TC4-based self-lubricating material and preparation method thereof

A self-lubricating material, TC4 technology, applied in the direction of additive manufacturing, additive processing, energy efficiency improvement, etc., can solve the effect of reducing friction and wear resistance between damaged friction pairs, affecting the service life of the coating, coating thickness and interface bonding ability Limited and other problems, to achieve excellent mechanical properties and tribological properties, improve the quality of material forming, and reduce the effect of residual thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

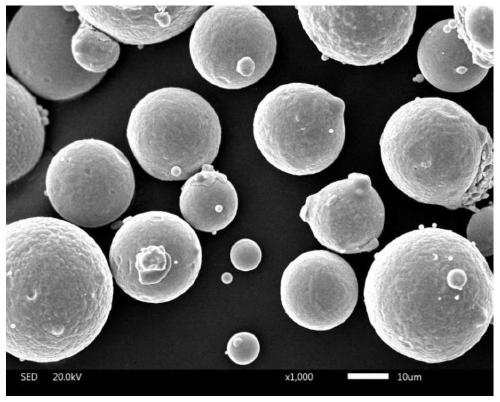

[0037] In the following examples, the TC4-based self-lubricating material with Sn-Ag-Cu and TiC as the lubricating and reinforcing phases is prepared from TC4 titanium alloy-based spherical powder containing Sn-Ag-Cu and TiC. to make. The present invention provides a specific preparation method, but does not limit the preparation method. TC4 titanium alloy-based spherical powder and TC4-based self-lubricating material containing Sn-Ag-Cu and TiC prepared by other methods meet the requirements of the present invention. The protection scope of the present invention.

[0038] The present invention provides a method for preparing TC4 titanium alloy-based spherical powder containing Sn-Ag-Cu and TiC, which includes the following steps:

[0039] 1) Sn powder, Ag powder and Cu powder are selected as Sn-Ag-Cu alloy raw material powder according to the mass ratio of each elemental powder; Ti powder, Al powder, V powder and Fe powder are selected as the mass percentage of each element in TC...

Embodiment 1

[0046] A TC4-based self-lubricating material with Sn-Ag-Cu and TiC as the lubricating and reinforcing phases, TC4 titanium alloy as the matrix, and Sn-Ag-Cu and TiC as the lubricating and reinforcing phases respectively; the matrix material The elements in TC4 titanium alloy by mass percentage are: Al 5.5%, V 3.5%, Fe 0.3%, Ti 90.7%; the mass ratio of Sn, Ag, Cu in the lubricating phase Sn-Ag-Cu alloy is 50:40: 10; The addition amount of Sn-Ag-Cu alloy powder is 6.0 wt.% of the mass of the TC4 titanium alloy, and the addition amount of TiC is 1.5 wt.% of the mass of the TC4 titanium alloy.

[0047] Such as figure 1 As shown, the above-mentioned TC4-based self-lubricating material with Sn-Ag-Cu and TiC as lubricating and reinforcing phases is prepared from TC4 titanium alloy-based spherical powder containing Sn-Ag-Cu and TiC. The preparation method specifically includes the following step:

[0048] 1) Select Ti powder 1814g, Al powder 110g, V powder 70g, and Fe powder 6g according ...

Embodiment 2

[0057] A TC4-based self-lubricating material with Sn-Ag-Cu and TiC as the lubricating and reinforcing phases, TC4 titanium alloy as the matrix, and Sn-Ag-Cu and TiC as the lubricating and reinforcing phases respectively; the matrix material The elements in TC4 titanium alloy are calculated by mass percentage: Al 6.0%, V 4.0%, Fe 0.3%, Ti 89.7%; the mass ratio of Sn, Ag, Cu in the lubricating phase Sn-Ag-Cu alloy is 50:40: 10; The addition amount of Sn-Ag-Cu alloy powder is 7.0 wt.% of the mass of the TC4 titanium alloy, and the addition amount of TiC is 1.75 wt.% of the mass of the TC4 titanium alloy.

[0058] Such as figure 1 As shown, the above-mentioned TC4-based self-lubricating material with Sn-Ag-Cu and TiC as lubricating and reinforcing phases is prepared from TC4 titanium alloy-based spherical powder containing Sn-Ag-Cu and TiC. The preparation method specifically includes the following step:

[0059] 1) Select 1794 grams of Ti powder, 120 grams of Al powder, 80 grams of V...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com