Insulating cap for terminal

A technology of insulating caps and wire terminals, applied in the direction of connecting end caps, etc., can solve problems such as electric shock accidents, easy deterioration of the adhesive layer of insulating tape, easy drying, cracking and loosening of insulating tape, and achieve the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

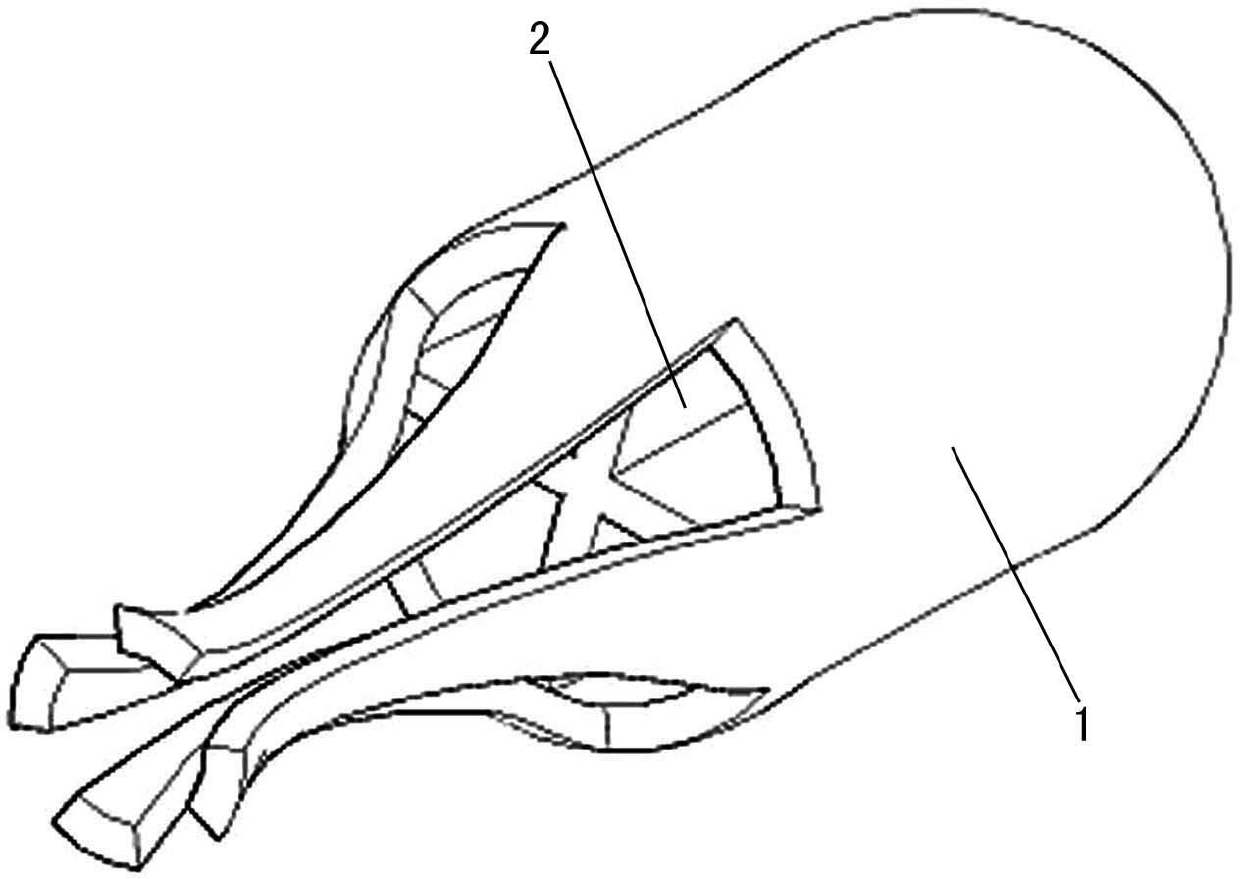

[0020] See figure 1 The shown insulating cap for isolating wire terminals has a round cap body 1 with a blind hole insulating cavity 2 for insulation after the wire terminals are inserted. Two symmetrical elastic clips 3 are arranged at the entrance of the cap body 1, and the exposed wires of the terminals inserted into the insulating cap are fixed by the elastic clips 3 to prevent the insulating cap from falling off. The depth of the blind hole insulating cavity 2 on the cap body 1 described in this embodiment should meet the basic requirement that all exposed metal parts of the wire terminals extend into it. In the present invention, at least two elastic clamps 3 on the cap body 1 are used to form a stable clamping body. In addition, the clamping end surface of the elastic clip 3 is an arc surface. According to needs, protruding teeth 4 can be provided on the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com