Traversing spiral discharge device for stock bin and discharging method

A technology of spiral unloading and silo, which is applied in the directions of packaging, loading/unloading, transportation and packaging, etc. It can solve problems such as equipment damage, casualties, and easy arching of materials, and achieve the effect of preventing accumulation and protecting reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

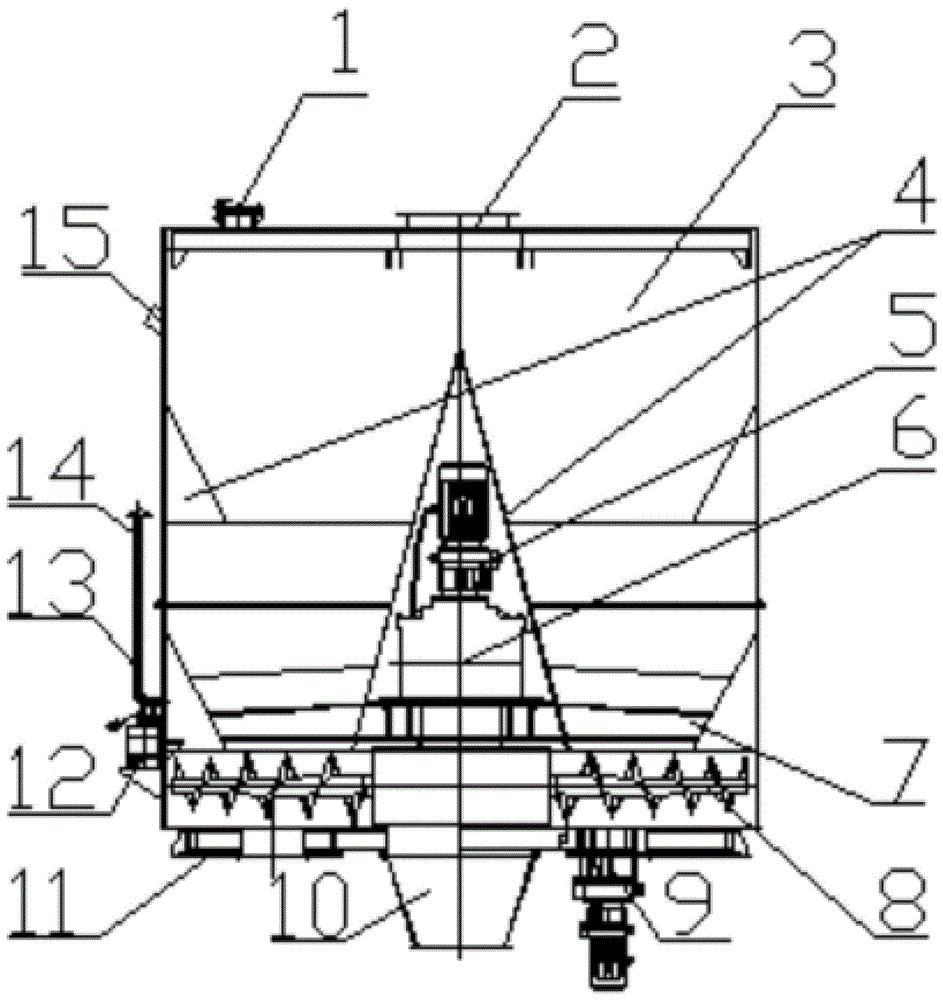

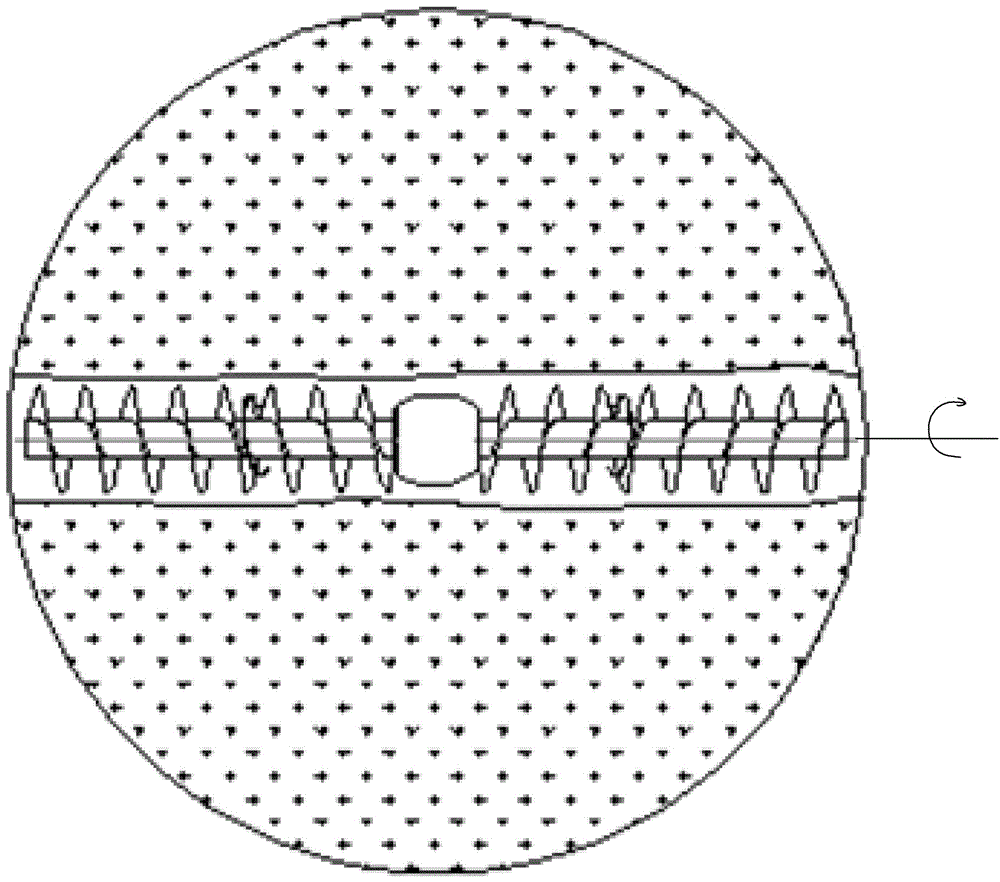

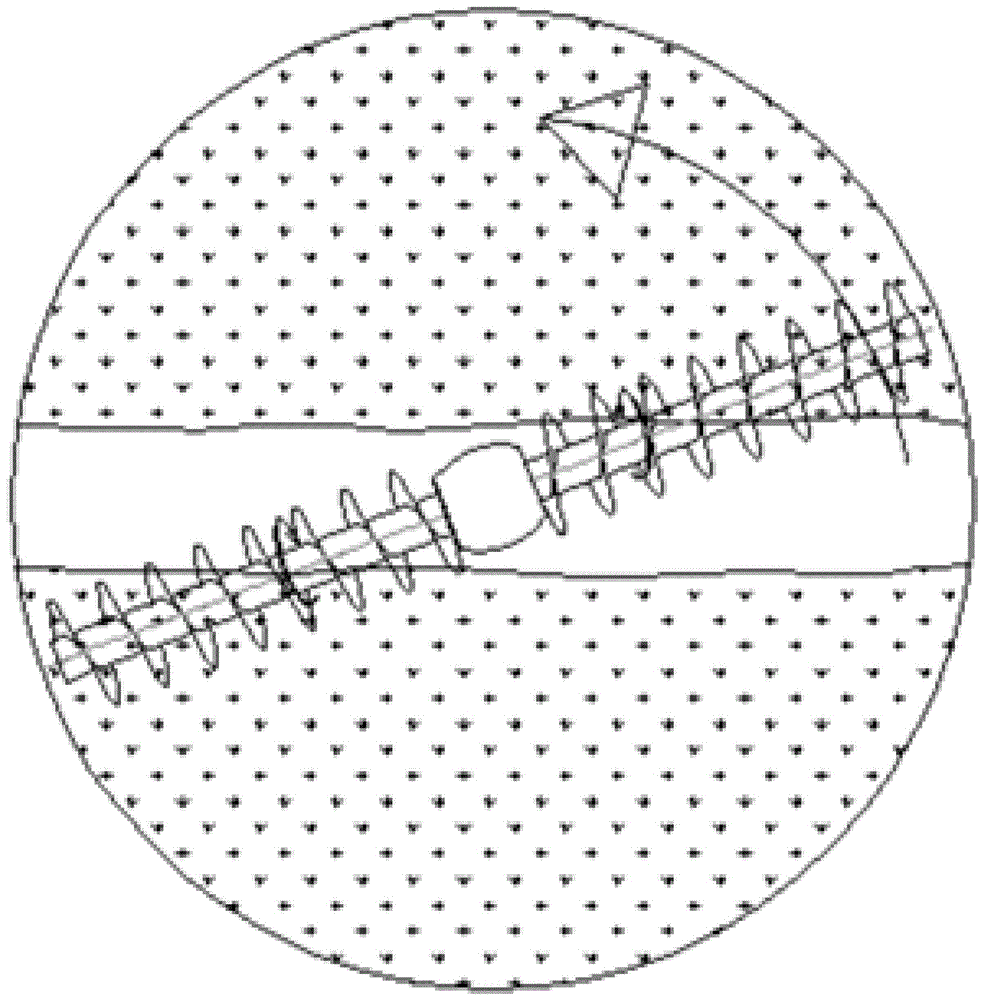

[0034] see Figure 1-3 , the silo traverses the screw unloading device, which includes a circular silo 3 fixed on the top of the installation base 11, the top center of the circular silo 3 is provided with a feed inlet 2, and The side of the feed port 2 is provided with an inspection door 1, and the inside of the circular feed bin 3 is equipped with a decompression cone cover 4, and the inside of the decompression cone cover 4 is equipped with a main rotating motor 5, and the main rotation The motor 5 is connected with the transmission box 6 to drive the screw shaft 8 to rotate along its own axis. The bottom of the circular feed bin 3 is provided with a discharge port 10, which is fixedly installed on the mounting base 11 on the side of the discharge port 10. There is a rotary transmission system 9, and the rotary transmission system 9 drives the screw shaft 8 to make a 360-degree rotary motion along the axis line of the circular feed bin 3.

[0035] Further, a lubricating sy...

Embodiment 2

[0045] The unloading method adopts the silo traversal screw unloading device, injects the material to be processed into the inside of the circular silo 3 through the feed port 2 on the top of the circular silo 3, and the material falls on the supporting decompression bridge 7, when accumulated to After a certain amount, start the main rotary motor 5 and the rotary transmission system 9, and the main rotary motor 5 drives the screw shaft 8 to rotate along its own axis, and the rotary transmission system 9 drives the screw shaft 8 along the direction of the circular feed bin 3. The axis line makes a 360-degree rotary motion. During the operation of the screw shaft 8, the long strips of winding materials in the warehouse are extracted and cut through the hook nails and shear blades provided on itself. The rotary motion can prevent the material from being damaged. Accumulate, and then ensure that the screw shaft 8 traverses the entire circular feed bin 3, and finally completes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com