A kind of multi-flow drying air knife and method for preparing perovskite thin film in perovskite solar cell by using the air knife

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low substrate coverage, inability to obtain uniform and dense perovskite thin films, uneven surface undulations, etc., to accelerate the solvent Evaporation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

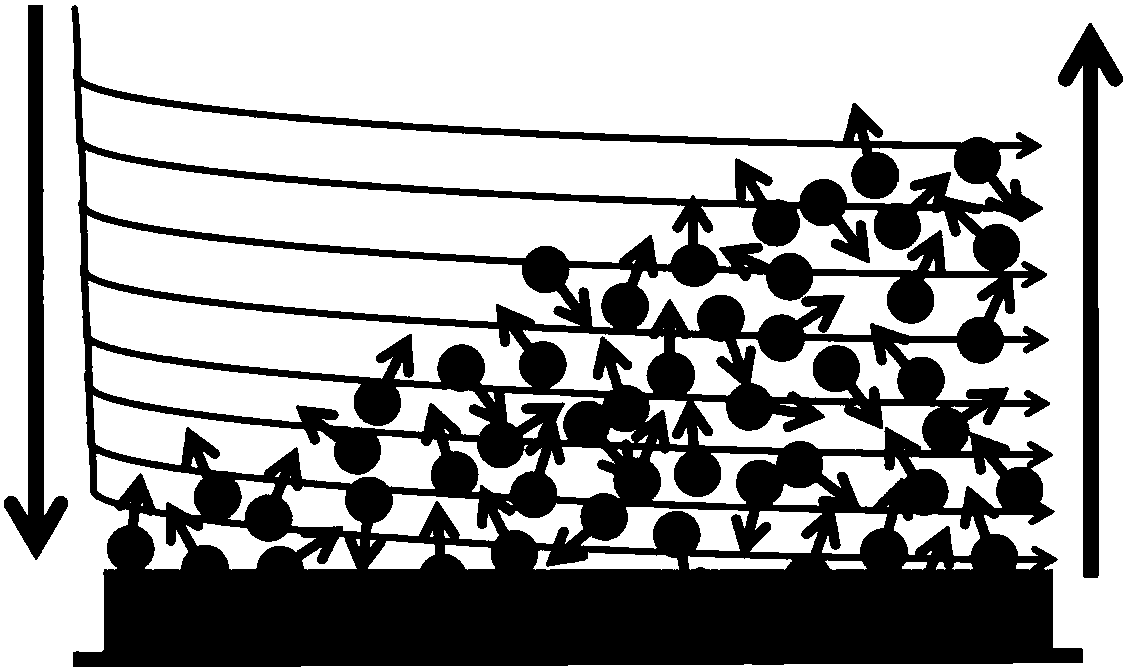

[0046] 1) Using DMF as a solvent, configure CH with a mass percent concentration of 35%. 3 NH 3 PB 3 Solution, spray a layer of prepared perovskite solution on the glass conductive substrate ITO by spraying method to obtain a layer of light yellow liquid film with a thickness of about 2000nm.

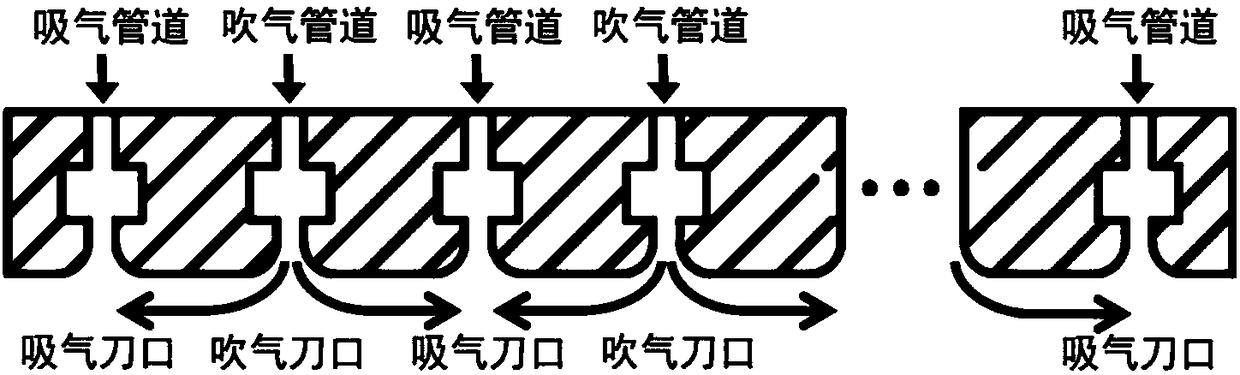

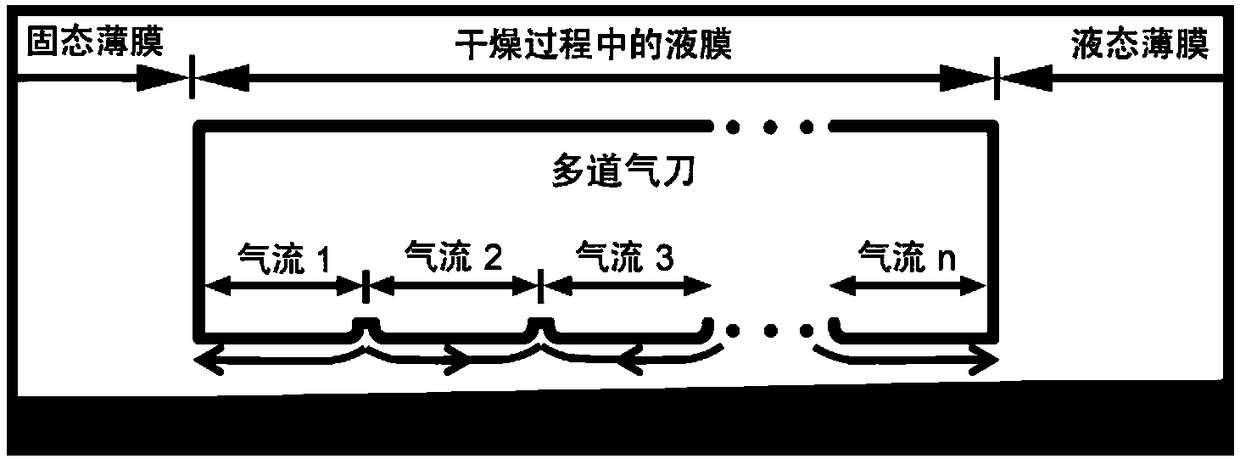

[0047] 2) Place the liquid film under a multi-flow dry air knife with a total blowing channel and a total suction channel at 1.0 mm intervals. The total blowing channel is divided into three branches, and the total suction channel is divided into three branches. , each blowing channel is arranged alternately with the suction channel, the total blowing channel blows at a flow rate of 100LPM (0.1MPa), the airflow temperature is 20°C, the total suction channel sucks at 450LPM, and the dry liquid film area is 50mm ×50mm, the air knife moves at a speed of 15mm / s, within 1.7s, the liquid film is completely dried, and a layer of brown film is obtained.

[0048] 3. Heat the dried film on a h...

Embodiment 2

[0050] 1) Using DMSO as a solvent, configure CH with a mass percentage concentration of 30% 3 NH 3 PB 3 Solution, scrape a layer of prepared perovskite solution on the conductive glass FTO substrate, the liquid film is light yellow and the thickness is about 2000nm.

[0051] 2) Place the liquid film under the multi-flow dry air knives arranged side by side and alternately arranged with three blowing channels and three suction channels at 1.5mm intervals, each blowing channel is blown at a flow rate (0.2MPa) of 200LPM Air, the air flow temperature is 100°C, each suction channel sucks at 250LPM, the area of the dried liquid film is 600mm×400mm, the air knife moves at a speed of 30mm / s, and within 2s, the liquid film is completely dried and a layer of brown is obtained film.

[0052] 3) Place the dried film on a hot plate at 120°C for 9 minutes to obtain a transparent dark brown perovskite film, whose microscopic appearance is as follows: Image 6 Shown in (a) and (b).

Embodiment 3

[0054] 1) Using γ-butyrolactone as a solvent, configure CH with a concentration of 10% by mass 2 (NH 2 ) 2 PbClI 2 Solution, coating a layer of prepared perovskite solution on the conductive glass FTO substrate, the liquid film is light yellow and the thickness is about 3000nm.

[0055] 2) Place the liquid film under the multi-flow dry air knives arranged side by side and alternately arranged with three blowing channels and three suction channels at 0.01mm intervals, each blowing channel is blown at a flow rate (0.05MPa) of 50LPM Air, the air flow temperature is -20°C, each suction channel inhales at 100LPM, the area of the dried liquid film is 80mm×30mm, the air knife moves at a speed of 10mm / s, within 3s, the liquid film is dried and a layer is obtained Brown film.

[0056] 3) Place the dried film on a hot plate at 50° C. for 10 h to obtain a layer of transparent dark brown perovskite film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com