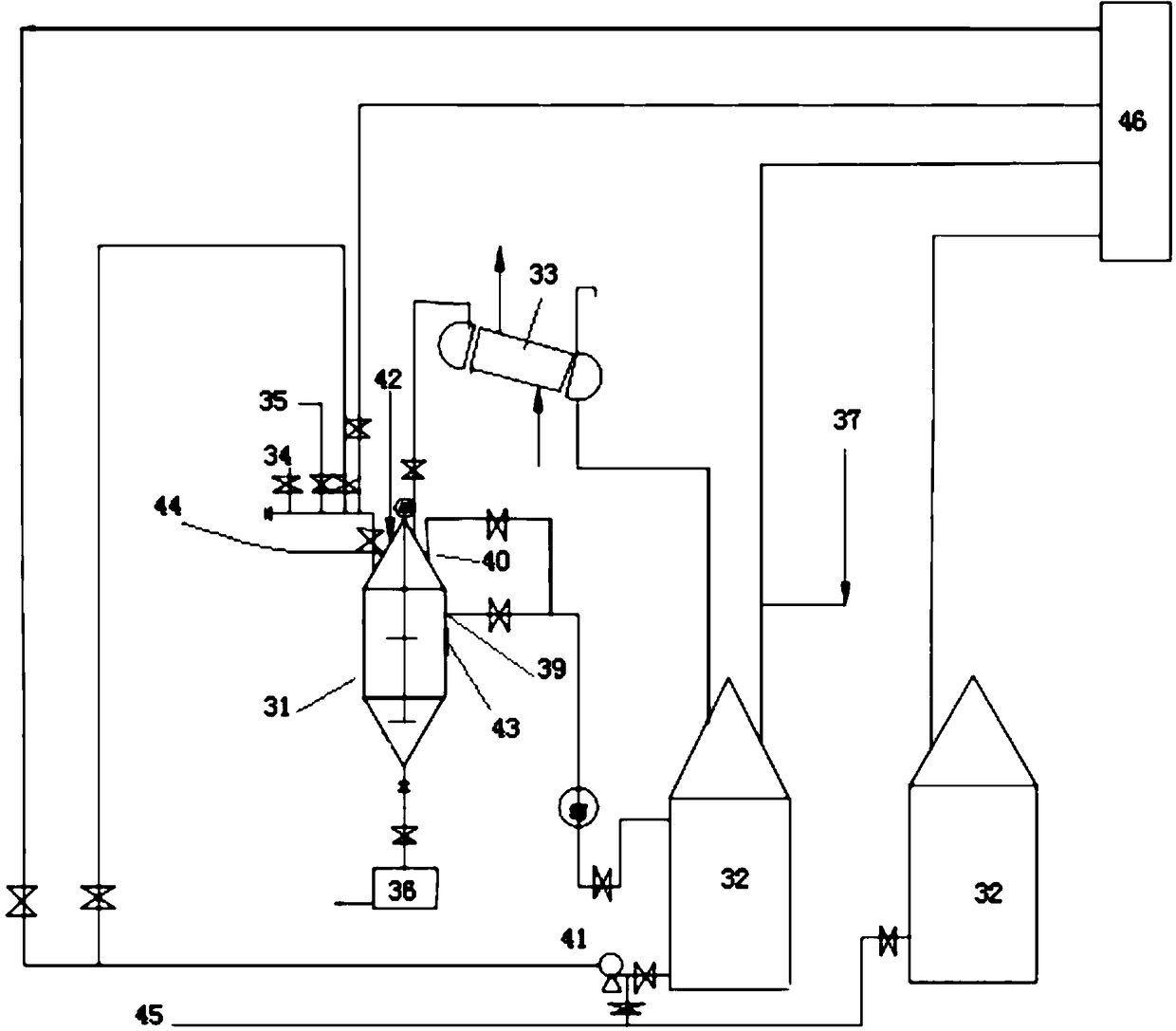

System and method for treating and recycling aged resin wastewater in production process of epoxy resin

PendingCN109110975ASolve stickyResolve recovery rateSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentEpoxySludge

The invention discloses a system and a method for treating and recycling aged resin wastewater in a production process of epoxy resin. The system comprises an aged resin precipitating and compressingdevice and a solvent extracting device, wherein the precipitating and compressing device comprises a precipitating tank, a centrifuging pump, a screw pump and a plate-and-frame filter press, wherein the inlet of the precipitating tank is connected with the outlet of the centrifuging pump; the inlet of the centrifuging pump is connected with a wastewater container; a flocculant filling pipeline isarranged on a centrifuging pump outlet pipeline and the flocculant filling pipeline is connected with a polyacrylamide solution container; a metering pump is arranged on the flocculant filling pipeline and the metering pump is connected with the precipitating tank; an overflow weir is arranged at the upper part of the precipitating tank; a clear water outflow pipe on the outer side of the overflowweir is connected with the precipitating tank; a discharging opening in the bottom of the precipitating tank is connected with a sludge tank through a discharging pipe; one side of the screw pump isconnected with the sludge tank through a pipeline; the other side of the screw pump is connected with the plate-and-frame filter press. According to the system and the method for treating and recycling the aged resin wastewater in the production process of epoxy resin, the aged resin wastewater is treated in the solvent extracting device by using a solvent extracting process; the problems that theaged resin treated by methylbenzene is viscous and the recycling rate of the epoxy resin is low are solved.

Owner:山东天茂新材料科技股份有限公司

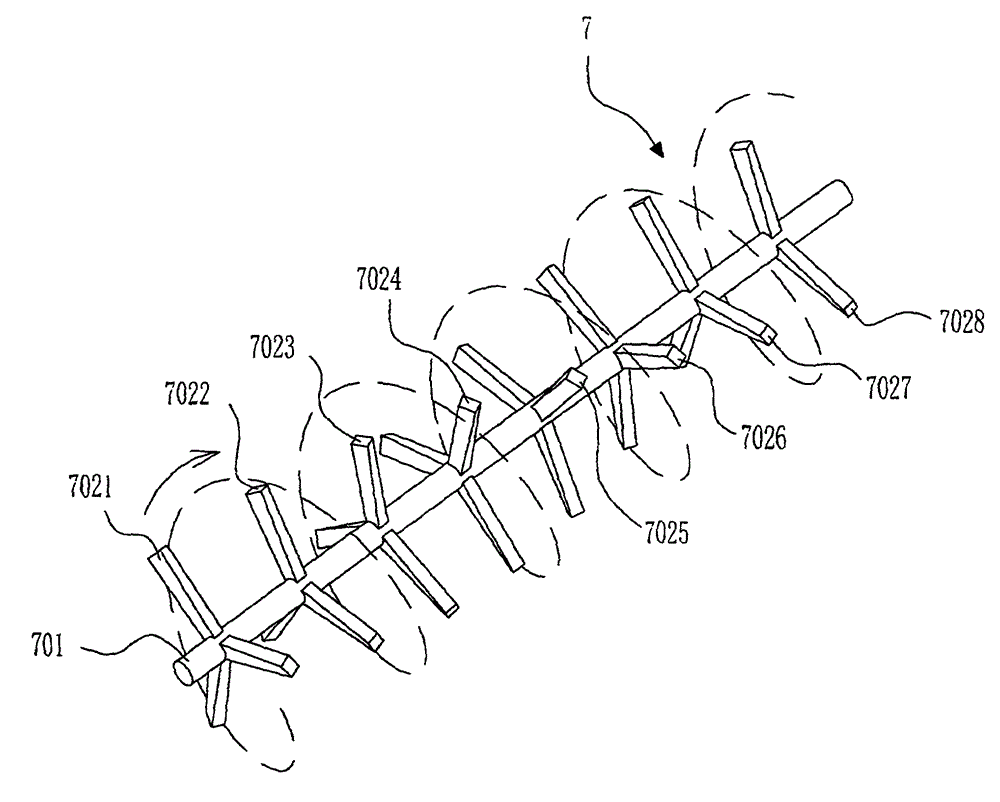

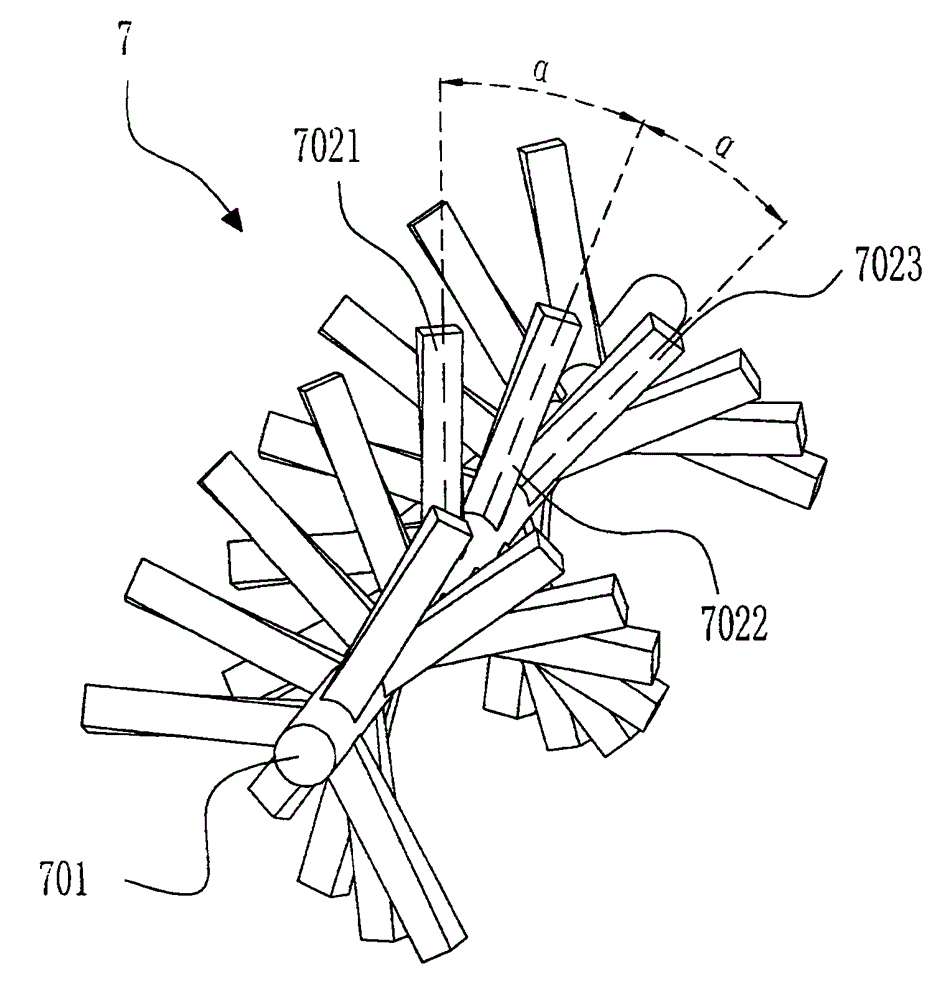

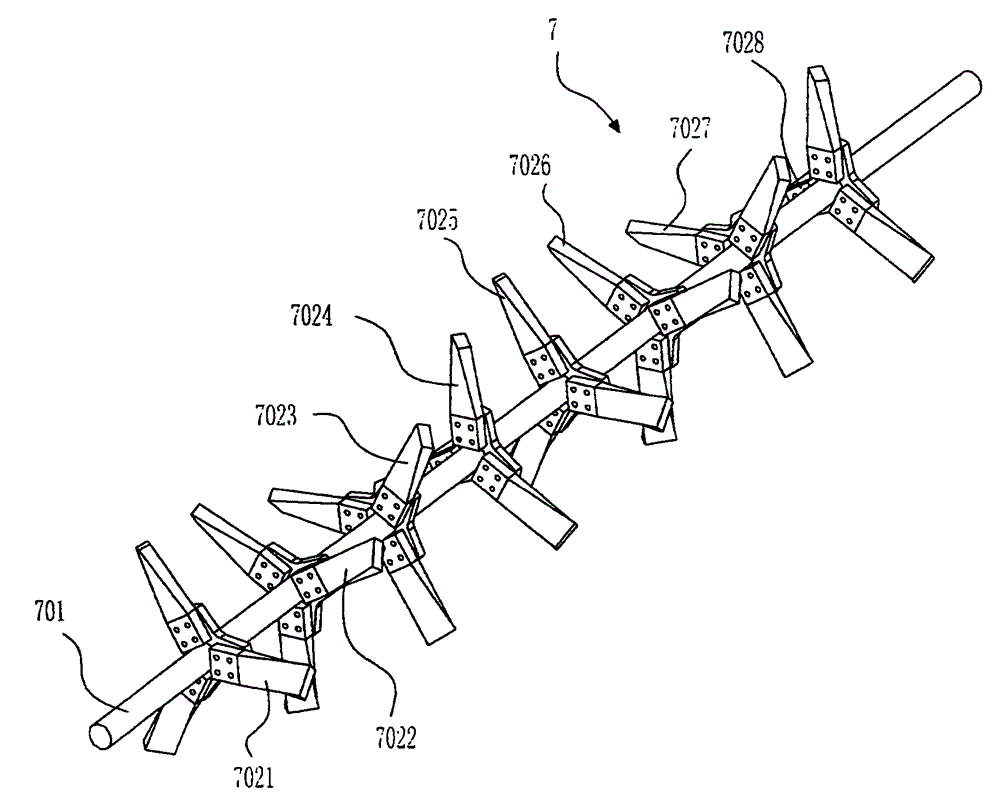

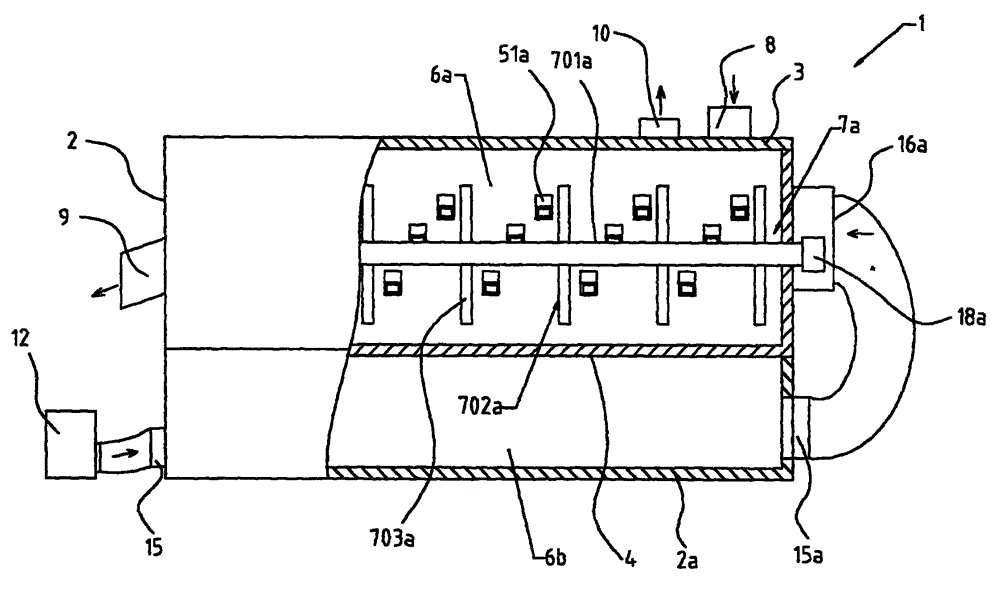

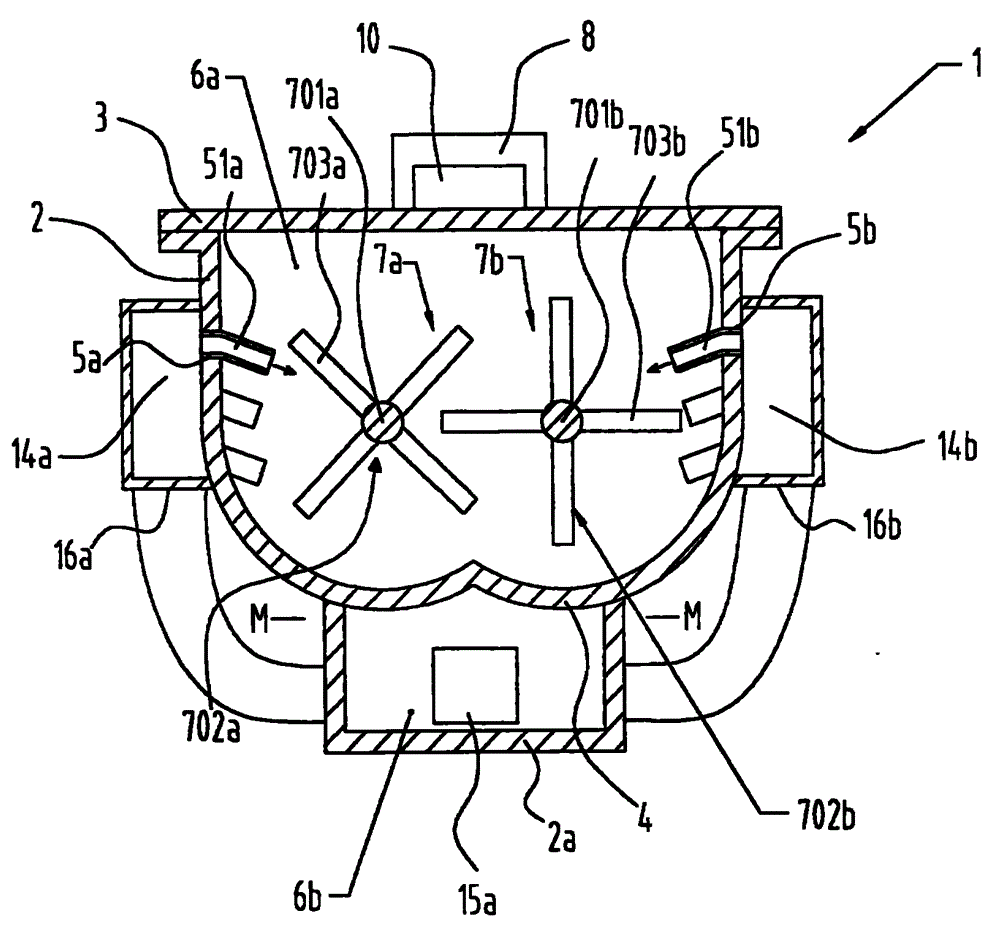

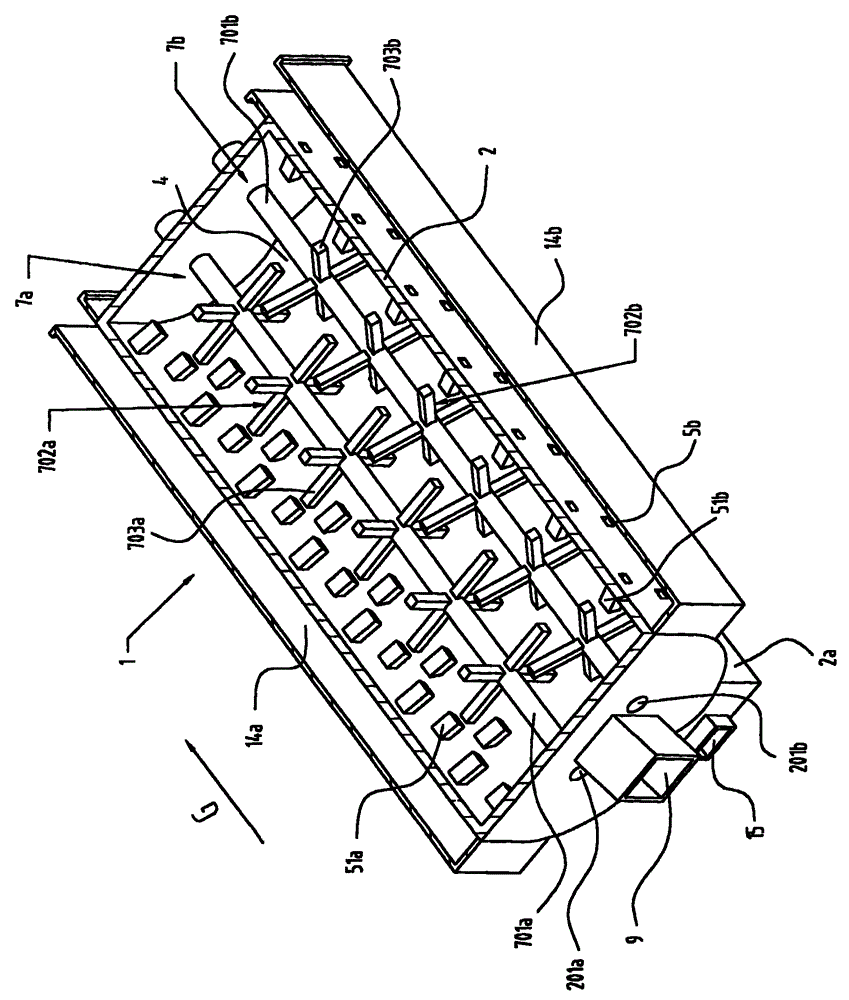

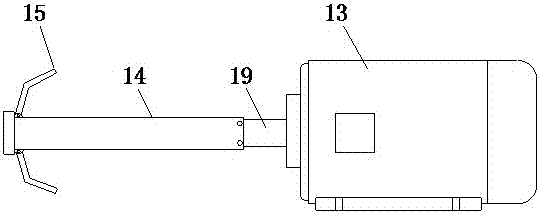

Stirring apparatus used for sludge drying device and drying apparatus thereof

ActiveCN105819658ASpeed up the flowImprove drying efficiencySludge treatment by de-watering/drying/thickeningDrying machinesSludgeEngineering

The invention provides a stirring apparatus used for sludge drying device. The stirring apparatus comprises a rotatable shaft, wherein, two ends of the rotatable shaft are arranged in shaft apertures at two end walls of a drying chamber arranged in the sludge drying device in a rotatable mode; several stirring components, wherein, several stirring components are fixedly arranged on the rotatable shaft with certain intervals and rotate with the rotatable shaft together, each stirring component in the several stirring components has blades or ratchets, wherein, the blades or the ratchets extend to outside along the shaft radial direction of the rotatable shaft; and every two adjacent stirring components in several stirring components between the blade or the ratchet have a separation angle of alpha along a circumference direction of the rotatable shaft. The invention also provides a drying apparatus by using the stirring apparatus.

Owner:广州正晟科技有限公司

High hardness and ultraviolet resistant modified unsaturated polyester resin fiber reinforced plastic grid

The invention discloses a high hardness and ultraviolet resistant modified unsaturated polyester resin fiber reinforced plastic grid. The raw materials include: modified unsaturated polyester resin, diphenylmethane bismaleimide, hydroquinone type liquid crystal bismaleimide, styrene, carbon nanotube, nano calcium carbonate, nano alumina, organic modified montmorillonite, ceramic powder, glass fiber, benzotriazole, a BYK-W940 wetting dispersant, methyl ethyl ketone peroxide, poly nano titanium dioxide ammonium, cobalt naphthenate, a BYK-S740 assistant, a silane coupling agent KH-560, a curing agent and an accelerator. The fiber reinforced plastic grid provided by the invention has high hardness and strong ultraviolet resistance.

Owner:NINGGUO CITY OF CAPE COMPOSITE MATERIAL LIMITED

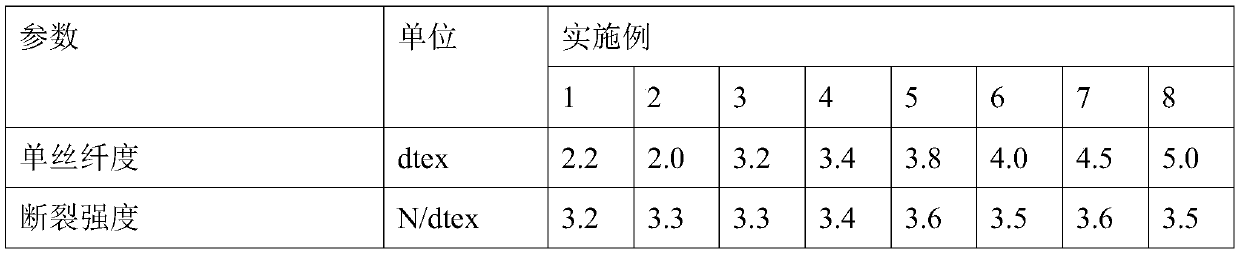

Low-content organic volatile low-melting-point polyester fiber and preparation method thereof

ActiveCN110952168AHigh glass transition temperatureSolve stickyFilament/thread formingConjugated synthetic polymer artificial filamentsFiberSulfonate

The invention relates to a low-content organic volatile low-melting-point polyester fiber and a preparation method thereof. The preparation method comprises the steps of taking terephthalic acid, phthalic acid, ethylene glycol, diethylene glycol, isophthalic acid sulfonate and 1, 4-butanediol as raw materials to prepare low-content organic volatile low-melting-point polyester, and then taking theprepared polyester as a sheath layer material and taking PET as a core layer material to prepare the low-content organic volatile low-melting-point polyester fiber through sheath-core composite spinning (a metal sand material in an assembly is Ni); and adding zinc oxide in an esterification reaction stage. The fiber has a sheath-core composite structure, and the sheath layer material is the low-content organic volatile low-melting-point polyester (a molecular chain is composed of a phthalic acid chain segment, an ethylene glycol chain segment, a diethylene glycol chain segment, an isophthalicacid sulfonate chain segment and a 1, 4-butanediol chain segment), and the core layer material is PET; and the total content of acetaldehyde and butenal in the fiber is less than 0.5 ppm. The method reduces the influence of organic volatile on fibers and avoids the problem of fiber adhesion.

Owner:扬州富威尔复合材料有限公司

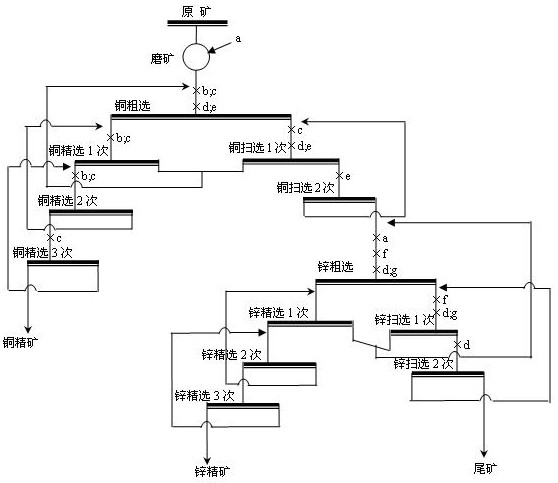

Flotation separation method for high-sulfur copper-zinc ore

The invention relates to a flotation separation method for high-sulfur copper-zinc ore, which comprises the steps of (1) grinding crushed high-sulfur copper-zinc raw ore to obtain ore pulp; (2) under the condition that the pH value of the ore pulp is 7-8, adding inhibitors, namely, sodium sulfite and zinc sulfate, a collecting agent, namely, butyl xanthate and a collecting foaming agent, namely, ester-23 for copper roughing, and respectively obtaining copper rough concentrate ore pulp and roughing tailing ore pulp; (3) enabling the copper rough concentrate pulp to be subjected to three-time concentration operation, and obtaining copper concentrate; (4) conducting copper scavenging operation on the roughing tailing pulp twice, and obtaining copper scavenging tailings; (5) sequentially adding lime, copper sulfate, butyl xanthate serving as a collecting agent and 2 # oil into the copper scavenging tailings for zinc roughing, and respectively obtaining zinc rough concentrate ore pulp and zinc roughing tailing ore pulp; (6) carrying out three times of concentration operation on the zinc rough concentrate pulp to obtain zinc concentrate; and (7) conducting zinc scavenging operation on the zinc roughing tailing pulp twice, and obtaining zinc scavenging tailings. Efficient flotation separation of copper and zinc is achieved, and copper flotation return water and zinc flotation return water are recycled.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

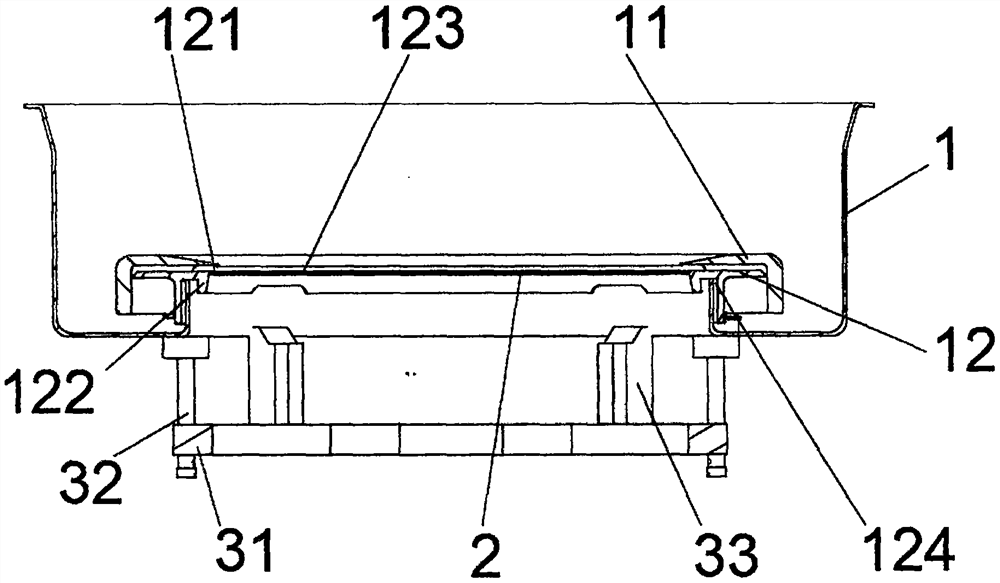

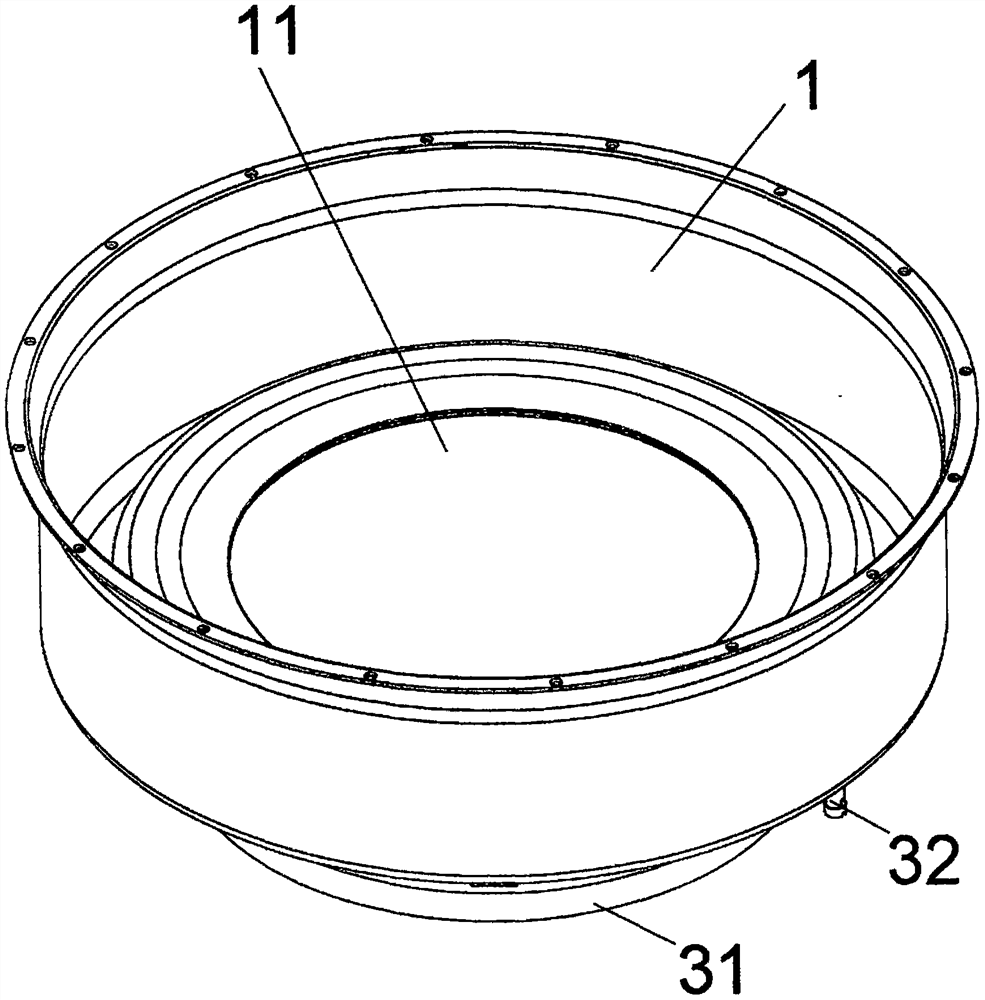

Wafer anti-sticking device

PendingCN112382602ASolve stickyEasy to processSemiconductor/solid-state device manufacturingPhysicsThin membrane

The invention relates to the technical field of wafer processing, and discloses a wafer anti-sticking device which comprises a protective cover, the bottom wall of the protective cover is arranged ina through mode, a lifting assembly is arranged at the bottom of the protective cover, a top shielding plate is arranged above the lifting assembly, and a wafer is placed on a wafer lifting ring. Due to the fact that the heater, the lower clamping ring and the top shielding plate which are arranged on the bottom movable plate make contact with one another at the wafer deposition position, deposition occurs, after film deposition, the bottom movable plate is controlled by the adjusting piece to move downwards, and the heater and the wafer are driven to start to move downwards. Due to the expansion effect of the lower tension spring, the lower clamping rings start to be separated from each other, the lower clamping rings move downwards to create pressing force so as to further move the waferand the top shielding plate to generate a large gap distance, so that the wafer and the top shielding plate are completely separated, the problem of wafer adhesion is solved, the wafer processing effect is improved, and machining requirements of users are met.

Owner:上海芯承电子科技有限公司

Method for detecting capsaicin compound in grease

The invention discloses a method for detecting a capsaicin compound in grease. The method for detecting the capsaicin compound in the grease comprises the following steps that capsaicin molecules in the grease are separated and extracted by using an immunoaffinity method in advance, then the capsaicin molecules separated and extracted are detected by using an immunochromatography, using the immuneaffinity method to separate and extract the capsaicin molecules in the grease means using a solution containing methanol and nano-titanium dioxide to dilute a grease sample, and then immunomagnetic beads specific binding to the capsaicin moleculesare added to capture the capsaicin molecules. The method combines immunochromatography with immunoaffinity technique, the workload of detection of capsaicin in the grease is greatly reduced, and the sensitivity of the detection is improved.

Owner:SHENZHEN CENT FOR DISEASE CONTROL & PREVENTION

Fresh-keeping storage method of fresh walnut with green husk removed

InactiveCN110250266AEasy to separateReduce churnSeed preservation by freezing/coolingSeed preservation by dryingCold chainInsect pest

The invention provides a fresh-keeping storage method of fresh walnut with green husk removed. The method includes harvesting when the maturity of walnut green fruits is 90%, removing green husk of green fruits without diseases and insect pests, cleaning and drying until the moisture content of nuts is 25-31%; when the moisture content of kernels is 19-22%, precooling for 24 hours under the conditions of light avoiding, ventilation and temperature of 0 DEG C; sealing in a self-regulating atmosphere bag, and storing under the conditions of light protection, ventilation and temperature of -10 DEG C; when the walnut is taken out of a warehouse for direct consumption, placing the walnut in an open manner for 2-3 hours under the condition of light avoiding and normal temperature; and when the walnut is taken out of the warehouse for transportation, taking the frozen fresh walnut with green husk removed out of the warehouse for cold chain packaging and transportation for consumption. The method solves the problems of mould, sticky and dehydration of seed shells occurring in the fresh-keeping storage process of the fresh walnut with the green husk removed, reduces the loss of walnut water, reduces the microbial pollution on the surface of the fresh walnut with the green husk removed, ensures the flavor and edible property of the fresh walnut, prolongs the storage time, prolongs the supply time of the walnut and overcomes the seasonal defect.

Owner:陇南市经济林研究院核桃研究所

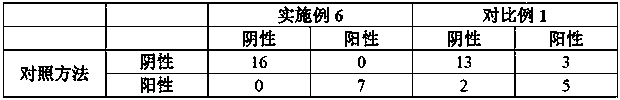

Compound premixed feed for wheat type growing finishing pigs

InactiveCN104543525AImprove the immunityImprove digestion and absorption rateAnimal feeding stuffSodium bicarbonatePhytase

The invention discloses a compound premixed feed for wheat type growing finishing pigs. The compound premixed feed consists of the following components in parts by weight: 130-150 parts of calcium hydrophosphate, 200-280 parts of limestone powder, 70-120 parts of salt, 7.5-15 parts of choline, 50-60 parts of compound microelements, 8-10 parts of compound vitamins, 60-80 parts of lysine, 56.2-234.2 parts of zeolite powder, 4.5-7.5 parts of compound enzyme, 2.5-7.5 parts of phytase, 20-40 parts of glycine betaine, 37.5-50 parts of sodium bicarbonate, 0.5-1 part of gamma-aminobutyric acid, 0.3-0.7 part of glutathione, 5-12 parts of vitamin E, 3-6.5 parts of vitamin C, 6-9.5 parts of saccharicterpenin, 2.5-5 parts of chromium nicotinate, and the like. By using the product, the pigs grow quickly, the body type is good-looking, the meat quality is bright-colored, and the meat storage time is long.

Owner:济南和美华动物营养品有限公司

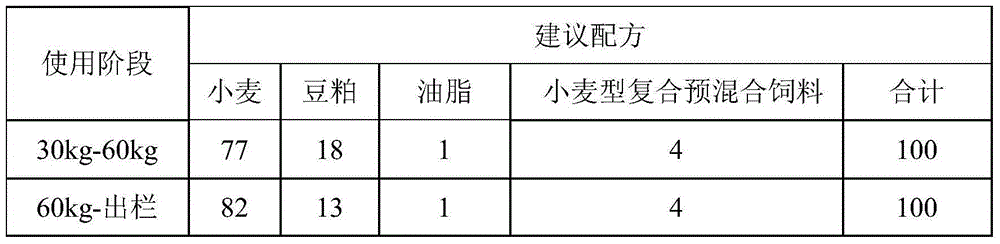

Dolomite-barite type lead zinc ore separation flotation method

The invention belongs to the technical field of mineral separation, and particularly discloses a dolomite-barite type lead zinc ore separation flotation method. The method comprises the steps: crushing dolomite-barite type lead zinc ore to screen out ore with the particle size being-20 + 2 mm, then feeding oversize fraction minerals after ore washing into a dense medium cyclone to be separated to obtain heavy products and light products; respectively draining the medium from the heavy product and the light product to obtain oversize products which are heavy minerals and light minerals; and carrying out coarse grinding and flotation on the heavy minerals to obtain sulphide ore flotation concentrate and non-sulphide ore, wherein the sulphide ore flotation concentrate is the mineral containing galena, sphalerite and pyrite, and the non-sulphide ore is the mineral containing barite. The method provided by the invention can realize separation of coarse-grained dolomite and sulphide ore, and fundamentally solves the problems that the dolomite is easy to be over-ground and argillized to cause foam stickiness, lead and zinc indexes are influenced and the like; and separation of sulfide ore and barite can be realized under the condition of relatively coarse granularity, so that a basis is provided for subsequent reselection and recovery of the barite.

Owner:INST OF RESOURCES COMPREHENSIVE UTILIZATION GUANGDONG ACAD OF SCI

Environment-friendly production process of reclaimed rubber from tire

InactiveCN108178841ARealize desulfurization treatmentEliminate the grinding processPlastic recyclingMicrowaveFiltration

The invention provides an environment-friendly production process of reclaimed rubber from a tire. The process comprises the following steps: (1) waste rubber is smashed into waste rubber powder; (2)the waste rubber powder and reclaiming auxiliary materials are jointly conveyed to a microwave reclaimer, are subjected to microwave desulfurization and reclaiming treatment in a pipe of the microwavereclaimer and move from a feed port of the pipe to a discharge port under the conveying and mixing actions of a conveying screw in the pipe, wherein the reclaiming auxiliary materials comprise a reclaiming activator, a reclaiming softener and lemon essential oil, the reclaiming activator accounts for 0.2%-1.1% of the mass of the waste rubber powder, the reclaiming softener accounts for 2%-30% ofthe mass of the waste rubber powder, and the lemon essential oil accounts for 2%-3% of the mass of the waste rubber powder; (3) the rubber powder subjected to desulfurization treatment is refined andformed by a refiner, extrusion and filtration are performed, and the reclaimed rubber from the tire is obtained. The novel production process of the reclaimed rubber from the tire is energy-saving andenvironmentally friendly, and the produced reclaimed rubber has the advantages of high strength, stable quality and the like.

Owner:江苏华兴橡胶科技有限公司

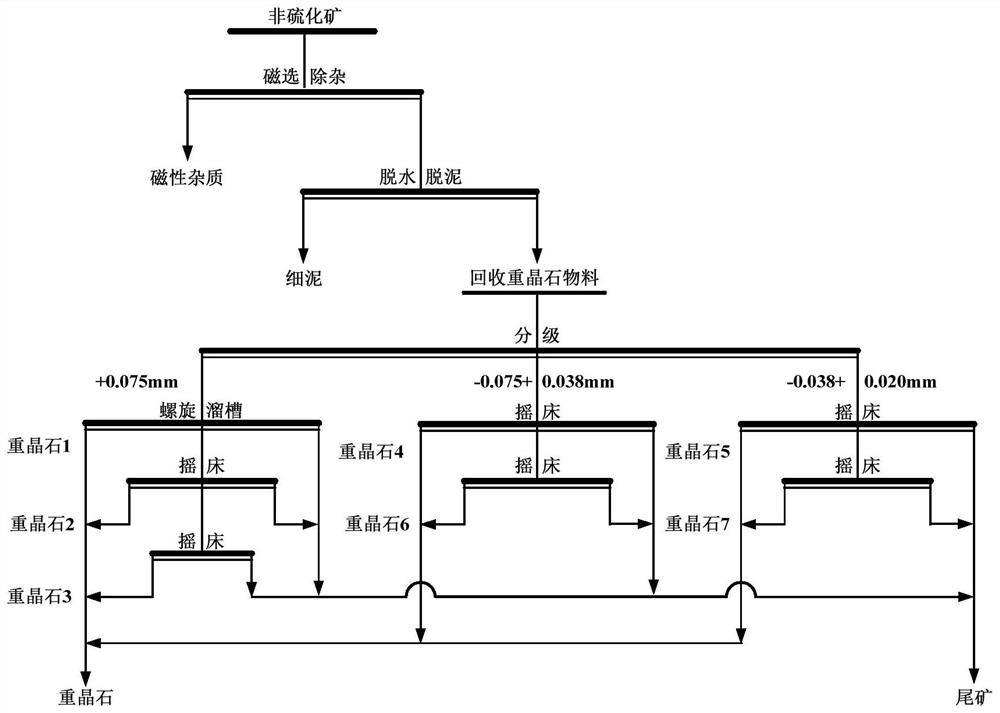

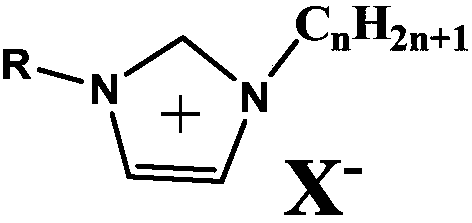

Iron-based cyanogroup-containing anion imidazole ionic liquid catalyst, and preparation method and applications thereof

ActiveCN107670690ASolve the common sticky problemSolve stickyGroup 4/14 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenSilanes

The invention belongs to the field of catalyst, and provides a preparation method of an iron-based cyanogroup-containing anion imidazole ionic liquid catalyst, and an application method of the iron-based cyanogroup-containing anion imidazole ionic liquid catalyst in catalyzing hydrosilylation of olefins with hydrogen-containing alkoxy silane. Problems in the prior art that in hydrosilylation, catalyst cost is high, a catalyst is unstable to store, and recovery of the catalyst is impossible to realize. The reaction conditions of the iron-based cyanogroup-containing anion imidazole ionic liquidcatalyst are mild; raw material conversion rate is high; catalytic activity is high; automatic phase separation of the products and the iron-based cyanogroup-containing anion imidazole ionic liquid catalyst can be realized after reaction; and catalyst recovery is realized.

Owner:CHANGZHOU UNIV

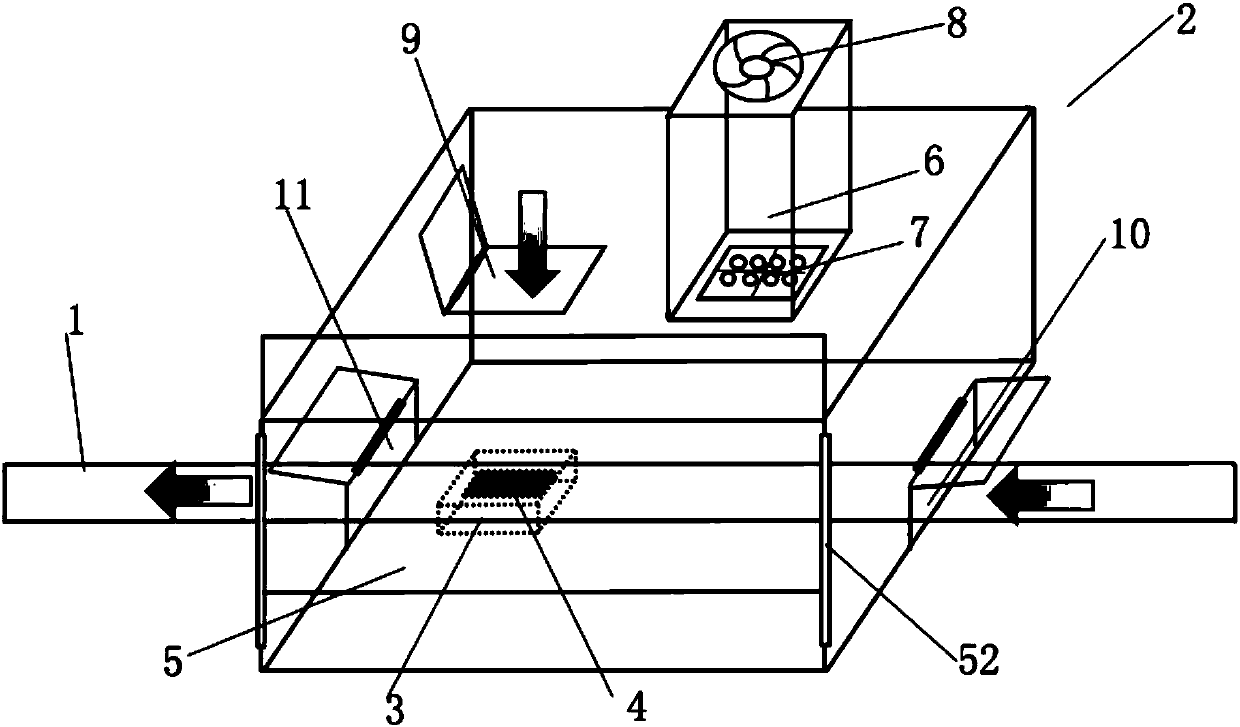

UV curing device with gas protection

InactiveCN107685013AFully curedAchieve continuous curingPretreated surfacesCoatingsUV curingOptical power

The invention discloses a UV curing device with gas protection. The UV curing device comprises a semi-closed curing box, a conveying device, a material bearing device and a UV curing light source device. The conveying device comprises a synchronous conveying belt and a sliding block, and the sliding block is mounted on the synchronous conveying belt. The material bearing device is placed on the sliding block. The UV curing light source device is mounted on the upper box wall of the semi-closed curing box. The semi-closed curing box is provided with a vent port. Protective gas enters the semi-closed curing box through the vent port. By forming the vent port in a box body of the semi-closed curing box for injecting the protective gas, oxygen on the surface of a material is isolated during acuring reaction of the material, so that the problem that the surface of the material is viscous and not dry is solved; by arranging the synchronous conveying belt, continuous curing of the material is achieved, meanwhile the conveying speed is adjusted, the illumination time of the different materials is guaranteed, and full curing of the material is ensured; and meanwhile the optical power is adjusted by changing the number of UV light source modules, and accordingly full curing of the material is achieved.

Owner:FOSHAN INST SUN YAT SEN UNIV +1

Anti-freezing saltpetering-resistant red mud baking-free brick and preparation method thereof

The invention relates to an anti-freezing saltpetering-resistant red mud-based baking-free brick and a preparation method thereof. The brick is prepared from the following raw material components: 20to 40 percent of red mud, 10 to 25 percent of power plant coal ash, 5 to 15 percent of electrolytic manganese slag, 20 to 30 percent of metallurgical slag, 5 to 9 percent of 42.5 Portland cement, 20 to 30 percent of graded coal gangue, 3 to 9 percent of excitant, 0.5 to 2 percent of modifier, 0.1 to 0.2 percent of naphthalene water reducer and 3 to 10 percent of composite phase change material microcapsule. The composite phase-change material microcapsule is prepared by taking modified fly ash as a supporting material to adsorb a phase-change material and then coating the phase-change materialwith organic resin. The composite phase change material microcapsules are added, so that the sensitivity of the baking-free brick to the temperature can be effectively reduced, and the expansion andcracking degrees of the baking-free brick in the freezing and thawing process are reduced. Based on the composite synergistic effect theory of various solid waste resources, the volcanic ash activityof solid waste such as power plant coal ash and metallurgical slag is fully excited, a crystalline or amorphous hydration product is formed, the internal pore structure of a matrix can be filled, Na <+> in the matrix is effectively cured, and saltpetering of the baking-free brick is inhibited.

Owner:UNIV OF SCI & TECH BEIJING +1

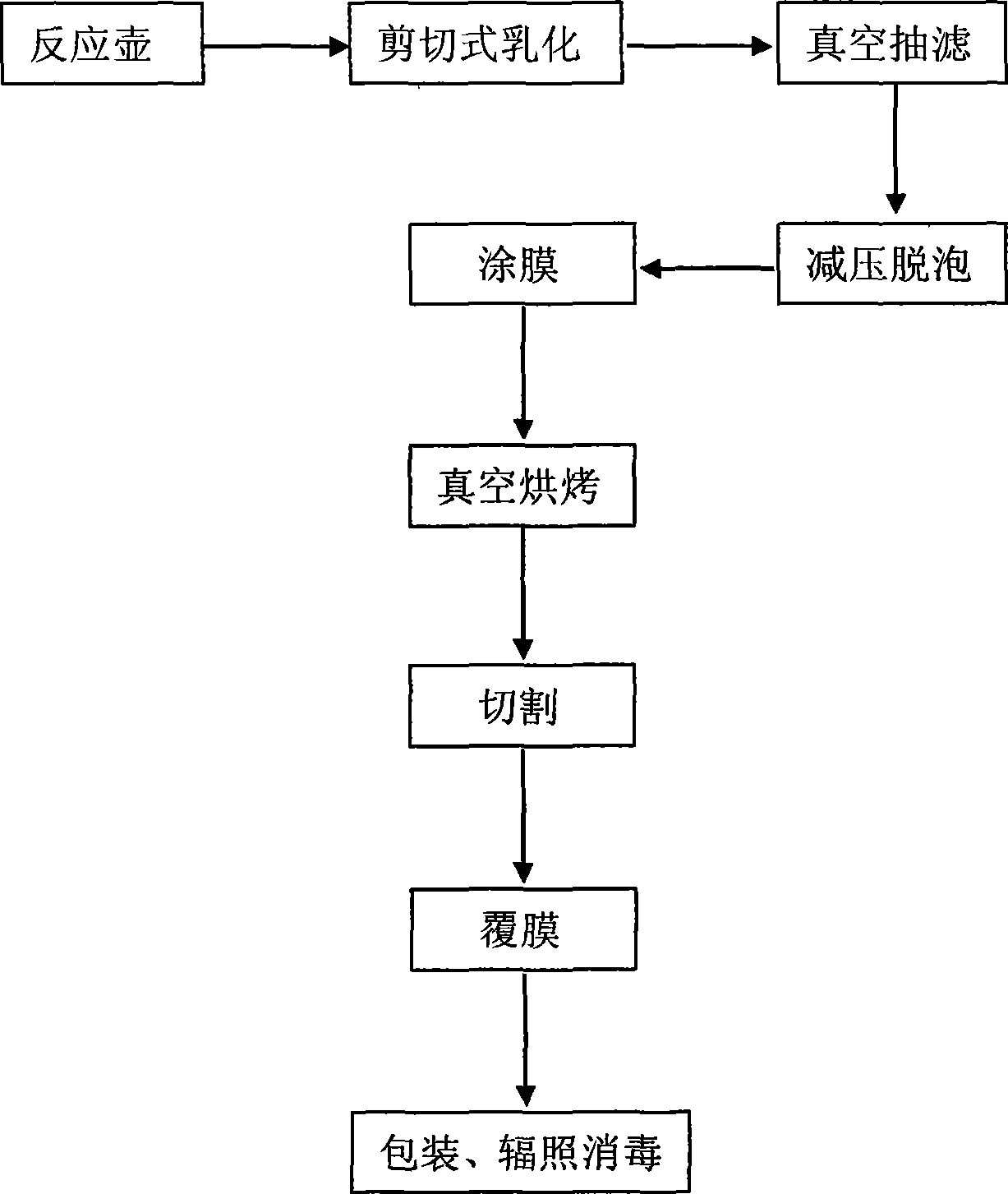

Dressing production process

ActiveCN101507828ASimple processEase of mass productionAdhesive dressingsAbsorbent padsMass ratioPolyurethane membrane

The invention discloses a process for producing dressing. The process comprises the following steps that: (1) an officinal quantity of water-soluble drug and purified water are mixed in the mass ratio of 1:20-50, stirred evenly, filtered and subjected to foam removal; (2) a solution after foam removal is poured into a die, baked at a temperature of between 40 and 60 DEG C and then released from the die so as to form a drug membrane; and (3) one surface of the drug membrane is covered with a non-woven fabric or a polyurethane membrane, and the other surface of the drug membrane is covered with release paper, and then the obtained product is cut, packed and disinfected. The production process provided by the invention has the advantages of wide application range, simple process, convenience for scale production, short production time, low cost and little environmental pollution. In addition, as the process adopts the die with a Teflon anti-sticking coating, the drug membrane is easy to peel away from the die and difficult to damage, and the obtained dressing is stable in quality and easy to control.

Owner:WUHAN HUMANWELL MEDICAL SUPPLIES

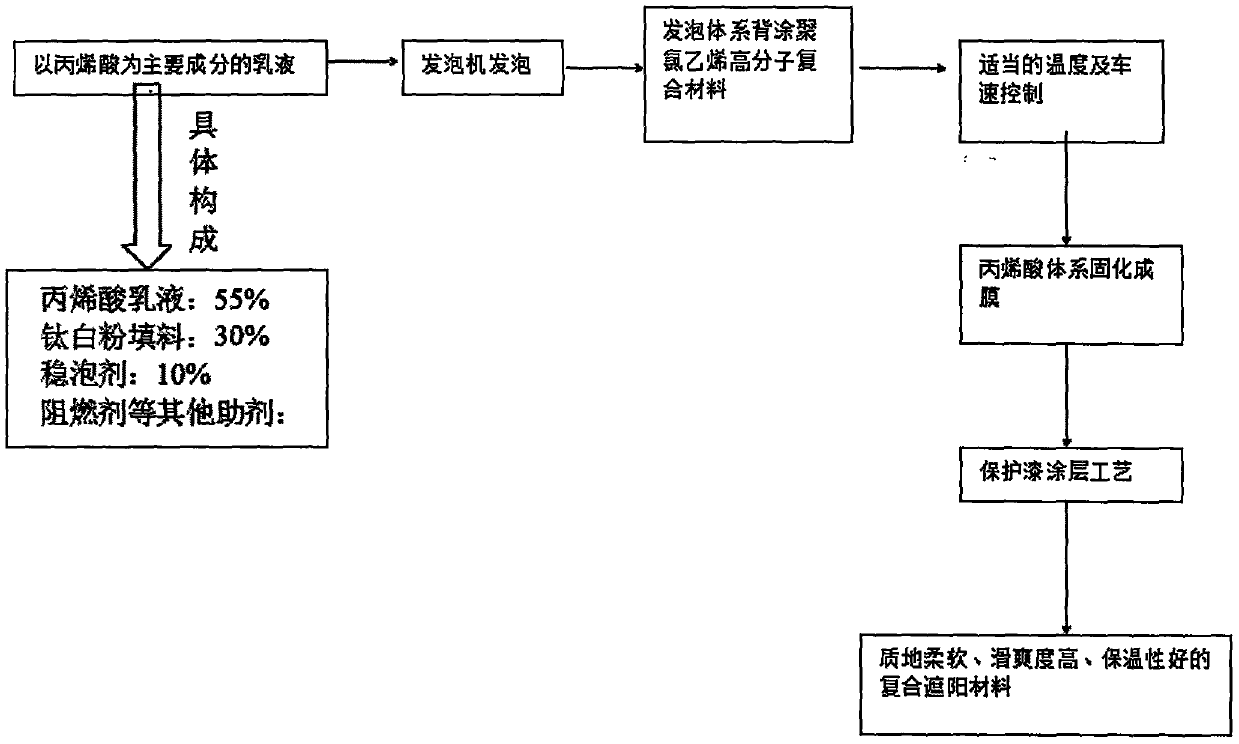

Composite sun-shading material of acrylic acid polyvinyl chloride polymer material

The invention provides a composite sun-shading material of an acrylic acid polyvinyl chloride polymer material, which mainly comprises the following raw materials: sunlight cloth fabric and coating slurry; wherein the sunlight fabric is woven by yarns coated with polyvinyl chloride and has a certain opening ratio and light transmittance; the coating slurry consists of acrylic emulsion, titanium dioxide filler, a foam stabilizer and a flame retardant; according to the invention, the acrylic emulsion serving as a main component of the coating slurry is synthesized through polymerization reactionby adopting acrylic monomer and C1-C8 acrylic acid alkyl ester thereof to synthesize an acrylic ester slurry agent copolymer adhesive and adding high-performance acrylic ester adhesive, and the curing point of the acrylic emulsion is about 150 DEG C; the problem that the foaming surface of the coating fabric is sticky is fundamentally solved, the defect rate of the product is reduced, the surfaceflatness of the product is improved, the cleanliness is increased, the product types are increased, and the core competitiveness of an enterprise is improved by playing a great promotion role for market promotion and product sale.

Owner:温多利遮阳材料(德州)股份有限公司

Direct air-intake sludge drying apparatus and method thereof

PendingCN105819657AFast dryingSolve stickySludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeMechanical engineering

The invention provides a direct air-intake sludge drying apparatus. The direct air-intake sludge drying apparatus comprises a casing, wherein, a dividing wall is arranged in the casing, so that the space in the casing is divided into a first drying chamber and a second drying chamber. A feed inlet and an air outlet are arranged on the upper part of the first drying chamber, and a discharge hatch is arranged on the circumferential wall of the first drying chamber. An air inlet and the air outlet are arranged on the circumferential wall or the bottom of the second drying chamber. A sludge stirring apparatus is arranged in the first drying chamber, wherein, the sludge stirring apparatus comprises a rotation shaft and a stirring component fixed on the rotation shaft. A distribution chamber is arranged at the outboard of a side wall of the first drying chamber, the air inlet and the side wall adjacent to the first drying chamber have the through holes, and the side wall of the first drying chamber drying chamber has the through hole. The through hole on the side wall of the first drying chamber is communicated with the side wall of the distribution chamber, and is communicated with the air outlet of the second drying chamber and the air inlet of the distribution chamber. The invention also provides a direct air-intake sludge drying method by using the direct air-intake sludge drying apparatus.

Owner:广州正晟科技有限公司

Soybean milk machine convenient to clean

InactiveCN107510389AAvoid scratchesSolve potential safety hazardsKitchen equipmentEngineeringWater level

The invention discloses an easy-to-clean soybean milk machine, which comprises a base, a stainless steel shell is connected above the base, a water level line is drawn on the outer wall of the stainless steel shell, and a handle is installed on one side of the stainless steel shell. The other side of the casing is connected with a flow port, and the flow port is connected with the stainless steel casing. The top of the stainless steel casing is connected with the machine head, and the outer wall of the machine head is provided with a power socket and a pulping key. The power socket is located at the pulping key. One end of the water guide pipe passes through the machine head and is located inside the stainless steel shell, a handle is connected above the machine head, and the lower cover connected to the bottom of the machine head is located inside the stainless steel shell, the lower cover The bottom of the water level electrode, anti-overflow electrode and electric motor are fixed. In this experiment, the shaft and the connecting rod are fixed and connected by bolts. cleaning problem.

Owner:南京苏格信息技术有限公司

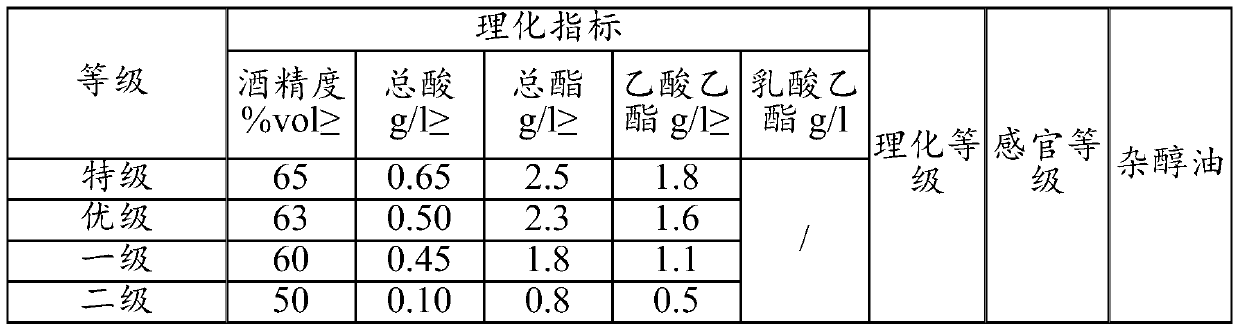

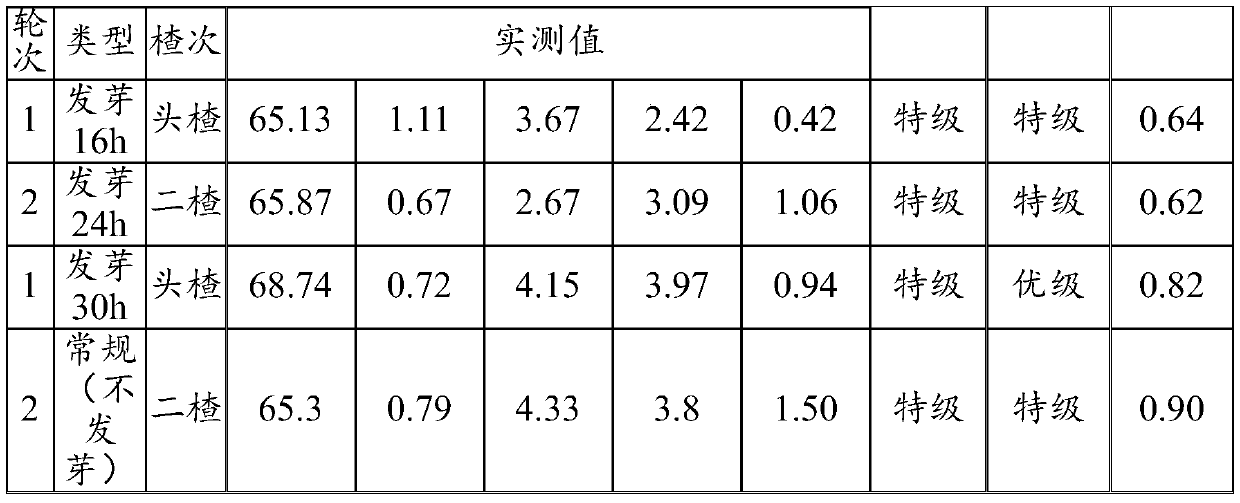

Highland barley wine brewing process and highland barley wine produced by same

PendingCN111378545AReduce contentSolve stickyAlcoholic beverage preparationBiotechnologyFusel alcohol

The invention provides a highland barley wine brewing process. The highland barley wine brewing process comprises the following steps: soaking highland barley, germinating the highland barley, cookingthe germinated highland barley, cooling and adding yeast in the cooked germinated highland barley, carrying out fermentation and filling the fermentation product into a steamer for distilling. The invention also provides highland barley wine brewed by the process. The process is more convenient to produce and easy to operate, the production efficiency is improved, and the production cost is reduced; and according to the brewed highland barley wine, harmful substances such as fusel oil and higher alcohol in the wine body are reduced.

Owner:青海互助天佑德青稞酒股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com