Method and device thereof for secondarily diluting and feeding coagulant

A technology of secondary dilution and coagulant, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of large consumption and uneven dispersion of coagulant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

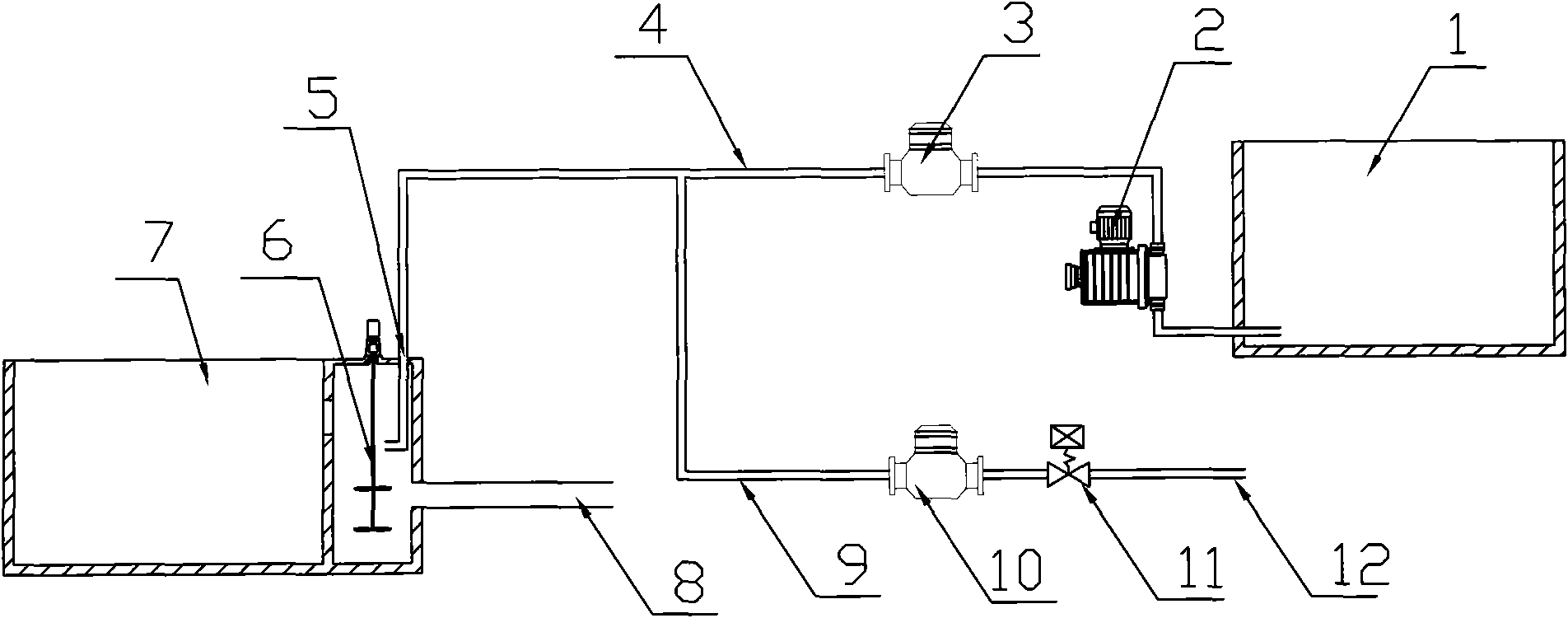

[0020] figure 1 Shown is a kind of equipment for implementing the second dilution and dosing method of coagulant, including dilution tank 1, flocculation reaction tank 7, mixing device 6, infusion pipeline 4, infusion pump 2, diluent flow meter 3, and water pipeline 9. Regulating valve 11 and water flow meter 10; the infusion pipeline 4 starts from the dilution tank 1 and connects to the mixing device before the flocculation reaction tank 7 through the infusion pump 2 and the dilution liquid flow meter 3. The mixing device is a stirring mixing device 6 ; The water delivery pipeline 9 is connected to the position before the diluent dosing point 5 after the diluent flow meter 3 in the delivery pipeline 4 through the regulating valve 11 and the water flow meter 10; The length between the connection position of the pipeline 9 and the diluent dosing point 5 is 120D, that is, 3m.

[0021] Using the above equipment to implement the coagulant secondary dilution dosing method, the fir...

Embodiment 2

[0023] Such as figure 2 Shown is another kind of equipment that implements the coagulant secondary dilution dosing method. The mixing device adopts a pipeline static mixer 13; the inner diameter of the infusion pipeline 4 is φ=32mm, and the infusion pipeline 4 is from the position where the water delivery pipeline 9 is connected to the diluted The length between the liquid dosing points 5 is 100D, that is, 3.2m. The rest are the same as in Example 1.

[0024] Use the above equipment to implement the coagulant secondary dilution dosing method, control the mass concentration of the coagulant primary dilution to 5% during the primary dilution; the dilution water injection point for the secondary dilution is 3.2m before the dilution point 5, control The mass concentration of the coagulant secondary dilution is 0.5%. The rest are the same as in Example 1.

Embodiment 3

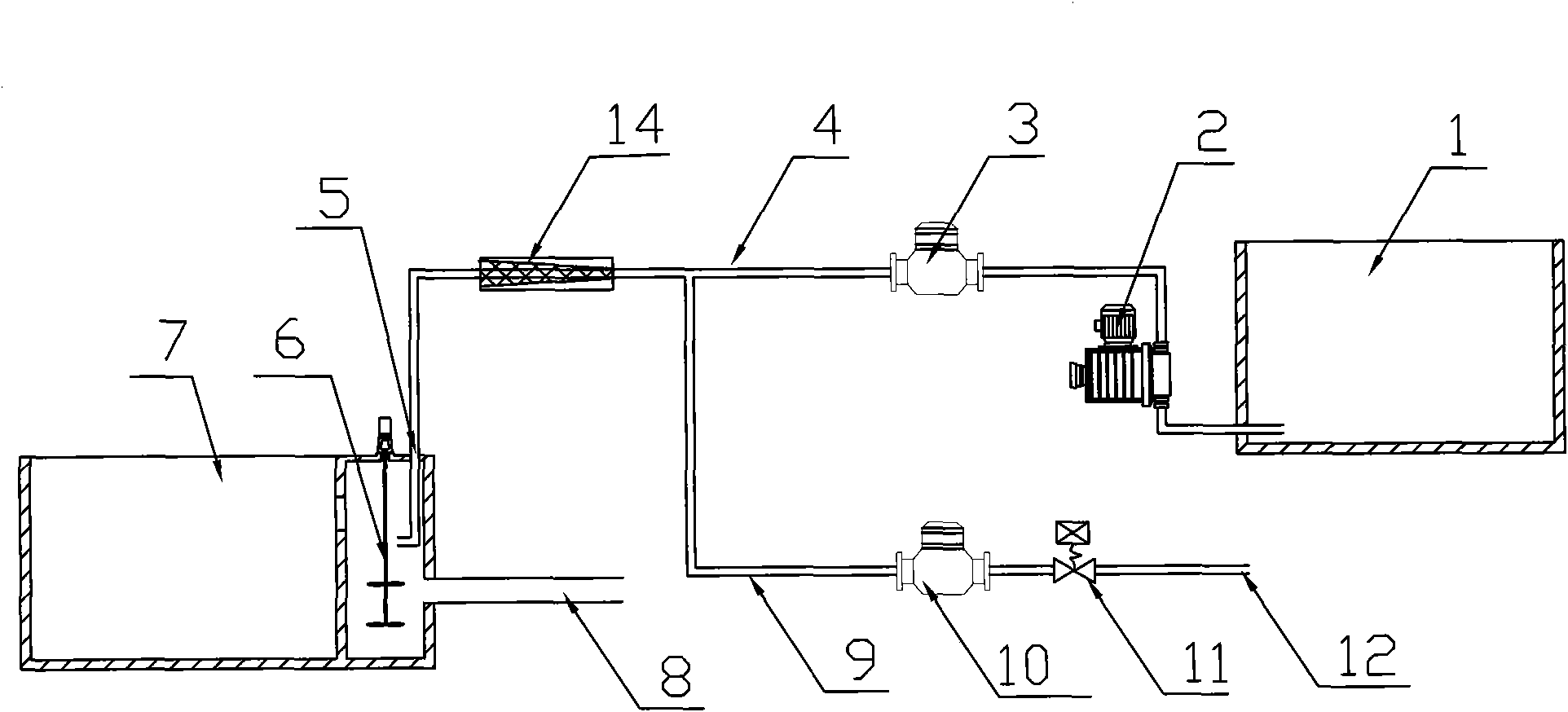

[0026] image 3 Shown is another kind of equipment that implements the coagulant secondary dilution dosing method, the inner diameter of the infusion pipeline 4 is φ=25mm, and the length of the infusion pipeline 4 from the position where the water delivery pipeline 9 is connected to the diluent dosing point 5 is 68D, that is, 1.7m; a static mixer 14 is provided after the connection position of the water delivery pipeline 9 in the infusion pipeline 4 and before the diluent dosing point 5 . The rest are the same as in Example 1.

[0027] Use the above equipment to implement the coagulant secondary dilution dosing method, control the mass concentration of the coagulant primary dilution to 10% during the primary dilution; the dilution water injection point for the secondary dilution is 1.7m before the dilution point 5, control The mass concentration of the secondary dilution of the coagulant is 0.8%. The rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com