Plasterboard composition, preparation of this composition and manufacture of plasterboards

a technology of plasterboard and composition, which is applied in the field of plasterboard composition, can solve the problems of high cost, high temperature shrinkage, and difficult dispersion of silicon and aluminium oxide in dry powder form, and achieves the effects of improving fire resistance, reducing production costs, and improving fire resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

[0112] The hot mechanical strength (also called the high-temperature core cohesion) of the control board and boards A, B, C and D prepared in Example 1 were measured.

[0113] The test used combined a thermal stress, exerted on both sides of the test sample by means of a Mecker burner delivering a flame having a constant temperature of 1020.degree. C., with a tensile mechanical stress of 0.2 kg / cm.sup.2.

[0114] The parameters recorded were the failure time and the final shrinkage.

[0115] The results are given in the following table:

2 Board Control A B C D Failure time (min) >100 >120 >120 109 93.5 Shrinkage (%) 4.4 2.1 2.95 1.5 1.3

[0116] It may be seen that failure of the control, A and B test specimens was reached after two hours of stressing. Moreover, all the formulations lasted at least 1 hour 30 minutes.

[0117] In the case of all the plasterboard test specimens according to the invention, it may be seen that the combination of micronized unexpanded vermiculite combined with clay allo...

example 3

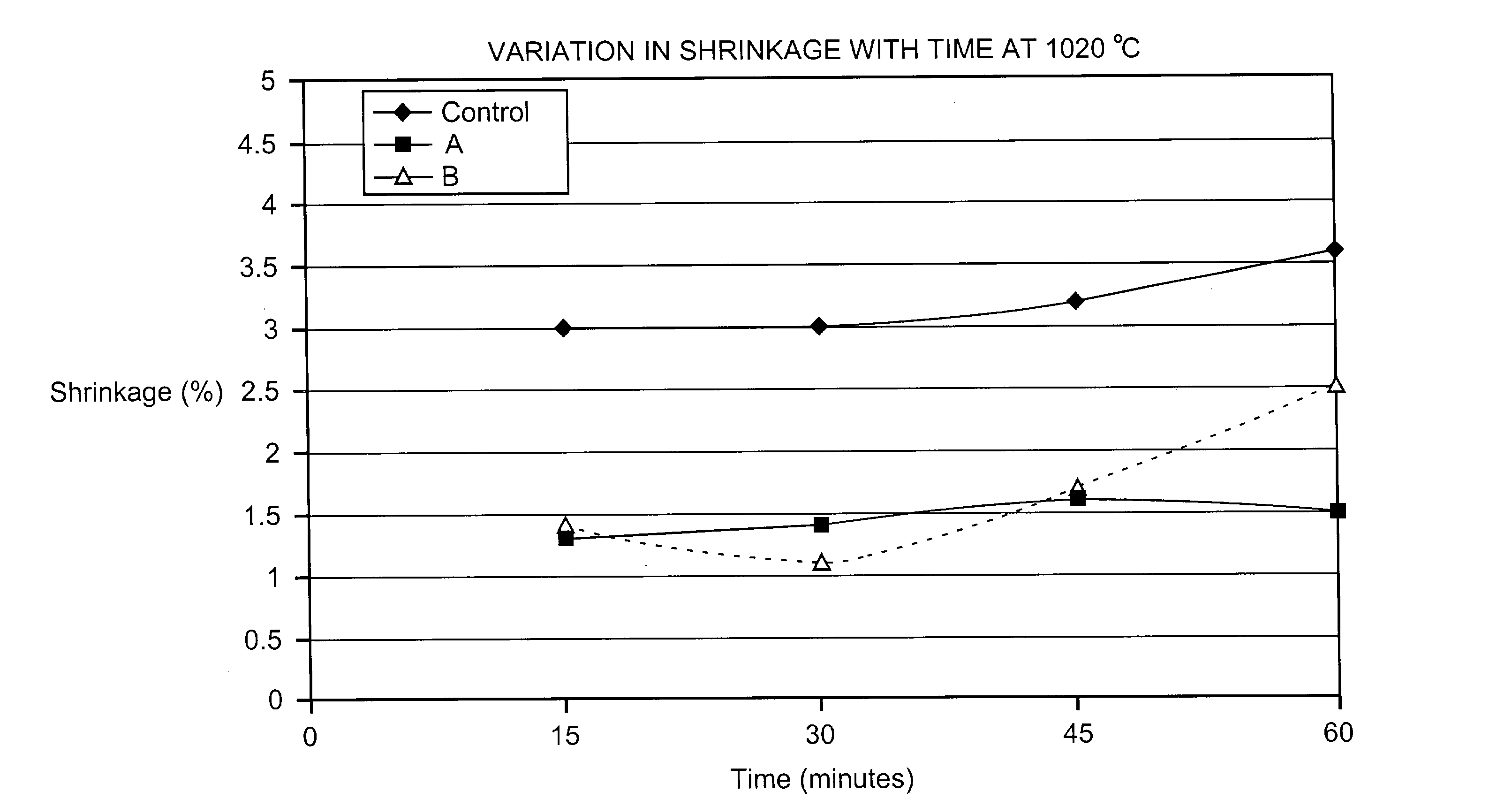

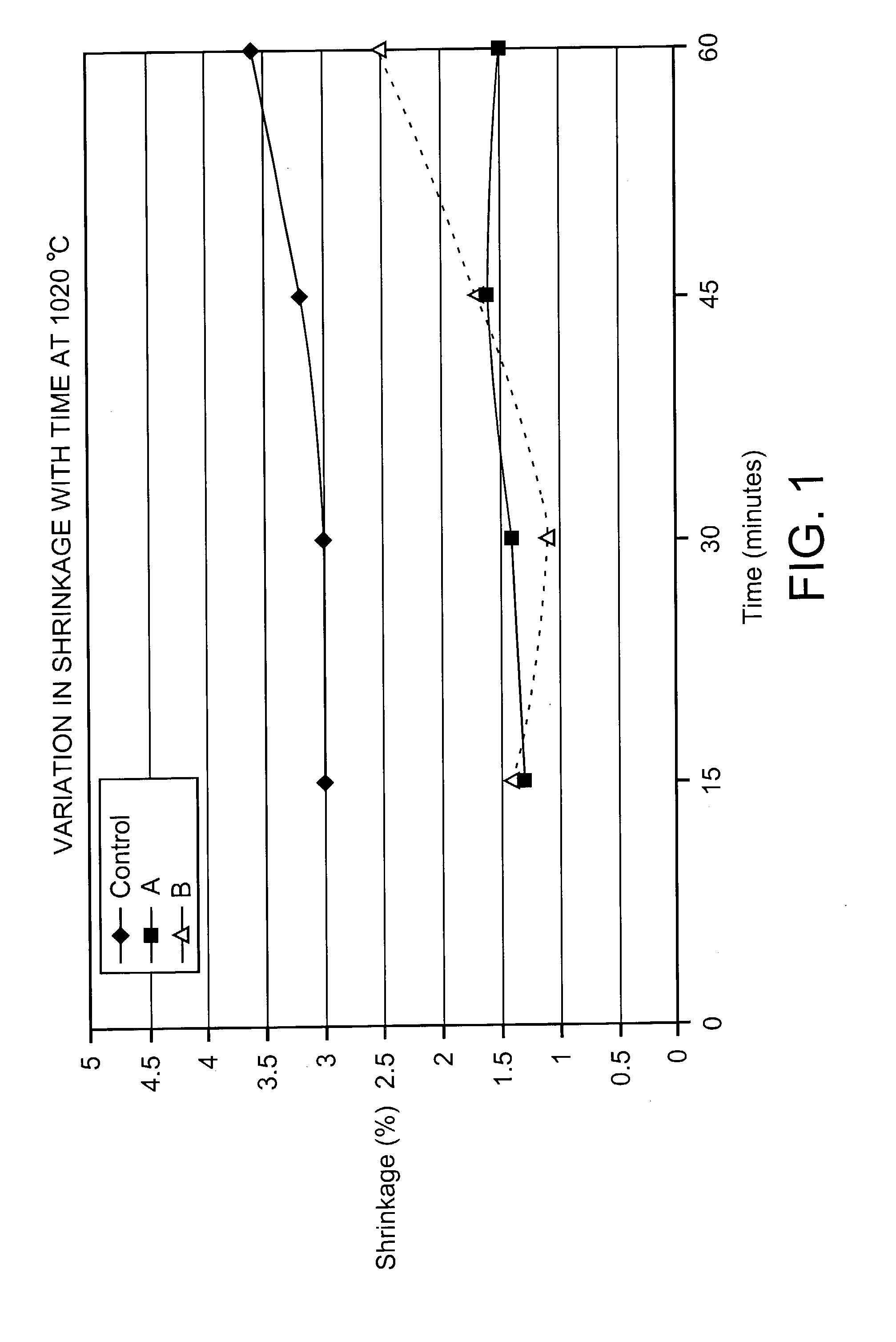

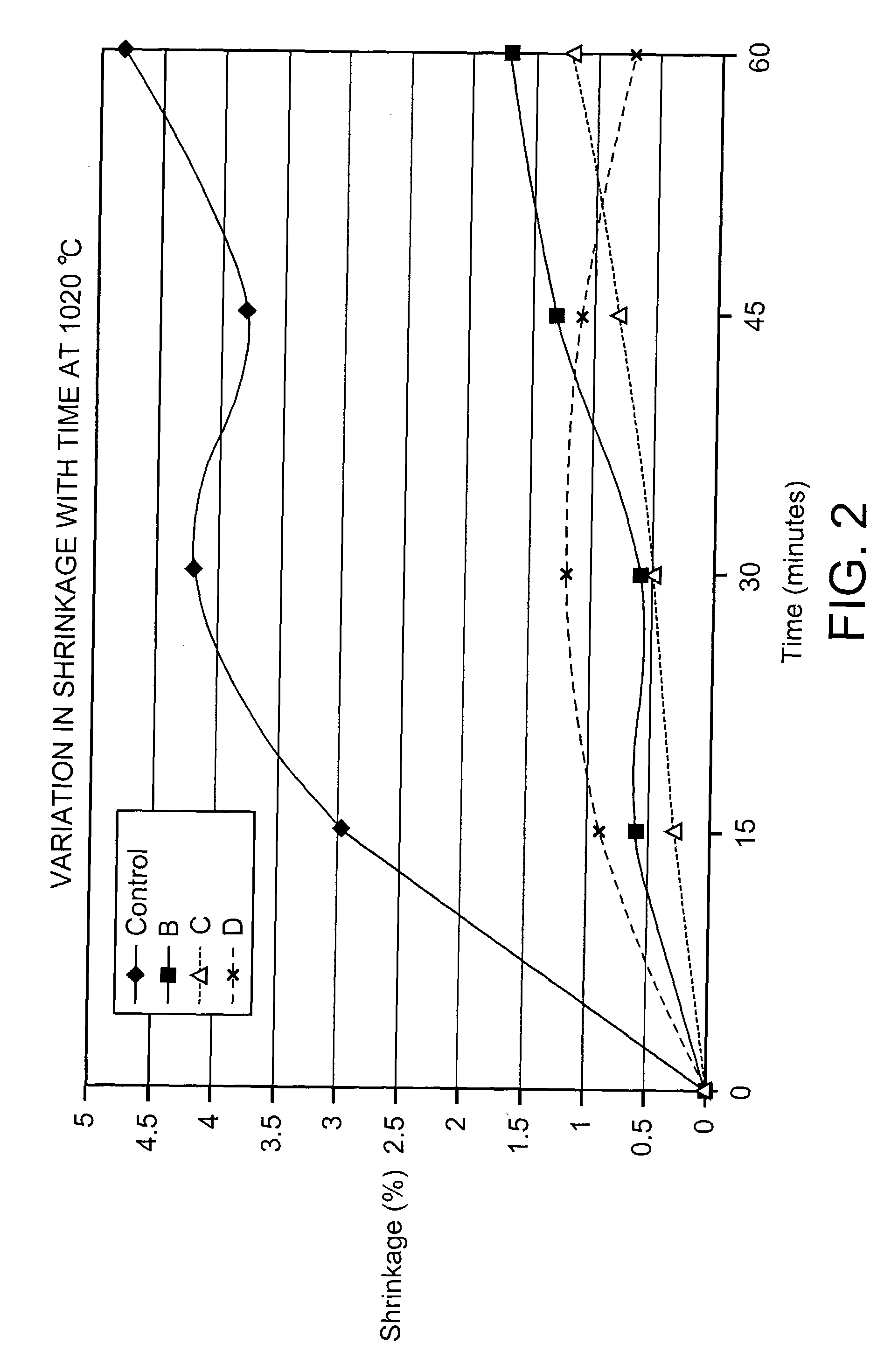

[0119] The shrinkage behaviour of the control board and boards A, B, C and D prepared in Example 1 was measured.

[0120] The test involved consisted in simply exerting the same thermal stress as in Example 2, in the absence of any mechanical stress.

[0121] The recorded parameter was the shrinkage after 15, 30, 45 and 60 minutes.

[0122] The results are given in the following table:

3 Shrinkage of the boards in % Time (min) Control A B C D 15 3.0 1.3 1.4 0.3 0.9 30 3.0 1.4 1.1 0.5 1.2 45 3.2 1.6 1.7 0.8 1.1 60 3.6 1.5 2.5 1.2 0.7

[0123] FIG. 1 shows the variation in the shrinkage as a function of time for the control board and boards A and B.

[0124] FIG. 2 shows the change in shrinkage as a function of time for the control board and boards B, C and D, during another test.

[0125] The difference between the control and the test specimens according to the invention is very marked, particularly in the initial phase (up to 30 minutes. The micronized unexpanded vermiculite / clay pair reduces the shr...

example 4

[0127] The heat transfer of the control board and boards A, B, C and D prepared in Example 1 was measured.

[0128] The test consisted in exerting a thermal stress on one side of the by means of a Mecker burner delivering a flame with a constant temperature of 1020.degree. C.

[0129] The parameters recorded were the temperature of the unexposed test specimen, the time to reach values corresponding to the Fire Wall and insulation classification criterion according to the French Decree of August 1999 and the EN 1361-1 and EN 13 501-2 standards, in which dt=140.degree. C. on average or a maximum of 180.degree. C. at any point.

[0130] In addition, the time to reach a temperature of 400.degree. C. was also recorded, as this time is a significant measure of the heat transfer after dehydration.

[0131] The results are given in the following table:

4 Time(s) to reach temperature Boards Temperature Control A B C D 160.degree. C. 595 525 655 640 570 200.degree. C. 645 615 710 690 635 400.degree. C. 94...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com