Stored grain temperature adjusting method

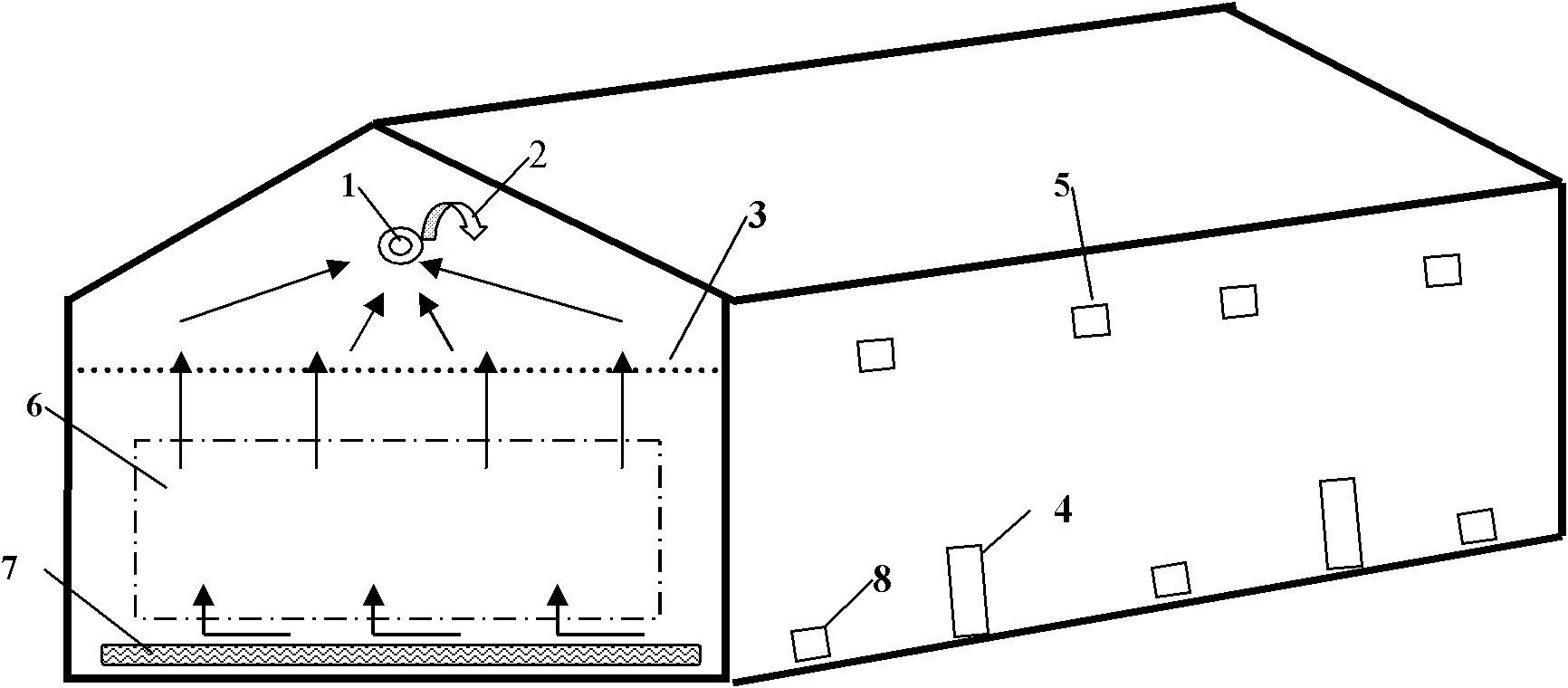

A technology of temperature regulation and grain stacking, which is applied in the direction of freezing/cooling to preserve seeds, food processing, etc., which can solve the problems of long working hours, inability to reduce the temperature of the grain on the upper layer of the grain stack, and high energy consumption, so as to reduce operating costs and reduce The effect of grain temperature and energy saving in the whole warehouse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Control warehouse No. 2, the experiment time was 7:30 pm on July 5, 2009, the ambient temperature outside the warehouse was 31°C, the accumulated temperature in the granary space was 38°C, and the temperature on the upper layer of the grain pile was 32°C. Traditional ventilation and heat dissipation were adopted. method, open the two symmetrical windows farthest from the axial flow fan on the top of the warehouse, and turn on the axial flow fan on the top of the warehouse for a total of 12 hours.

Embodiment 2

[0018] Experimental warehouse No. 1, the experiment time was 5:30 pm on July 5, 2009, the ambient temperature outside the warehouse was 33°C, the accumulated temperature in the granary space was 38°C, and the grain temperature on the upper layer of the grain pile was 32°C. Close all doors, windows and vents, and turn on the axial flow fan on the top of the silo for 2 hours without the entry of outside air. Stop the machine to detect that the accumulated temperature in the granary space has dropped from 38°C to 28°C, and the grain temperature on the upper layer of the grain pile has dropped from 32°C to 28°C. ℃. After that, from July 6th to July 29th, it will be turned on for 2 hours at around 6:00 pm every day. Using this method for temperature adjustment, the grain temperature in the upper layer of the grain pile does not exceed 28°C, the grain temperature in the middle and lower layers rises by 1°C in 14 days in total, and the average daily rise is less than 0.1°C, which has...

Embodiment 3

[0020] Control warehouse No. 2, the experiment time was 7:30 pm on August 2, 2009, the ambient temperature was 33°C, the temperature of the granary space was 38.5°C, and the temperature of the upper layer of the grain pile was 33.5°C. Open all the windows of the warehouse to allow the heat in the grain pile to dissipate naturally from the windows. Connect three 45kw grain coolers to the vents of the above-ground cages, and start up and run continuously to supplement cooling. Because the grain cooler is only used alone, the cold air enters through the vent, and the cold air can only rely on its own pressure to make the cold air go up slowly and penetrate the grain layer. After 240 hours of cold, that is, at 7:30 pm on August 12, the temperature on the upper layer of the grain pile dropped from 32°C to 20°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com