Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

320results about "Connection end caps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrical wire connector

ActiveUS7255592B1Smooth connectionStrength optimizationConnection end capsContact members penetrating/cutting insulation/cable strandsElectrical connectorElectrical conduction

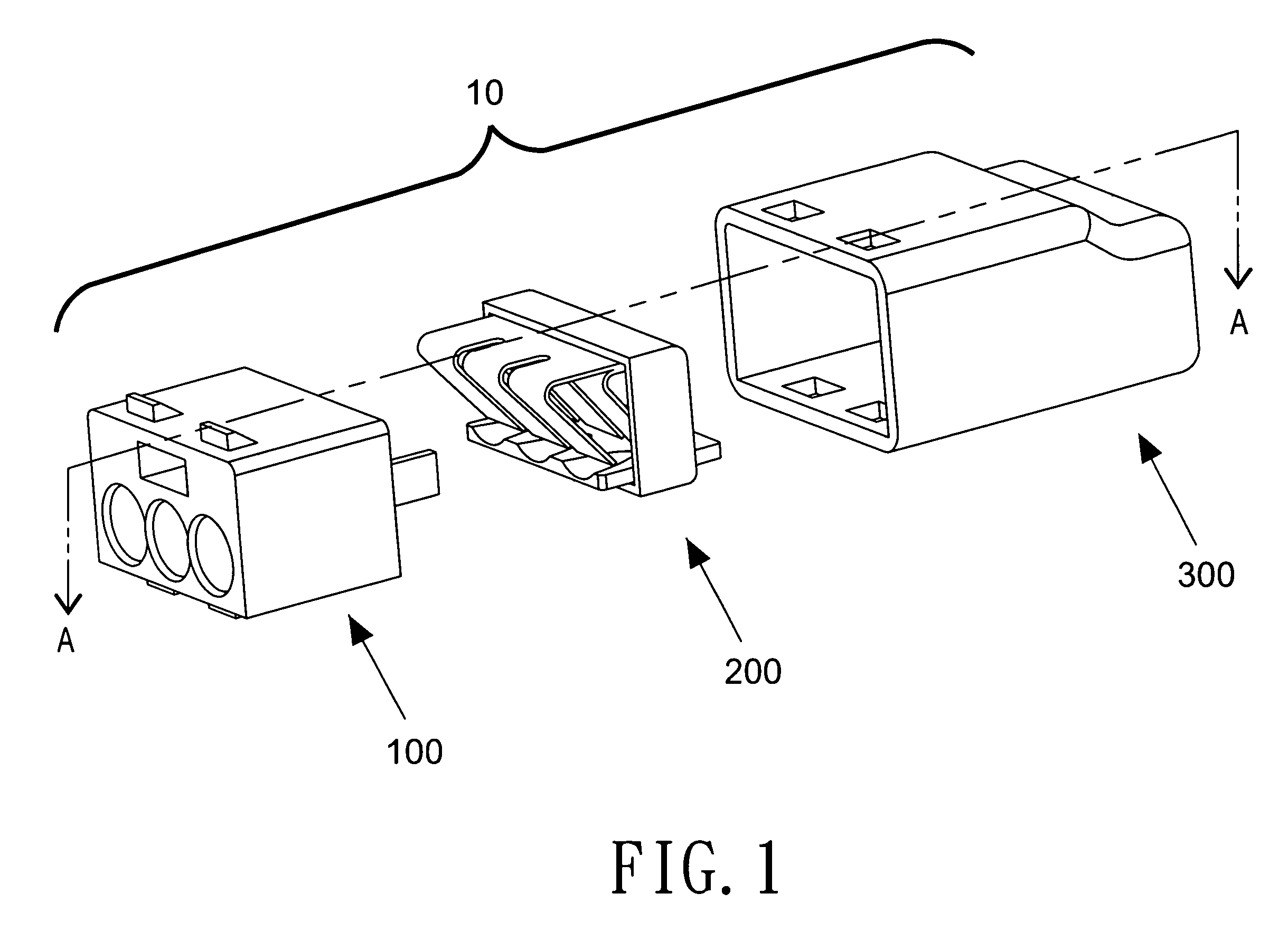

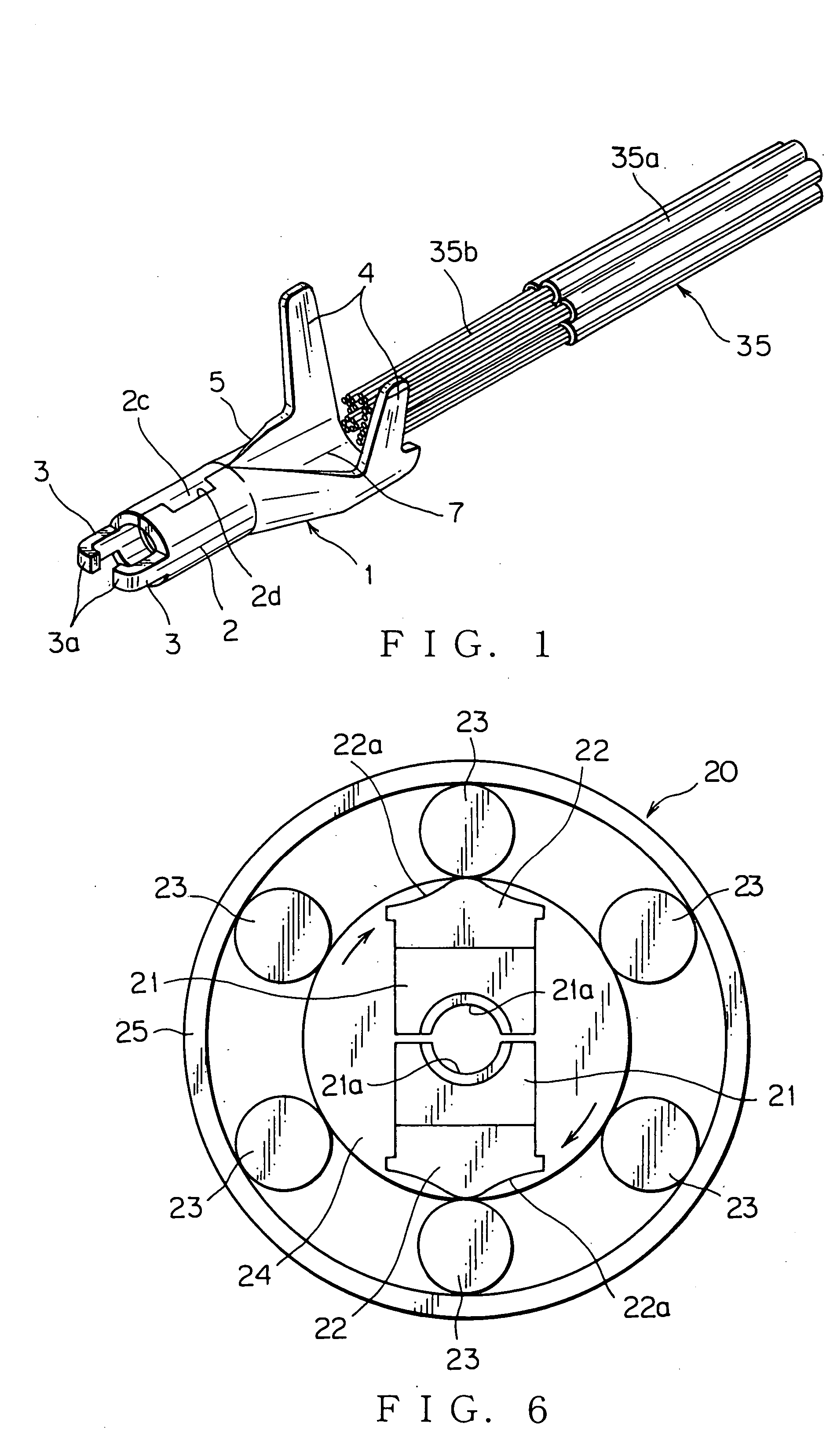

A push-in wire connector for electrically interconnecting multiple wires together is disclosed to have a guide and lock element, which is mated with a conduction and retention element and assembled inside the enclosing space of an enclosing element. Multiple wire insertion channels are provided inside the connector for receiving the insertion of wires. Each of the insertion channels includes a main port section led in by an insertion port for guiding the insertion of a stripped end of a wire. A wire engagement segment follows the main portion section formed by the surrounding of a conduction plate at the bottom, an insertion channel separation wall at one or both sides, and the resilient spring legs on the top. The wire engagement segment prevents the bending or deflection of the inserted wire end thereby ensuring secure and good electrical conduction between the inserted wires.

Owner:HEAVY POWER

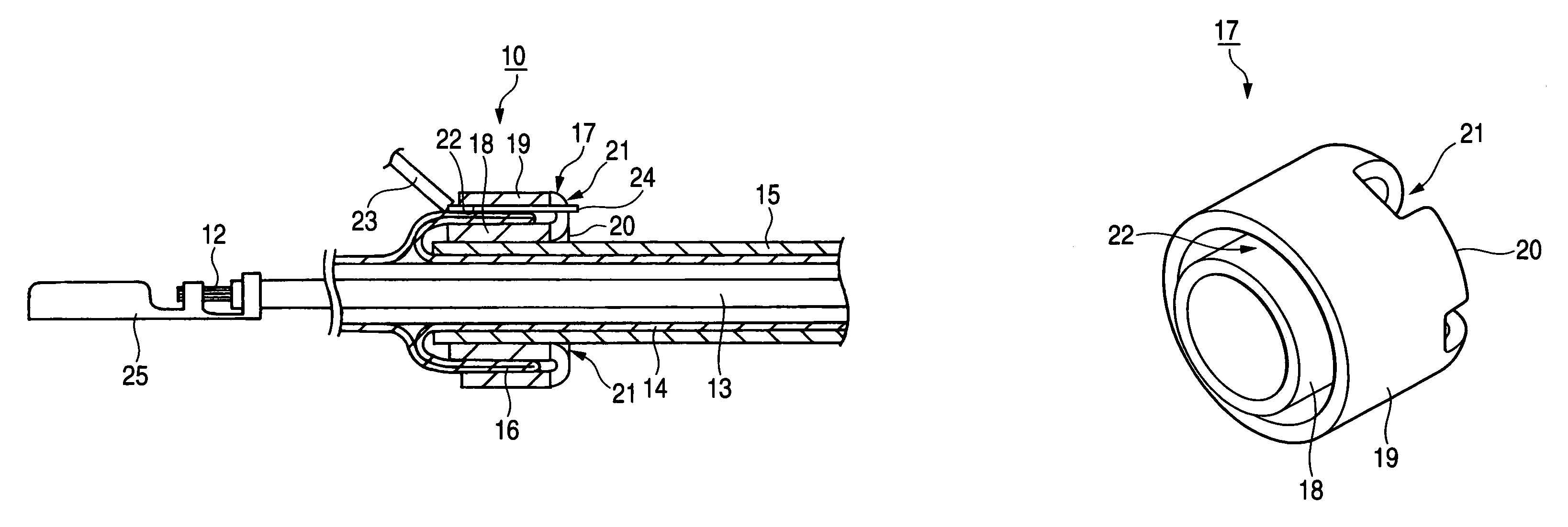

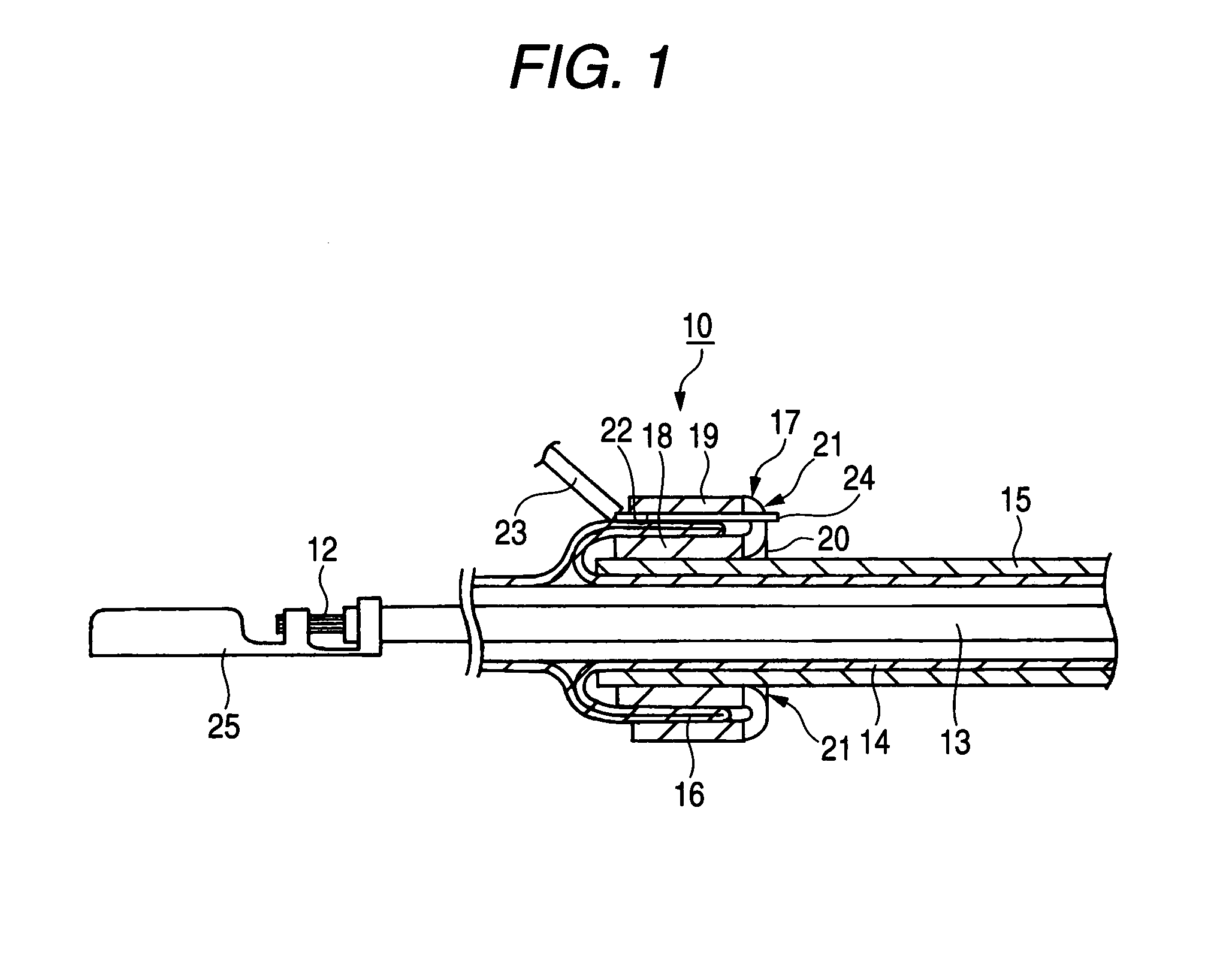

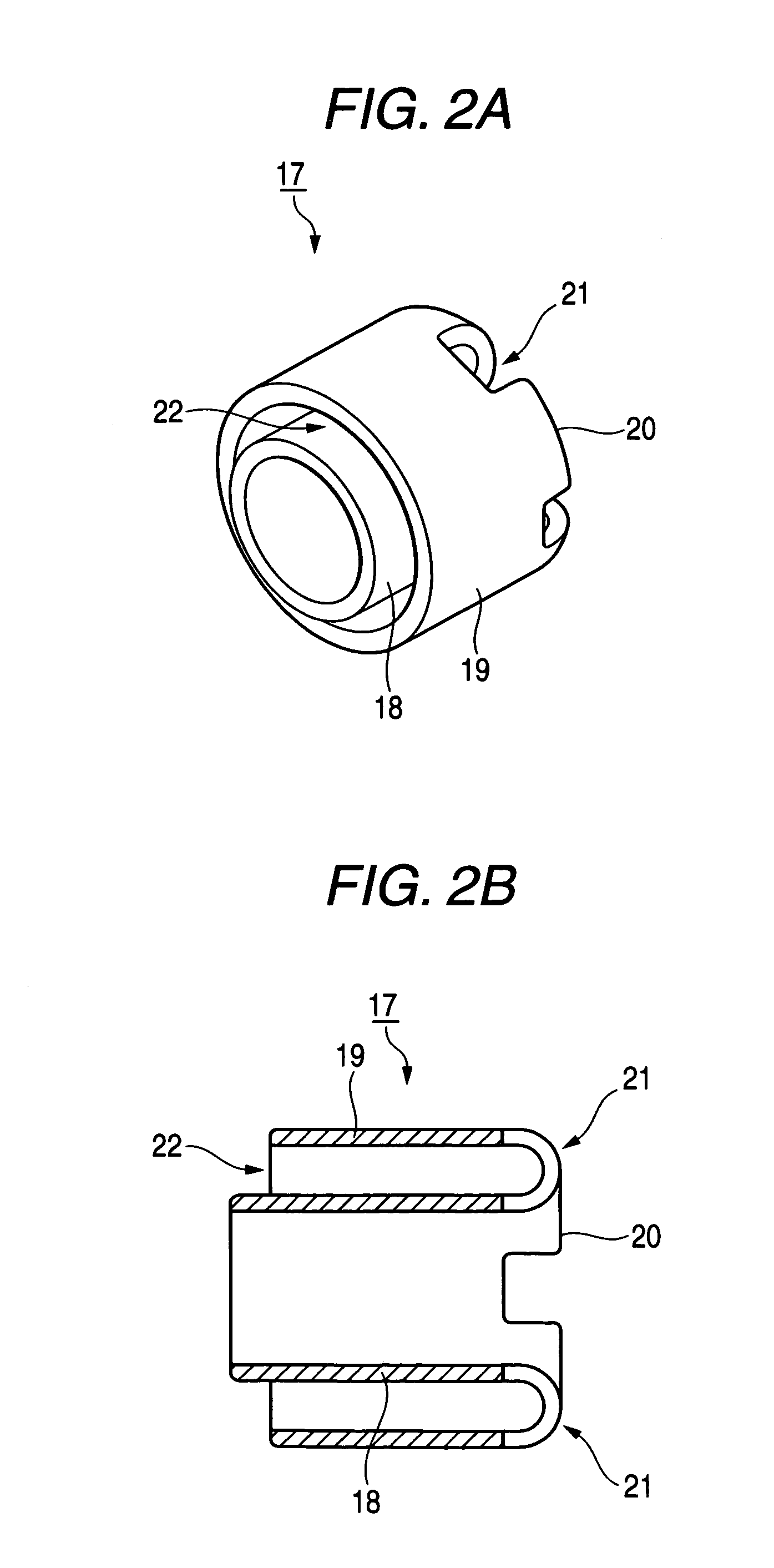

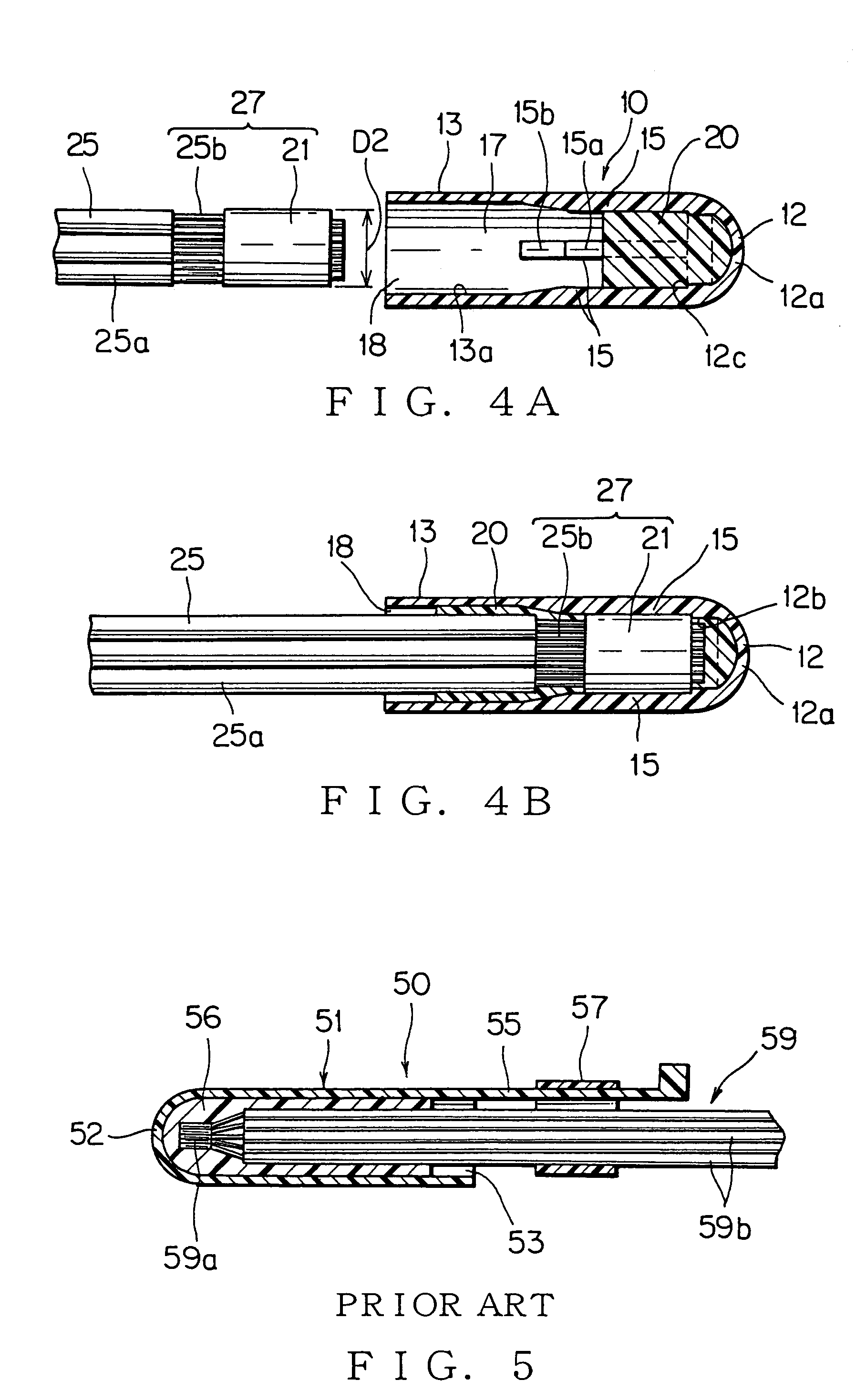

Method of grounding shielded wire and structure for grounding shielded wire

ActiveUS7044756B1Firmly connectedQuality improvementConnection end capsCoupling protective earth/shielding arrangementsEngineering

Owner:YAZAKI CORP

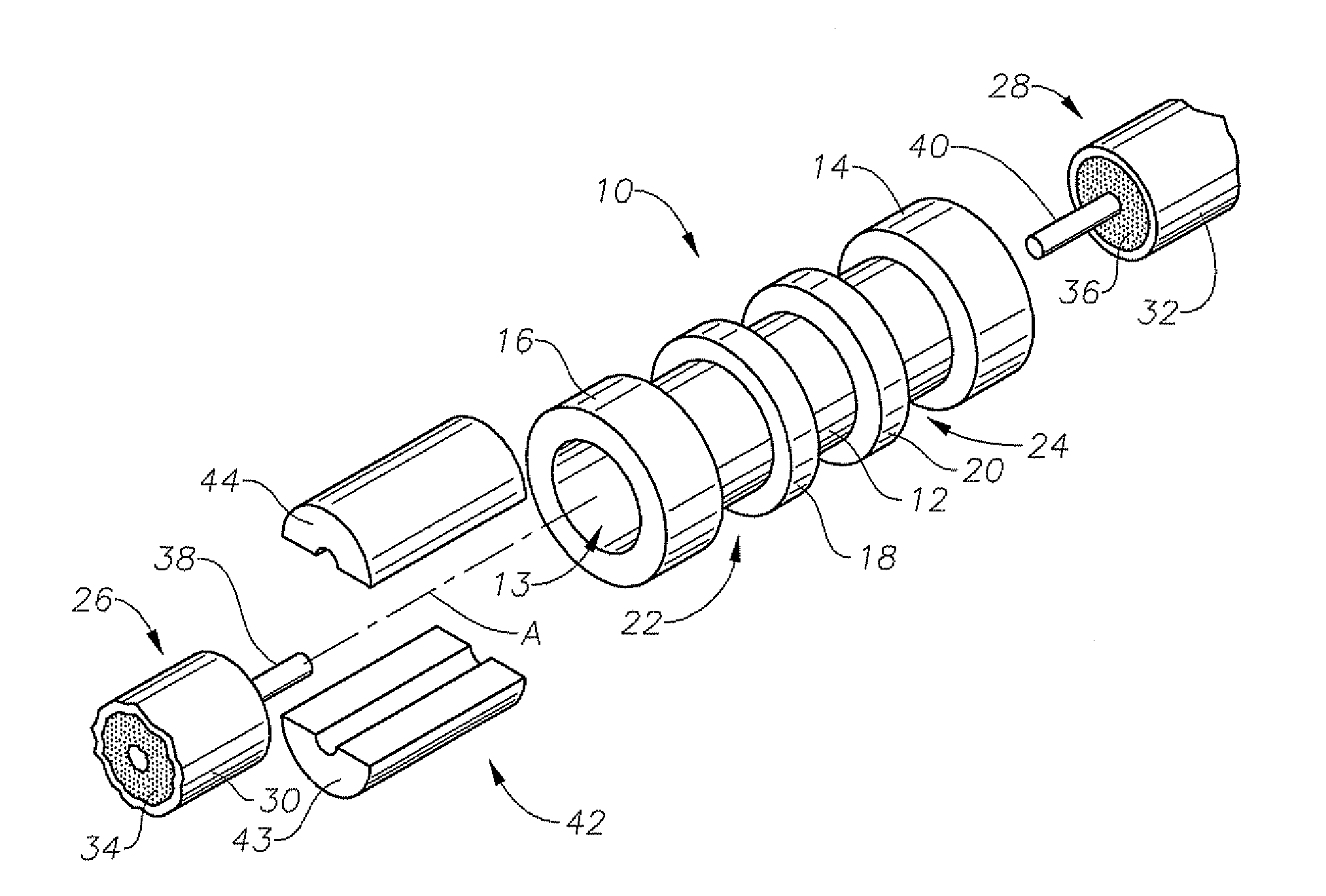

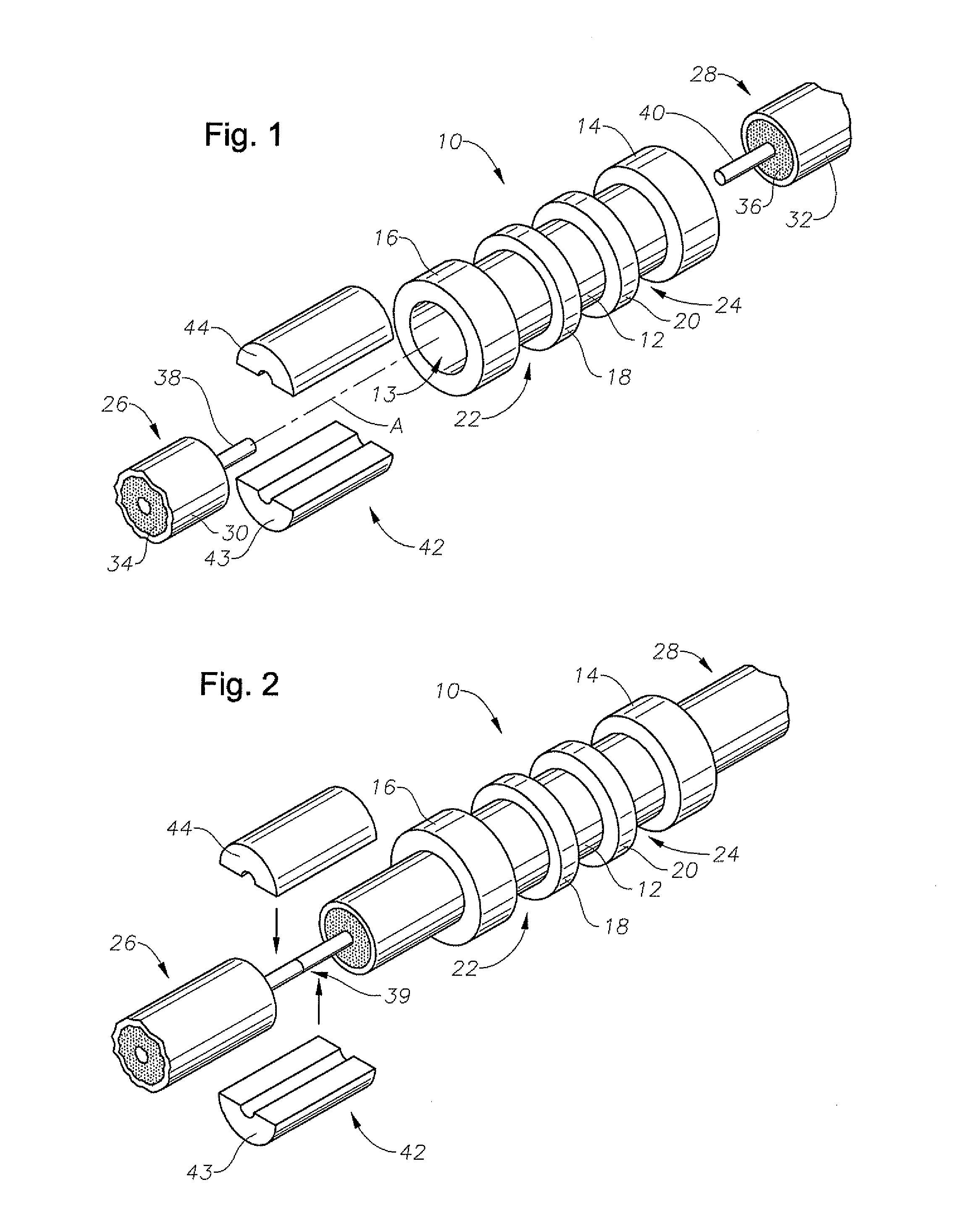

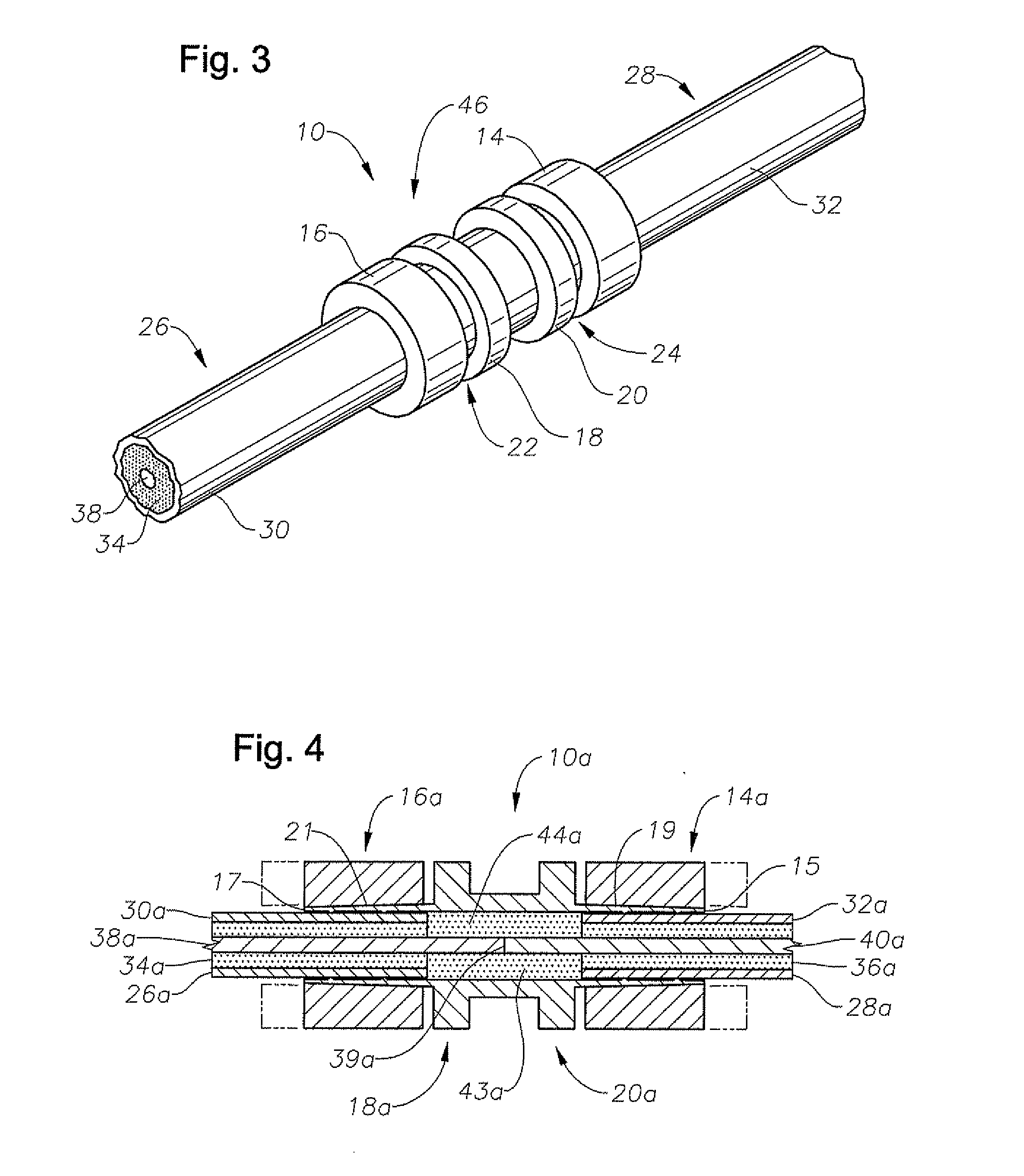

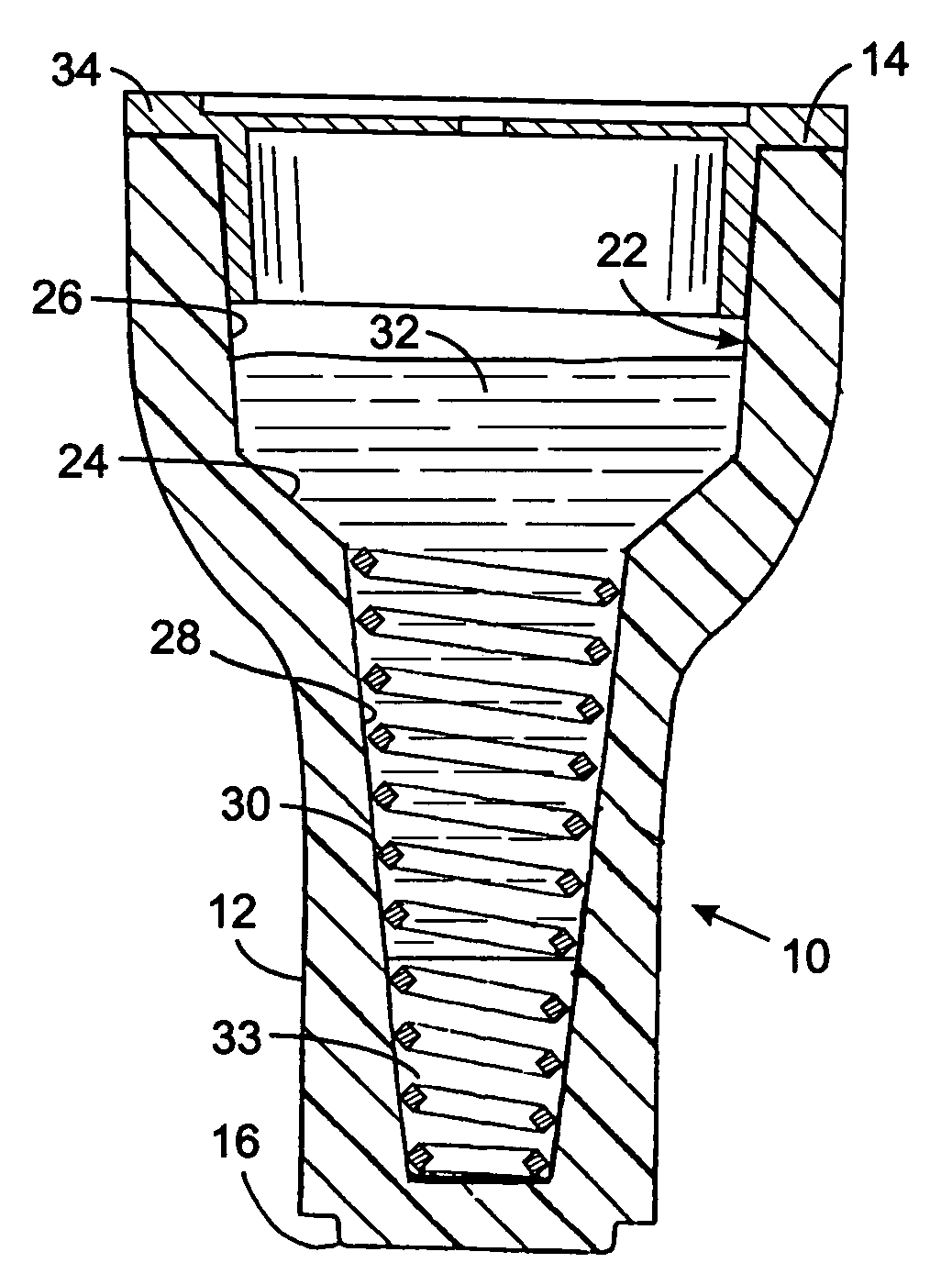

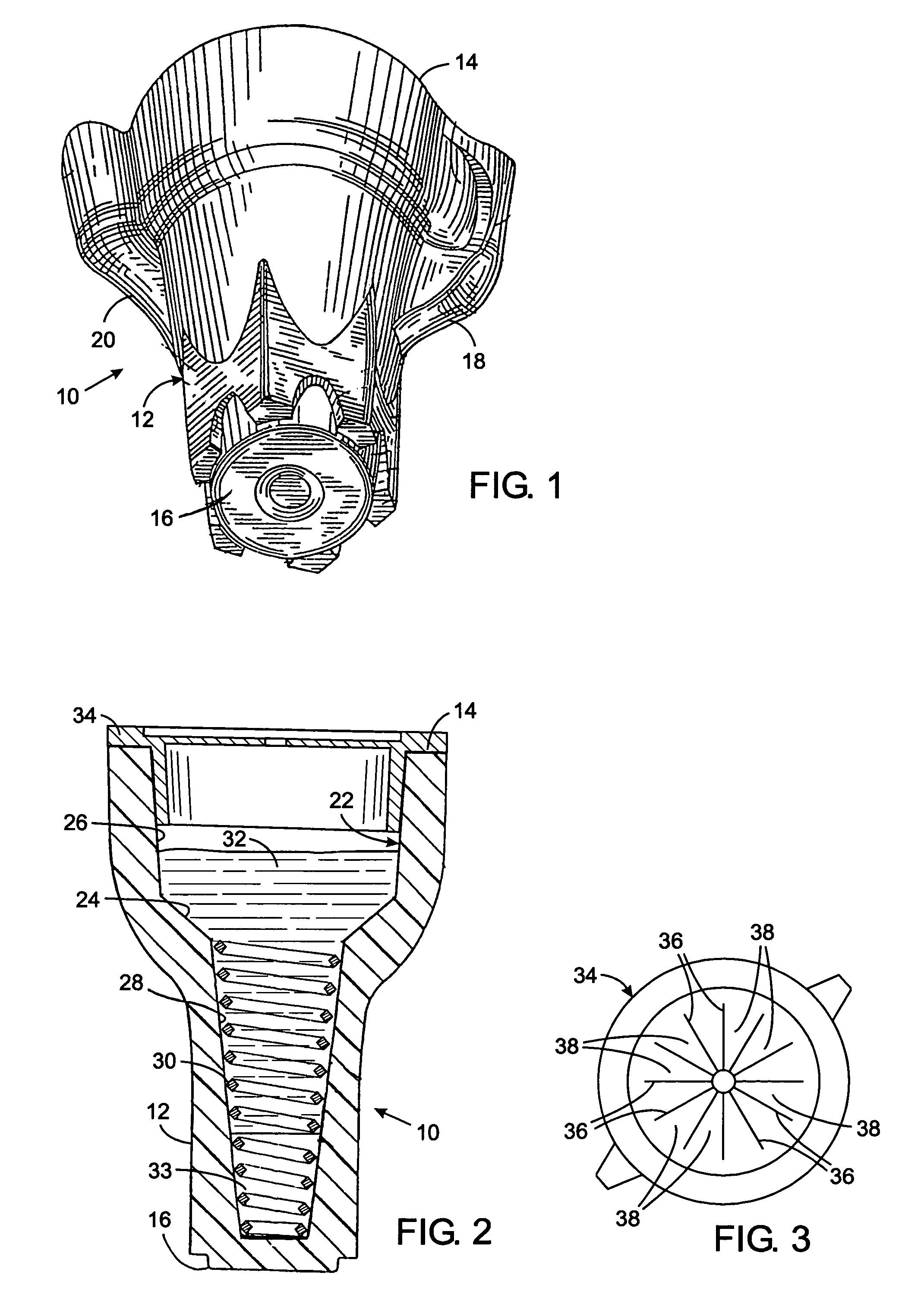

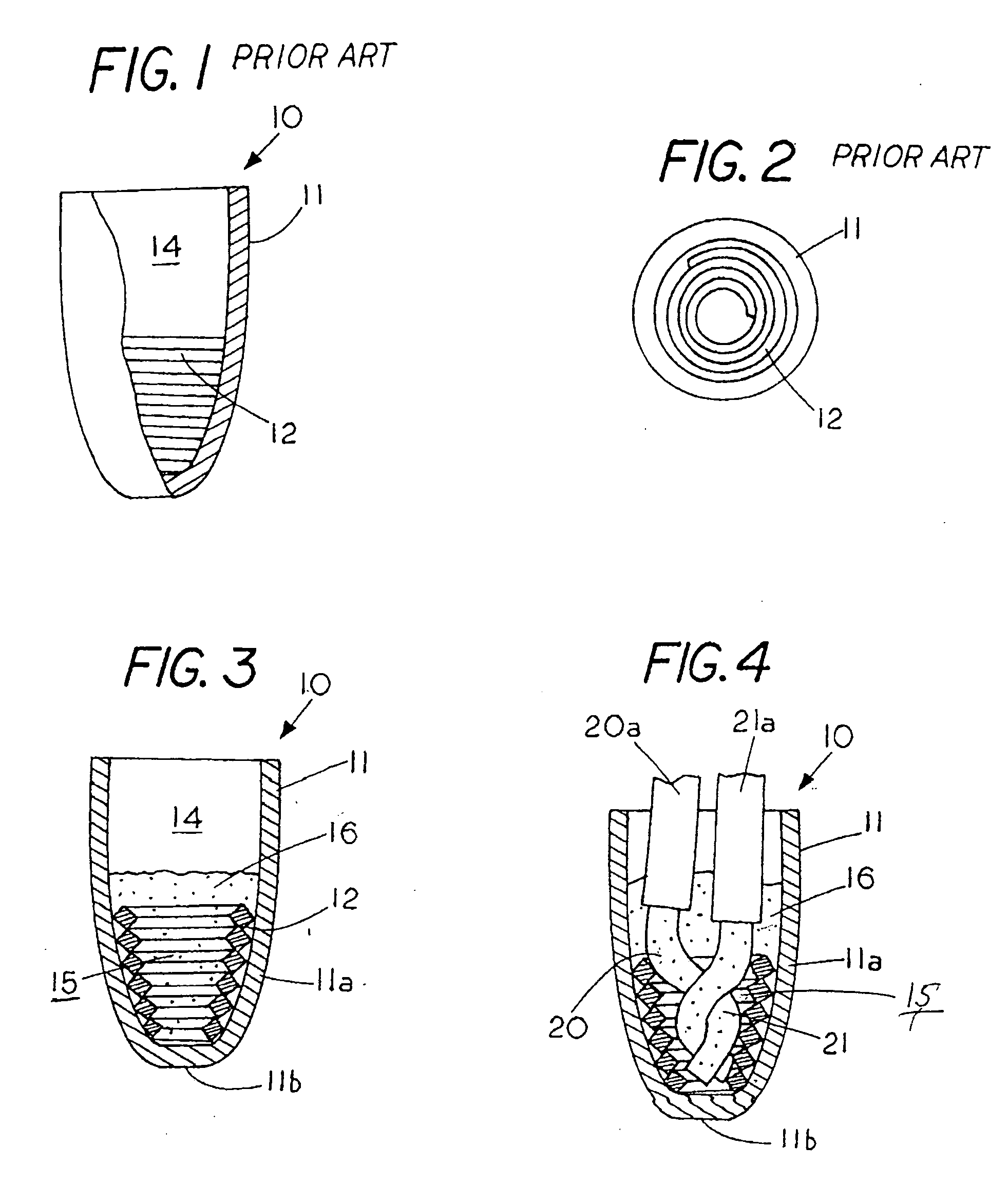

Mineral insulated metal sheathed cable connector and method of forming the connector

A connection for a mineral insulated metal sheathed cable, wherein the connection employs a compression fitting. The connection may make up two or more mineral insulated metal sheathed cables wherein one or more of the cables may be secured with a compression fitting. The connection may splice together two individual cables, or a cable to an electrical element.

Owner:ACCUTRU INT

Method for forming an electrical connector with voltage detection point insulation shield

ActiveUS7150098B2Reduce frictionReduce irregularitiesContact member manufacturingRelieving strain on wire connectionThermoplasticElectrical conductor

In a method for forming an electrical cable connector having a voltage detection test point, an insulative shield is first molded from a thermoplastic and a conductive voltage detection test point terminal is inserted within the plastic insulative shield. After the pre-assembled insulative plastic shield and test point terminal are positioned adjacent the opening of the conductive outer shield, and after the conductive outer shield and an internal conductor are positioned within a mold cavity, an inner insulative housing is molded within the conductive outer shield and around the internal conductor.

Owner:THOMAS & BETTS INT INC

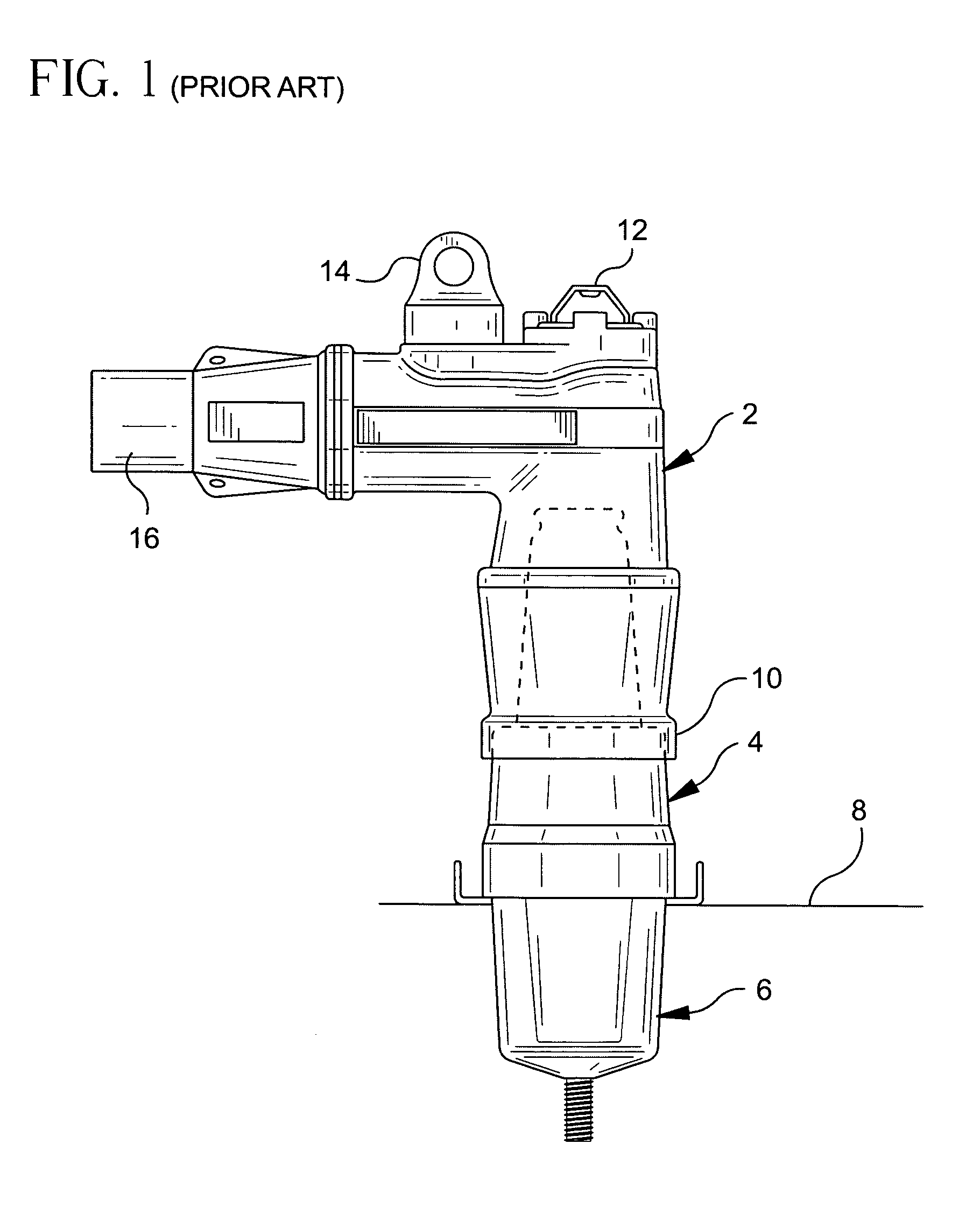

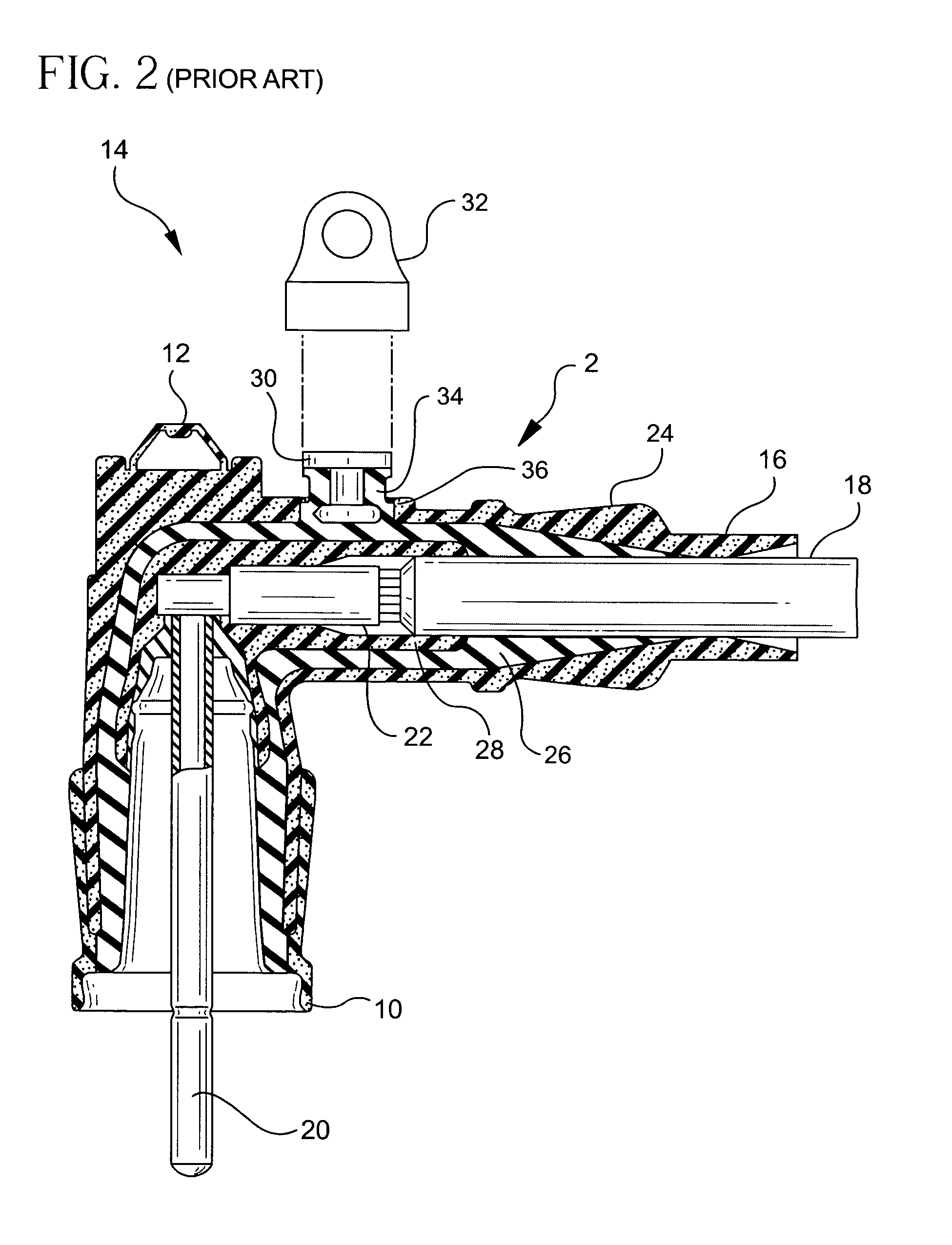

Insulated cable termination assembly and method of fabrication

ActiveUS7192319B1Avoid flowPrevents damaging current flowConnection end capsClamped/spring connectionsEngineeringElectrical and Electronics engineering

Owner:EATON INTELLIGENT POWER LIMITED

Crimping terminal for connection between electric cables

InactiveUS6658735B2Avoid flowCouplings bases/casesConnections effected by permanent deformationAdhesiveElectric cables

Owner:SUMITOMO WIRING SYST LTD

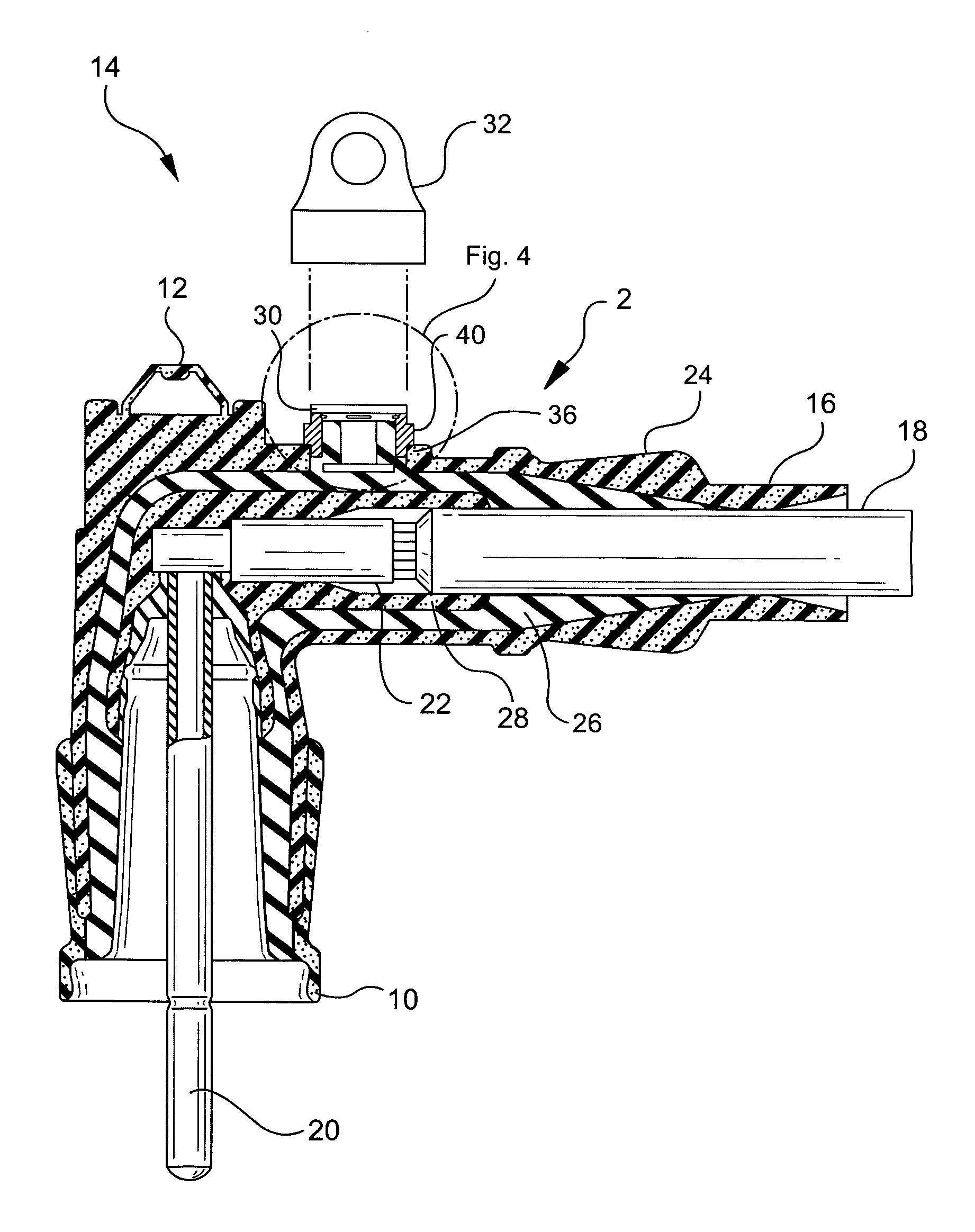

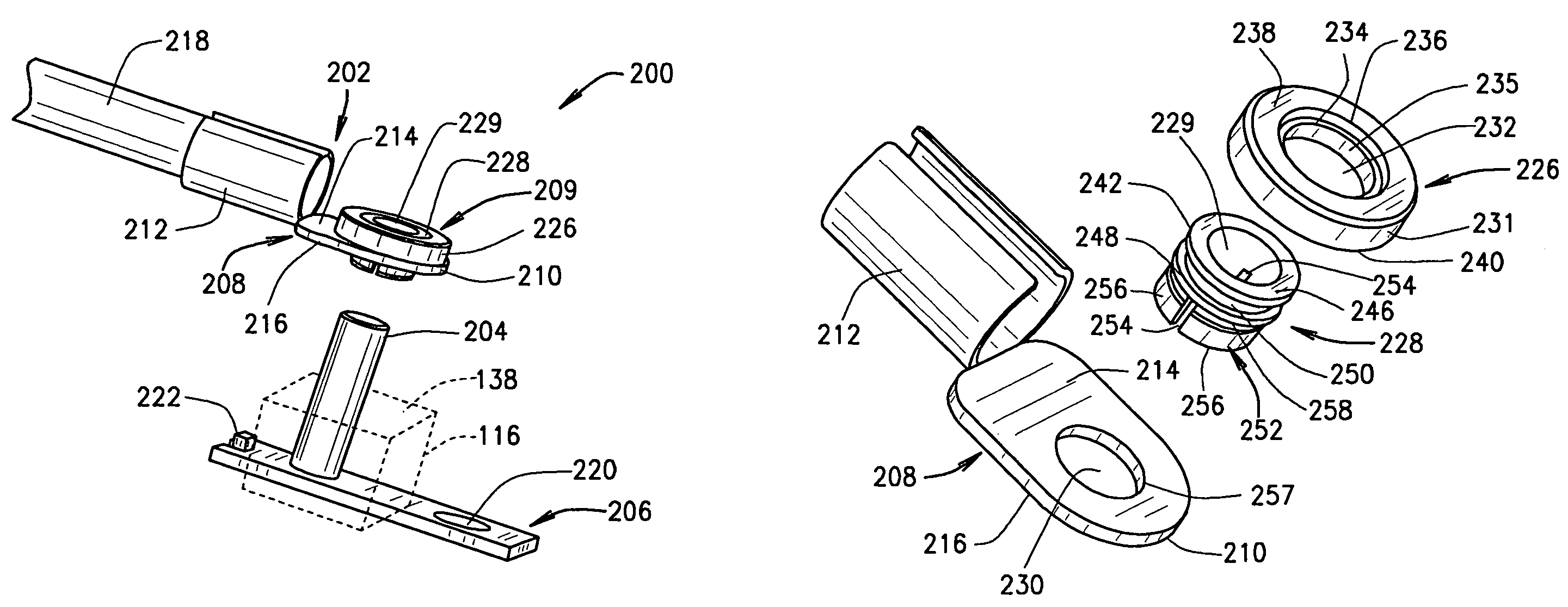

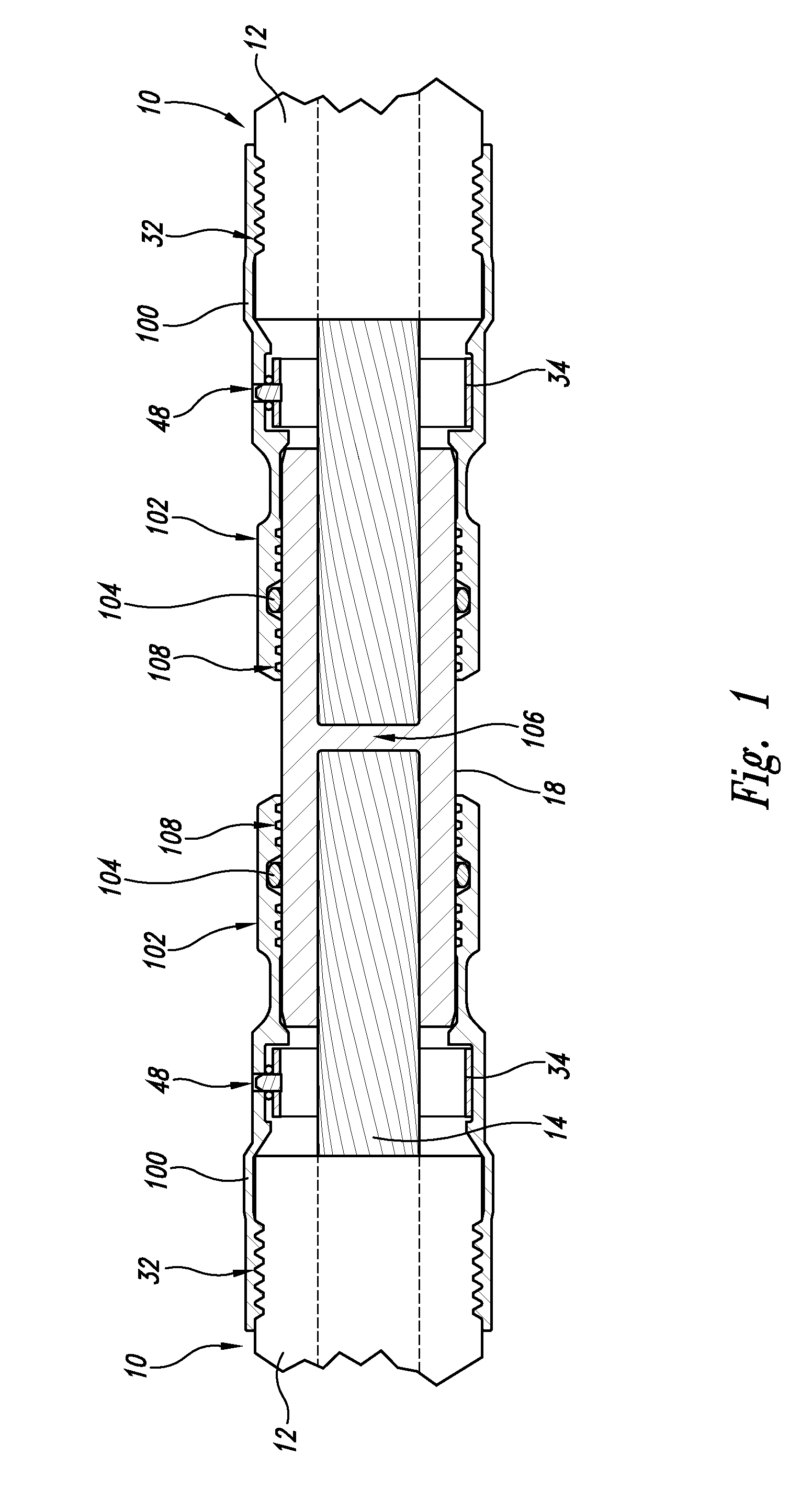

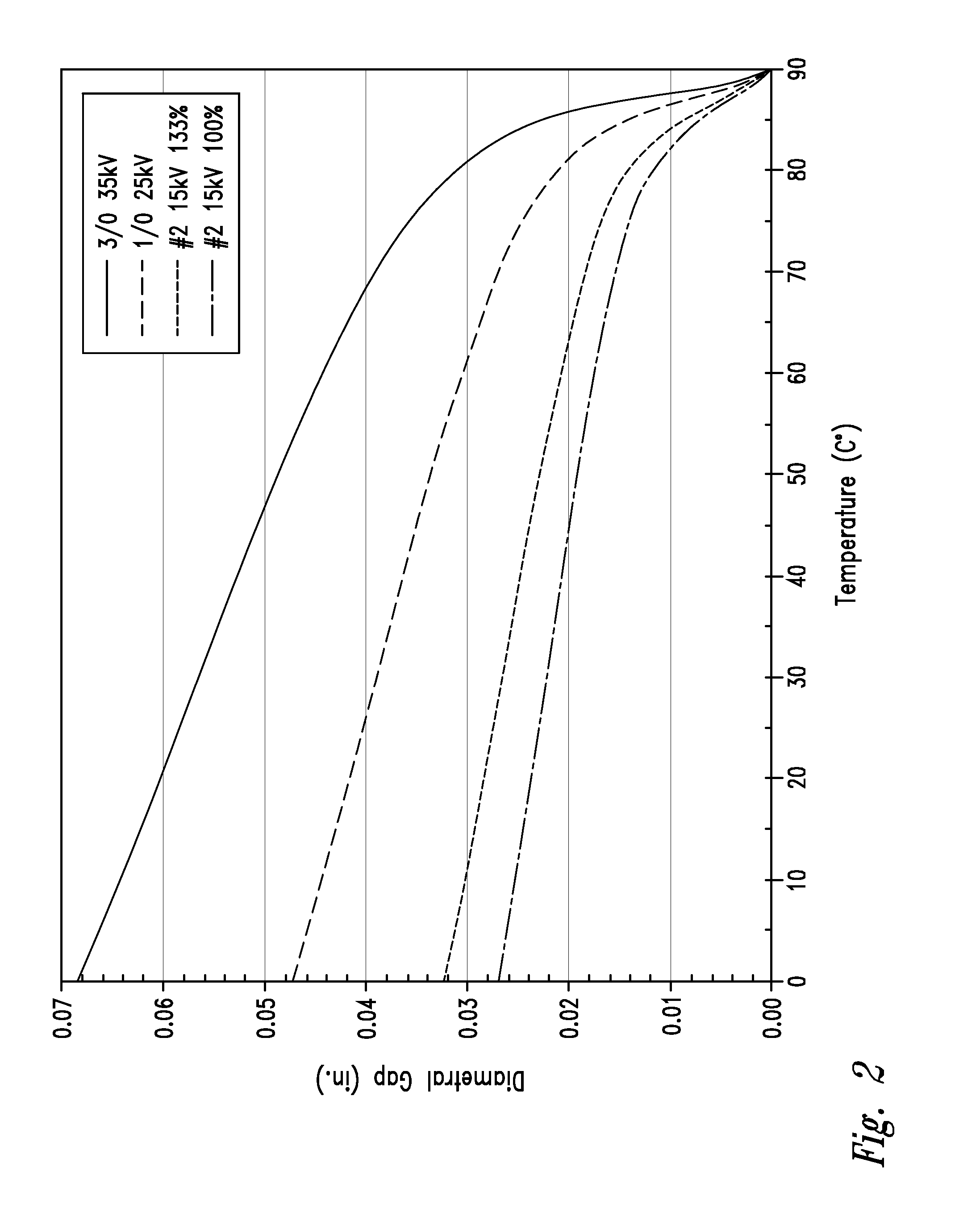

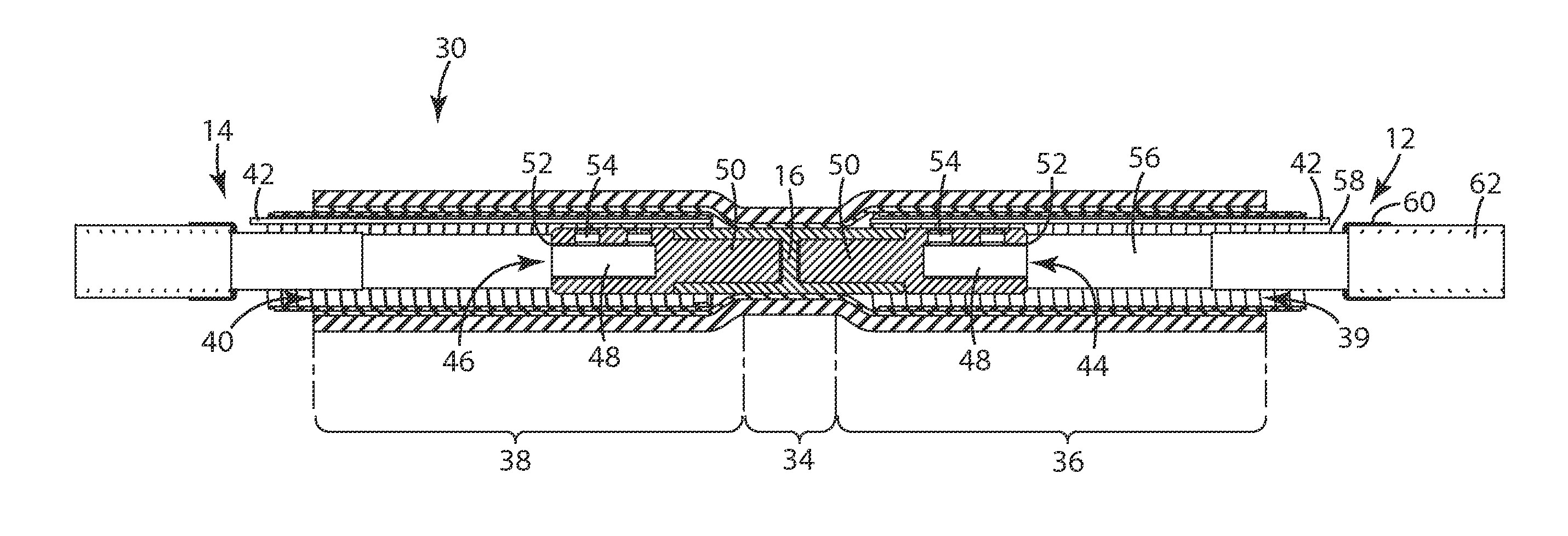

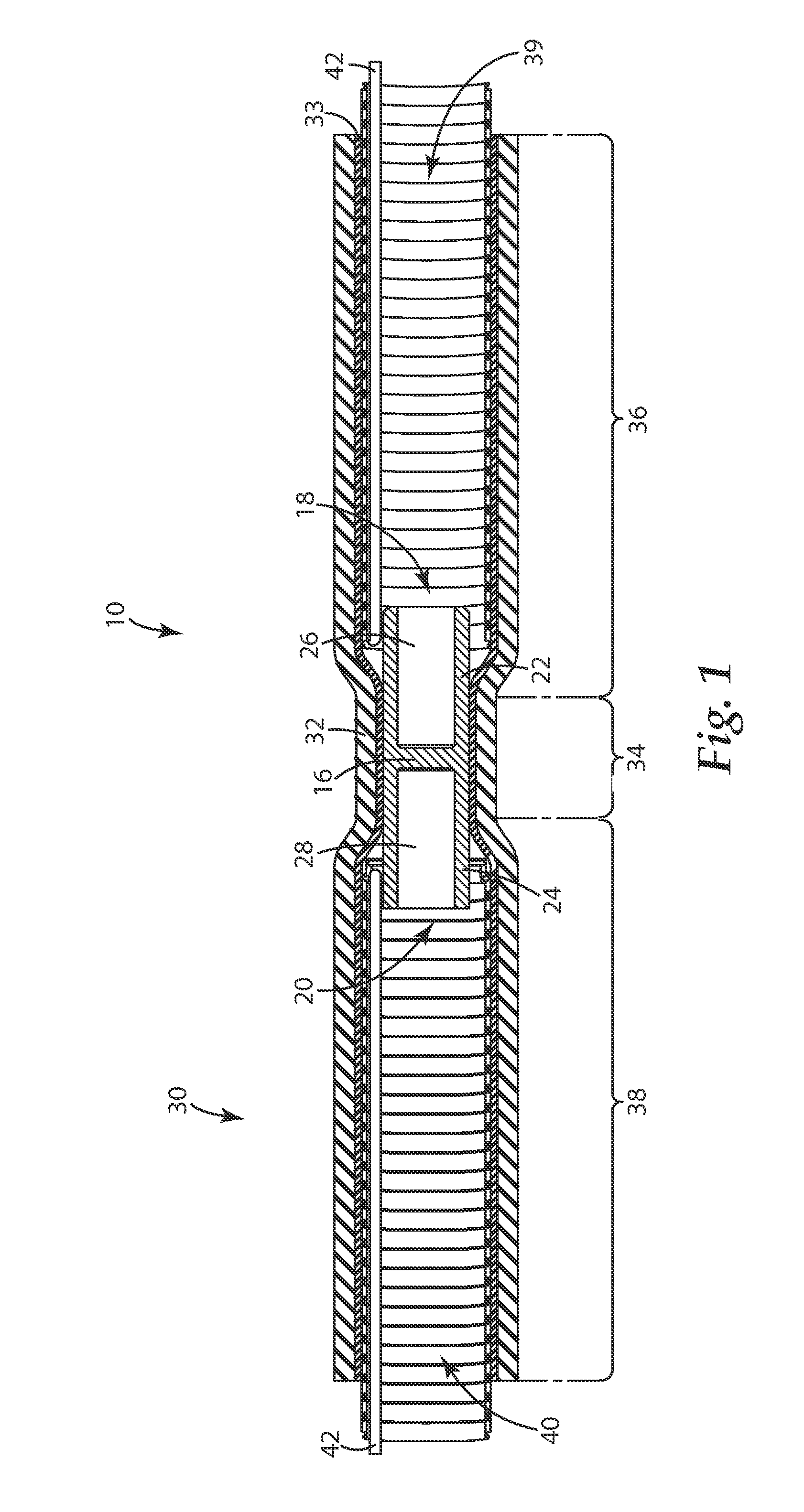

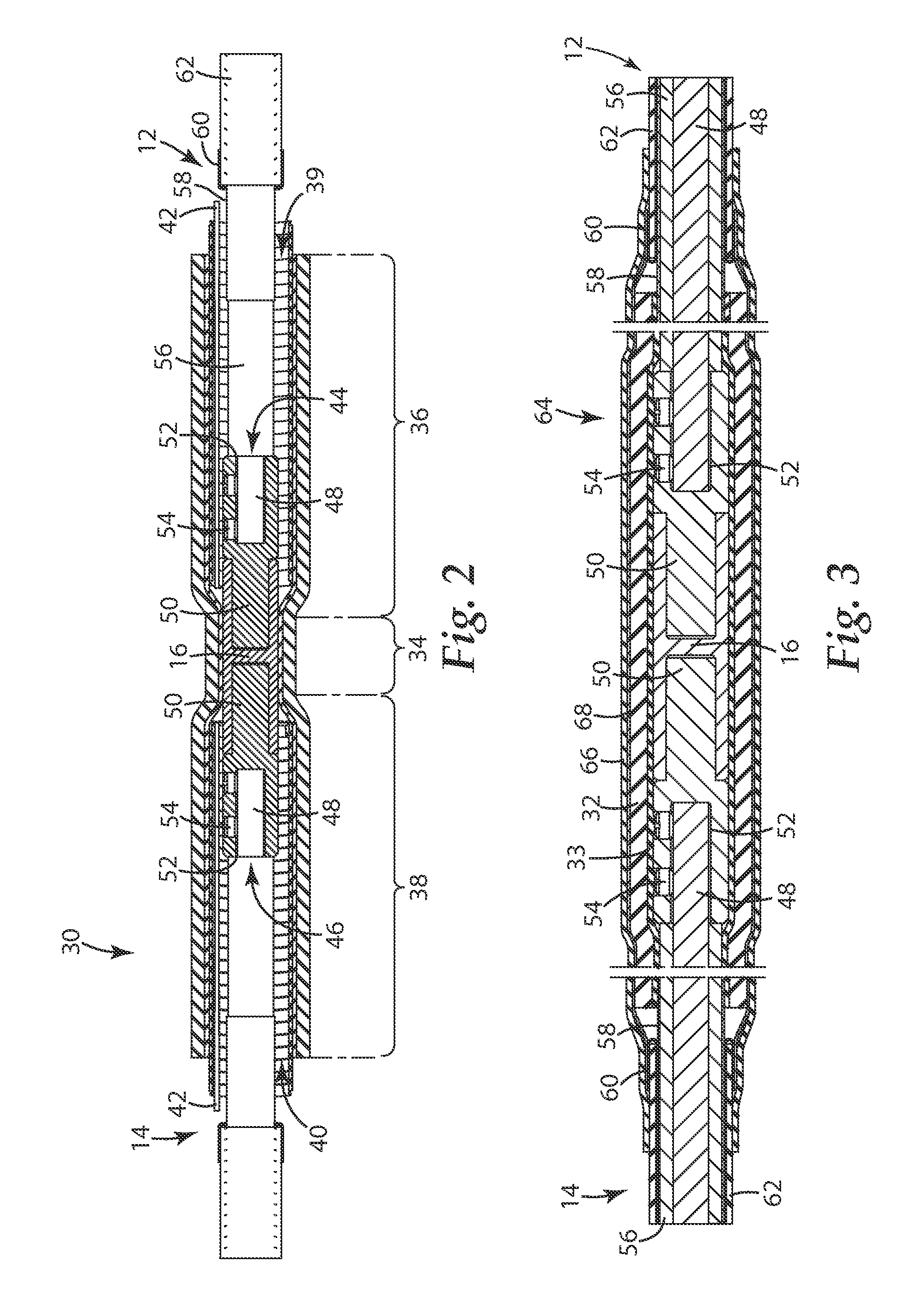

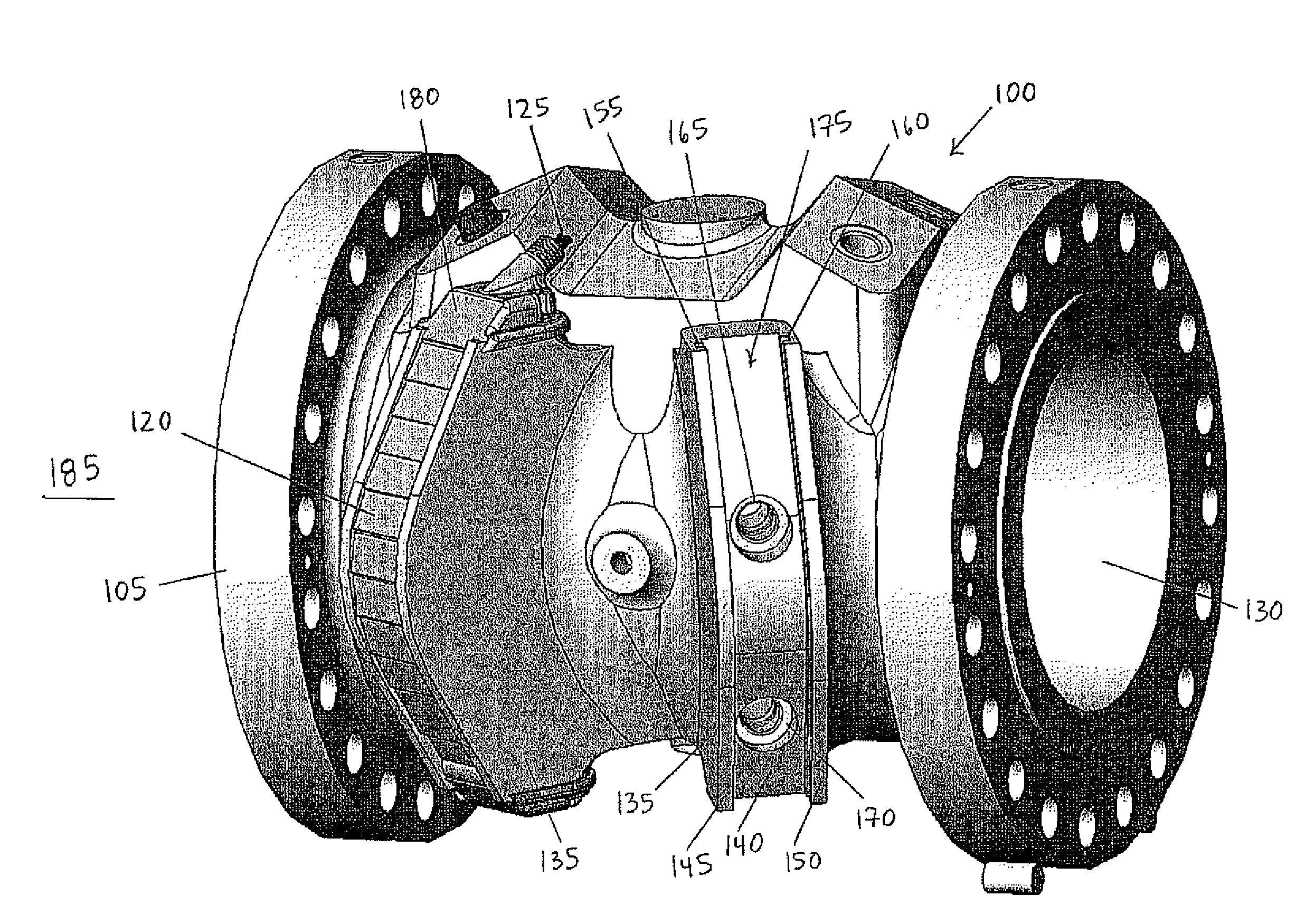

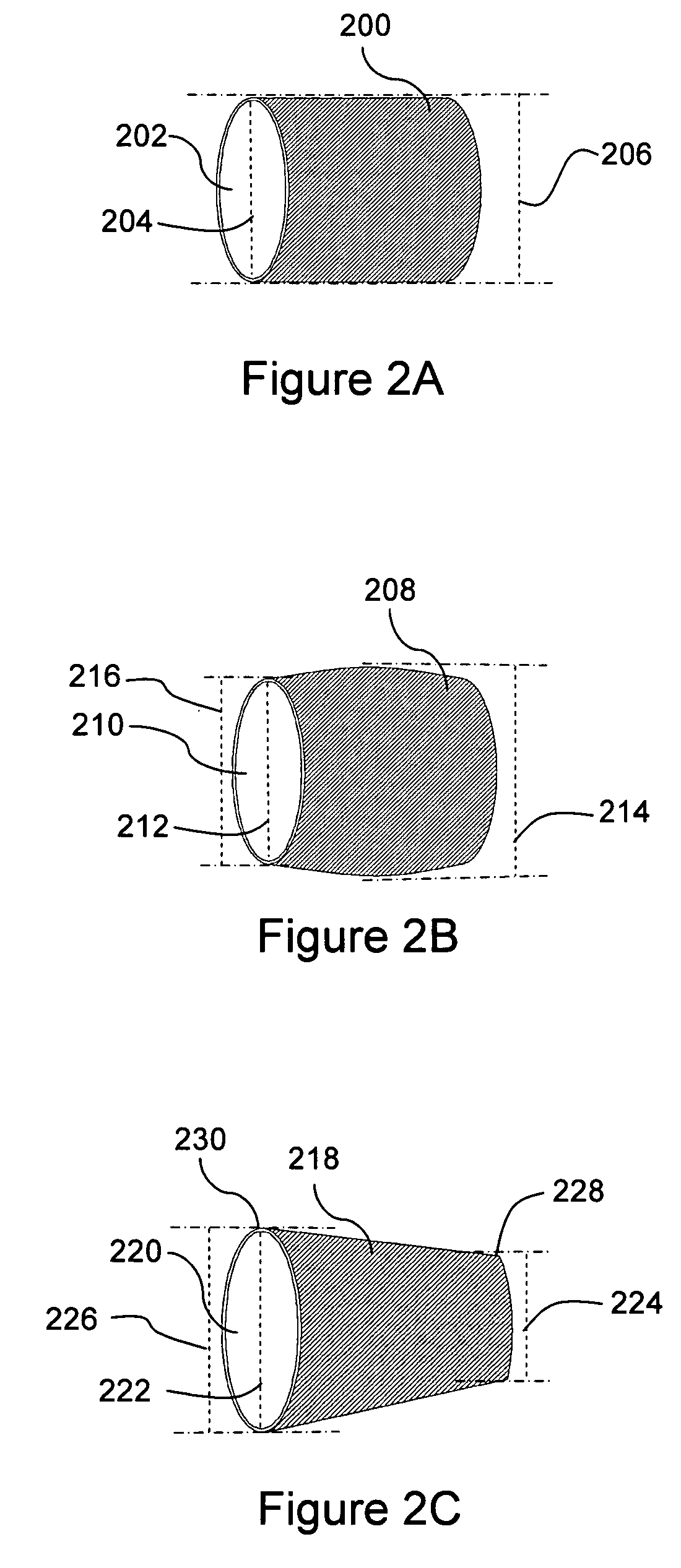

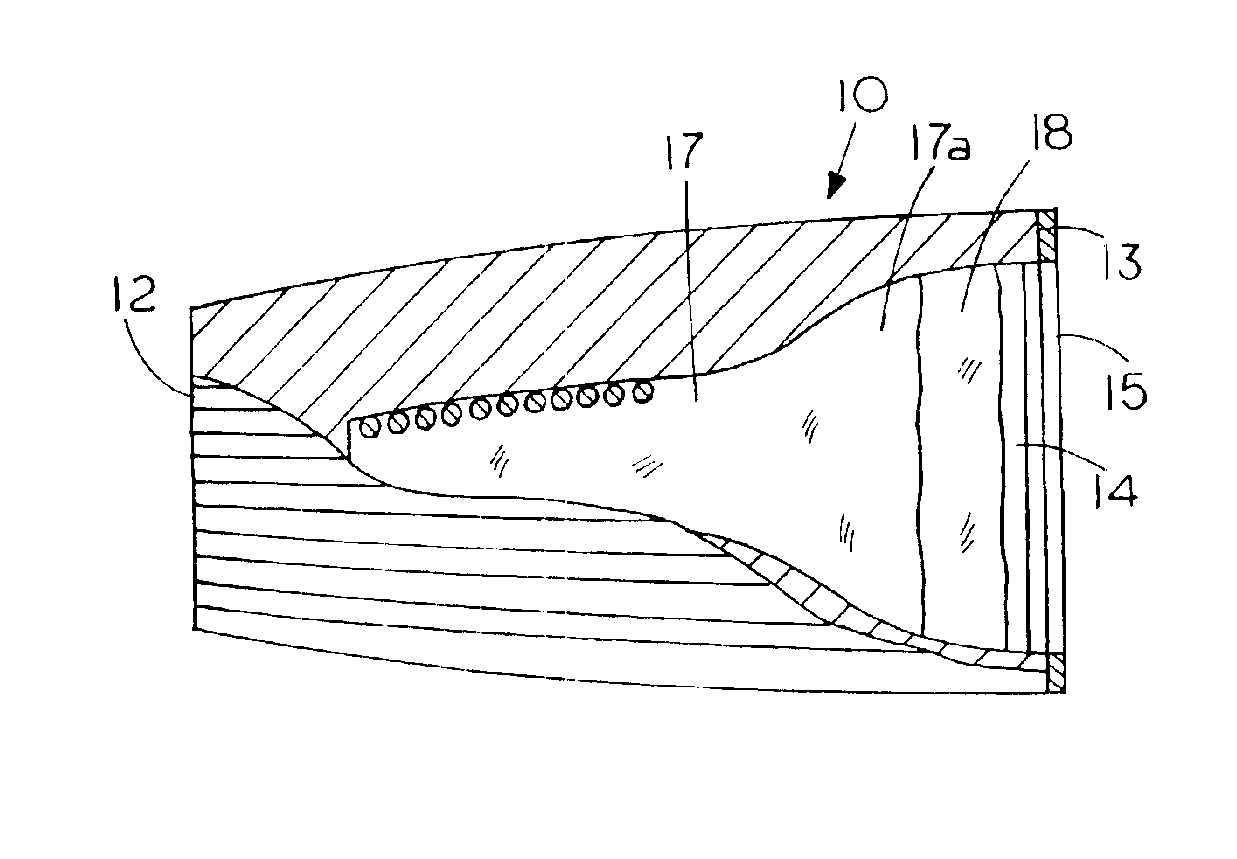

Swagable high-pressure cable connectors having improved sealing means

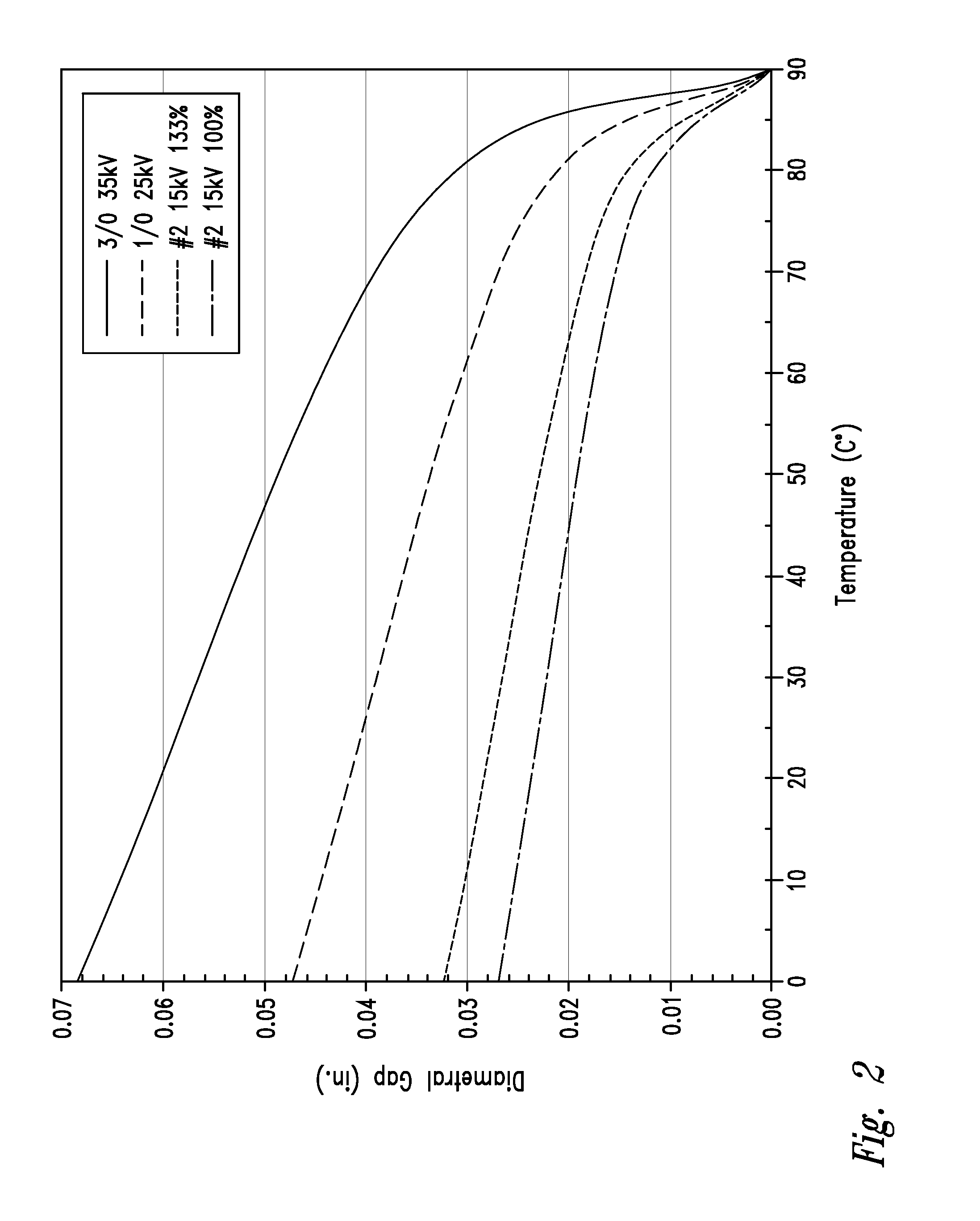

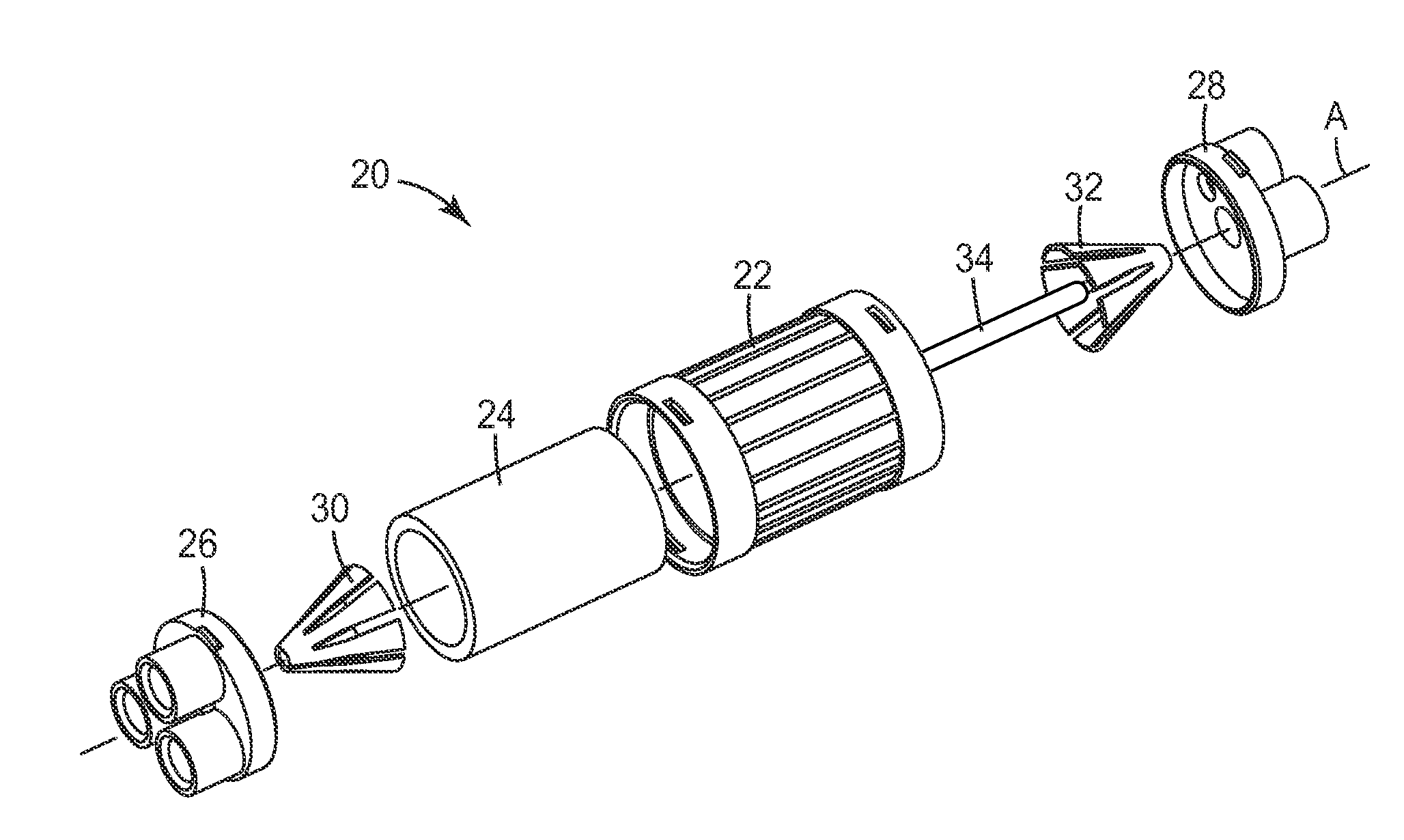

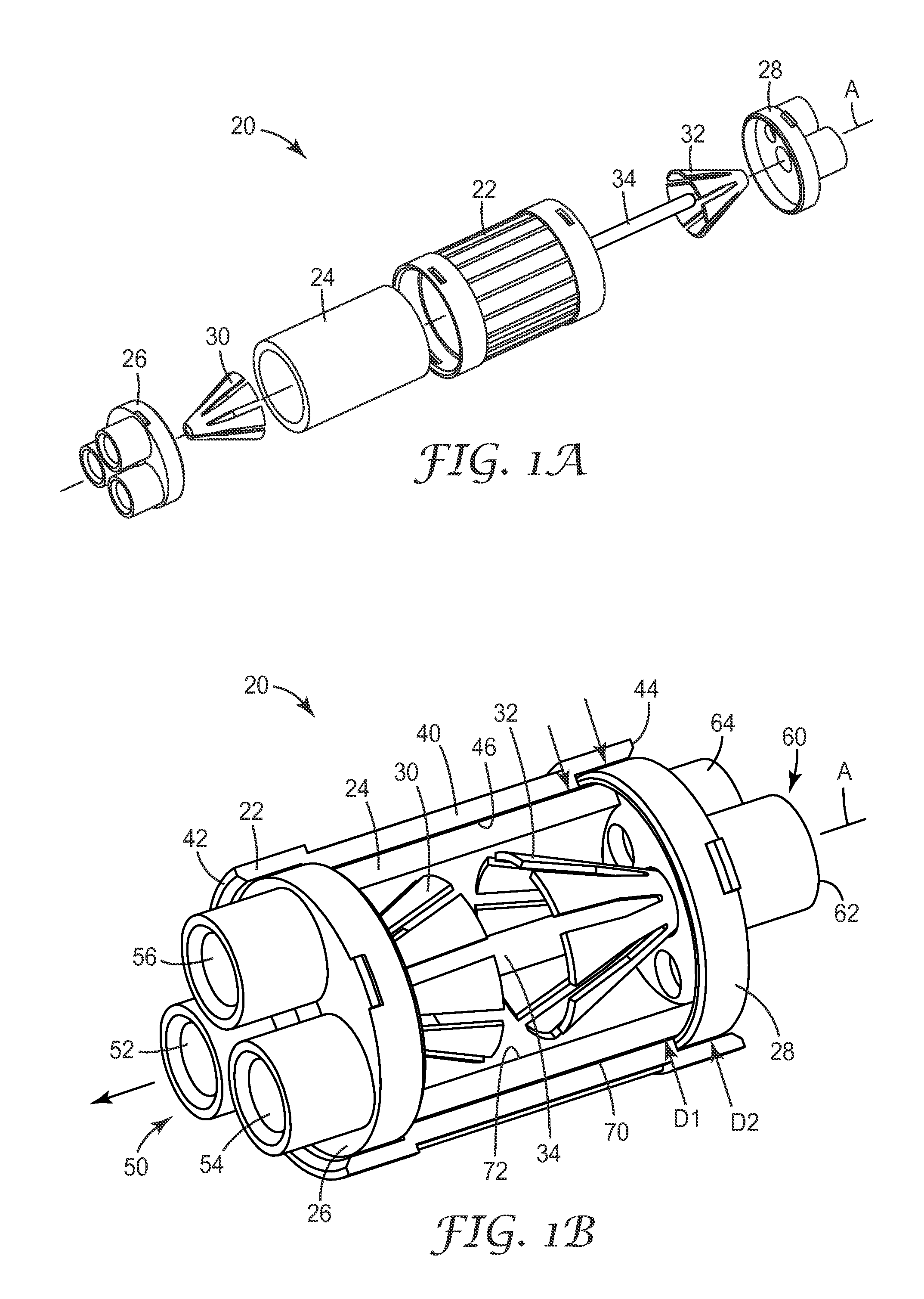

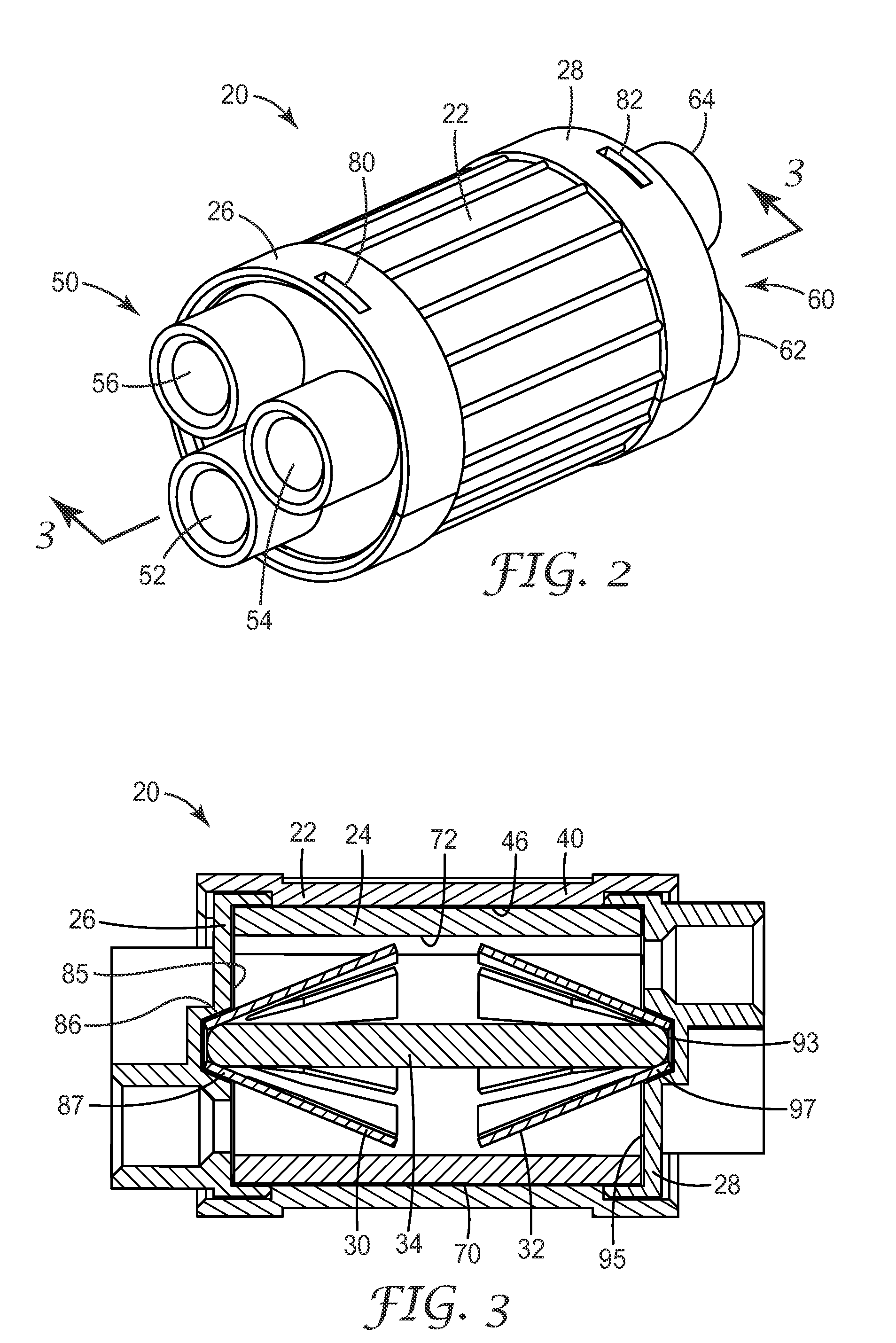

A high-pressure connector for an electrical power cable section having a central stranded conductor encased in a polymeric insulation jacket and having an interstitial void volume in the region of the stranded conductor, the high-pressure connector being suited for confining a fluid within the interstitial void volume at a residual pressure above atmospheric, but below the elastic limit of the polymeric insulation jacket, the high-pressure connector comprising a housing having a wall defining an interior chamber configured to be in fluid communication with the interstitial void volume and an end portion sized to receive the insulation jacket within the interior chamber and to overlap at least a portion of the insulation jacket at an end thereof with the cable section extending from the housing end portion and at least a portion of the stranded conductor positioned within the interior chamber. The housing wall of the housing end portion has an engagement portion comprised of a swagable material to secure the housing wall to the insulation jacket in fluid-tight sealed engagement therewith upon inward swaging of the engagement portion of the housing wall of the housing end portion to the insulation jacket to confine the fluid at the residual pressure within the interior chamber and the interstitial void volume. The housing includes at least one axially-projecting engagement member located within the interior chamber at the engagement portion of the housing wall of the housing end portion.

Owner:NOVINIUM LLC

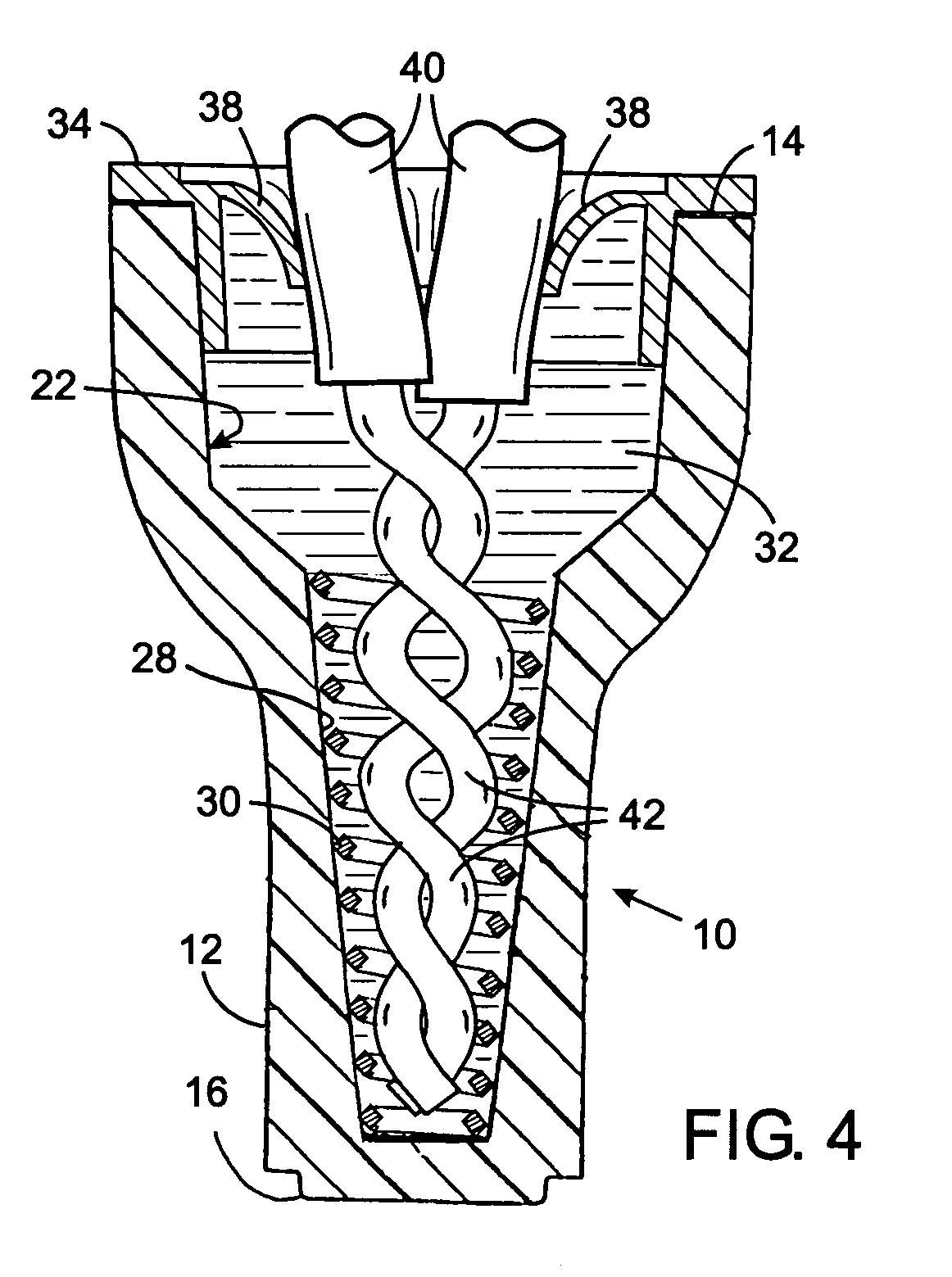

Waterproof twist-on connector for electrical wires

InactiveUS6958449B1Prevent curingSoldered/welded conductive connectionsCouplings bases/casesElectrical conductorEngineering

A twist-on connector for joining ends of electrical conductors has a shell of electrically insulating material with an aperture. An anaerobic sealant is within the aperture. Prior to use, the volume of sealant is sufficiently large so that curing of the sealant is inhibited. Upon insertion of wires into the shell, the anaerobic sealant is dispersed into gaps between the wires and the shell that are sufficiently small to trigger curing of the anaerobic sealant into a hardened state.

Owner:ACTUANT CORP

Tubular terminal for a cable

InactiveUS7767909B2Firmly connectedProvide bendabilitySecuring/insulating coupling contact membersConnections effected by permanent deformationEngineeringElectrical contacts

The tubular terminal for a cable, in particular a medium or high voltage cable, comprises a first connector having at least one terminal end for connecting to at least one mating second connector adapted to be connected to a cable and engaged with the first connector for making electrical contact therewith upon connection of the second connector to the at least one terminal end of the first connector. Furthermore, the tubular terminal comprises a shrinkable sleeve having a first tubular portion and a second tubular portion extending from the first tubular portion. The first tubular portion of the shrinkable sleeve is fixedly arranged around the first connector. The second tubular portion of the shrinkable sleeve is adapted to extend beyond the at least one terminal end of the first connector for covering a mating second connector and cable attached thereto when the second connector is connected to the at least one terminal end of the first connector.

Owner:3M INNOVATIVE PROPERTIES CO

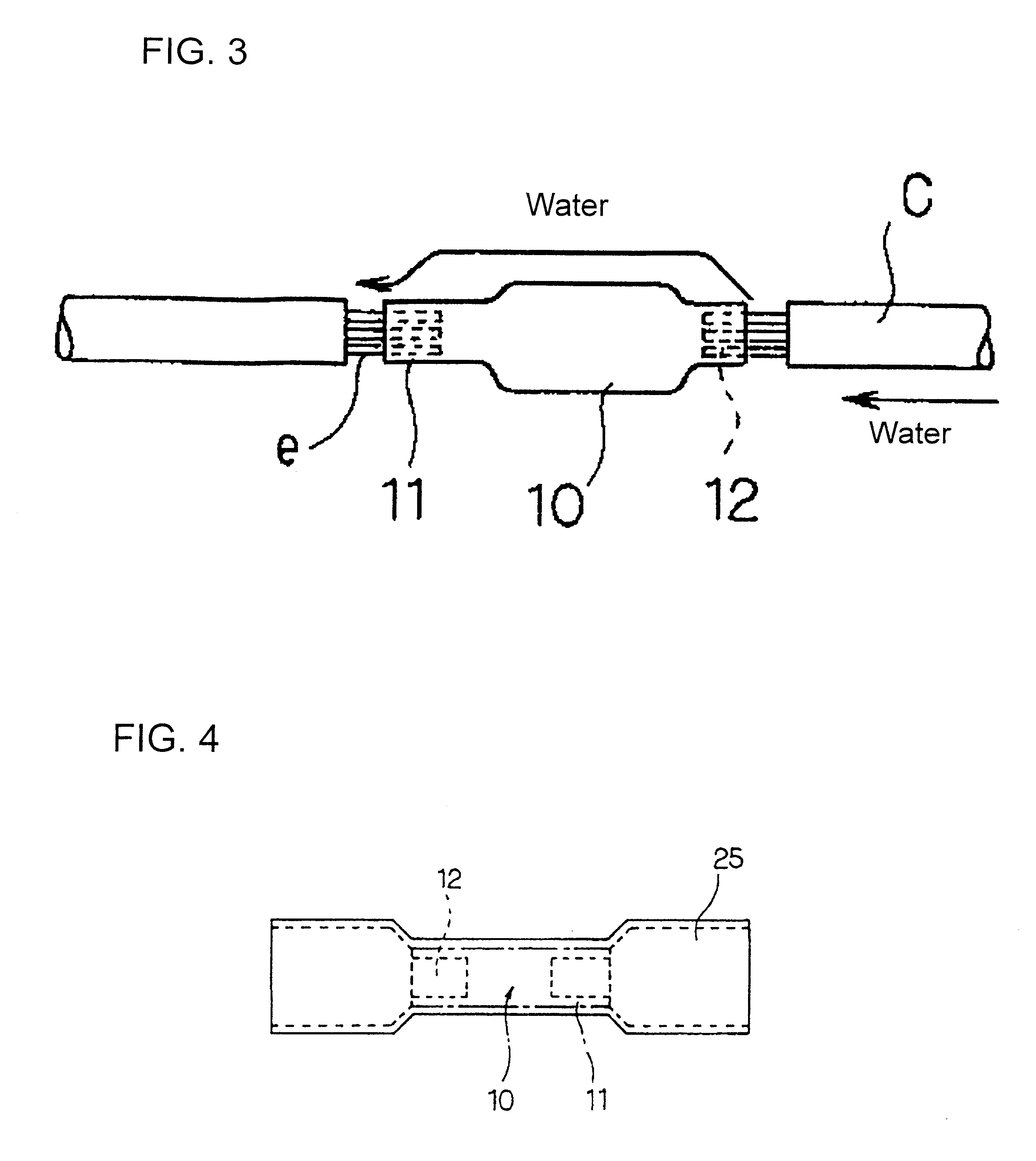

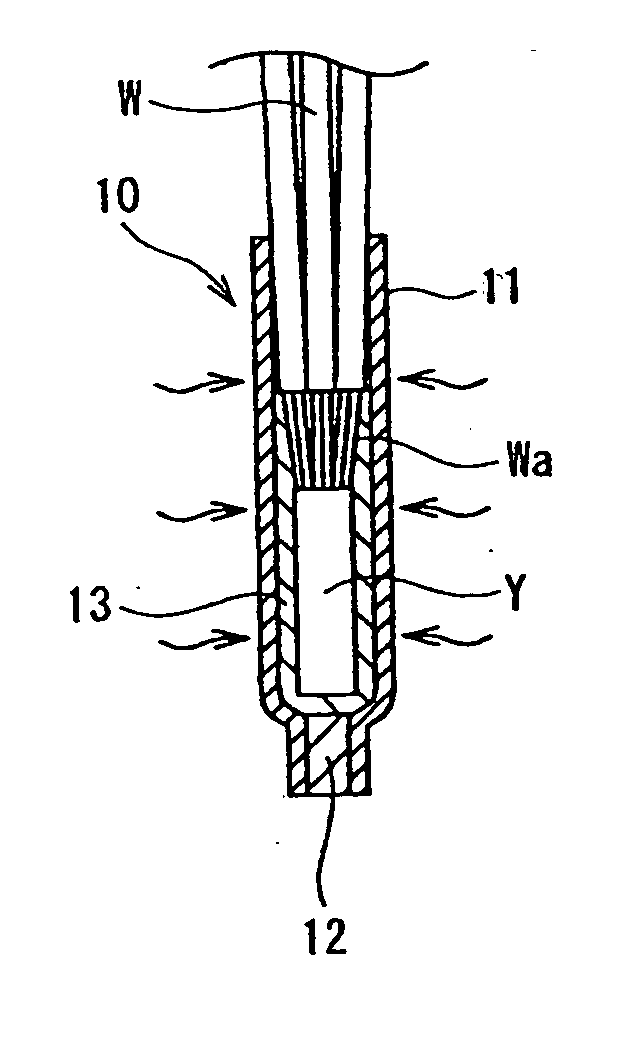

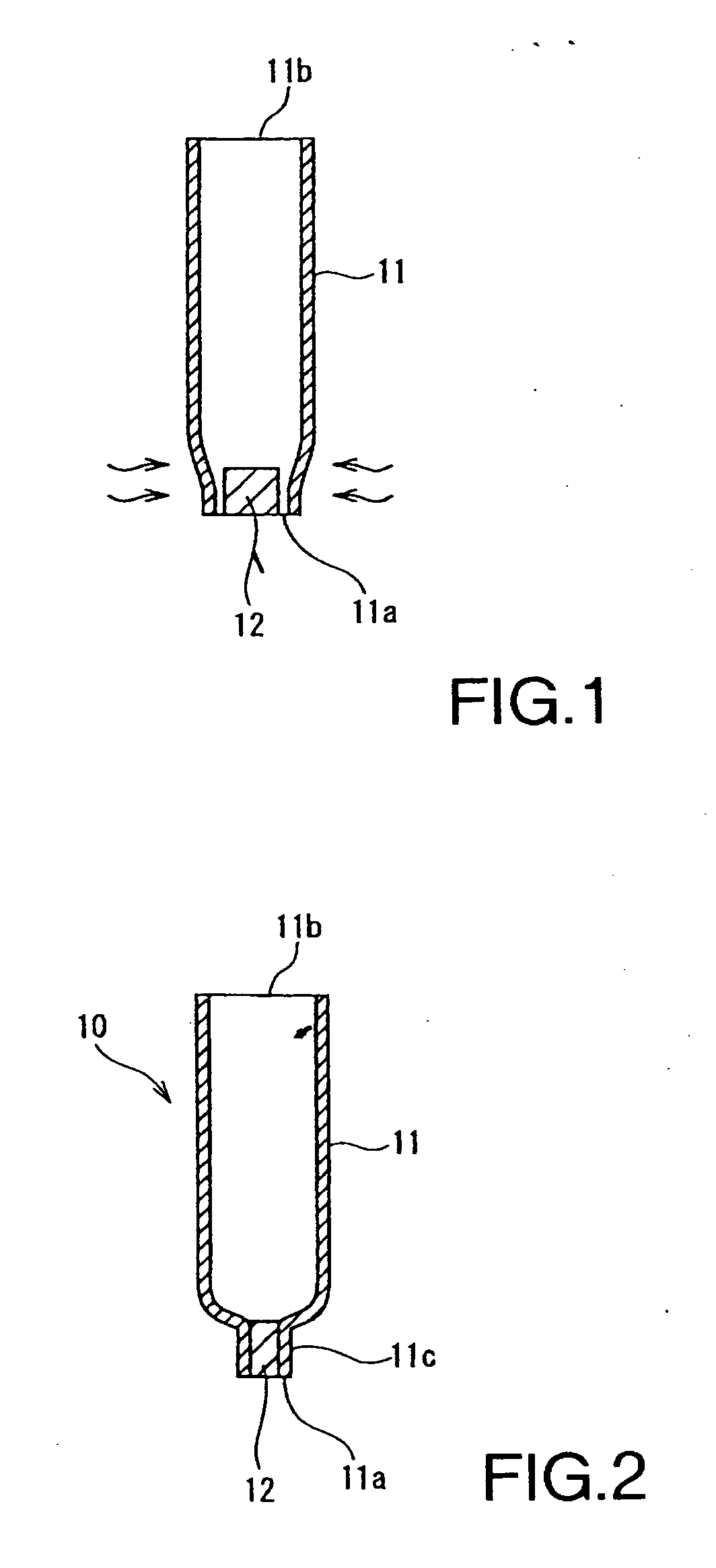

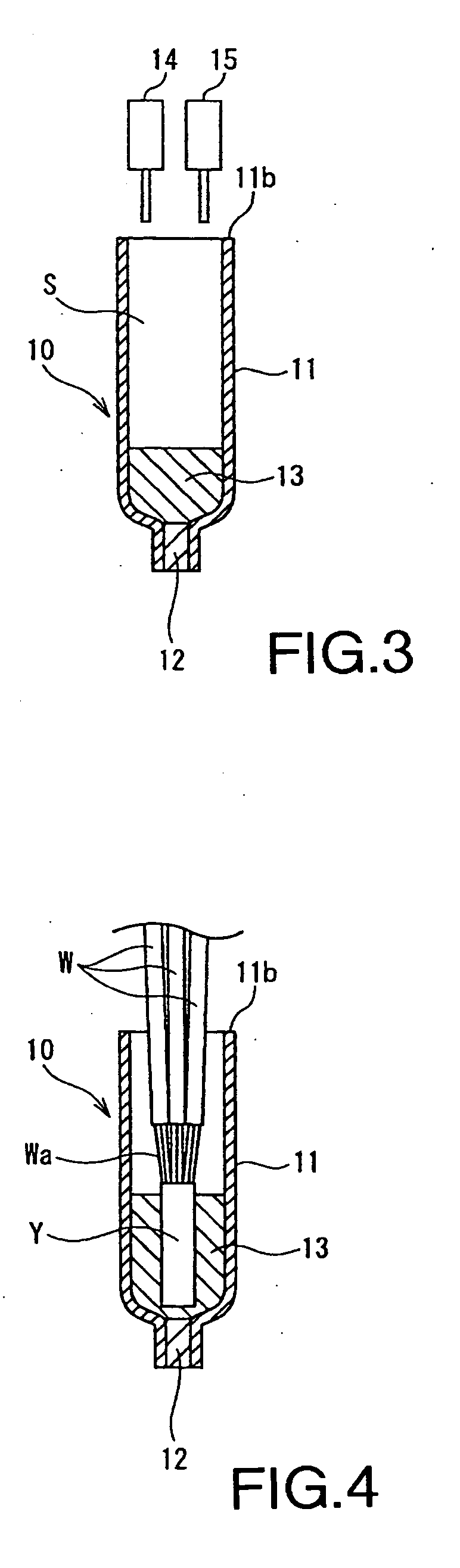

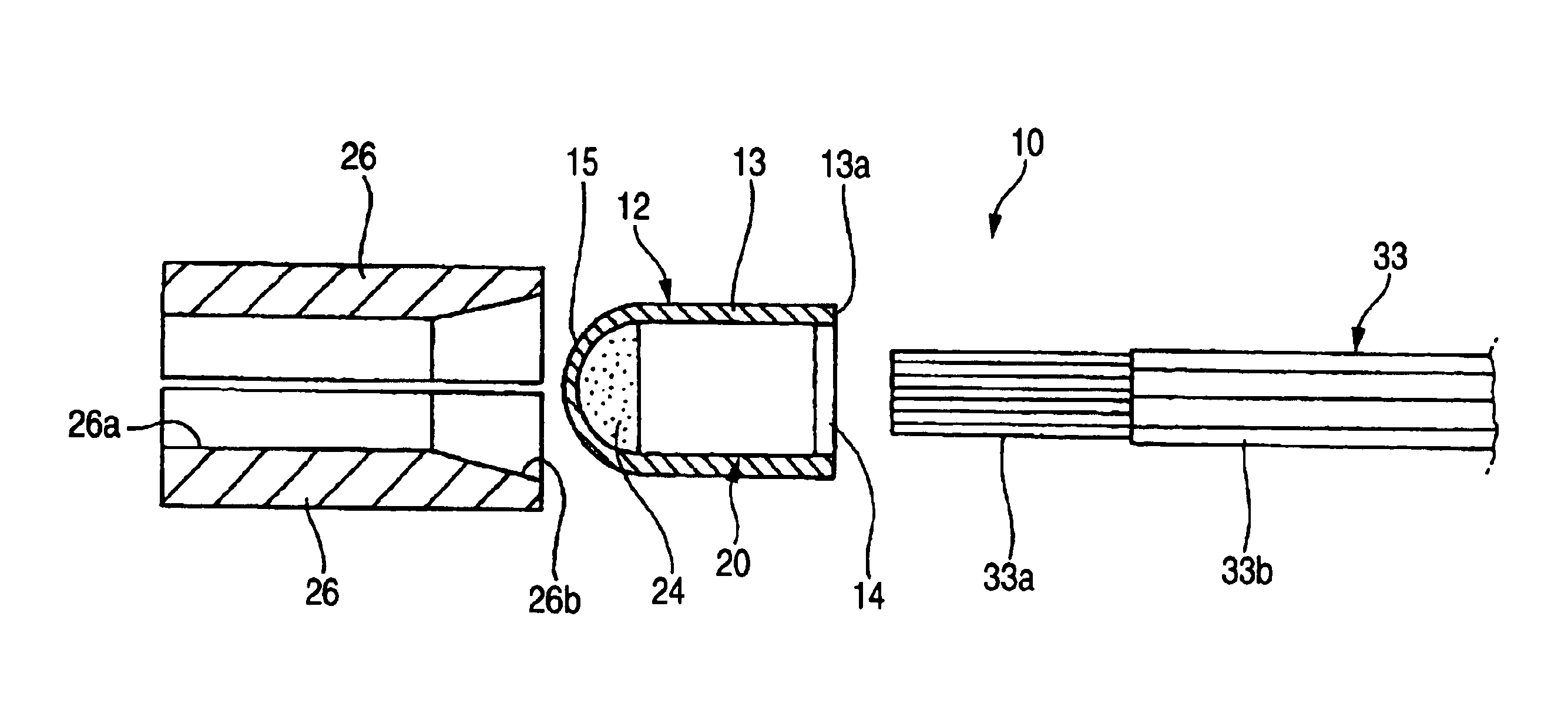

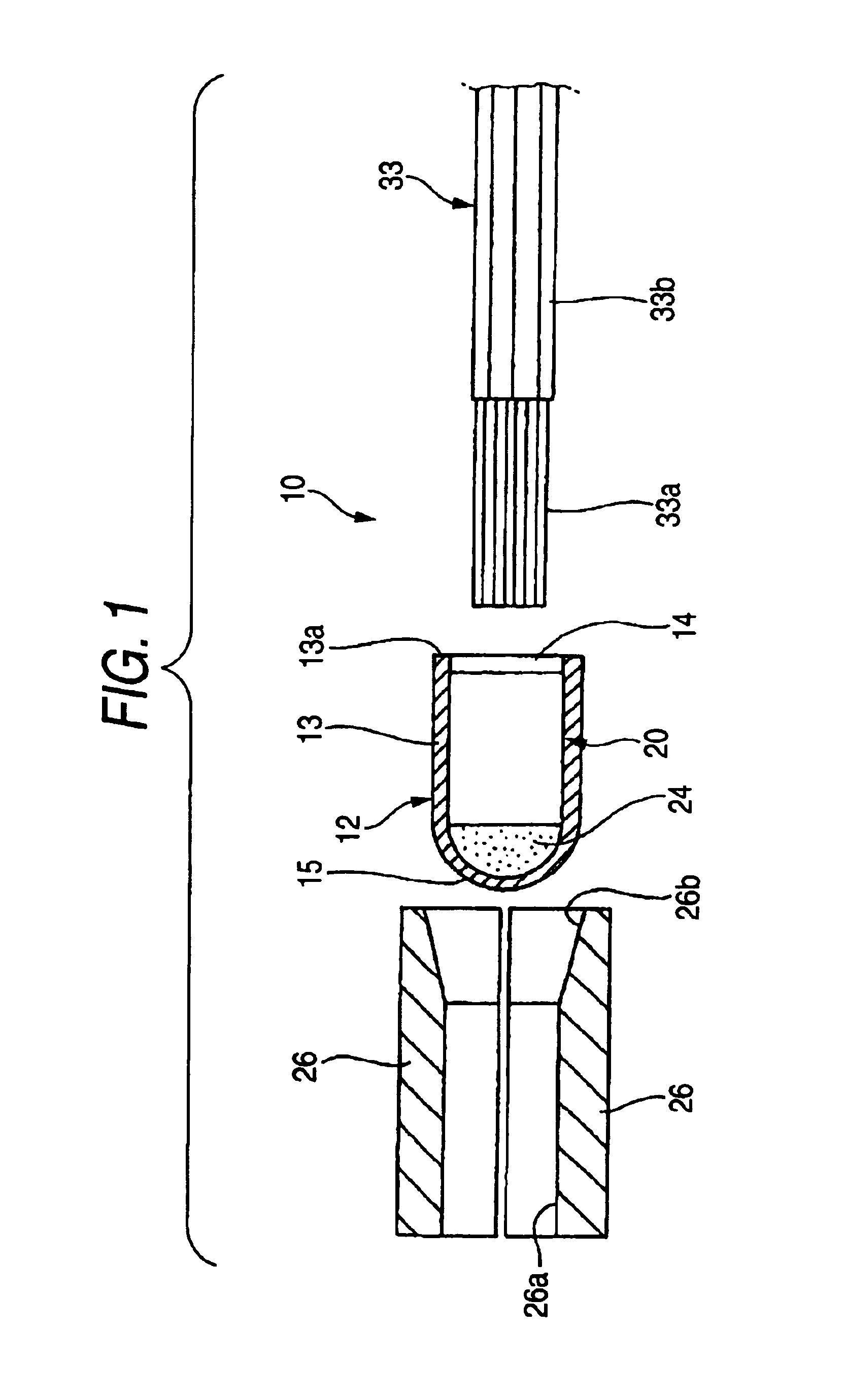

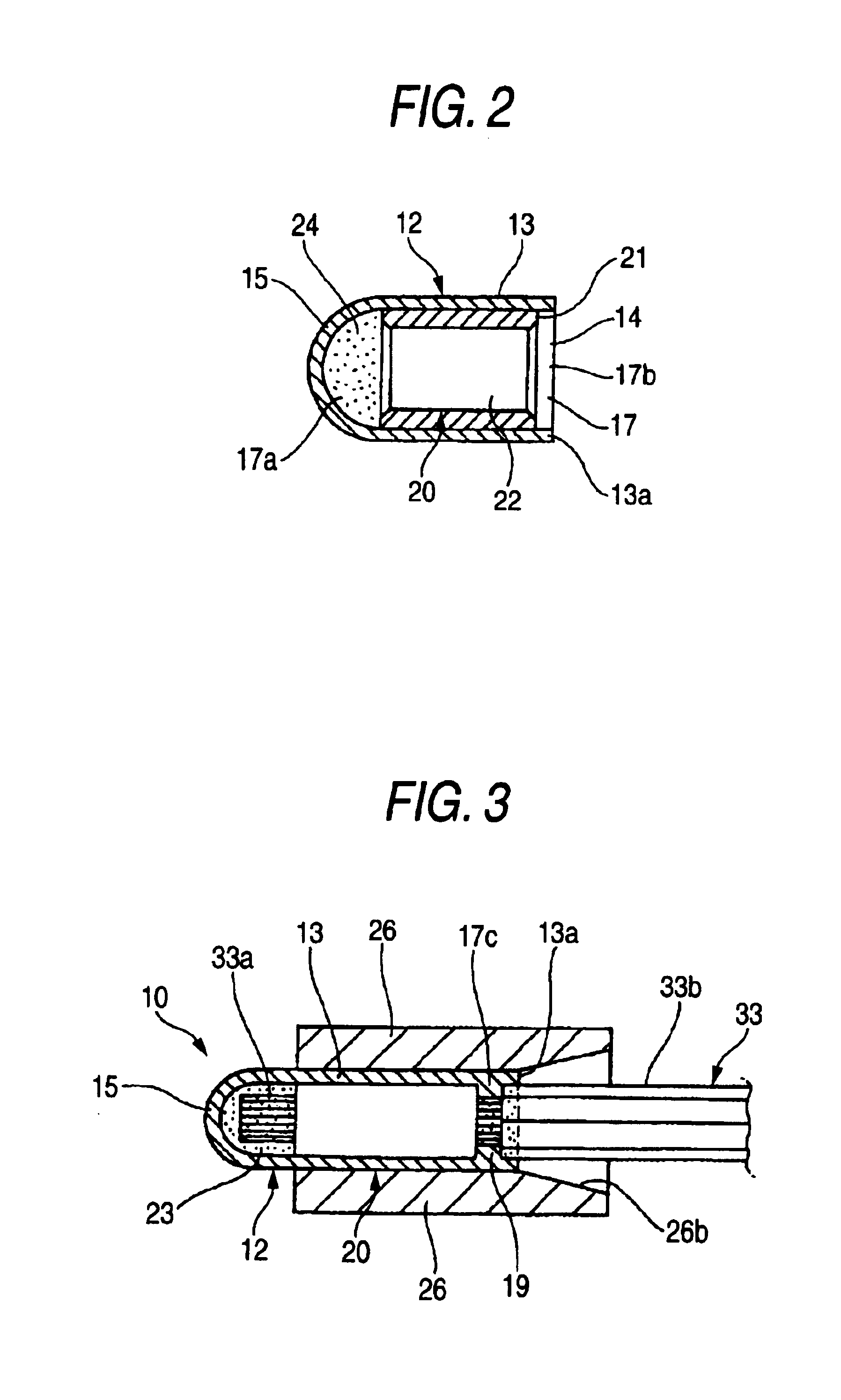

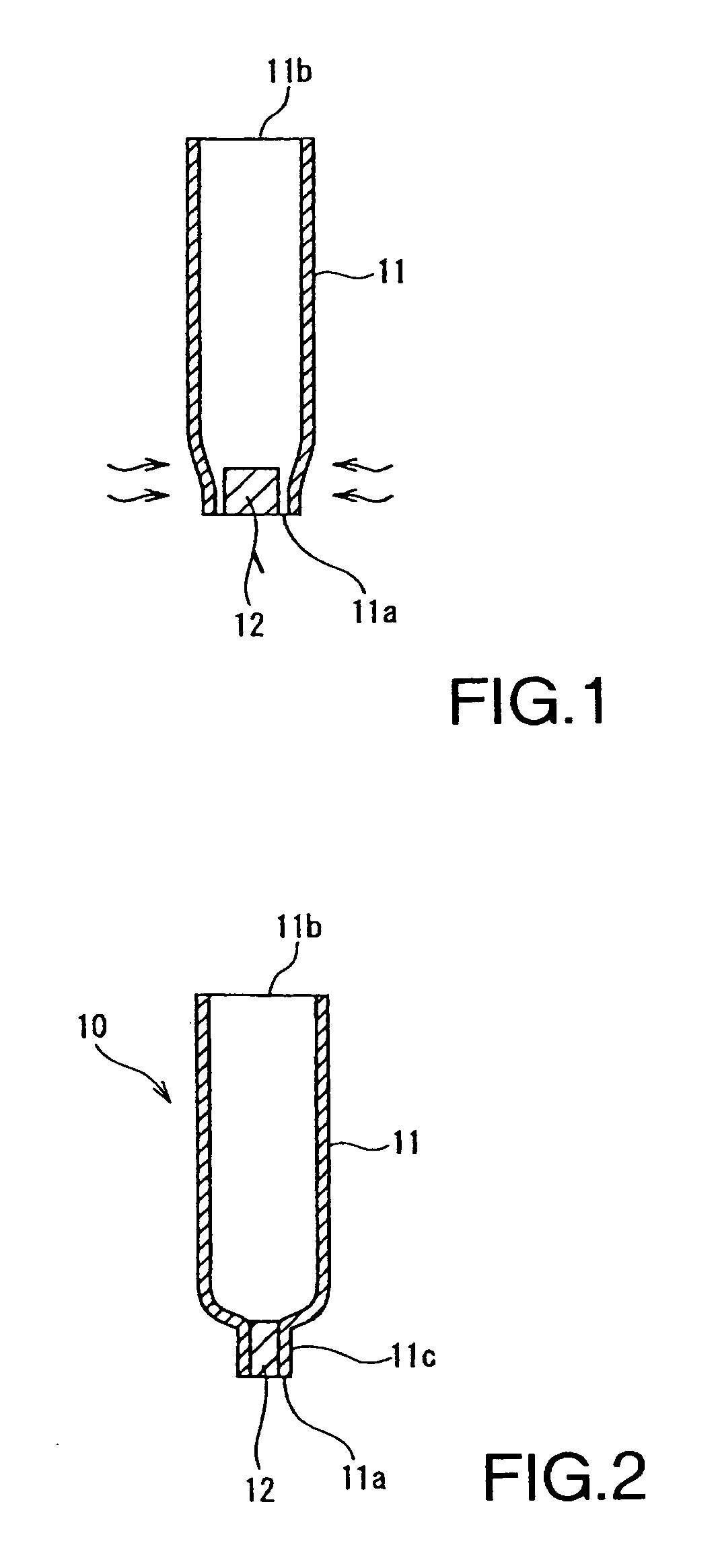

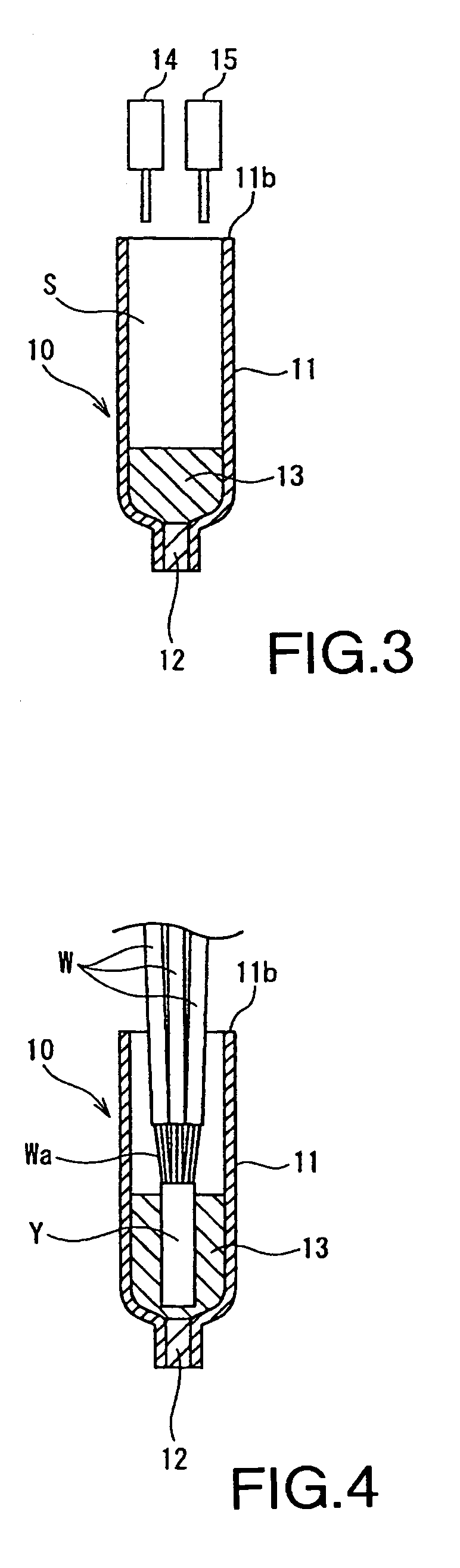

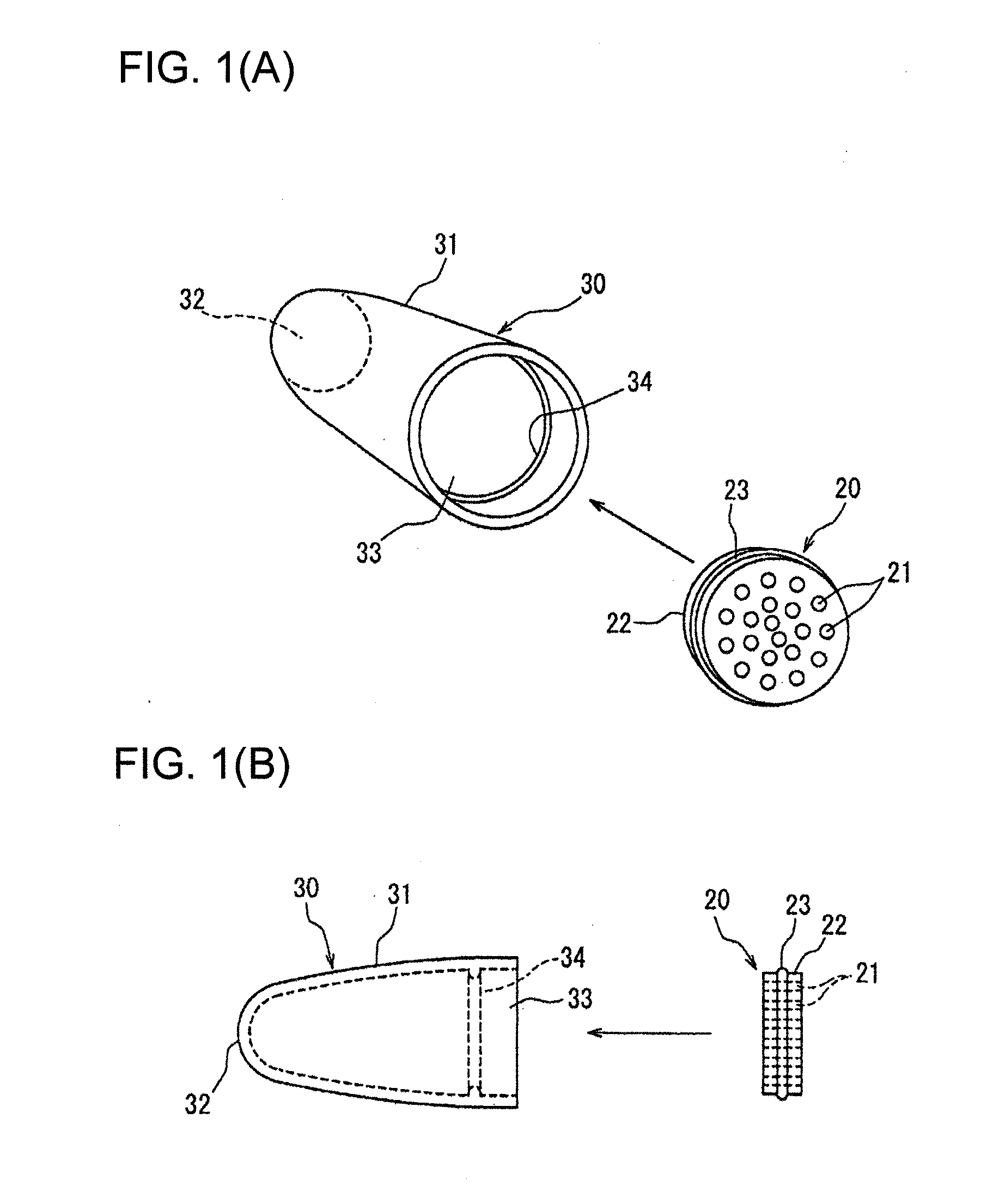

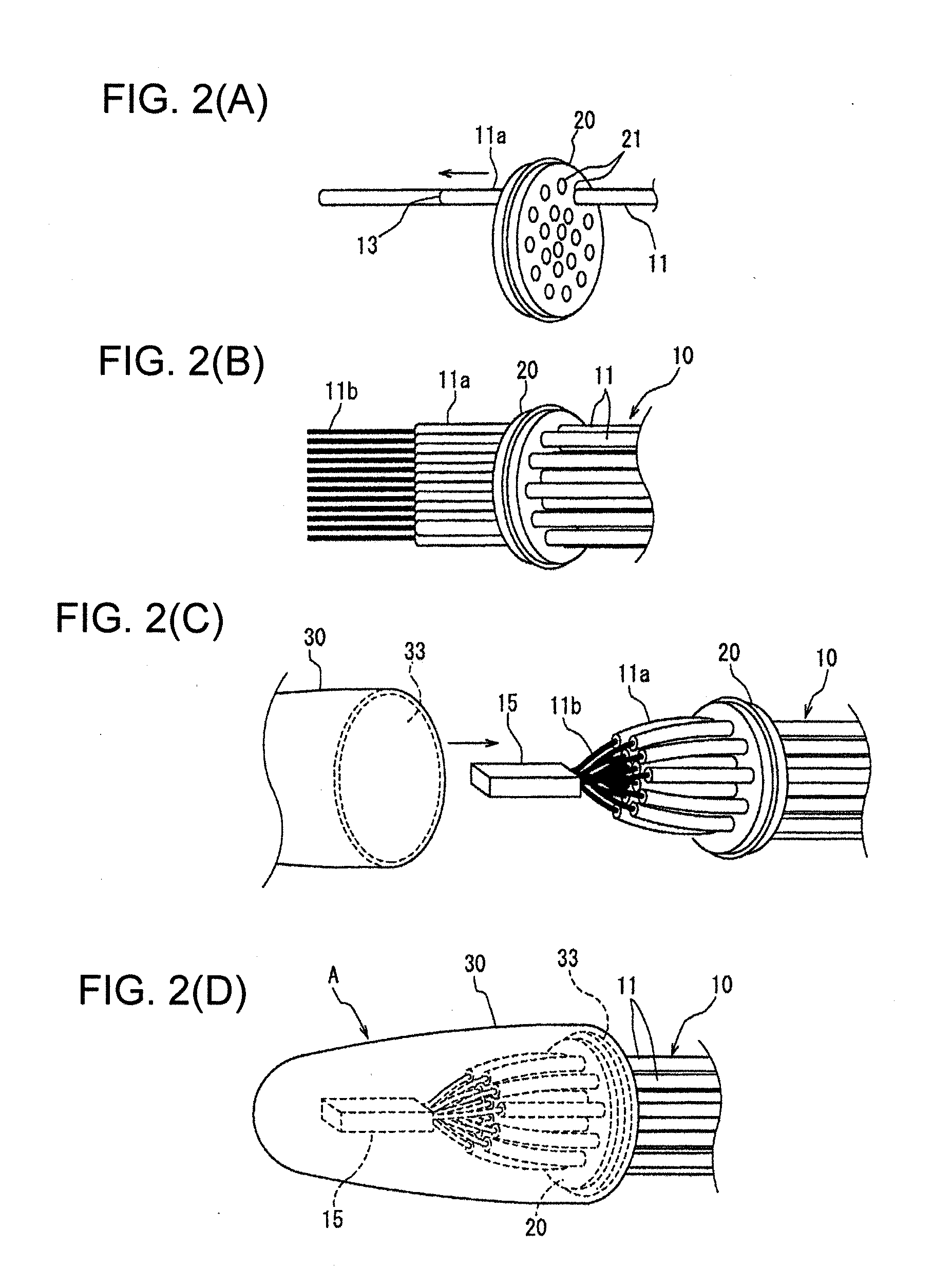

Method and structure for waterproofing a terminal splice

ActiveUS20060048965A1Reduce the overall diameterImprove performanceDustproof/splashproof/drip-proof/waterproof/flameproof connectionCouplings bases/casesHeat-shrink tubing

To decrease cap diameter covering a terminal splice and improve workability and waterproof performance, a stopper is inserted in one opening of a heat shrinkable tube. The heat shrinkable tube is heat-shrunk in this state, then a cap having end an closure is formed. A fluid thermosetting waterproofing agent is injected into the cap from a second opening. A thermal splice, which is formed from welded strands stripped from a plurality of wire terminals, is inserted and immersed in the thermosetting waterproofing agent. Then, the entire cap is heated and heat-shrunk at a predetermined temperature and the thermosetting waterproofing agent is heat-hardened.

Owner:SUMITOMO WIRING SYST LTD

Push-in wire connector with improved busbar

Owner:IDEAL IND INC

Connection cap and cable connection method utilizing same

InactiveUS7074077B2Improve sealingEasy to manufactureCouplings bases/casesConnection end capsMechanical engineeringEngineering

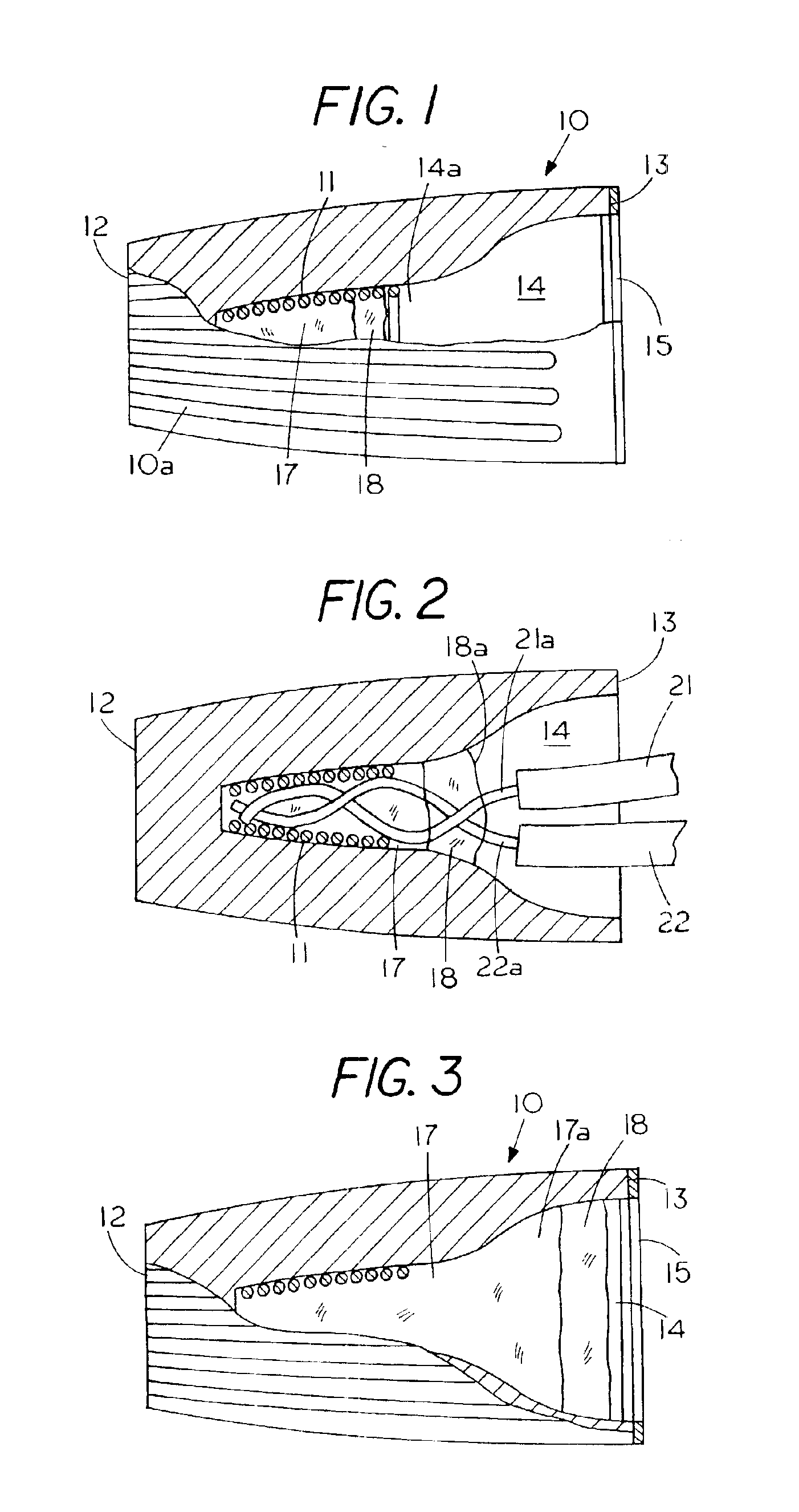

A connection cap that includes a rear end wall positioned at a rear end of the connection cap for confining a sealing uncured resin, an opening positioned at a forward end of the connection cap for inserting a jointing portion of core wires of electrical cables, and a cylindrical wall extending from the opening to the rear end wall. The cylindrical wall has an inner surface formed with a plurality of ribs for positioning the jointing portion in the connection cap. The ribs are distributed in a circumferential direction to uniformly support the electrical cable. The uncured resin intrudes clearances each defined between adjacent two of the ribs. The inner surfaces of ribs define an inscribed circle having a diameter substantially the same as an outer diameter of a conductive sleeve for crimping the core wires. Advantageously, the ribs each have a forward end portion formed with a tapered surface gradually rising toward the rear end of connection cap.

Owner:YAZAKI CORP

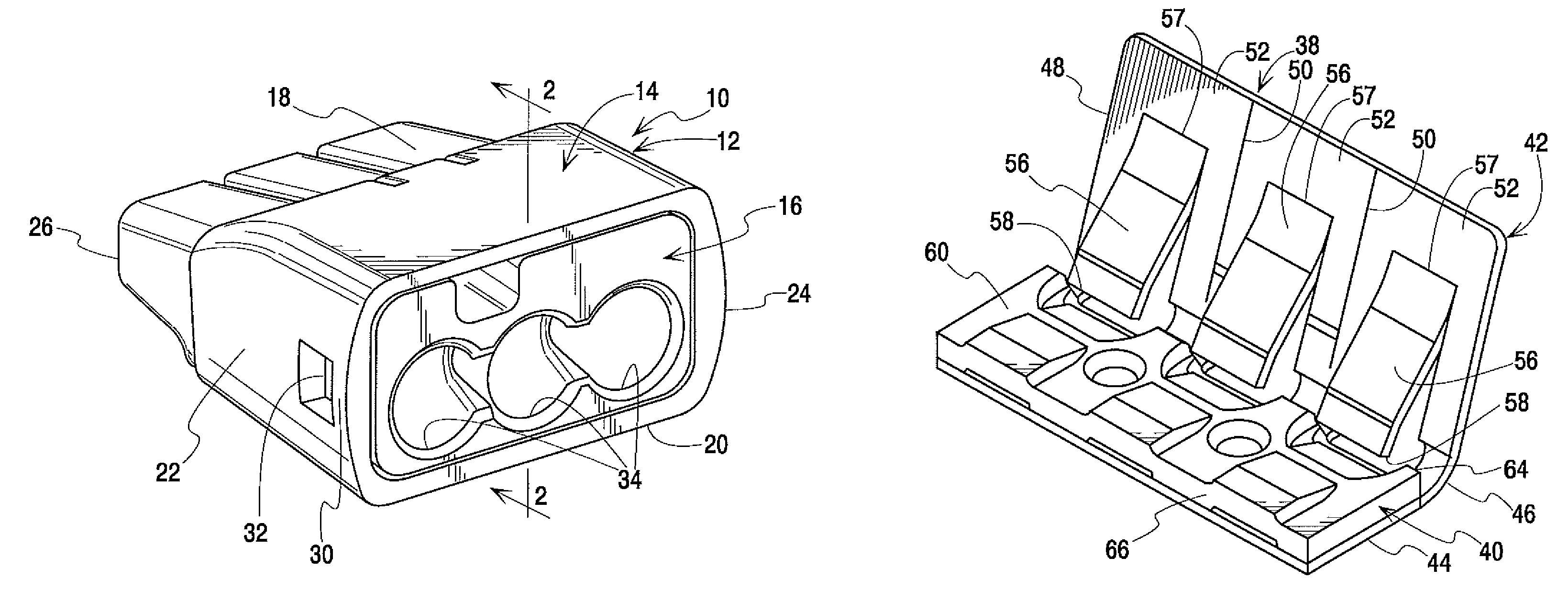

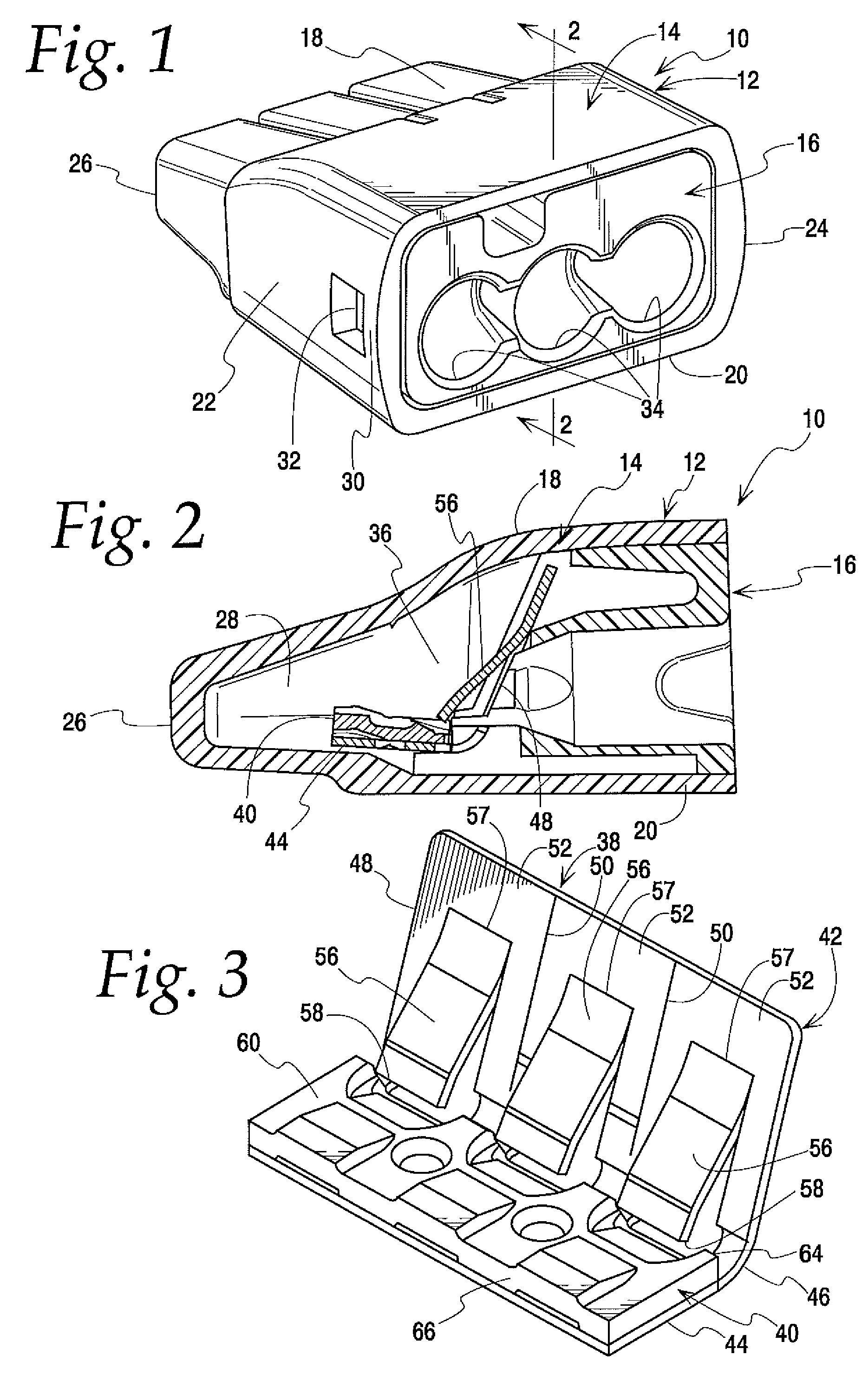

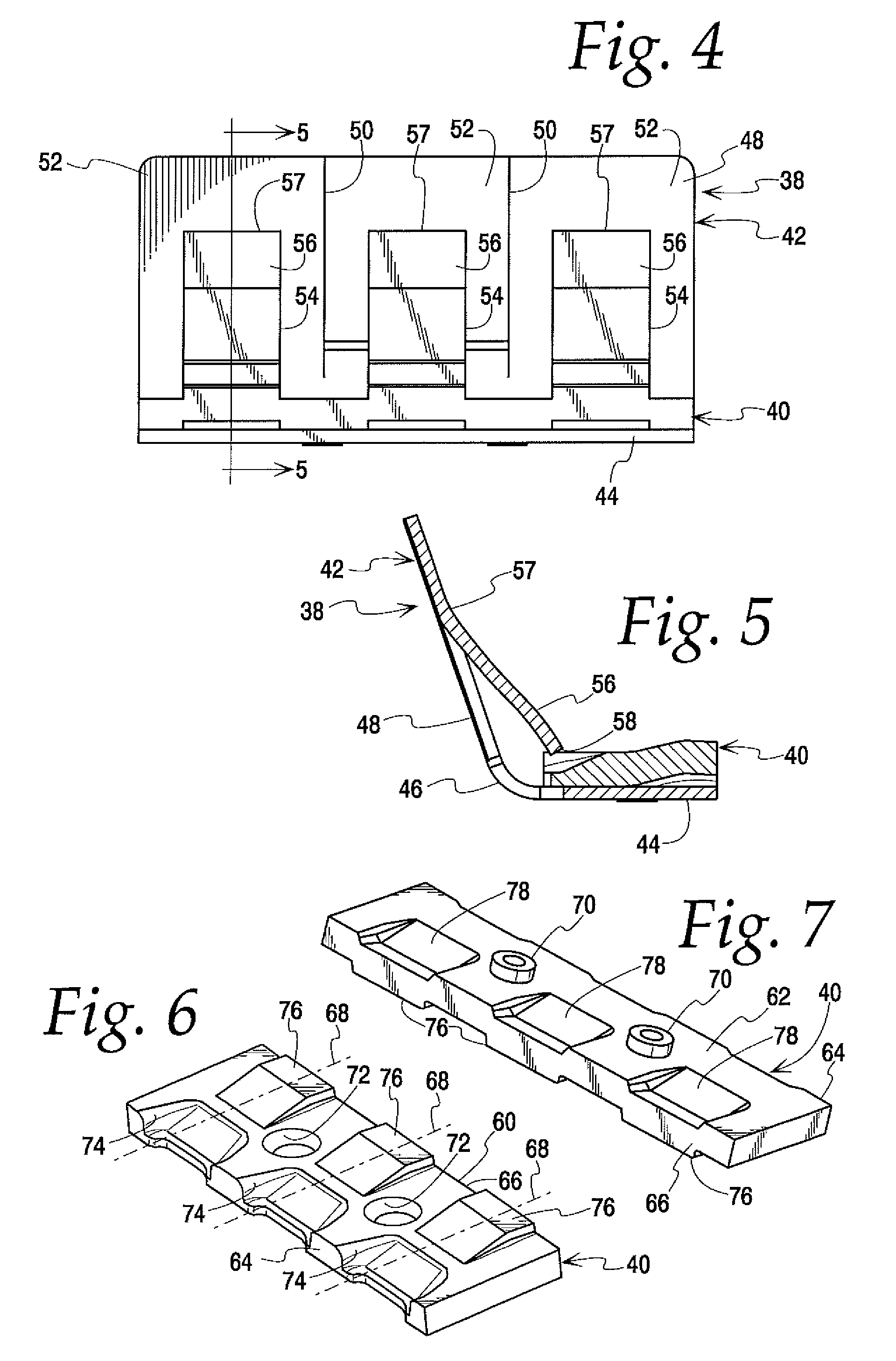

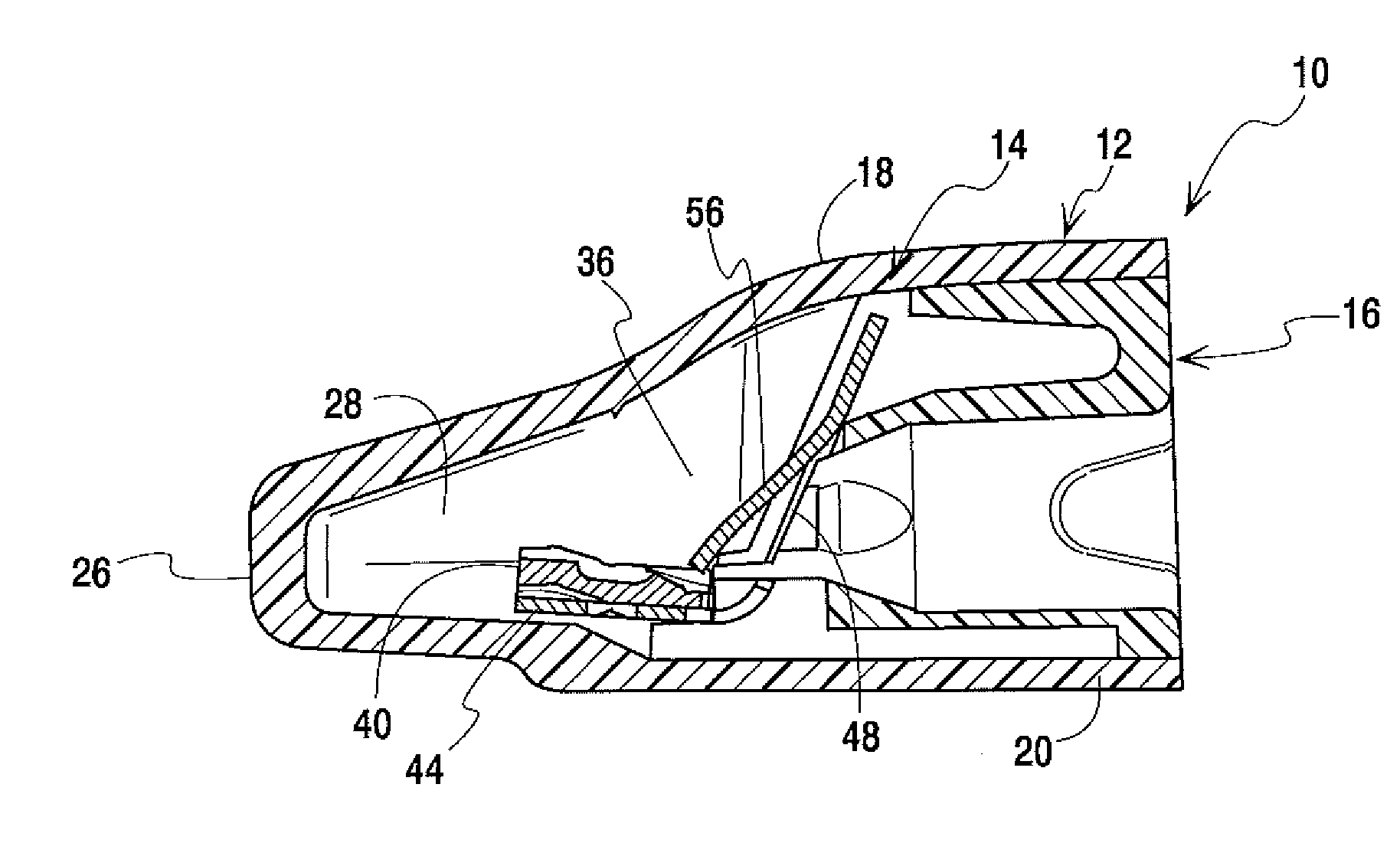

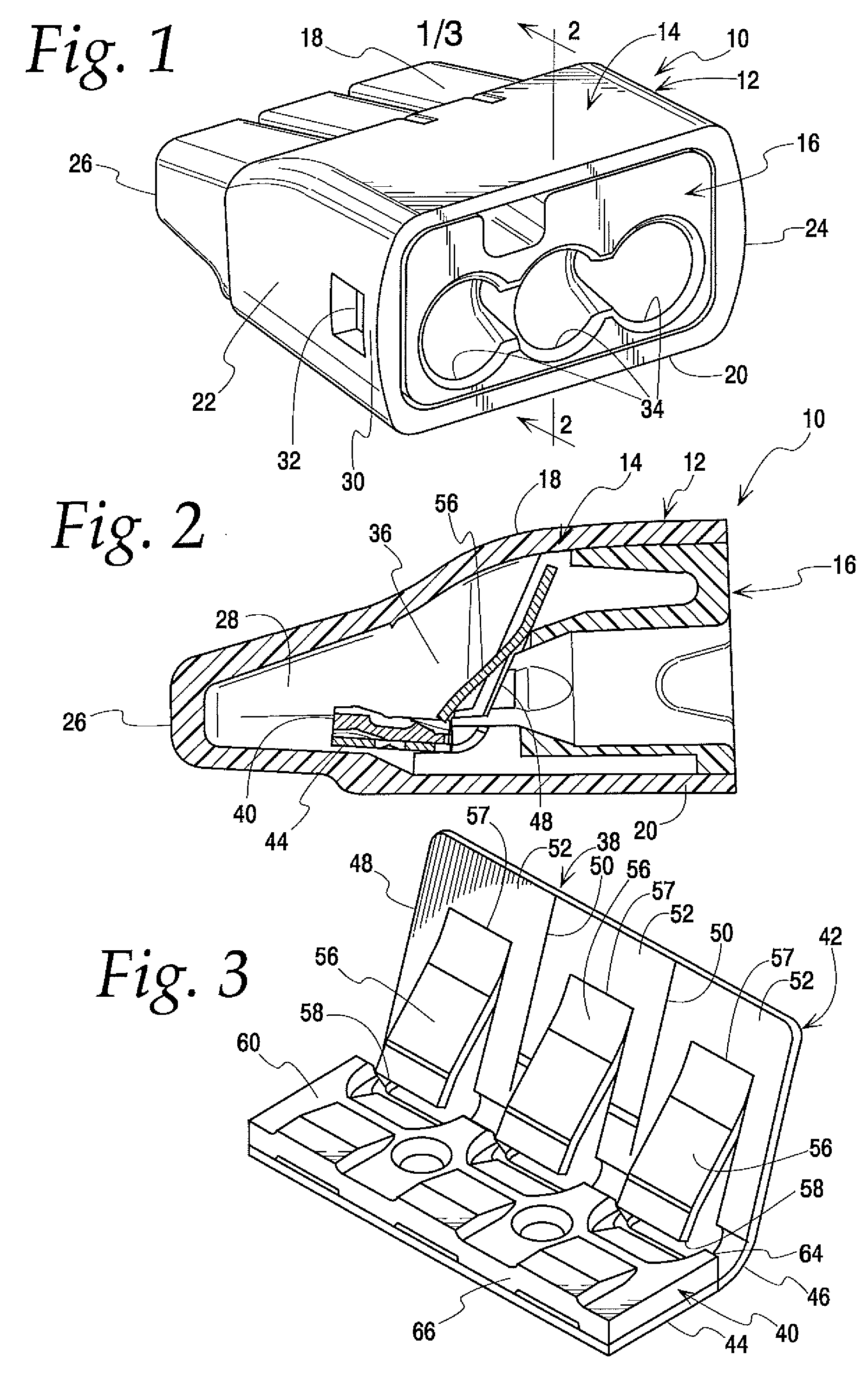

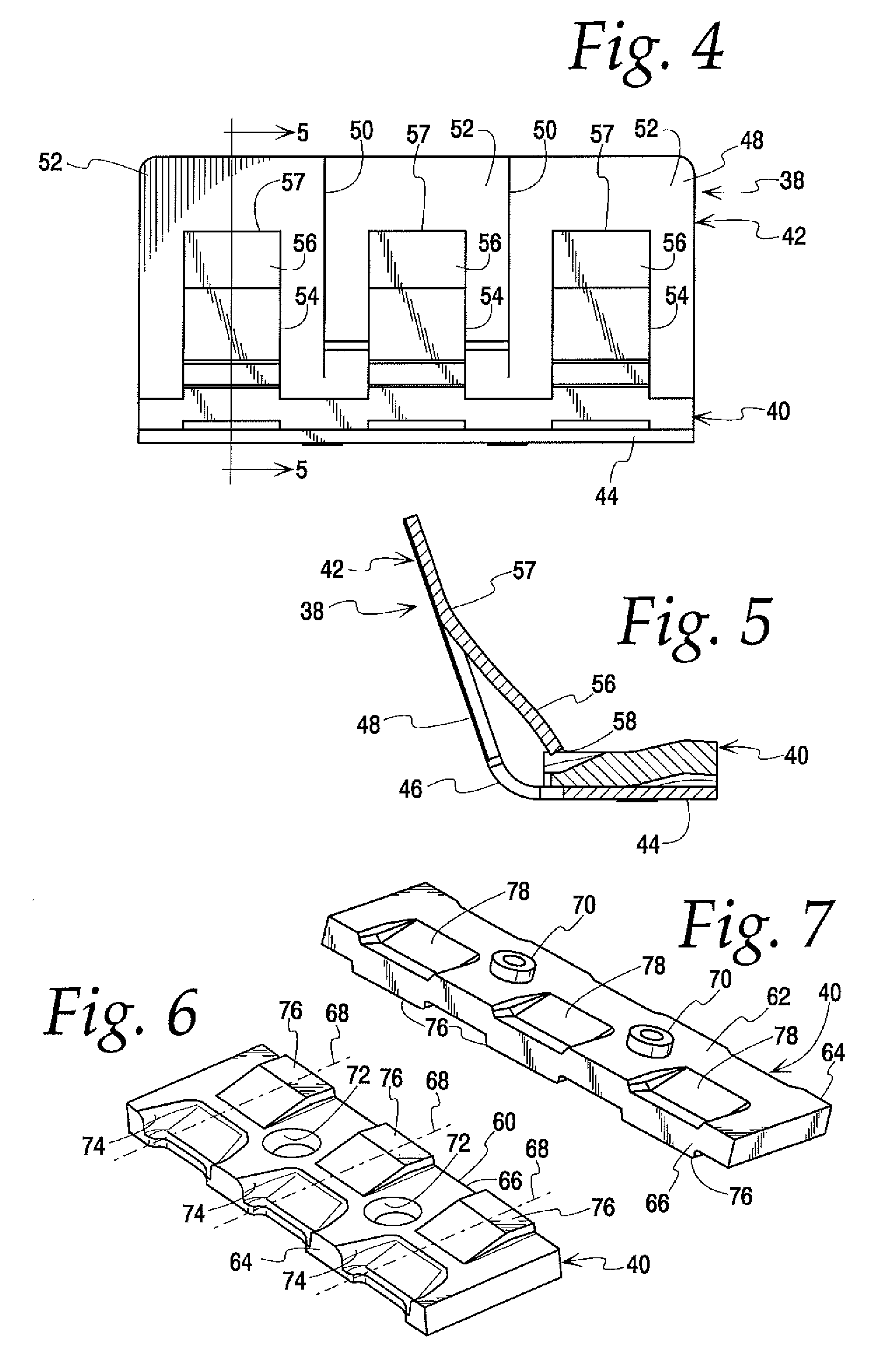

Push-in wire connector with improved busbar

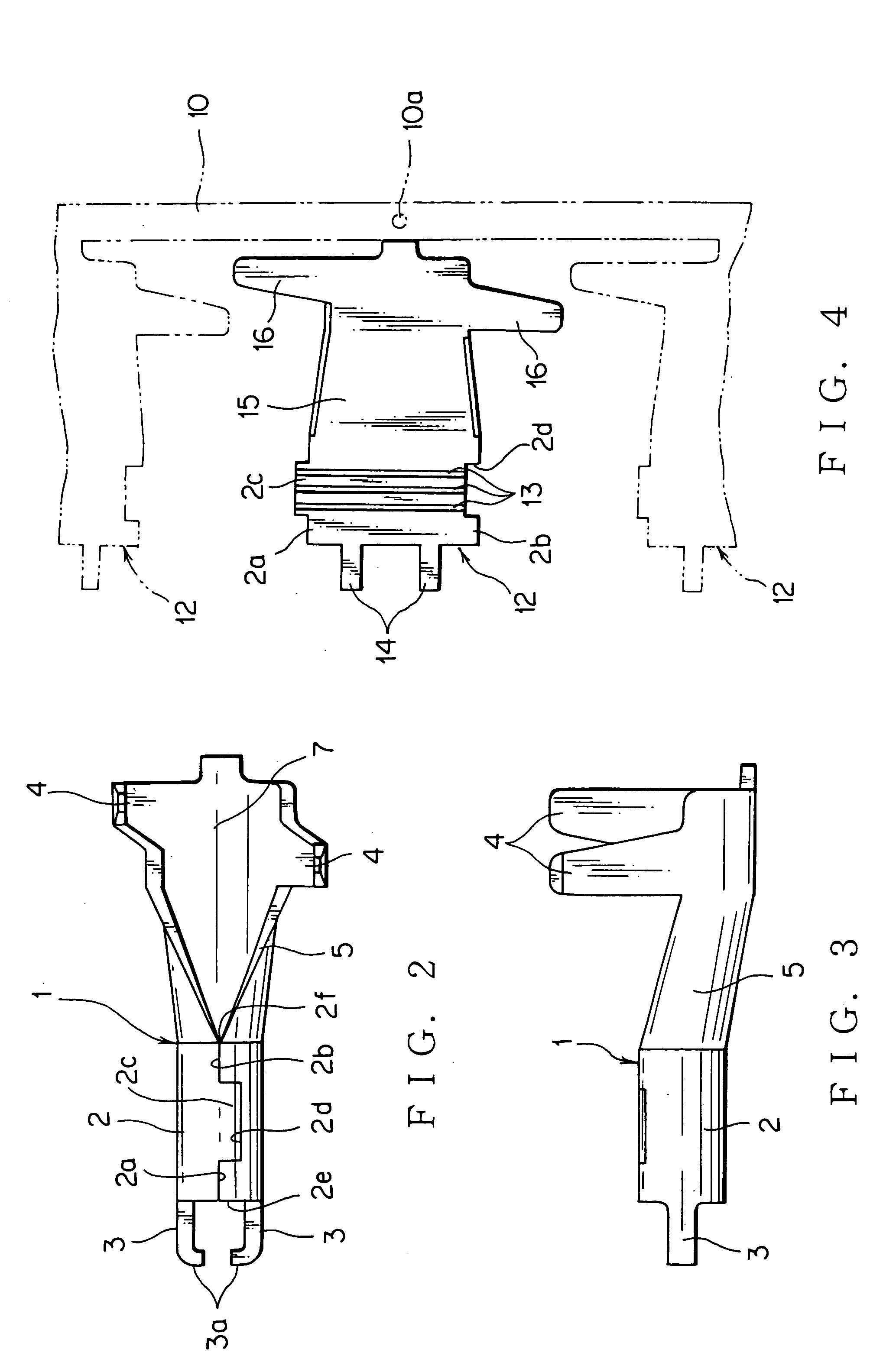

A push-in wire connector has an improved busbar suitable for use with either solid or stranded wire. The connector has a housing with a hollow interior. At least two openings in the housing provide access to the interior for the ends of wires inserted into the connector. A busbar is mounted in the housing. The busbar defines at least two wire-crossing axes extending from an entry edge to an exit edge and a thickness between a top face and a bottom face. The busbar has a wire-receiving pocket extending below the top face on each of the wire-crossing axes and a wire-engaging protrusion extending above the top face on each of the wire-crossing axes.

Owner:IDEAL IND INC

Connection cap and wire connection method using same

InactiveUS6951491B2Highly-reliable electrical performanceReduce processing stepsCouplings bases/casesLive contact access preventionElectrical conductorElectric wire

Owner:YAZAKI CORP

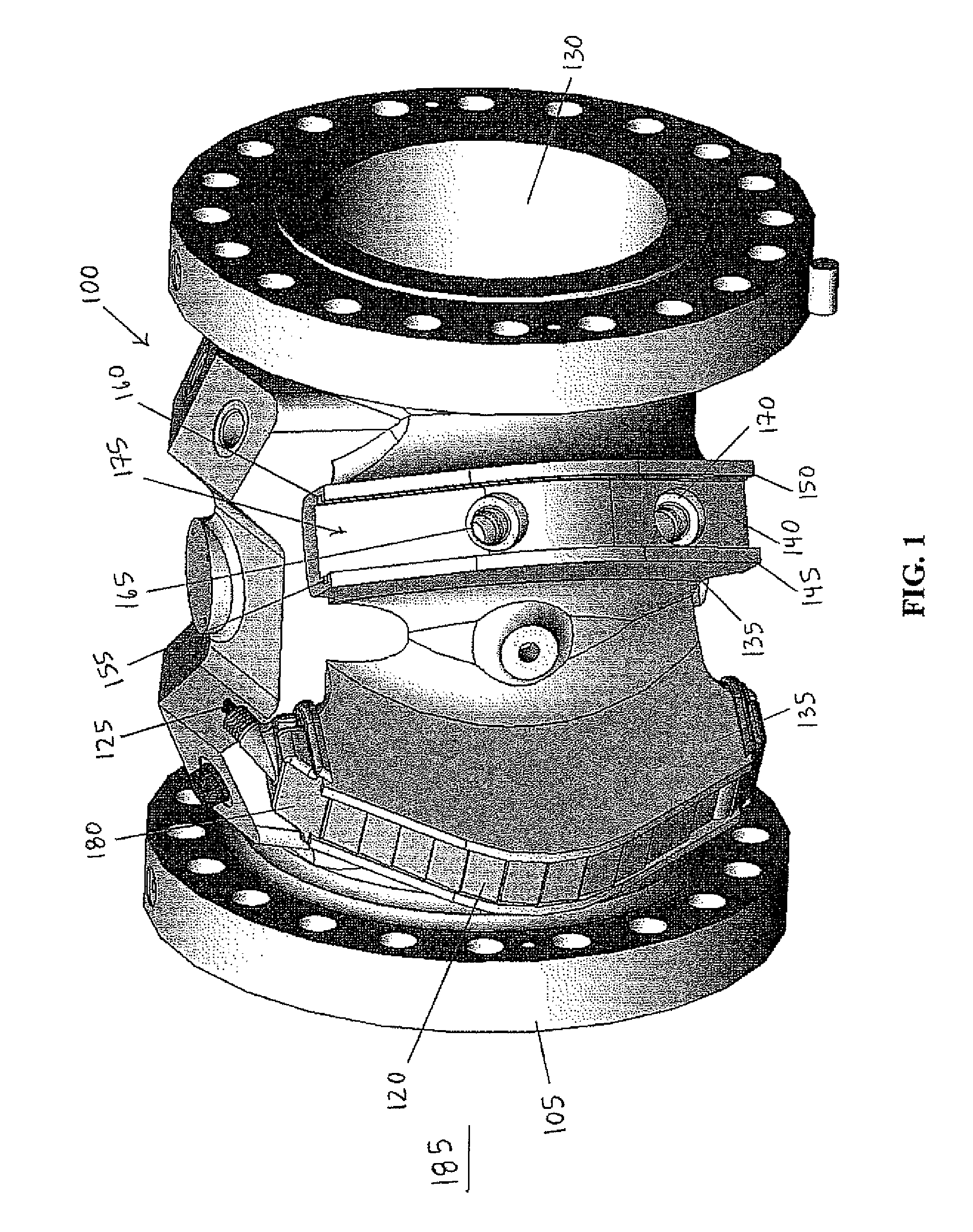

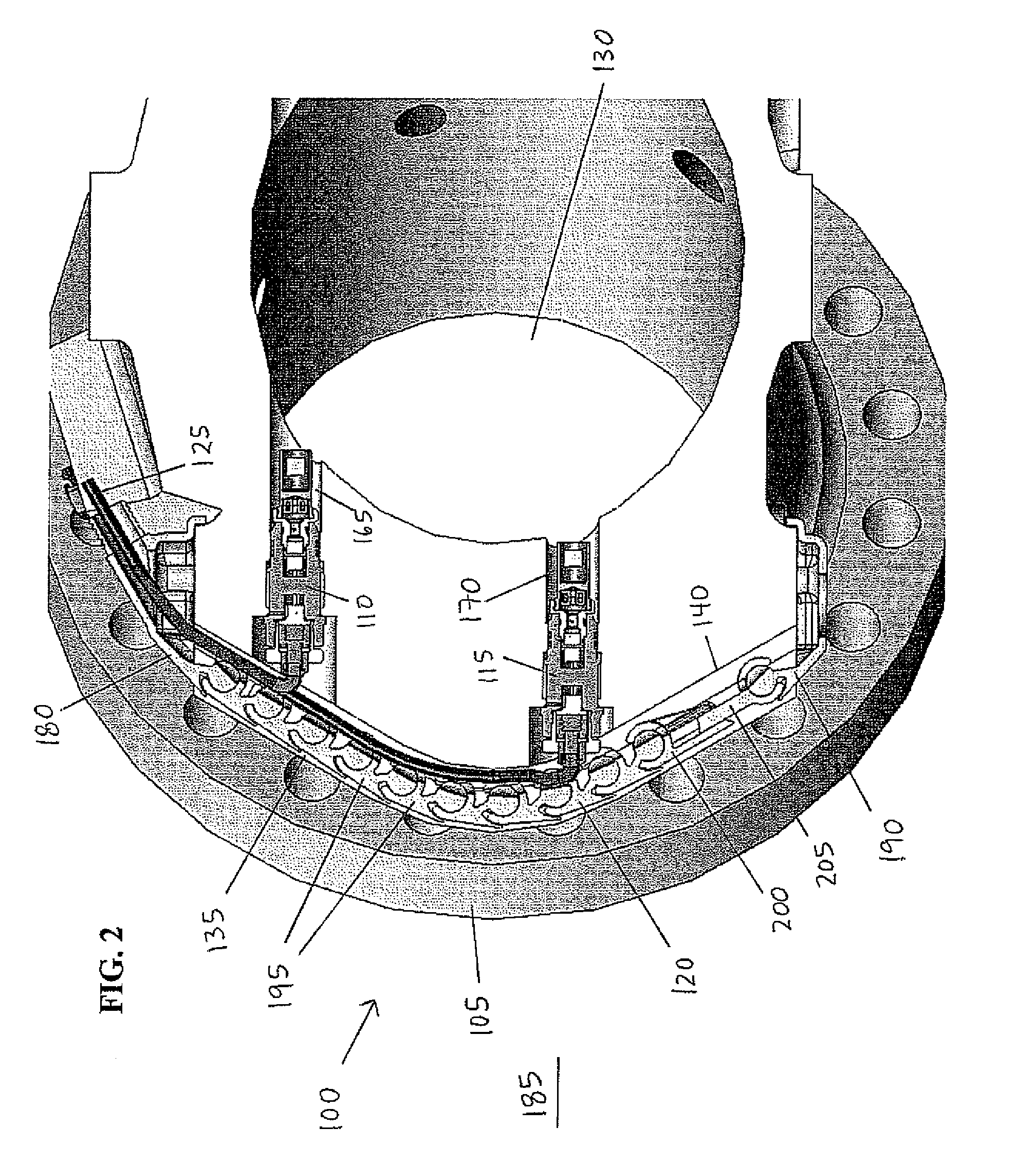

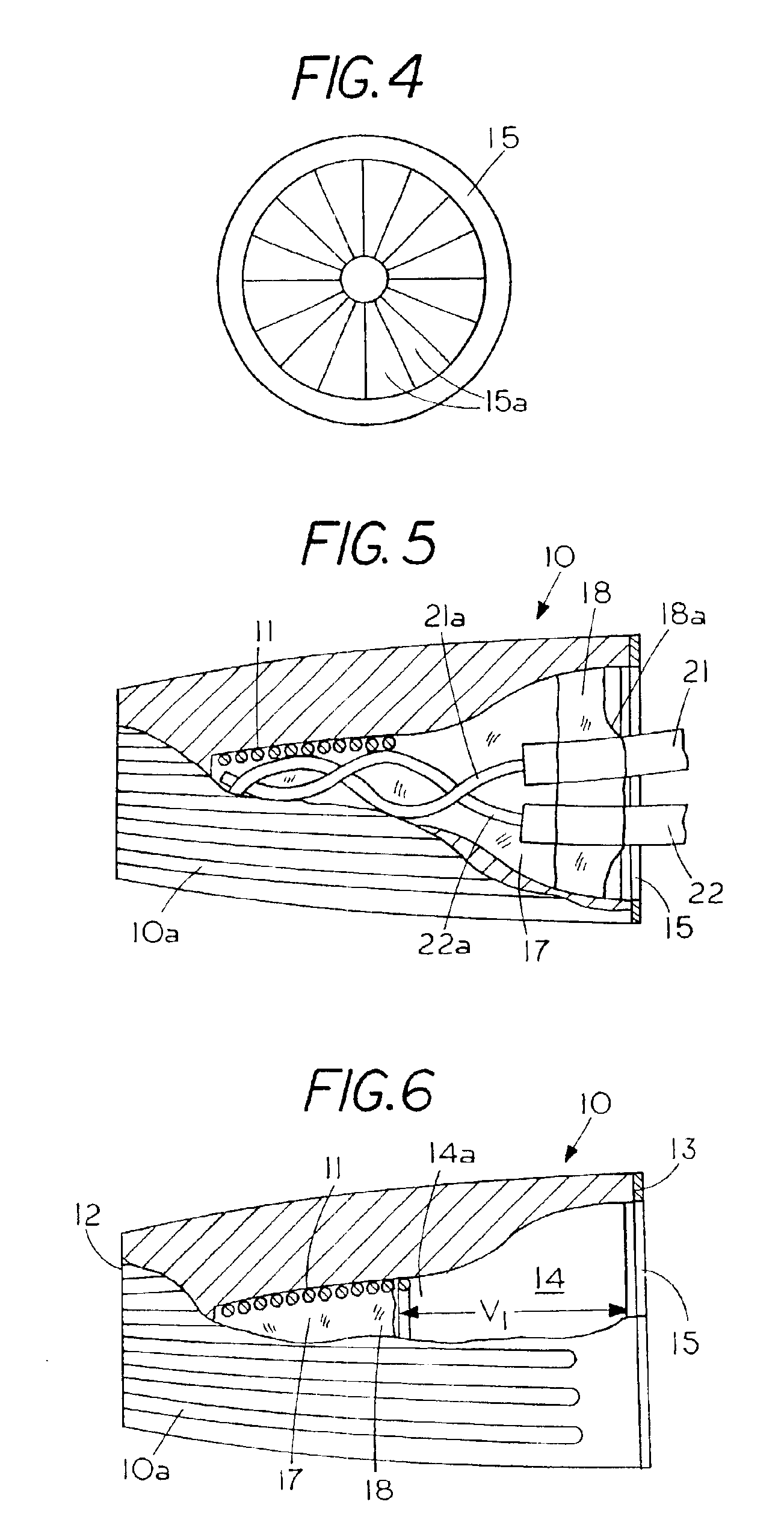

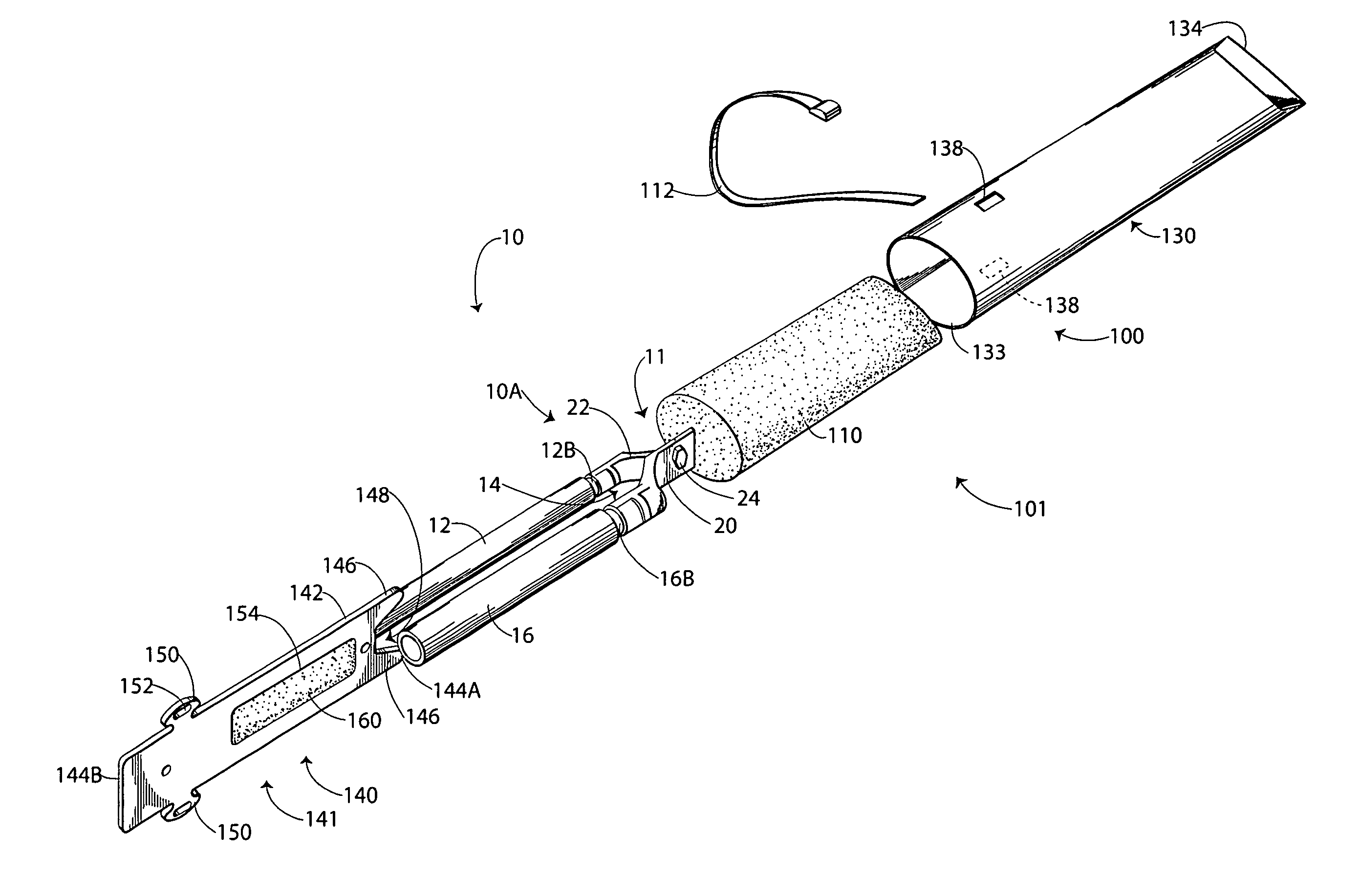

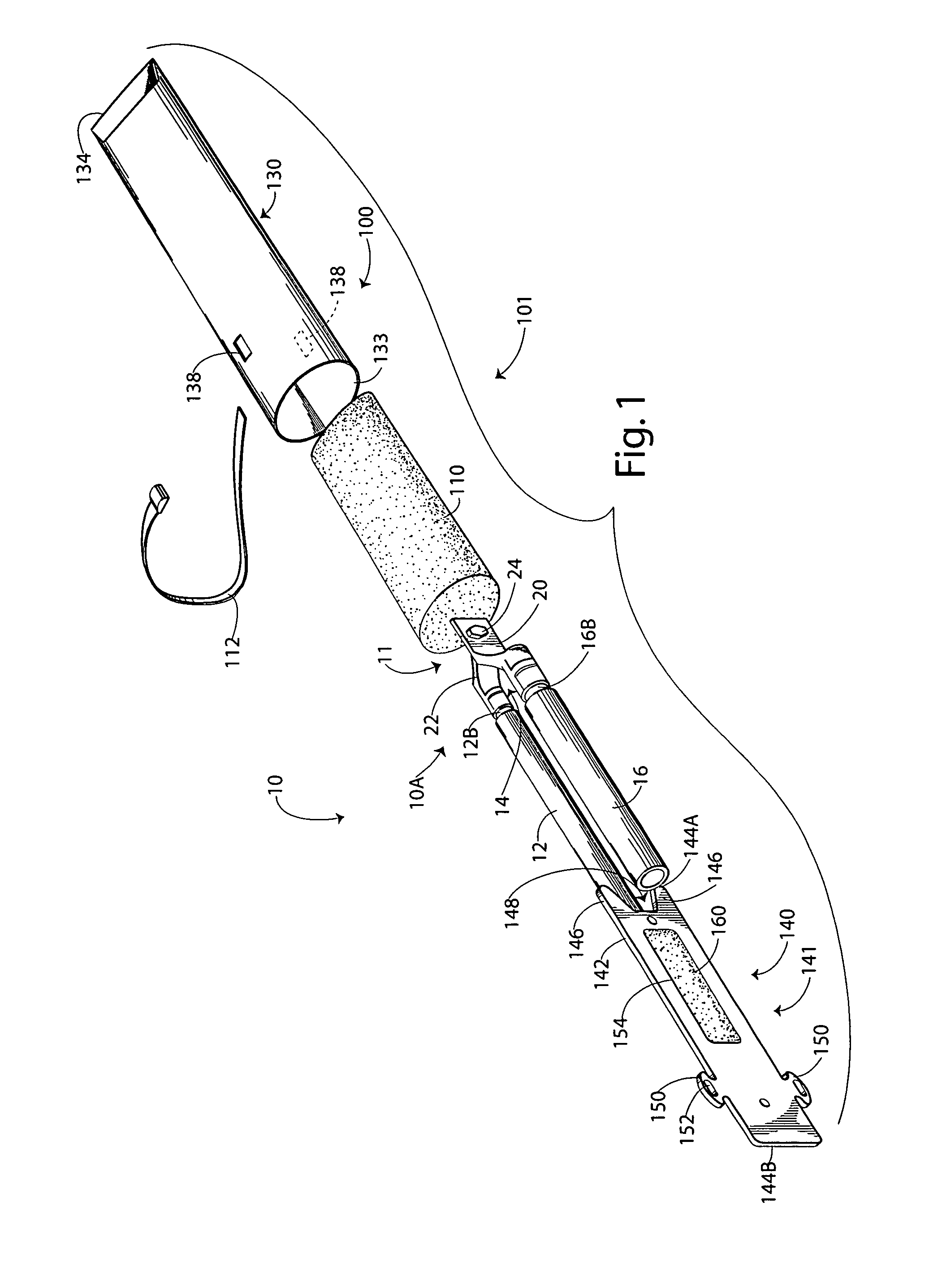

Cable Cover for an Ultrasonic Flow Meter

A cable cover for an ultrasonic flow meter is disclosed. In some embodiments, the cable cover includes multiple interlockable pieces configured to couple to a spoolpiece of an ultrasonic flow meter. Each interlockable piece includes a body having a dowel and a slot. The interlockable pieces are assembled in a series with the dowel of each interlockable piece inserted into the slot of another interlockable piece.

Owner:MICRO MOTION INC

Instant wire splice wrap

InactiveUS20060254799A1Quickly and securely splicingConnection end capsCable terminationsBiomedical engineeringElectrical equipment

Owner:GREGOREK MARK R

Method and structure for waterproofing a terminal splice

ActiveUS7834268B2Reduce the overall diameterImprove performanceDustproof/splashproof/drip-proof/waterproof/flameproof connectionCouplings bases/casesEngineeringMechanical engineering

A method of waterproofing a terminal that includes a stopper inserted in one opening of a heat shrinkable tube. The heat shrinkable tube is heat-shrunk in this state to form a cap having a end closure. A fluid thermosetting waterproofing agent is injected into the cap from a second opening. A thermal splice, which is formed from welded strands stripped from a plurality of wire terminals, is inserted and immersed in the thermosetting waterproofing agent. Then, the entire cap is heated and heat-shrunk at a predetermined temperature and the thermosetting waterproofing agent is heat-hardened.

Owner:SUMITOMO WIRING SYST LTD

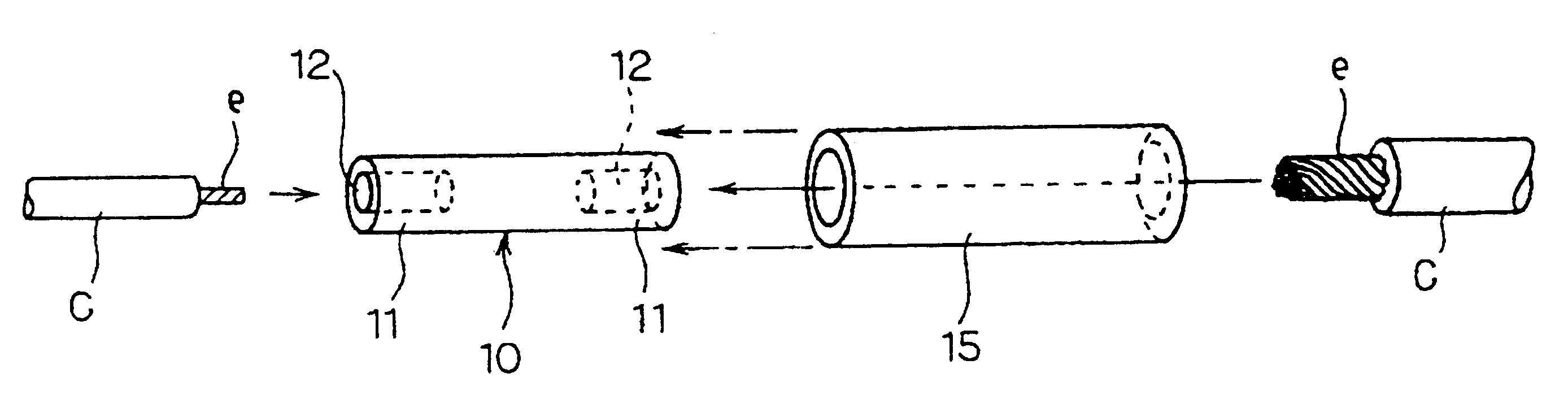

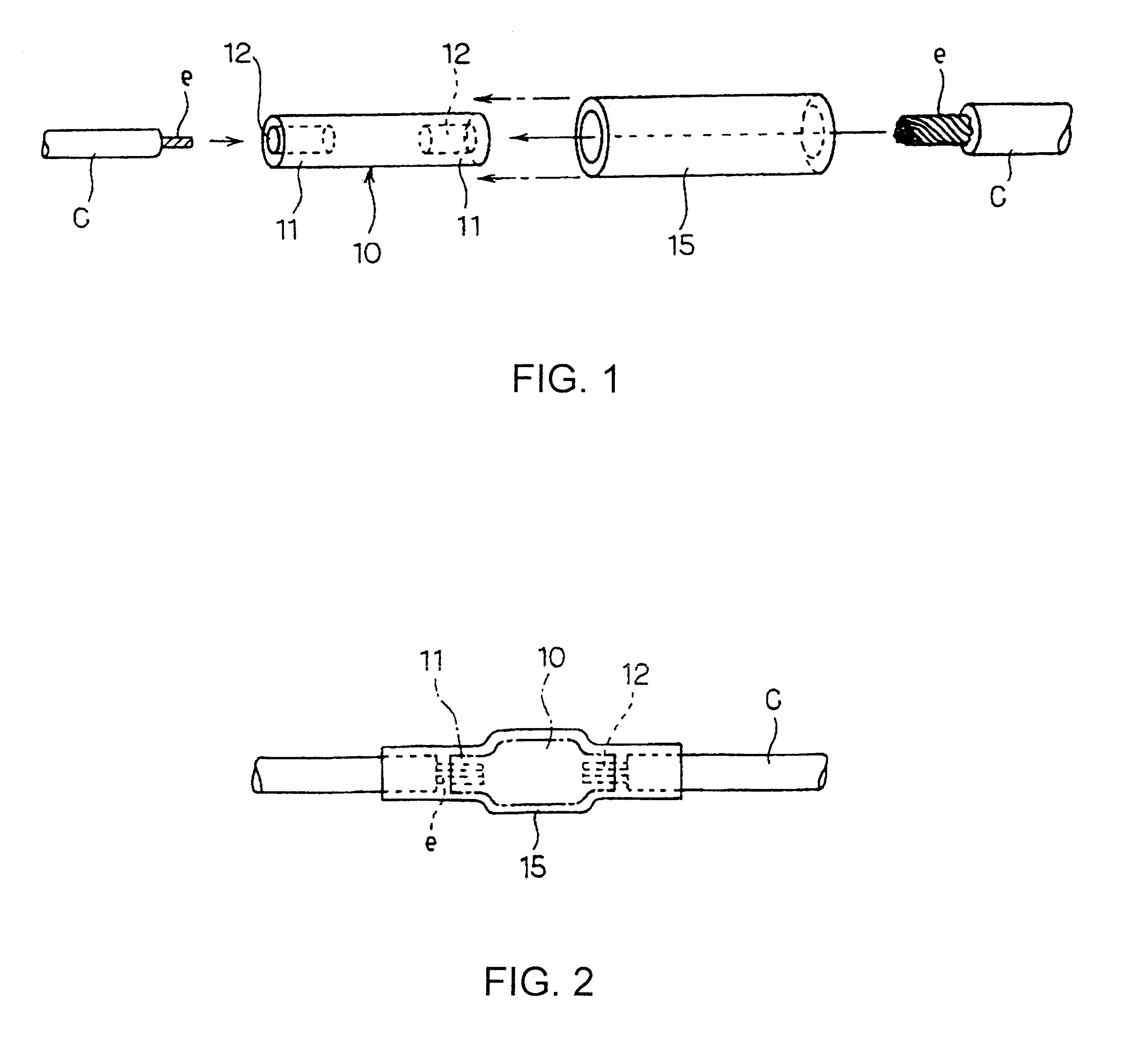

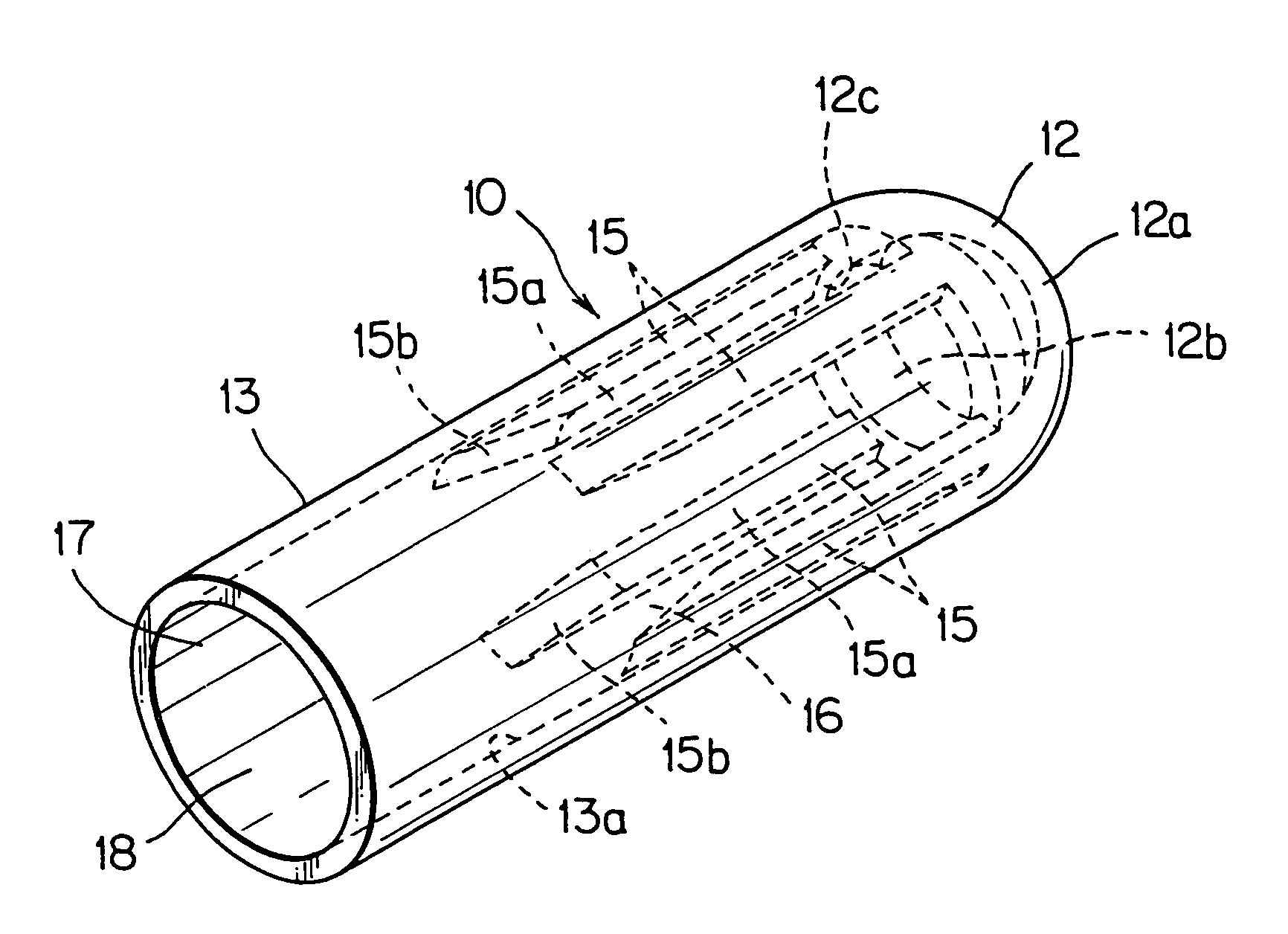

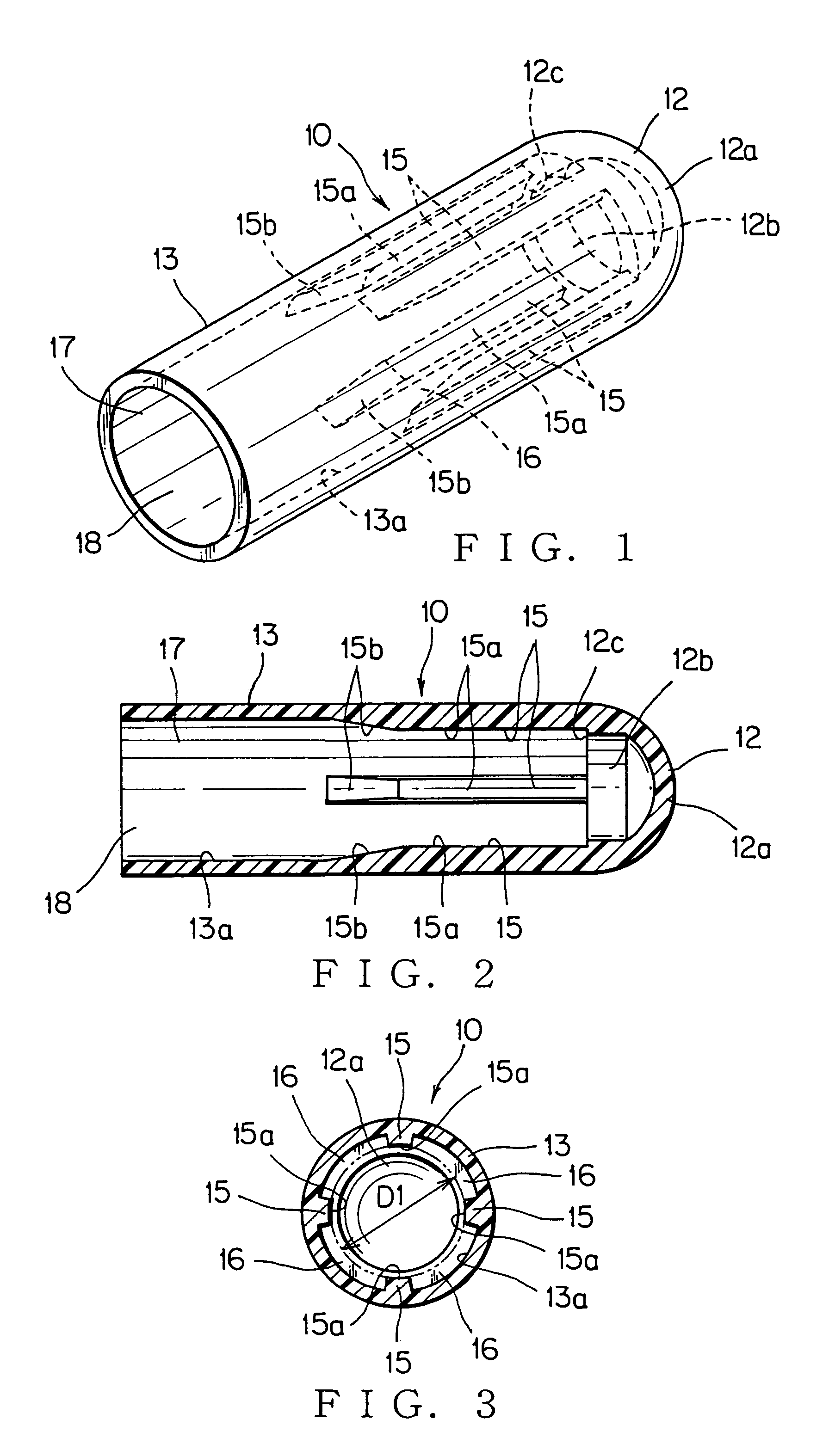

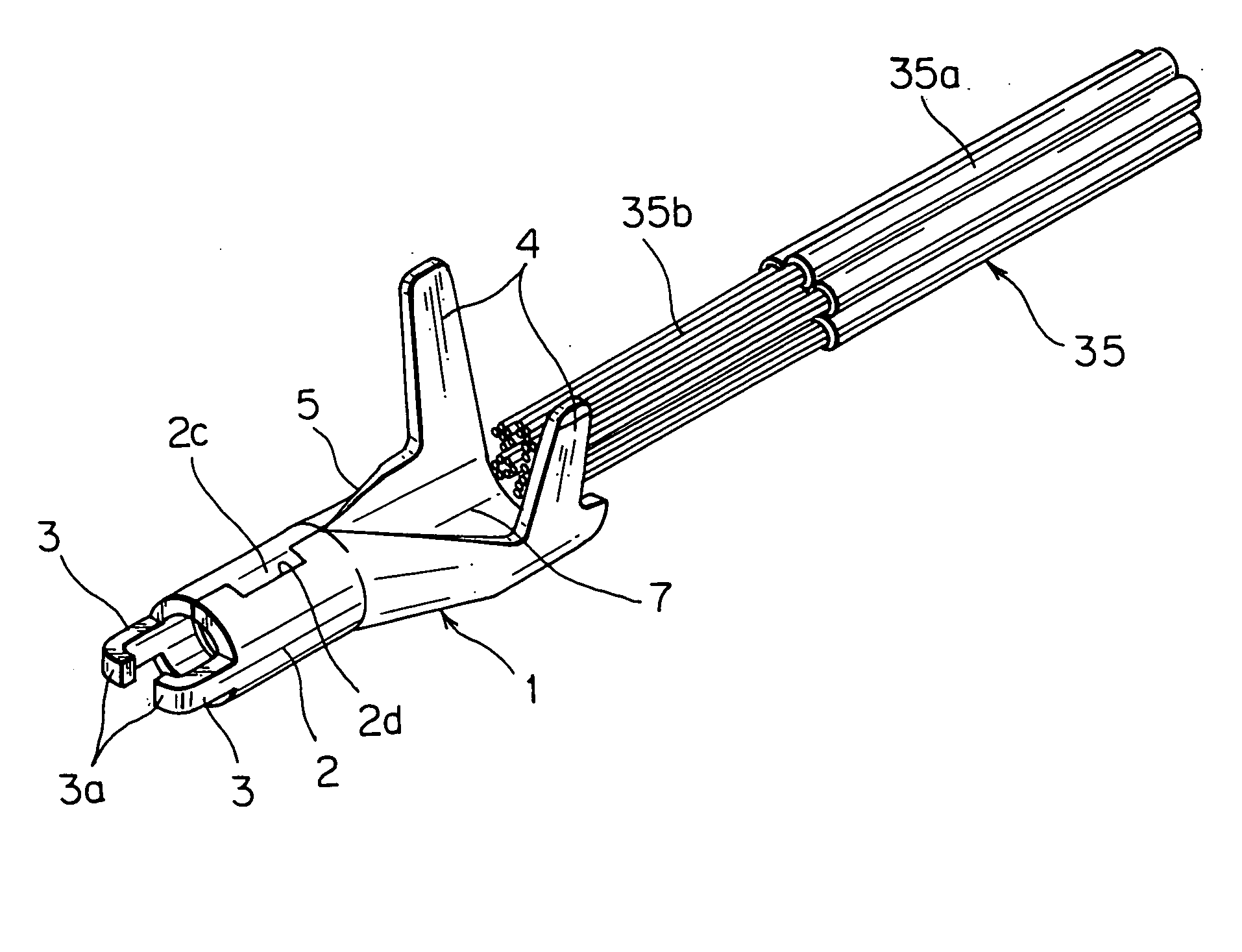

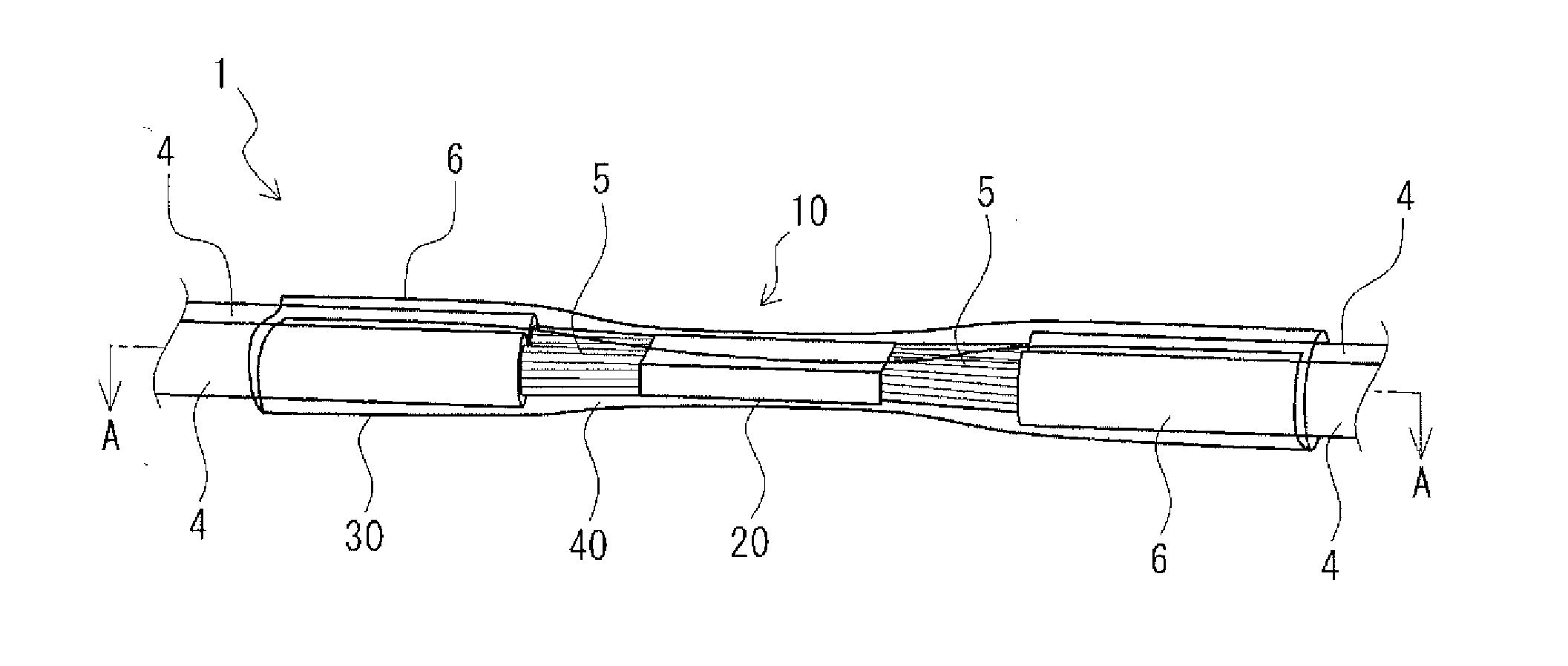

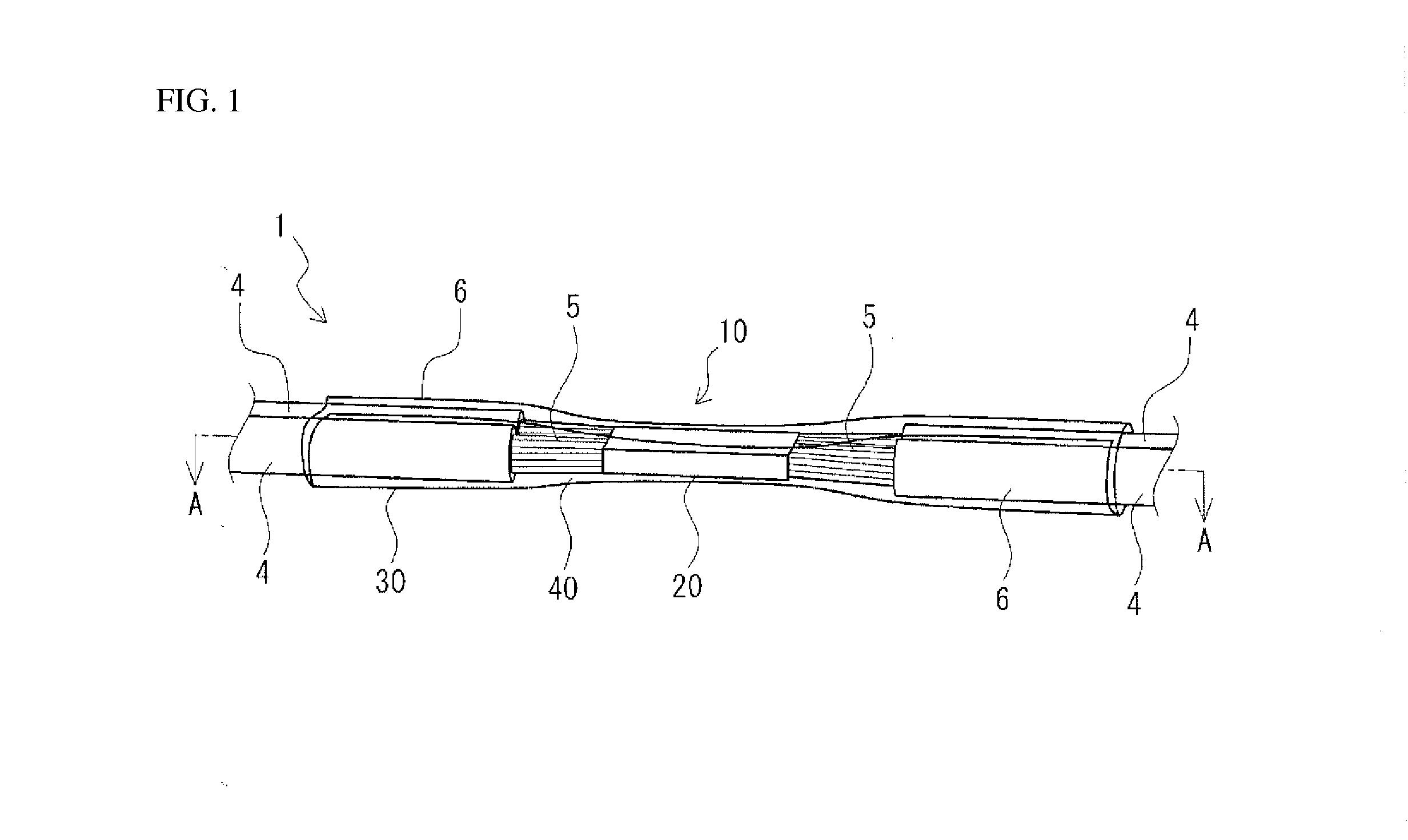

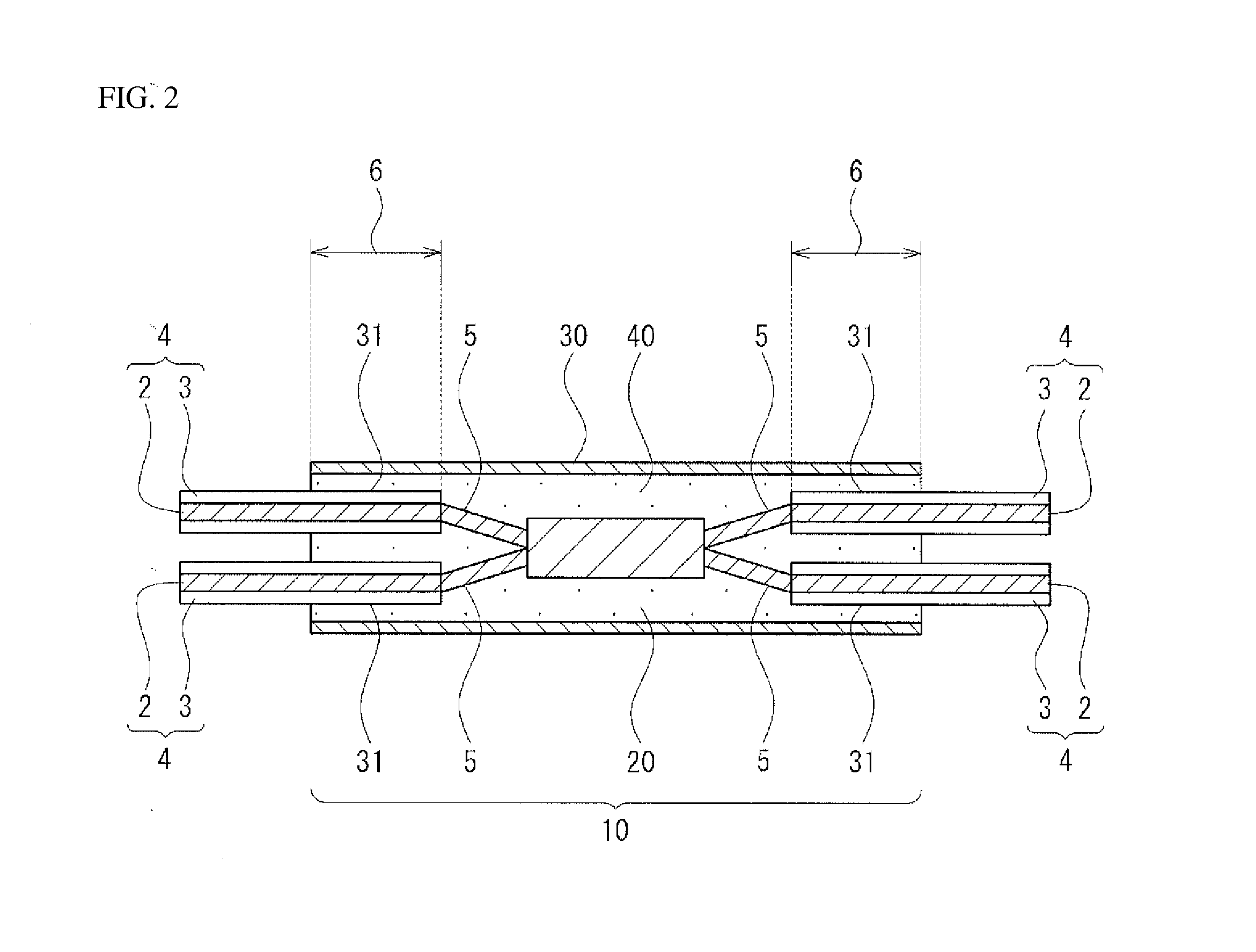

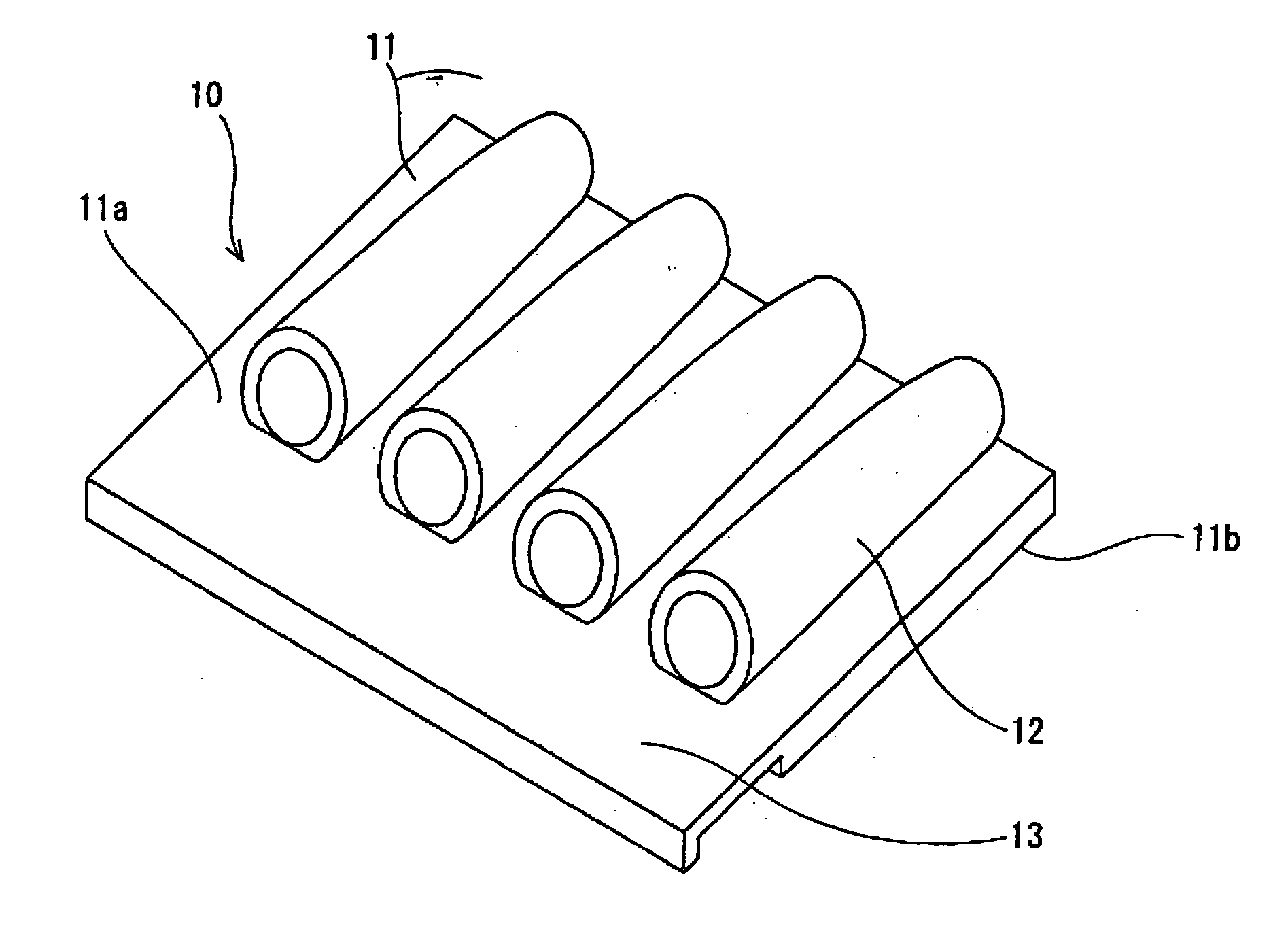

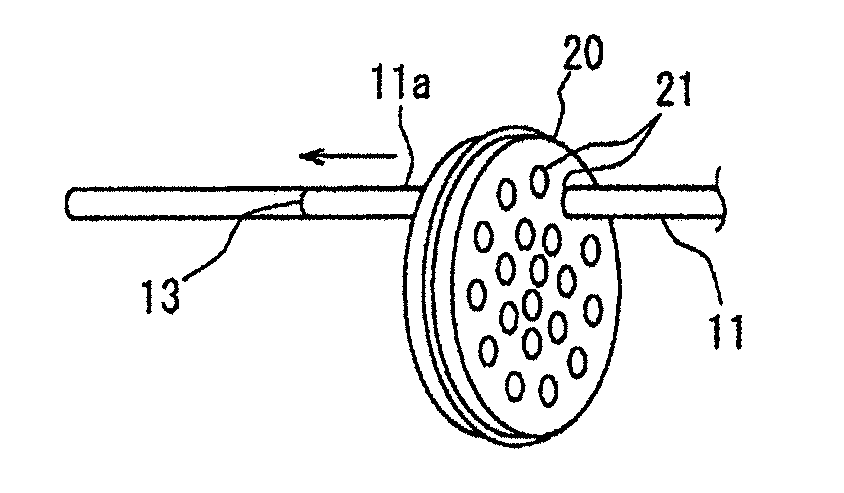

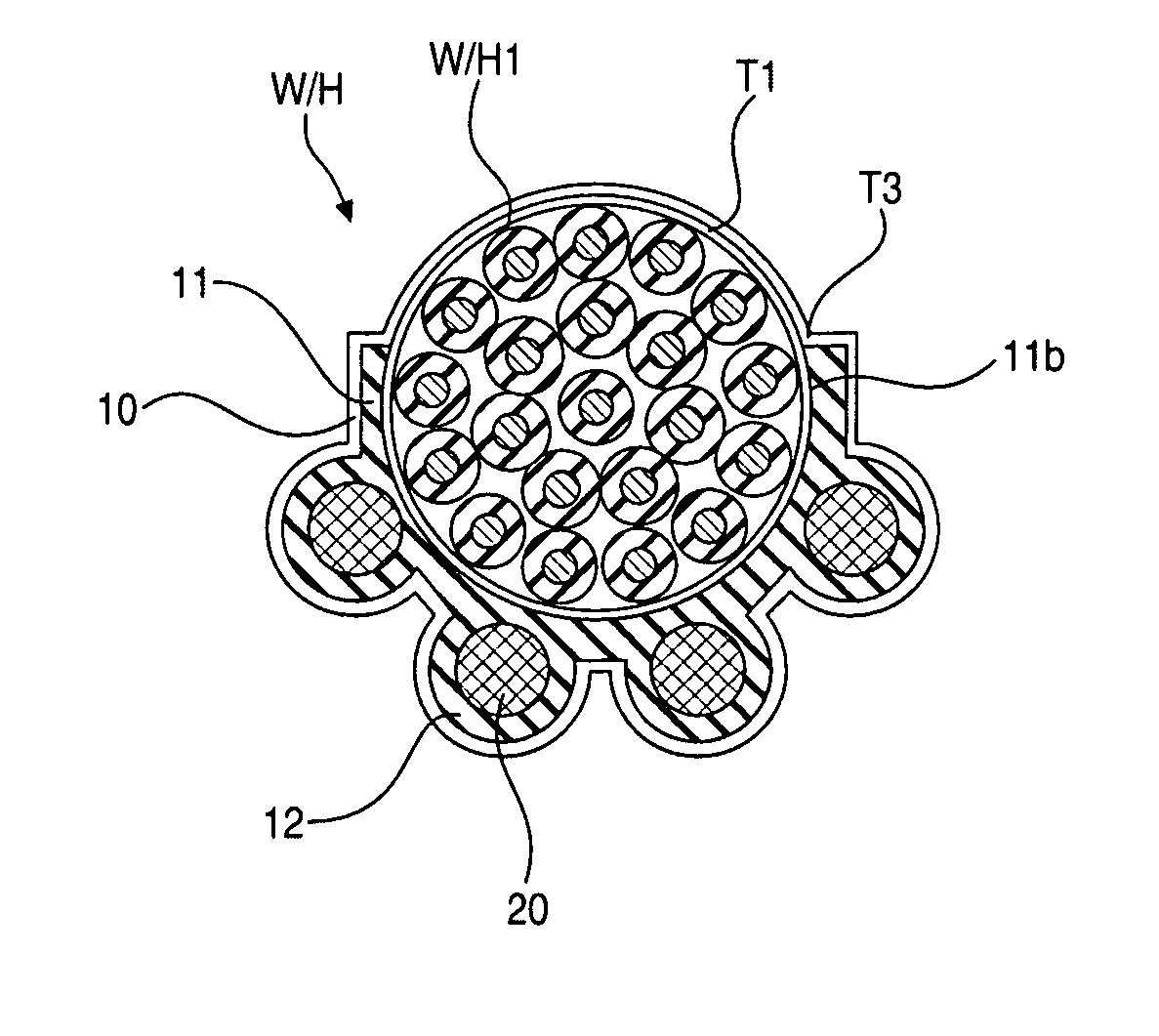

Jointing sleeve component and joint electric wire

ActiveUS20060057904A1Improve reliabilityReduce material costsLine/current collector detailsCoupling contact membersEngineeringElectric wire

The jointing sleeve component includes a sleeve made of electrically conductive metal. A diameter of the sleeve is to be reduced by swaging on a condition that core wire ends of a plurality of coated electric wires are received in the sleeve. Each core wire end is obtained by removing an insulating coating from the coated electric wire. The jointing sleeve component electrically connects the core wire ends to each other. The sleeve is formed in a pipe-shape from a developed material, which is stamped out from a plate made of the electrically conductive metal to have a specific shape.

Owner:YAZAKI CORP

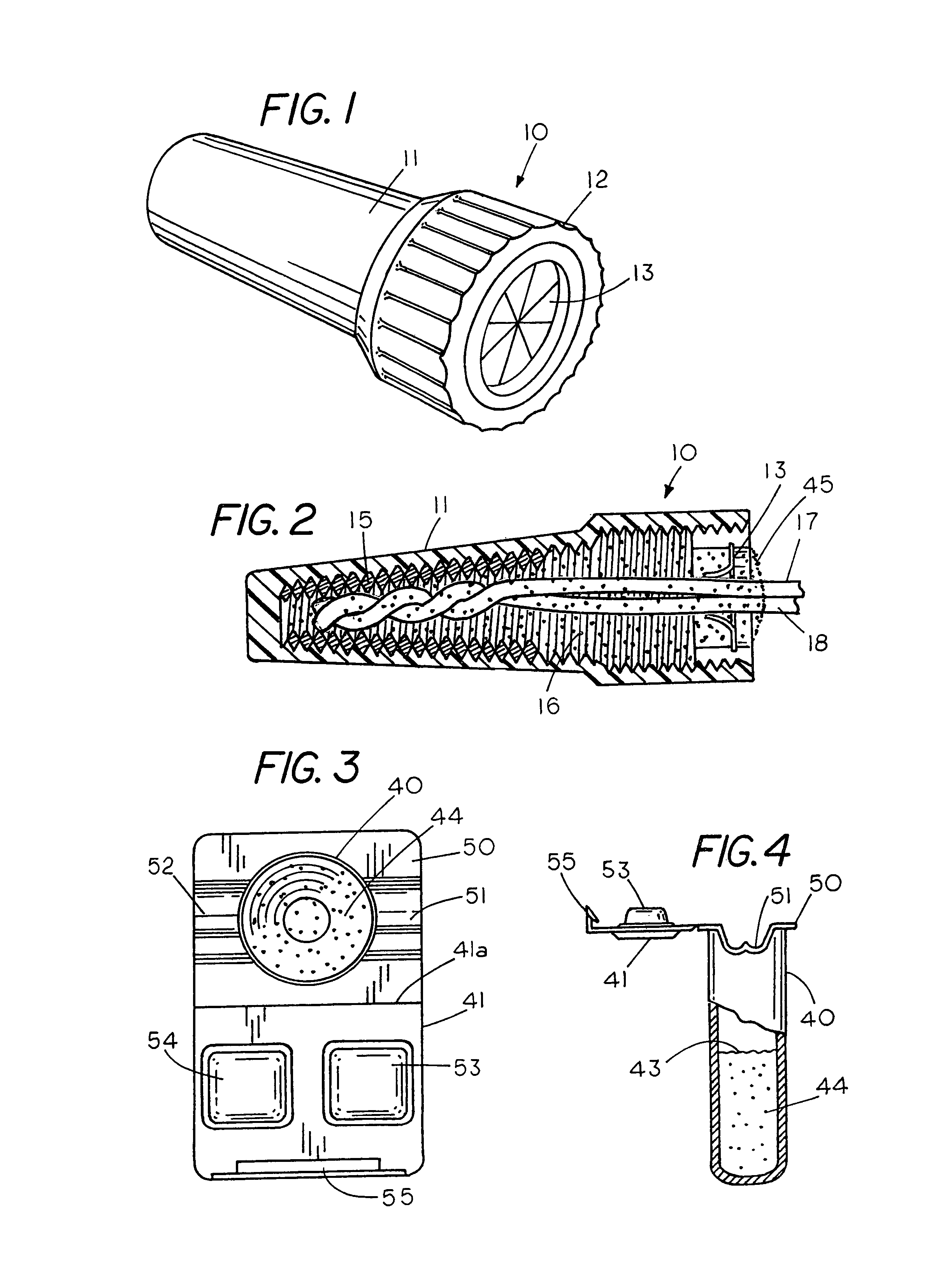

Twist-on wire connector

InactiveUS6878880B2Improve current carrying capacityCouplings bases/casesConnections effected by permanent deformationElectrical connectionElectric wire

An on-the-go twist-on wire connector for enhancing the current carrying capacity of the electrical wires contained therein with the housing having a closed end and an open end with a wire engaging coil located in the closed end of the housing for bringing a plurality of wires into surface-to-surface contact to provide a direct surface-to-surface electrical path for flow of electrical energy therebetween. Located in the twist-on wire connector is a wire adhereable electrically conducting medium the adhereable electrical conducting medium is conformable around the plurality of wires as the plurality of wires are brought into surface-to-surface engagement with the conformable electrical conducting medium thereby forming an indirect current path between the ends of the plurality of wires while retaining the on-the-go ability of the twist-on wire connector to form the electrical connection solely through twisting action.

Owner:THE PATENT STORE

Curing material, wire harness, and manufacturing method thereof

ActiveUS20150340848A1Short timeInhibit migrationInsulated cablesPolyurea/polyurethane coatingsSolubilityElectrical conductor

A curing material, having a solubility parameter of 9.4 or more, contains at least a chain transfer agent that contains a compound containing a polyether structure and two or more urethane bonds or two or more urea bonds in a molecule, and a metal-containing compound. A wire harness is manufactured by supplying the curing material to a conductor exposed portion of a wire bundle including a plurality of bundled insulated wires each having a conductor covered with a covering material made of an insulating body, the conductor exposed portion being formed by removing a part of the covering material of the wire bundle to expose the conductor inside; and curing the curing material by irradiating light in a state in which a surface of the curing material is covered with a protective member formed from a resin containing a plasticizer and having light transmissivity, thereby forming a waterproof portion.

Owner:AUTONETWORKS TECH LTD +3

Swagable high-pressure cable connectors having improved sealing means

A high-pressure connector for an electrical power cable section having a central stranded conductor encased in a polymeric insulation jacket and having an interstitial void volume in the region of the stranded conductor, the high-pressure connector being suited for confining a fluid within the interstitial void volume at a residual pressure above atmospheric, but below the elastic limit of the polymeric insulation jacket, the high-pressure connector comprising a housing having a wall defining an interior chamber configured to be in fluid communication with the interstitial void volume and an end portion sized to receive the insulation jacket within the interior chamber and to overlap at least a portion of the insulation jacket at an end thereof with the cable section extending from the housing end portion and at least a portion of the stranded conductor positioned within the interior chamber. The housing wall of the housing end portion has an engagement portion comprised of a swagable material to secure the housing wall to the insulation jacket in fluid-tight sealed engagement therewith upon inward swaging of the engagement portion of the housing wall of the housing end portion to the insulation jacket to confine the fluid at the residual pressure within the interior chamber and the interstitial void volume. The housing includes at least one axially-projecting engagement member located within the interior chamber at the engagement portion of the housing wall of the housing end portion.

Owner:NOVINIUM LLC

Electrical splice connector

InactiveUS20090163086A1Coupling device detailsElectric connection structural associationsElectrical conductorEngineering

Owner:3M INNOVATIVE PROPERTIES CO

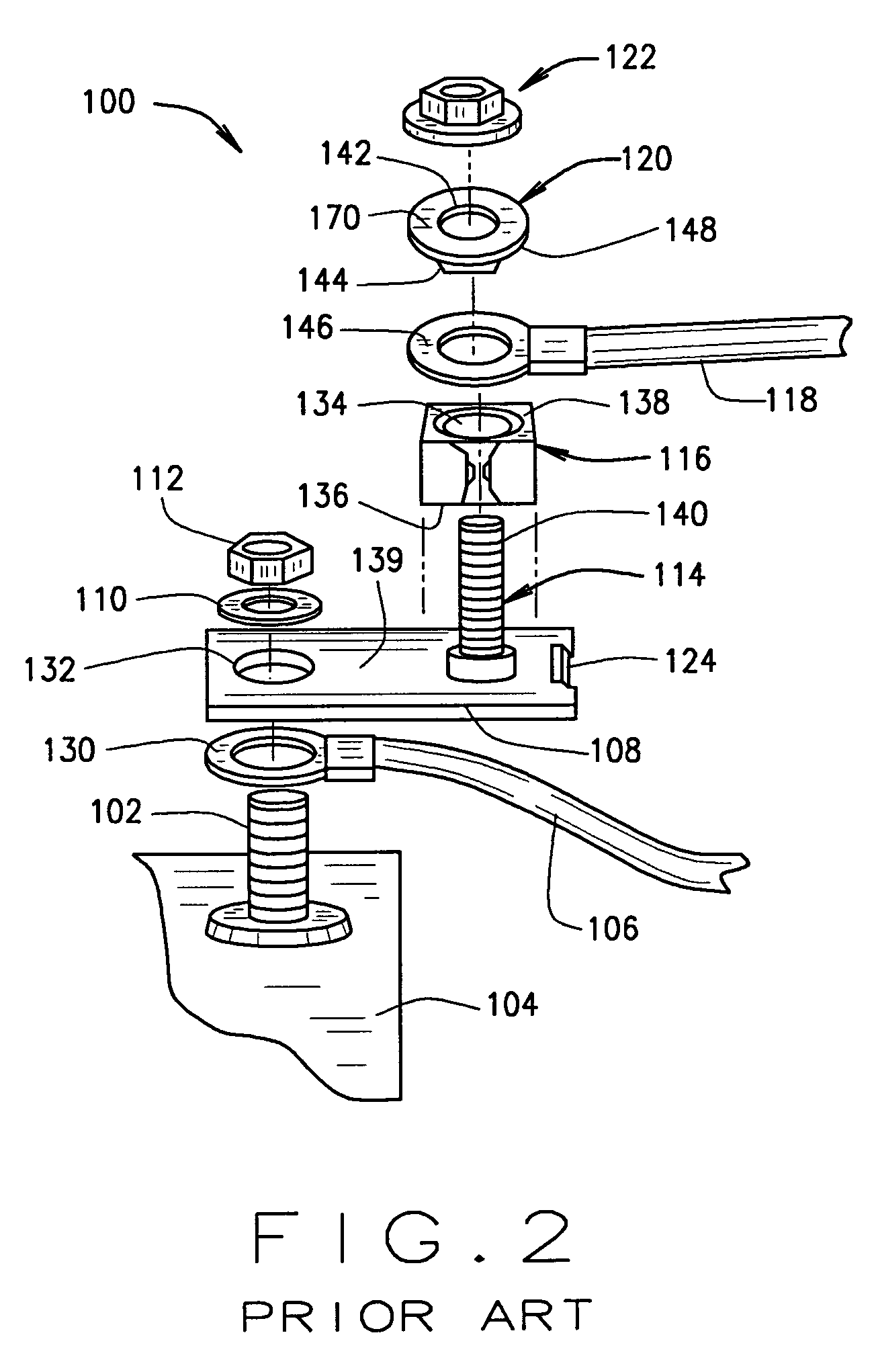

Electrical connection protector kits, insert assemblies and methods for using the same

ActiveUS7109423B1Control displacementConnection end capsCable junctionsElectrical conductorElectrical connection

A connection protector kit for use with an electrical stub connection assembly, the stub connection assembly including first and second conductors forming a connection and defining a crotch therebetween, includes an insert assembly. The insert assembly includes an insert member and a sealant pad mounted on the insert member. The insert assembly is adapted to fit within the crotch of the stub connection assembly. The kit may further include a cap defining a cavity and an opening communicating with the cavity, wherein the cavity and the opening are adapted to receive the stub connection assembly and the insert assembly is adapted to fit within the crotch of the stub connection assembly when the stub connection assembly is mounted in the cavity.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

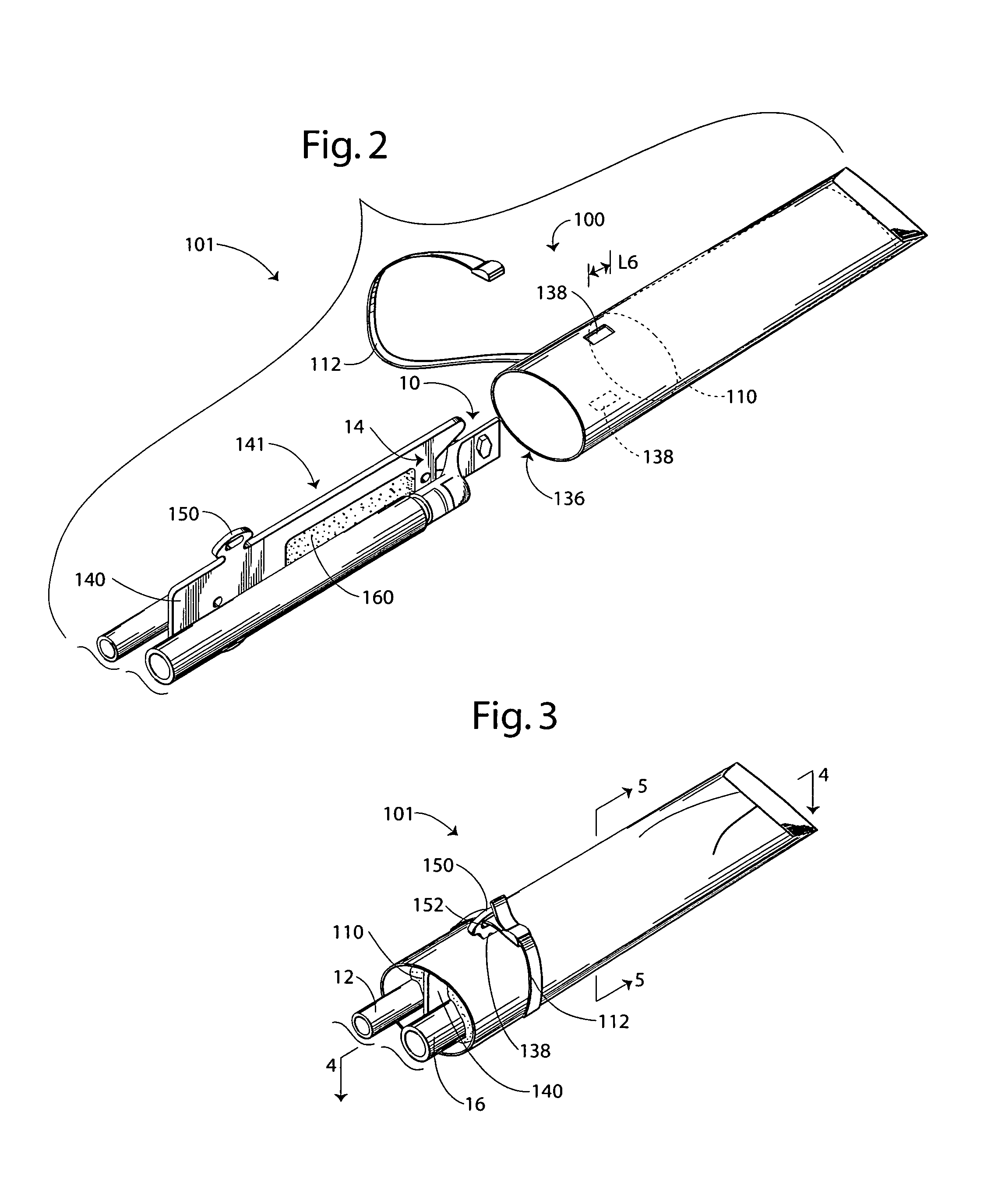

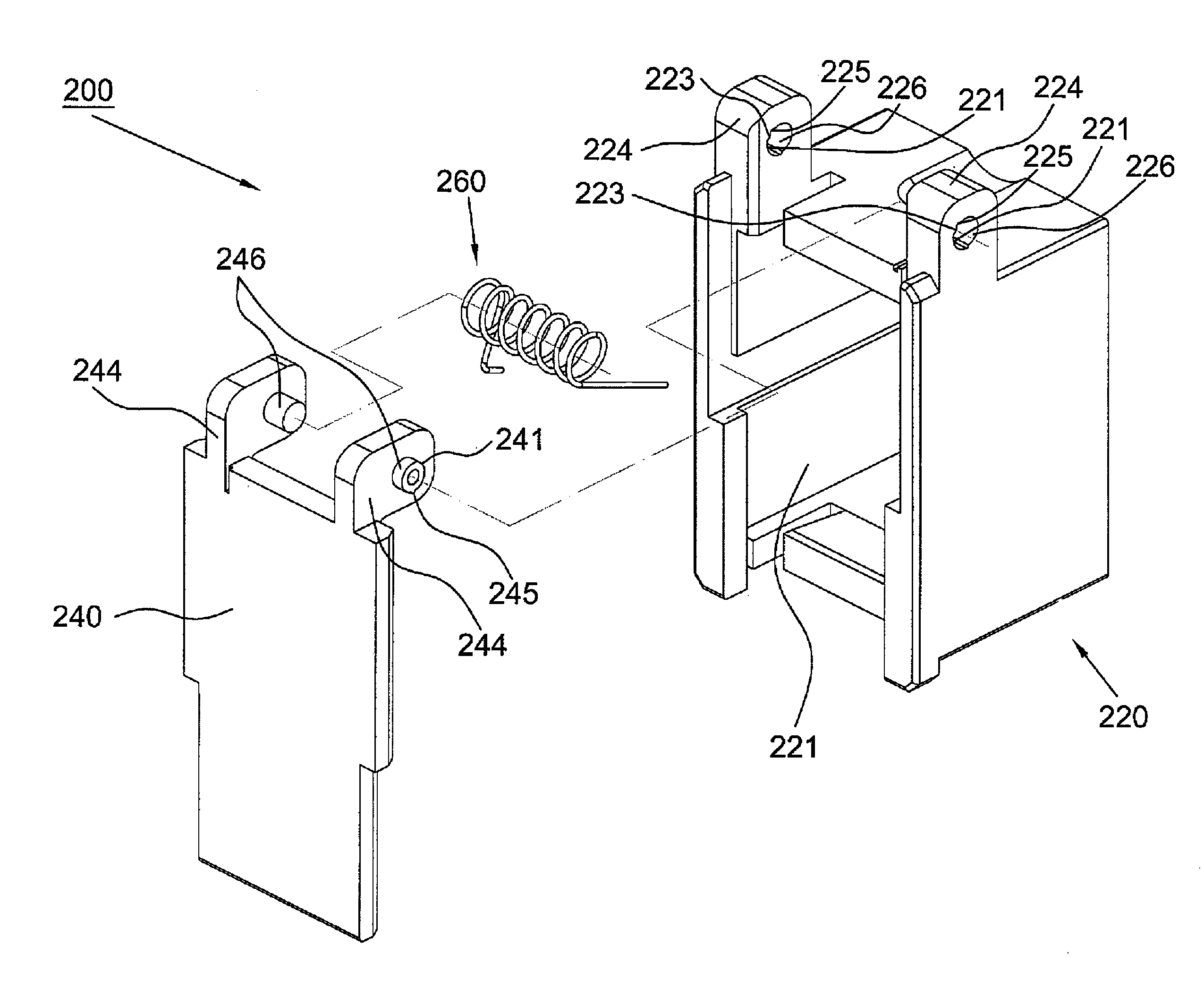

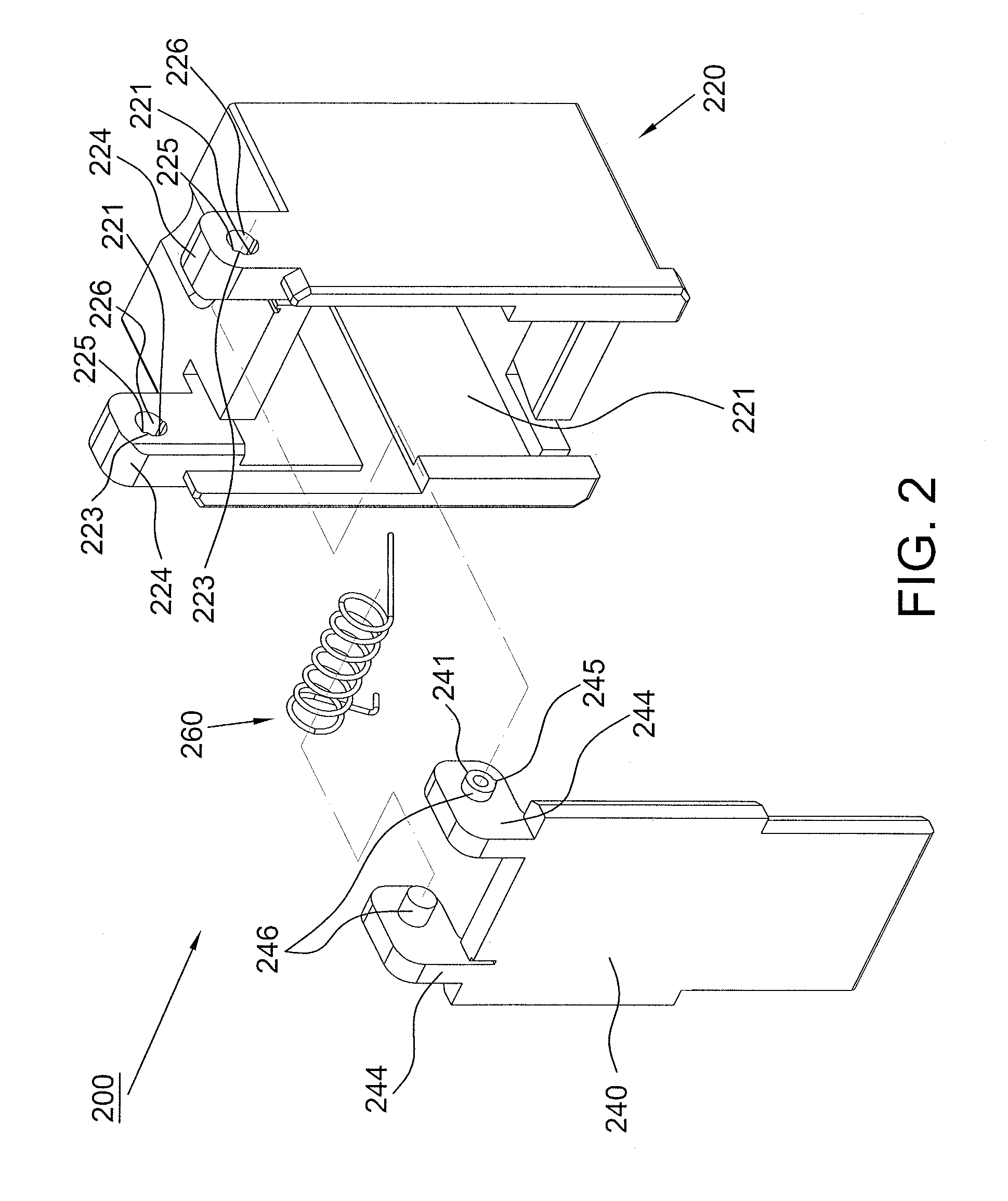

Electric binding terminal

ActiveCN101060207ALarge clamping forceLarge pulling forceOne pole connectionsElectric connection structural associationsEngineeringSpring steel

The present invention relates to a connecting terminal for electric wires. The terminal operates with a leaf spring tongue die-cut (or blanked) from a piece of spring steel plate and has a busbar extending over all clamping locations. The object of the invention is to reduce the structural height of the terminal. This task was solved by a new positioning of the edge areas of the spring steel plates so that they were each closely adjacent to the wires. The reduction in structural height is also achieved by a new contact configuration with special pre-deformation of the leaf spring tongues.

Owner:维哥经营公司MBH

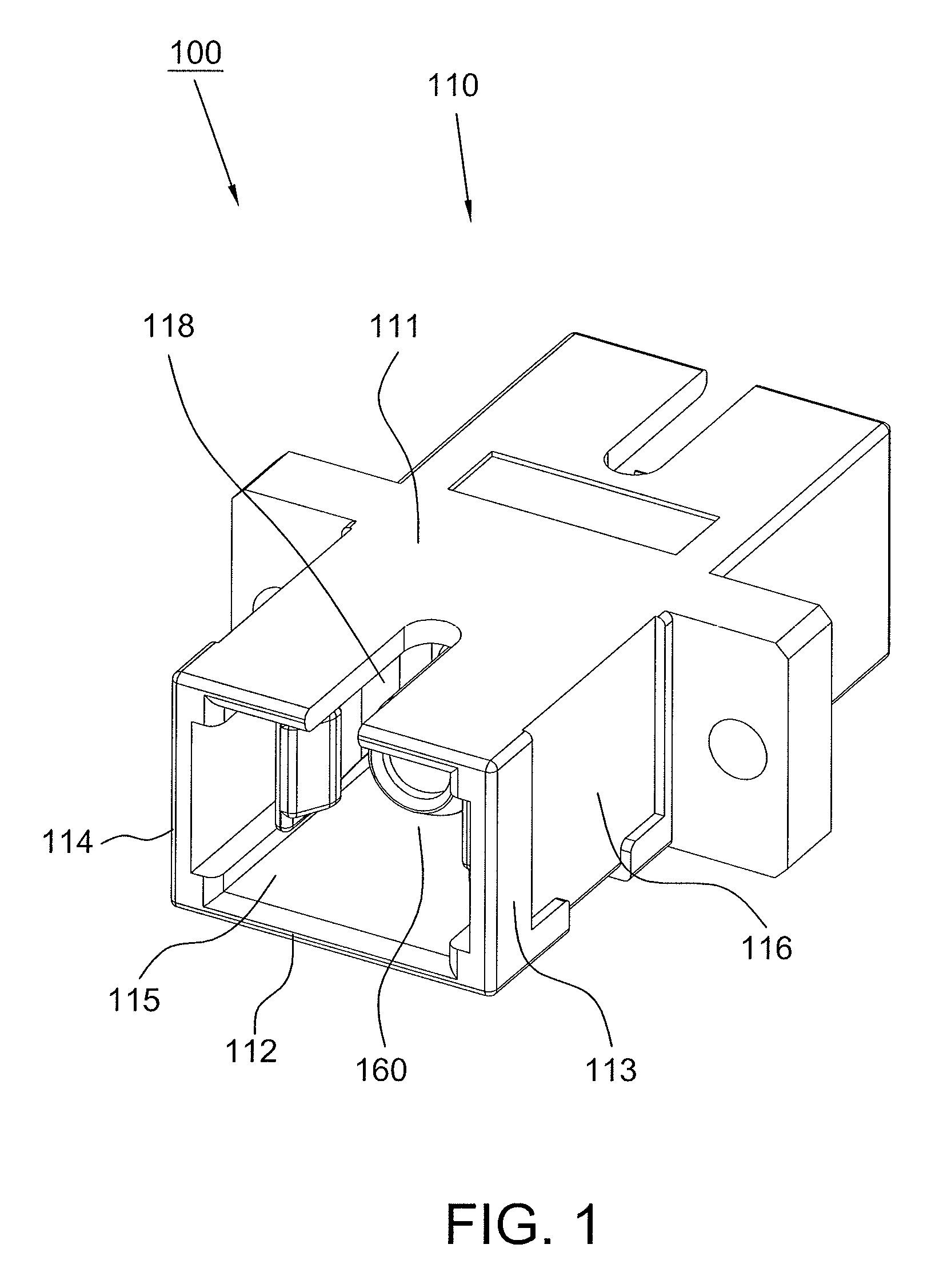

Protection cap for optical fiber adapter

ActiveUS8690459B2Rotary current collectorLive contact access preventionElectrical and Electronics engineeringOptical fiber

A protect cap for an optical fiber adapter according to the present disclosure is provided. The protect cap includes a casing defining a passage for receiving the optical fiber adapter, a pair of supporting lugs formed on the casing, a covering lid, and a pair of supporting arms extending from the covering lid. Each of the supporting lugs defines a shaft hole. Each of the supporting arms is provided with a shaft, wherein the shafts are positioned in the shaft holes, respectively such that the covering lid is pivotally connected to the casing. A first protrusion is formed on one of the shafts and a second protrusion is formed on an inner surface of one of the shaft holes. When the shafts are rotated to bring the first protrusion into contact with the second protrusion, the covering lid is kept in an open position with respect to the casing.

Owner:EZONTEK TECH

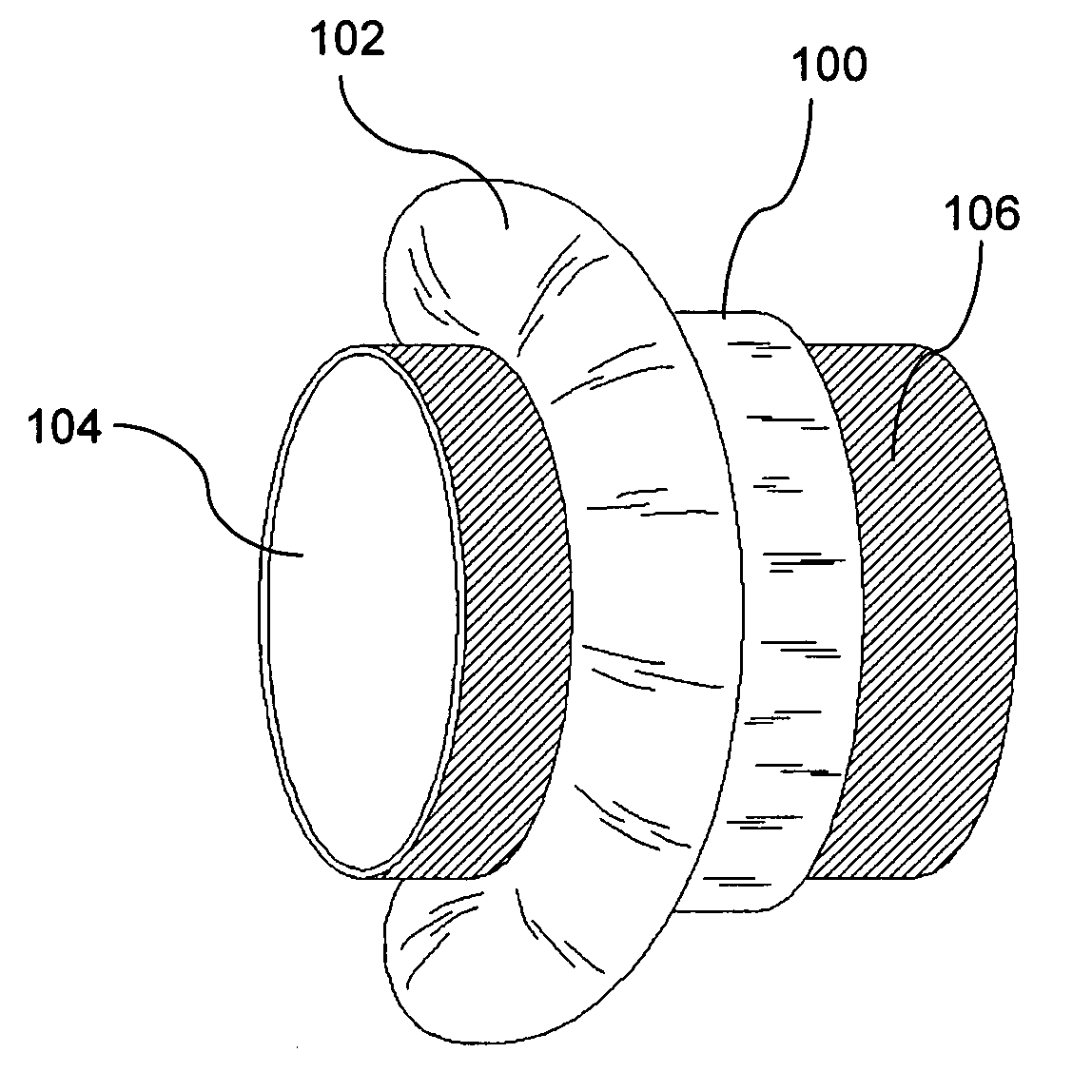

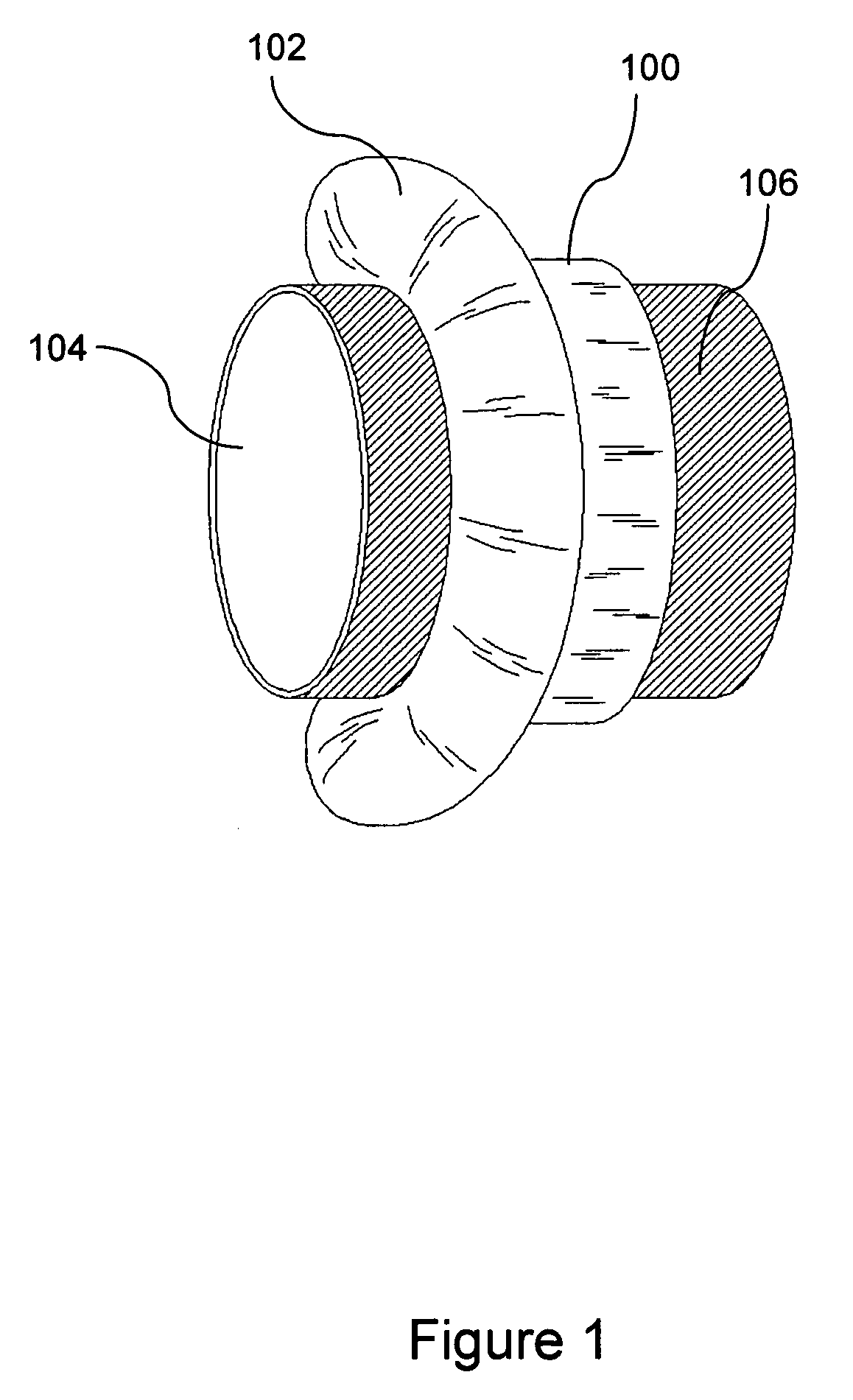

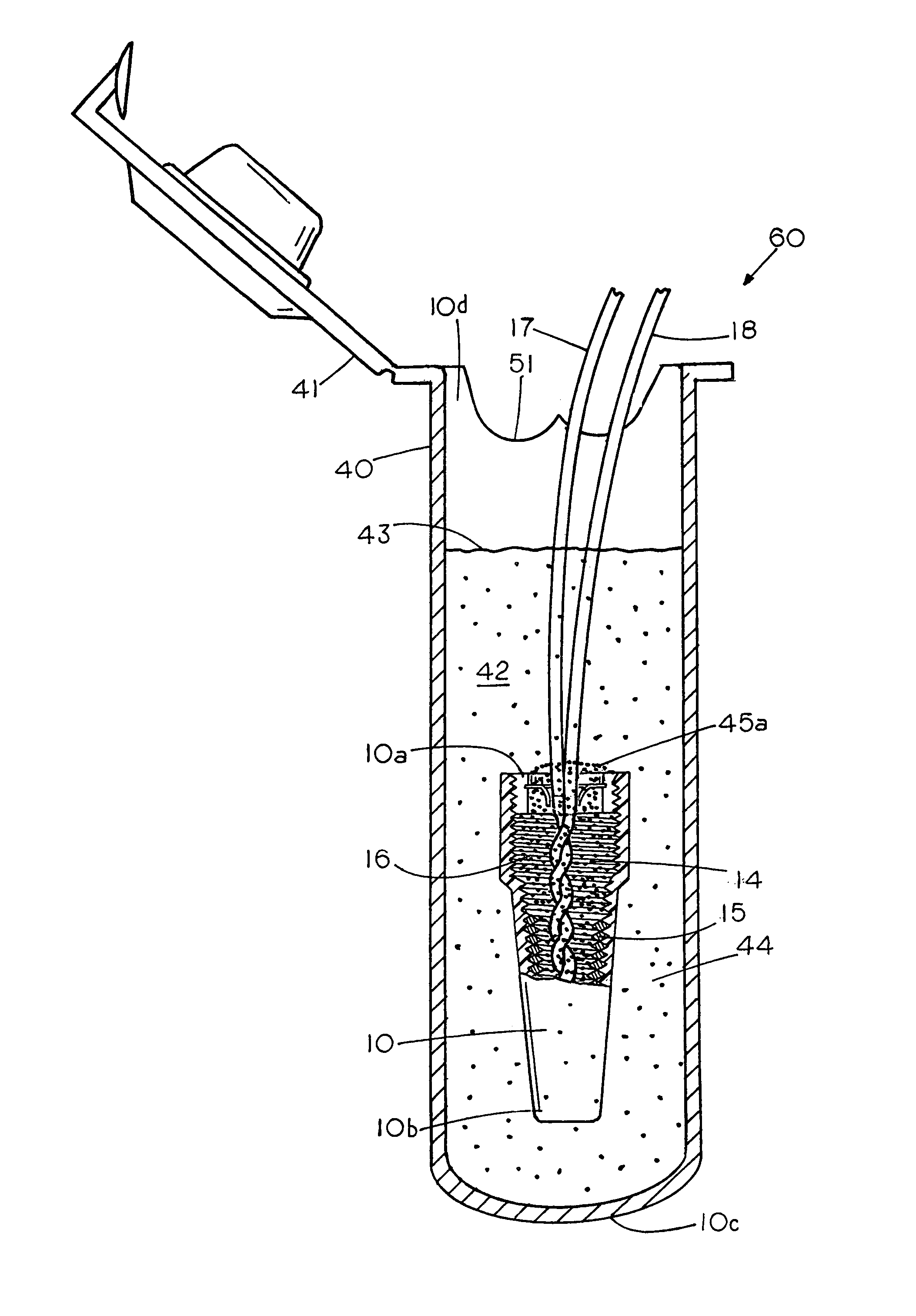

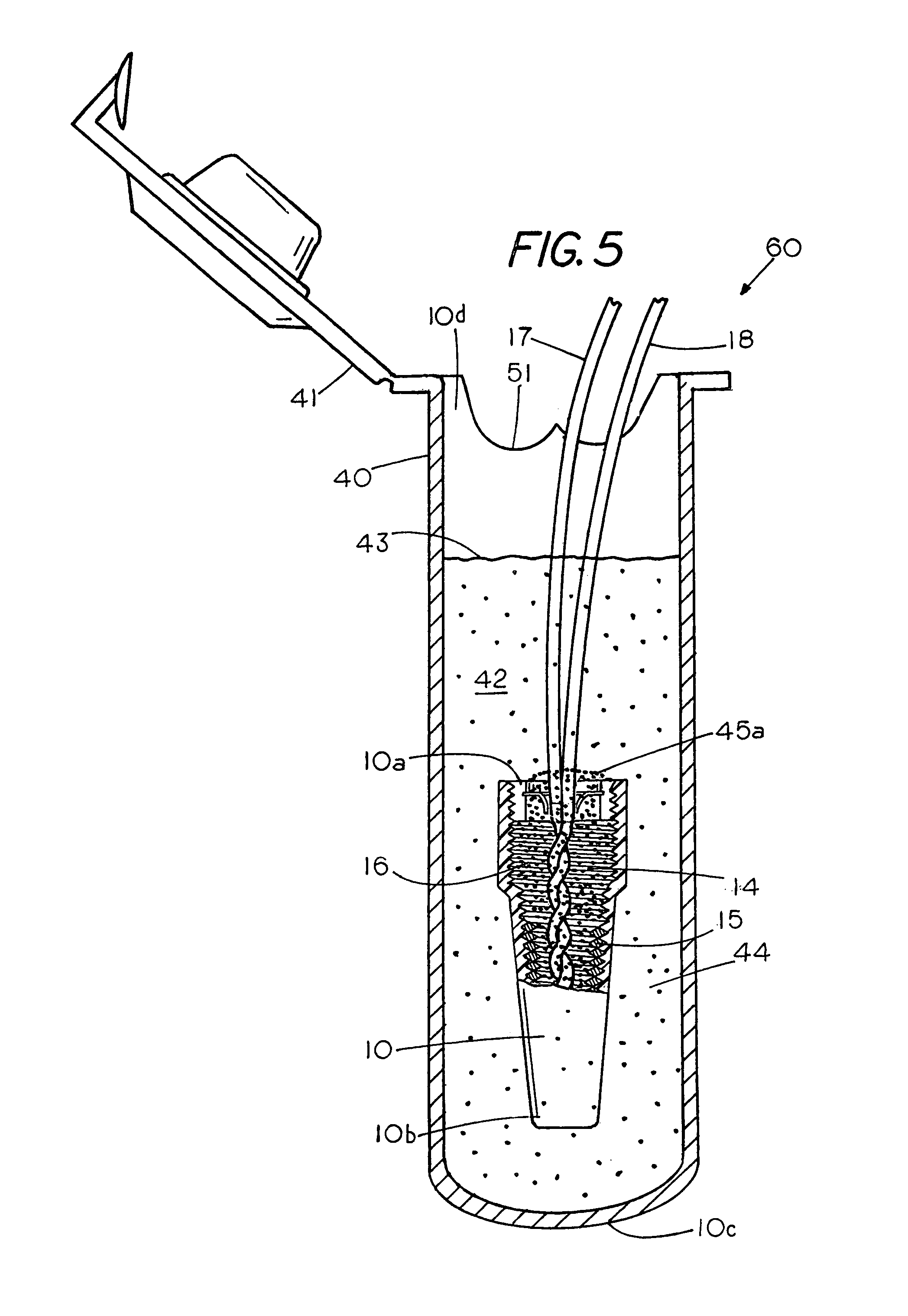

Two sealant two phase wire connector

ActiveUS9391388B1Avoid failureContact member assembly/disassemblyCouplings bases/casesElectrical FailureElectrical connection

A two sealant two-phase wire connector having sequential sealant interfaces for preventing an electrical failure through interactive sealant sharing between a twist-on electrical wire connector having a spiral cavity containing a first waterproof sealant which is immersed in a tube that contains a second water proof sealant, wherein the first water proof sealant and the second water proof sealant each form an interface that shields an electrical connection from the environment.

Owner:THE PATENT STORE

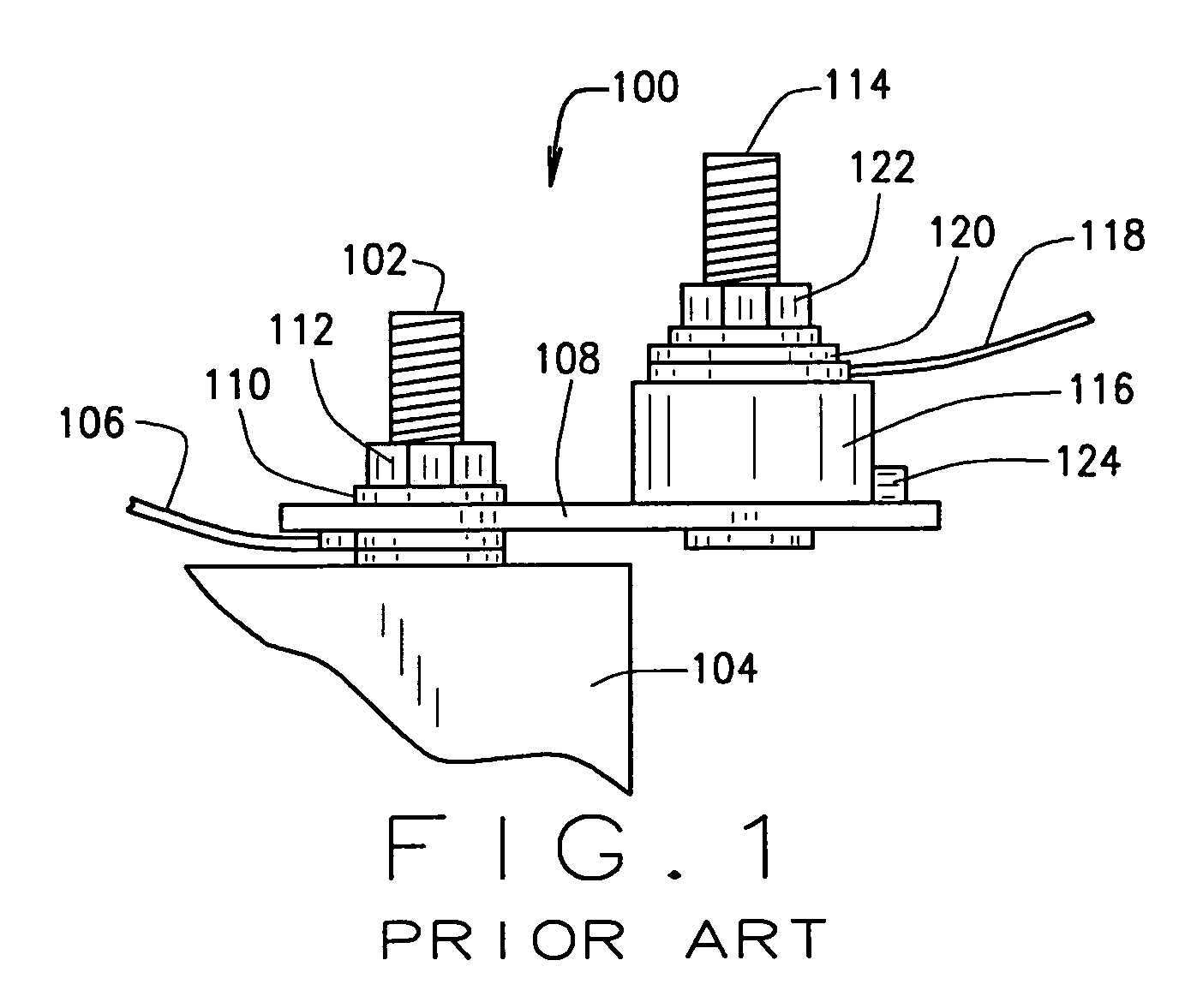

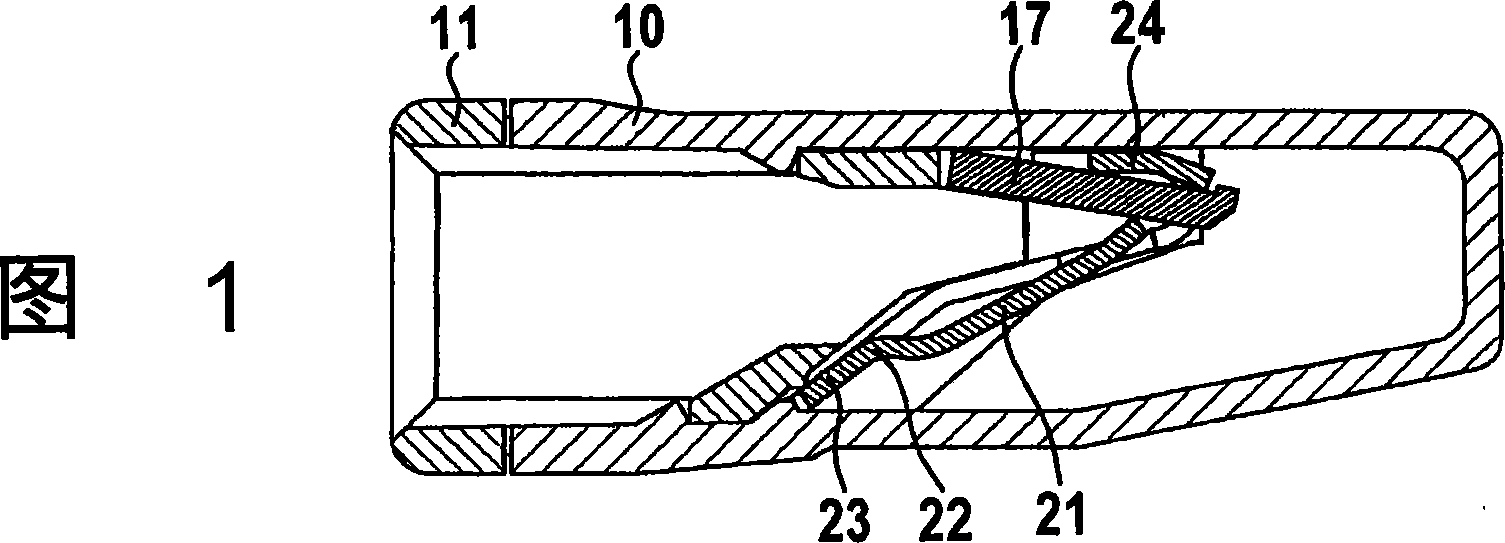

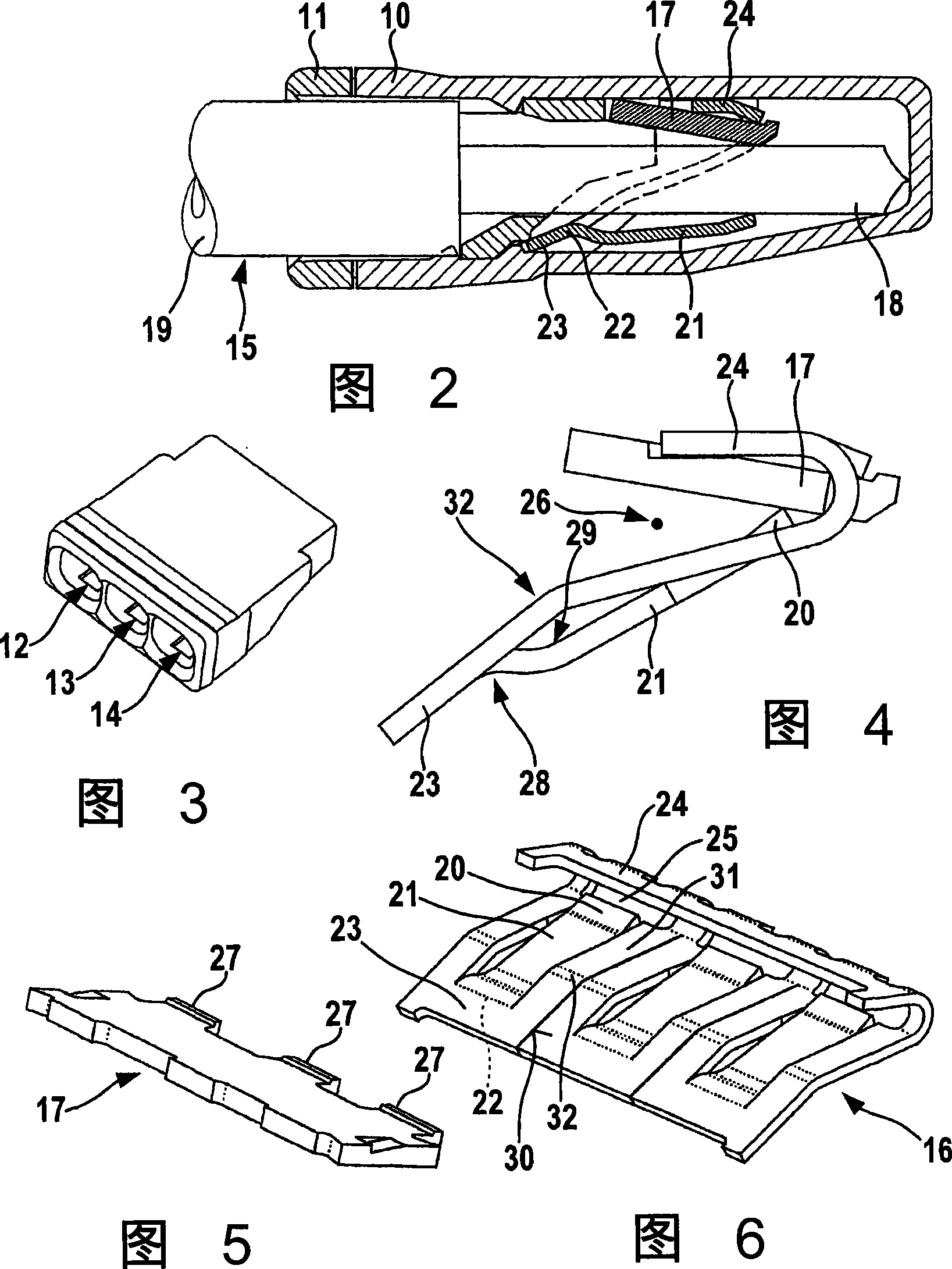

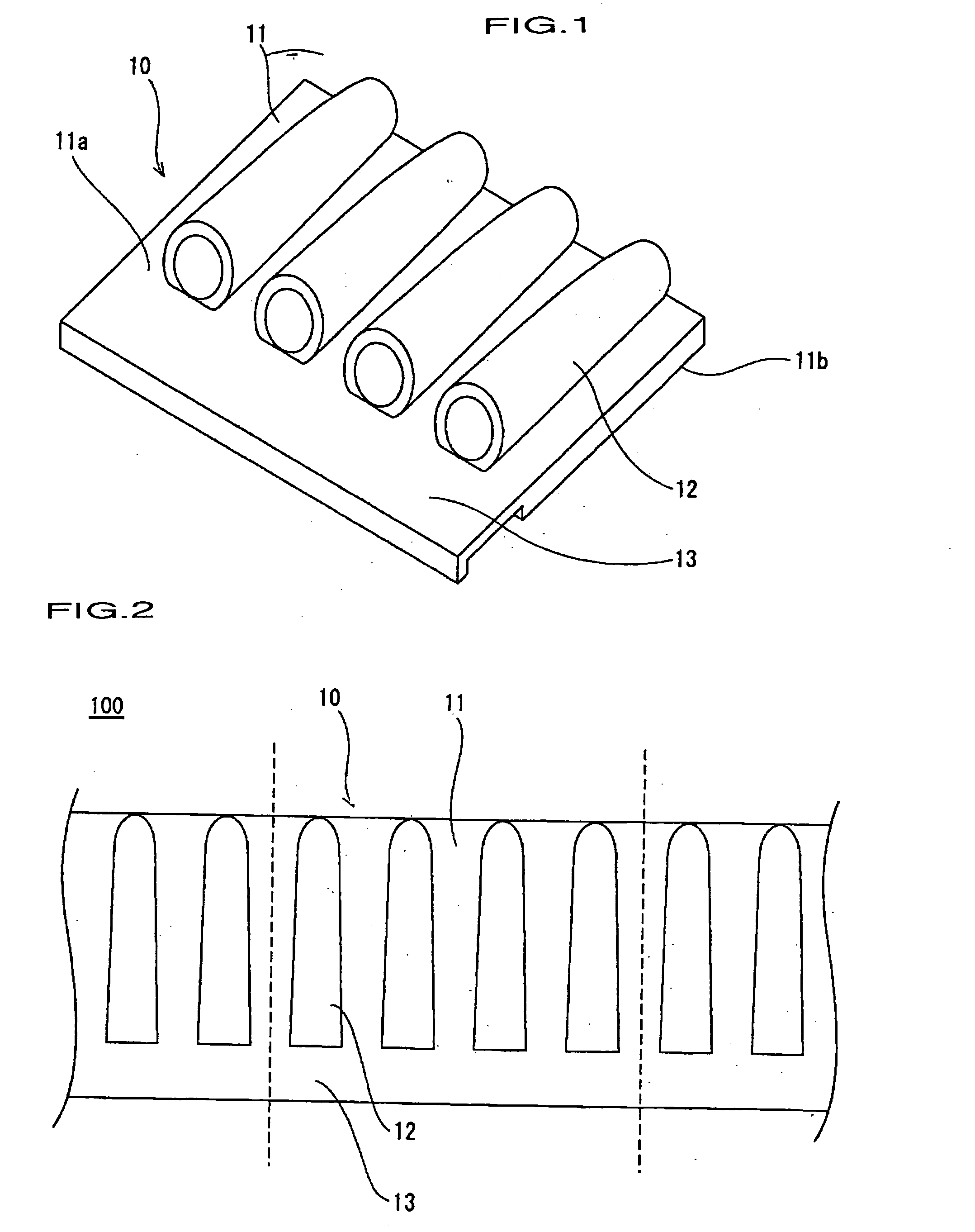

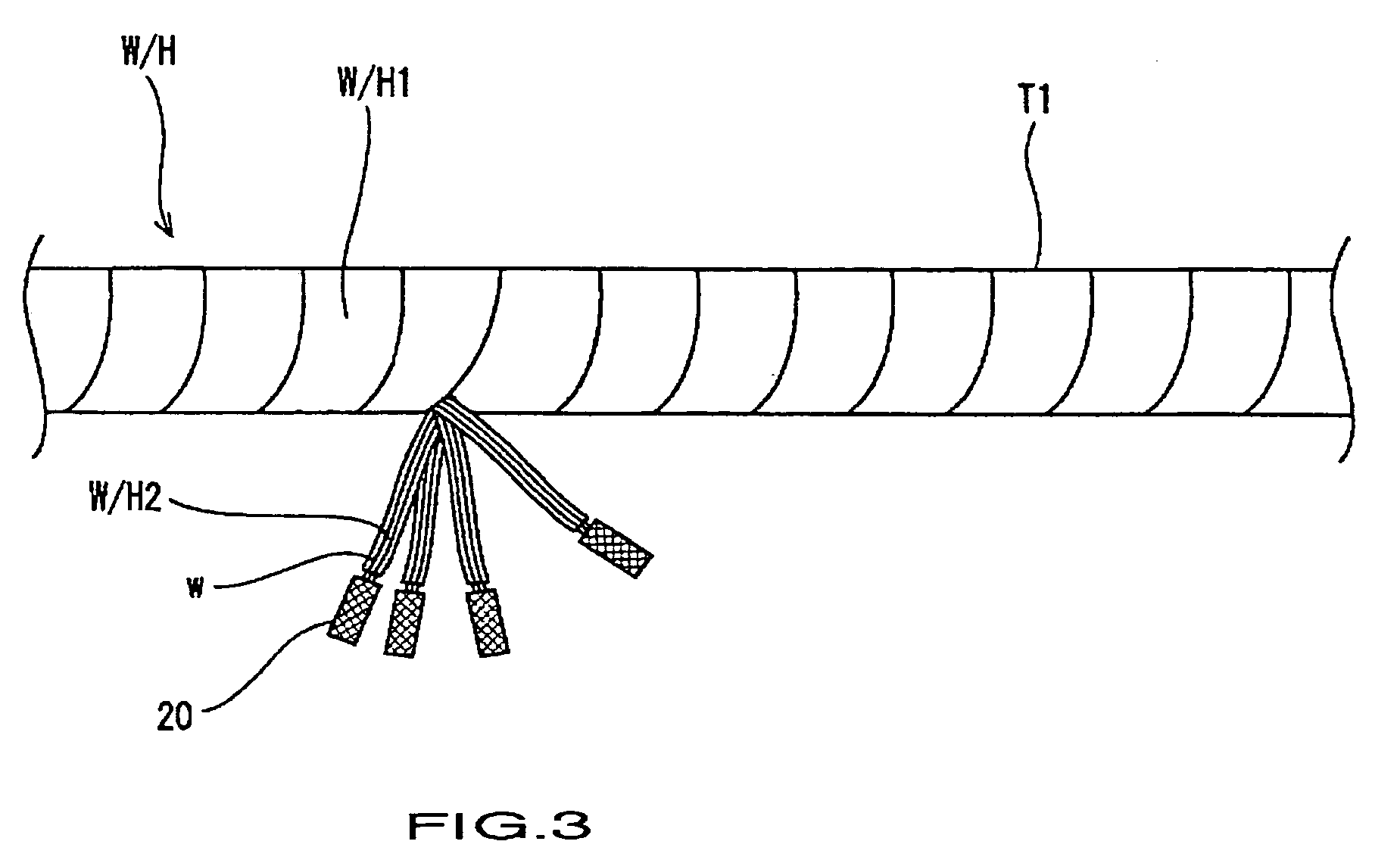

Protector cover for terminal group

InactiveUS20050133247A1Reduce the amount requiredLess spaceInsulated cablesConnection end capsEngineeringFlange

A protector cover that protects multiple collected wire terminal group splices while reducing the space occupied by the wire harness by locating the protector cover on the wire harness. The protector cover encloses solder joined terminal group splices formed at the ends of branch wires that separate from trunk wires of a wire harness. Multiple caps, each into which a terminal group splice is inserted, are formed at intervals on one or both sides of a planar support member, and a taping flange is formed as an extension at the open end of the caps. A terminal group splice is inserted into each cap and secured therein by a tape wrapping that encompasses the taping flange and the branch wires. The planar support member is then attached to the circumference of the trunk wires through a tape wrapping.

Owner:SUMITOMO WIRING SYST LTD

Twist-on wire connector with peelable covering

InactiveUS20060180336A1Fast formingCoupling device detailsConnection end capsEngineeringMechanical engineering

A twist-on wire connector containing a mass of a cohering gel in a gel state therein for forming a protective covering over a wire connection in the twist-on wire connector with the gel thereon removal from the twist-on wire connector and peelable from the wire connection to enable one to quickly form a further wire connection without having to wipe off the wire connection.

Owner:KING LLOYD HERBERT JR +3

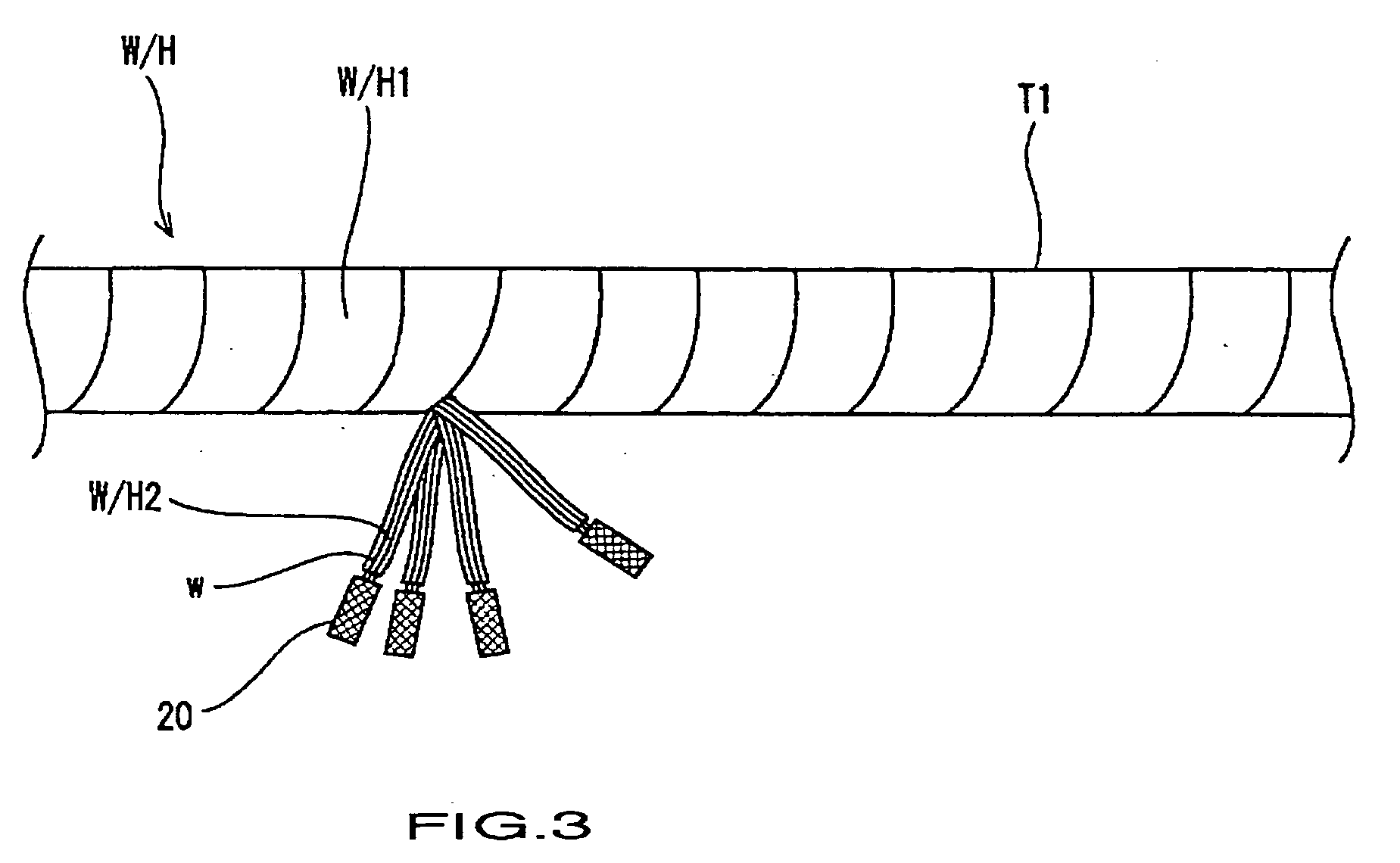

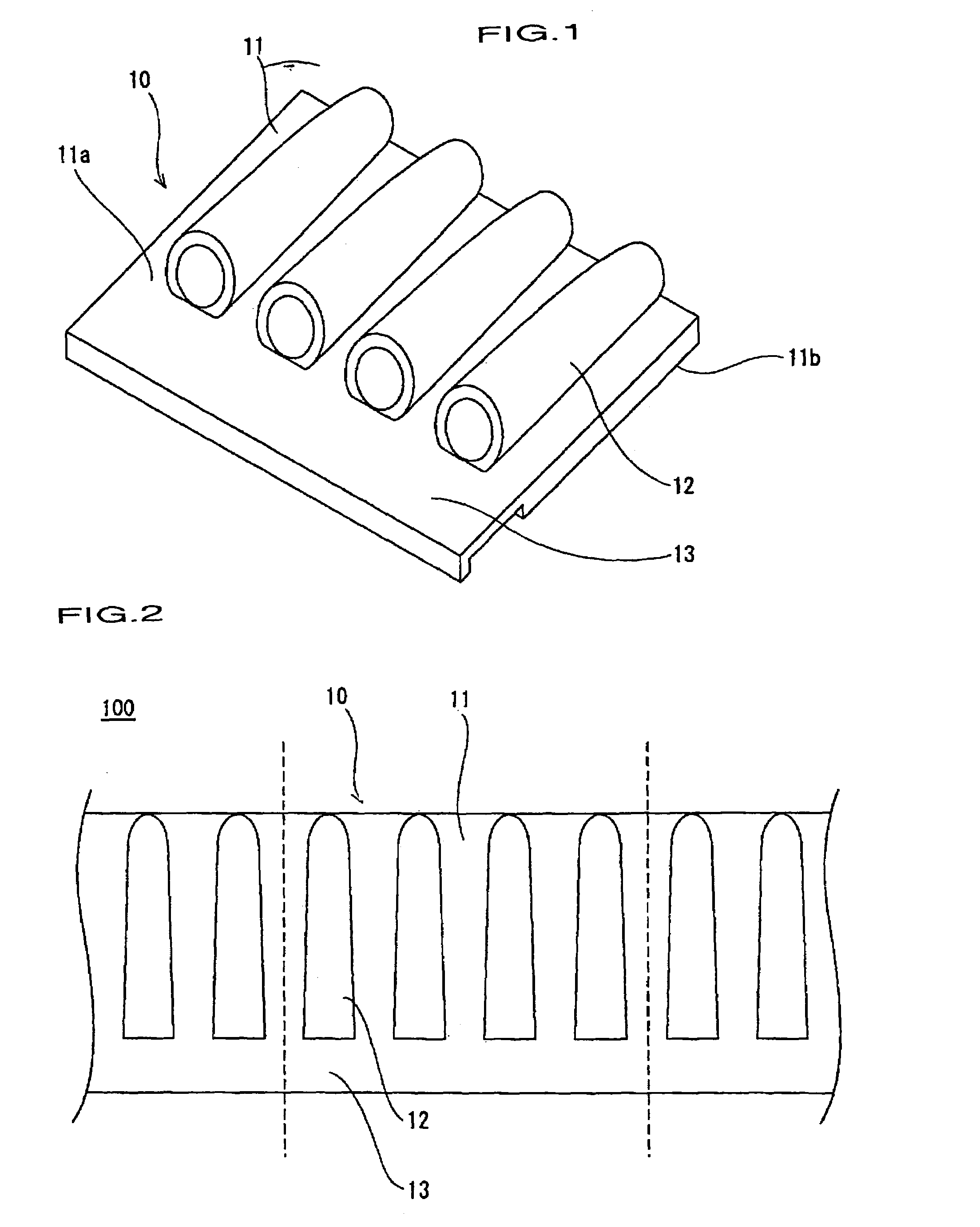

Waterproof joint section forming method and wire harness provided with waterproof joint section formed by the method

InactiveUS20100300748A1Reduce the number of partsReduce effortVehicle connectorsCharging stationsEngineeringFront end of line

Leading end sides of a plurality of wires to be electrically connected with each other are respectively inserted through a plurality of through holes formed in a waterproof rubber lid and the outer circumferential surfaces of insulating coatings of the respective wires are held in close contact with the inner circumferential surfaces of the respective through holes for sealing. The insulating coatings are peeled off at the passed-through ends of the wires to expose cores. The exposed cores are welded, fusion-bonded, soldered or fastened by a crimping terminal to form a terminal joint section. The terminal joint section is inserted into a protection cap made of a bottomed resin molding through an opening end. The waterproof rubber lid is fitted to an opening end of the protection cap to seal the interior of the protection cap accommodating the terminal joint section without injecting a waterproofing agent into the protection cap.

Owner:SUMITOMO WIRING SYST LTD

Protector cover for terminal group

InactiveUS7112745B2Reduce the amount requiredLess spaceInsulated cablesConnections effected by permanent deformationFlangeCable harness

A protector cover that protects multiple collected wire terminal group splices while reducing the space occupied by the wire harness by locating the protector cover on the wire harness. The protector cover encloses solder joined terminal group splices formed at the ends of branch wires that separate from trunk wires of a wire harness. Multiple caps, each into which a terminal group splice is inserted, are formed at intervals on one or both sides of a planar support member, and a taping flange is formed as an extension at the open end of the caps. A terminal group splice is inserted into each cap and secured therein by a tape wrapping that encompasses the taping flange and the branch wires. The planar support member is then attached to the circumference of the trunk wires through a tape wrapping.

Owner:SUMITOMO WIRING SYST LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com