Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Improve lubrication performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing modified graphene oxide anti-wear agent

ActiveCN104017627AImprove lubrication performanceReduce friction and wearAdditivesSolventRare-earth element

The invention relates to a method for preparing a modified graphene oxide anti-wear agent. The method disclosed by the invention comprises the following steps: adding graphene oxide and a compound containing boron, molybdenum, calcium, copper and rare earth elements into a three-mouth flask, adding an organic solvent into the container, stirring, heating, adding concentrated sulphuric acid serving as a catalyst to react, heating to the boiling point temperature of the solvent to evaporate the solvent, putting the product into a vacuum drying oven to obtain the modified graphene oxide anti-wear agent. The method disclosed by the invention has the advantages that the problems that oily lubricants and solid lubricants are high in cost, strict in service condition, troublesome in replacement, not friendly to environment due to produced wastes and the like are solved; by utilizing the characteristics that the graphene oxide is ultrathin, ultrahard, ultra lubricative and resistant to corrosion and high temperature, the novel anti-wear agent with excellent performances is prepared through the surface modification of the elements with the anti-wear property; by means of the product, the lubricating property of the lubricants can be remarkably improved, the friction and the wear of the mechanical movement surface are reduced by a big margin and the efficacies of saving material and energy are provided.

Owner:扬州智创企业运营管理服务有限公司

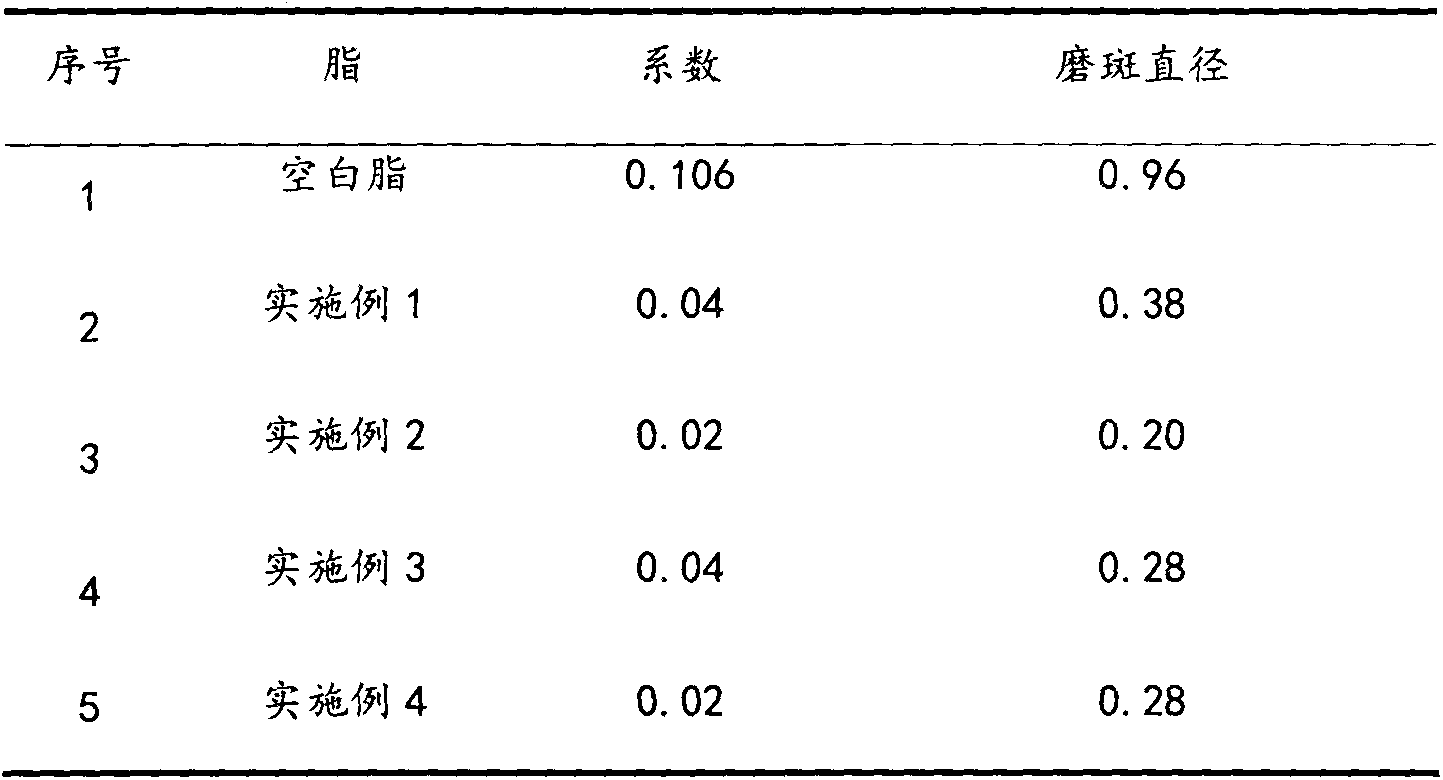

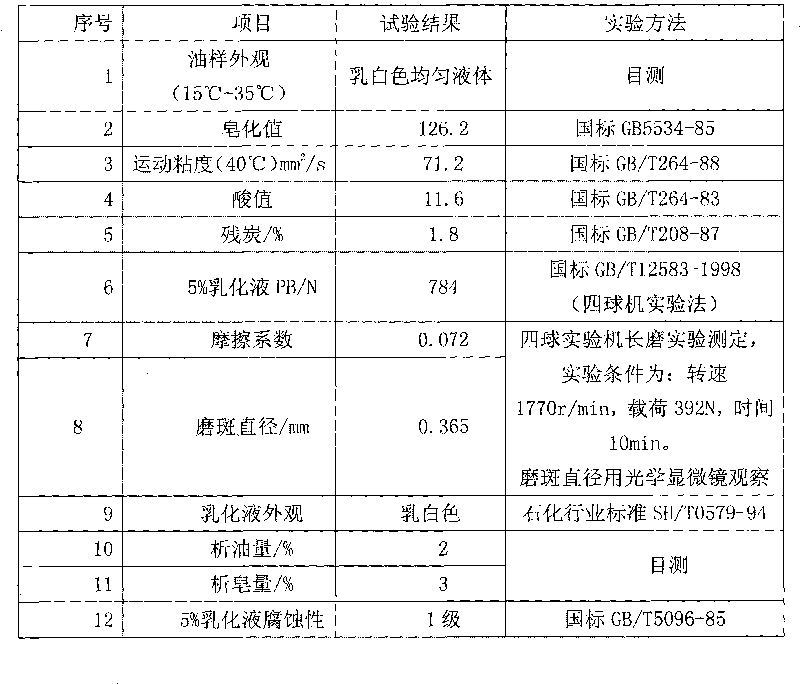

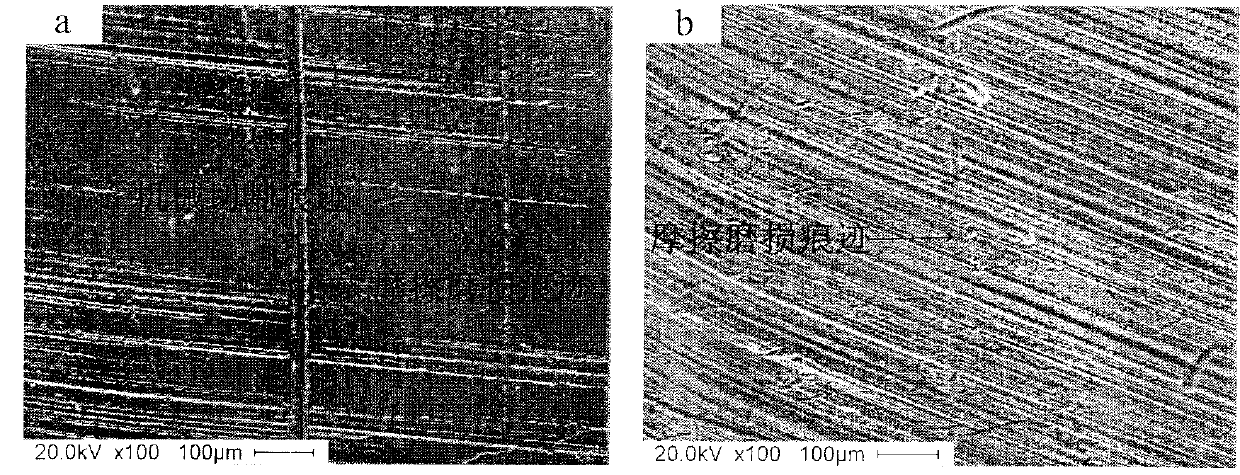

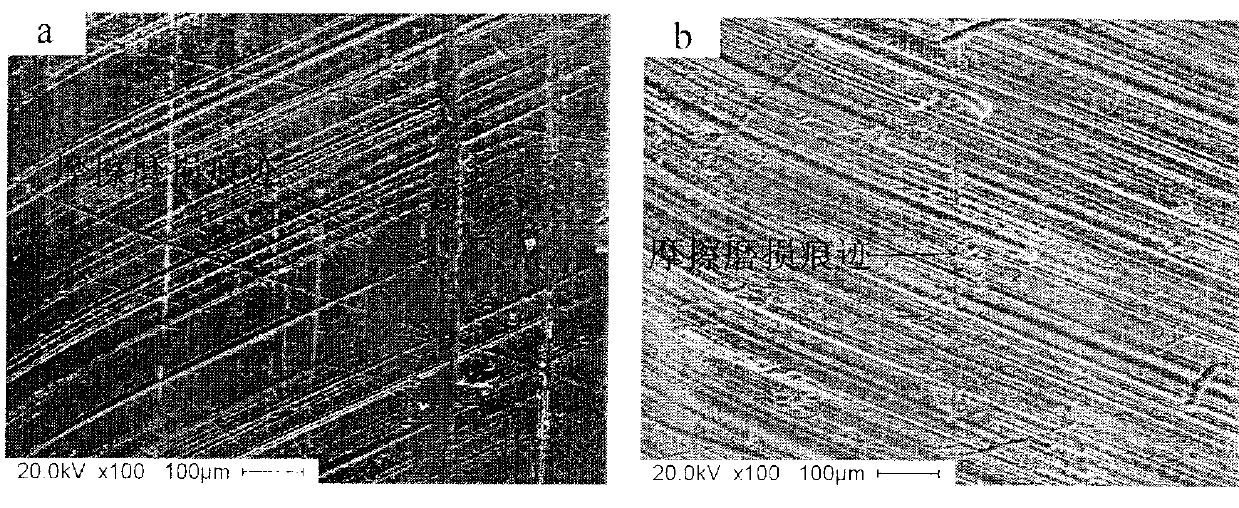

Plate-strip steel cold-rolling emulsified oil containing nanometer hexagonal boron nitride particles, and preparation method

InactiveCN101698808AReduce wearImprove lubrication performanceAdditivesPigment treatment with non-polymer organic compoundsLubricationEmulsion

The invention belongs to the technical field of lubricant, and relates to plate-strip steel cold-rolling emulsified oil containing nanometer hexagonal boron nitride particles, and a preparation method, which is used for lubrication in a plate-strip steel cold-rolling process. The emulsified oil comprises the following components in percentage by weight: 0.2 to 1 percent of nanometer hexagonal boron nitride particles, 62 to 72 percent of 12-DEG C palm oil, 0 to 5 percent of vulcanized castor oil, 10 to 12 percent of Span to 80, 6 to 8 percent of Tween-60, 5 to 6 percent of oleic acid, 1.5 to 2 percent of triethanolamine, 4 to 5 percent of petroleum sodium sulfonate with 35 to 45 percent of active substances, and 0 to 2 percent of triorthocresol phosphate. The preparation method adopts the Span-80 serving as an emulsifier and the oleic acid serving as polymeric fatty acid in a formulation to achieve the aim of dispersing nanoparticles through surface modification and molecular complexation without changing the properties of nanometer hexagonal boron nitride or affecting the stability and rust resistance of the primary rolling emulsion. After the plate-strip steel cold-rolling emulsified oil containing nanometer boron nitride particles is diluted with water into the emulsion with volume concentration between 2 and 8 percent, the emulsion can be directly used in the cold-rolling process of plate-band steel. Moreover, the emulsified oil has the advantages of high extreme-pressure lubrication performance, good cooling property, long antirust cycle and safe environmental-friendly use.

Owner:UNIV OF SCI & TECH BEIJING

Reciprocating compressor for refrigerator

InactiveUS20060048523A1Improve lubrication performanceImprove the lubrication effectPositive displacement pump componentsHeat-exchange elementsRefrigerantLubrication

A reciprocating compressor with an improved lubrication performance by using a lubricant in harmony with a refrigerant compressed therein, which includes: a hermetic container (6) to which a suction pipe (2) for sucking a refrigerant and a discharge pipe (4) for discharging a compressed refrigerant; a driving unit (8) disposed inside the hermetic container (6) and generating a reciprocal motional force; a compression unit (10) for receiving the reciprocal motional force from the driving unit (8) and compressing an ethane group-based R134a refrigerant; and a lubrication unit (12) for supplying a lubricant to each motional portion of the driving unit (8) and the compression unit (10) and performing a lubricating operation thereon and using an ester-based lubricant, a sort of synthetic fluid with a density of 0.91˜0.99 (15 / 4° C.)

Owner:LG ELECTRONICS INC

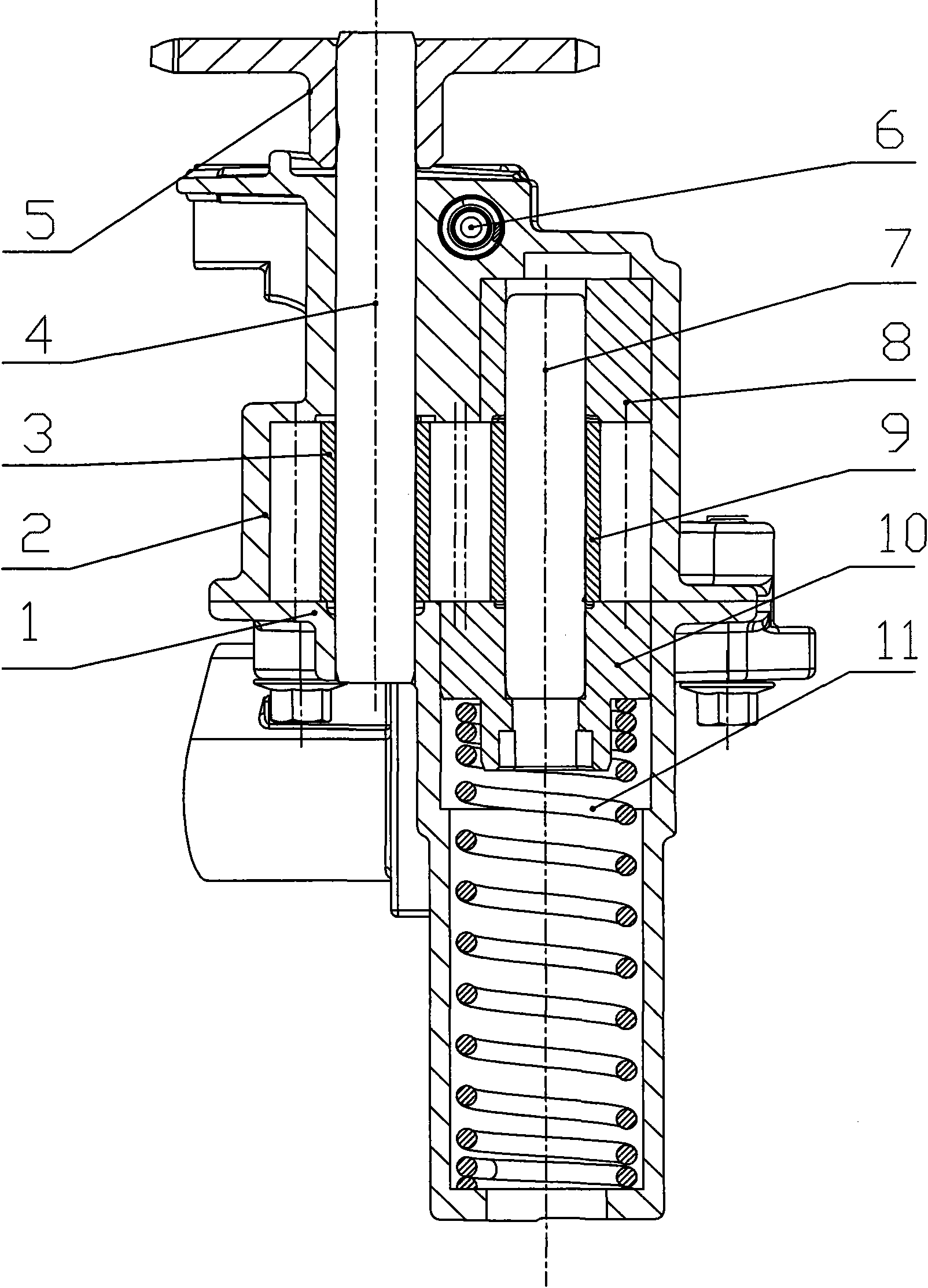

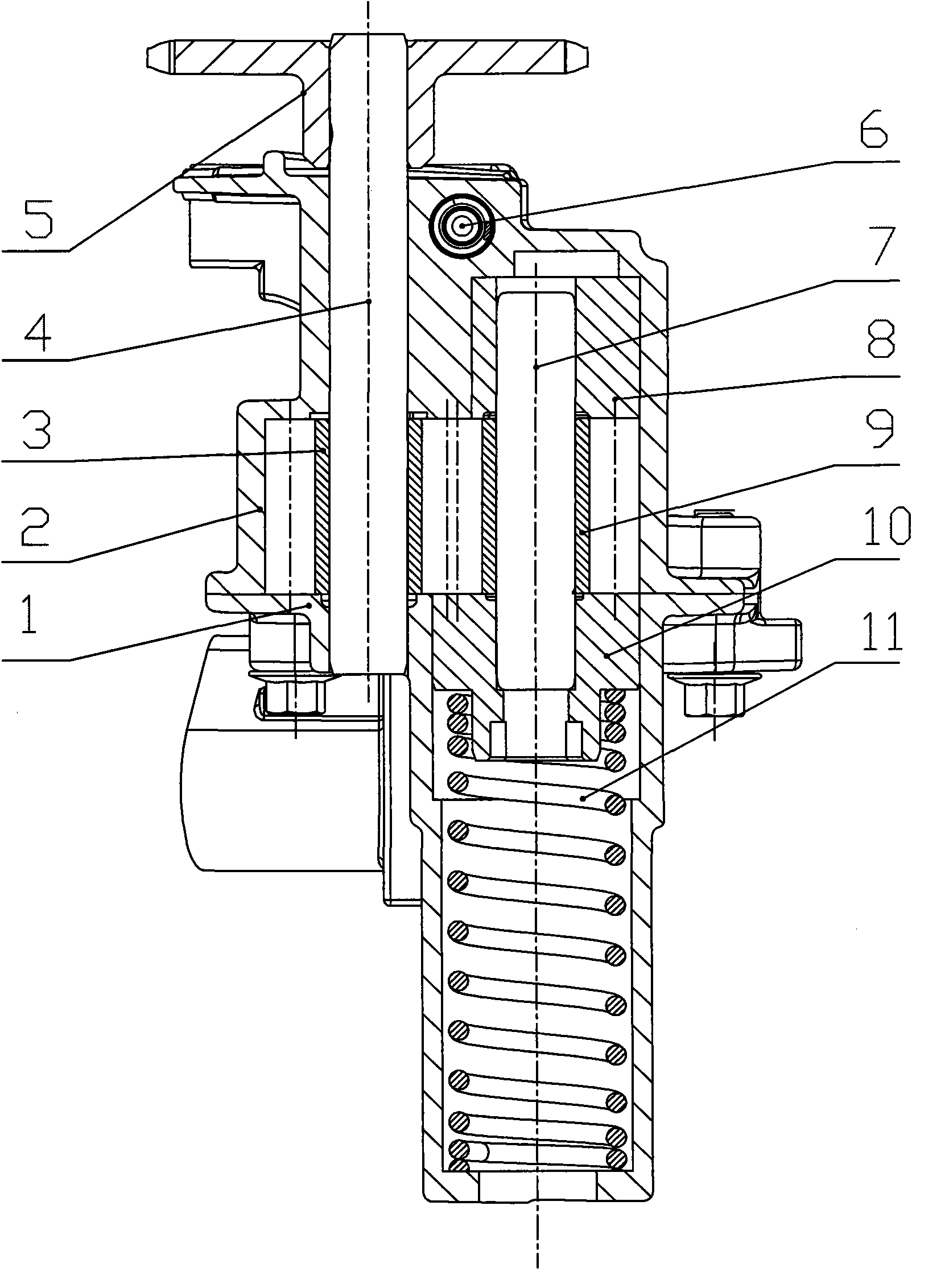

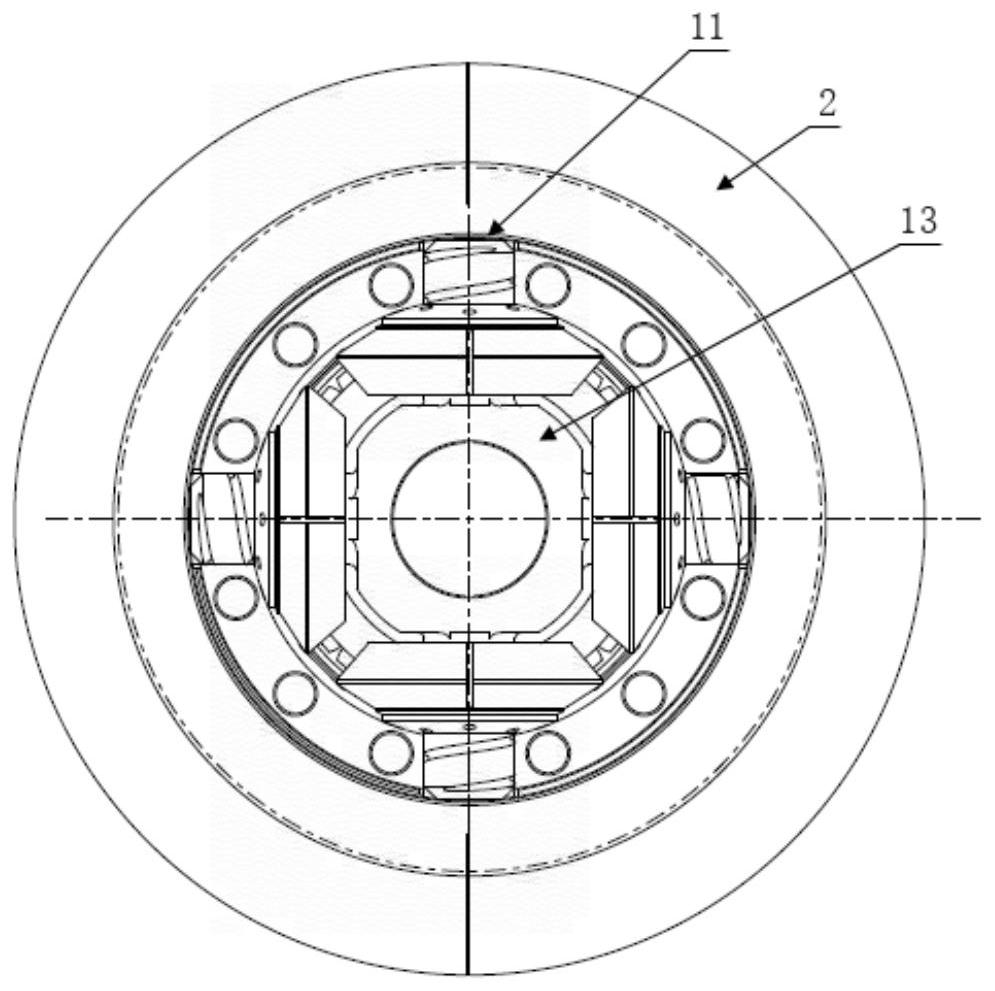

Variable-displacement gear-type oil pump

InactiveCN101881368AReduce the temperatureImprove lubrication performanceLubricating pumpsEngineeringVariable displacement

The invention provides a variable-displacement gear-type oil pump comprising a pump cover 1, a pump body 2, a driving gear 3, a driving shaft 4, a transmission gear 5, adjustment valve components 6, a driven shaft 7, a segmental sliding block 8, a driven gear 9, a whole-circle sliding block 10 and a spring 11, wherein the driving shaft 4 is mounted in the axial hole of the pump body 2 and the pump cover 1; the transmission gear 5 is in press fit with the outer end of the driving shaft 4; the driving gear 3 in interference fit is mounted in the middle of the driving shaft 4 to constitute a transmission component; the driven shaft 7, the segmental sliding block 8, the driven gear 9, the whole-circle sliding block 10 and the spring 11 constitute a variable component; the adjustment valve components 6 are arranged at intervals on the outer edge of the segmental sliding block which is separated from the driving shaft 4; and the transmission component of the driving gear 3 and the variable component of the driven gear 9 are arranged oppositely, and the transmission component of the driving gear 3, the variable component of the driven gear 9 and the adjustment valve components 6 can be combined into the variable-displacement gear-type oil pump. Accordingly, the invention can reduce the temperature of the lubricating oil, improve the lubricating performance of the engine oil, reduce the power loss of the engine, improve the efficiency and economical efficiency of the engine and reduce the production cost.

Owner:HUNAN OIL PUMP

Low sulfur diesel antiwear additive

InactiveCN103289763ALow acid valueImprove lubrication performanceLiquid carbonaceous fuelsFuel additivesRicinelaidic acidToluene

The invention discloses a low sulfur diesel antiwear additive. The low sulfur diesel antiwear additive is prepared from the components in parts by weight: 3-8 parts of triethanolamine, 10-30 parts of toluene, 30-80 parts of castor oil acid, 10-30 parts of glycerol, 5-20 parts of polyethylene glycol and 2-6 parts of antioxidant. According to the low sulfur diesel antiwear additive disclosed by the invention, the glycerol and the polyethylene glycol with a proper proportion are used as polyhydric alcohols, and reaction is carried out on the polyhydric alcohols and the castor oil acid to prepare the low sulfur diesel antiwear additive. The low sulfur diesel antiwear additive has the advantage of low acid value and can be used for obviously improving the lubricating property of diesel.

Owner:WUJIANG DEZUO DAILY CHEM PROD

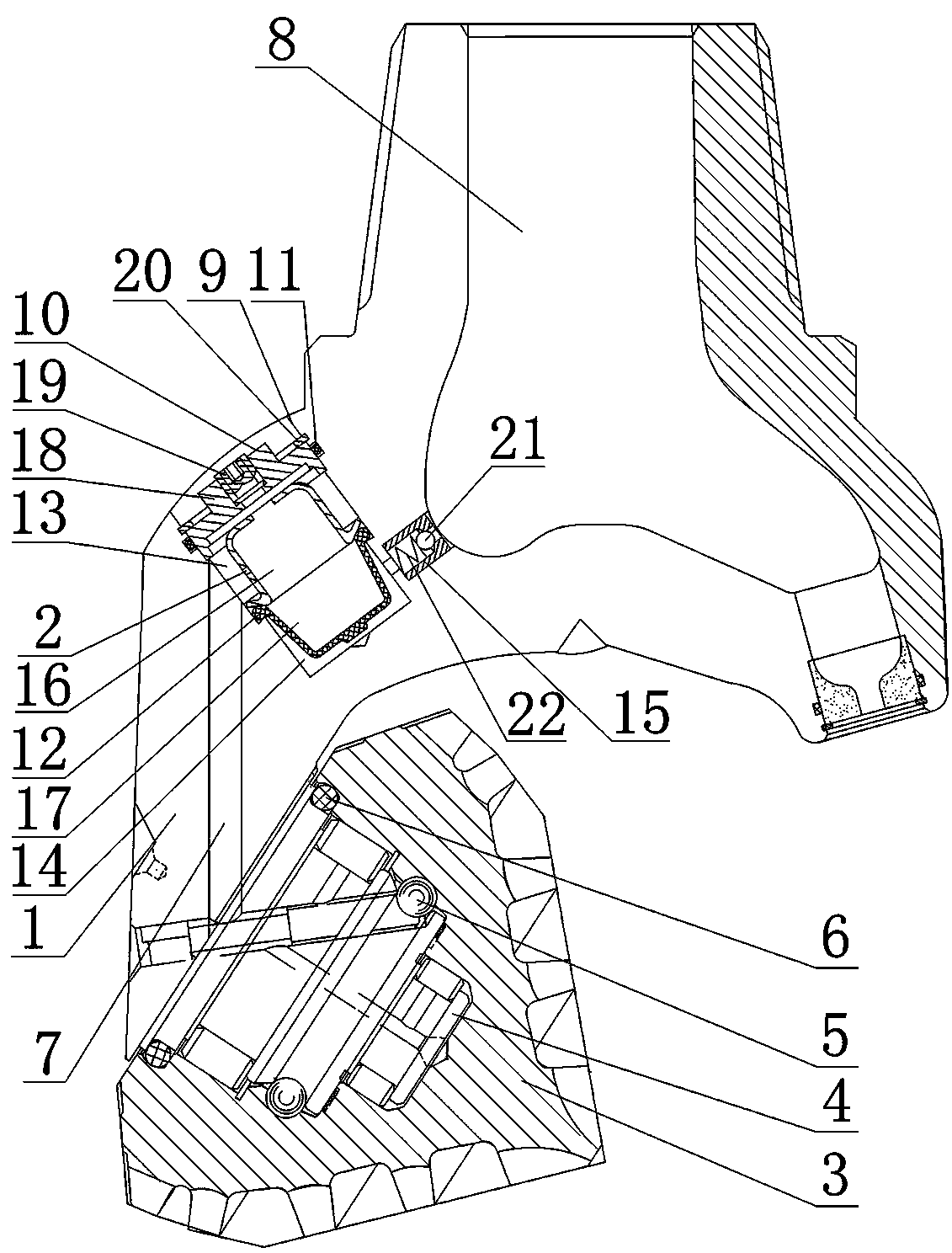

Micro-positive pressure auto-compensation rock bit lubricating system

ActiveCN103233682AImprove lubrication performanceExtended service lifeDrill bitsLubricationCounter flow

The invention discloses a micro-positive pressure auto-compensation rock bit lubricating system which comprises a tooth claw (1) and a tooth wheel (3). A slurry channel (8) is arranged in the tooth claw (1), an oil storage bag hole (9) is arranged on the upper portion of the tooth claw (1), an oil storage bag (10) is arranged in the oil storage bag hole (9) and is internally communicated with an oil passing channel (7) through an oil duct, and a compensation cavity (14) is communicated with the slurry channel (8) through a pressure leading hole (15). The micro-positive pressure auto-compensation rock bit lubricating system has the advantages that pressure of slurry in a bit serves as driving force of the auto-compensation rock bit lubricating system, the pressure leading hole cannot be blocked easily, service life of the rock bit is prolonged; pressure of slurry in the rock bit serves as compensation lubrication power and is larger than annulus pressure, pressure differential of the lubricating system is remarkably increased, and micro-positive pressure auto-compensation is achieved; a roll ball and a spring are arranged, pressure drop is formed, counter flow of the slurry is avoided, stability of the driving force is enhanced, and lubricating efficiency is improved.

Owner:四川保瑞特钻头有限公司

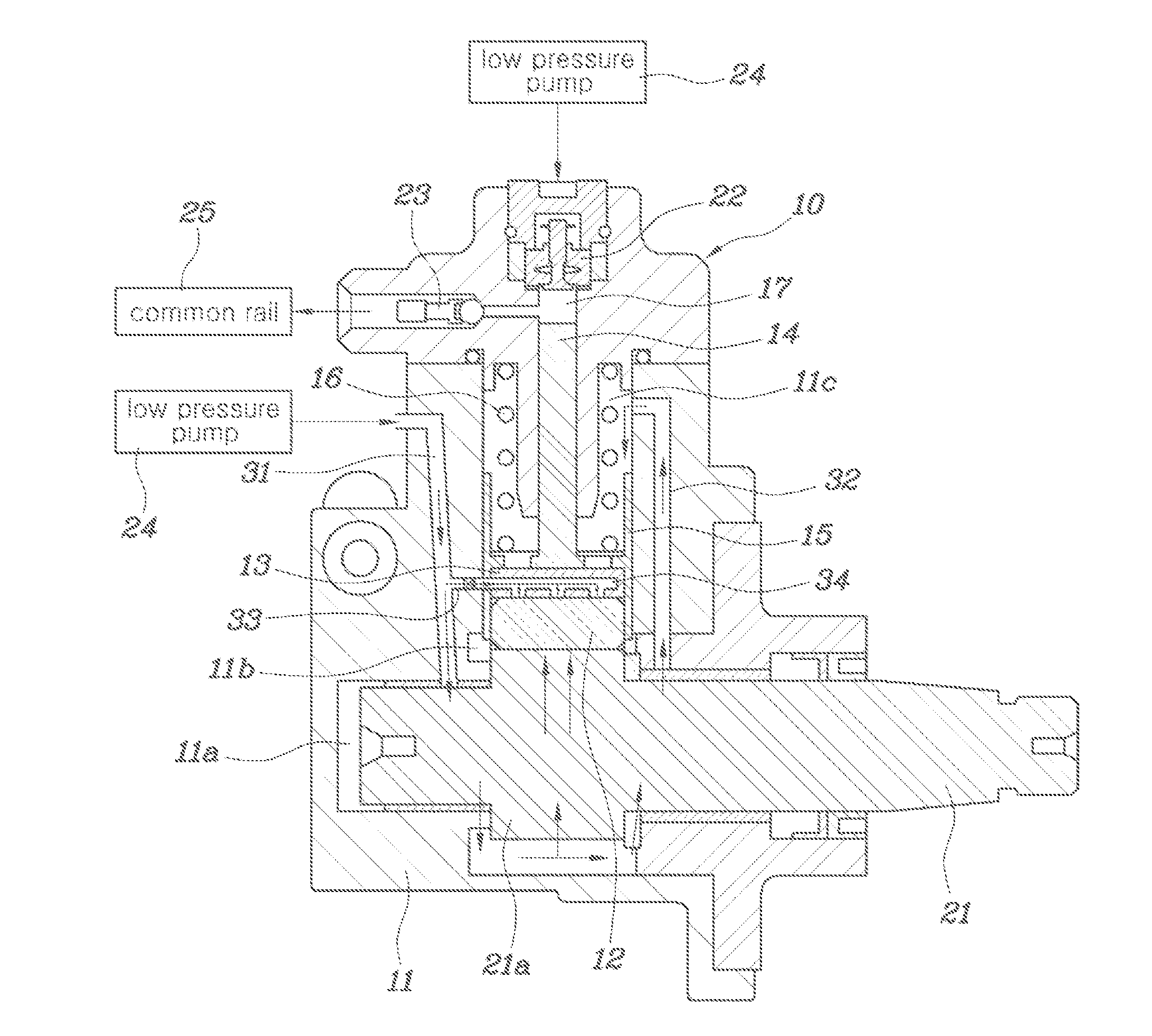

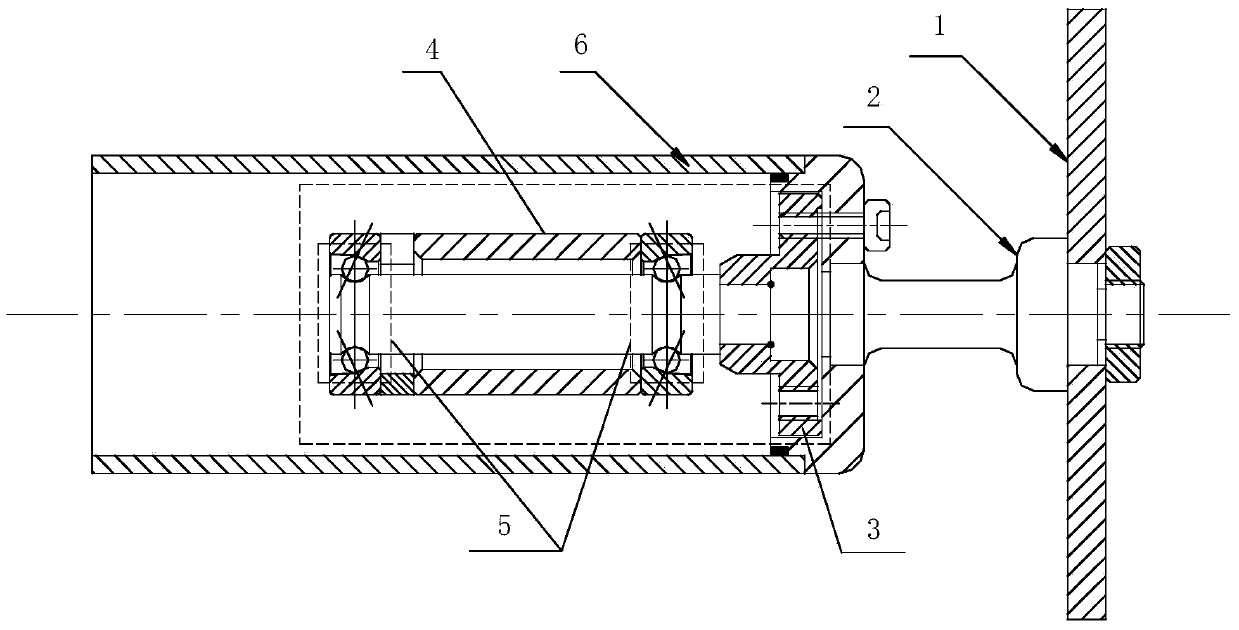

Lubrication apparatus of high pressure pump for common rail system

InactiveUS20150004012A1Shorten lengthImprove lubrication performancePositive displacement pump componentsFuel injecting pumpsLubricationEngineering

A lubrication apparatus of a high pressure pump for a common rail system is configured such that a sufficient amount of lubrication fuel can be supplied from a low pressure pump to the frictional junction between a roller and a shoe within a short period of time, thereby efficiently improving the lubrication performance of the frictional junction.

Owner:HYUNDAI MOTOR CO LTD

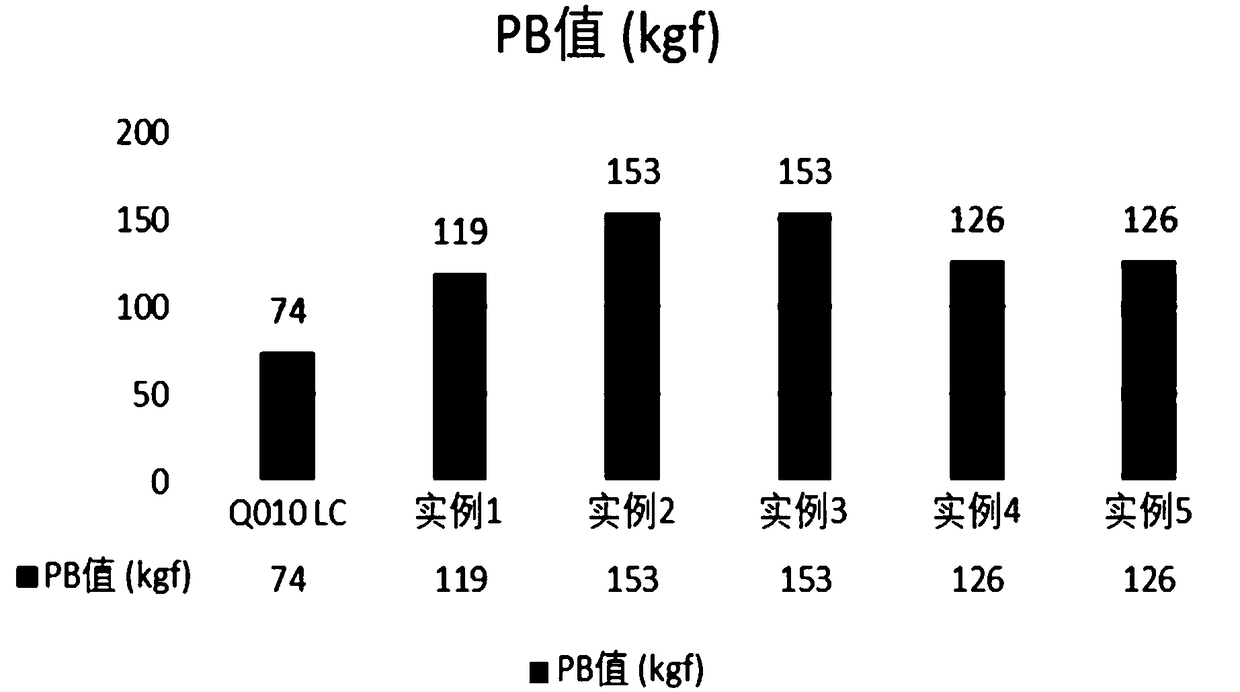

Graphene lubricating grease and preparation method and application thereof

PendingCN109401823AImprove lubrication performanceReduce coefficient of frictionThickenersCorrosion resistantGraphene

The invention provides graphene lubricating grease. The compound is prepared from the following components in parts by weight: 70-80% of lubricating grease, 13-17% of a thickening agent, 1-3% of an additive and the balance of graphene base oil. The invention further provides a preparation method of the compound and application of the compound to preparation of lubricating oil with energy saving and emission reduction effects. The compound provided by the invention has the advantages that the lubricating performance of the lubricating oil can be significantly improved, the friction coefficientis decreased, the abrasion loss is greatly reduced, and the significant friction corrosion resistant performance is achieved; meanwhile, by dispersing a surface-modified graphene nano material into the base oil for the lubricating oil, a layer of abrasion resistant graphene film can be formed on a friction interface; therefore, the graphene lubricating grease has great lubricating performance, abrasion resistance, corrosion resistance, oxidation resistance and rust resistance, and can significantly prolong the life of mechanical parts.

Owner:唐山久鑫科技有限公司

Super-high lubricating property cutting oil and preparation method thereof

ActiveCN109439419AImprove lubrication performancePromote degradationLubricant compositionLubricationAntioxidant

The invention discloses super-high lubricating property cutting oil which comprises the following components in percentage by weight: 35.0-65.0% of a synthetic ester oil composition, 30.0-45.0% of rapeseed oil, 1.5-3.0% of a penetrant, 0.1-1.5% of an antioxidant, 0.1-0.5% of a copper corrosion inhibitor, 0.5-3.0% of an anti-wearing agent, 5.0-10.0% of an extreme pressure agent, 1.0-5.0% of a purification dispersant and 0.1-0.5% of an oil mist resistant agent. According to the super-high lubricating property cutting oil disclosed by the invention, the lubricating properties of the cutting oil can be improved by using the penetrant, the penetrant and a synthetic ester have synergistic effects, the anti-wearing agent and the extreme pressure agent can be rapidly infiltrated into contact areasof cutters and metals through chemical mechanisms in the mechanical processing process, lubricating functions of the anti-wearing agent and the extreme pressure agent can be brought into play sufficiently, lubrication requirements of heavy load processing of refractory materials can be met, and heavy load processing comprises hole reaming, deep hole drilling, tapping and broaching.

Owner:QUAKER CHEM CHINA

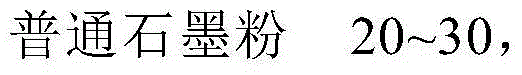

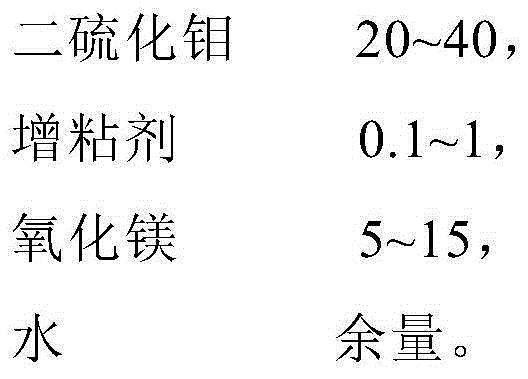

Nano graphite composite lubricant for cold extrusion, and preparation method and application thereof

ActiveCN104946346AExcellent Diffusion and Protective ColloidImprove lubrication performanceAdditivesDecompositionToxicity

The invention relates to a nano graphite composite lubricant for cold extrusion, and a preparation method and application thereof. 0.6-1.5 wt% of nano graphite and 3-9 wt% of chemical dispersant are added into a common graphite lubricant for cold extrusion to obtain the nano graphite composite lubricant for cold extrusion. Compared with the prior art, due to the addition of the nano graphite particle, the lubricating property of the lubricant is further enhanced as compared with the traditional cold extrusion lubricant, and the lubricant has the advantages of high temperature resistance, stable chemical properties, low tendency to decomposition and no toxicity or odor. Due to the special properties of the graphite granules, the friction factor in the extrusion forming process is further lowered, and the surface quality of the formed part is further enhanced, thereby satisfying the production of parts with higher requirements for dimensional accuracy and surface quality.

Owner:SHANGHAI UNIV OF ENG SCI

Preparation method of slow release type caking-preventing granular fertilizer

InactiveCN107963923AImprove lubrication performanceImprove liquidityAnimal corpse fertilisersOrganic phosphatic fertilisersFertilizerUrea

The invention discloses a preparation method of a slow release type caking-preventing granular fertilizer, and belongs to technical field of agricultural fertilizer preparation. Poly (allyl amine) andan organic solvent are used under the effects of carbon dioxide gas, pretreatment is used for granular urea; chicken feather, water and sucrose are stirred and mixed, Baclicus lincheniformis is added, and after isothermal stirring and fermentation are carried out, disinfection, filtering and condensation are carried out in order to prepare feather hydrolysate; ultrasonic dispersion is carried outfor mica powder, phosphatide, mucoprotein and water in order to obtain dispersion liquid; feather hydrolysate and dispersion liquid are mixed in order to obtain film forming liquid; and finally, in afluidized bed, the film forming liquid is atomized and coated on the surface of the pretreated granular urea, drying is carried out, and the slow release type caking-preventing granular fertilizer isobtained. The slow release type caking-preventing granular fertilizer has excellent slow releasing effects and anti-caking performance.

Owner:常州杰轩纺织科技有限公司

TC4-based self-lubricating material and preparation method thereof

ActiveCN111266576AImprove lubrication performanceImproves Strength and ToughnessAdditive manufacturing apparatusIncreasing energy efficiencyTribologyTitanium alloy

The invention relates to a TC4-based self-lubricating material and a preparation method thereof. A TC4 titanium alloy is a matrix, and Sn-Ag-Cu and TiC are a lubricating phase and a reinforcing phase,wherein the addition amount of the Sn-Ag-Cu is (6.0-8.0) wt.% of the mass of the TC4 titanium alloy of the matrix, the addition amount of TiC is (1.5-2.0) wt% of the mass of the TC4 titanium alloy ofthe matrix, and the material is prepared is prepared by TC4 titanium alloy matrix spherical powder containing the Sn-Ag-Cu and the TiC through a selective laser sintering method. The TC4-based self-lubricating material compounds the Sn-Ag-Cu and the TiC in situ in the TC4 titanium alloy matrix, the obtained self-lubricating material has excellent mechanical property and tribological property, thefriction coefficient and the wear rate in the friction and wear process are low, the material preparation efficiency is high, the preparation method is simple and novel, process parameters in the preparation process are easy to control, and the self-lubricating material is suitable for popularization and application.

Owner:HENAN INST OF ENG

Fully-synthesized aqueous watch-drilling fluid, preparation method and using method thereof

ActiveCN102703195AGood emulsifying and dispersing abilityImprove lubrication performanceLubricant compositionChemistryTotal synthesis

The invention discloses a fully-synthesized aqueous watch-drilling fluid, and a preparation method and a using method thereof. According to the fully-synthesized aqueous watch-drilling fluid, a synthetic ester is replaced by a special polymeric self-emulsifying ester, such that the drilling lubricating fluid has a good emulsifying and dispersing ability; by virtue of inversion performance of the polymeric polyether, the lubricating property of the drilling lubricating fluid is improved; through an environment-friendly coupling agent and a special rust-proof agent, the drilling lubricating fluid also has a bactericidal effect and the service life of the drilling lubricating liquid is effectively prolonged; indexes of the drilling lubricating liquid meet or exceed relevant indexes of GB6144-85; the drilling lubricating liquid is long in service life; the drain interval for a concentrated oil pool is more than two years; and the drain interval for a single oil pool is more than six months.

Owner:AMER TECH CO LTD

Cutting fluid and preparation method thereof

ActiveCN107011977AImprove lubrication performanceReduce the roughness of the machined surfaceLubricant compositionContrast mediumWater soluble

The invention discloses a cutting fluid and a preparation method thereof. The preparation method comprises the steps of mixing trimethylolpropane fatty acid ester, ternary polycarboxylate, sebacic acid, triethanolamine, guerbet alcohol, ethylene oxide cyclohexylamine and benzotriazole at the ratio, adding to water, stirring evenly, heating, reacting for a certain period of time to form a transparent solution and a solid without particles and preparing a water-soluble cutting fluid complex agent; and adding fatty alcohol-polyoxyethylene ether and starcide BK into the water-soluble cutting fluid complex agent, stirring at a uniform sped at room temperature for a certain period of time until the solution is transparent, adding graphene oxide, further stirring at a uniform sped at the room temperature till the solution is semitransparent, thus obtaining the cutting fluid containing the graphene oxide. The cutting fluid is green, environment-friendly and pollution-free in components and good in lubricating property.

Owner:UNIV OF JINAN

Novel antifriction lubricant additive containing nano ferrous sulphide

InactiveCN103289790AGood dispersion and stabilityImprove lubrication performanceAdditivesPetrochemicalMetallurgy

The invention relates to a lubricant additive containing nano ferrous sulphide granules. The lubricant additive is composed of 1-20wt% of nano ferrous sulphide granules and 80-99wt% of basic lubricating oil, and granularity of nano ferrous sulphide is 10-50nm. The lubricant additive can serve as additives of multifunctional lubricating oil and lubricating grease and also can serve as a repairing antiwear agent for a lubricating system of large-scale mechanical equipment used for various vehicles, ships, petrochemical engineering and mines.

Owner:梅滨 +1

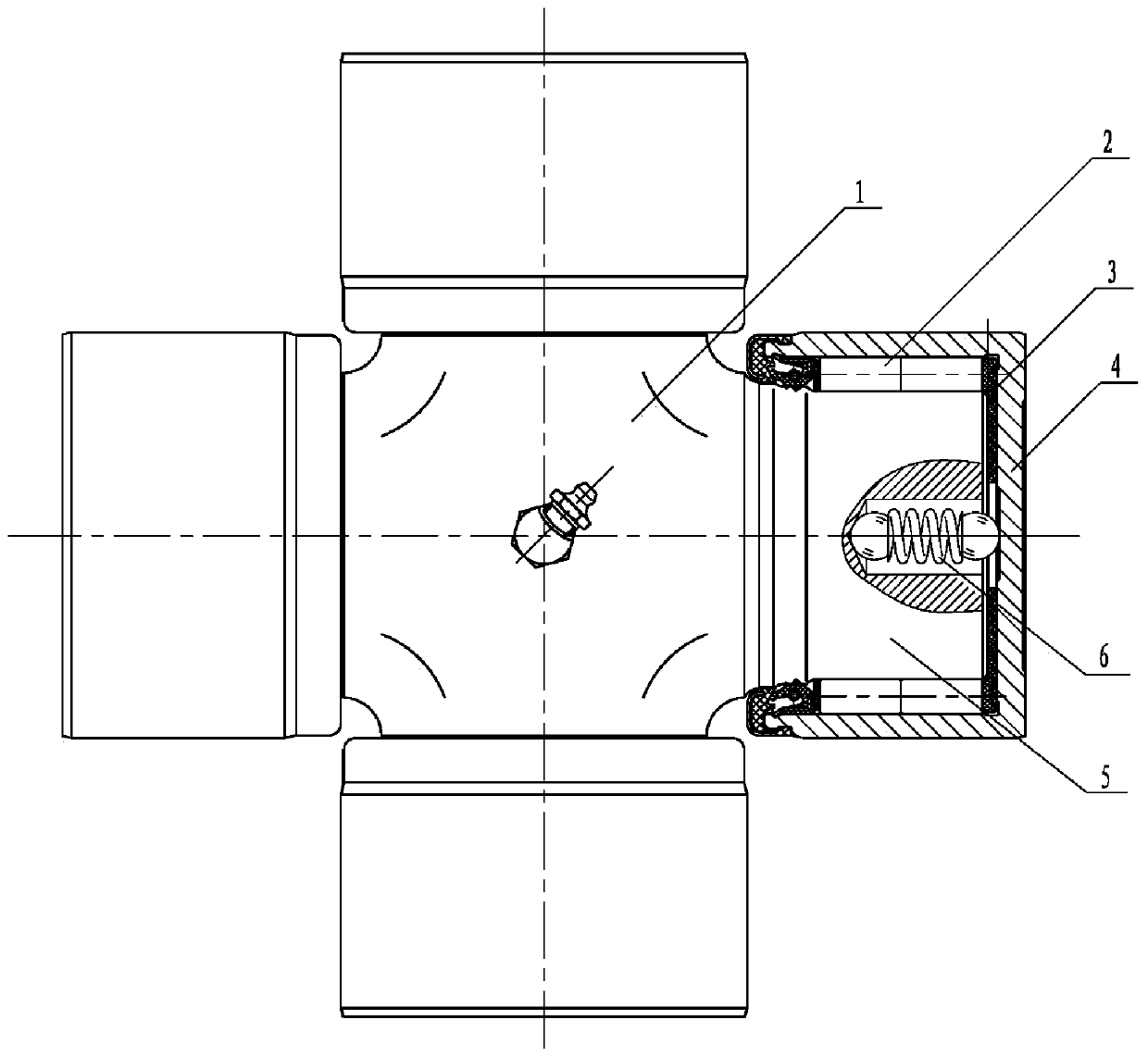

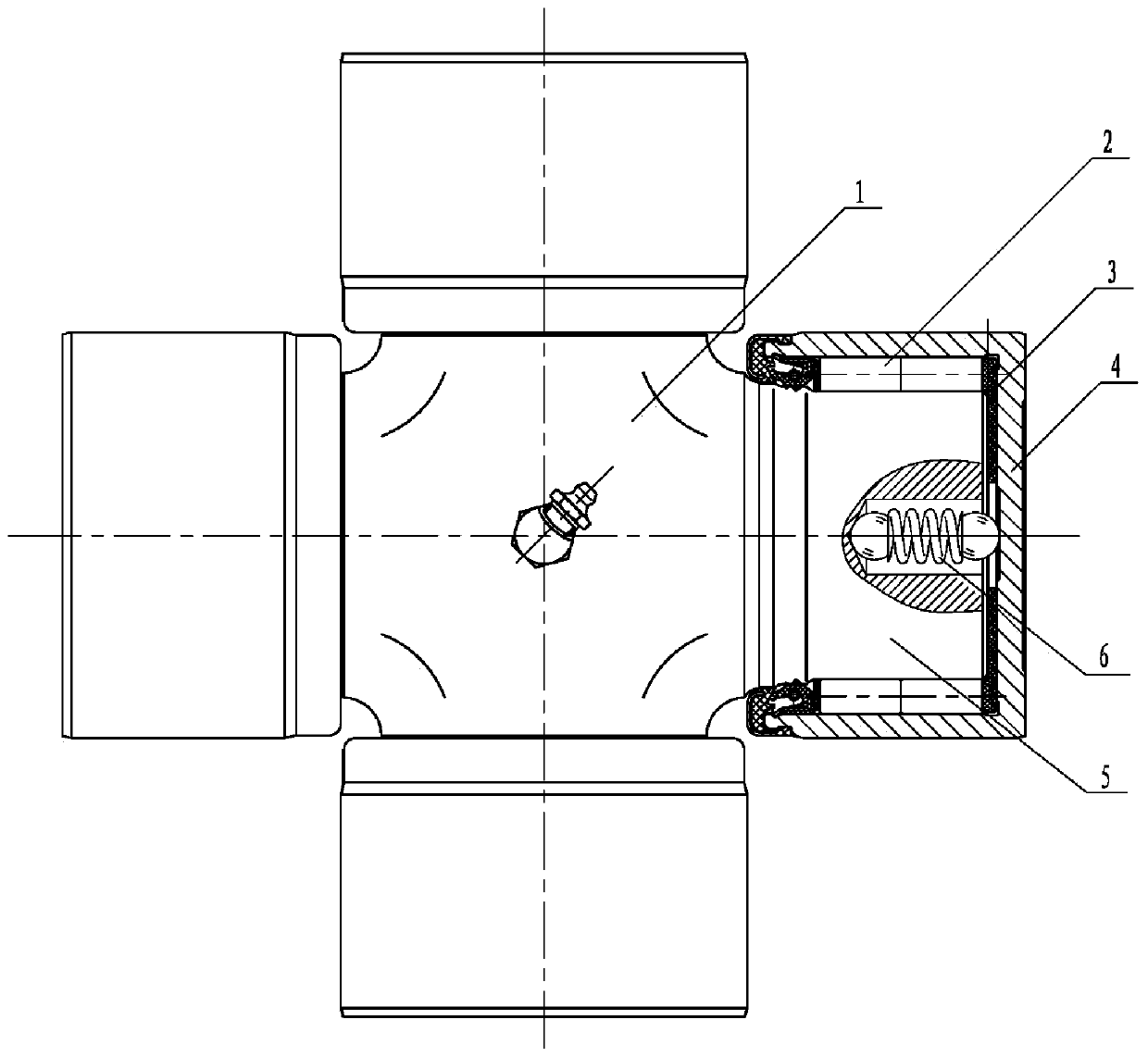

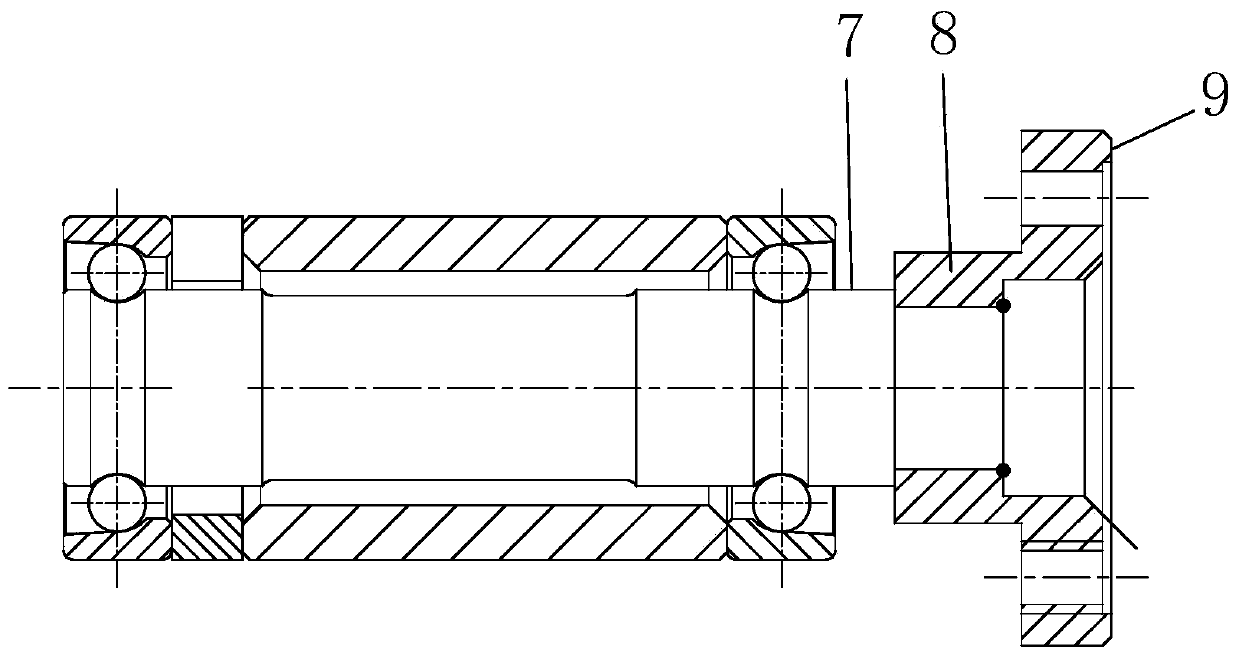

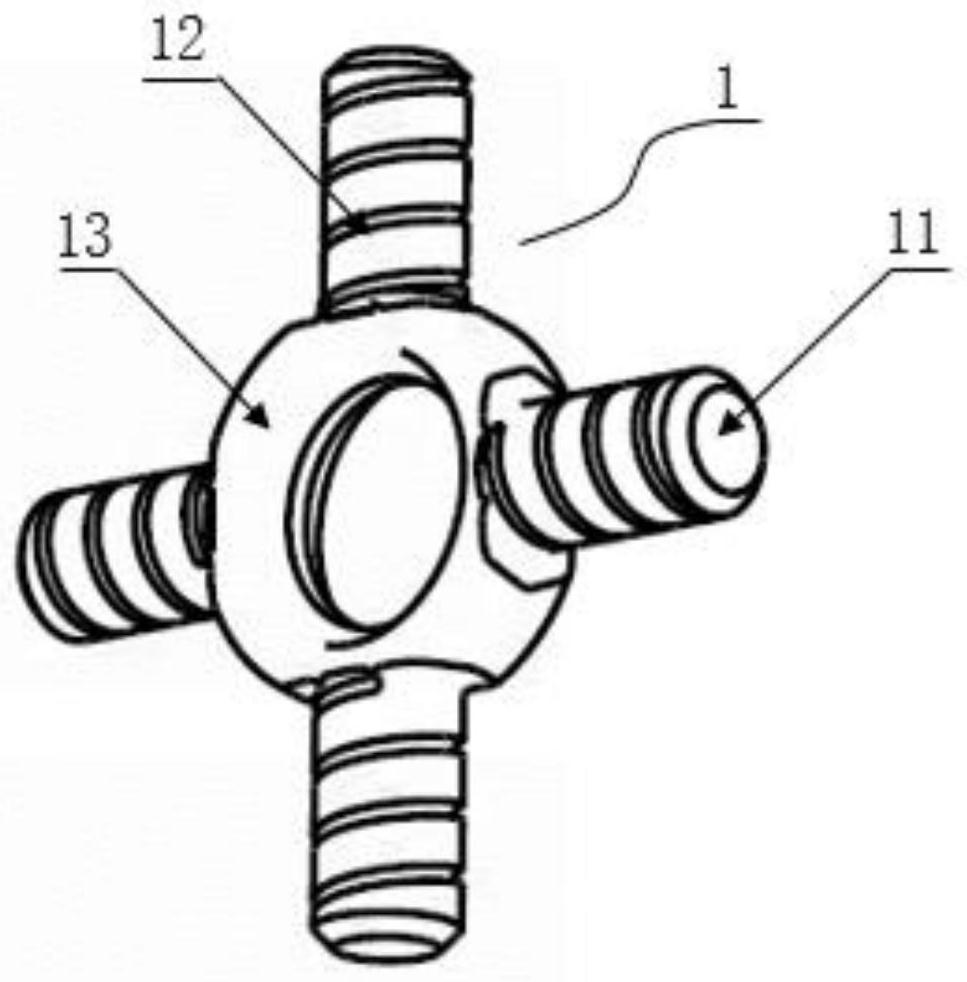

Vibration-absorption long-life universal joint

PendingCN110030288AImprove lubrication performanceReduce damageRotating vibration suppressionYielding couplingInternal energyPotential energy

The invention discloses a vibration-absorption long-life universal joint. The vibration-absorption long-life universal joint mainly comprises a cross shaft, four bearings of the cross shaft are sleeved with shaft sleeves, and a circle of quill rollers are arranged between the shaft sleeves and the bearings; vibration-absorption gaskets are arranged between the quill rollers and the shaft sleeves;the bearings are provided with blind holes; and steel ball springs are installed between the bottoms of the blind holes and the vibration-absorption gaskets. According to the vibration-absorption long-life universal joint, the steel ball springs and the multiple gaskets are arranged between the universal joint cross shaft blind holes and the bearings, and the two-stage vibration absorption structure is formed. The porous gaskets can greatly increase the oil storage area, sufficiently absorb axial impact energy of the cross shaft to the bearings and buffer impact of the cross shaft to the bearings. The steel ball springs can convert kinetic energy which is generated when the cross shaft acts periodically in the axial direction into the elastic potential energy of the springs, the elastic potential energy of the springs is converted into internal energy through deformation energy of the spring structure, finally the internal energy is exhausted, and accordingly, the vibration absorptioneffect is achieved. Universal joint damage caused by impact of the cross shaft in the axial direction of the shaft diameter to the bearings is reduced, the lubricating performance of the bearings is improved, and the service life of the universal joint is prolonged.

Owner:WANXIANGQIANCHAO CO LTD +1

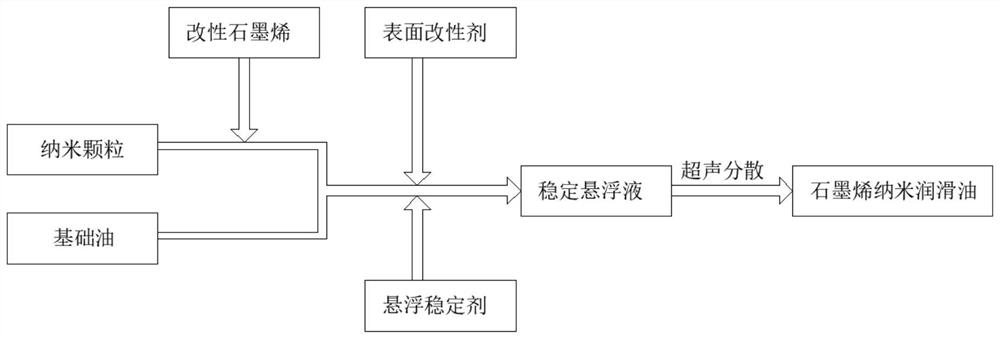

Preparation method of graphene lubricating oil for vehicles

InactiveCN111621350AGood suspension stabilityImprove lubrication performanceAdditivesNano sio2Graphene nanoparticles

The invention discloses a preparation method of graphene lubricating oil for vehicles. The preparation method comprises the following steps: modification of graphene, preparation of nano lubricating oil, preparation of a stable suspension, preparation of graphene nano lubricating oil, and preparation of the required graphene lubricating oil for the vehicles. The prepared graphene lubricating oil for the vehicles does not have any layering or sinking phenomenon after a standing experiment for 60 days at the temperature of -20 DEG C; in addition, the graphene and the nano SiO2 particles cannot be settled; the prepared lubricating oil for the vehicles is proved to have good suspension stability, the lubricating performance of the lubricating oil is improved through graphene of modified graphene, meanwhile, good low-temperature flowing performance can be kept at a low temperature, and the lubricating performance of traditional lubricating oil for vehicles is improved.

Owner:青岛鑫乐驰润滑油有限公司

Antistatic release film with light release force

InactiveCN106220880AStrong antistatic abilityImprove lubrication performanceElectrically-conductive paintsSolventDefoaming Agents

The invention discloses an antistatic release film with a light release force. The antistatic release film with the light release force is characterized by comprising a base film layer, wherein a release layer is arranged on the base film layer and formed by coating a release agent, and the release agent comprises the following components in parts by mass: 5 to 10 parts of polyethylene wax particles, 20 to 42 parts of vinyl organic silicon resin, 10 to 18 parts of polyvinyl alcohol, 2 to 5 parts of conductive polymers, 0.2 to 2 parts of pigment, 1 to 5 parts of coupling agents, 0.5 to 3 parts of defoaming agents, and 10 to 25 parts of solvents. The release film has the excellent antistatic ability, and further contains the polyethylene wax particles, so that the surface composition of the release film is changed, the surface lubricity of the release film is improved, the stereoscopic sense and glossiness of the release film are increased, and then the obtained release film is relatively light and stable in release force. In addition, the polyethylene wax particles are excellent in wear resistance, thus the anti-scratch performance of the release film can be improved.

Owner:苏州睿利斯电子材料科技有限公司

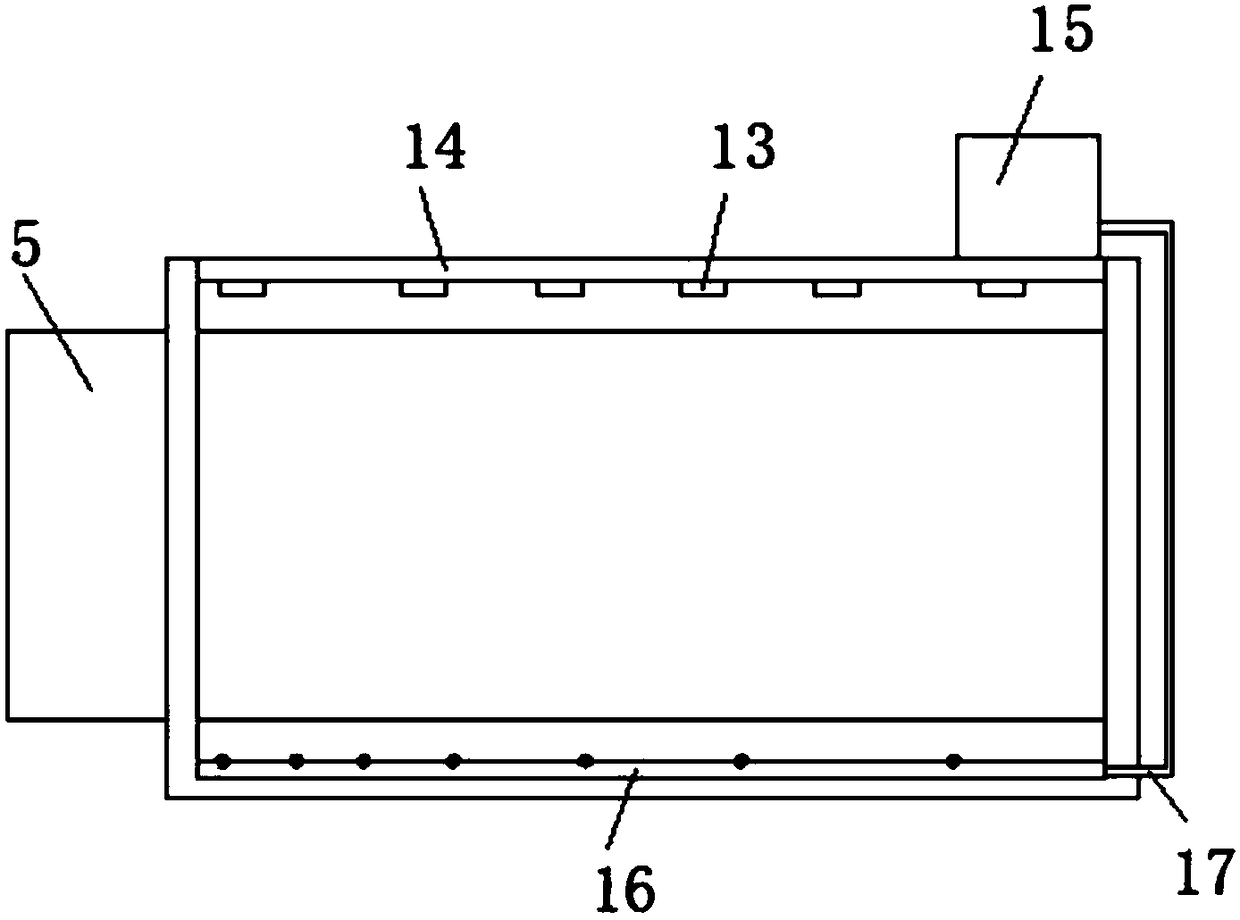

Heat resistance and conduction structure of bearing for medical imaging equipment

ActiveCN104188678AReduce the temperatureImprove lubrication performanceComputerised tomographsTomographyMedical imagingThin walled

The invention discloses a heat resistance and conduction structure of a bearing for medical imaging equipment. The heat resistance and conduction structure comprises a bearing body portion, a bearing neck portion and a bearing flange. One side of the bearing flange extends in the direction of the bearing body portion to form a hollow heat radiation column, the hollow heat radiation column is connected with the bearing neck portion, and the bearing neck portion is connected with the bearing body portion. The sectional structure of the side wall of the hollow heat radiation column is of a combined structure formed by arranging a plurality of layers of thin walls in a zigzag shape. The structure is adopted, the thickness of the thin walls of the hollow heat radiation column of the structure is smaller than that of the side wall of an existing hollow heat radiation column, the thickness of the thin walls is reduced to 1.5 mm from 1.75 mm for bearings for CT machine ball pipes, the thickness of the thin walls is only 1.0 mm for bearings for X-ray ball pipes, the heat transfer distance is approximate N times that of original thin walls (N is the number of the layers of thin walls), and therefore heat transfer can be slowed greatly. According to the structure, the temperature of a bearing work area of the bearing body portion can be reduced greatly, the lubrication performance of solid lubricants is greatly improved, and the service life of the bearing is prolonged.

Owner:上海天虹微型轴承有限公司

Aromatic mechanical lubricant auxiliary

InactiveCN104263463AImprove lubrication performanceReduce mechanical working noise and power lossAdditivesCitrate sodiumDichloromethane

The invention relates to an aromatic mechanical lubricant auxiliary. The auxiliary is prepared from the following raw materials: sodium citrate, rose essence, hydrochloric acid, naphthene-base rubber oil, zinc butyl octanol sulfate, N-tert-butyl-2-benzothiazolesulfenamide, bamboo charcoal, vinyl dibutyrate, silicone oil, monopotassium phosphate, silicon dioxide micro-powder, dichloromethane, monosuccinimide and sorbitan monooleate. The auxiliary is capable of improving the lubricating performance of the lubricant, reducing mechanical working noise and power consumption and prolonging service life.

Owner:QINGDAO HI TECH PATENT TECH TRANSFER PLATFORM

Low-temperature-resistant graphene lubricating oil and preparation method thereof

InactiveCN110760363AImprove lubrication performanceImprove anti-friction performanceAdditivesPoly methacrylateAntifoam agent

The invention relates to the technical field of lubricating oil and discloses low-temperature-resistant graphene lubricating oil and a preparation method thereof. The lubricating oil comprises, by weight, 70-80 parts of base oil, 10-15 parts of modified graphene, 3-6 parts of sepiolite powder, 1-3 parts of di-n-butyl phosphite anti-wear agent, 1-2 parts of polymethacrylate pour point depressant, 0.5-1 part of siloxane defoamer and 0.5-1 part of aromatic amine antioxidant. According to the preparation method, firstly, the modified graphene, the sepiolite powder and the base oil are added into astirrer to be stirred and dispersed, then the di-n-butyl phosphite anti-wear agent, the polymethacrylate pour point depressant, the siloxane defoamer and the aromatic amine antioxidant are added, themixture continues to be stirred and dispersed, and the lubricating oil is obtained. According to the lubricating oil, the graphene can be dispersed at a high degree, and the lubricating oil has goodlubricating performance and low-temperature flowing performance.

Owner:蔡樟森

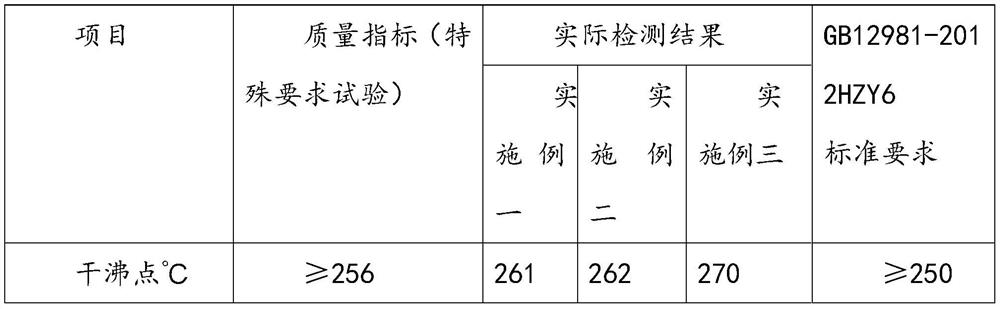

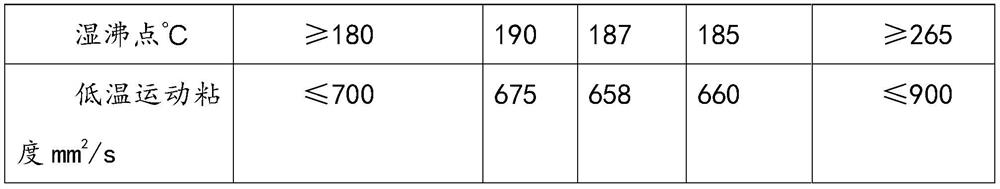

Borate type automobile brake fluid

PendingCN112481004AImprove air resistance performanceImprove lubrication performanceLubricant compositionAutomotive engineeringCorrosion inhibitor

The invention relates to the technical field of automobile brake fluid, and discloses borate type automobile brake fluid which is prepared from the following raw materials in parts by weight: 60-70 parts of propylene glycol monomethyl ether borate, 3-7 parts of silicone oil, 10-40 parts of polyethylene glycol monoalkyl ether, 75-85 parts of triethylene glycol monomethyl ether borate, 0.2-0.8 partof 6-methyl-2-mercaptobenzothiazole, 0.5-0.9 part of an antioxidant; 1-3 parts of an alkalinity regulator, 1-3 parts of a corrosion inhibitor and 0.1-0.3 part of a metal preservative. According to theborate type automobile brake fluid, the brake fluid is prepared from borate, the production cost of the brake fluid is effectively reduced, industrial production is facilitated, the product quality meets the GB12981-2012HZY6 standard requirement, and the borate type automobile brake fluid not only has high dry and wet boiling points, but also has good low-temperature kinematic viscosity, and canmeet the requirements that the dry boiling point is greater than 270 DEG C and the wet boiling point is greater than 190 DEG C; the technical requirement that the low-temperature kinematic viscosity is not higher than 650 mm < 2 > / s is met, and meanwhile, the experimental requirement of 240-hour long-term metal corrosion resistance specified by the standard can be met.

Owner:安徽天驰先锋油品制造有限公司

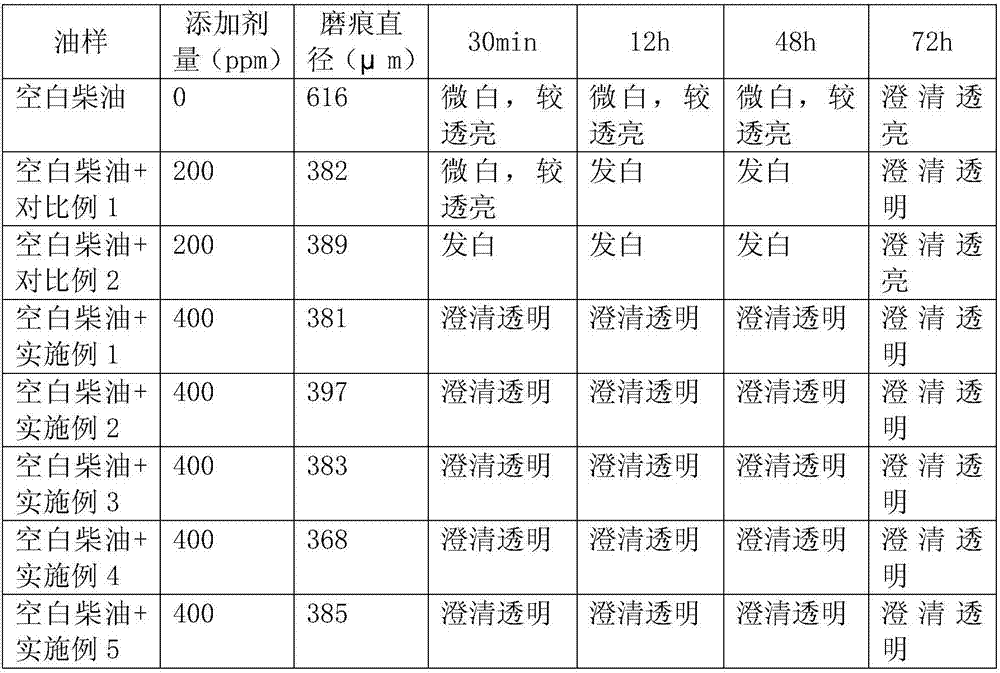

Anti-wear agent for diesel oil

ActiveCN107573975AImprove lubrication performanceEasy to prepareLiquid carbonaceous fuelsFuel additivesEtherFatty acid ester

The invention relates to an anti-wear agent for diesel oil. The anti-wear agent for diesel oil is prepared by uniformly mixing plant fatty acid ester, an organic solvent and polysiloxane-allylpolyoxyethylene polyoxypropylene methyl ether in a weight ratio of (1-70): (1-55): (1-15). The addition amount of the anti-wear agent in diesel oil is normally 50 to 2000 ppm; the anti-wear agent for diesel oil can improve the anti-wear performance of diesel oil and effectively overcome the problem that diesel oil emulsifies when coming across water during transportation; the raw materials are easily available; preparation process is simple; and production conditions are mild.

Owner:SINOPEC YANGZI PETROCHEM +1

Flat gate valve with seal grease being automatically injected

InactiveCN102313034AReduce maintenance timesImprove lubrication performanceSlide valvePistonLubrication

The invention relates to a flat gate valve with seal grease being automatically injected. The valve comprises a valve body, a valve cover, a valve rod, a gate plate, a valve seat, a bracket and a driver, wherein two automatic grease injection mechanisms are fixedly arranged on the two sides of the gate plate above the valve seat in the same axial direction with the gate plate respectively; the automatic grease injection mechanism consists of a grease storage cylinder and a piston which is coaxially, hermetically and slidably arranged in the grease storage cylinder; the lower end of the grease storage cylinder is fixedly connected with a grease injection groove inlet which is formed in the valve seat; a sealing surface of the gate plate at a grease injection groove outlet is provided with a gate plate waist-shaped groove in a matching way; and a valve seat annular groove which is coaxial with the valve seat is formed on the seal matching surface of the valve seat, which is contacted with the valve plate. The flat gate valve is scientific in design, rational in structure and reliable in sealing; lubrication and auxiliary sealing effects are achieved by automatic grease injection; the sealing property is effectively improved; zero leakage is achieved by the valve; the service life of the valve is effectively prolonged; and the flat gate valve is safe and reliable and can be used for high-pressure oil and gas pipeline systems.

Owner:TIANJIN BAILIZHANFA GRP

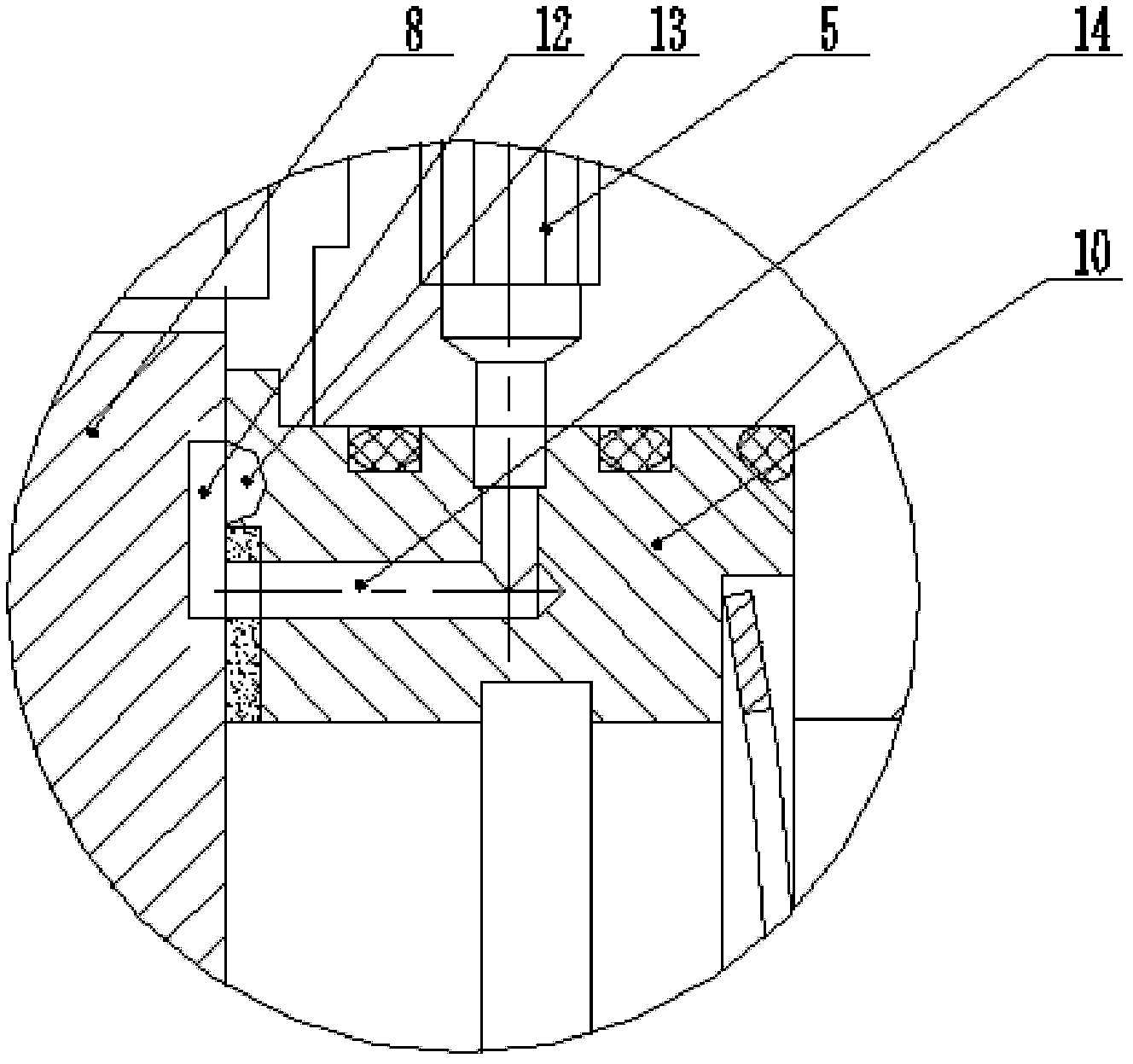

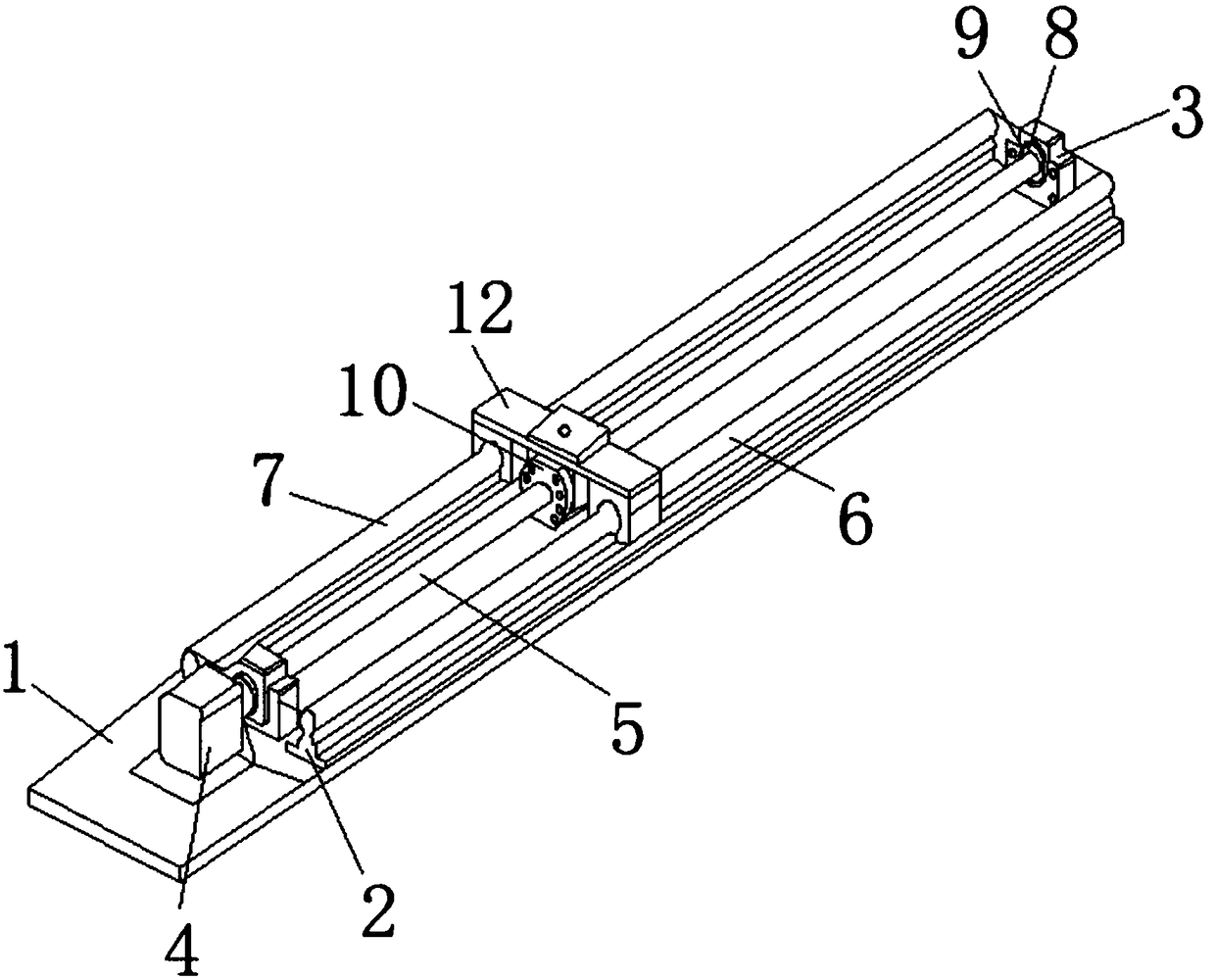

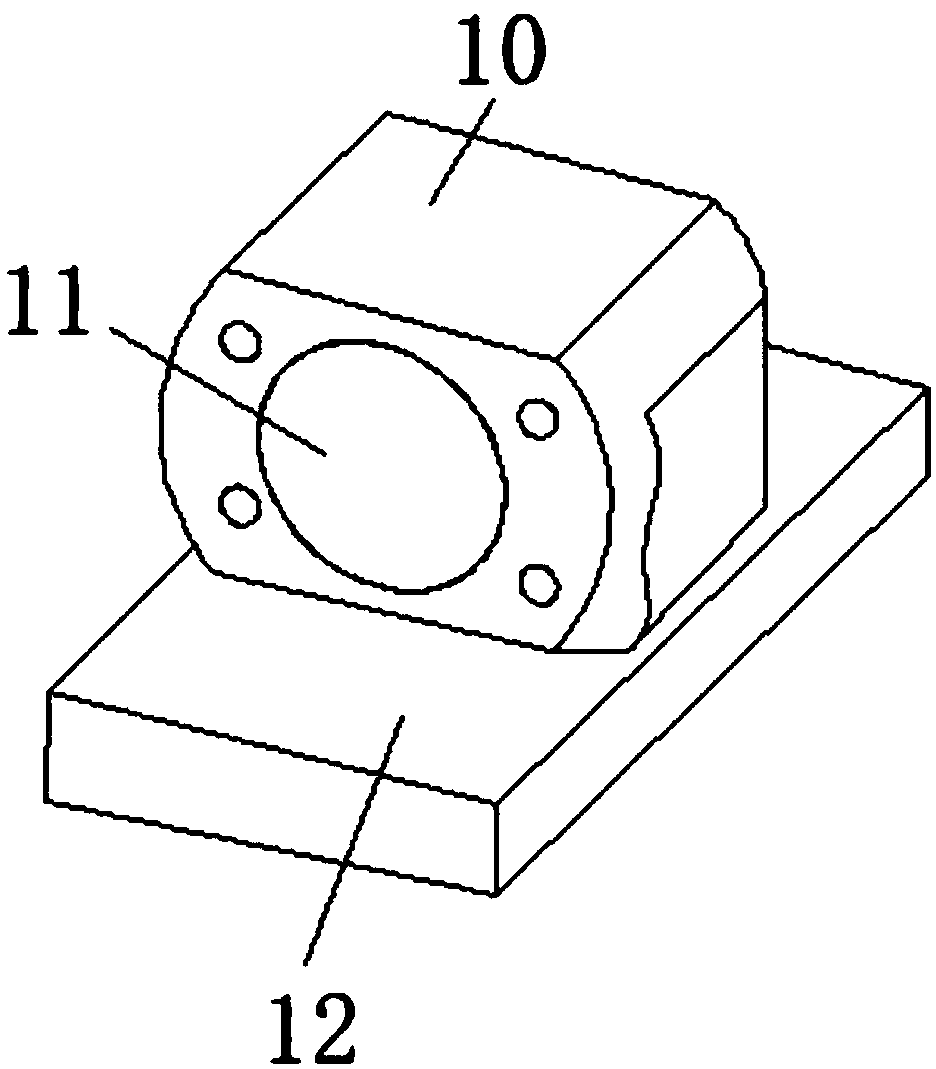

Screw rod transmission mechanism utilized in computer numerical control equipment

PendingCN108468770AImprove work efficiency and work qualityImprove lubrication performanceGearingGear lubrication/coolingDrive motorEngineering

The invention discloses a screw rod transmission mechanism utilized in computer numerical control equipment. The screw rod transmission mechanism comprises a transmission seat, wherein a No.1 transmission plate is arranged at one end of the upper part of the transmission seat; a No.2 transmission plate is arranged at the other end of the upper part of the transmission seat; a driving motor is mounted on one side of the No.1 transmission plate; a screw rod is movably connected with one end of the driving motor; the No.1 transmission plate is connected with the No.2 transmission plate through the screw rod; a No.1 auxiliary guiding rod is arranged on one side of the screw rod; a No.2 auxiliary guiding rod is arranged on the other side of the screw rod; and the No.2 transmission plate is connected with the screw rod through a connecting shaft. The screw rod transmission mechanism disclosed by the invention has the beneficial effects that through the parallel arrangement of the screw rod as well as the No.1 auxiliary guiding rod and the No.2 auxiliary guiding rod which are positioned on two sides of the screw rod, the traction can be formed on the two sides of the screw rod during thetransmission process, and then the screw rod can be prevented from shaking up and down as well as left and right during the transmission process; during the work of computer numerical control precision equipment, the screw rod transmission mechanism can move smoothly and accurately; and the working efficiency and the working quality of a computer numerical control machine tool can be effectively improved.

Owner:平湖市祥瑞机械设备制造有限公司

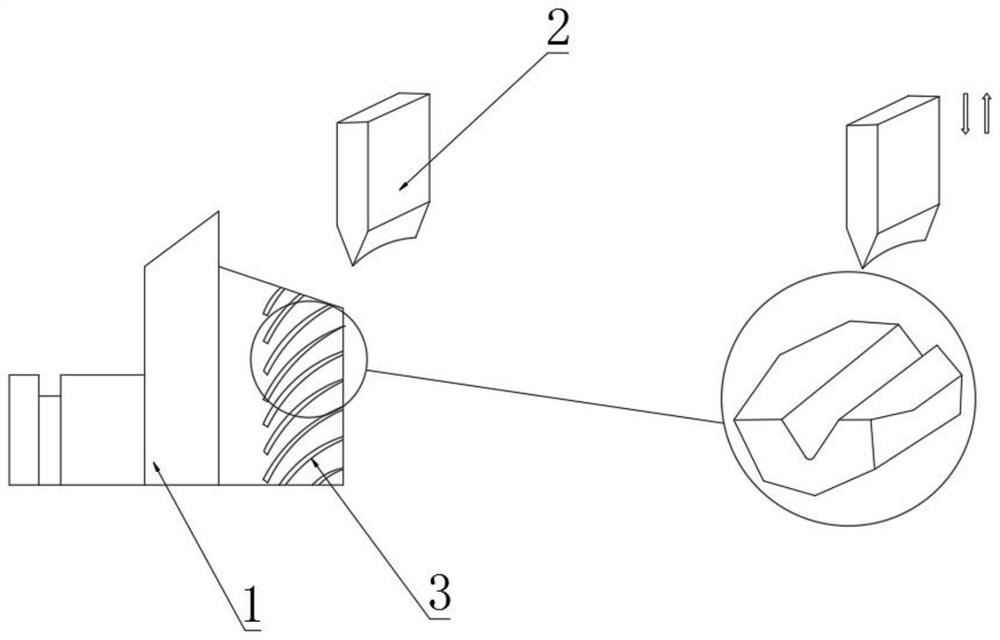

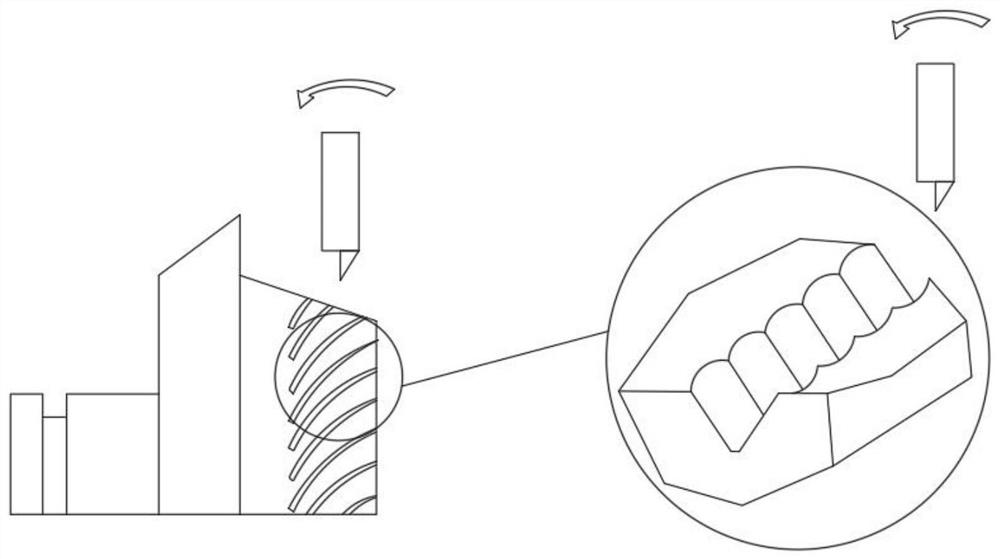

Backflow line extrusion forming cutter and backflow line cold extrusion forming process

InactiveCN111702433AImprove lubrication performanceExtended service lifeMetallic material coating processesEngineeringForming processes

The invention discloses a backflow line extrusion forming cutter and a backflow line cold extrusion forming process. The backflow line cold extrusion forming process comprises the following steps: material selection, annealing treatment, machining, phosphating saponification treatment, cleaning, extrusion forming and tempering treatment. Through phosphating saponification treatment on a semi-finished oil seal die, the lubricating performance of the semi-finished oil seal die can be improved, the extrusion pressure on the die can be reduced, and the service life of the die can be prolonged; thesurface of the semi-finished oil seal die can be extruded through the extrusion cutter to form a backflow line, no gap exists in the backflow line, and therefore the backflow line does not need polishing or other treatment; and the oil sealing performance of an oil seal can be improved when the oil seal is produced through the die.

Owner:陕西奉航科技有限责任公司

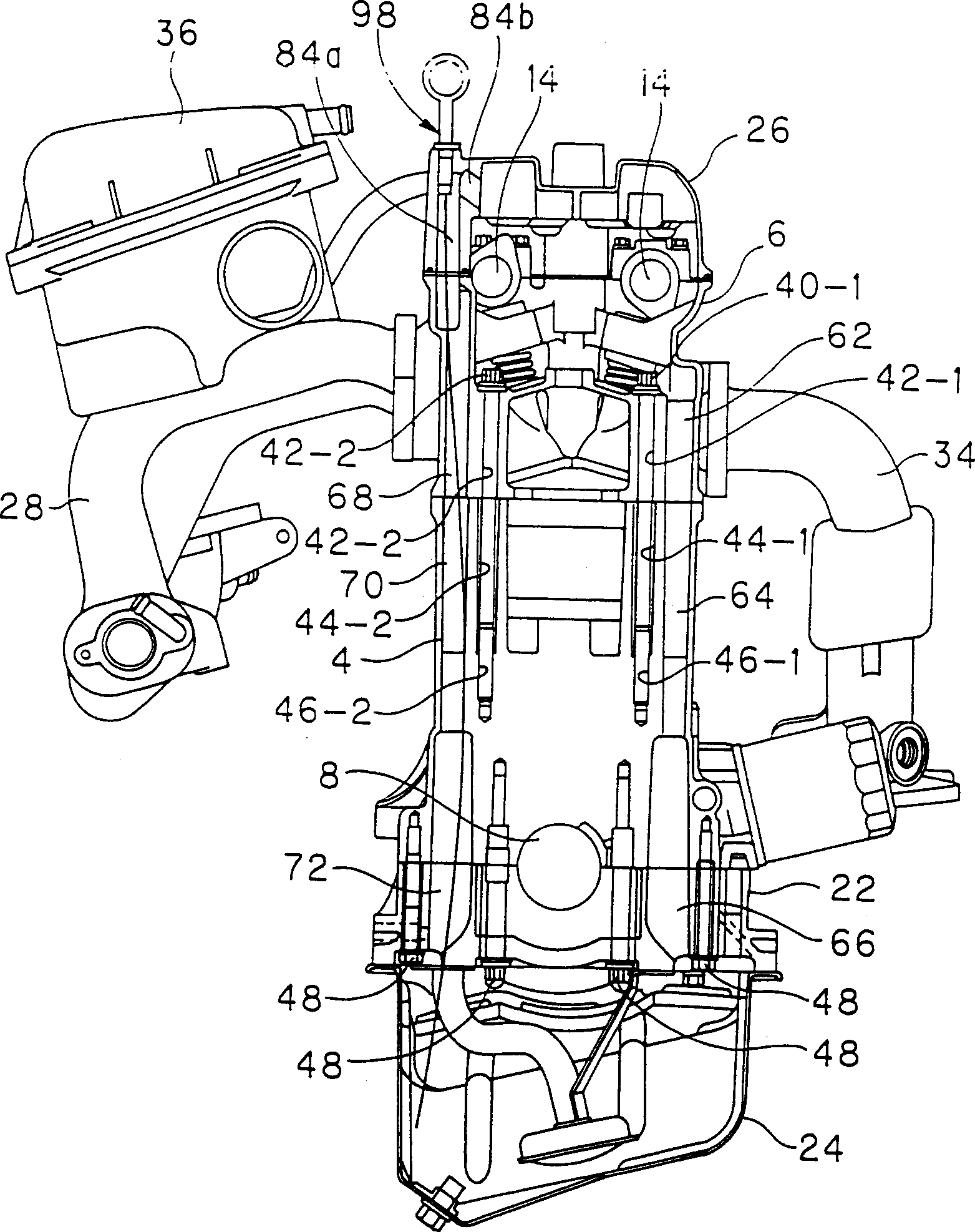

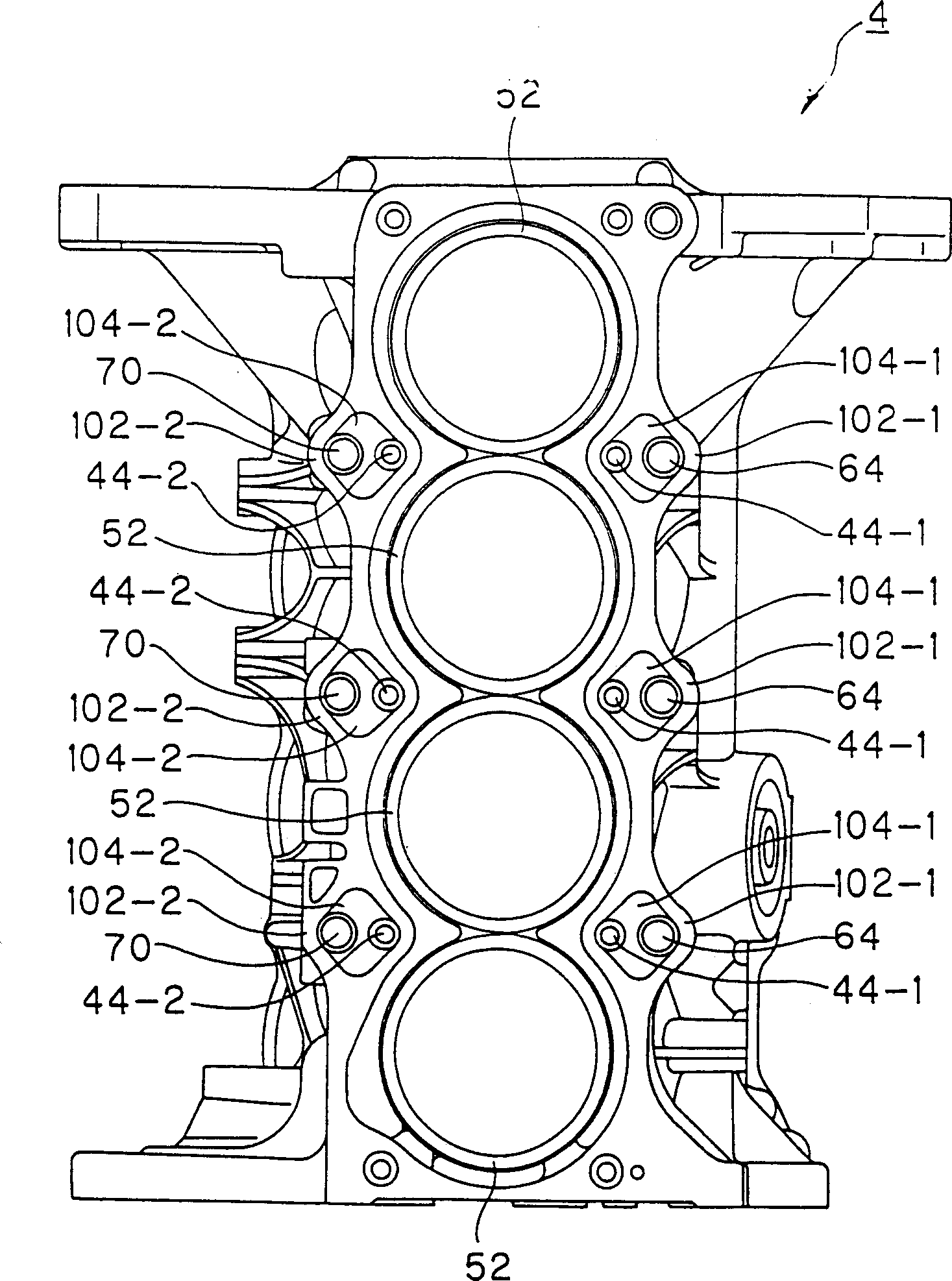

Leaked fuel gas return-flow structure for engine

InactiveCN1123675CImprove lubrication performanceReduce weightCasingsCylinder headsEngineeringCylinder block

A blowby gas-returning structure for an engine which is adapted to provide smooth returning of a blowby gas, and to provide a light-weight or compact engine. The blowby gas-returning structure is provided with passage-forming object or wall in order to continue blowby gas passages without interruption. Further, the cylinder block may be provided with void space sections which share space with the blowby gas passages and the cylinder head-mounting bolt holes. In addition, the blowby gas passage in the cylinder head may be disposed offset substantially midway along the length thereof.

Owner:SUZUKI MOTOR CO LTD

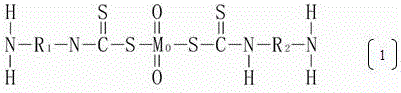

High-activity organic molybdenum compound and preparation and application method thereof

InactiveCN105859785AImprove lubrication performanceReduce mechanical wearAdditivesGroup 6/16 organic compounds without C-metal linkagesDiamineMolybdenum disulfide

The invention relates to a high-activity organic molybdenum compound and a preparation and application method thereof. The general chemical formula of the organic molybdenum compound is as shown in the general formula (1), wherein Mo is used as the nucleophilic center and grafted with two S=C-S- groups to allow the molecular structure of the organic molybdenum compound to have the features of -S-Mo-S- and the features of -S=S-Mo-S=C-S-; Mo has the structural form and features similar to molybdenum disulfide in the molecular structure of the organic molybdenum compound; R1 is grafted with alkyl diamine, R2 is grafted with alkyl diamine, that is to say, R1 and R2 in the molecular structure of the organic molybdenum compound respectively contain 2 diamines, and the molecular structure of the organic molybdenum compound contains 4 amino groups. Two S=C-S- groups are grafted in the molecular structure of the organic molybdenum compound, so that the molecular structure of the organic molybdenum compound contains two SCS (simplified form) groups or two groups similar to SCS (for short).

Owner:文万军

Long-life lubricating oil

InactiveCN108977256AImprove the quality of useImprove lubrication performanceLubricant compositionDimethyl oxalateEpoxidized soybean oil

The invention discloses a long-life lubricating oil. The long-life lubricating oil is prepared from the following components: sucrose polyester, polycaprolactone, butyl isocyanate, dimethyl oxalate, dimethylacetamide, attapulgite, kaolin, graphite, crylic acid glyceride, and epoxidized soybean oil. The long-life lubricating oil obviously improves the use quality of the lubricating oil by reasonable matching of a plurality of raw materials, and the added attapulgite, kaolin and graphene of different particle ratios can effectively improve the lubricating performance of the lubricating oil and reduce friction of the components, and the lubricating oil has high use stability and can extend the life by more than 30%, and has good economic benefits and production use value.

Owner:安徽江杰实业有限公司

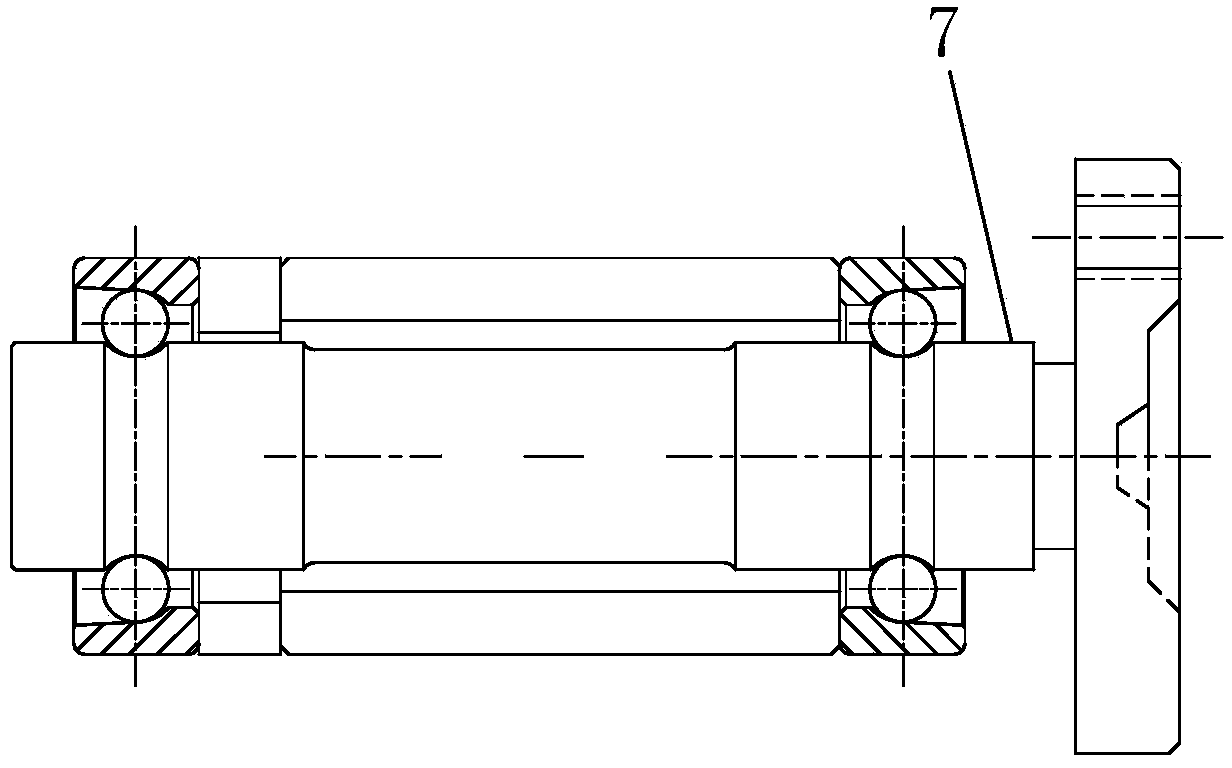

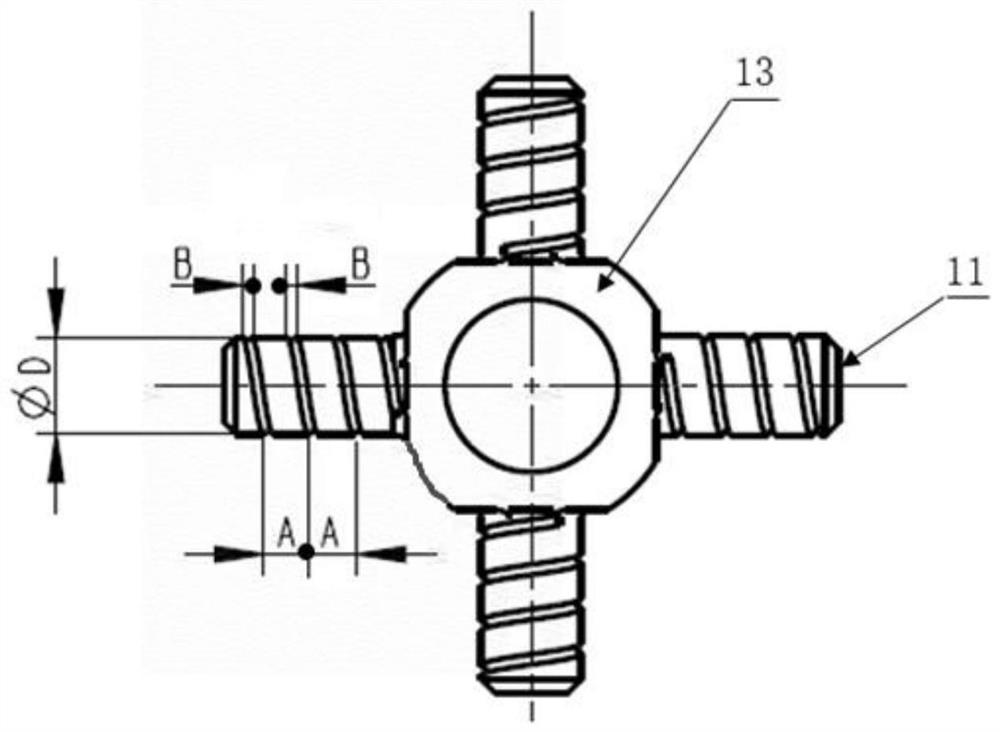

Cross shaft with spiral line oil storage grooves and differential mechanism

InactiveCN111911521AImprove lubrication performanceReduce wear and erosionGear lubrication/coolingCrossheadsPhysicsEngineering

The invention relates to a cross shaft with spiral line oil storage grooves and a differential mechanism, and relates to the technical field of transmission speed change walking systems. The spiral line oil storage grooves are formed in the cylindrical surfaces of four shaft necks of the cross shaft; the differential mechanism comprises a right shell and a planetary bevel gear; the differential mechanism further comprises the cross shaft with the spiral line oil storage grooves; each shaft neck of the cross shaft is divided into two sections; one outward section is inserted in a correspondinghole of the right shell; and the other section is sleeved with the planetary bevel gear. According to the cross shaft with spiral line oil storage grooves and the differential mechanism, the spiral line oil storage grooves are formed in the cylindrical surfaces of the shaft necks of the cross shaft, the lubricating performance between the planetary bevel gear and the cross shaft is improved.

Owner:DONGFENG COMML VEHICLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com