Combined collecting agent and beneficiation method for recovering copper, lead and silver from copper lead zinc and silver polymetallic ore

A technology combining collectors and beneficiation methods, which is applied in flotation, solid separation, etc., can solve the problems of easy calcium accumulation in pipelines and filters, low recovery rate of associated gold and silver, and sticky flotation foam, etc., and achieves good results. Application prospects, safe and stable use, and efficient recycling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0035] (1) The mass percent of copper is 0.10%~0.25% in the raw ore ore of high-sulfur high-arsenic copper-lead-zinc-silver polymetallic ore of the present invention, and the mass percent of lead is 0.50%~1.20%, and the mass percent of zinc is 3.00% % to 4.50%, the mass percentage of silver is 0.009% to 0.013%, the mass percentage of sulfur is 14.00% to 20.00%, and the mass percentage of arsenic is 2.50% to 3.50%.

[0036] (2) The "low alkalinity" mentioned in the present invention refers to the pulp pH value of 8.0 to 9.5 during the beneficiation process of recovering copper, lead and silver from high-sulfur and high-arsenic copper-lead-zinc-silver polymetallic ore.

[0037](3) In step 1, the addition amount of the combination regulator is 400-700g / t, for example: it can be 400g / t, 450g / t, 500g / t, 550g / t, 600g / t, 650g / t Or 700g / t, and the specific point values between the above values, due to space limitations and for the sake of brevity, the present invention will not list...

Embodiment 1

[0068] The grade of copper in a copper-lead-zinc-silver polymetallic mine in Inner Mongolia is 0.25%, the grade of lead is 1.14%, the grade of silver is 118.14g / t, the grade of sulfur is 14.50%, and the grade of arsenic is 2.54%. The copper minerals in this ore are mainly chalcopyrite, the lead minerals are galena, the zinc minerals are sphalerite, the silver minerals are mainly argentite, and other metal sulfides are mainly pyrrhotite and arsenopyrite. Another small amount of pyrite. The gangue minerals are mainly quartz and muscovite, and a small amount of biotite, chlorite, kaolinite and fluorite.

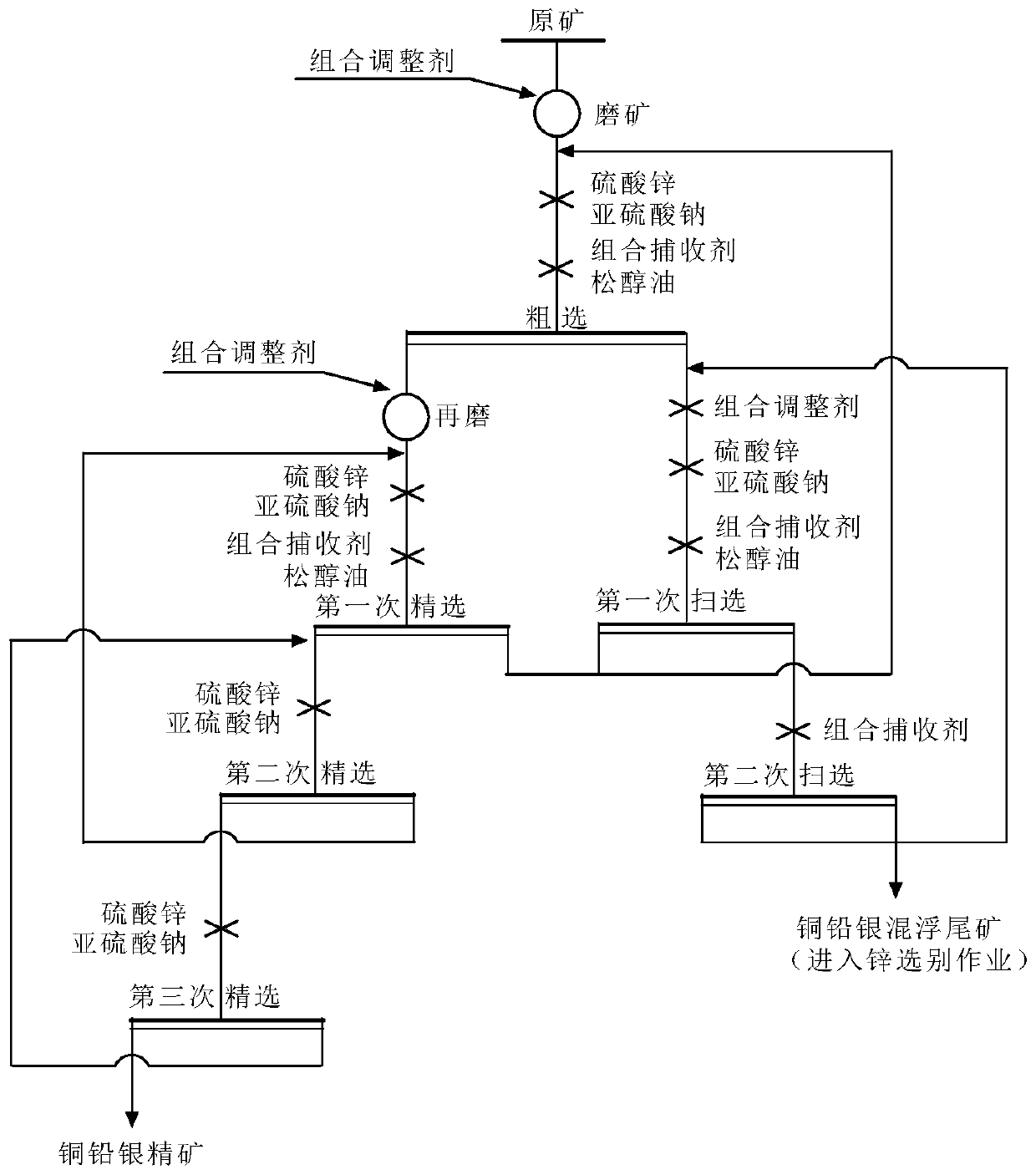

[0069] like figure 1 As shown, a mineral processing method for recovering copper, lead, and silver from high-sulfur, high-arsenic copper-lead-zinc-silver polymetallic ore under low alkalinity conditions is used to process the above-mentioned copper-lead-zinc-silver polymetallic ore in Inner Mongolia, which can include the following step:

[0070] Step 1. Add a combination reg...

Embodiment 2

[0077] The grade of copper in a copper-lead-zinc-silver polymetallic mine in Xinjiang is 0.18%, the grade of lead is 0.91%, the grade of silver is 98.56g / t, the grade of sulfur is 17.32%, and the grade of arsenic is 3.06%. The copper minerals in this ore are mainly chalcopyrite, the lead minerals are galena, the zinc minerals are sphalerite, the silver minerals are mainly argentite, and other metal sulfides are mainly pyrite and arsenopyrite. There is a small amount of pyrrhotite. Gangue minerals are mainly quartz, chlorite, kaolinite and fluorite.

[0078] A mineral processing method for recovering copper, lead, and silver from high-sulfur, high-arsenic copper-lead-zinc-silver polymetallic ores under low alkalinity conditions is used to process the above-mentioned copper-lead-zinc-silver polymetallic ore in Xinjiang, which may include the following steps:

[0079] Step 1. Add a combination regulator to the raw ore of the above-mentioned copper-lead-zinc-silver polymetallic o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com