Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

250 results about "Ricinelaidic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ricinelaidic acid or (+)-(R)-ricinelaidic acid is an unsaturated omega-9 trans fatty acid. It is the trans-isomer of the fatty acid ricinoleic acid.

Tooth whitening compositions and delivery systems therefor

InactiveUS20060024244A1Sufficient amountCosmetic preparationsContainers for annular articlesPolyphosphateSilicon dioxide

Stain-removing oral compositions, such as gum compositions are herein provided. The compositions include an orally acceptable carrier and a stain-removing anionic surfactant. The surfactant includes a fatty acid salt having at least one hydroxyl functionality. The fatty acid salt may be a salt of ricinoleic acid, and may be combined with a chelating agent and / or an abrasive. The chelating agent may be a polyphosphate and the abrasive may be a silica abrasive.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Elastomeric material compositions obtained from castor oil and epoxidized soybean oil

Elastomers are formed from castor oil and / or ricinoleic acid estolides and a polyester formed from an epoxidized vegetable oil such as ESO and a polycarboxylic acid such as sebacic acid, optionally in the presence of a peroxide initiator, or include crosslinked reaction products derived from ricinoleic acid or castor oil estolides, epoxy group-containing compounds such as epoxy resins and / or epoxidized vegetable oil, epoxy hardeners such as polyamine and polycarboxylic acid hardeners, thermally activated free radical initiators such as peroxides, and optionally but preferably include fillers such as limestone or wood flour. The elastomers can be prepared using a two-step, solvent-less procedure at elevated or ambient temperatures. These predominantly "all-natural" elastomers have physical properties comparable to conventional petroleum-based elastomers and composites and exhibit good flexibility, resiliency, abrasion resistance and inertness to hydrolysis. The resulting elastomers display good mechanical strength and resiliency, are resistant to abrasion and hydrolysis, and can be processed into sheet materials, which makes them attractive as floor covering components.

Owner:AFI LICENSING +1

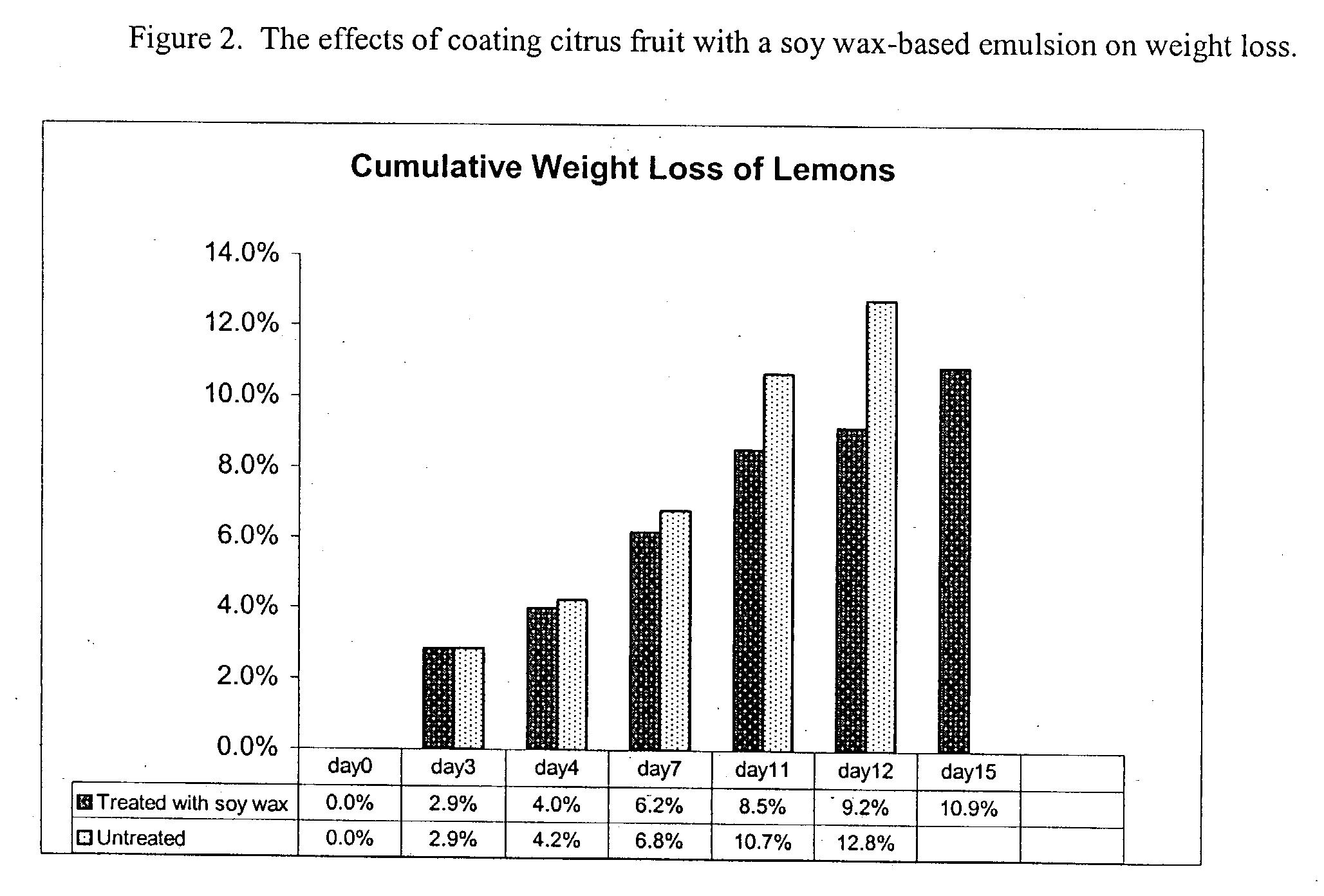

Novel wax emulsion coating applications

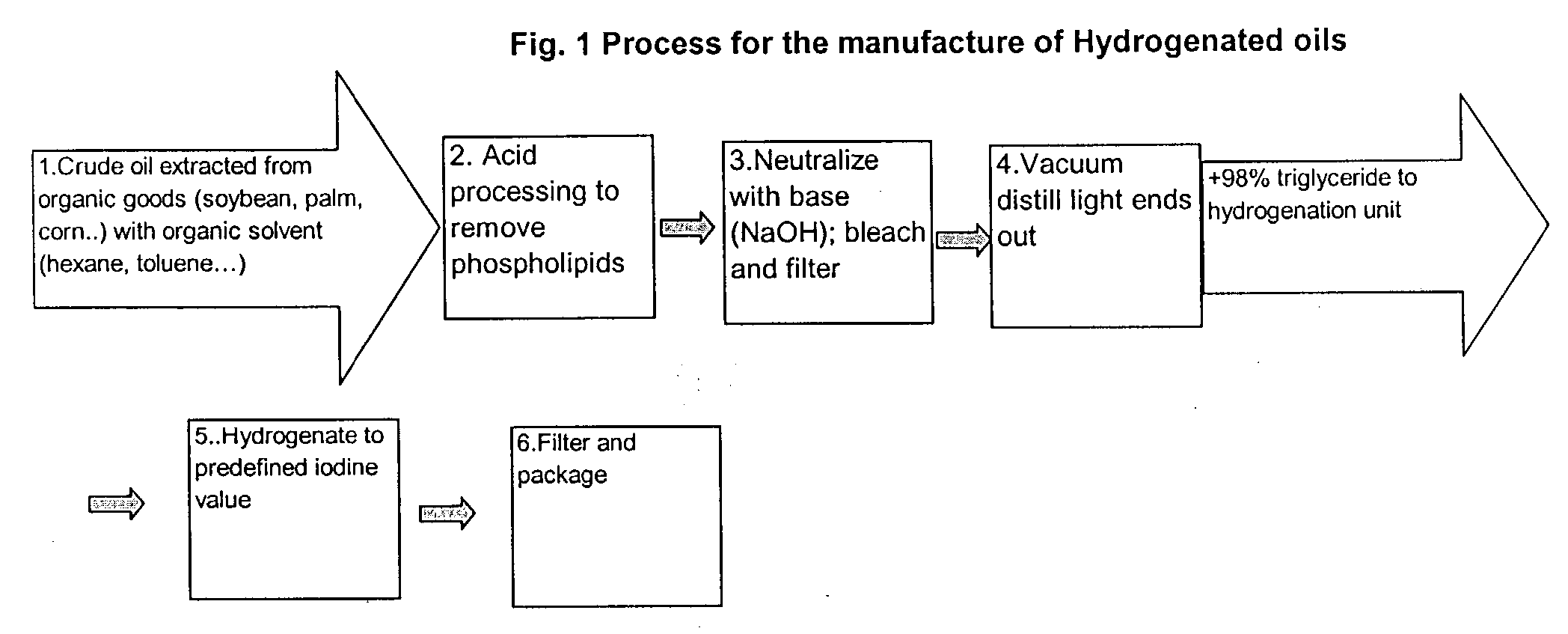

Waxes prepared from hydrogenated plant oils, such as castor, palm, and soybean, are used to prepare water based emulsions. The inventive waxes, obtained from naturally derived, renewable resources, were emulsified under anionic, cationic and nonionic conditions, producing emulsions having a solids content up to about 45% solids. When used to coat fibrous cellulosic articles, such as paperboard, the emulsions' performance was similar to emulsions containing petroleum-derived waxes. The inventive waxes have a low iodine value (between 2-5), and melting points between approximately 120-200 degrees F. (Mettler Drop Point). These waxes comprise a triglyceride whose fatty acids are predominantly stearic acid or ricinoleic acid. The inventive waxes are used as an alternative to petroleum-derived, or expensive naturally-occurring waxes in the manufacture of emulsions used in coatings, polishes, adhesives, paper products, paperboard and other manufacturing operations.

Owner:MARCUS OIL & CHEM

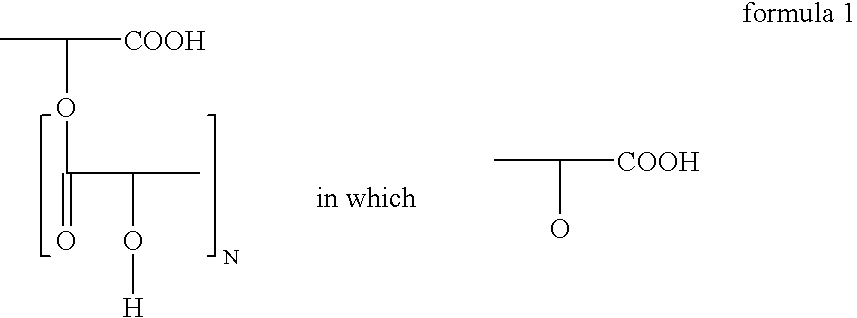

Polyglycerol partial esters of polyricinoleic acid and polyfunctional carboxylic acids and the use thereof for producing emulsions and dispersions

ActiveUS20060165627A1Low viscosityFeel lightCosmetic preparationsFatty acid chemical modificationEmulsionTricarboxylic acid

The invention relates to polyglycerol partial esters of polyricinoleic acid and polyfunctional carboxylic acids, obtainable by esterification of a a) polyglycerol mixture with b) at least one polyricinoleic acid and c) at least one di- and / or tricarboxylic acid and optionally d) at least one fatty acid having 6 to 22 carbon atoms by methods known per se, and to the use thereof for producing cosmetic or pharmaceutical emulsions or dispersions.

Owner:EVONIK DEGUSSA GMBH

Moisture-absorbing and perspiring anti-bacterial fabric and preparation technology thereof

InactiveCN105421055AImprove antibacterial propertiesSoft and wear-resistantBiochemical fibre treatmentLiquid/gas/vapor removalWater basedMoisture

The invention relates to a moisture-absorbing and perspiring anti-bacterial fabric and a preparation technology thereof. The moisture-absorbing and perspiring anti-bacterial fabric is blended and weaved by the following raw materials in parts by weight: 40 to 80 parts of bamboo fibers, 40 to 80 parts of long staple, 10 to 30 parts of ramie, 10 to 30 parts of coolmax fibers, 10 to 20 parts of corn fibers, 10 to 20 parts of Delight fibers, and 5 to 20 parts of Tancel, and then is treated by anti-bacterial finishing liquid; the anti-bacterial finishing liquid comprises 5 to 10 parts of chitosan, 5 to 10 parts of silk fibroin, 0.5 to 3 parts of butyl ricinoleate sodium sulfate, 0.5 to 3 parts of lemon acid, 0.5 to 2 parts of butyl methacrylate, 5 to 8 parts of dodecyl diphenyl ether sodium disulfonate, 5 to 10 parts of hydroxypropyl methyl cellulose, 5 to 10 parts of polyhexamethylene biguanidine, 5 to 15 parts of organosilicon quaternary ammonium salt, 3 to 8 parts of dodecyl trimethyl ammonium chloride, and 5 to 10 parts of water-based polyurethane. The moisture-absorbing and perspiring anti-bacterial fabric has the advantages that the anti-bacterial property is higher, the moisture-absorbing, perspiring, anti-pilling and air-ventilation properties are realized, the softness is realized, and the abrasion is resisted; the moisture-absorbing and perspiring anti-bacterial fabric is particularly suitable for being applied to the fields of underwear, overwear, sportswear and bedding articles.

Owner:杜名胜

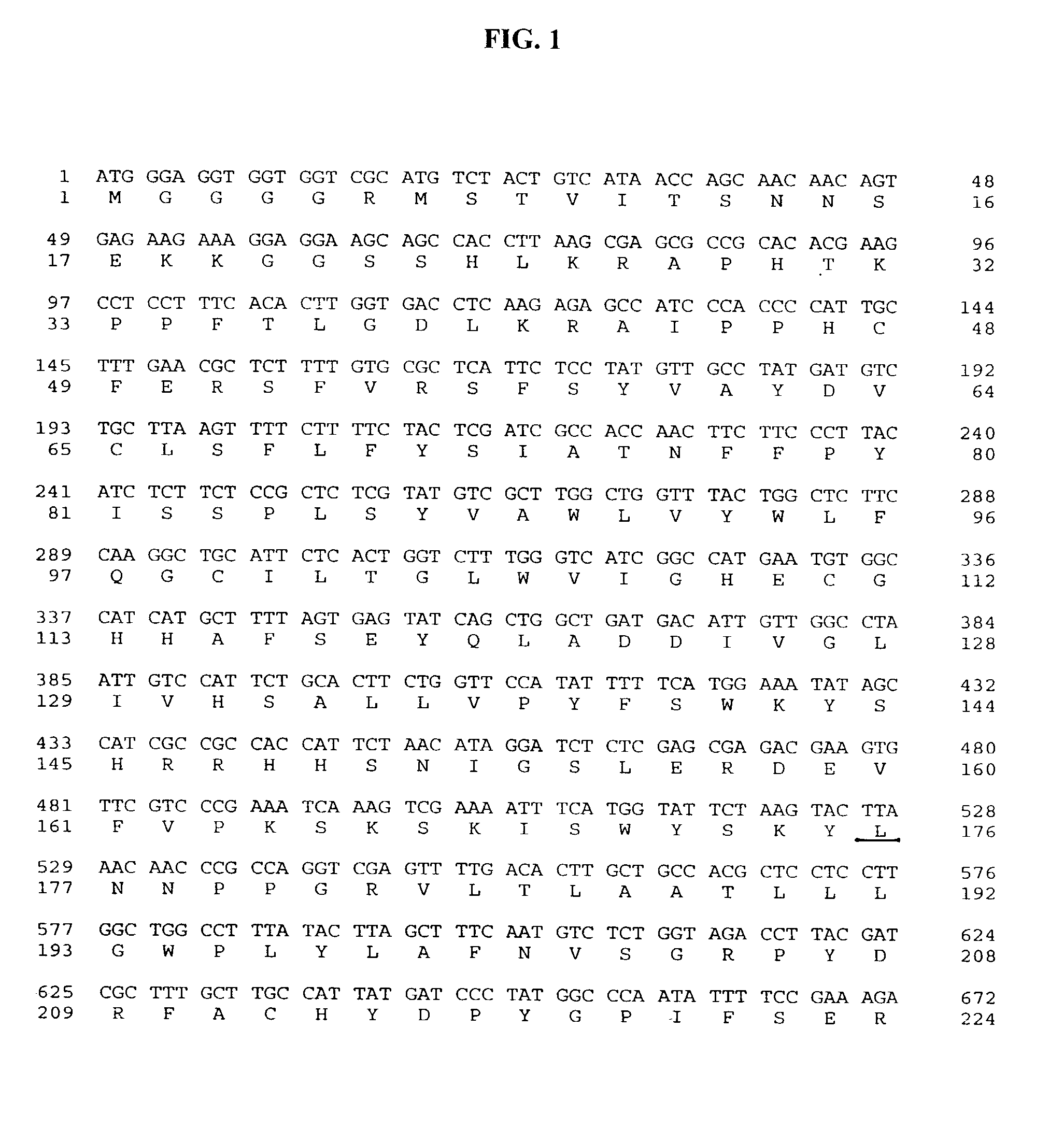

Isoform of castor oleate hydroxylase

Owner:BROOKHAVEN SCI ASSOCS

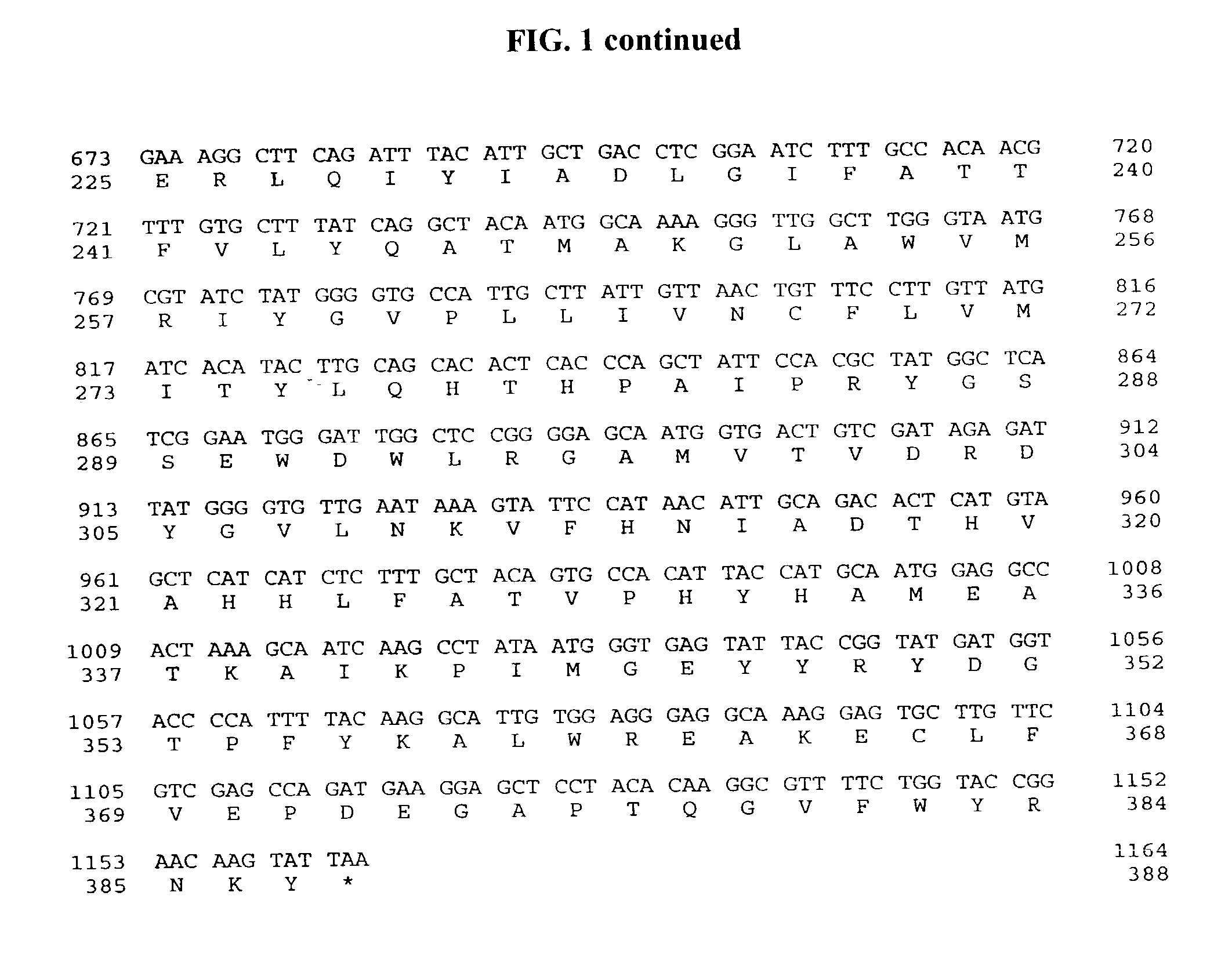

Method for preparing long-chain hydroxyacids, diacids and oligomers and polymers thereof

Owner:POLYTECHNIC INST OF NEW YORK +1

Micro-emulsion cutting fluid for aluminum alloy, and preparation method of micro-emulsion cutting fluid

The invention discloses a micro-emulsion cutting fluid for aluminum alloy and a preparation method of the micro-emulsion cutting fluid. The micro-emulsion cutting fluid comprises the following raw materials in parts by weight: 12-16 parts of paraffin-based oil, 3-5 parts of star anise oil, 4-7 parts of eucalyptus oil, 5-7 parts of sorbitan fatty acid, 3-4 parts of triethanolamine oleate, 3-4 parts of petroleum sodium sulfonate, 7-8 parts of sorbitan monooleate, 3-4 parts of monoethanolamine, 6-7 parts of zinc sulfate, 4-7 parts of sodium oleate, 6-8 parts of dimethicone, 2-4 parts of sodium molybdate, 4-7 parts of octylphenol polyoxyethylene ether, 4-7 parts of chlorinated paraffin, 4-5 parts of ricinoleic acid, 0.5-1.5 parts of dodecanol, 1.2-1.5 parts of imidazolidinyl urea, 10-15 parts of additives and 15-25 parts of deionized water. The micro-emulsion cutting fluid for aluminum alloy also has the outstanding performances on the aspects of corrosion inhibition property, corrosion resistance, lubrication, rust resistance, defoaming property, service life and the like.

Owner:江苏悠谷未来科技有限公司

Epoxy resin seepy material and preparation method thereof and application

ActiveCN106277932AGood water permeability and air permeabilityUniform pore size distributionCeramicwareAbsorption rateChemistry

The invention belongs to the technical field of epoxy resin preparation and discloses an epoxy resin seepy material and a preparation method thereof and application. The epoxy resin seepy material is prepared from, by weight percentage, 5-35% of epoxy resin, 5-30% of modified self-emulsifying epoxy hardener, 0.5-3% of polyether polyamine, 0.5-3.5% of epoxy resin accelerator, 1-3.5% of epoxy resin diluent, 35-10% of water and 53-15% of inorganic filler. The modified self-emulsifying epoxy hardener is ricinoleic acid and / or fatty polyamine and / or alicyclic polyamine modified by a polymer of the ricinoleic acid. The epoxy resin seepy material has excellent seepy and breathable performances, the pore diameter of the epoxy resin seepy material is smaller than 20 [mu]m, the porosity is larger than 20%, the water absorption rate is larger than 20%, the pore diameter distribution is uniform, the surface is bright and clean, and the epoxy resin seepy material can be used for manufacturing ceramic industry slip casting dies, filter materials and air purification materials.

Owner:国科广化(南雄)新材料研究院有限公司 +1

Water-soluble metalworking oil agent and usage thereof

ActiveUS20120184475A1Improve machinabilityTool lifetime be significantly increasedAdditivesPolyolAlcohol

A water-soluble metalworking oil agent is provided by blending the following components A, B, C and D:(A) at least one of a condensed fatty acid obtained by dehydration-condensing a ricinoleic acid, and a condensed fatty acid obtained by dehydration-condensing a monovalent carboxylic acid with an alcoholic hydroxyl group of a condensed fatty acid obtained by dehydration-condensing a ricinoleic acid;(B) an ester compound provided by a dehydration condensate of a monovalent or multivalent alcohol and a monovalent carboxylic acid;(C) an amine compound; and(D) water. A blend ratio of the component A is 10 mass % or more of a total amount of the oil agent and a blend ratio of the component B is 5 mass % or more of the total amount of the oil agent.

Owner:IDEMITSU KOSAN CO LTD

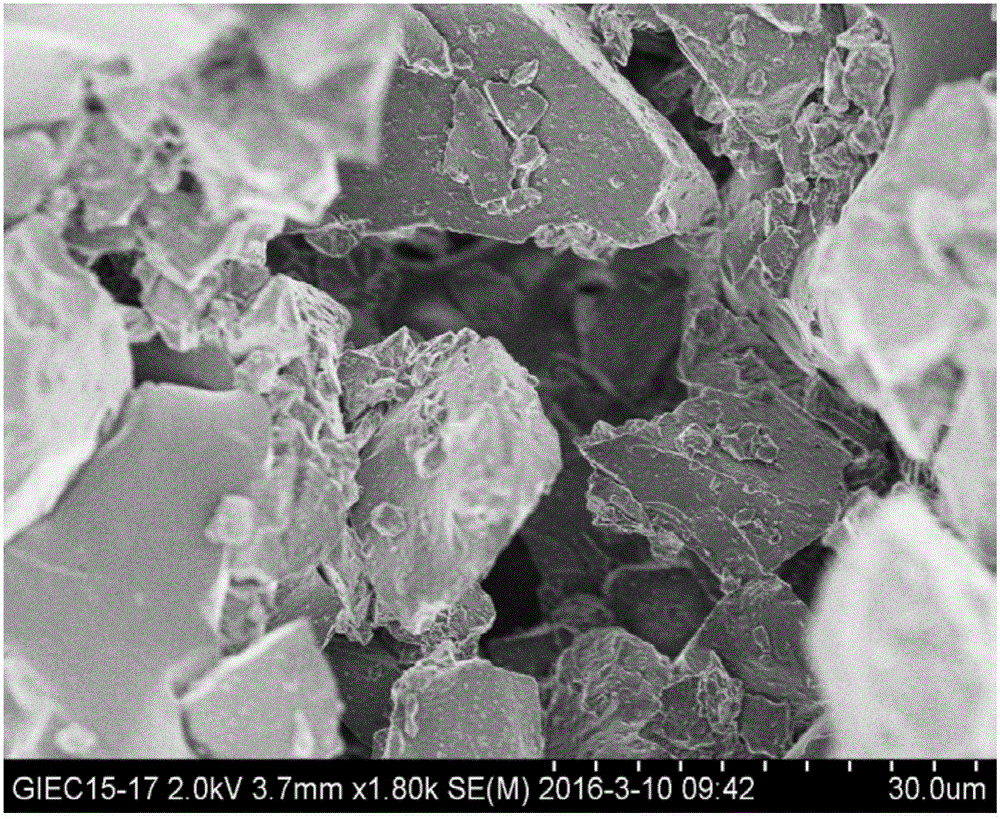

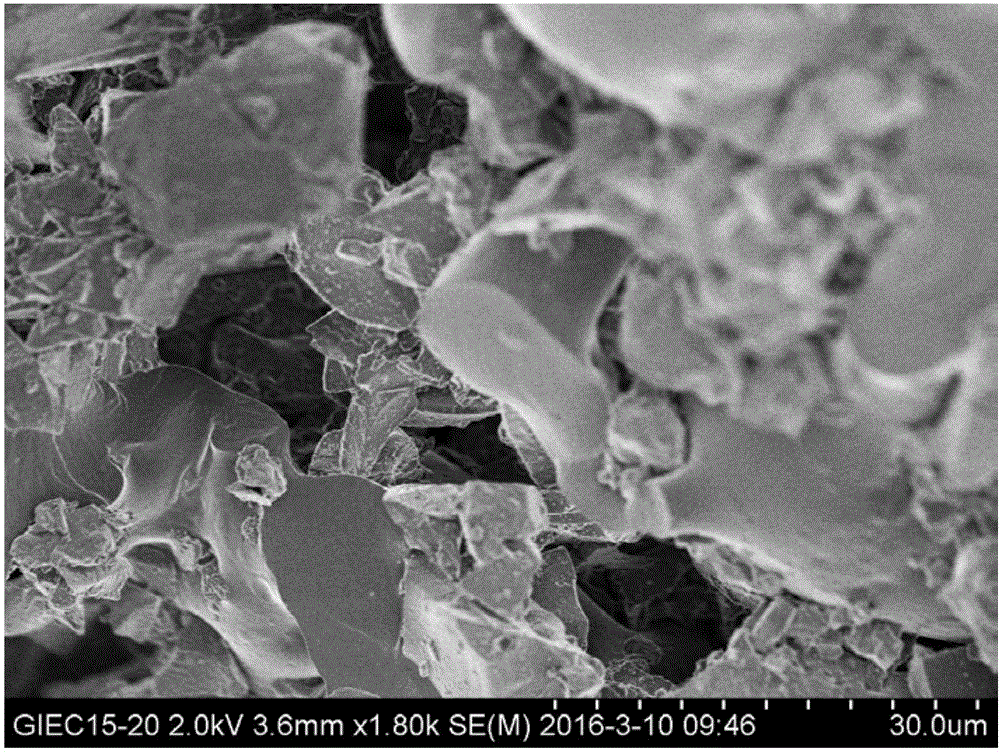

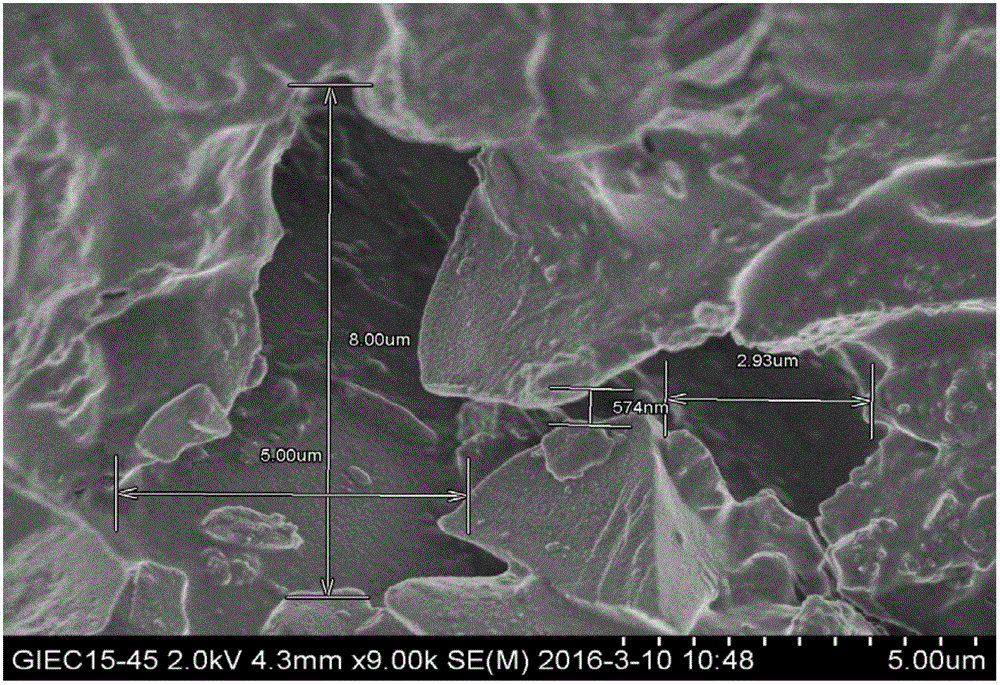

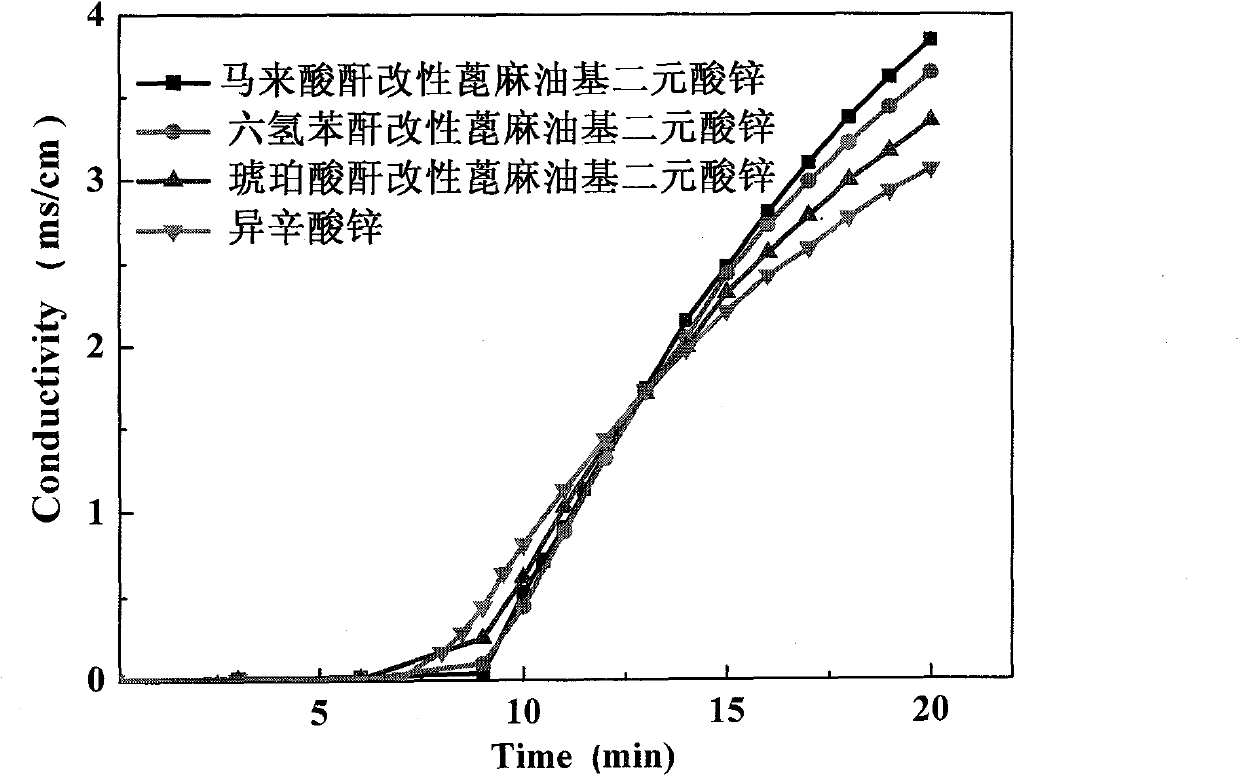

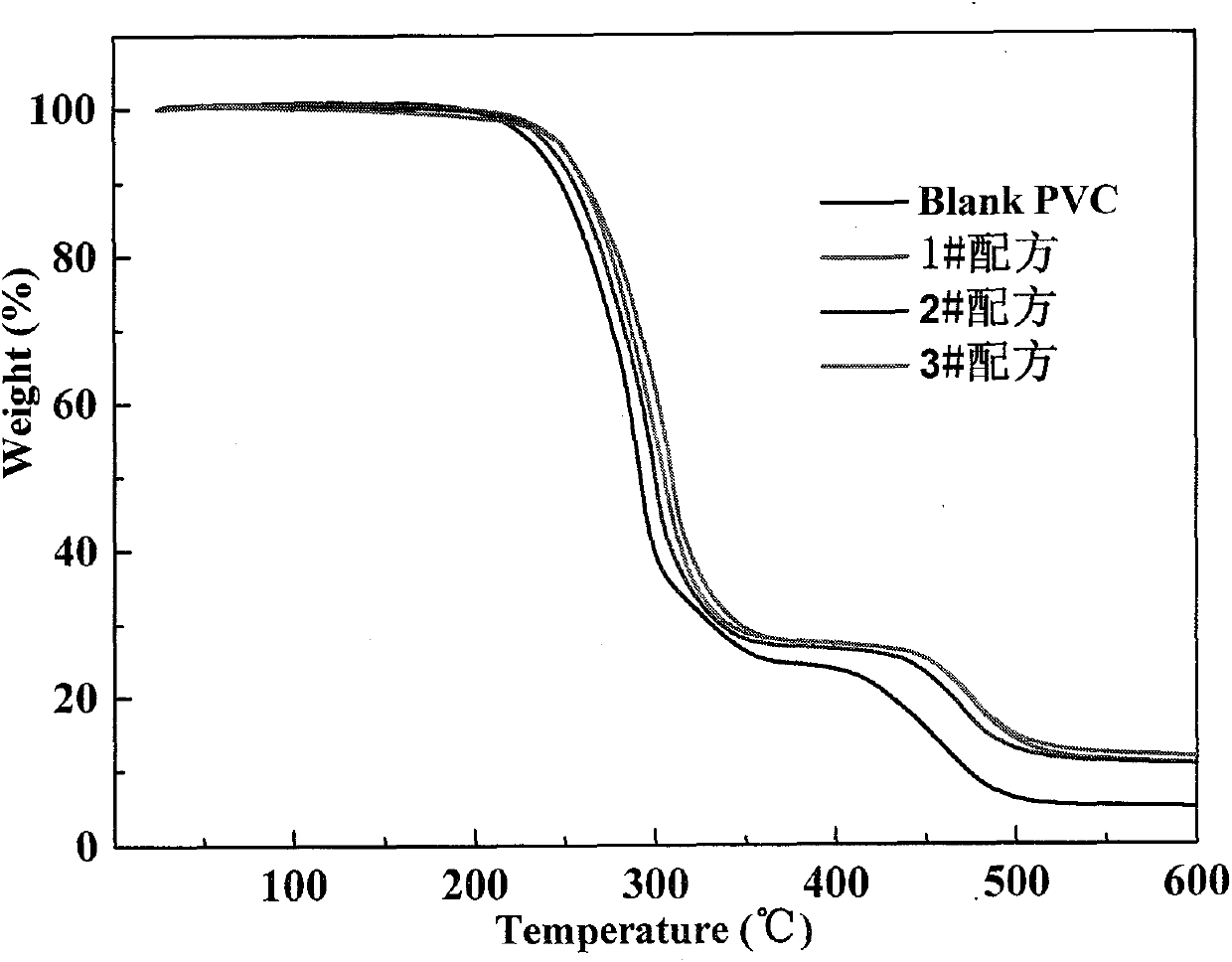

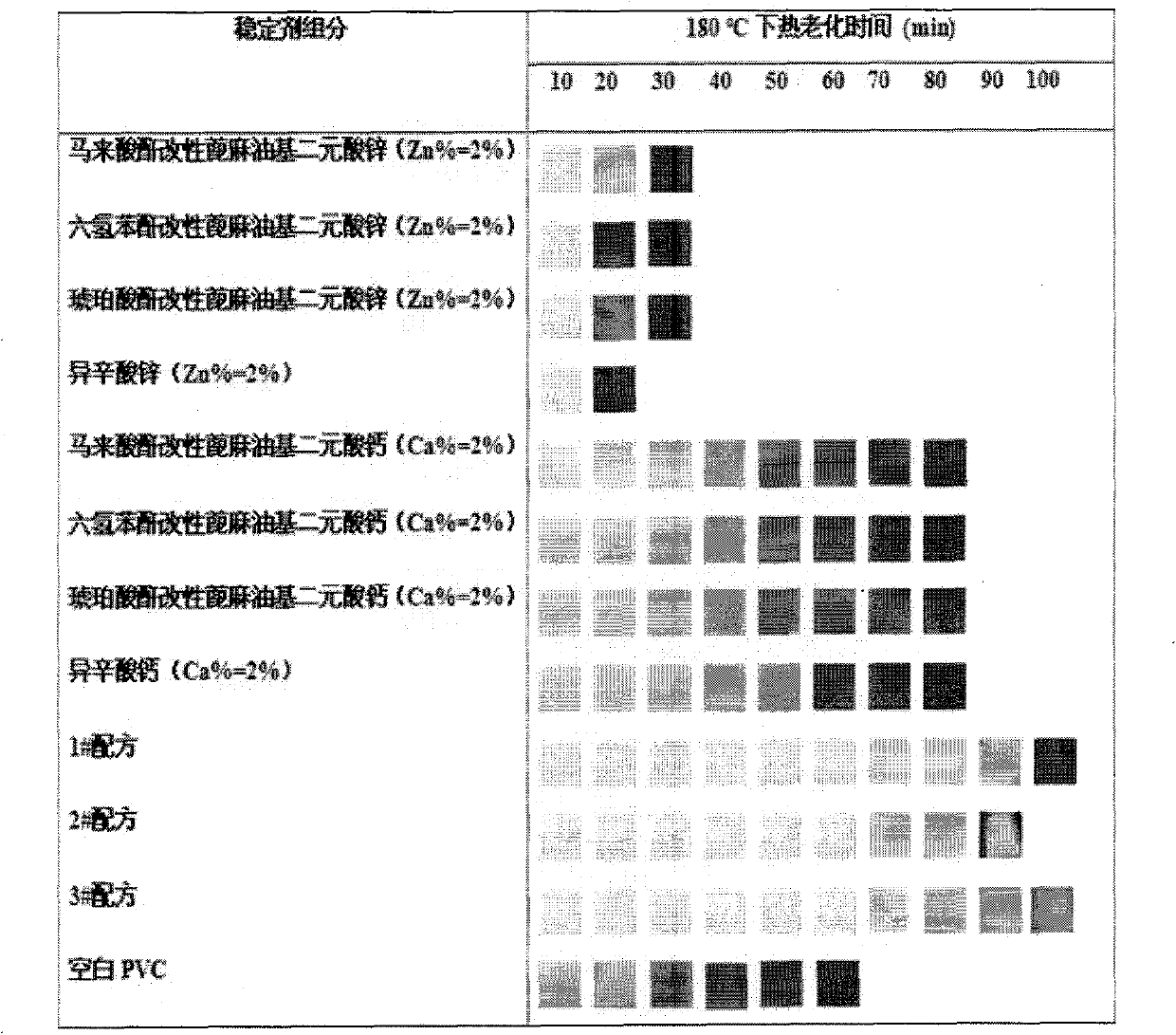

Castor oil-based calcium-zinc composite heat stabilizers and preparation method thereof

InactiveCN104177647ANot easy to "zinc burn"Improve thermal stabilityPhosphoric Acid EstersVegetable oil

The invention provides castor oil-based calcium-zinc composite heat stabilizers and a preparation method thereof; with castor oil as a raw material, a series of novel castor oil-based dicarboxylic acids are designed and are made into the castor oil-based calcium-zinc composite heat stabilizers. The prepared castor oil-based calcium-zinc composite heat stabilizers are each composed of a calcium salt, a zinc salt, an antioxidant, an epoxy compound, phosphite ester, beta-diketone, the castor oil-based dicarboxylic acid, a solvent and the like. The prepared castor oil-based calcium-zinc composite heat stabilizers have higher thermal stability, the product early whiteness retention time of a heat aging oven method at the temperature of 180 DEG C can reach up to 60 min or more, and the castor oil-based calcium-zinc liquid composite heat stabilizers are mainly derived from vegetable oil, have the advantages of no toxicity, environmental protection, simple synthesis process and the like, contains no heavy metals, and are expected to replace petroleum-based heat stabilizers to be used as a new generation of green environmental-protection heat stabilizers.

Owner:蒋平平

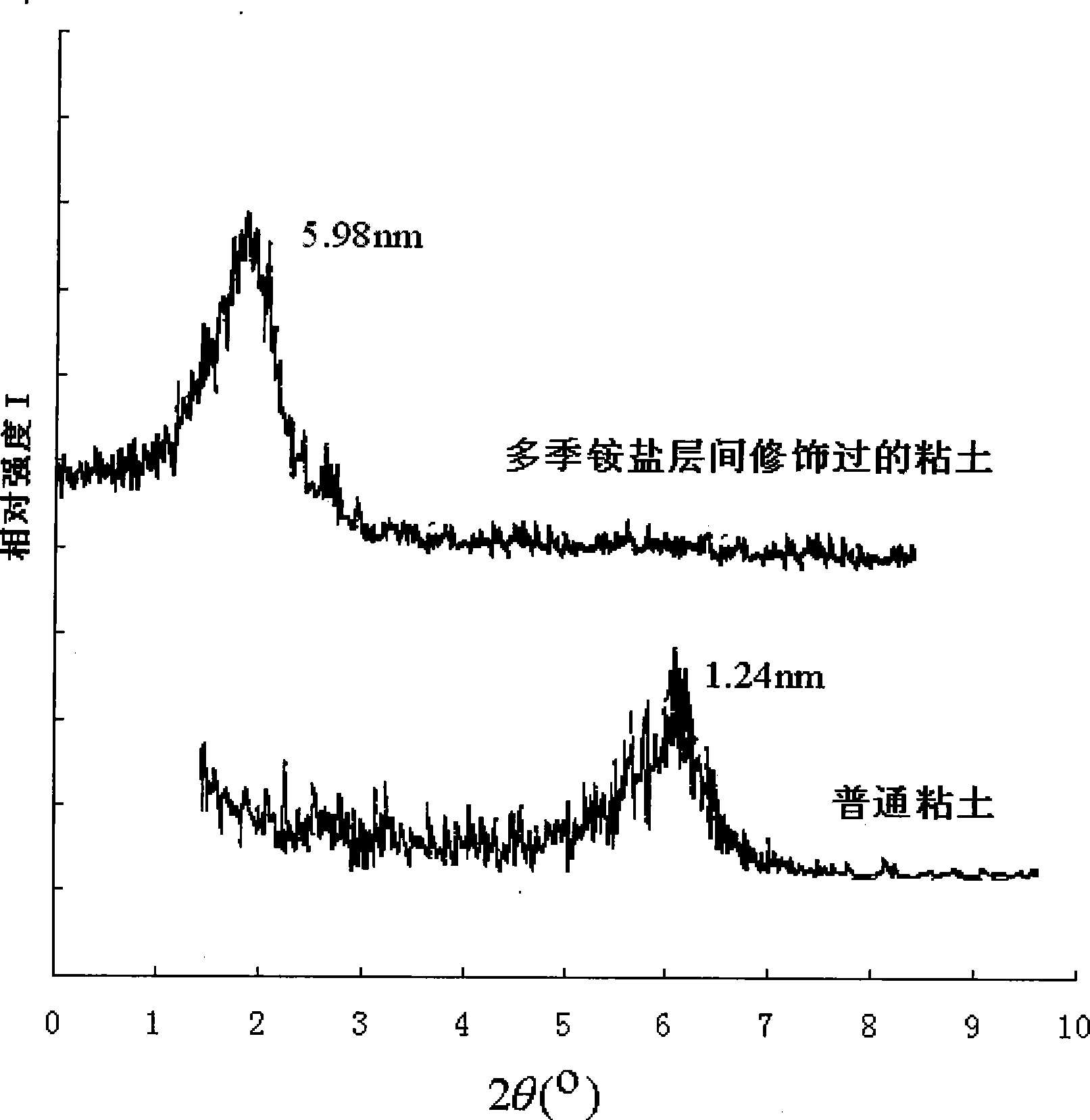

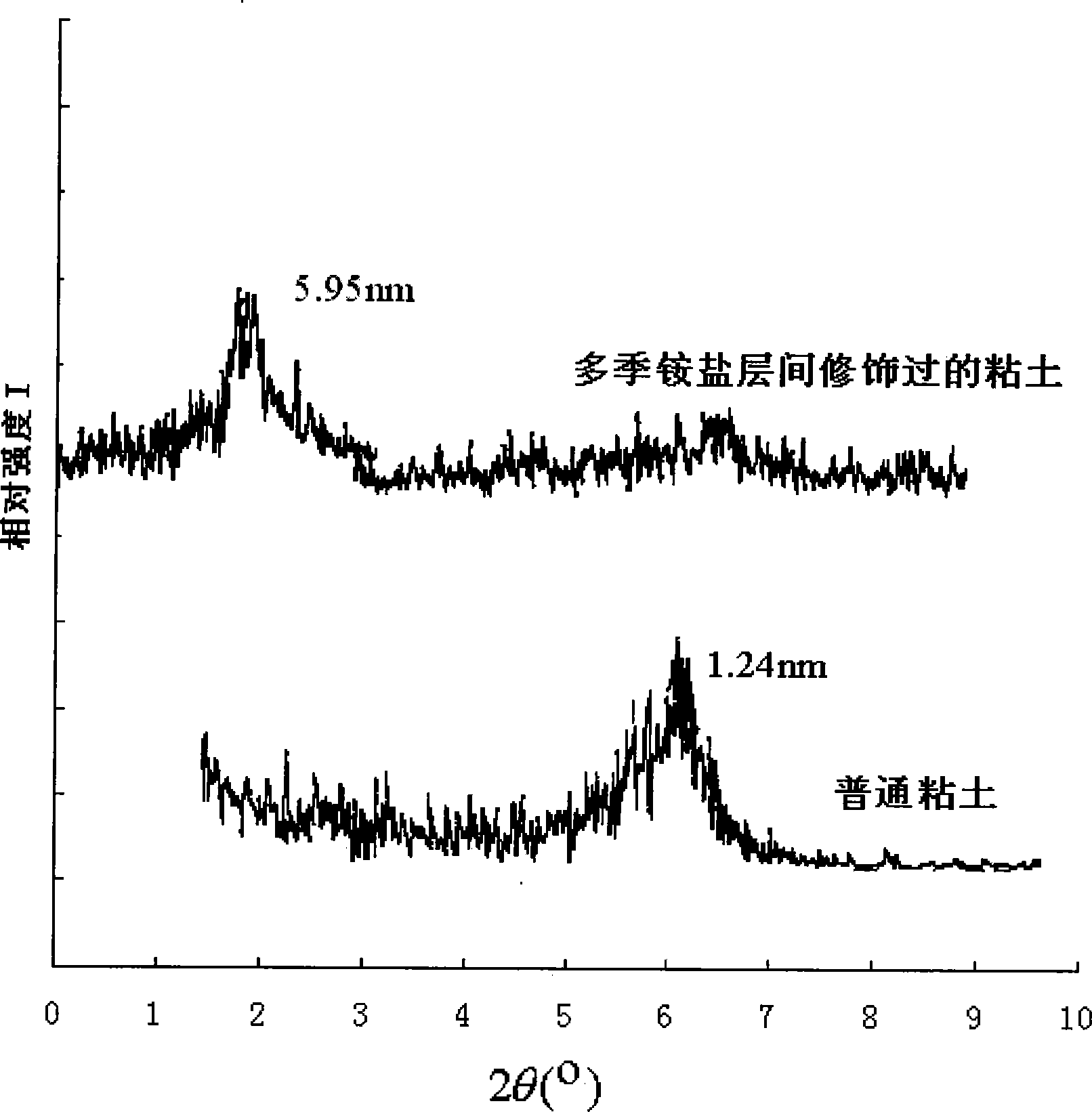

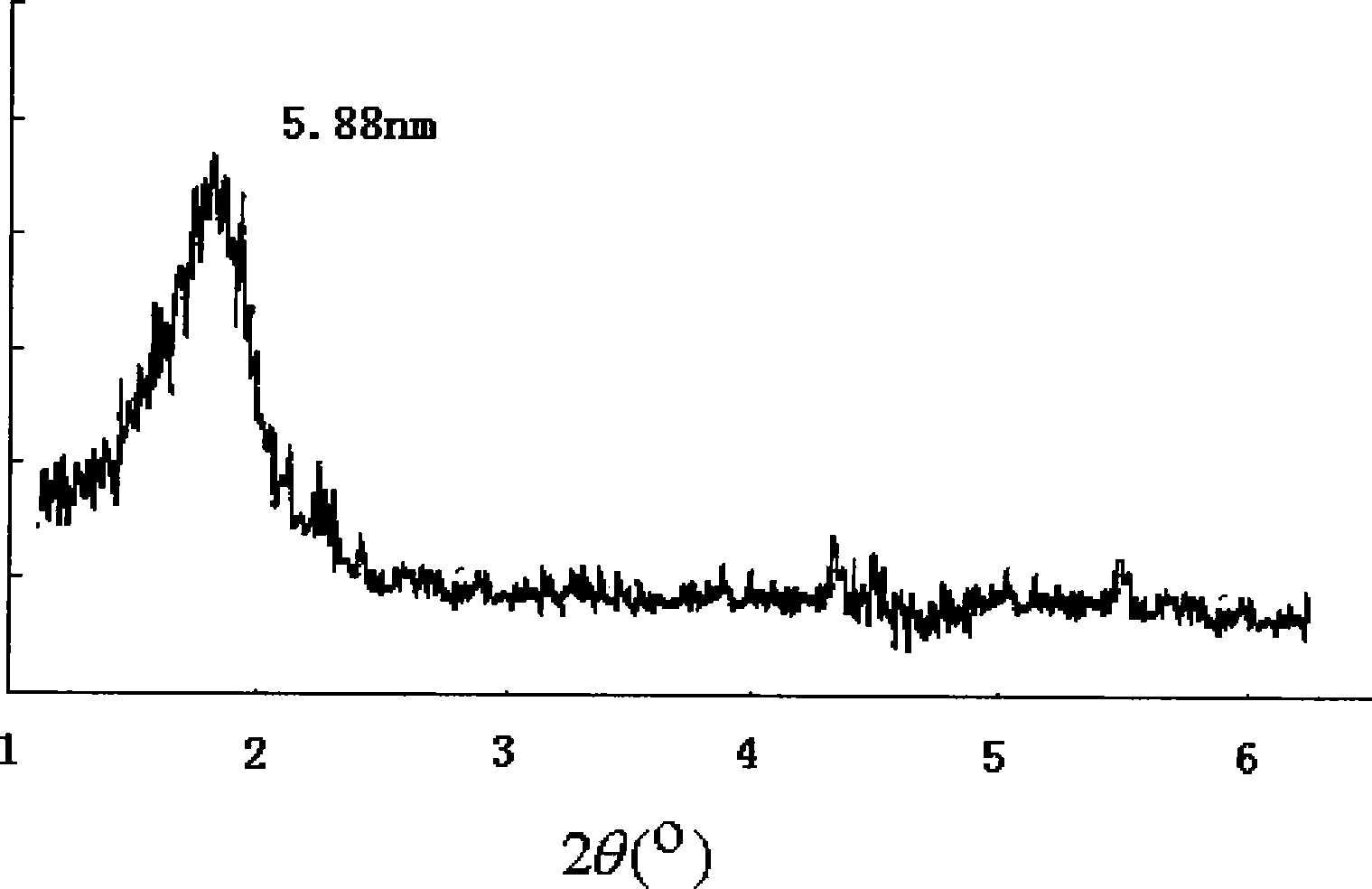

Multiple quaternary ammonium salts clay interlaminar modifier and preparation method thereof

The invention discloses multiple quaternary ammoniums salts type clay-intercalated modification agent and a process for preparation. The steps of the process for preparation comprise 1) dissolving unsaturated fatty acid into dimethylbenzene and mixing with catalyst, heating up to 180-220 DEG C, then adding with diethylenetriamine to react and obtaining bisamide, 2), mixing the bisamide with ethanol, heating up to 30-40 DEG C, adding with polyethylene polyamine and reacting at the temperature of 70-80 DEG C, wherein the unsaturated fatty acid is nutmeg oleic acid, kittul oleic acid, oleic acid, castor-oil plant oleic acid or erucic acid, the polyethylene polyamine is quadrol, triethylene tetramine, tetraethylene pentamine or 3-chlorine-2-hydroxypropyl trimethylammonium, the mol ratio of the unsaturated fatty acid, diethylenetriamine and polyethylene polyamine is 1.5-2:0.8-1:0.8-1. The multiple quaternary ammoniums salts type clay-intercalated modification agent provided by the invention increases solubility and suspension property of clay in water, and can enlarge the distance of the clay-intercalated from 1.24nm to 5.98nm.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Technique for preparing ricinoleic acid by using combined lipase to hydrolyzing castor oil

InactiveCN101100628AHigh yieldUndamagedFatty acid chemical modificationHydrolasesHydrelioxRicinelaidic acid

Production of ricinolic acid from combined lipase hydrolysable castor oil is carried out by: reacting at 35-60 deg. C for 10-30 hrs in proportion of water and castor oil=1-50:1 mol in biochemical reactor, and hydrolyzing. The recovery rate is not less than 90% and hydroxide radical isn't destructed. It's efficient and has less consumption.

Owner:TSINGHUA UNIV

Lipid and Nitrous Oxide Combination as Adjuvant for the Enhancement of the Efficacy of Vaccines

InactiveUS20090010964A1Improve actionStimulate immune responseAntibacterial agentsBacterial antigen ingredientsAntigenAdjuvant

The invention provides for a method of enhancing immunological responses to an antigen in a vaccine formulation, and for a vaccine formulation that provides for an enhanced immunological response to an antigen. In the method and formulation the antigen is administered with an adjuvant which adjuvant comprises a solution of nitrous oxide gas in a pharmaceutically acceptable carrier solvent for the gas and which adjuvant includes at least one fatty acid or ester or other suitable derivative thereof selected from the group consisting of oleic acid, linoleic acid, alpha-linolenic acid, gamma-linolenic acid, arachidonic acid, eicosapentaenoic acid [C20: 5ω3], decosahexaenoic acid [C22: 6ω3], ricinoleic acid and derivatives thereof selected from the group consisting of the C1 to C6 alkyl esters thereof, the glycerol-polyethylene glycol esters thereof and the reaction product of hydrogenated natural oils composed largely of ricinoleic acid based oils, such as castor oil with ethylene oxide.

Owner:EXHAUSTO +1

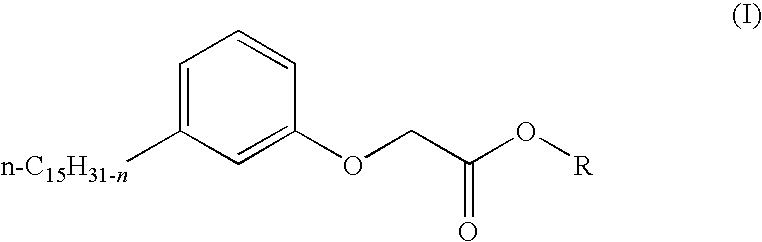

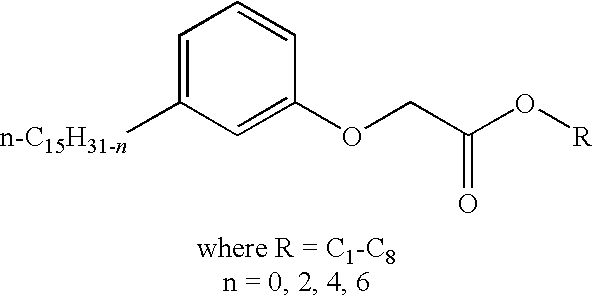

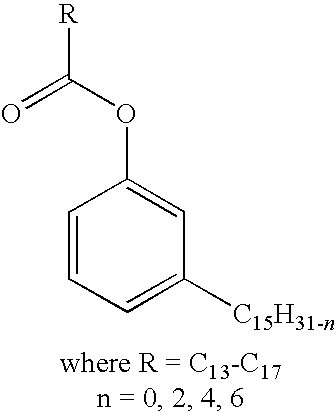

Lubricity improving additive composition for low sulfur diesel fuel

The present invention relates to a additive composition for use as lubricity improver for low sulphur diesel, comprising c) 0.1-10% by weight of ester derivative derived from cashew nut shell liquid (CNSL esters) of formula (I); f) 0.1-10% by weight of ester derivative derived from cashew nut shell liquid of formula (II); g) 50-95% by weight of free fatty acid of the formula RCOOH in which R represents an alkyl / alkenyl group with 12 to 24 carbon atoms. h) 1-30% by weight of synthetic esters derived by esterifying tri, tetra, penta hydric alcohols with carboxylic acids such as lauric, palmitic, linoleic, ricinoleic etc.

Owner:INDIAN OIL CORPORATION

Synthetic multiple-effect lubricant additive and preparation method thereof

The invention relates to a synthetic multiple-effect lubricant additive and a preparation method thereof and in particular relates to a fully-synthetic multiple-effect lubricant additive which does not contain S and Cl and takes a metal processing lubricant as a main product. The fully-synthetic multiple-effect lubricant additive is a mixture containing glycerol single ricinoleate, a carboxylic acid synthetic ester lubricant, iso-tridecanol polyoxyethylene ether, an antirust agent, amine phosphate, a non-ferrous metal corrosion inhibitor and a carboxyl hexyl-2-cyclohexene-1-octadeca-carbonic acid. The fully-synthetic multiple-effect lubricant additive has the advantages of good wear resistance, good anti-rust performance, good synergy and environmental friendliness. The fully-synthetic multiple-effect lubricant additive is applicable to blending emulsified oil, micro-emulsifying liquid, fully-synthetic metal working fluid, metal rolling liquid and metal molding working fluid as well as lubricating oil products such as water-based fire-resistant hydraulic oil.

Owner:GUANGDONG AOLIDAN IND

Method for Lightening Skin

Skin lightening additives and skin lightening compositions having at least one of a heterosubstituted, saturated or unsaturated aliphatic acid are described. The compositions are suitable for topical application and may comprise 12-hydroxystearic acid, ricinoleic acid or both.

Owner:CONOPCO INC D B A UNILEVER

High-temperature wire drawing lubricant and preparation method thereof

The invention discloses a high-temperature wire drawing lubricant and a preparation method thereof. The lubricant and the preparation method are characterized in that: the lubricant is prepared from following raw materials by weight: 2-3 parts of sodium dodecyl benzene sulfonate, 1-2 parts of boric acid, 2-3 parts of triethanolamine borate, 1-2 parts of ricinoleic acid polyester, 12-15 parts of ricinus oil, 1-2 parts of a polyoxyethylene alkyl ether, 10-12 parts of glycol, 1-2 parts of citric acid, 1-2 parts of triethanolamine oleate soap, 10-14 parts of an antiwear agent and 1000 parts of water; nano aluminium nitride powder is added into the antiwear agent, thus promoting heat dissipation so that cooling effects are good, enhancing the film-forming property and prolonging the service lifetime of a wire drawing die; the lubricant can resolve issues of extreme-pressure wear resistance, resistance to high-temperature oxidation, surface rust protection, and the like of metal wires at high-temperature environments; the method is simple and the cost is reduced; problems of failure at high temperature, etc. of conventional lubricants are solved; and the lubricant is suitable for wire drawing processes of various metals and alloys.

Owner:全威(铜陵)铜业科技有限公司

Synthesis method of ricinoleic acid based polyester polyol

The invention provides a synthesis method of ricinoleic acid based polyester polyol, and relates to the field of polyurethane industry, in particular to the synthesis method of the ricinoleic acid based polyester polyol. The method comprises the following steps that castor oil methyl ester is prepared; in a 500mL three-necked flask provided with an electric stirrer, a backflow condenser and a temperature indicator, 250g of castor oil subjected to pre-dehydration treatment is added; after the constant-temperature water bath heating is performed to 35 DEG C, 54g of 5-percent KOH-CH30H solution is added; stirring reaction is performed for 2h, then, 10-percent HCl is added for neutralization until a pH value is 4 to 4.5; reaction liquid is poured into a separating funnel; standing is performed for layer seperation, so that a lower layer glycerol-methanol solution is separated out; an upper layer is washed for 3 times by 100 mL of deionized water until a neutral state is formed; reduced pressure distillation dewatering is performed to obtain 247g of clear and transparent castor oil methyl ester. The synthesis method has the advantages that the operation is simple; the processing is convenient; the product quality is ensured; the product performance is improved; good film forming performance, high hardness, excellent adhesion force and good water-resistant and oil-resistant performance are realized.

Owner:SHAANXI HI-TECH IND CO LTD

Water-based graphene conductive alkyd resin and preparation method thereof

InactiveCN105017512AExpand the scope of applicationExpand fieldElectrically-conductive paintsPolyester coatingsDiethylene glycol monobutyl etherPolymer science

The invention provides water-based graphene conductive alkyd resin. Ricinoleic acid, neopentyl glycol, trimethylolpropane, m-benzene, trimellitic anhydride, diethylene glycol monobutyl ether, butanol and graphene xylene liquor are used as the raw materials, the mechanical strength and the electric conductivity of a coating prepared through traditional conductive coating paint cannot be easily improved at the same time, the density of the coating is large, and all the problems greatly restrain the application range of the coating. A recently-developed material using graphene as conductive filler can hopefully solve the above problems existing in the conductive coating paint, and the application range and field of the conductive coating paint are greatly widened. However, graphene cannot be dispersed in a water-based system easily in general, and thus the graphene is evenly dispersed in water-based alkyd resin through resin synthesis. High-performance conductive coating paint can be prepared through the resin. The problems that the mechanical strength and the electric conductivity of the coating prepared through the traditional conductive coating paint cannot be easily improved at the same time, and the density of the coating is large.

Owner:张东海

Anionic latex product and processing process therefor

An anionic latex product and a processing process therefor. The invention provides the anionic latex product, which is soft in touch and rich in resilience and has antibacterial characteristic, and the processing process therefor. The anionic latex product contains the following ingredients in parts by weight: 80-100 parts of natural latex, 2-5 parts of anion powder, 0.1-3 parts of quaternary ammonium salt antibacterial agent, 1-5 parts of sulfur, 1-5 parts of vulcanization accelerator, 1-6 parts of zinc oxide, 0.1-0.3 part of potassium pyrophosphate, 1-4 parts of sodium stearate and 0.1-2 parts of potassium ricinoleate. The latex product provided by the invention contains the anion powder, and anions have an extremely high degermation action, guarantees air cleanness and can also be used for improving allergic constitution, promoting the synthesis and storage of vitamins of human bodies and improving quality of sleep; and meanwhile, the latex product contains the quaternary ammonium salt antibacterial agent, and the quaternary ammonium salt antibacterial agent is grafted to a latex high polymer, so that antibacterial natural latex products with low toxicity, long antibacterial time and light environmental pollution can be prepared. The latex product provided by the invention is antibacterial, practical, sanitary and reliable.

Owner:江苏金世缘乳胶制品股份有限公司 +1

Good-pressure-resistance salt elimination concealed pipe for saline and alkali soil and application of the same

ActiveCN105037886AHigh compressive strengthNo softening and deformation phenomenonSoil lifting machinesTubular articlesSodium bicarbonateAlkali soil

The invention provides a good-pressure-resistance salt elimination concealed pipe for saline and alkali soil. The concealed pipe comprises, by weight, 50-55 parts of polyethylene, 18-20 parts of polycarbonate, 15-19 parts of fatty alcohol phosphate ester, 1-3 parts of sodium bicarbonate, 2.3-3.5 parts of rock wool, 1.2-1.9 parts of nano calcium oxide powder, 2.5-4.2 parts of butadiene styrene rubber, 5-7 parts of alkyd resin, 5.2-6.9 parts of isothiazolinone and 0.8-1.3 parts of calcium ricinoleate. The concealed pipe is a corrugated pipe, the nominal outside diameter is 112 mm, and the wall thickness is 5 mm. Water inflow holes are formed in the concealed pipe and are oval, and according to the ovality, the ratio of the maximum outer diameter to the minimum inner diameter is not larger than 120%. The number of the water inflow holes on the same circumference is three. Every three water inflow holes are evenly distributed at the interval of 120 degrees, and the overall water inflow area is 38 cm <2> / m. The concealed pipe is high in pressure resistance, good in thermal tolerance, and the deformation ratio of the concealed pipe is low.

Owner:WEIFANG YOURONG IND

Corrosion-resistant, moisture-resistant and wear-resistant paint for ships and preparation method thereof

InactiveCN104312412AImprove water resistanceImprove corrosion resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsCarbon fibersAluminum silicate

The invention discloses corrosion-resistant, moisture-resistant and wear-resistant paint for ships and a preparation method thereof. The corrosion-resistant, moisture-resistant and wear-resistant paint is prepared from 30-36 parts by weight of aliphatic polyurethane acrylate resin, 14-16 parts by weight of vinisol, 5-7 parts by weight of self-crosslinked acrylic emulsion, 0.4-1.0 part of glycerol monolaurate, 0.3-0.6 parts by weight of nanometer ferroferric oxide, 0.3-0.6 parts by weight of methyl benzimidazolecarbamate, 0.3-0.5 parts by weight of tetrachloroisophthalonitrile, 3-5 parts by weight of polyacrylate, 2-3 parts by weight of ricinoleic acid, 2-3 parts by weight of aluminum triphosphate, 2-3 parts by weight of carbon fibers, 4-6 parts by weight of vinyltriamine, 8-11 parts by weight of modified waste clay-bonded sand, 12-14 parts by weight of modified asphalt, 2-3 parts by weight of ultrafine alumina silicate, 5-7 parts by weight of xylene, 7-10 parts by weight of n-tetradecane, 6-8 parts by weight of butyl acetate and 1-2 parts by weight of cobalt-manganese-rare earth alloy. The vinisol used in the paint for ships can improve paint film water resistance, corrosion resistance and toughness. The used carbon fibers have good acid and alkali corrosion resistance. The used modified waste clay-bonded sand can solve the problem of environmental pollution and can improve paint film wear resistance and prolong a service life. The used modified asphalt improves paint corrosion resistance, adhesion, oxidation resistance and weatherability. Therefore, the corrosion-resistant, moisture-resistant and wear-resistant paint has excellent moisture resistance and wear resistance.

Owner:TIANCHANG JULONG TRAVEL PAINT

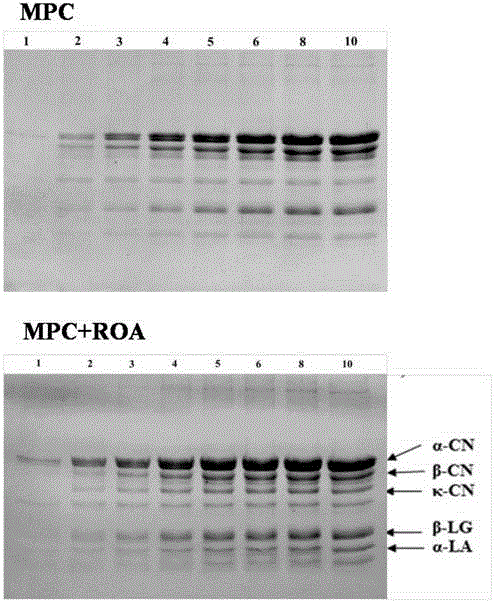

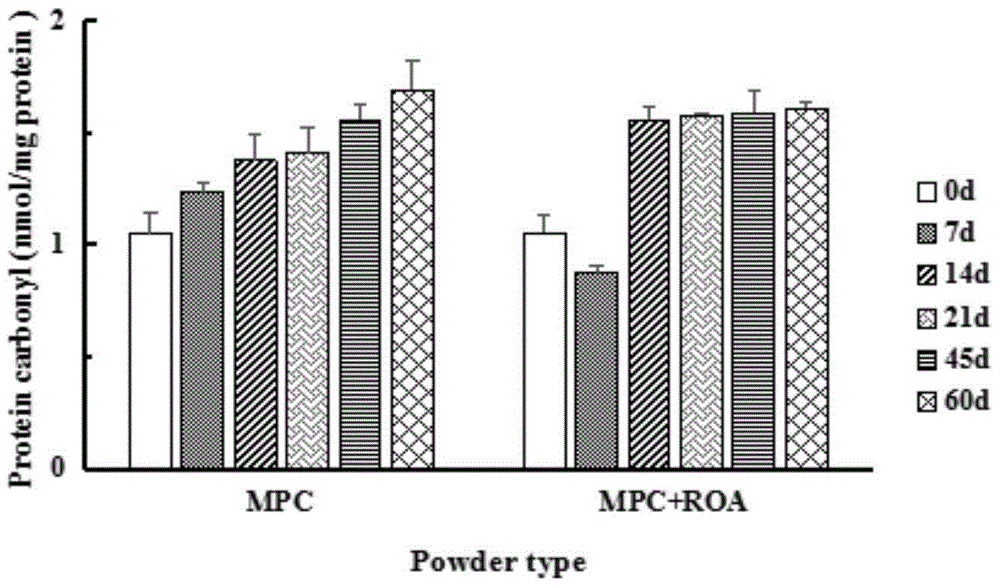

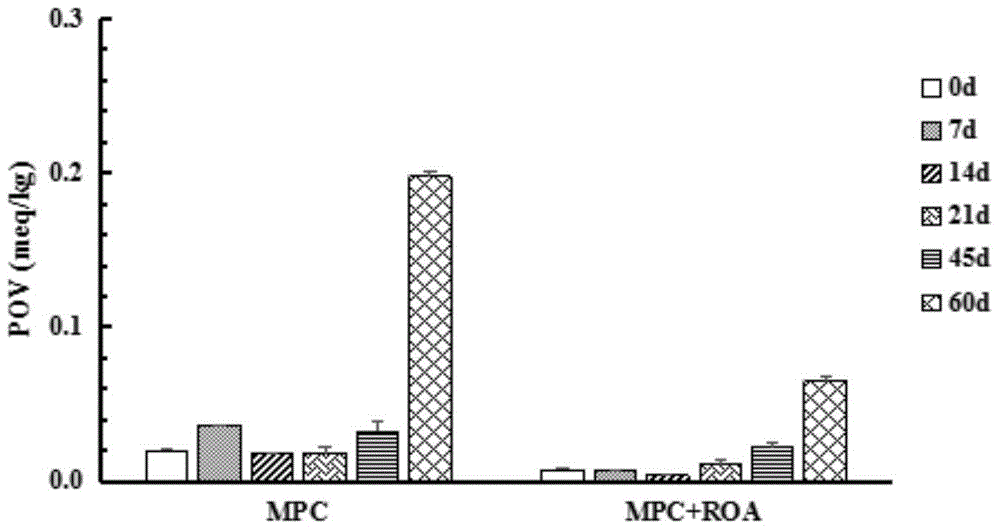

Method for protecting and delaying unsaturated fatty acid from oxidation through lactoprotein microcapsule

InactiveCN105685765AReduce oxidationPromote oxidationFood ingredient as antioxidantFood preservationSolubilityFish oil

The invention relates to a method for protecting and delaying unsaturated fatty acid from oxidation through a lactoprotein microcapsule. The unsaturated fatty acid (including unsaturated fatty acids, which are different in carbon atom number and double bond quantity, of oleic acid, ricinoleic acid, [alpha]-linolenic acid, eicosapentaenoic acid, docosapentaenoic acid, docosahexaenoic acid, linoleic acid, dihomo-[gamma]-linolenic acid, [gamma]-linolenic acid, arachidonic acid, eicosatrienoic acid and the like, and vegetable or animal oil and fat rich in fatty acid, such as olive oil, aloe oil, safflower seed oil, castor oil, fish oil and the like) are under the protection of the lactoprotein microcapsule, the oxidation process of the fatty acid is retarded; the stability and the shelf life of a product are obviously improved. The method has the following advantages that I, a production and preparation technical process is simple, convenient and pollution-free; II, the obtained product unsaturated fatty acid lactoprotein microcapsule is better in solubility and higher in storage stability, and can also be used for producing multiple functional foods and healthcare products of a liquid milk beverage, high-protein acidophilus milk, cheese, a high-protein nutritional bar and the like.

Owner:JIANGNAN UNIV

Composite additive and process for producing methanol diesel oil thereof

The invention relates to a preparation method for a compound additive and the methanol diesel oil thereof. The compound additive consists of the components with the following weight percentages: 5 to 20 portions of fatty acid ester, 1 to 25 portions of castor oil acid, 1 to 10 portions of normal butanol, 1 to 25 portions of ethyl acetate, 1 to 10 portions of carbon lauryl alcohol, 1 to 8 portions of cetane number improver, 1 to 8 portions of igniter, 1 to 10 portions of butanone, 1 to 10 portions of heat value increaser, 0.1 to 2 portions of antidetonator, 0.1 to 1 portion of swelling-resistant agent, 0.1 to 1 portion of antiseptic, 1 to 8 portions of antiwear agent as well as 1 to 12 portions of waterproof agent. The methanol diesel oil has the advantages of low cost, excellent performance, good environment protection effect, remarkable economic benefit and convenient popularization.

Owner:王宇

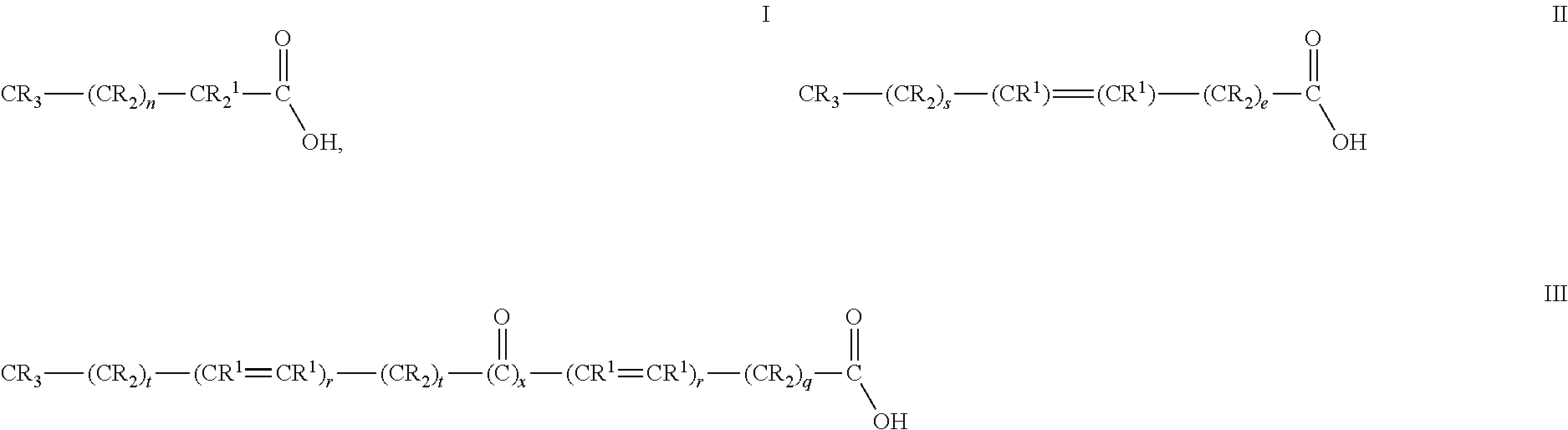

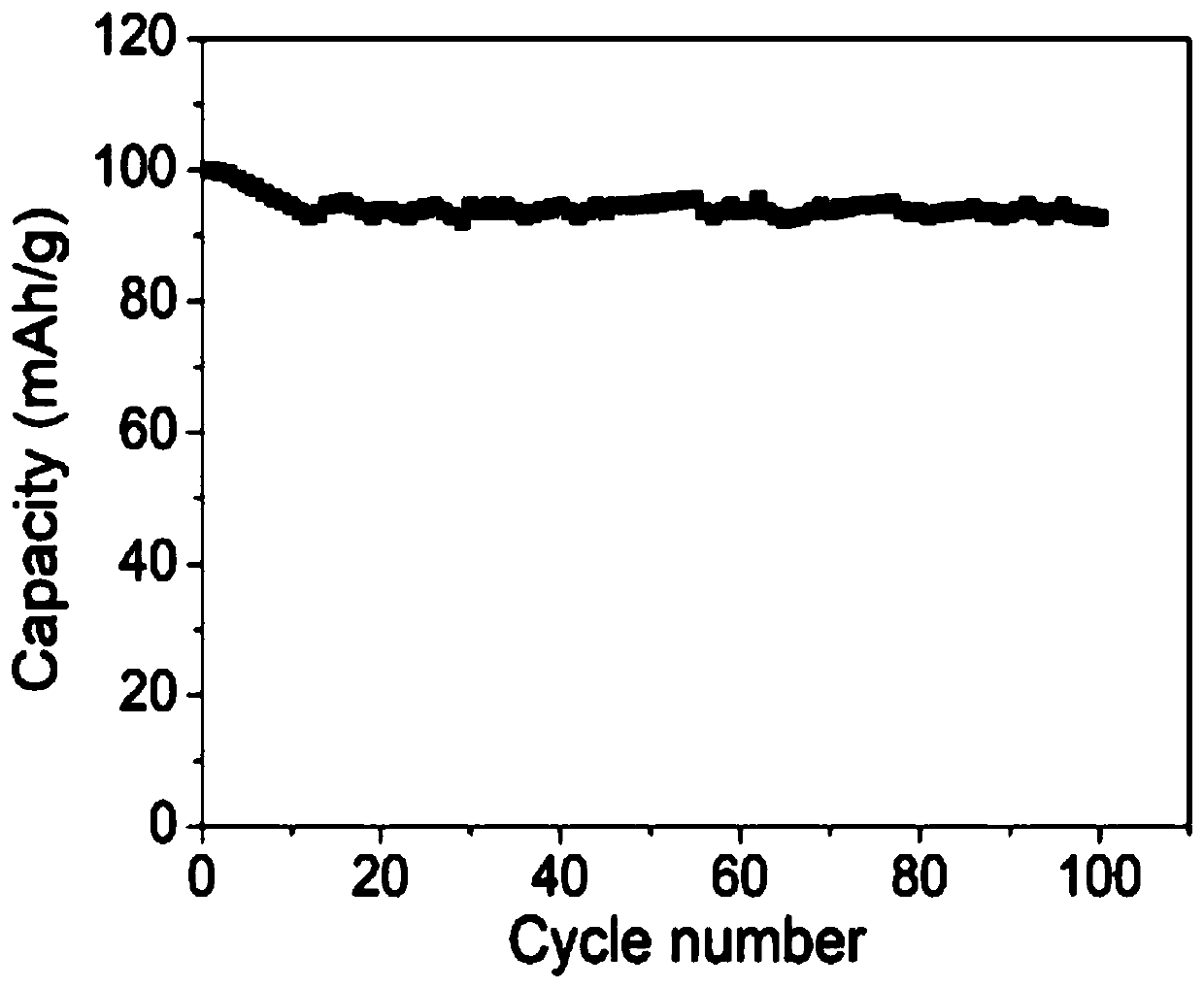

Acrylate adhesive modified by long-chain unsaturated carboxylic acid or derivative of long-chain unsaturated carboxylic acid and production method and application of acrylate adhesive modified by long-chain unsaturated carboxylic acid or derivative of long-chain unsaturated carboxylic acid

ActiveCN110627945AUniform appearanceNo stratificationCell electrodesSecondary cellsAdhesiveCarboxylic salt

The invention discloses acrylate adhesive modified by a long-chain unsaturated carboxylic acid or a derivative of the long-chain unsaturated carboxylic acid and a production method and application ofthe acrylate adhesive modified by the long-chain unsaturated carboxylic acid or the derivative of the long-chain unsaturated carboxylic acid. According to the acrylate adhesive modified by the long-chain unsaturated carboxylic acid or the derivative of the long-chain unsaturated carboxylic acid, the long-chain unsaturated carboxylic acid or the derivative of the long-chain unsaturated carboxylic acid is introduced into a molecular chain of the acrylate adhesive, the long-chain unsaturated carboxylic acid is an unsaturated carboxylic acid with carbon chain length equal to or larger than 12, thederivative of the long-chain unsaturated carboxylic acid is a derivative carboxylate, ester, amide, acyl halide or anhydride, and the long-chain unsaturated carboxylic acid or the derivative of the long-chain unsaturated carboxylic acid is preferably an oleic acid, a ricinoleic acid or a glyceride. According to the acrylate adhesive modified by the long-chain unsaturated carboxylic acid or the derivative of the long-chain unsaturated carboxylic acid and the production method and application of the acrylate adhesive modified by the long-chain unsaturated carboxylic acid or the derivative of the long-chain unsaturated carboxylic acid, the long-chain unsaturated carboxylic acid and the derivative of the long-chain unsaturated carboxylic acid, which are represented by the oleic acid, the ricinoleic acid or the glyceride, are selected as modifying monomers, raw materials are simple and easy to obtain, the cost is low, in the premise of guaranteeing a good modifying effect, the raw materialcost can be effectively controlled, and the obtained lithium battery adhesive has the characters of high adhesion, electrolyte resistance, low water absorption, flexibility and the like at the same time, and can well meet the production requirements of lithium battery ceramic diaphragm slurry, negative electrode slurry and positive electrode slurry respectively.

Owner:湖南高瑞电源材料有限公司

Improved mechanical processing lubricating oil

InactiveCN104830463ALubricates and coolsImprove high temperature resistanceLubricant compositionTetramethylammonium hydroxidePolyester

Improved mechanical processing lubricating oil comprises the following raw materials by weight: 6-9 parts of sodium sulfite, 4-7 parts of ricinoleic acid polyester, 3-5 parts of hydroxyl sodium sulfonate, 4-8 parts of polyethylene glycol monomethyl ether, 2-4 parts of ethanolamine, 7-9 parts of nitromethane, 3-6 parts of triethanolamine, 4-9 parts of Turkey red oil, 6-8 parts of low molecular polyethylene wax, 2-6 parts of benzene methanol, 3-8 parts of paraffin, 4-10 parts of tetramethylammonium hydroxide, 2-5 parts of methyl polytetrafluoroethylene, 1-4 parts of sodium hydroxide, 2-6 parts of epoxy ethane and 15-24 parts of base oil. The beneficial effects are that the mechanical processing lubricating oil can be used to well play the lubricating and cooling effect, reduces the friction, and has good high temperature tolerance.

Owner:QINGDAO BAOLIKANG NEW MATERIALS

Foamed rubber sole special rubber material and preparation method thereof

InactiveCN109096626AImprove wear resistanceImprove mechanical propertiesSolesRubber materialPolymer science

The invention discloses a foamed rubber sole special rubber material and a preparation method thereof. The rubber material is made of the following raw materials by weight: 45-65 parts of bromobutyl rubber, 35-45 parts of acrylate rubber, 5-10 parts of ethylene-vinyl acetate copolymer, 4-8 parts of dipentamethylene thiuram tetrasulfide, 3-6 parts of dicumyl peroxide, 1-4 parts of vulcanizing agent, 3-7 parts of activator, 2-6 parts of modified urea-formaldehyde resin, 4-8 parts of reinforcing additive, 2-4 parts of talc, 5-10 parts of dibutyl phthalate, 3-6 parts of pentaerythritol stearate, 3-7 parts of ricinoleate, 2-5 parts of foaming agent, 1-3 parts of softener, 0.5-1.5 parts of vulcanization accelerator and 0.4-0.8 part of anti-aging agent. The foamed rubber sole special rubber material has good wear resistance and mechanical properties and is light in weight, good in elasticity and excellent in aging resistance.

Owner:HEFEI YUANKE GARMENT DESIGN CO LTD

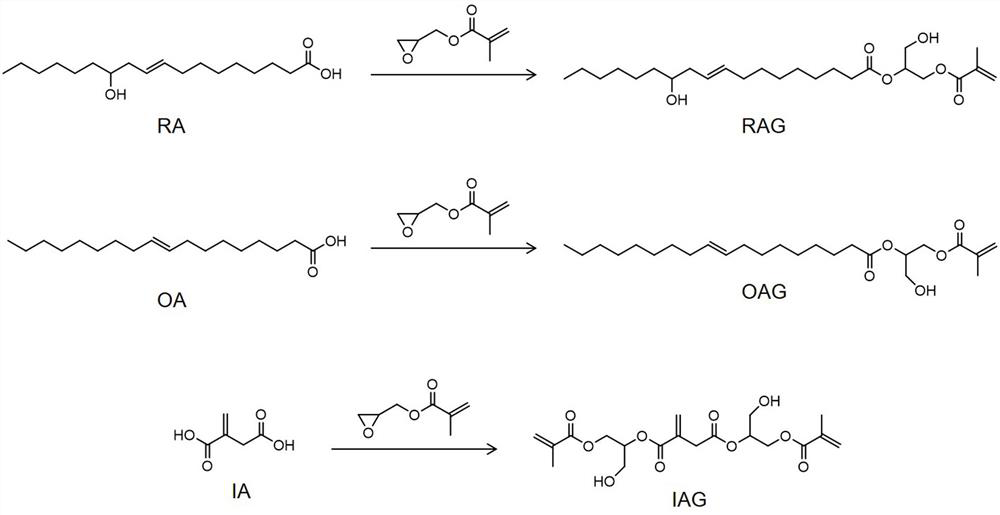

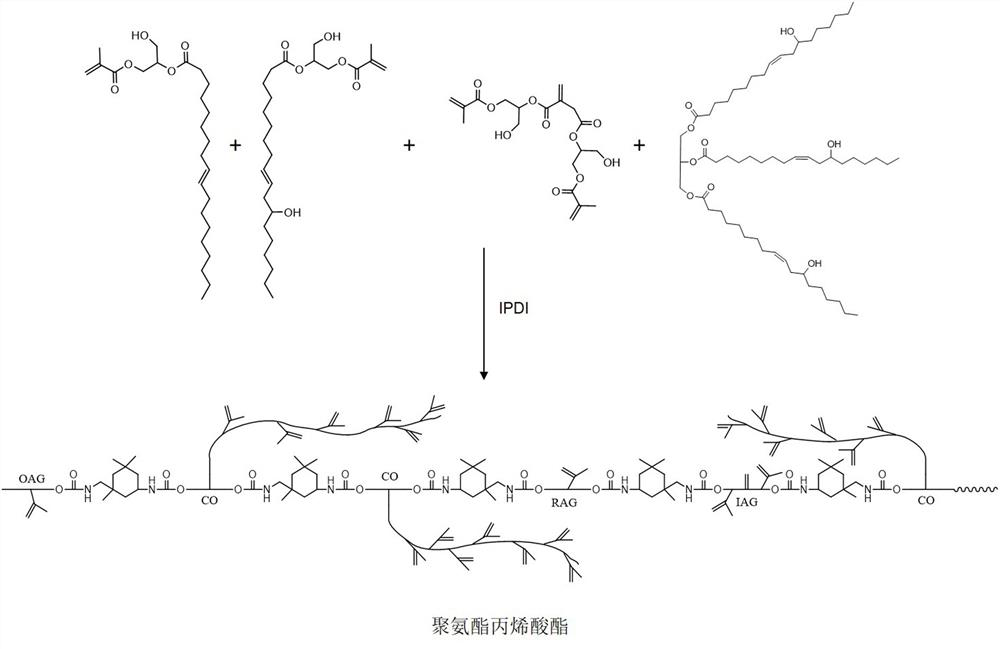

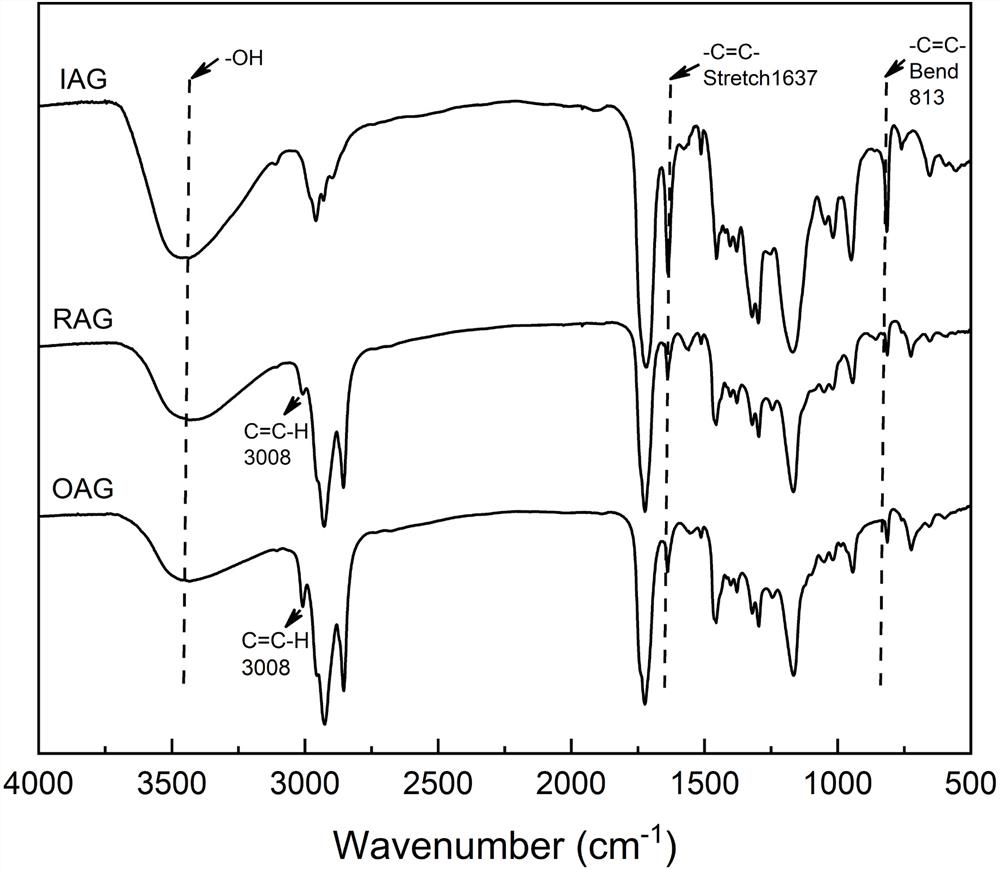

Multifunctional bio-based urethane acrylate as well as preparation method and application thereof

ActiveCN112358597AReduce usageHigh functionalityAdditive manufacturing apparatusPolyureas/polyurethane adhesivesPolymer scienceUV curing

The invention belongs to the field of UV curing materials, and particularly relates to multifunctional bio-based urethane acrylate as well as a preparation method and the application thereof. The preparation method comprises the following steps: respectively preparing oleic acid acrylate, ricinoleic acid acrylate and itaconic acid diacrylate; slowly dropwise adding a mixture of diisocyanate and acatalyst into the prepared mixture of oleic acid acrylate, ricinoleic acid acrylate, itaconic acid diacrylate and castor oil at 15-35 DEG C, heating to 50-80 DEG C, and stirring to react for 5-8 hours, thereby obtaining the multifunctional bio-based urethane acrylate. Firstly, the synthesis steps of urethane acrylate are reduced to one-step reaction from the original two steps; secondly, double bonds are introduced into a main chain of urethane acrylate, so that the functionality of urethane acrylate is improved to a great extent; and thirdly, the bio-based raw materials are introduced into the urethane acrylate, so that the use of petrochemical resources is reduced.

Owner:GUANGDONG LANYANG SCI & TECH +1

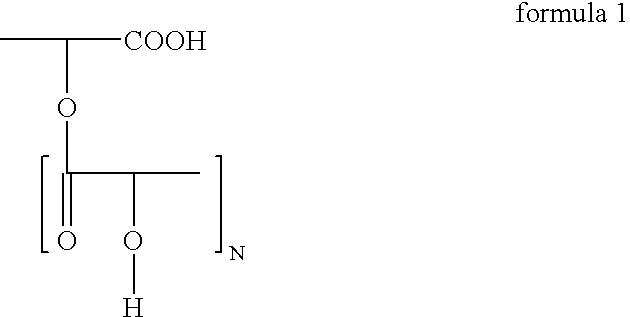

Copolymer and lubricating oil composition

InactiveUS20180201864A1Heat suppressionMaintain adhesionAdditivesBase-materialsChemical compositionHeat resistance

The present invention addresses the problem of providing a lubricating oil composition having excellent heat resistance (suppression of discoloration in heating) and tackiness while maintaining excellent viscosity properties of a lubricating oil composition using a ricinolic acid polymer. The present invention provides a copolymer (B) containing structural units (a) derived from ricinolic acid, structural units (b) derived from an aliphatic dicarboxylic acid and structural units (c) derived from a diol having 2 to 10 carbon atoms in a specific ratio and having a specific intrinsic viscosity, and provides a lubricating oil composition containing a base oil and the copolymer (B) and having a mass ratio (mass of (A) / mass of (B)) of the base oil (A) to the copolymer (B) of 60 / 40 to 99.5 / 0.5.

Owner:MITSUI CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com