Low-content organic volatile low-melting-point polyester fiber and preparation method thereof

A technology of organic volatiles and low-melting polyester, which is applied in the field of polyester fibers, can solve problems such as side reactions, b value increase, and catalyst addition, and achieve the effects of weakening influence, increasing glass transition temperature, and avoiding adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

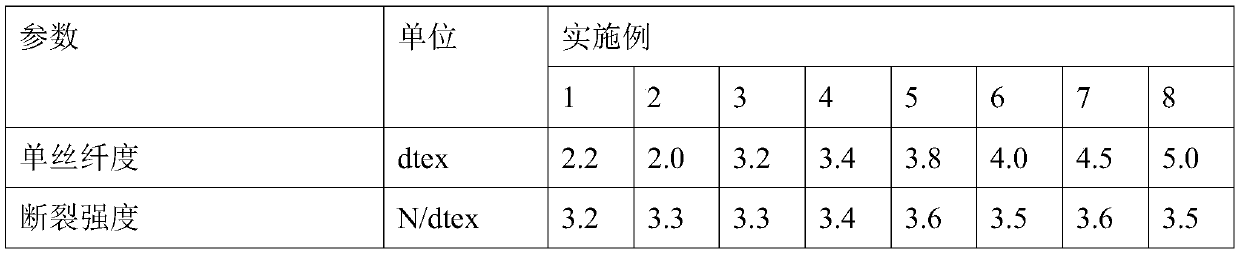

Examples

Embodiment 1

[0043] A kind of preparation method of low content organic volatile matter low melting point polyester fiber, its process is as follows:

[0044] (1) Esterification reaction;

[0045] After preparing terephthalic acid, isophthalic acid, ethylene glycol, diethylene glycol, calcium sulfonate isophthalate, 1,4-butanediol and zinc oxide into slurry, at a temperature of 190°C and a pressure of Under the nitrogen atmosphere of 0.95KPa, react until the amount of water distilled reaches 90% of the theoretical value; among them, terephthalic acid, isophthalic acid, ethylene glycol, diethylene glycol, calcium sulfonate isophthalate and 1, The molar ratio of 4-butanediol is 1:0.3:0.8:0.09:0.01:1.0; the mass addition of zinc oxide is the mass addition of phthalic acid (that is, the mass addition of terephthalic acid and isophthalic acid) and 0.01% of ).

[0046] (2) polycondensation reaction;

[0047] Add ethylene glycol antimony and triphenyl phosphate to the system of step (1), react...

Embodiment 2

[0061] A kind of preparation method of low content organic volatile matter low melting point polyester fiber, its process is as follows:

[0062] (1) Esterification reaction;

[0063] After preparing terephthalic acid, isophthalic acid, ethylene glycol, diethylene glycol, calcium sulfonate isophthalate, 1,4-butanediol and zinc oxide into slurry, at a temperature of 180°C and a pressure of Under the nitrogen atmosphere of 0.95KPa, react until the amount of water distilled reaches 91% of the theoretical value; among them, terephthalic acid, isophthalic acid, ethylene glycol, diethylene glycol, calcium sulfonate isophthalate and 1, The molar ratio of 4-butanediol is 1:0.4:0.9:0.11:0.02:11; the mass addition of zinc oxide is 0.012% of the mass addition of phthalic acid.

[0064] (2) polycondensation reaction;

[0065] Add ethylene glycol antimony and triphenyl phosphate to the system of step (1), react at a temperature of 260°C and a pressure of 460Pa for 35 minutes, and then re...

Embodiment 3

[0070] A kind of preparation method of low content organic volatile matter low melting point polyester fiber, its process is as follows:

[0071] (1) Esterification reaction;

[0072] After preparing terephthalic acid, isophthalic acid, ethylene glycol, diethylene glycol, calcium sulfonate isophthalate, 1,4-butanediol and zinc oxide into slurry, at a temperature of 185°C and a pressure of Under the nitrogen atmosphere of 0.98KPa, react until the amount of water distilled reaches 90% of the theoretical value; wherein, terephthalic acid, isophthalic acid, ethylene glycol, diethylene glycol, calcium sulfonate isophthalate and 1, The molar ratio of 4-butanediol is 1:0.3:0.9:0.10:0.01:1.0; the mass addition of zinc oxide is 0.011% of the mass addition of phthalic acid.

[0073] (2) polycondensation reaction;

[0074] Add ethylene glycol antimony and triphenyl phosphate to the system of step (1), react at a temperature of 263°C and a pressure of 480Pa for 35 minutes, and then reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number of curls | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com