Method for depositing rare earth through oxalic acid

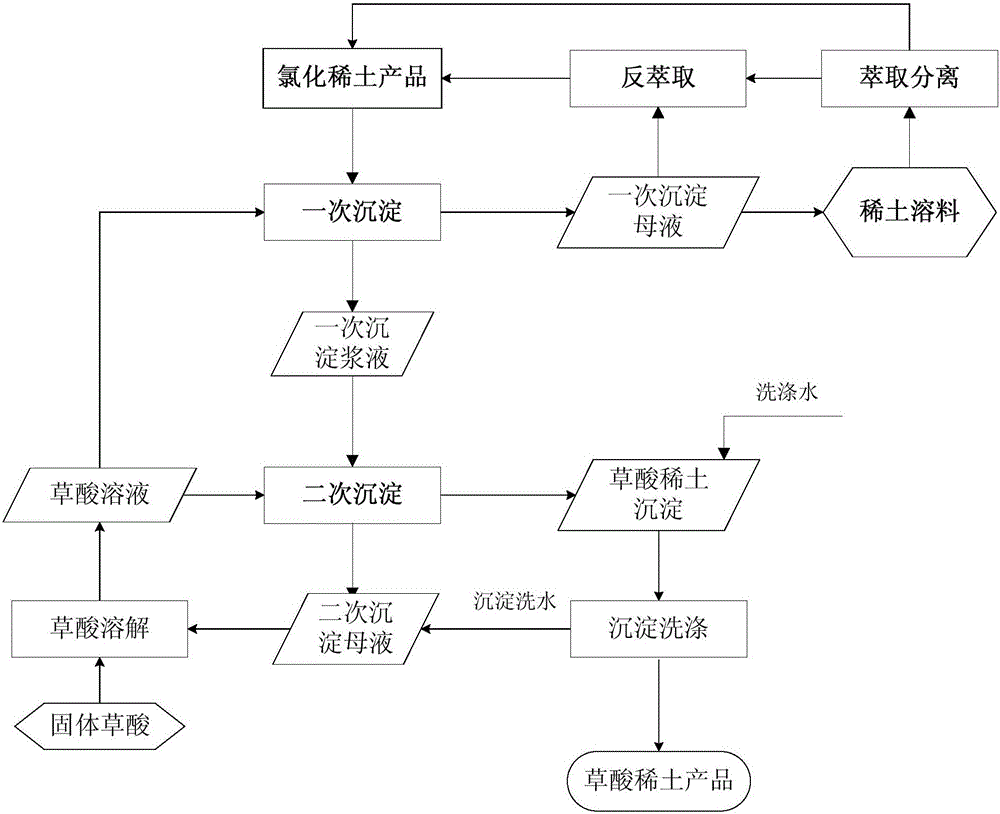

A rare earth, oxalic acid technology, applied in the direction of improving process efficiency, can solve the problems of complicated operation and long process, and achieve the effect of saving reagent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]An enterprise originally precipitated yttrium oxalate. Under the traditional precipitation method, the rare earth recovery rate is 98.5%. The average production ton of yttrium oxide consumes about 2.1 tons of oxalic acid, and the back extraction consumes 3.5 tons of 31% hydrochloric acid, producing about 15 cubic meters of grass precipitation mother liquor (oxalic acid precipitation mother liquor , the same below), neutralizing these grass sink mother liquors needs to consume 1.3 tons of 80% lime.

[0032] The method of the invention is adopted to improve the precipitation step and recover the primary and secondary precipitation mother liquors for the stripping of easy-to-extract components and the preparation process of the oxalic acid solution.

[0033] After improving the process, the rare earth content and oxalic acid concentration in the primary precipitation mother liquor are both about 0.05mol / L, and the average concentration of HCl is 2mol / L. In the primary preci...

Embodiment 2

[0035] An enterprise originally precipitated lanthanum oxalate, and the original process produced 1 ton of lanthanum oxide and consumed 1.4 tons of oxalic acid on average, and produced about 10 cubic meters of grass-sedimented mother liquor. Neutralizing these grass-settled mother liquors consumed 0.85 tons of lime.

[0036] The method of the invention is adopted to improve the precipitation step and recover part of the precipitation mother liquor for the dissolution of raw material oxide and the preparation process of oxalic acid solution.

[0037] After improving the process, the rare earth content in the primary precipitation mother liquor is 0.5mol / L, the concentration of oxalic acid is 0.01mol / L, and the concentration of hydrochloric acid is 3mol / L, and the primary precipitation mother liquor is used for the dissolution process of raw material oxides, saving an average of 31% per ton of oxides 2.2 tons of dissolved hydrochloric acid; the concentration of HCl in the seconda...

Embodiment 3

[0039] A southern mine separation company originally precipitated gadolinium oxalate. Under the traditional precipitation method, the rare earth recovery rate is 98.9%. The average production ton of gadolinium oxide consumes about 1.3 tons of oxalic acid, and the back extraction consumes 2.0 tons of 31% hydrochloric acid, producing about 8 cubic meters of grass precipitation mother liquor. Neutralizing the mother liquor of these grass deposits needs to consume 0.8 tons of 80% lime.

[0040] The method of the invention is adopted to improve the precipitation step and recover the primary and secondary precipitation mother liquors for the stripping of easy-to-extract components and the preparation process of the oxalic acid solution.

[0041] After improving the process, the rare earth content and oxalic acid concentration in the primary precipitation mother liquor are both about 0.02mol / L, and the average concentration of HCl is 1mol / L. After the primary precipitation mother liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com