Castor oil-based calcium-zinc composite heat stabilizers and preparation method thereof

A composite heat stabilizer and castor oil-based technology, which is applied in the field of preparation of the stabilizer, can solve the problems of complex process, poor stabilization effect, and heavy metals in the heat stabilizer, and achieve good thermal stability and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

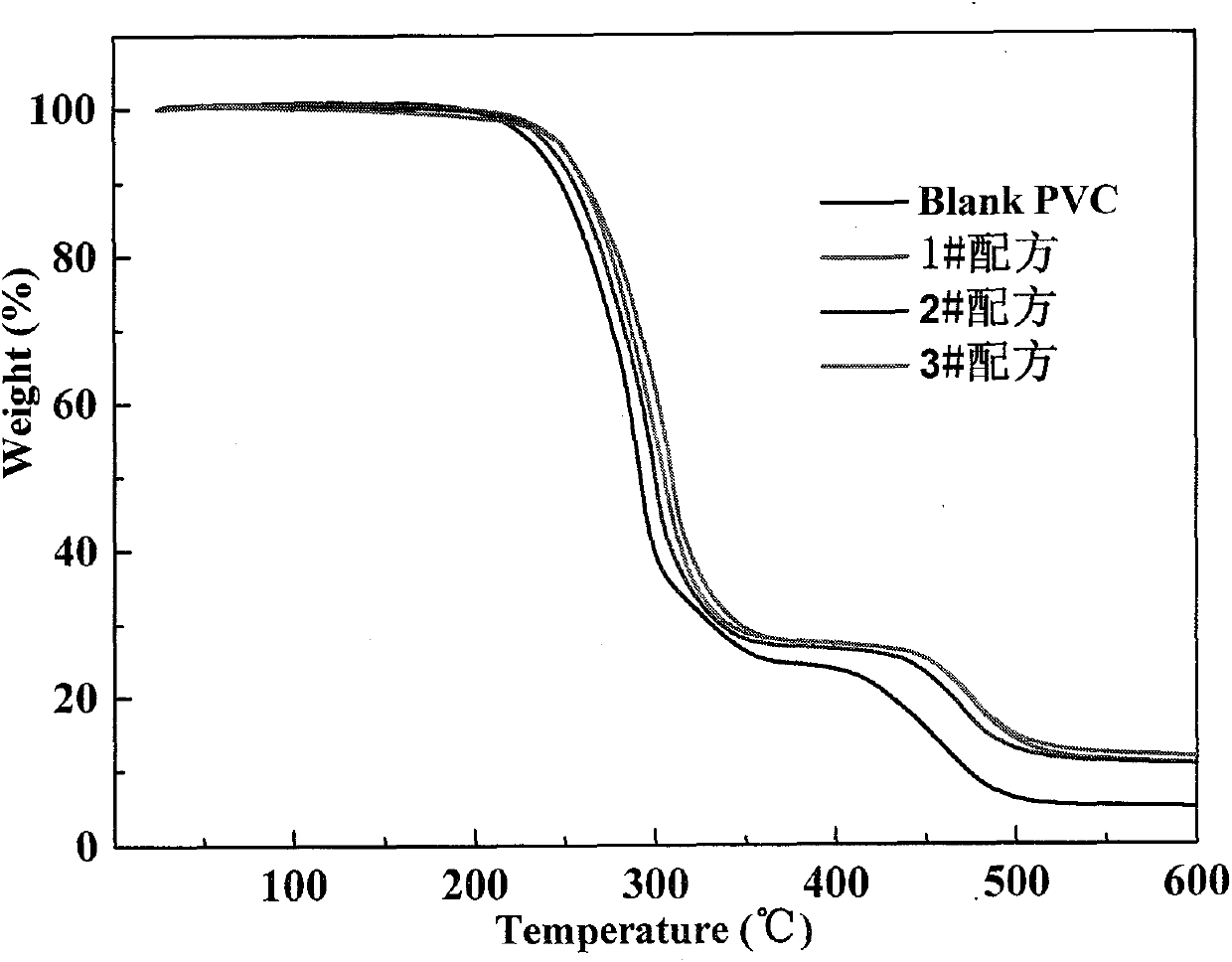

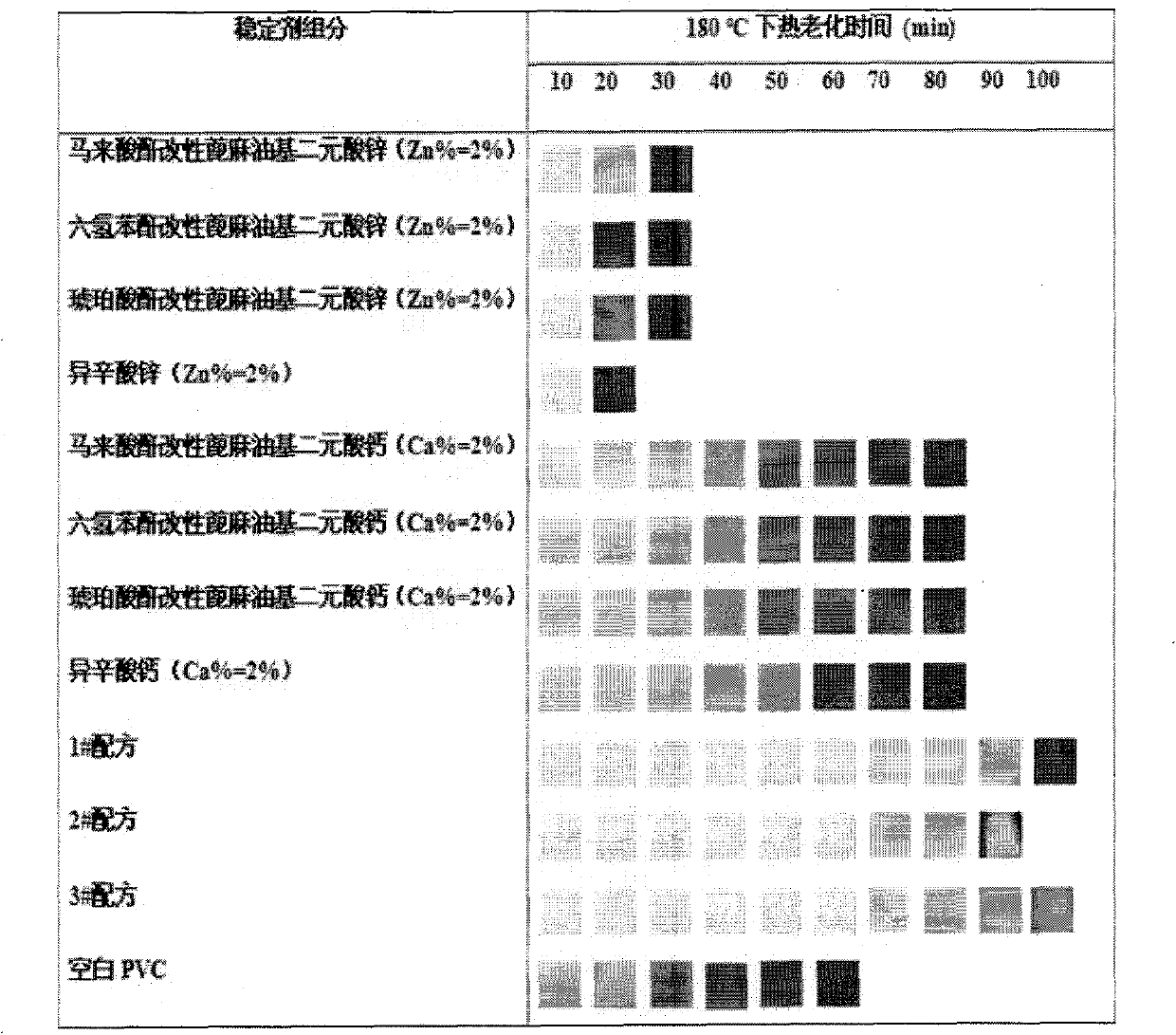

Examples

Embodiment 1

[0033] Preparation of castor oil-based dibasic acid

[0034] (1) Preparation of maleic anhydride modified castor oil-based dibasic acid

[0035] Add 68.62g of ricinoleic acid and 21.58g of maleic anhydride into a 250ml three-necked flask with a condenser and stir evenly. Raise the temperature to 90°C and react for 3.5 hours to obtain maleic anhydride-modified castor oil dibasic acid.

[0036] (2) Preparation of hexahydrophthalic anhydride modified castor oil-based dibasic acid

[0037] Add 68.62g of ricinoleic acid and 33.92g of hexahydrophthalic anhydride into a 250ml three-necked flask with a condenser, stir evenly, and react at 100°C for 3.5h to obtain hexahydrophthalic anhydride-modified castor oil-based dibasic acid.

[0038] (3) Preparation of succinic phthalic anhydride modified castor oil-based dibasic acid

[0039] Add 68.62g of ricinoleic acid and 22.02g of succinic phthalic anhydride into a 250ml three-necked flask with a condenser, stir evenly, and react for 2 h...

Embodiment 2

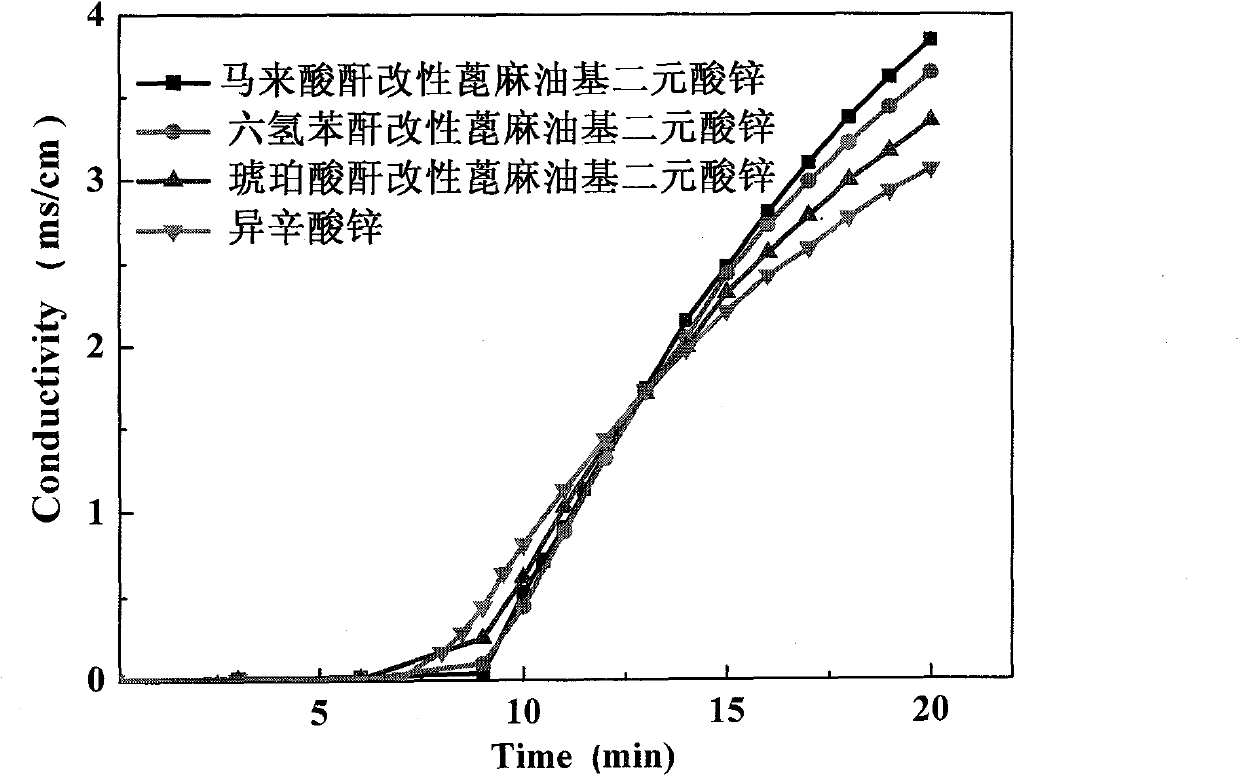

[0041] Preparation of Castor Oil-Based Dibasic Acid Zinc Salt

[0042] (1) Preparation of maleic anhydride modified castor oil-based zinc dibasic acid

[0043] Add 45.12g of maleic anhydride-modified castor oil-based dibasic acid, 12.18g of diethylene glycol monobutyl ether and 1.35g of ethylene glycol phenyl ether into a 250ml three-necked flask with a condenser tube and stir evenly. At 110°C, add 7.98g of ZnO powder in batches and react for 2.5 hours. After the reaction is complete, distill under reduced pressure until the water no longer escapes and stop the distillation. Add an appropriate amount of odorless kerosene, control the temperature at about 70°C, and stir for 15 minutes to obtain Maleic anhydride modified castor oil-based zinc dibasic acid, sealed and preserved.

[0044] (2) Preparation of hexahydrophthalic anhydride modified castor oil-based dibasic acid zinc

[0045]Add 52.04g of hexahydrophthalic anhydride-modified castor oil-based dibasic acid and an approp...

Embodiment 3

[0049] Preparation of Castor Oil-Based Dibasic Acid Calcium Salt

[0050] (1) Preparation of maleic anhydride modified castor oil-based calcium dibasic acid

[0051] Add 45.12g of maleic anhydride-modified castor oil-based dibasic acid, 7.89g of diethylene glycol monobutyl ether and 7.89g of ethylene glycol phenyl ether into a 250ml three-necked flask with a condenser and stir evenly. At 130°C, add 6.67g Ca(OH) in batches 2 Powder, react for 3.5 hours, after the reaction is completed, distill under reduced pressure until the water no longer comes out, stop the distillation, add an appropriate amount of odorless kerosene, control the temperature at about 70°C, and stir for 15 minutes to obtain maleic anhydride modified castor oil-based dibasic acid Calcium, sealed and preserved.

[0052] (2) Preparation and implementation of hexahydrophthalic anhydride modified castor oil-based calcium dibasic acid

[0053] Add 52.04g of hexahydrophthalic anhydride-modified castor oil-based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com