Molybdenum sulfide/carbon composite material and preparation method and application thereof

A carbon composite material, molybdenum sulfide technology, applied in electrochemical generators, active material electrodes, electrical components, etc., can solve the problems of high price and difficult to disperse, and achieve the effects of simple operation, mild reaction conditions and lower production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Molybdenum acetylacetonate, sodium sulfide and glucose are mixed and dissolved in deionized water according to the molar ratio of molybdenum / sulfur / carbon of 1:3:10, and after stirring evenly, a mixed solution having a molybdenum ion concentration of 0.01mol / L is obtained; Add cotton cloth to the mixed solution at a mass ratio of 1:10 according to the molybdenum source / cotton carbon source to obtain the mixture;

[0057] (2) Transfer the mixture obtained in step (1) to a closed reaction kettle, and heat it in an oven at 180° C. for 48 hours; centrifuge the hydroheated product, and wash it to obtain a precursor of molybdenum sulfide / carbon material;

[0058] (3) The precursor obtained in step (2) was heat-treated at 750° C. for 3 hours to obtain a molybdenum sulfide / carbon composite material.

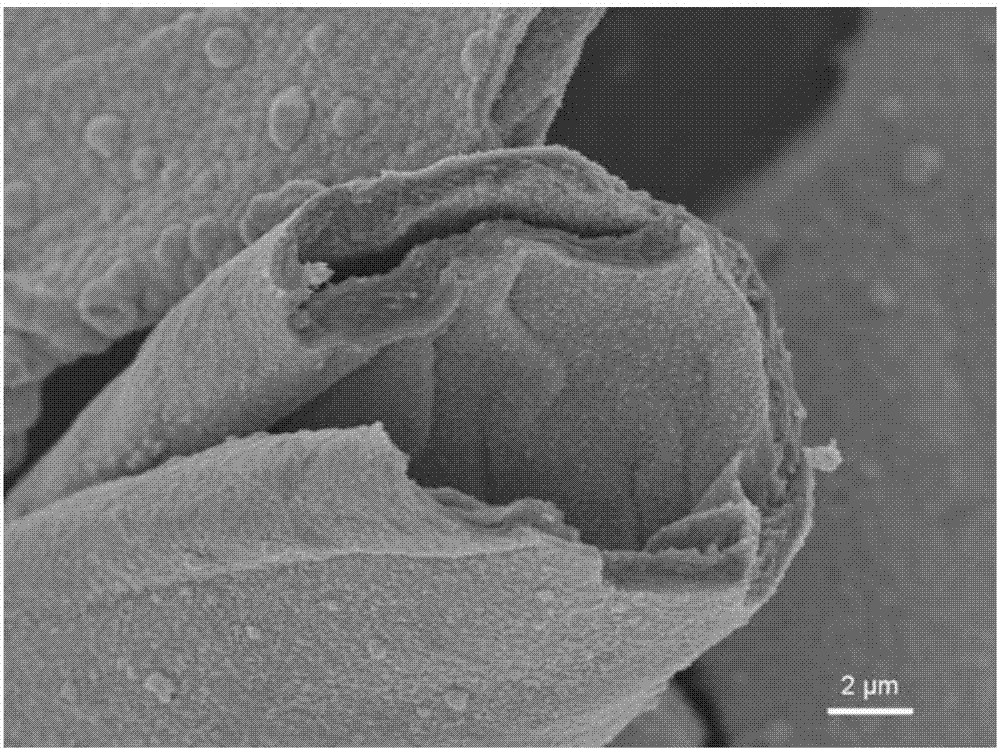

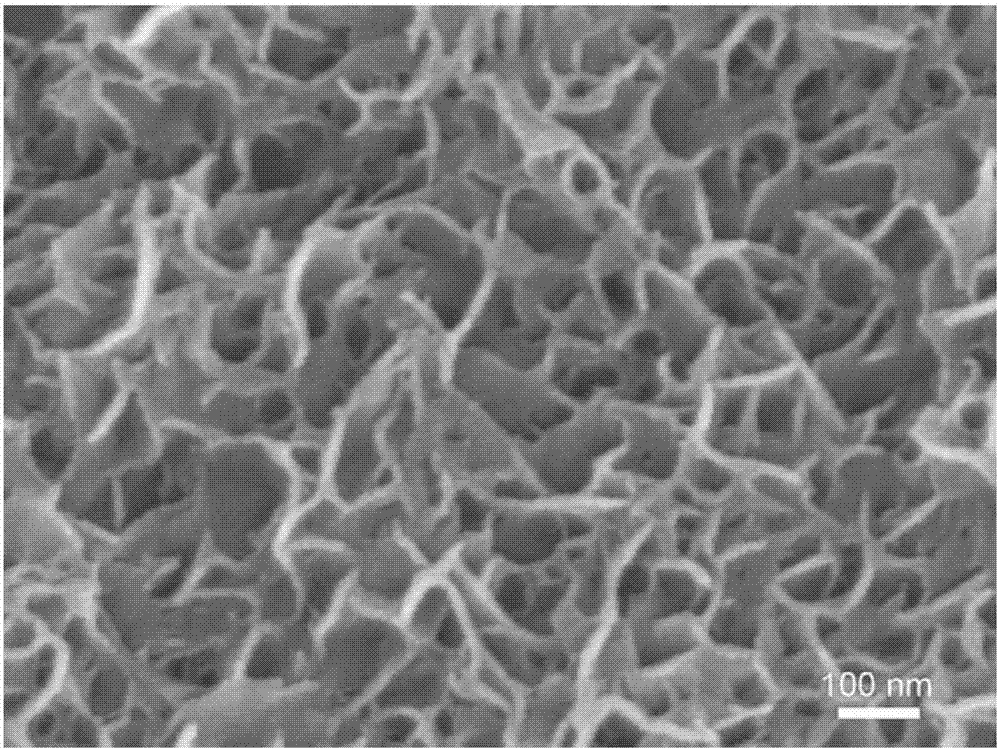

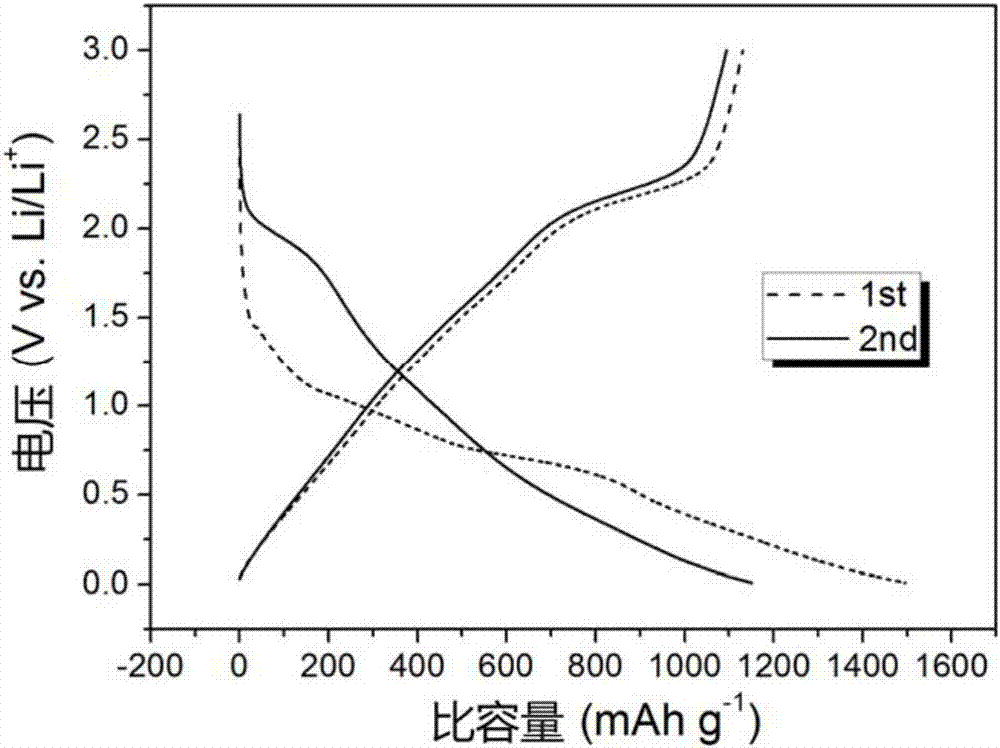

[0059] Carry out SEM characterization to the molybdenum sulfide / carbon composite material that this implementation obtains, as figure 1 and figure 2 As shown, molybdenum su...

Embodiment 2

[0063] (1) Sodium molybdate, thiourea and starch are mixed and dissolved in deionized water according to the molar ratio of molybdenum / sulfur / carbon of 1:10:20, and after stirring evenly, a mixed solution having a molybdenum ion concentration of 0.2mol / L is obtained; According to the mass ratio of molybdenum source / cotton carbon source being 1:20, clothes are added to the mixed solution to obtain the mixture;

[0064] (2) Transfer the mixture obtained in step (1) to a closed reaction kettle, and heat it in an oven at 210° C. for 10 hours; filter the hydroheated product, and wash it to obtain a precursor of molybdenum sulfide / carbon material;

[0065] (3) The precursor obtained in step (2) was heat-treated at 500° C. for 10 h to obtain a molybdenum sulfide / carbon composite material.

[0066] The SEM characterization of the molybdenum sulfide / carbon composite material obtained in this implementation shows that the molybdenum sulfide presents an ordered nano-sheet structure, unif...

Embodiment 3

[0069] (1) Ammonium molybdate, sodium molybdate, sodium thiosulfate and sucrose are mixed and dissolved in deionized water according to the molar ratio of molybdenum / sulfur / carbon of 1:1:3 (ammonium molybdate and sodium molybdate are in any proportion ), stirring evenly to obtain a mixed solution with a molybdenum ion concentration of 0.5mol / L; adding cotton cloth to the mixed solution at a mass ratio of 1:40 according to the molybdenum source / cotton carbon source, to obtain a mixture;

[0070] (2) Transfer the mixture obtained in step (1) to a closed reaction kettle, and heat it in an oven at 250° C. for 8 hours; centrifuge and wash the product after hydroheating to obtain a precursor of molybdenum sulfide / carbon material;

[0071] (3) heat-treating the precursor obtained in step (2) at 900° C. for 1 h to obtain a molybdenum sulfide / carbon composite material.

[0072] The SEM characterization of the molybdenum sulfide / carbon composite material obtained in this implementation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com