Method for protecting and delaying unsaturated fatty acid from oxidation through lactoprotein microcapsule

A technology of unsaturated fatty acid and microcapsules, which is applied in the field of unsaturated fatty acid processing, can solve the problems of easy oxidation, etc., and achieve the effect of delaying oxidation, improving related performance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0025] A kind of is with MPC485 as raw material, utilizes the method for delaying the oxidation of ricinoleic acid by MPC microcapsule wall material, and its specific process steps are as follows:

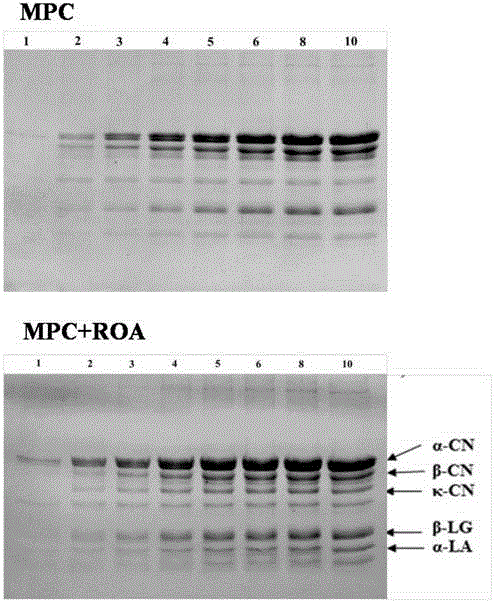

[0026] Example 1: Take 1kg of commercial concentrated milk protein MPC485 and rehydrate it, adjust the pH of the solution to 7.0, and then add 160g of ricinoleic acid and ultrapure water to a total mass of 8kg at 50°C in a constant temperature shaking water bath for 1 hour, stir evenly, and pre-homogenize for 2 minutes After that, it was continuously homogenized for 4 times in an ultra-high pressure homogenizer with a homogenization pressure of 28Mpa, and finally spray-dried at 105°C / 65°C. In addition, MPC was prepared from a solution without ricinoleic acid as a control group. In order to ensure the repeatability of the process, each type of solution was paralleled once. Under the condition of 25°C, the protein dissolution of the sample in the first 10 minutes in ultrapure water ...

Embodiment example 2

[0028] A kind of is with MPC485 as raw material, utilizes the method for delaying oleic acid oxidation of MPC microcapsule wall material, and its specific process steps are as follows:

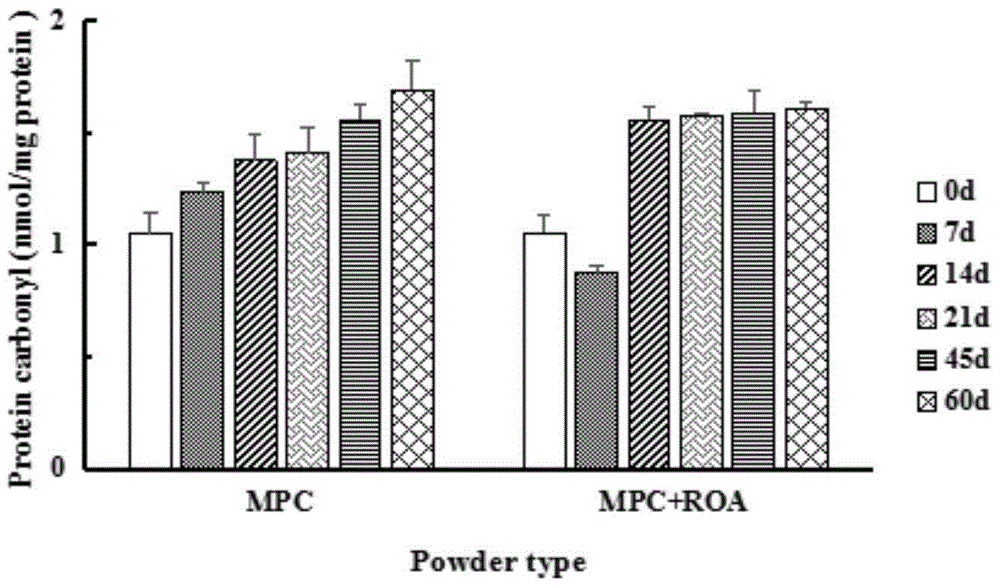

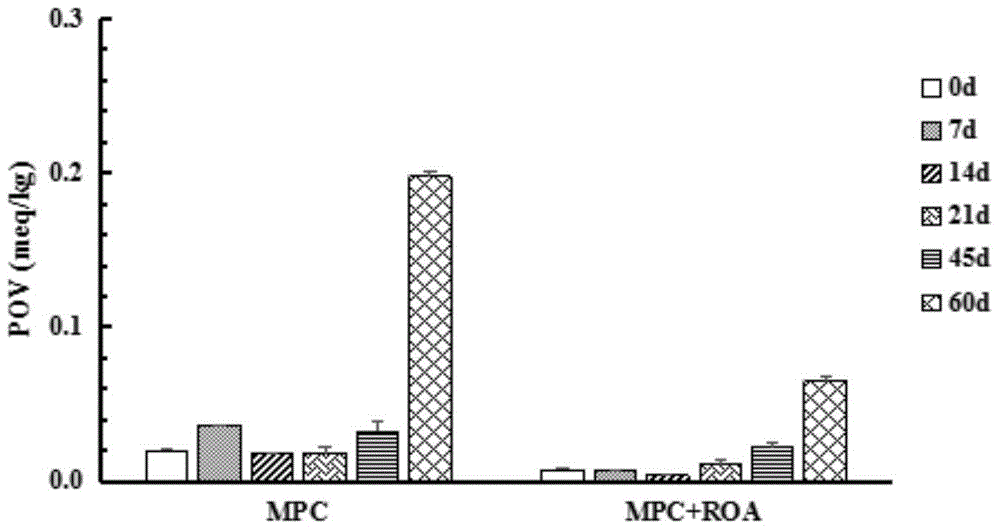

[0029] Example 1: Take 600g of commercial concentrated milk protein MPC485 and rehydrate, adjust the pH of the solution to 7.0, and then add 100g of oleic acid and ultrapure water to a total mass of 4kg at 50°C in a constant temperature shaking water bath for 1 hour, stir evenly, and pre-homogenize for 2 minutes Continuously homogenize for 4 times in an ultra-high pressure homogenizer with a homogenization pressure of 28Mpa, and finally spray dry at 105°C / 65°C. In addition, MPC was prepared from a solution without oleic acid as a control group. In order to ensure the repeatability of the process, each type of solution was paralleled once. The protection of MPC microcapsule wall material to oleic acid was characterized by detecting the changes of POV and carbonyl value of milk powder during st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com