Chemical analyzer, method for dispensing and dilution cup

A technology of injection volume and gravity direction, applied in the field of dilution cups, can solve problems such as strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

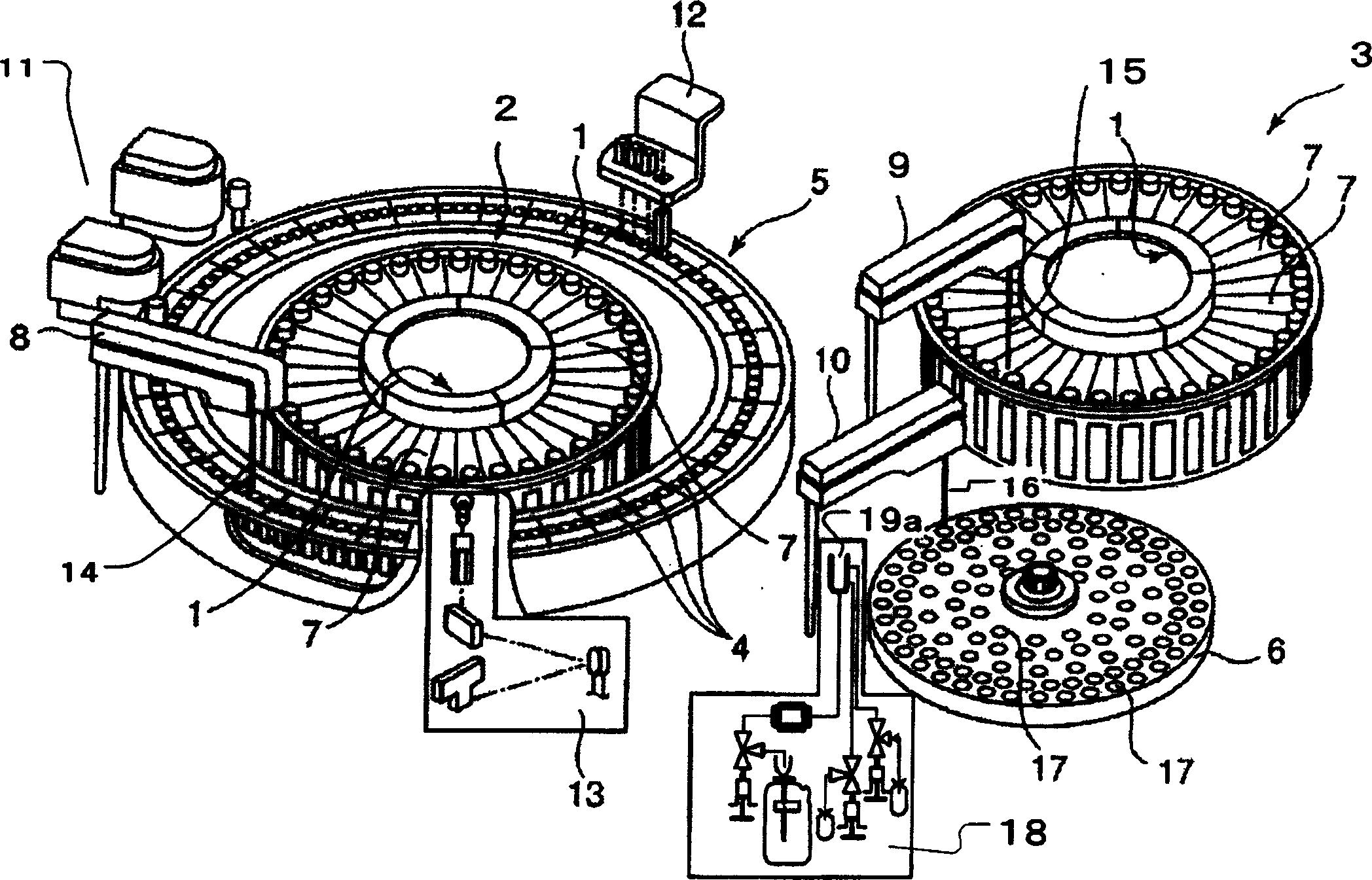

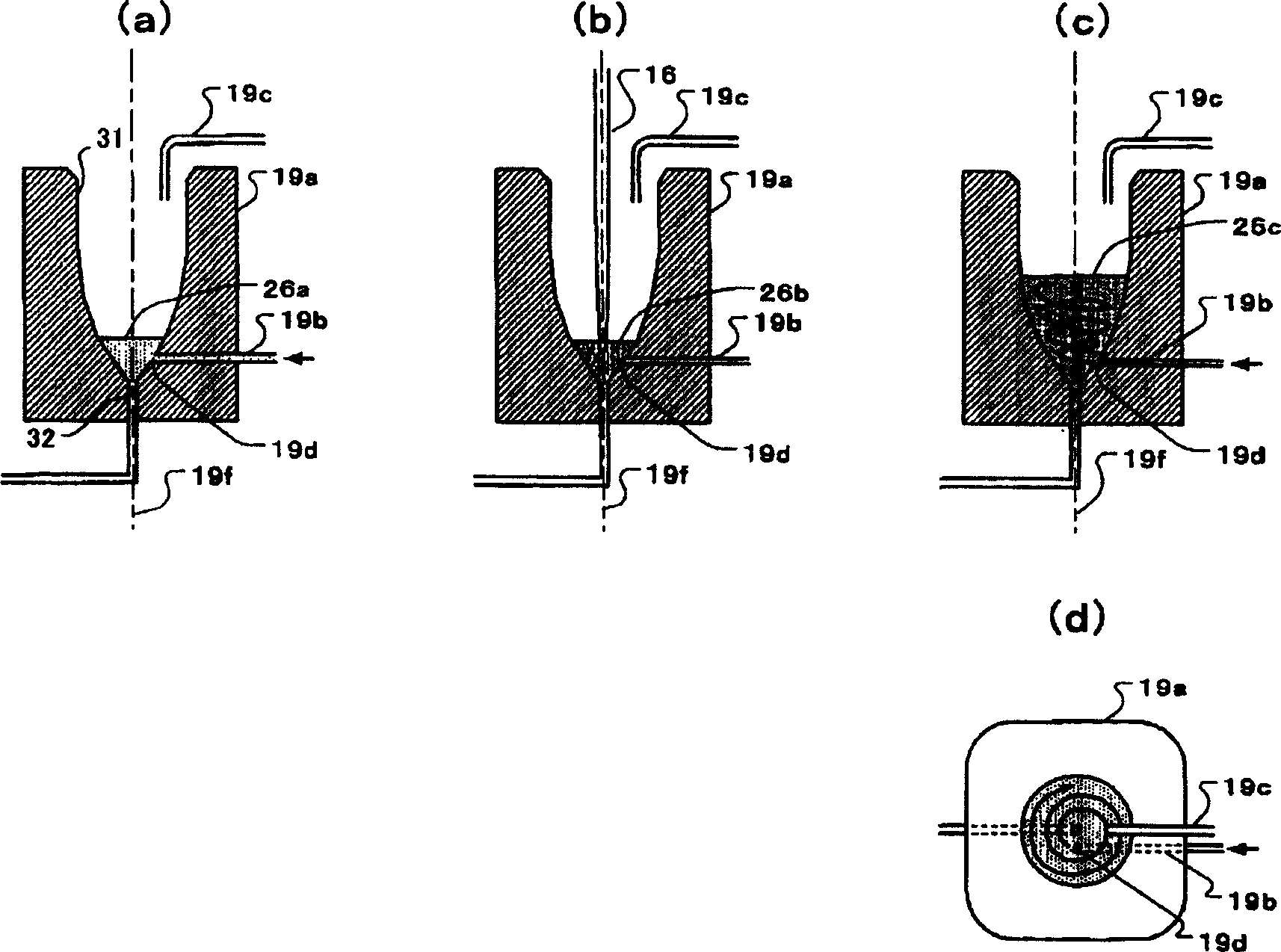

[0026] Refer below Figure 1 to Figure 5 The chemical analysis device, its filling method and dilution cup are explained.

[0027] figure 1 The configuration of the chemical analysis device of the present invention is shown.

[0028] This chemical analysis device has: a reagent rack 1 that accommodates a plurality of reagent bottles 7 containing reagents that react with various components of the test sample, reagent boxes 2 and 3 where the reagent rack 1 can be placed, and A reaction disk 5 serving as a container of a plurality of reaction tubes 4 is disposed thereon. In addition, this chemical analysis device also has: a disc sampler 6 for placing a test sample container 17 for storing a test sample, and a sample injection arm 8, a second reagent injection arm 9, and a sample injection arm 10. The photometric unit 13 for measuring the mixed solution of the test sample and the reagent injected into the reaction tube 4, and the electrolyte measuring unit 18 for measuring th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com