Process for upgrading heavy crude oil production

A crude oil and heavy technology, applied in chemical dehydration/demulsification, petroleum industry, refined hydrocarbon oil, etc., can solve the problems of continuous pollution treatment, difficult separation of solid substances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

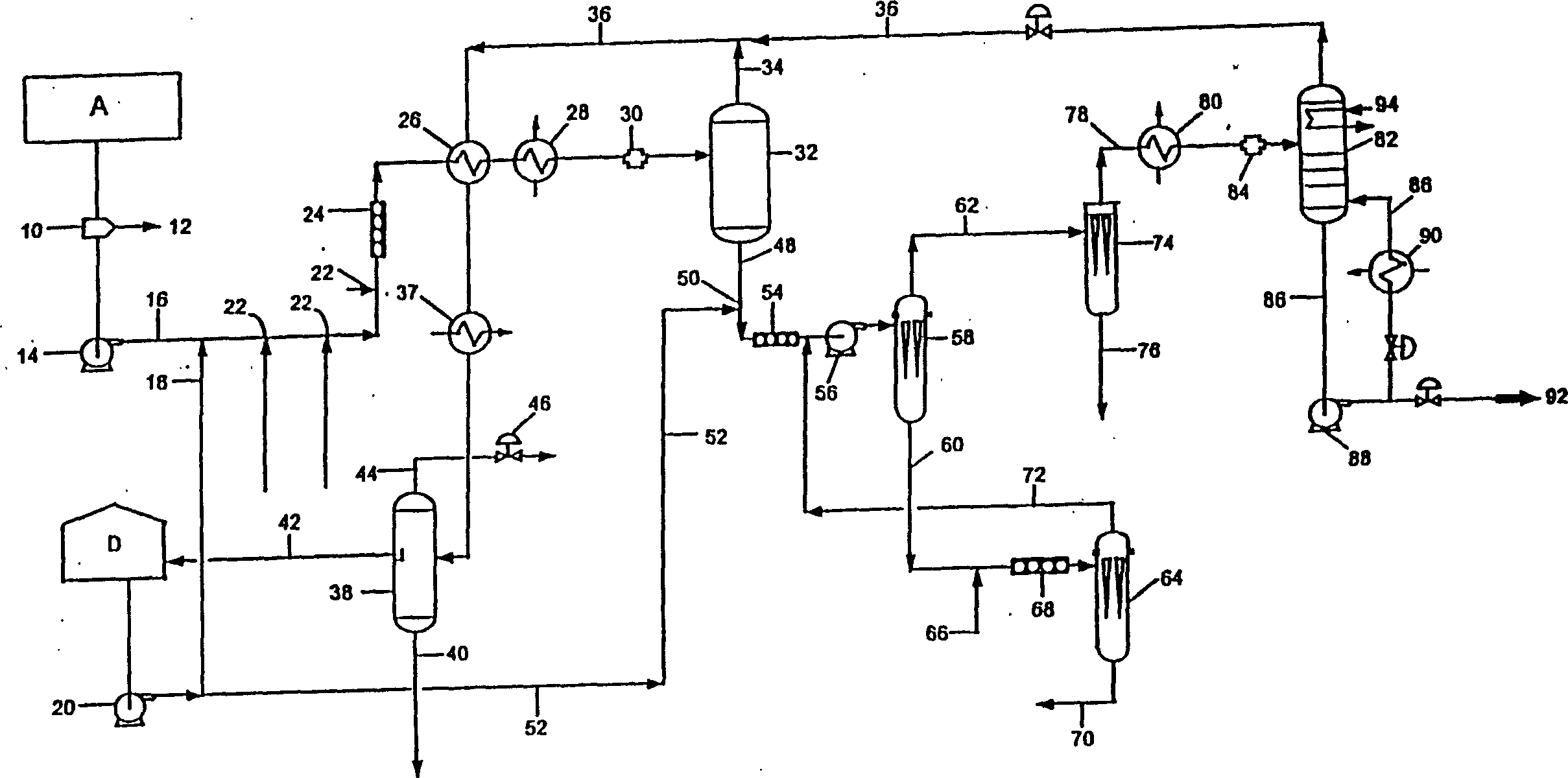

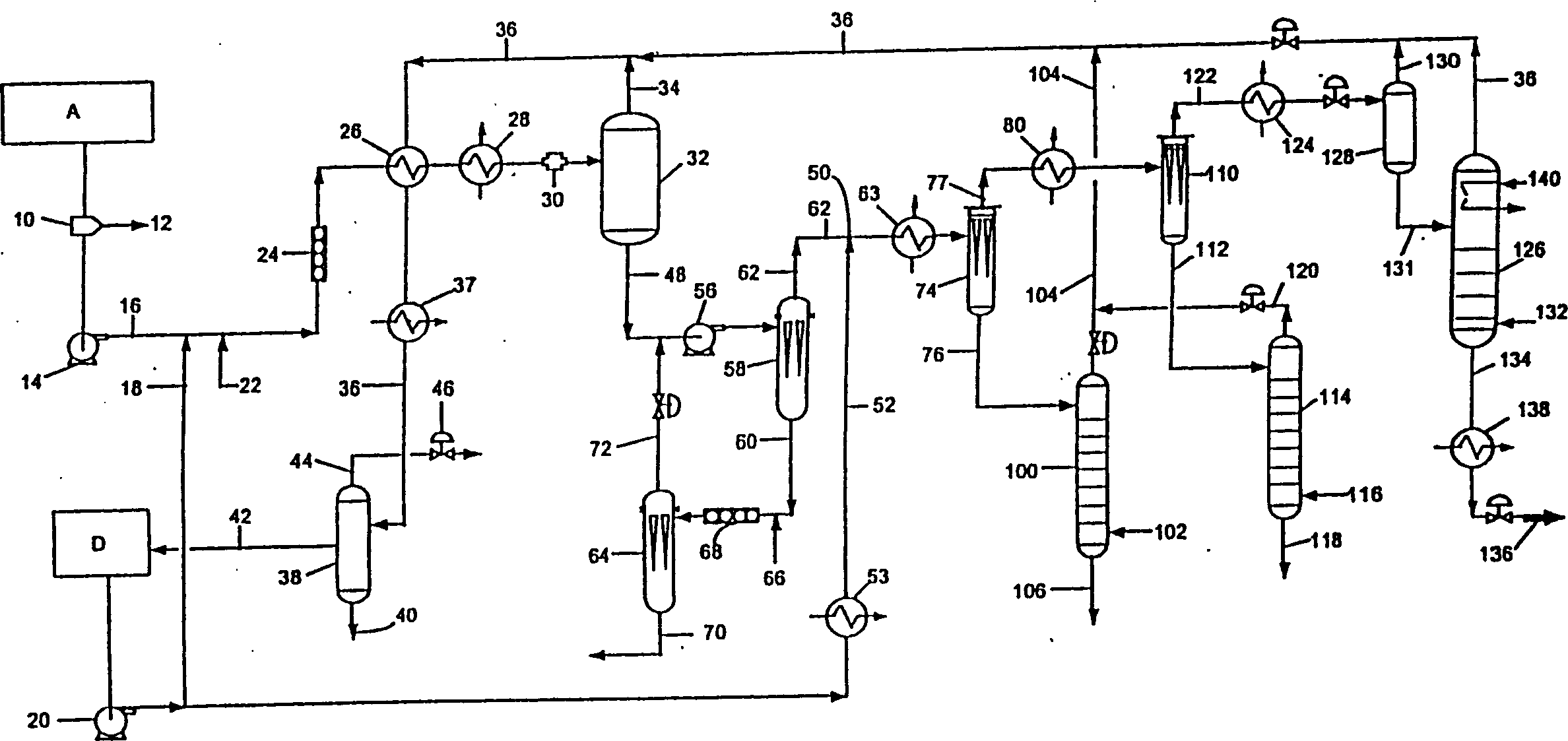

[0015] This method is used to recover useful crude oil from solids such as sand or coke or semi-solids such as bitumen. It is a flexible method that can be used by those skilled in the art to upgrade the quality of many different heavy crudes.

[0016] An integrated process includes the complete processing steps of unrefined heavy crude which may include many, but not necessarily all, of the following steps. Crude oils, especially heavy crudes, vary widely in character, composition and properties. Many variations of the processing method will be apparent from the following description of the processing method for improving the quality of heavy crude oil. Those skilled in the art will recognize many beneficial variations in the practice of the present invention. The vast majority of these steps are well known.

[0017] Coarse mechanical impurities are first removed from the crude oil by passing it through a suitable sized sieve. The sieving devices are arranged in a double ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com