MOS2 (molybdenum disulfide) and TiO2 (titanium dioxide) nanocomposites and production method thereof

A technology of composite materials and nanorods, which is applied in the field of MOS2/TiO2 nanocomposite materials and their preparation, can solve the problems of large-scale production limitations and achieve the effect of improving capacitance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

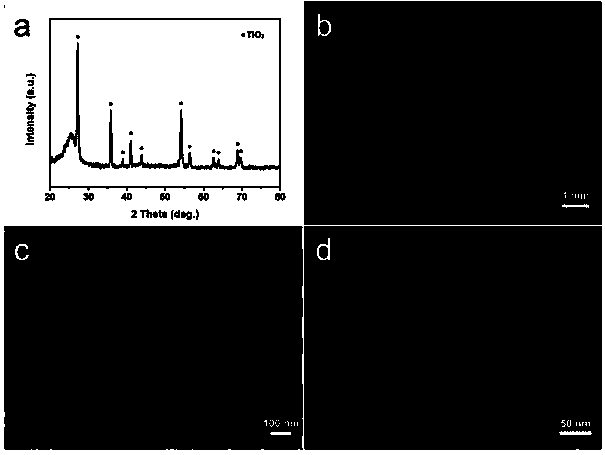

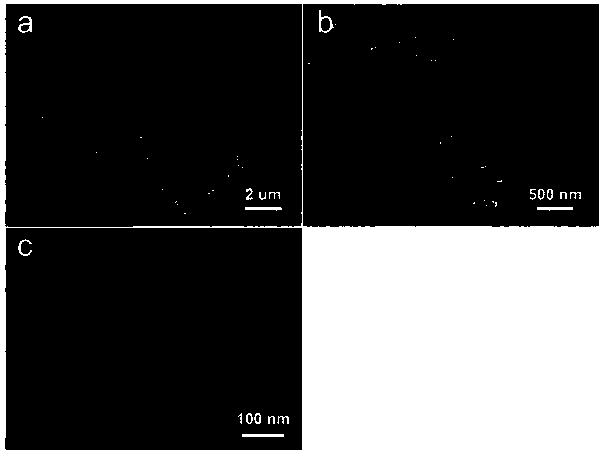

[0035] TiO 2 The synthesis of nanorods on commercial carbon cloths was achieved by a seed-layer-assisted hydrothermal method. Before the hydrothermal reaction of the seed layer, commercial carbon cloth (3 cm x 5 cm) was ultrasonically cleaned in deionized water, ethanol, acetone, and deionized water for 10 minutes, and then dried with compressed air for later use. Dip a cleaned commercial carbon cloth into a solution containing 20 mL of TiCl 4 (0.2 mol / L) aqueous solution in a vial, let it stand for 5 min. Then take it out and spin dry, put it in the oven that has been preheated to 300 o C on a hot plate for 10 min. After cooling, repeat the above operation once, and get a large amount of TiO 2 Commercial carbon cloth with nanoparticles. The commercial carbon cloth obtained above was placed in a volume of 40 mL filled with TiO 2 In the autoclave of nanorod growth solution (reaction solution is generally 80% of reactor volume), hydrothermal reaction is at 160 o C for 5 ...

Embodiment 2

[0039] MoS 2 The synthesis directly on commercial carbon cloth was achieved by direct hydrothermal method. Commercial carbon cloth was placed in a volume of 40 mL filled with MoS 2 In the high-pressure reactor of the growth solution (the reaction solution is generally 80% of the reactor volume), the hydrothermal reaction is carried out at 190 o C for 12 h. MoS 2 The hydrothermal reaction solution consisted of 60 mg sodium molybdate, 100 mg thioacetamide, and 40 mL deionized water. Cool to room temperature after the reaction finishes, and the gained sample is washed three times repeatedly with deionized water, 80 o C to dry

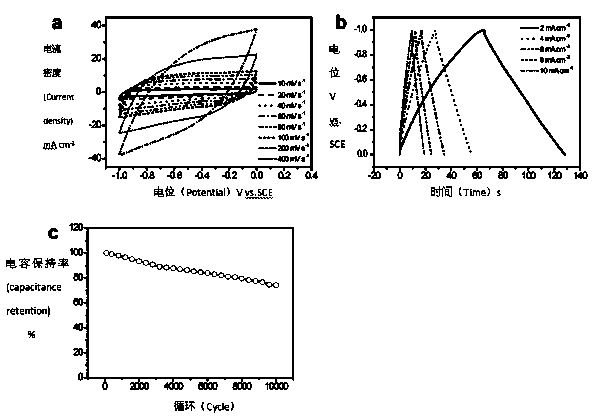

[0040] Cyclic voltammetry and galvanostatic charge-discharge tests in electrochemical methods were used to study MoS grown directly on carbon cloth 2 Supercapacitor performance, the maximum specific capacitance value obtained by calculation is 132 F / g, which is far less than that of MoS in Example 1 2 / TiO 2 nanocomposites. This is mainly due to t...

Embodiment 3

[0042] The invention is based on the scheme of Example 1, by adjusting different reaction conditions, affecting MoS 2 / TiO 2 growth, and its relationship is shown in Table 1 and Table 2.

[0043] Table 1. TiO 2 Growth regulation of nanorods

[0044]

[0045] Table 2. MoS 2 growth regulation

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com