Geothermal-energy low-temperature grain storage system for grain store

A low-temperature, granary technology, applied in the field of ground energy low-temperature grain storage system, can solve the problems of HCFC's damage to the ozone layer, high refrigeration cost, and unsuitable use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

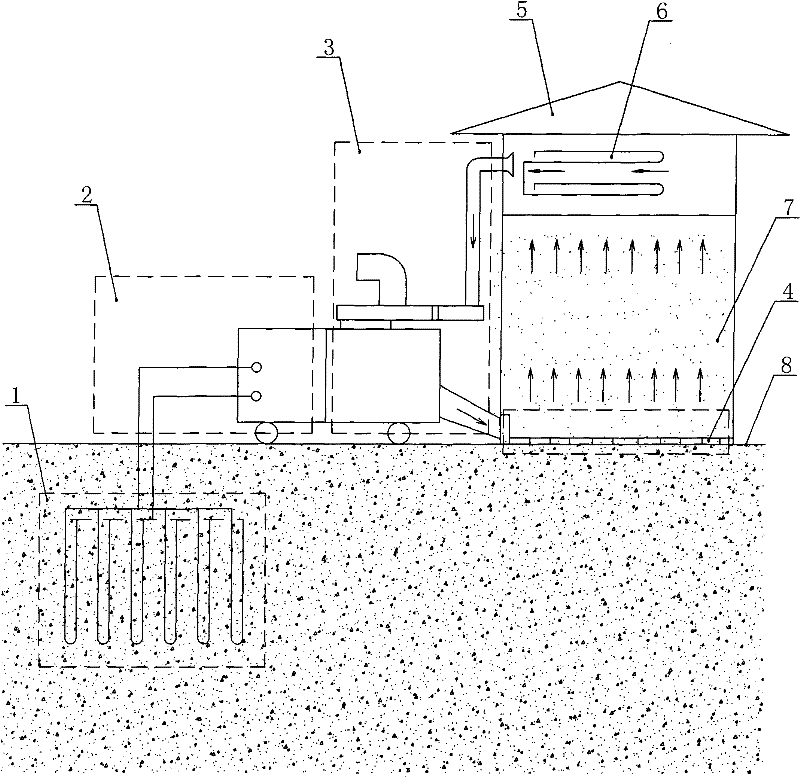

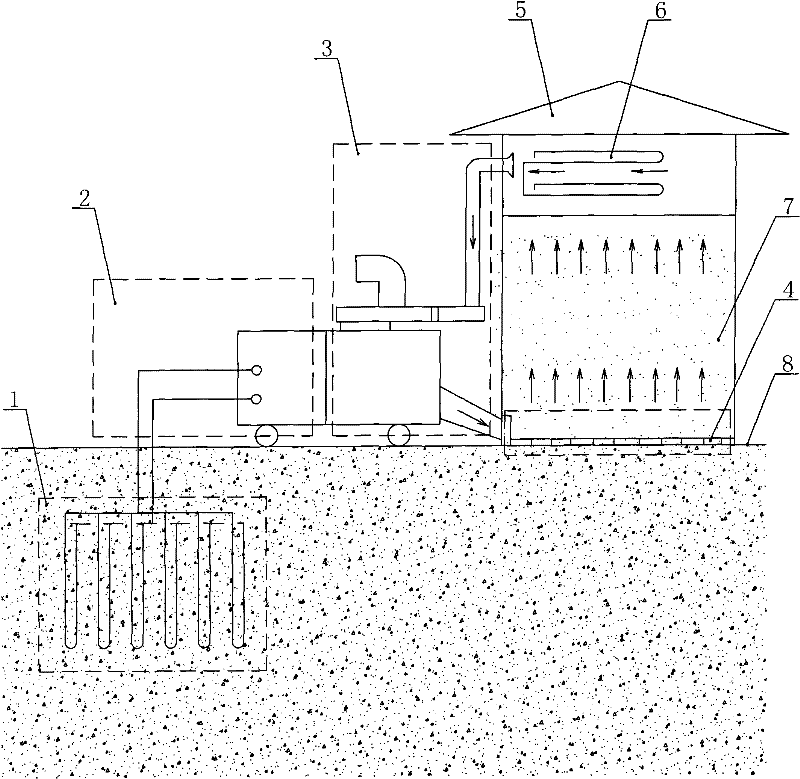

[0010] Such as figure 1 As shown, it is a low-temperature grain storage system using ground energy for granaries, including a shallow ground energy collection system 1 for collecting ground energy. The shallow ground energy collection system 1 is a group of pipelines buried vertically under the ground 8. The shallow ground energy collection system The system 1 is connected to the energy conversion system 2, the output of the energy conversion system 2 is connected to the refrigerant circulation system 3, the refrigerant circulation system 3 is connected to the warehouse 5, the warehouse 5 is equipped with a ventilation system 4 at the bottom, and the grain surface circulation is provided at the top of the warehouse The pipe 6 and the refrigerant circulation system 3 are heat pump units, the air outlet of the heat pump unit is connected to the ventilation system 4 in the warehouse, and the air inlet of the heat pump unit is connected to the grain surface circulation pipe 6 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com