Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

334results about "Seed preservation by freezing/cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preservation System for Nutritional Substances

ActiveUS20130273222A1Promote degradationEasy maintenanceMaterial analysis using sonic/ultrasonic/infrasonic wavesDigital data processing detailsBiologyNutritional content

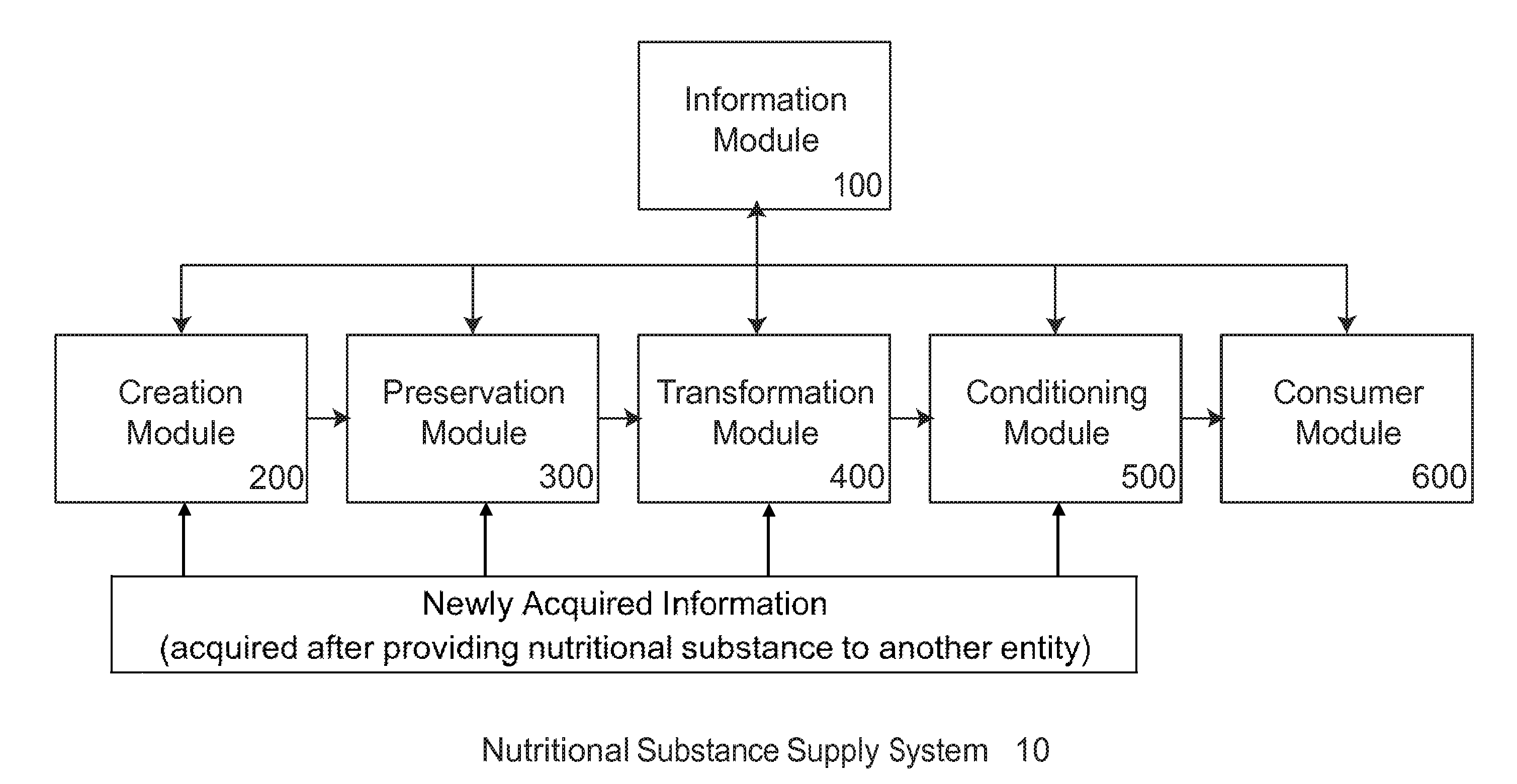

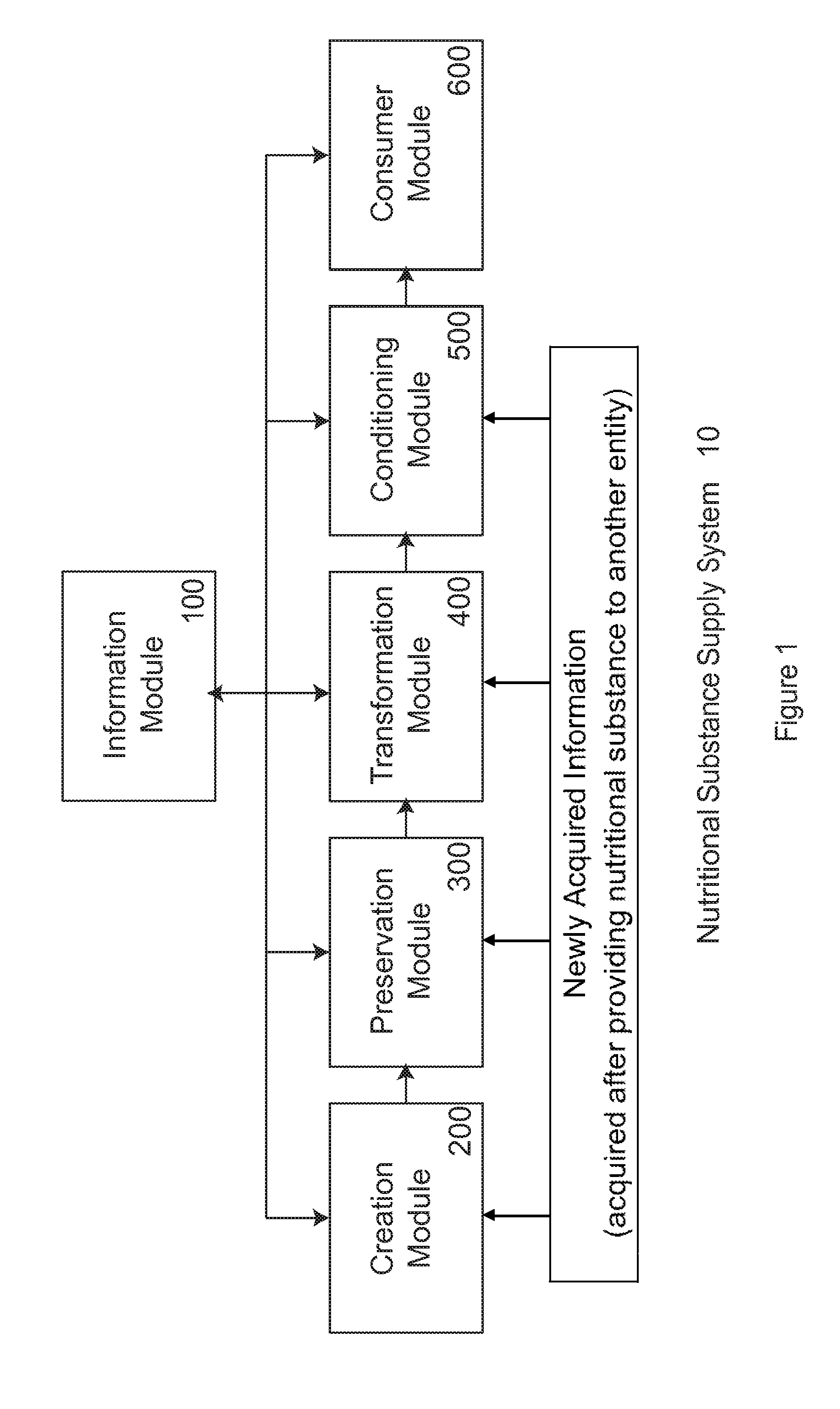

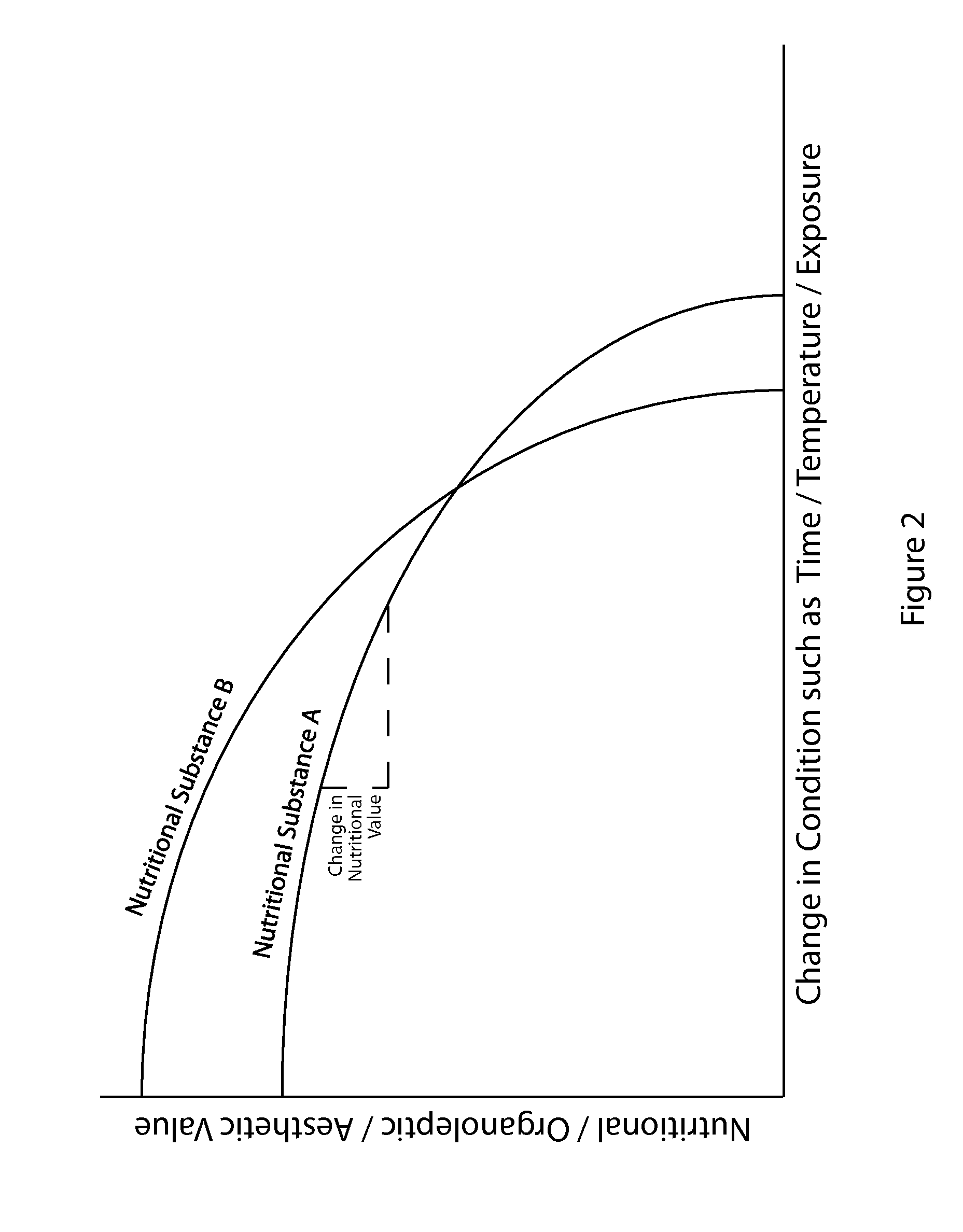

Disclosed herein is preservation system for nutritional substances. The preservation system obtains information about the nutritional substance to be preserved, senses and measures the external environment to the preservation system, senses and measures the internal environment to the preservation system, senses and measures the state of the nutritional substance, and stores such information throughout the period of preservation. Using this accumulated information, the preservation system can measure, or estimate, changes in nutritional content (usually degradation) during the period of preservation. Additionally, the preservation system can use this information to dynamically modify the preservation system to minimize detrimental changes to the nutritional content of the nutritional substance, and in some cases actually improve the nutritional substance attributes.

Owner:ICEBERG LUXEMBOURG S A R L

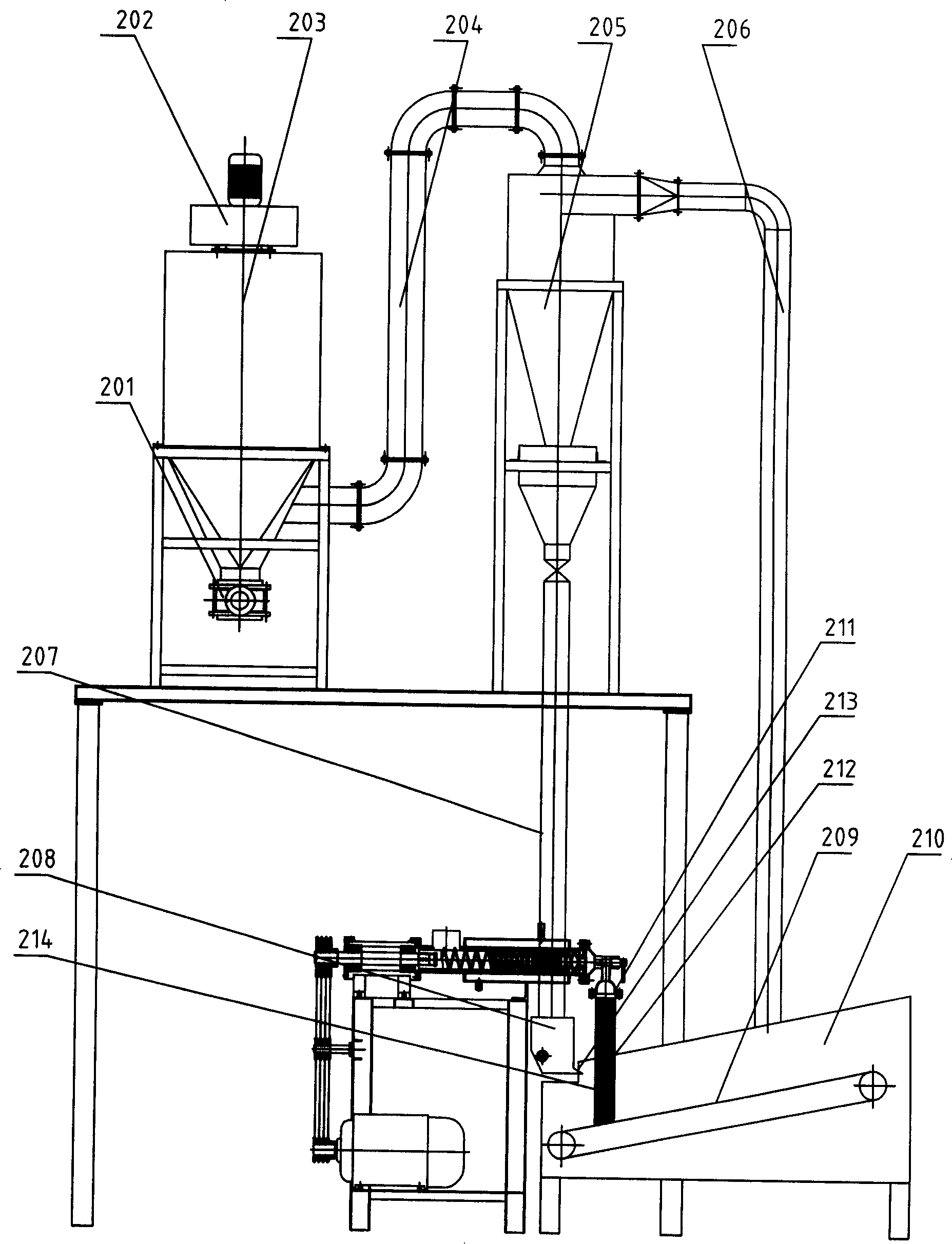

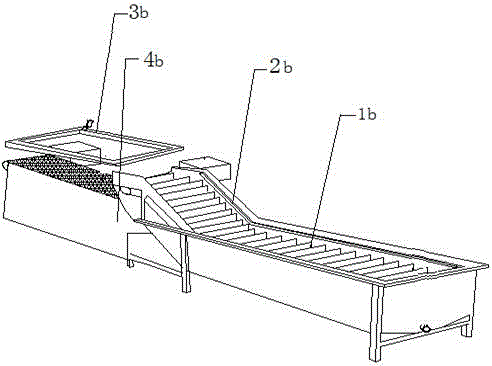

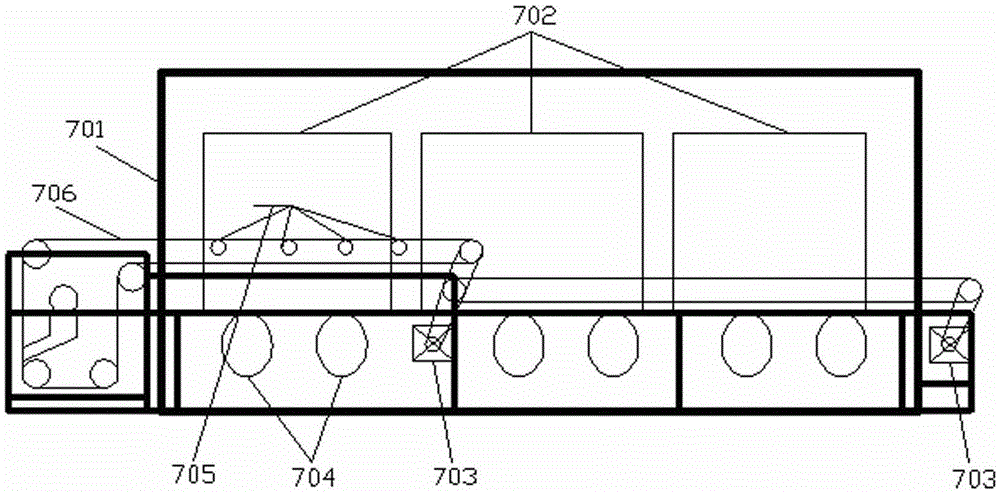

Fully-automatic convenient instant rice flour noodle production line and production technology thereof

InactiveCN101167541AQuality productionGreat tasteSeed preservation by freezing/coolingFood shapingEngineeringFully automatic

The invention relates to a production line of convenient instant rice flour and process technology, wherein the production line of the convenient instant rice flour comprises a rice treatment device, a cooking flour-mixing machine, a self-mature wire-extruding device, an aging device, a quantitative disconnecting device, a boxing shaping device, a powder block drying device, a powder block cooling device, and a packaging conveying device, which are orderly arranged according to the transfer direction of materials. The aging device comprises a rice vermicelli refrigerator, an aging machine and a continuous fluffer. The invention has the advantages of excellent product quality, wide adaptability, high performance, automaticity, low consumption, energy saving, high yield, health and environmental protection.

Owner:广州尧先机械有限公司

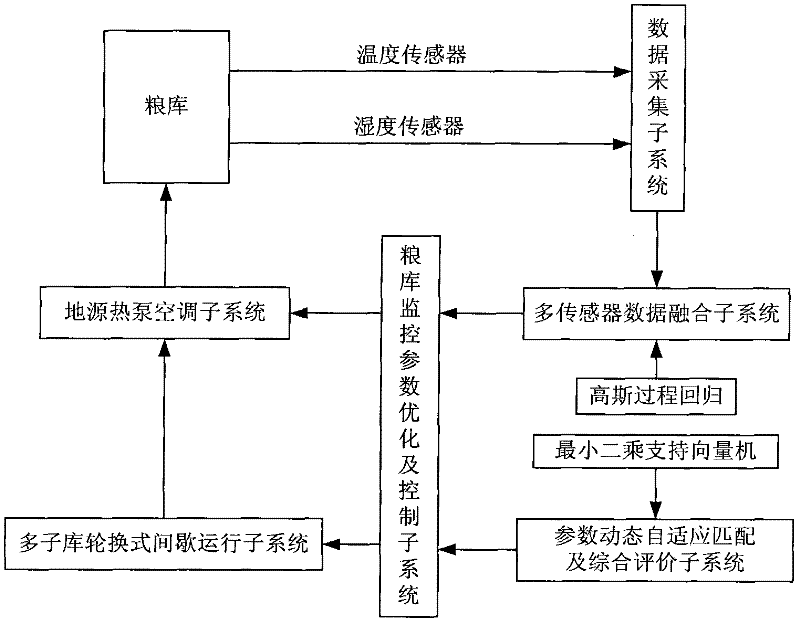

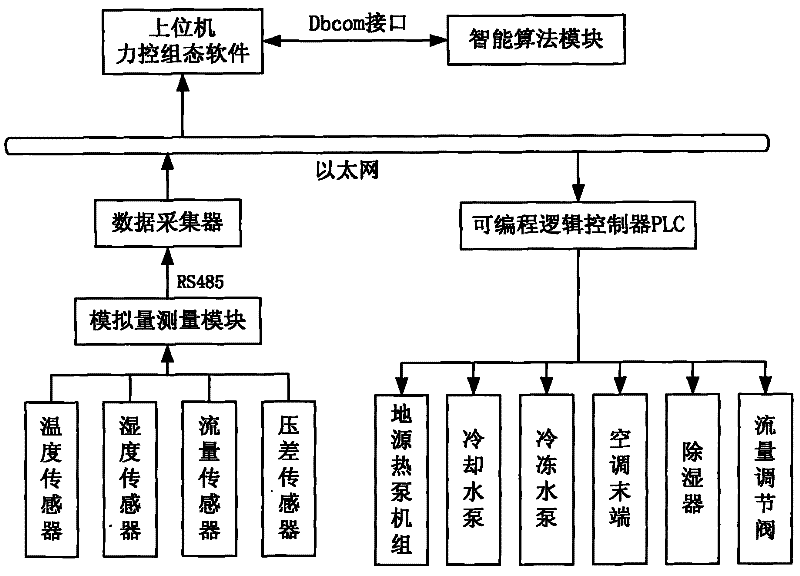

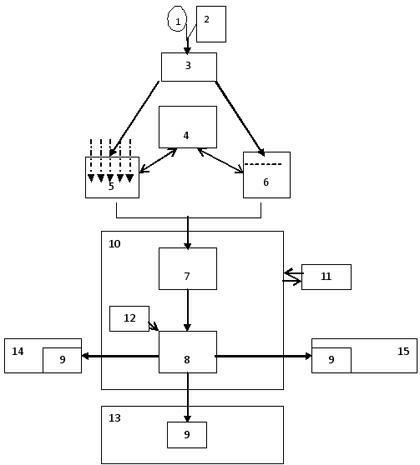

Intelligent shallow ground energy low temperature grain storage system

InactiveCN102283283AGuaranteed temperature and humiditySave moneyFood processingClimate change adaptationData acquisitionLeast squares support vector machine

The invention discloses an intelligentized superficial geothermal energy low-temperature grain storage system which comprises a ground source heat pump air conditioner subsystem, a data acquisition subsystem, a multi-sensor data fusion subsystem, a grain bin monitoring parameter optimization and control subsystem, a parameter dynamic adaptive matching and comprehensive evaluating subsystem and a multi-subbin rotational intermittent operation subsystem, wherein the ground source heat pump air conditioner subsystem is used as a cold energy source of a grain bin in the intelligentized superficial geothermal energy low-temperature grain storage system, and an automatic grain-condition monitoring center of the grain bin is established by combining with a Gaussian process regression-based data fusion technology; and a least square support vector machine optimized by using an optimal-worst particle swarm algorithm is applied to the prediction and control of grain storage environmental parameters of the grain bin so that dynamic adaptive matching of cold energy supply and cold energy demand is realized. The intelligentized superficial geothermal energy low-temperature grain storage systemhas the characteristics of high efficiency, intellectualization, man-machine interaction, energy saving, environmental friendliness and the like.

Owner:GUANGXI UNIV

Sweet corn grain production line and sweet corn grain production process

InactiveCN104799172AImprove qualityGuaranteed freshSeed preservation by freezing/coolingFood preparationProduction lineAgricultural science

The invention discloses a sweet corn grain production line and a sweet corn grain production process. The sweet corn grain production line comprises a withering system, a peeling machine, a threshing machine, a sweet corn grain uniform spreading and selection device, a sweet corn grain processing rinsing machine, a sweet corn grain processing blanching device, a cooling system, a sweet corn grain processing draining device, a quick-freezing system, a sweet corn grain selection mechanism, a sweet corn grain processing last-stage metal detection mechanism, a packaging mechanism and a metal detector, which are sequentially arranged in the material conveying direction. The sweet corn grain production process comprises the steps of raw material acceptance check, withering, peeling, threshing, selection, rinsing, blanching, cooling, draining, quick-freezing, selection, gold detection before packaging, packaging, gold detection after packaging and warehousing. By adopting the sweet corn grain production line and the sweet corn production process, the sweet corn grains with good quality can be produced, the freshness of the corn grain can be guaranteed, the nutrition of the corn can be prevented from being lost, the automation degree is high in the processing process, the labor intensity can be alleviated, and the streamline operation can be realized.

Owner:HENAN KEXI FOOD

Walnut kernel fresh-keeping method

InactiveCN102894080ASolve the preservation problemExtended shelf lifeSeed preservation by freezing/coolingNitrogenBiology

The invention discloses a walnut kernel fresh-keeping method. Walnut kernels are soaked, packaged in vacuum or nitrogen, added with a deoxidant and stored, so as to solve the problem of walnut kernel fresh-keeping, and prolong shelf life of walnut kernels. The method does not cause loss of nutritional components of walnut kernels, preserves almost all the nutritional value of walnut kernels, and is simple for processing and easy for industrial production; and the walnut kernels stored by the method provided by the invention do not degenerate for at least 6 months and generate no rancid odor; therefore, the method has obvious fresh-keeping effect.

Owner:GANSU LONGXIN CONSOLIDATED TRADING

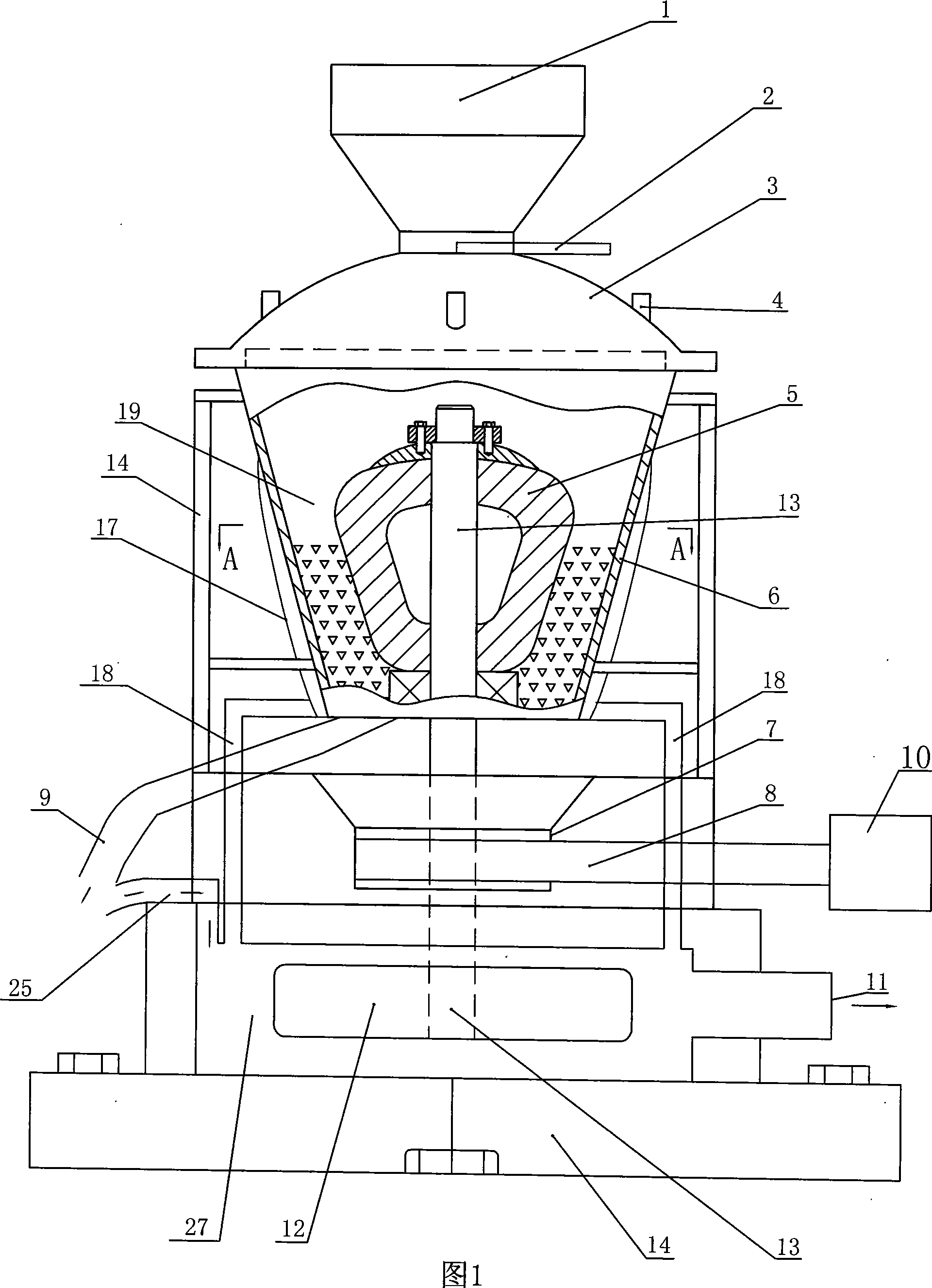

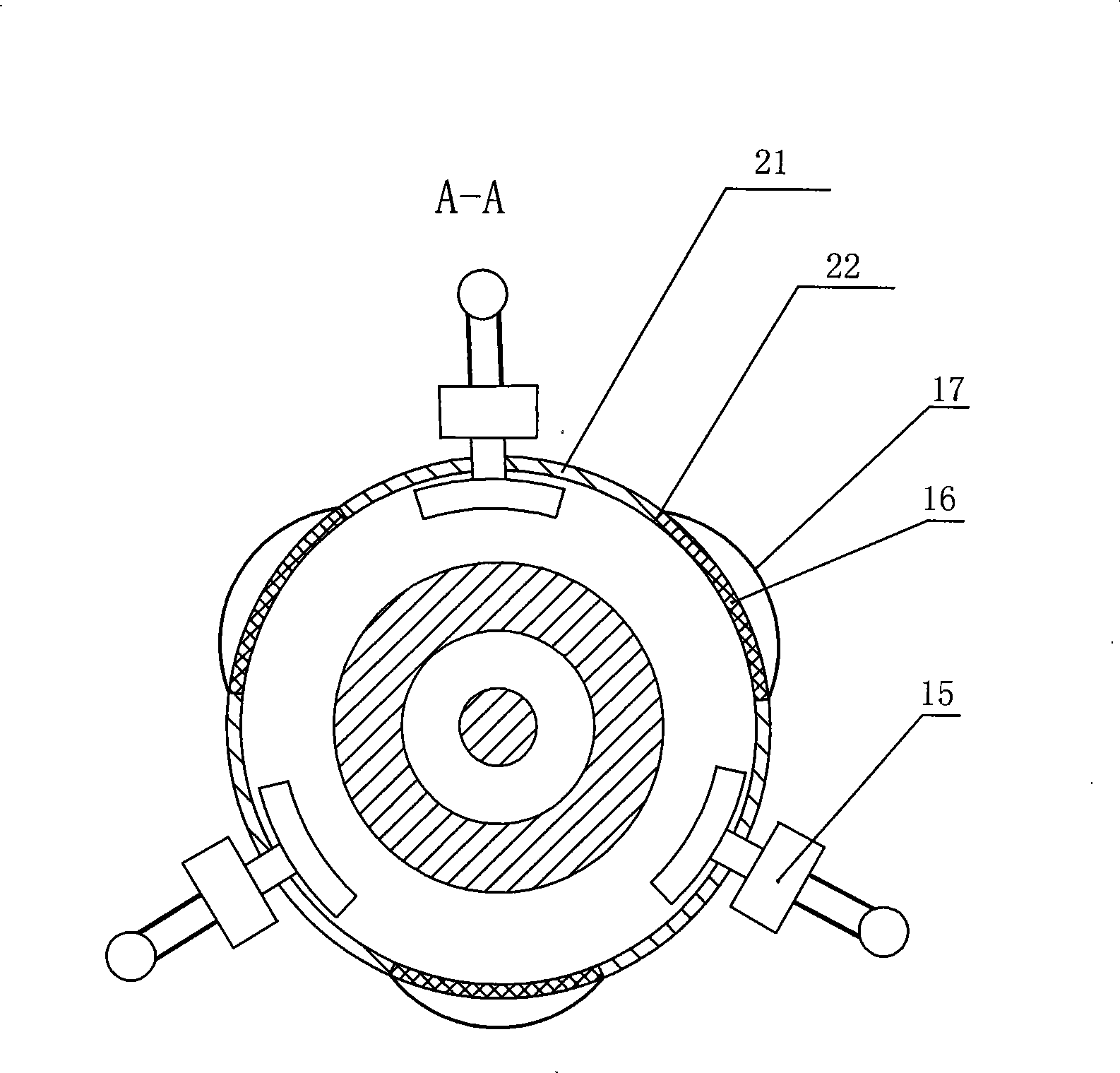

Method for peeling fresh kernel corn and machine for peeling quick freezing fresh kernel corn

ActiveCN101433363AGood peeling effectNo loss of nutritionSeed preservation by freezing/coolingVegetable peelingQuick FreezeHardness

The invention relates to a shelling method for fresh corn kernels and a quickly frozen fresh corn kernel sheller. The invention relates to the shelling method and the sheller. The invention solves the problem that the prior common grain sheller can not shell the fresh corn kernels. The shelling method comprises the following main steps: the fresh corn kernels are selected, stored and shelled in an environment of -40 to -30 DEG C and shelled after enzyme deactivation treatment and threshing; and the temperature in a grind cavity of the quickly frozen fresh corn kernel sheller is kept below -5 DEG C and chaff is removed. A grinding wheel (5) is arranged inside a grinding vessel (6); and at least one cooling air inlet (4) is arranged on a sealing cover (3). The fresh corn shelled through the method has good shelling effects and does not lose the nutrition of the fresh corn; the quickly frozen fresh corn kernel sheller is provided with the cooling air inlet, thereby having good heat dissipation effect, ensuring that the quickly frozen fresh corn kernels are not unfrozen by frictional heat during the process of shelling through mechanical friction, and consequently ensuring the hardness of the quickly frozen fresh corn kernels.

Owner:辽宁富安农业发展有限公司

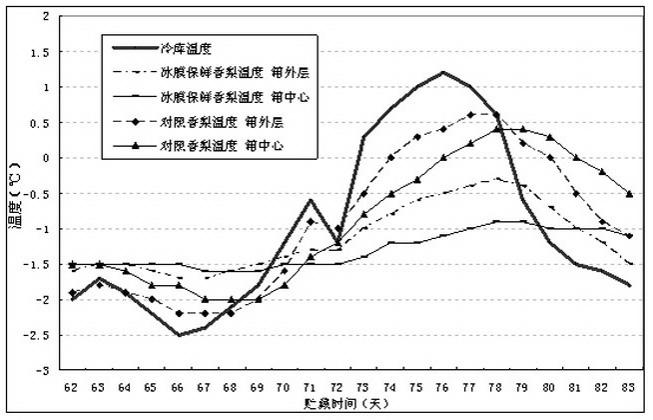

Fresh and alive agricultural product ice film freshness-retaining method

InactiveCN102144655AWith cold storage functionGuaranteed uptimeSeed preservation by coatingSeed preservation by freezing/coolingAgricultural engineeringAbsorbent material

The invention discloses a fresh and alive agricultural product ice film freshness-retaining method. The method comprises the following steps of: wrapping the product by using a water absorbent material; placing the product into a waterproof packaging box with holes; and soaking the product in water or spraying water on the product and then placing the product into a refrigerator to cool, so that water on the surface of the product and the water absorbent material are frozen into an ice film. In the whole storage period, the product is controlled to be stably in the temperature range of below 0 DEG C and above the freezing point of the product; and water is sprayed on the packaging box in due time, so that the thickness of the ice film is maintained. The method has the characteristics of good freshness-retaining effect, simple and reliable process, low investment and operating cost, capacity of storing by using the conventional refrigerator, and high commercial popularization value.

Owner:SHENZHEN YANGLIN TECH

Manufacturing process of quick-freezing corn

InactiveCN103734306AKeep fresh and plumpStop lossSeed preservation by heatingSeed preservation by freezing/coolingQuick FreezeMicroorganism

The invention discloses a manufacturing process of quick-freezing corn. A preparation method comprises the following steps: peeling and inspecting; soaking and cleaning; blanching; cooling, and draining; shaping; quickly freezing; inspecting and packaging; storing. The manufacturing process has the characteristics that the freshness and fullness of the corn are maintained after the corn is stored for 12 months; by adopting the blanching technique, the loss of nutrition components of corn is well prevented, and the microorganisms and ova attached on the corn are killed, so that the edible safety is ensured; the air in the corn is removed, the pressure formed by the ice crystals during freezing is reduced, the oxidizing degree of the raw material is correspondingly decreased, and the color and nutrition of the corn are favorably maintained; the corn is convenient to carry, and the fresh corn can be eaten at any time and any place.

Owner:周光英

Natural and crisp biscuit prepared by freezing method and preparation process thereof

InactiveCN101579083AImprove retentionHigh nutritional valueSeed preservation by freezing/coolingFood preparationYeastFood additive

The invention provides a natural and crisp biscuit prepared by a freezing method and a preparation process thereof. The preparation process comprises the following steps of: cooking and mixing raw materials of flour type and raw materials of starch type to prepare a biscuit parison; freezing the biscuit parison at the temperature ranging from -18 DEG C to -20 DEG C for 72-168 hours, subsequently taking out the biscuit parison, defreezing and drying the biscuit parison, thus preparing the biscuit with natural and crisp taste. The freezing method is adopted to naturally expand the biscuit, the methods of deep-fry, expansion and baking are not adopted, yeast powder, leavening agent, baking powder and various other chemical food additives are not needed to be added, the biscuit product is loosen and delicious, has no harmful additives, and is beneficial to human health; furthermore, the preparation process is simple and practicable and is suitable for large-scale popularization and application.

Owner:陈义

Stored grain temperature adjusting method

InactiveCN101919442ASpeed up heat dissipationEfficient use ofFood processingSeed preservation by freezing/coolingTemperature controlCold air

The invention discloses a stored grain temperature adjusting method, which comprises the following steps of: A, closing all windows and ventilation openings of a warehouse to make the warehouse in a sealed state; and B, starting an axial flow fan on the top of the warehouse to make the whole warehouse and grain piles form negative pressure, discharging the accumulated temperature of the warehouse space part, and making the cold air of the cold cores of the grain piles move to the upper layers the grain piles so as to reduce the grain temperature of the upper layers of the grain piles and the temperature in the warehouse and meet the temperature requirement of temperature-controlled stored grain. The method also comprises a step of compensating cold quantity by using a refrigerator, wherein the axial flow fan on the top of the warehouse is started in the step B, when the accumulated temperature of the warehouse space and the grain temperature of the upper layers of the grain piles is reduced by not more than 28 DEG C, the ventilation openings of a ground cage ventilation pipe network of the warehouse are opened and linked with the refrigerator, and the refrigerator is started for refrigeration, so the stored grain temperature can be reduced and the requirement of standard low-temperature grain storage is met. Because a sealed system is adopted and the negative pressure is formed in the warehouse and the grain piles, the radiating speed of the granary is improved, the cold sources of the cold cores of the grain piles are effectively utilized, the energy is saved and the operating cost is reduced.

Owner:陈国利 +4

Production equipment and production method of quick-frozen corns

InactiveCN105380082AEasy to processEasy laborSeed preservation by freezing/coolingThreshersQuick FreezeProduction line

The invention discloses production equipment and production method of quick-frozen corns. The production equipment comprises a peeling machine, a head and tail cutting machine, a corn stigma washing machine, a conveyor, a pre-cooking machine, a steaming machine, a cooler, an elevator, a vibration material distribution machine, a quick-freezing machine and a cutting machine, wherein the machines are arrayed in sequence to form a production line. With the adoption of the production line, the production of the quick-frozen corns is realized; and the production method comprises the following eleven steps: peeling off, cutting heads and tails, removing corn stigmas and washing, pre-boiling, steaming, cooling, lifting and distributing materials, quickly freezing, cutting, checking and packaging and storing. According to the production method of the quick-frozen corns, the corresponding production equipment is used for carrying out all steps of treating the corns and all production equipment can be communicated through a conveying belt; and the automation degree is high, manual operation steps are greatly reduced, the production efficiency is high, the labor of workers becomes easy, time and labor are saved, and the safety of foods is effectively improved.

Owner:HEBEI DELI FOODSTUFF CO LTD

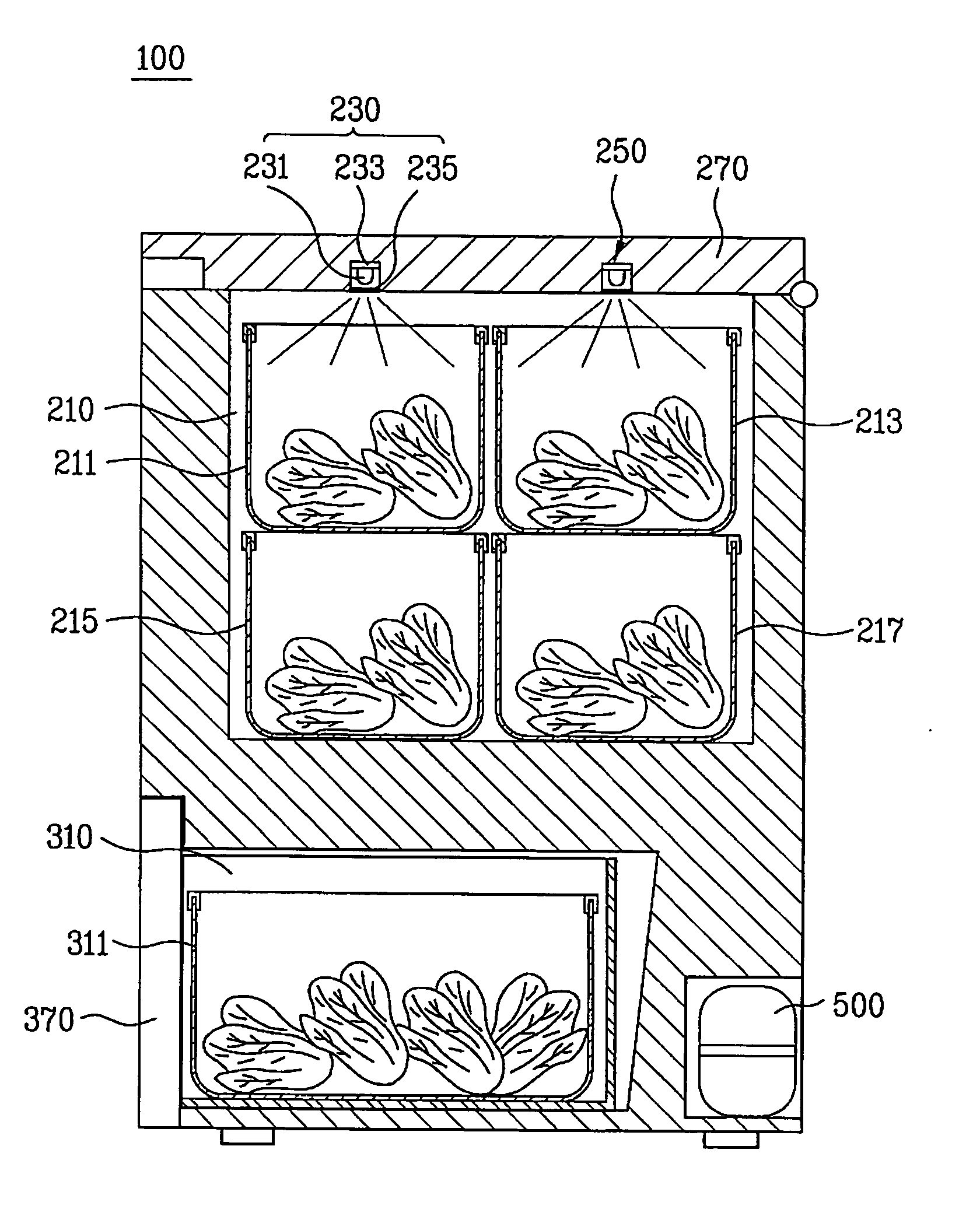

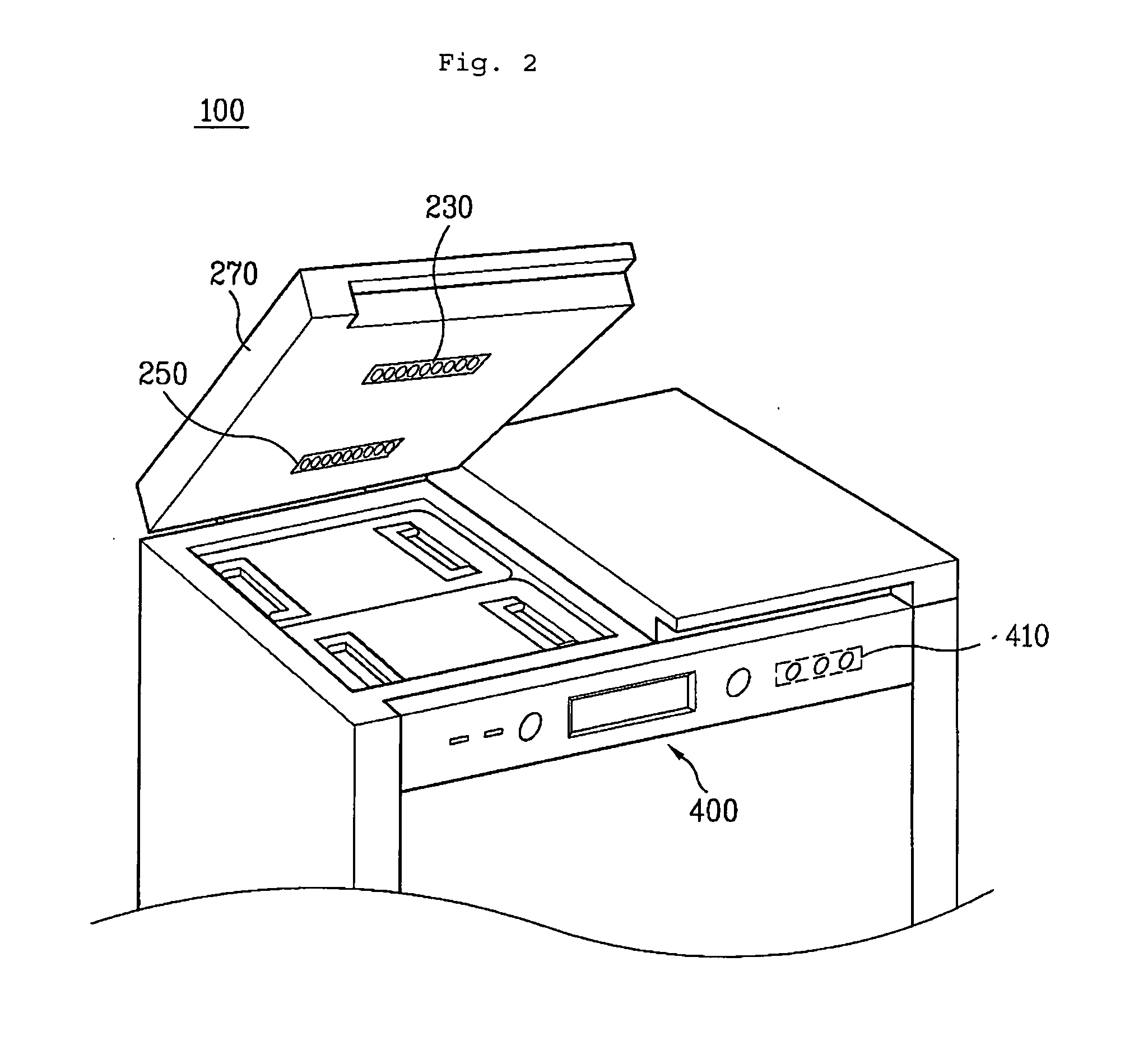

Kimchi refrigerator and control method of the same

ActiveUS20070180843A1Improve scalabilityImprove sour tasteAir-treating devicesMilk treatmentEngineeringRefrigerated temperature

Owner:LG ELECTRONICS INC

Chinese chestnut brown stain preventing processing technology

ActiveCN102084894AIncrease the degree of glycationImprove the flavor of the valleySeed preservation using chemicalsSeed preservation by heatingAlcoholSweetness

The invention discloses a Chinese chestnut brown stain preventing processing method which comprises the following steps of: 1, screening Chinese chestnuts; 2, processing at low temperature; 3, processing with CO2: putting the Chinese chestnuts in an environment with the CO2 concentration of 5-30 percent (volume) and temperature of 10-20 DEG C and relative humidity of 85-95 percent for 2-20 days; 4, carrying out gas stifling treatment on the Chinese chestnuts by adopting ethylene or alcohol; 5, removing hulls and red skins; 6, inactivating enzyme: putting Chinese chestnut kernels in food-grade acidic liquid with the temperature of 80-100 DEG C or food-grade acidic stream with the temperature of 100-110 DEG C, and controlling the pH value of the liquid or stream to be 1-6 and the processing time to be 5-20min; 7, curing: putting the Chinese chestnut kernels into food-grade alkali liquid with pH value of 7-12 at a temperature of 90-100 DEG C, and processing for 5-20min; 8, bagging and sealing; 9, sterilizing with back pressure at high temperature and high pressure; and 10, cooling to normal temperature for storing. The Chinese chestnuts processed by using the technology maintain the special grain flavor and the sweetness while keeping the natural yellow color, and is best in color, favor and taste.

Owner:TIANJIN UNIV OF SCI & TECH +3

Storing and processing method of rice

InactiveCN103053685AImprove freshnessIncrease elasticitySeed preservation by freezing/coolingRice dishesAgricultural engineering

The invention relates to a storing and processing method of rice and belongs to the technical field of crop processing. The process disclosed by the invention comprises the following steps: feeding into a warehouse: feeding wet rice into the warehouse; removing water: controlling the water content of the rice to 15-16% in a manner of warehouse ventilation; storing at low temperature: reducing the temperature of the warehouse to 18-25 DEG C to carry out low-temperature storage; and carrying out low-temperature and high-humidity processing. According to the process disclosed by the invention, the water content and the temperature of processing and storing the rice are controlled and the low-temperature and high-humidity processing is carried out at the water content and the temperature, so that the oxidation degree of fatty acid is low and the water absorbing speed in a process of immersing the rice to make rice is low; and the rice has the characteristics of small cracks in the water, good elasticity, good appearance and high freshness, and the rice has good edible quality, good mouth feel and good taste.

Owner:银尧明

Green soybeans whose color is prevented from discoloring

InactiveUS7018669B2Avoid decompositionRetain colorMilk preparationDough treatmentChlorophyll aDecomposition

A green soybean having a deep green color, prevented from discoloring, and being adaptable for chilled distribution is provided as a cooked and frozen product. The green soybean is hard to discolor and is frozen after cooking. The green color is retained even in a condition exposed to illumination of light. The green soybean contains chlorophyll a of not less than 3.8 g / 100 g wet weight. A material for suppressing decomposition of chlorophyll, preferably an anti-oxidation material, e.g., β-carotene, is accumulated in tissues of the green soybean. Preferably, β-carotene of not less than 750 μg / 100 g wet weight is accumulated in the green soybean. The invention also provides a green soybean thawed from the frozen green soybean. The thawed green soybean is adaptable for chilled distribution.

Owner:NIPPON SUISAN KAISHA LTD

Process for storing and processing walnuts

InactiveCN103349312AExtended shelf lifeChurn does not causeSeed preservation by freezing/coolingFood preparationWalnut NutProcess engineering

The invention discloses a process for storing and processing walnuts. The process comprises the following steps: S1, picking out diseased walnuts from dry walnuts; S2, removing walnut shells, grading, screening, and removing impurities; S3, drying walnut kernels; S4, packaging the walnut kernels; S5, storing the walnut kernels; and S6, processing the walnut kernels. The process has the benefits as follows: a storage process of drying, vacuum packaging and refrigerating is adopted instead of a processing process of frying, boiling or the like of the walnut kernels, causing the loss of the nutrient content of the walnut kernels before storage, so that the quality guarantee period of the walnut kernels can be prolonged and the loss of the nutrient content of the walnut kernels cannot be caused; the process is simple, low in cost and easy to realize; and the stored walnut kernels are processed, so that the quality guarantee period of a product is further prolonged and the added value of the product is increased at the same time.

Owner:SICHUAN MAOHUA FOOD

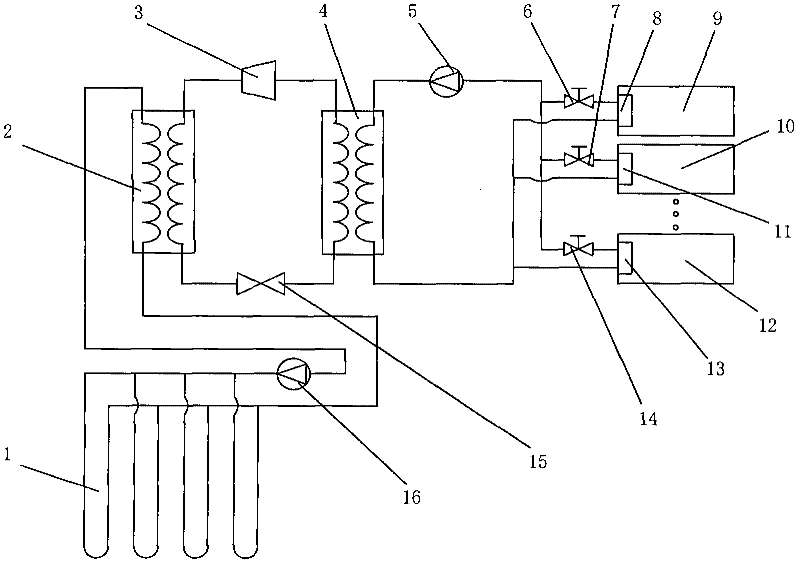

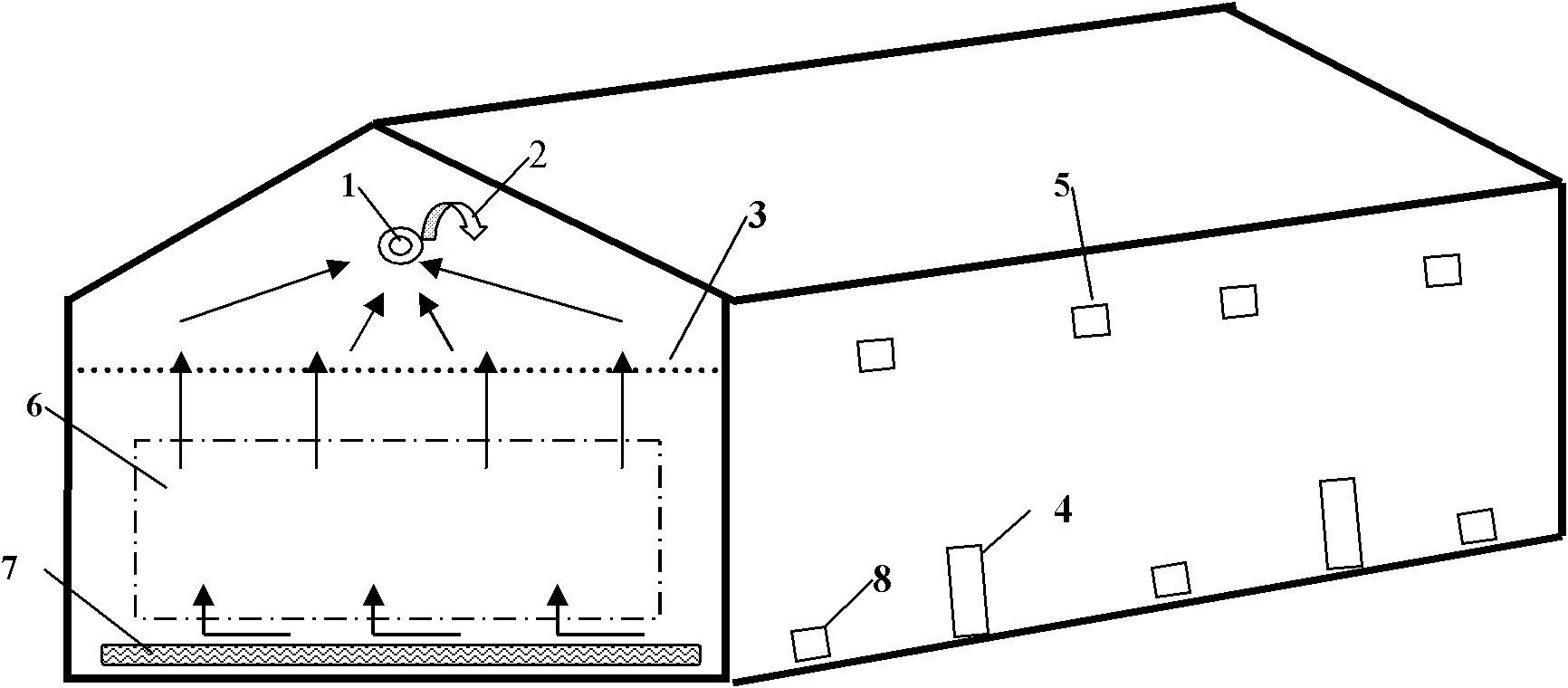

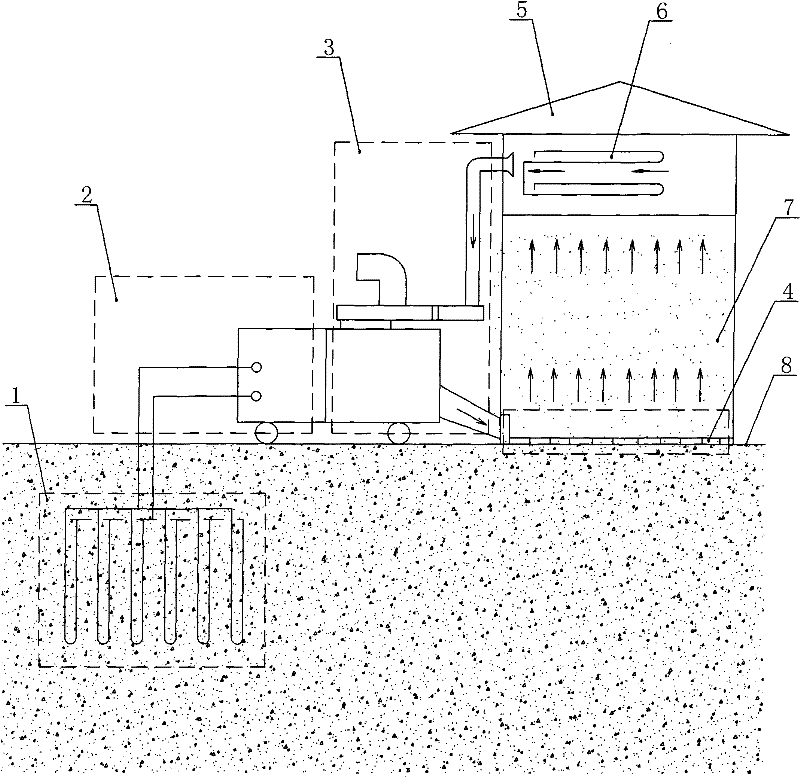

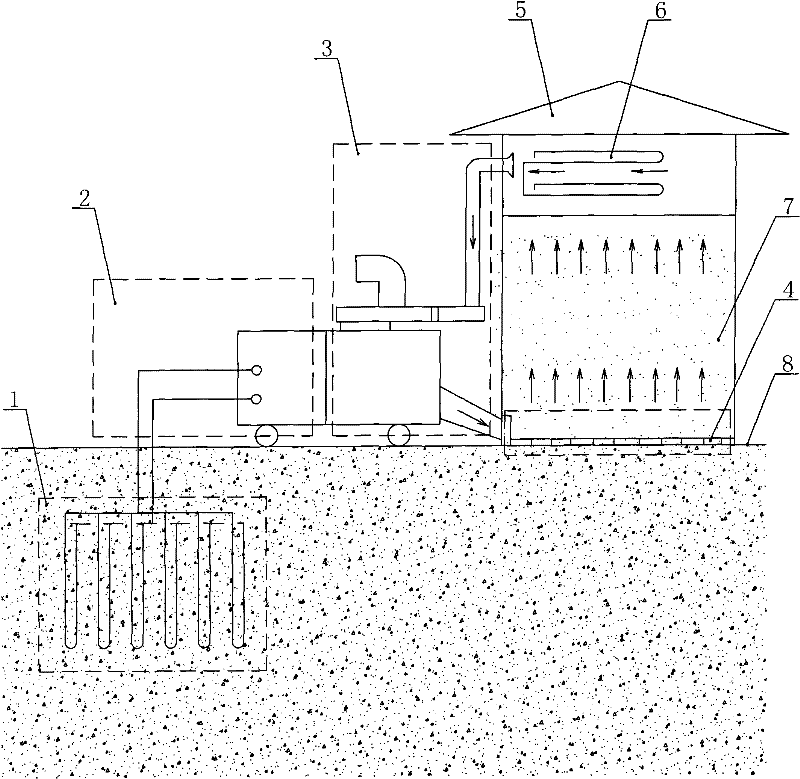

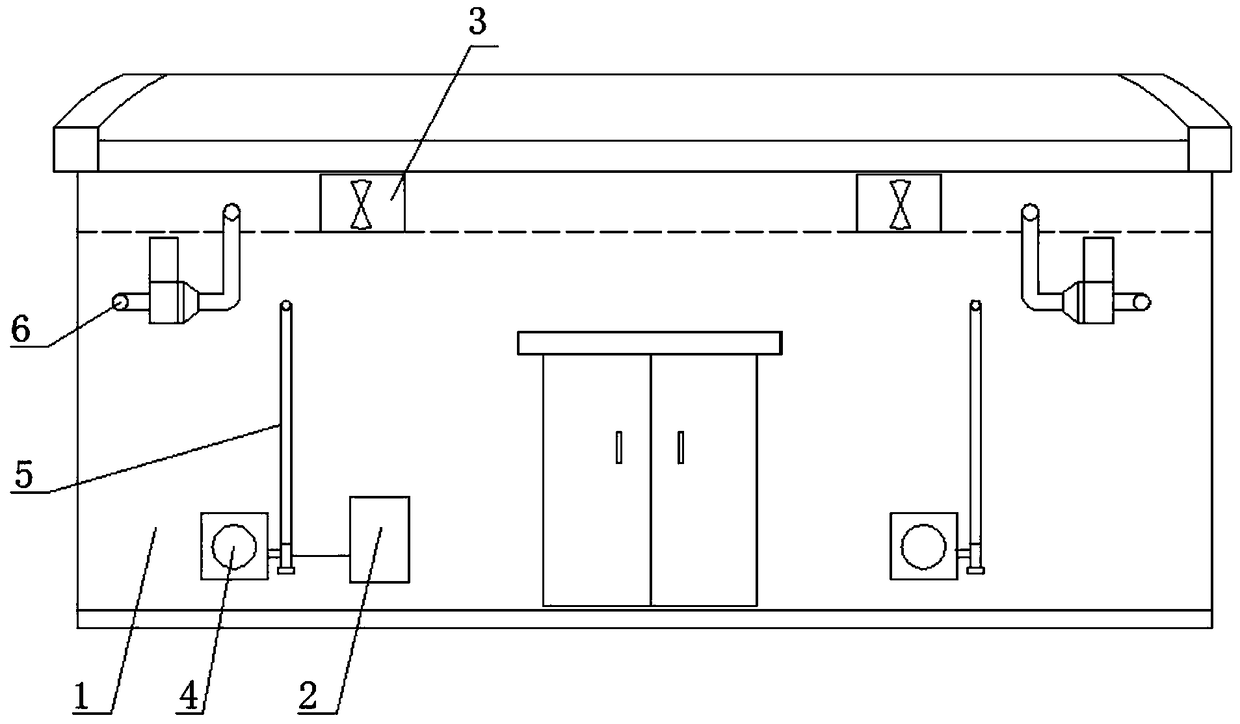

Geothermal-energy low-temperature grain storage system for grain store

InactiveCN102524382AImprove cooling effectReduce cooling costsLighting and heating apparatusFree-cooling systemsGrain storageEngineering

The invention discloses a geothermal-energy low-temperature grain storage system for a grain store in the field of refrigerating plants. The geothermal-energy low-temperature grain storage system comprises a shallow geothermal-energy collecting system for collecting geothermal energy, wherein the shallow geothermal-energy collecting system is connected with an energy conversion system; an output end of the energy conversion system is connected with a refrigerant circulating system; the refrigerant circulating system is connected with a storehouse; an intra-store ventilation system is arranged on the bottom part of the storehouse; and a grain flour circulation pipe is arranged on the top part in the store. According to the invention, the geothermal-energy conversion system is used for converting the geothermal energy into refrigerating energy for refrigerating grain in the grain store, so that the problems that the requirement of natural refrigeration on seasonality is high and the mechanical refrigeration is high in cost in the prior art are solved. The geothermal-energy low-temperature grain storage system is suitable to being used for refrigerating various grain stores.

Owner:王诚本

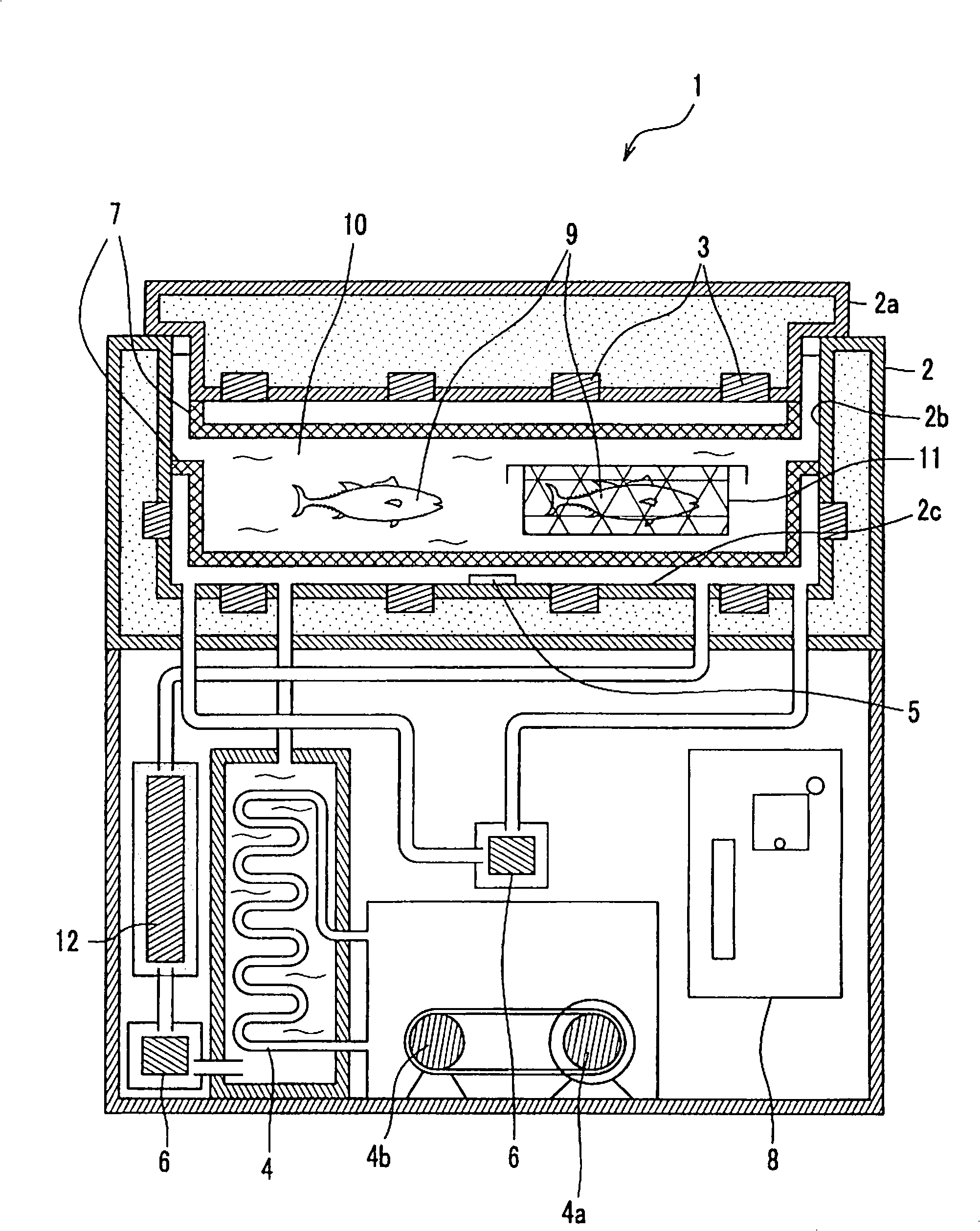

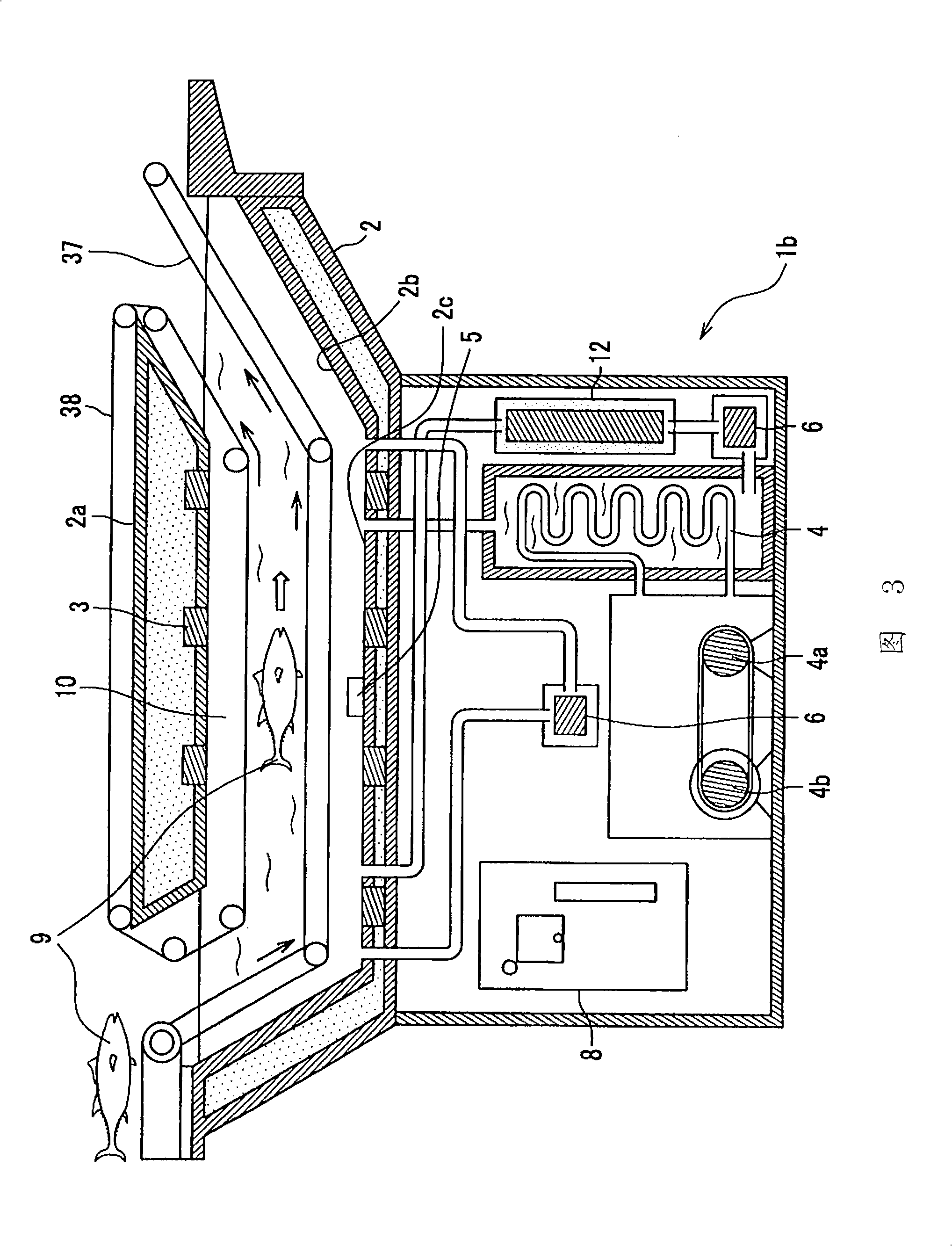

Apparatus for cooling food under water and maintaining water temperature therefor

InactiveCN101336746AKeep freshMaintain qualityMeat/fish preservation by heatingFruits/vegetable preservation by heatingCold airCelsius Degree

The present invention provides an underwater-cooling water-temperature maintaining apparatus of food, and the aim of the invention is to provide an apparatus which cools and preserves the food without freezing the food through a method without cold air. The underwater-cooling water-temperature maintaining apparatus of food includes: a water tank where a cooled stuff and cooling treated water of which a freezing point is not more than zero Celsius degree; a treated water cooler configured to cool the cooling treated water; a water temperature detection sensor configured to detect a water temperature of the cooling treated water; an agitator pump configured to equalize the water temperature of the cooling treated water in the water tank; ultrasonic vibrators configured to oscillate ultrasound toward an inside of the water tank in order to prevent the cooled stuff from being frozen; and a controller configured to control the ultrasonic vibrators, the water temperature detection sensor, the treated water cooler, and the agitator pump so as to maintain the water temperature of the cooling treated water at a temperature at which the cooled stuff is not frozen.

Owner:SHINYOU SANGYO

Paddy quality-guaranteeing storing process

InactiveCN108307813AAgriculture tools and machinesSeed preservation by freezing/coolingAutomatic controlGrain storage

The invention discloses a paddy quality-guaranteeing storing process. According to the process, detected temperature and humidity parameters are compared, and according to the precise judgment of ecological conditions in different grain storing ecological regions, barn maintenance structures and targeted grain temperature of different months, real-time automatic control of ventilation devices, refrigeration devices, circulation devices and the like is timely carried out, so that the targeted temperatures of each point and each layer in the grain piles during the whole period of paddy storing are met, and the purposes of quality guaranteeing and loss reduction of paddy storage are achieved. The grain pile volume in the barn is large, so that the temperature inside the grain piles is low insummer, and the surface grain temperature of the grain piles is high. The cold storage performance of the barn is fully utilized in the process, the cooling capacity of the natural environment is utilized for cold storage in winter, and the cooling capacity stored inside the grain piles is utilized for cooling the surface grains in summer, so that the storing process provided by the invention hasthe advantages of energy conservation and uniform grain storage temperature.

Owner:CHINA GRAIN RESERVES CORP CHENGDU GRAIN STORAGE SCI INST

Rice seed cold storage method

ActiveCN104126661ASolve dehydrationSolve agingSeed preservation by freezing/coolingSeed preservation by dryingGas compositionProduction chain

The present invention discloses a rice seed cold storage method, and relates to a field of agricultural product fresh keeping storage. The method includes the following steps: cleaning and selecting, pre-cooling, sterilization, spraying of a fresh-keeping agent, loading of a moisture bag, warehouse disinfection, controlling of the temperature, controlling of the content of oxygen and carbon dioxide, controlling of the moisture of warehouse and ex-warehousing. The method of the present invention has the following advantages that the cold storage method determines appropriate conditions for the rice seed storage, ensures reasonable temperature, moisture and gas composition inside the warehouse, solves the problems of water losing, aging, yellowing, germination, fast decaying during the process of rice seed storage, improves the rice storage time without destroying the texture of the rice seed, promotes the development of the rice industry, increases the added value and promotes the construction of an agricultural production chain demonstration mode.

Owner:巢湖春友种业科技有限公司

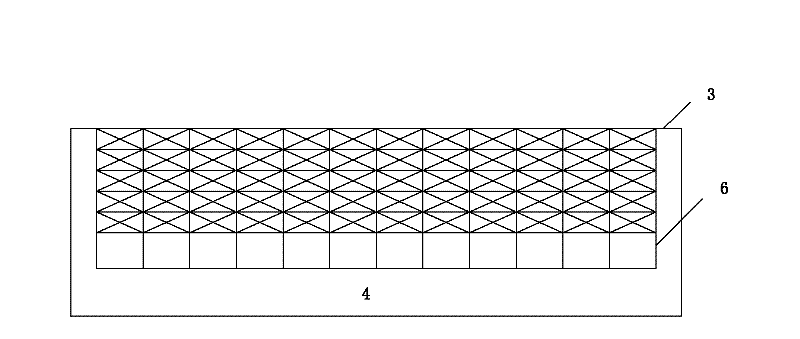

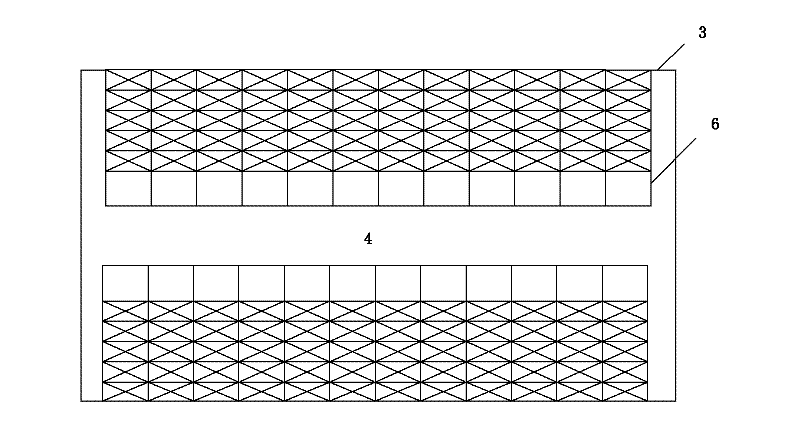

Unitized storage granary and storage method thereof

InactiveCN102187772AGuaranteed qualityLong storage periodAgriculture tools and machinesSeed preservation by freezing/coolingOperational costsMonitoring system

The invention discloses a unitized storage granary which comprises at least one layer of compartment, wherein the compartment of each layer comprises a plurality of storage units with independent and controllable storage conditions, and the storage capacity range of each storage unit is 5-1,000 tons; and the compartment of each layer comprises an operating area for independently carrying out feed and delivery for one or more storage units. Each storage unit with independent and controllable storage condition comprises a temperature monitoring system, a humidity monitoring system, a gas component monitoring system, a ventilation monitoring system and / or a fumigation system. Each storage unit has heat insulation and / or airtight function. The operating area can be arranged at two sides, one side or the middle of the compartment. Fixed and / or mobile conveying equipment is arranged in the operating area. The unitized storage granary has the advantages of prolonging the storage life of grains, reducing energy consumption, reducing the consumption of chemical fumigant and reducing environmental pollution; and because of the storage units, the storage units are mutually separated with the operating area, mutual influence is avoided, scientific management is facilitated, and the operating cost is saved.

Owner:ACAD OF STATE GRAIN ADMINISTRATION +2

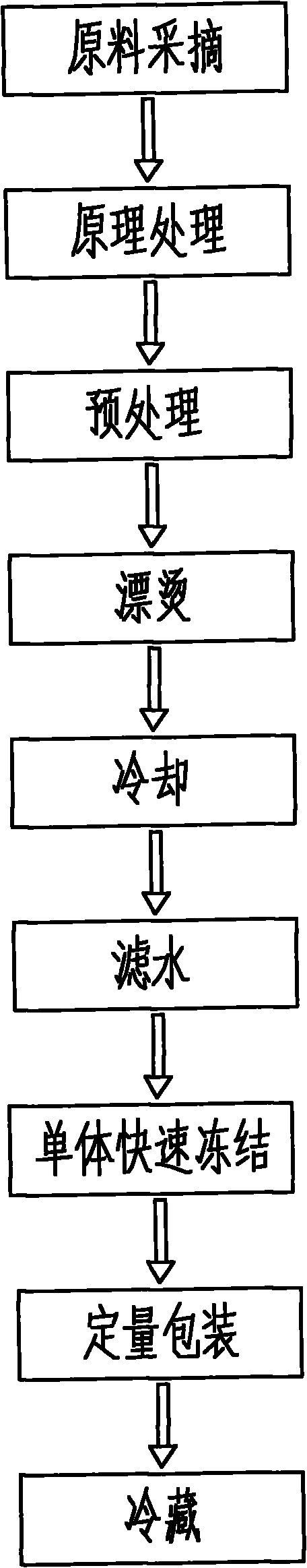

Processing method of green sword beans

InactiveCN102461659AMaintain nutrientsAvoid churnSeed preservation by heatingSeed preservation by freezing/coolingFlavorPre cooling

The invention discloses a quick-freezing and drying method of green sword beans, comprising the following steps of: selecting, removing ends and veins, washing, blanching, precooling, detearing, individually quick freezing, packaging and storing. The freshness of the produced green sword beans is maintained to the maximum. In addition, original color, flavor and nutritional components of the green sword beans are also maintained.

Owner:DONGTAI OLIVERFOOD

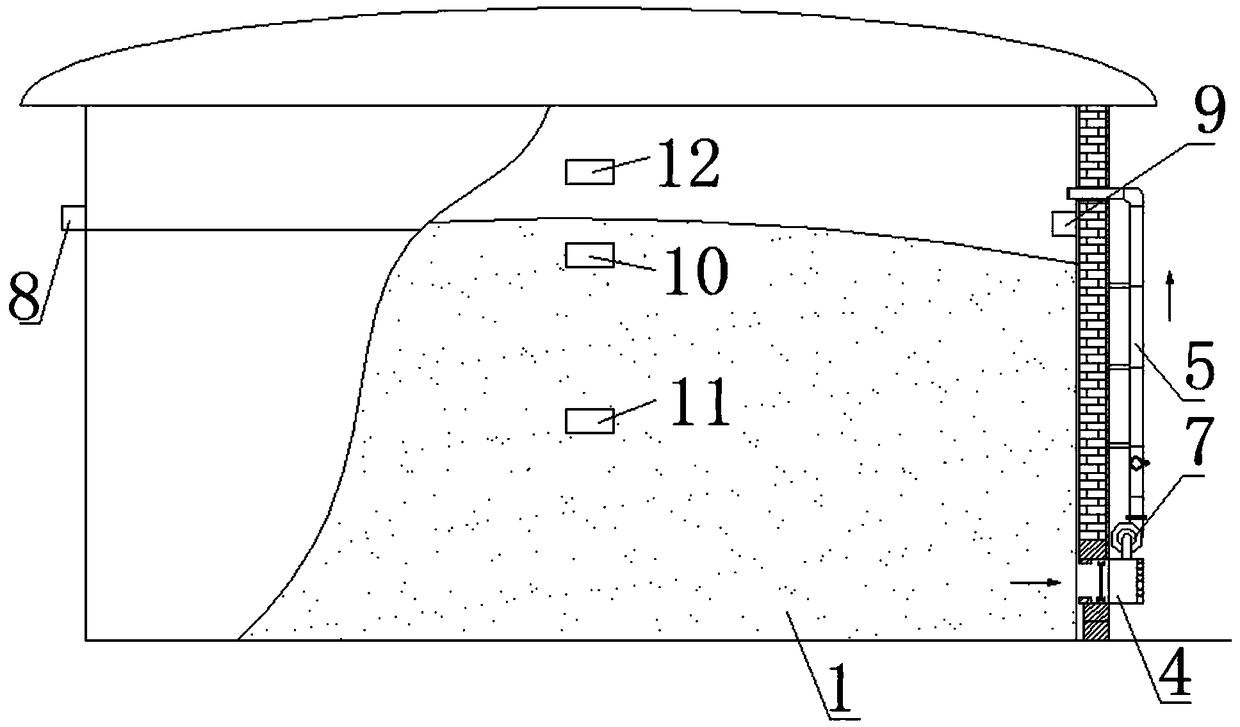

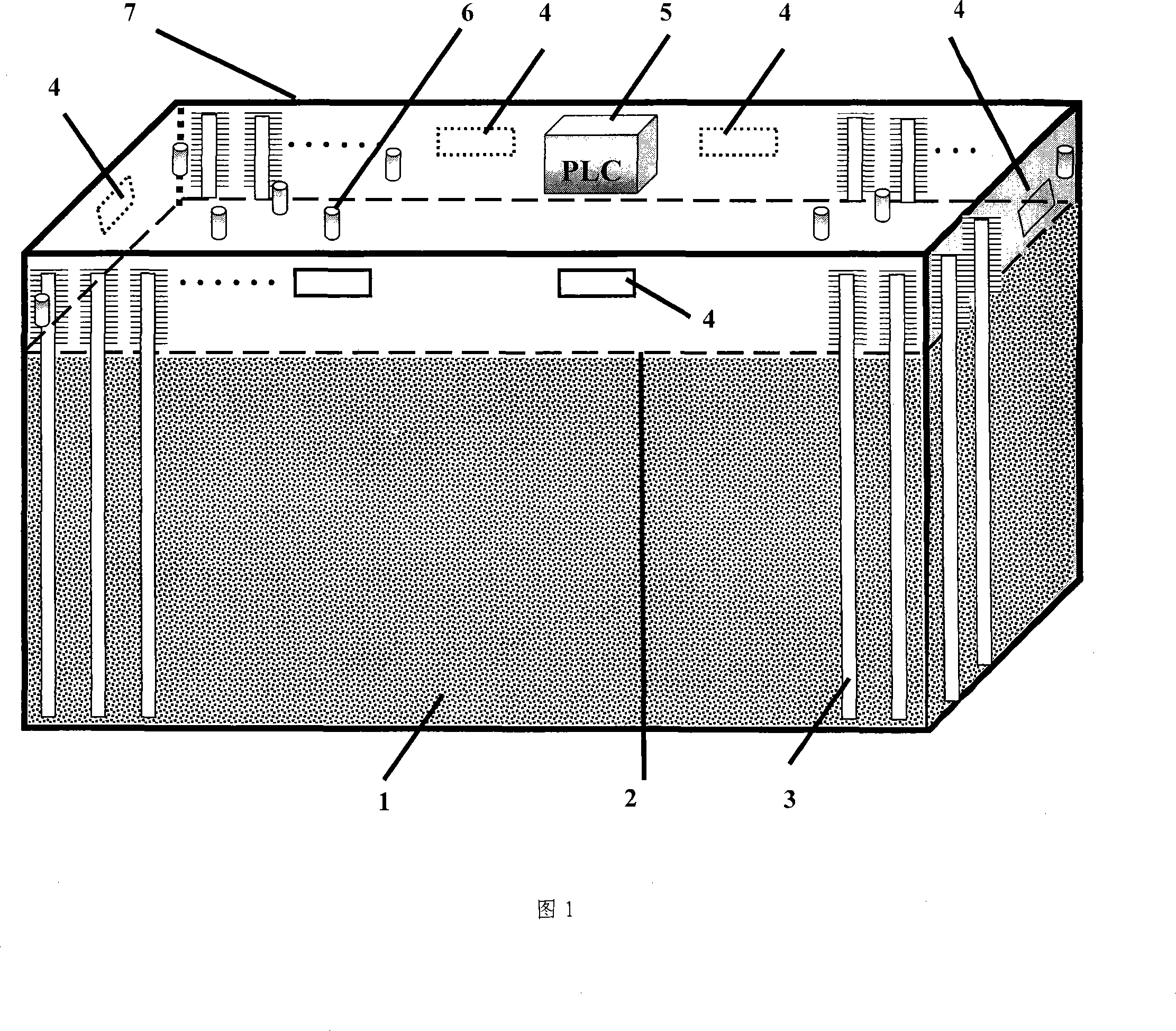

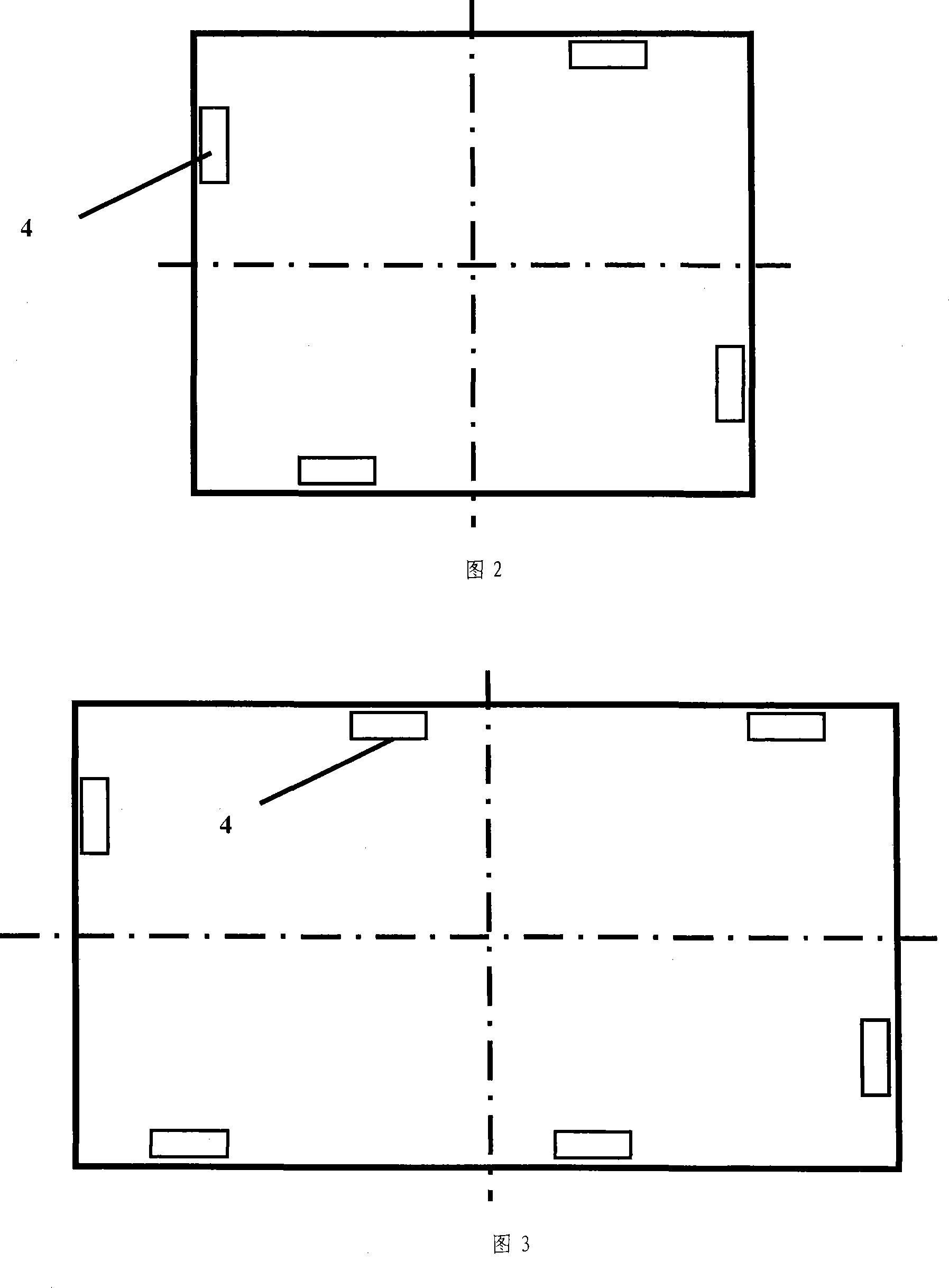

Low temperature storing grain method and system

InactiveCN101156628AExtended service lifeAvoid damageSpace heating and ventilation safety systemsLighting and heating apparatusPower conditionerAutomatic control

The invention provides a grain storage method and the system thereof in the low temperature, and belongs to the low temperature grain storage technical field. The method and the device thereof are characterized in that (1) the heat conducted from the outside can be brought to the top space of the grain pile by a low-temperature gravity assisted heat pipe 3 which is arranged in the grain pile distributed around the storehouse; (2) the cool air in the space above the grain pile can flow circularly under the function of four to six sets of frequency converting air conditioners 4 to ensure the temperature in the space above the grain pile to be even; (3) the temperature signal can be monitored by temperature sensors 6 distributed in the storehouse, the start and the close of the frequency converting air conditioners 4 can be controlled by a PLC control system 5. The invention has high efficiency, simple system, long service life, and simple operation; is energy-saving, all-weather, and maintenance-free; and does not condense moisture.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for preserving fresh walnut fruit

ActiveCN104286168AExtended shelf lifeGood fresh-keeping effectSeed preservation using chemicalsSeed preservation by freezing/coolingAcid valueChloride

The invention relates to a method for preserving fresh walnut fruit, aiming at solving the problems that oxidation, rancidity, molding, sprouting, dehydration and the like of fresh walnut fruit are easy to occur when the fresh walnut fruit are preserved. The method mainly comprises the following steps: selecting complete fruits, soaking in calcium chloride in a refrigeration house, fumigating with thiabendazole, leaving the fruit to stand, sealing, packaging in vacuum, storing, delivering, and the like, thereby achieving preservation of the fresh walnut fruit. As the walnut fruit is sealed and packaged under an anaerobic condition, the green peel of walnuts can be prevented from being softened, the fresh walnuts are prevented from rot or metamorphism, the water content of the fresh walnut fruit is kept, the change velocities of grease acid values and peroxidation values are reduced, the generation of malondialdehyde is inhibited, the iodine value can be relatively well maintained, the good quality is maintained, the brown stain index of the green peel of the fresh walnut fruit after being preserved for 120 days is 0.13, the complete fruit rate is more than 95%, and the preserved fresh walnut fruit is all good in color, fragrance, taste and shape.

Owner:陕西大统生态产业开发有限公司

Method for fresh keeping of fresh walnuts by slow-freezing and slow-unfreezing freshelizing technology

PendingCN107549308AExtended shelf lifeAchieving annual supplySeed preservation by freezing/coolingFrozen storageSlow freezing

The invention relates to a fresh-keeping method for fresh walnuts, in particular to a method for fresh-keeping walnuts by slow freezing-slow thawing and refreshment process. The technical scheme of the invention includes peeling, grading, slow freezing, frozen storage, slow thawing and freshening. The technology of the invention extends the preservation period of fresh walnuts from 2 to 4 months to more than 10 to 12 months, and realizes the annual supply of fresh walnuts.

Owner:甘肃省农业科学院农产品贮藏加工研究所

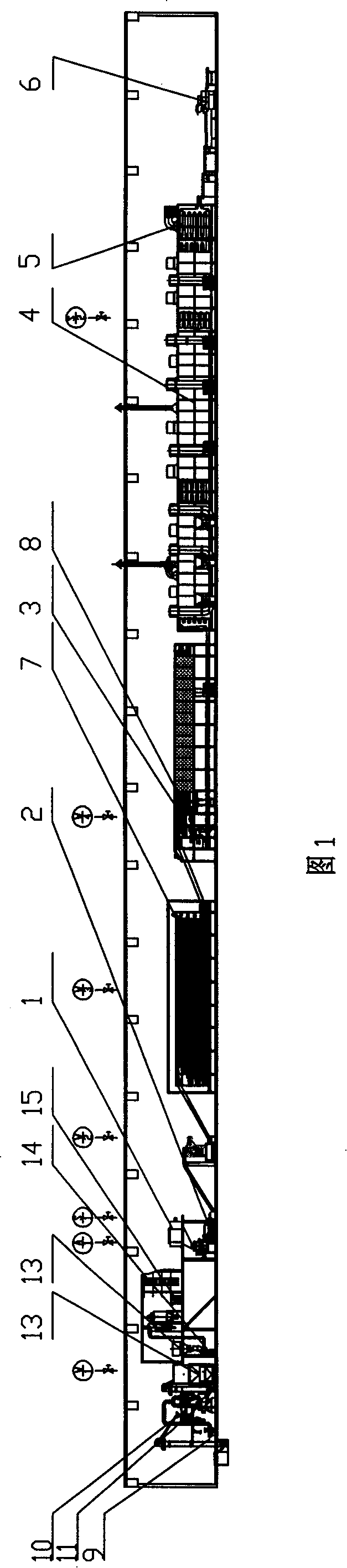

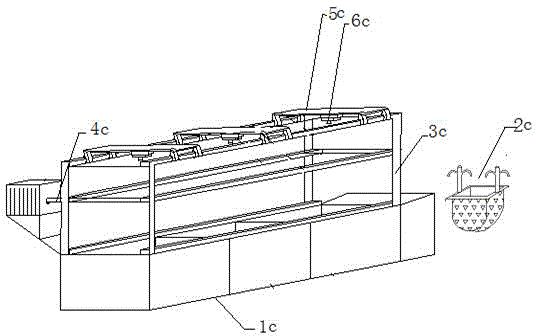

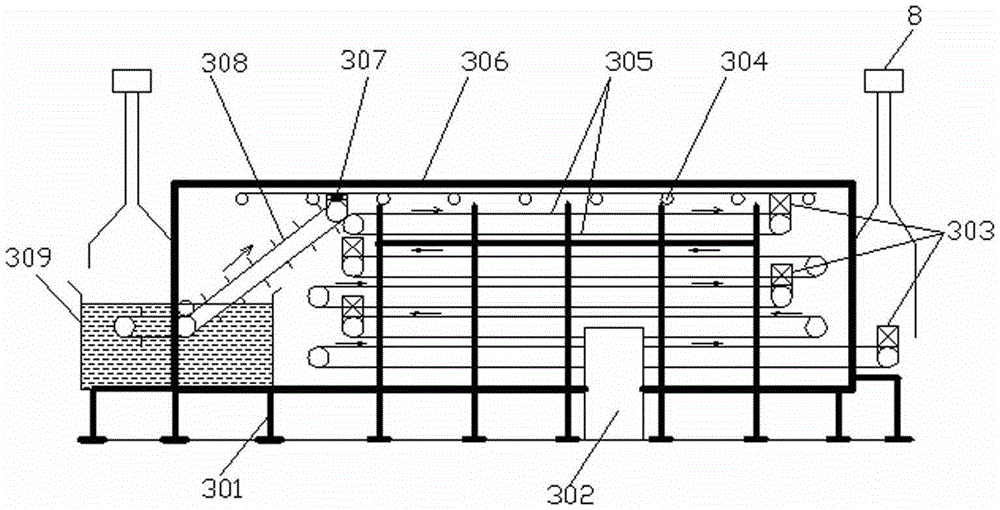

Quick-frozen sweet corn kernel processing technology

In the batch processing process of quick-frozen sweet corn kernels, line production is needed, the corn processing streamline of some present enterprises is not perfect and can only realize the line production of some part, and a complete quick-frozen sweet corn processing streamline having the advantages does not exist at present, so present sweet corn processing technologies have the disadvantages of low labor efficiency, high energy consumption and low output in the sweet corn processing process. The invention provides a line production technology for the batch processing of quick-frozen sweet corn kernels. A technical scheme adopted in the invention is characterized in that an apparatus for implementing the quick-frozen sweet corn kernel processing streamline technology comprises a raw material elevator, a sweet corn ear head cutter, a sweet corn ear screw scalding machine, a sweet corn ear stripping machine, a sweet corn threshing machine, a winnower, a continuous blanching machine, a first ice water cooler, a second ice water precooler, a vibration draining machine, a fluidized bed type instant food cabinet freezing tunnel and a grading vibrating scalper. The complete quick-frozen sweet corn kernel line production flow formed by using the above devices allows 200-300t of sweet corn to be processed every day, and can satisfy the large-scale mechanical processing production technology of sweet corn, so the production efficiency and the labor efficiency are greatly improved.

Owner:李一波

Euryale ferox salisb stem processing and fresh-keeping method

InactiveCN101999453ASimple processLow costSeed preservation by heatingSeed preservation by freezing/coolingChlorideSalt solution

The invention discloses a euryale ferox salisb stem processing and fresh-keeping method, which comprises the following steps of: after cleaning, impurity removal, peeling, section cutting and pre-cooling of the selected euryale ferox salisb stem raw material, soaking the euryale ferox salisb stems into 0.5 to 2.0 percent salt solution or 0.05 to 0.5 percent citric acid solution to protect color for 1 to 5 hours, hardening the color protected euryale ferox salisb stems for 0.5 to 2 hours in the solution containing 0.05 to 0.2 percent calcium chloride, 0.5 to 2 percent sodium dihydrogen phosphate and 0.1 to 0.2 percent citric acid, putting the hardened clean euryale ferox salisb stems into boiling water of 85 to 100 DEG C, blanching the euryale ferox salisb stems for 1 to 10 minutes, adding the solution containing 0. 1 to 0.2 percent calcium chloride and 0.1 to 0.5 percent citric acid into the blanching solution, performing further color protection and hardening treatment on the euryale ferox salisb stems, and then performing cooling, quick monomer freezing and quantitative packing. The fresh-keeping method has the advantages of simple process and low cost, keeps the original luster and taste of the euryale ferox salisb stems, and meets the requirements of natural green food.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Fresh-keeping technology of fresh walnuts

InactiveCN107372815AGood for healthExtended shelf lifeSeed preservation by irradiation/electric treatmentSeed preservation by heatingAssembly lineChemical residue

The invention discloses a fresh-keeping technology of fresh walnuts. The fresh-keeping technology comprises the following technological steps: spraying a wood-vinegar solution before picking, picking and screening, peeling green peels, immersing with the wood-vinegar solution, carrying out infrared sterilization treatment, carrying out 60Cogamma ray radiation, packaging in vacuum and freezing and storing. The fresh-keeping technology of the fresh walnuts, disclosed by the invention, has the beneficial effects that the walnuts are treated by utilizing the wood-vinegar solution and chemical medicaments are not used, so that natural sterilization and corrosion prevention are realized; the fresh-keeping technology is environmentally friendly and chemical residues are not caused, so that the treated walnuts are beneficial to health of human bodies and the environment; infrared irradiation and 60Cogamma ray radiation are utilized and fresh-keeping storage is carried out from the radical reason of walnut decaying; the fresh walnuts are stored by freezing in a vacuum fresh-keeping bag so that the storage period of the walnuts is greatly prolonged; the walnuts are stored after the green peels of the walnuts are removed, so that a storage space is saved and the storage energy consumption is reduced, and the walnuts are also convenient to eat; technological steps are suitable for industrialized assembly line production so that the utilization of manpower is reduced and mechanical production can be realized.

Owner:温县华鑫家庭农场

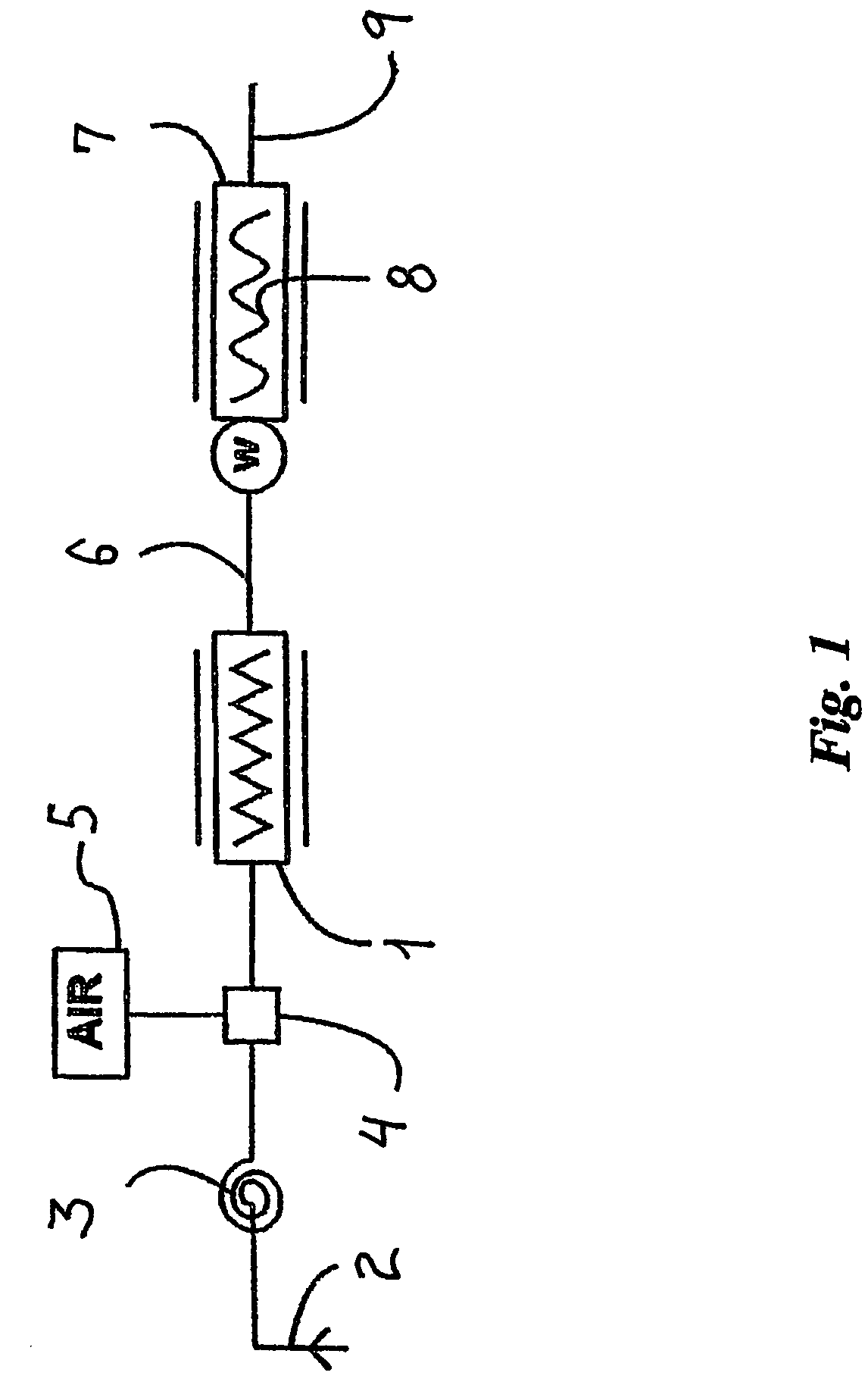

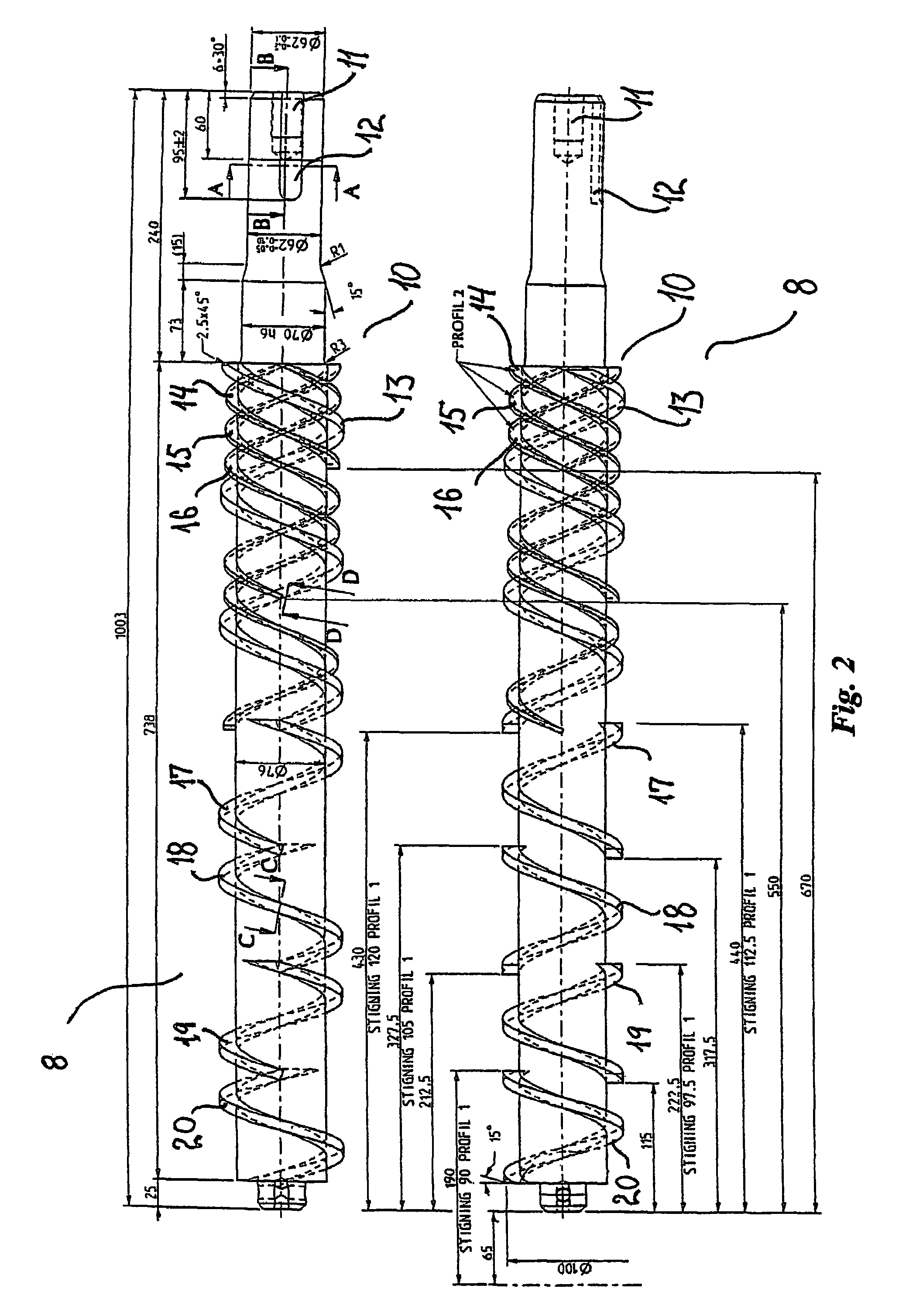

Conveyor screw for use as surface scraper in cooling and freezing units

ActiveUS7596963B2Improve heat transfer performanceNecessary inlet pressureRotary stirring mixersFrozen sweetsEngineeringScrew thread

Owner:TETRA LAVAL HLDG & FINANCE SA

Low-temperature rice storage method

InactiveCN102047953ALong retention periodGuaranteed qualitySeed preservation by freezing/coolingFlavorGram

The invention relates to a low-temperature rice storage method which comprises the following steps: (1) packing the processed rice into bags with plastic film, stacking in a low-temperature storehouse, and adjusting the temperature of the low-temperature storehouse to below 15 DEG C; (2) sucking air from each packing bag, filling carbon dioxide into the packing bags according to the ratio of 8-12 kilograms of carbon dioxide to 10,000 kilograms of rice, and sealing the packing bags; and (3) putting aluminium phosphide sheets on the top end of the stack of rice packing bags according to the addition of 2 grams of aluminium phosphide per each cubic meter of stack. The low-temperature rice storage method provided by the invention organically combines various storage methods, makes full use of the advantages of various storage methods, can effectively prolong the rice preservation time and at least doubles the rice storage time while ensuring the rice quality and keeping the original flavor of rice.

Owner:肖振东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com