Method for determining chemical pulp kappa number with visible-near infrared spectrometry

A chemical pulp and near-infrared technology, which is applied in the fields of automatic pulping process, cellulose pulp post-treatment, color/spectral characteristic measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

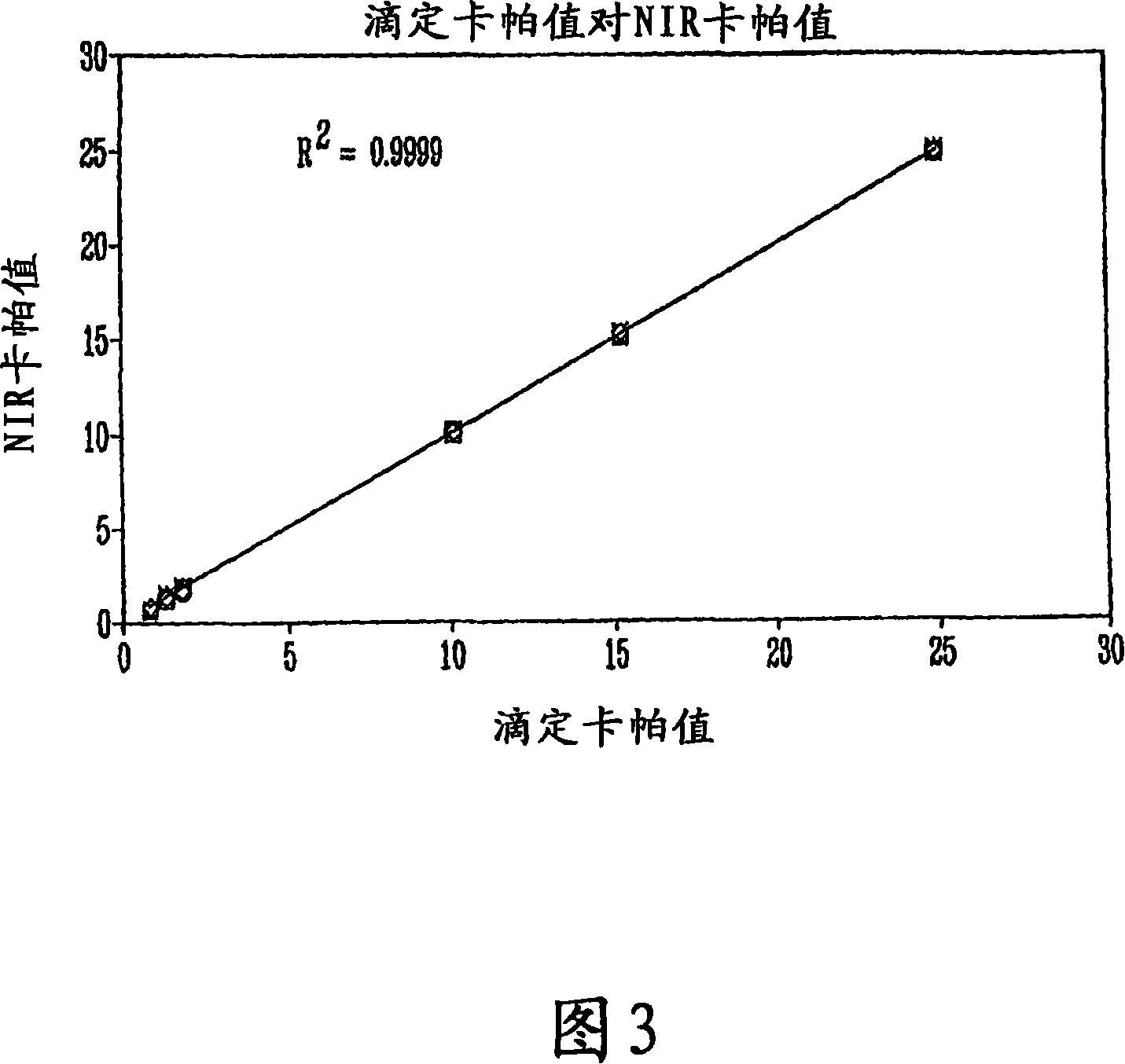

[0051] Pulp fiber samples were first squeezed by hand to remove excess water and placed on a sample tray. During data collection, rotate the tray to provide better averaging and improve statistical significance. Figure 3 shows the results obtained for hemlock pulp, which was sampled from the final natural stock washer and all the individual washers of the bleach plant. A local least squares multivariate calibration was used, resulting in a calibration using a combination of the preferred spectral regions 350nm to 750nm and 1100nm to 2400nm. Generating the plot with 6 factors gives an R of 0.9999 2 model. Note that there are 10 data points at each concentration level, demonstrating the extremely good reproducibility of the invention. The estimated root mean square standard error (RMSEP) was 0.2 kappa with a reproducibility of 0.05 kappa. Furthermore, these results also show that the present invention is capable of measuring the residual lignin content of chemical pulps full...

example 2

[0053] Figure 4 plots the results produced with the same data set described above, but with the selected calibration region spanning only the NIR range of 1100nm to 2500nm, as indicated in the prior art. The results proved to be poor data with an expected error of ±2 kappa, much higher than the results obtained in the present invention.

example 3

[0055] Figure 5 plots the results produced with the same data set above, but calibrated at another spectral range taught by the prior art, namely 850nm to 1050nm. As shown, the results obtained with the prior art teaching, again the teaching is not suitable for use in the present invention, as the expected error is on the order of ±4 kappa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flow consistency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com