Flotation process for difficultly selected coal slime with high middle density substance content

A flotation and density technology, applied in flotation, solid separation, etc., can solve the problems of low product recovery and production efficiency, and restrict the quality of clean coal products, so as to achieve low operating costs, reduce adverse effects, and high separation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

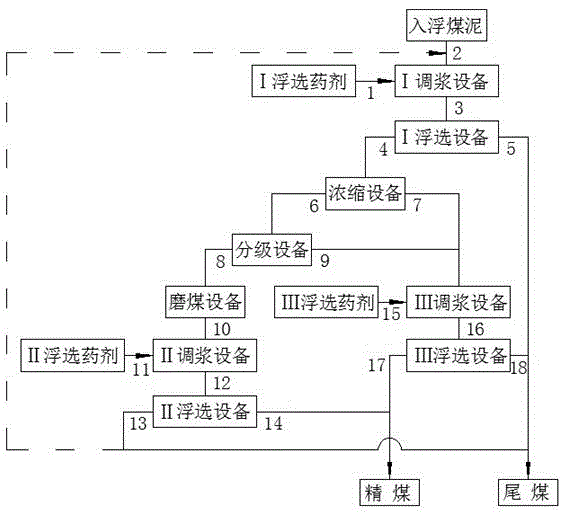

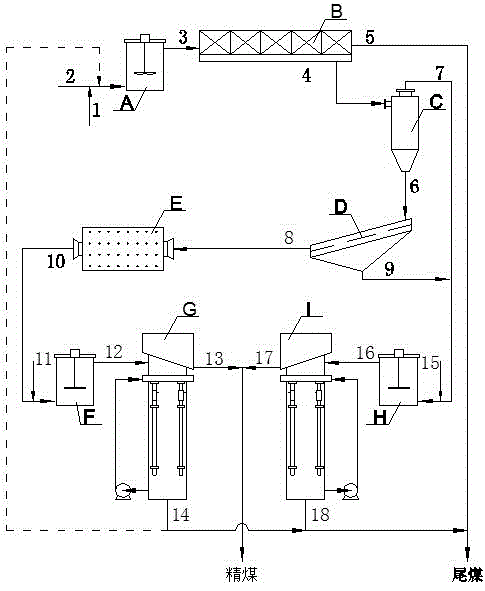

[0018] An implementation of the present invention will be further described below in conjunction with accompanying drawing:

[0019] The flotation process of the refractory coal slime with high intermediate density content of the present invention adopts slurry adjustment equipment, flotation equipment B, concentration equipment C, classification equipment D, and coal grinding equipment E, and its process steps are as follows:

[0020] a. The floating coal slime 2 added with I flotation agent 1 is sent to I slurry conditioning equipment A, and the floating coal slurry 2 added with I flotation agent 1 is conditioned through I slurry conditioning equipment A to obtain a well-conditioned slurry slime water 3;

[0021] b. Send the slurry prepared I coal slime water 3 to I flotation equipment B for roughing operation, and obtain I flotation clean coal 4 and I flotation tailing coal 5;

[0022] c. Send the I flotation clean coal 4 floated by the I flotation equipment B to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com