Multifunctional bio-based urethane acrylate as well as preparation method and application thereof

A polyurethane acrylate and multi-functionality technology, which is applied in polyurea/polyurethane coatings, polyurea/polyurethane adhesives, applications, etc., can solve the problem that the functionality is difficult to obtain a great degree of improvement, and achieve enhanced acid resistance Alkali resistance and boiling water resistance, the effect of improving pencil hardness and enhancing crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

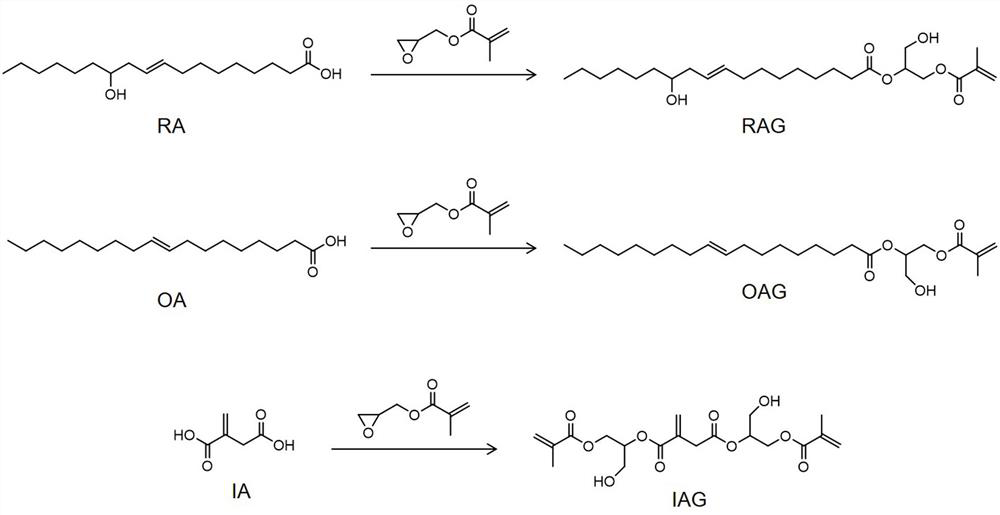

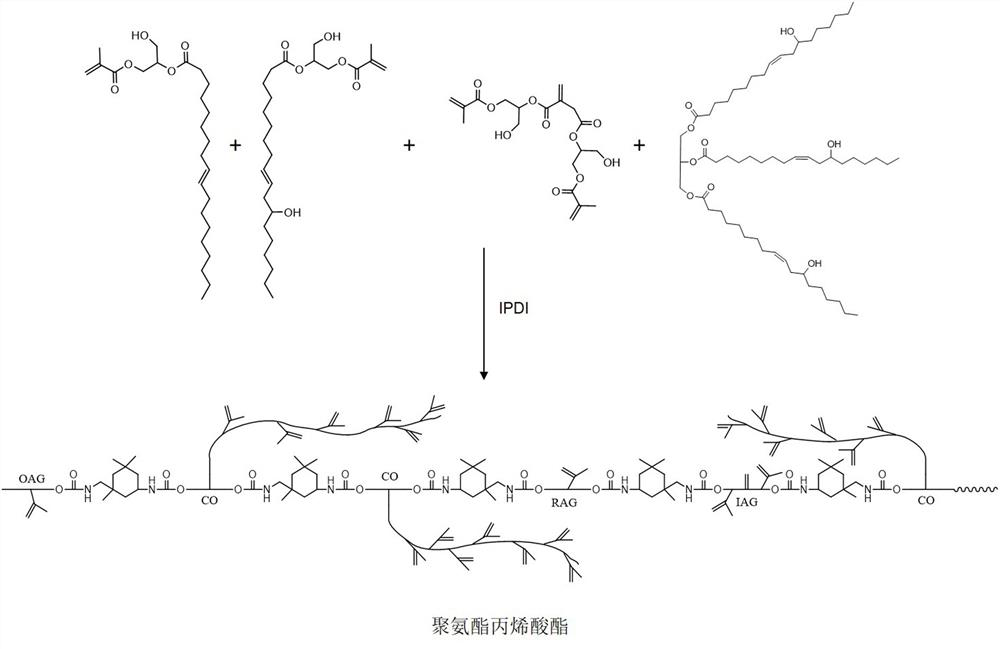

[0038] A preparation method of multifunctional bio-based polyurethane acrylate, comprising the steps of:

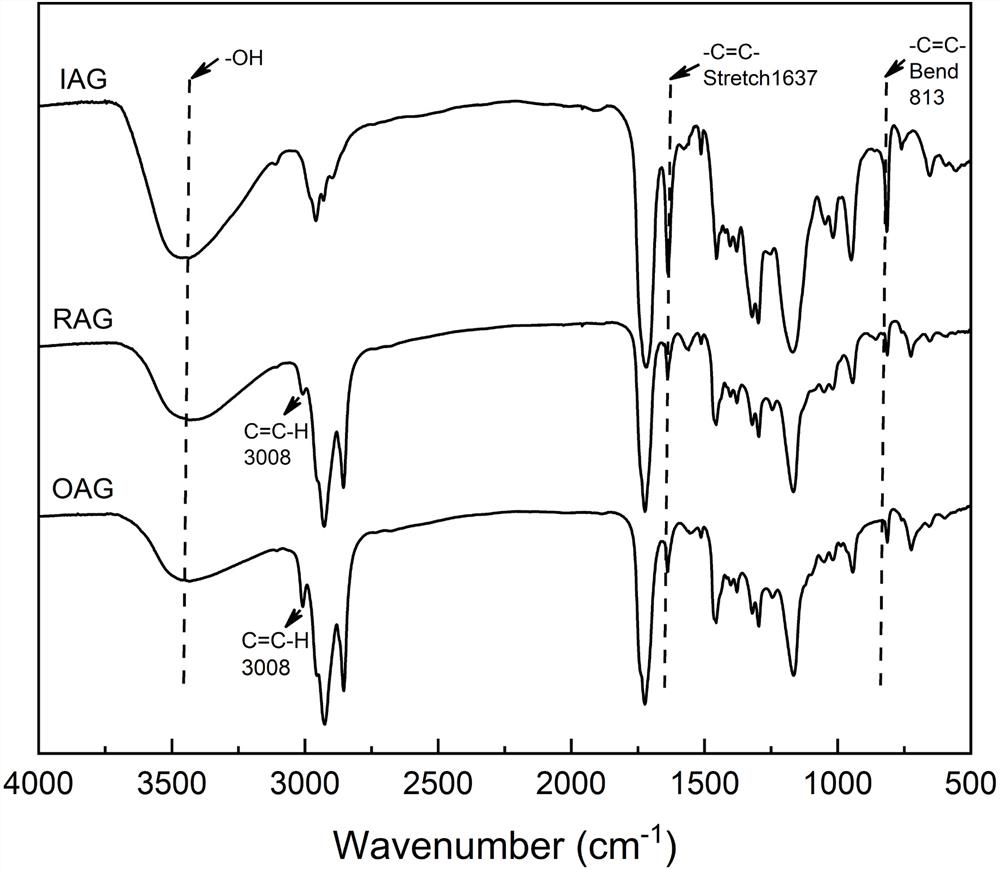

[0039] (1) Add oleic acid into the reaction kettle, stir and heat up to 60°C, add tertiary ammonium salt catalyst N, N-dimethylethanolamine with 1% by weight of oleic acid, then heat up to 80°C and add dropwise The glycidyl methacrylate of the polymerization agent was reacted for 1.5h, and then heated to 90°C for 4h to obtain oleic acid acrylate, whose infrared spectrum was shown in image 3 , NMR file Figure 4 ; The molar ratio between the carboxylic acid group in the oleic acid and the epoxy group in the glycidyl methacrylate is 1:1.

[0040] (2) Add ricinoleic acid into the reaction kettle, stir and heat up to 60°C, add a tertiary ammonium salt catalyst with 1% weight of ricinoleic acid, then heat up to 80°C and dropwise add methacrylic acid containing 0.5% polymerization inhibitor Glycidyl ester, reacted for 1.5h, and then heated up to 90°C for 4h to obtain ricinol...

Embodiment 2

[0044] A preparation method of multifunctional bio-based urethane acrylate, which is the same as Example 1 except for the following steps: the diisocyanate is TDI, and the isocyanate group and the oleic acid acrylate and ricinoleic acid acrylate , Itaconic acid diacrylate or castor oil contains a molar ratio of hydroxyl groups of 4.9:1:2:1:1.

Embodiment 3

[0046] A preparation method of multifunctional bio-based urethane acrylate, which is the same as in Example 1 except for the following steps: the diisocyanate is MDI, and the isocyanate group and the oleic acid acrylate and ricinoleic acid acrylate , Itaconic acid diacrylate or castor oil contains hydroxyl groups in a molar ratio of 4.9:1:1:2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com