Method for cooking grass raw materials at two stages with soda anthraquinone by adding black liquor

A technology of caustic soda anthraquinone and black liquor, which is applied in fiber raw material treatment, cellulose raw material pulping, pulping with inorganic alkali, etc. It can solve unfavorable lignin removal, unreasonable cooking, low pulp yield, etc. problems, to achieve the effects of small sieving rate, good bleachability, and increased yield of fine pulp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

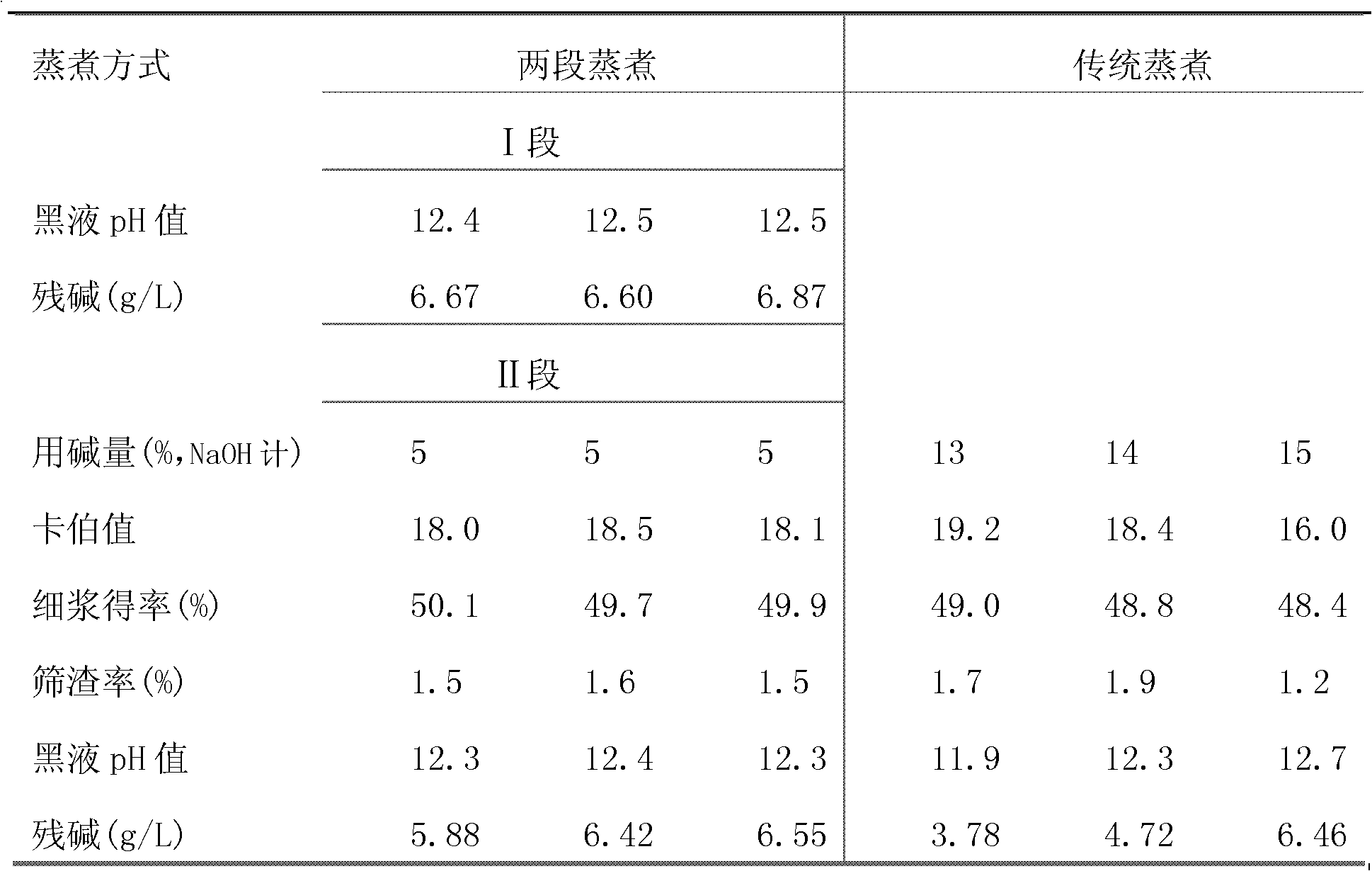

[0014] The two-stage cooking method of wheat straw caustic soda anthraquinone added with black liquor provided by this embodiment comprises the following steps carried out in order:

[0015] 1) Cut the wheat straw into 30-50mm long grass slices, filter and remove dust for cooking;

[0016] 2) White liquor and black liquor with residual alkali of 5.6g / L are mixed to form stage I cooking liquor;

[0017] 3) Phase I cooking: mix the above-mentioned grass slices with the cooking liquid of Phase I and put them into the digester, then (within what time) heat up to 75°C, the amount of alkali used is 9% (NaOH), and the liquid ratio is 1: 7. The dosage of anthraquinone is 0.03%, and then keep warm for 10 minutes to make wheat straw semi-slurry;

[0018] 3) Stage II cooking: Squeeze out the black liquor in the above-mentioned wheat straw semi-slurry, directly add stage II cooking liquor prepared by white liquor and black liquor with a residual alkali of 6.3g / L without washing, and then...

Embodiment 2

[0020] The two-stage cooking method of bagasse caustic soda anthraquinone added with black liquor provided by this embodiment comprises the following steps carried out in order:

[0021] 1) The bagasse that is stored in a dry way and depilled is directly used as cooking raw material;

[0022] 2) White liquor and black liquor with residual alkali of 5.6g / L are mixed to form stage I cooking liquor;

[0023] 3) Stage I cooking: mix the above-mentioned bagasse with the stage I cooking liquid and put it into a digester, then heat up to 70°C within 10 minutes, use an alkali amount of 9.5% (NaOH), and a liquid ratio of 1:7. The dosage of anthraquinone is 0.04%, and then kept for 20 minutes to make bagasse semi-slurry;

[0024] 3) Stage II cooking: extrude the black liquor in the above-mentioned bagasse semi-slurry, without washing, directly add the stage II cooking liquor prepared by white liquor and black liquor with a residual alkali of 7g / L, and then in 50min The temperature is ...

Embodiment 3

[0026] The two-stage cooking method of caustic soda anthraquinone adding black liquor provided by the present embodiment comprises the following steps carried out in order:

[0027] 1) Cut the grass into 30-50mm long pieces, sieve to remove dust and debris, and use for cooking;

[0028] 2) White liquor and black liquor with residual alkali of 8g / L are mixed to make stage I cooking liquor;

[0029] 3) Stage I cooking: add the above-mentioned hawthorn slices and stage I cooking liquid into the digester at the same time, then heat up to 80°C within 20 minutes, use an alkali amount of 10%, a liquid ratio of 1:7, and an anthraquinone dosage of 0.05%, and then keep warm for 10 minutes to make hami half slurry;

[0030] 4) Stage II cooking: Squeeze out the black liquor in the above-mentioned grass half-slurry, directly add stage II cooking liquor prepared by white liquor and black liquor with a residual alkali of 8.2g / L without washing, and then cook in 40min The temperature is rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com