Vibration-absorption long-life universal joint

A universal joint, long-life technology, applied in the direction of vibration suppression adjustment, rotation vibration suppression, engine lubrication, etc., can solve problems such as abnormal vibration, premature ablation of universal joints, and affecting the service life of universal joints. Effects of reducing damage, enhancing lubricating performance, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

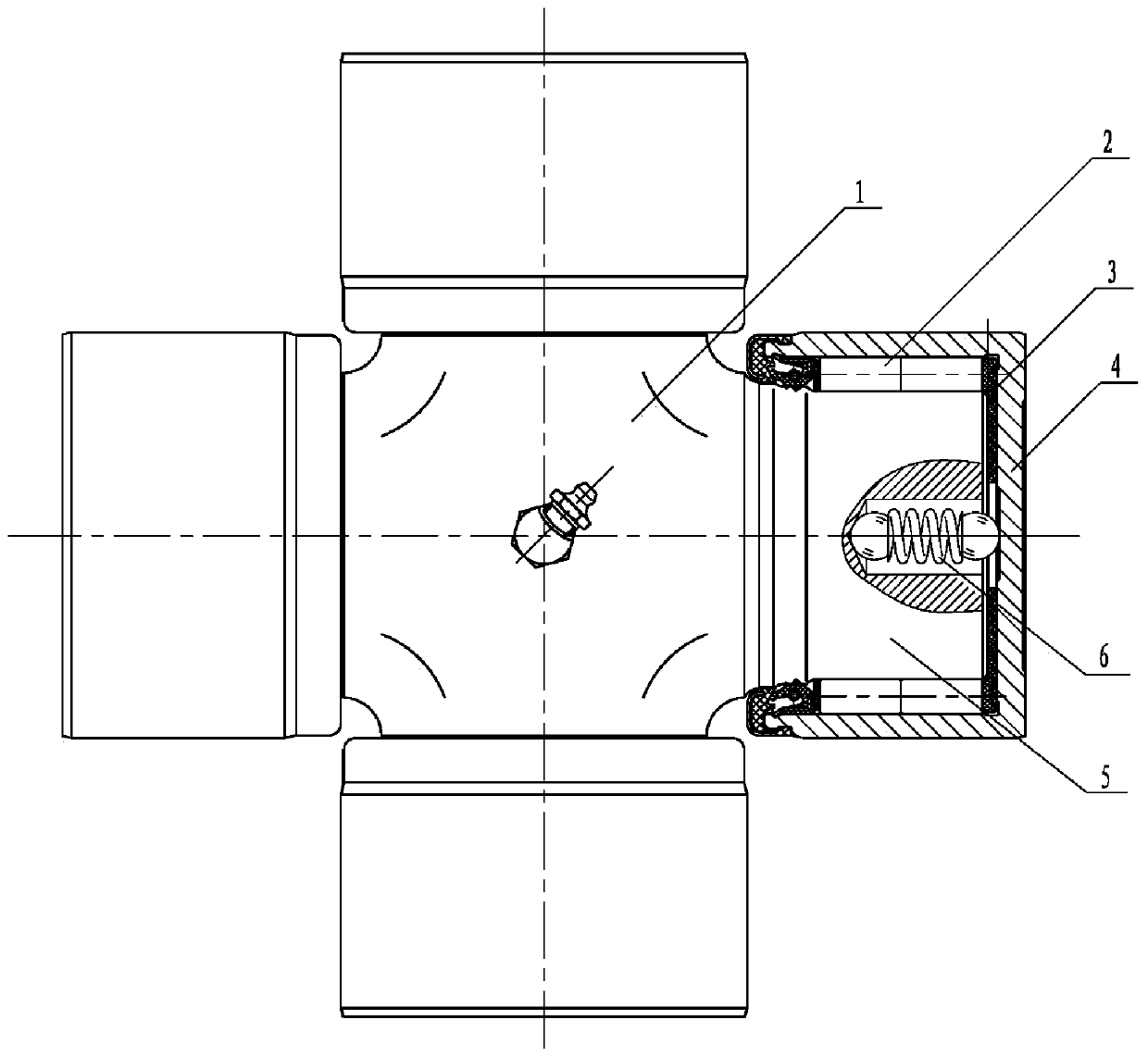

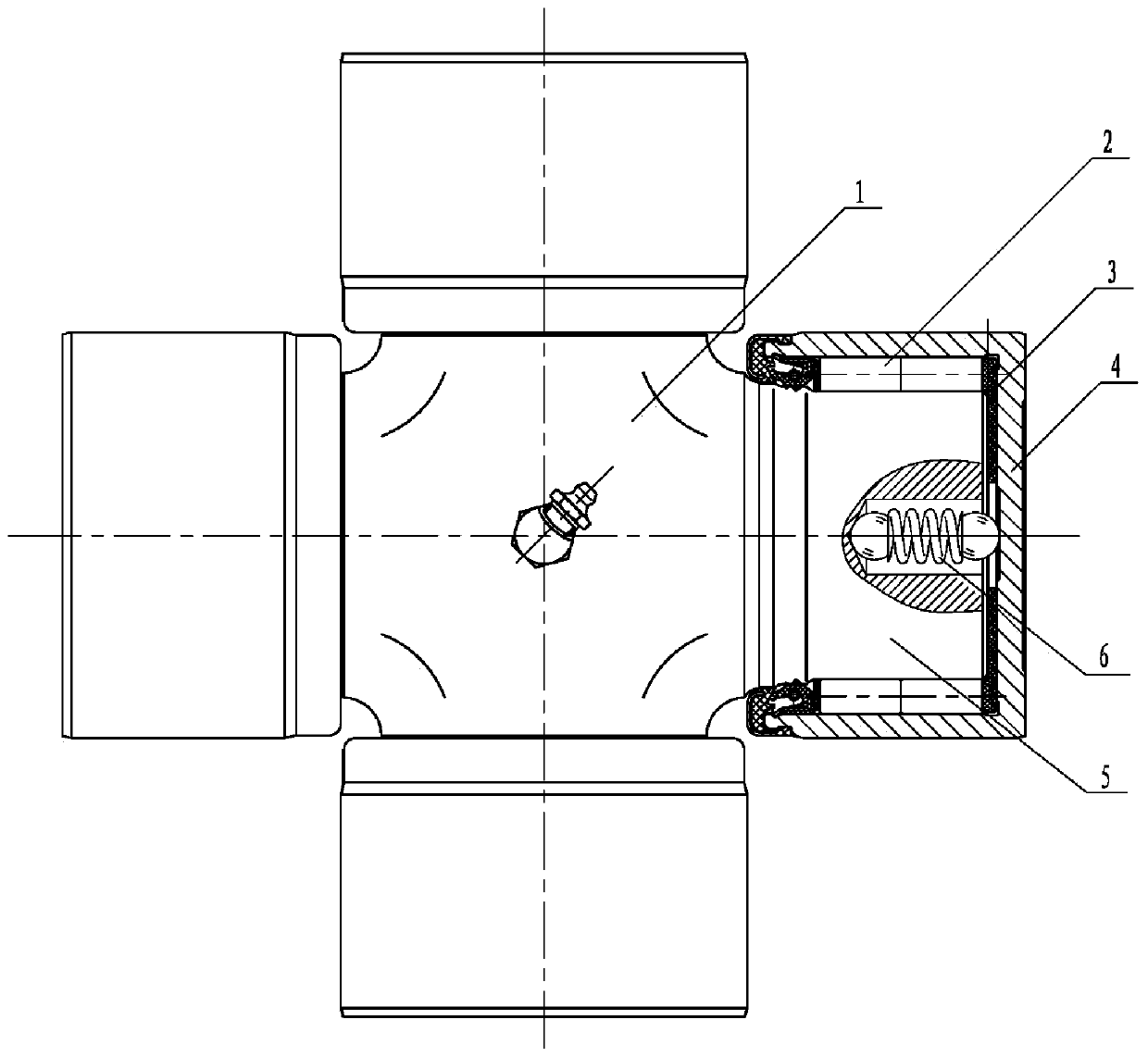

[0013] Embodiment: As shown in the accompanying drawings, this kind of vibration-absorbing long-life universal joint mainly includes a cross shaft 1, four bearings 5 of the cross shaft 1 are covered with a bushing 4, and the shaft sleeve 4 and the journal of the bearing 5 A ring of needle rollers 2 is arranged between them, and a vibration-absorbing gasket 3 is arranged between the needle roller 2 and the bushing 4. A blind hole 7 is opened on the bearing 5, and a vibration-absorbing gasket 3 is installed between the bottom of the blind hole 7 and the The steel ball spring 6 can effectively prevent the extrusion damage of the traditional flat end spring to the gasket and the blind hole of the cross shaft. Both ends of the steel ball spring 6 have small steel balls. The structure can be made of steel, nylon, etc. according to the requirements of the working conditions. , rubber and other materials.

[0014] As a preference, the vibration-absorbing gasket 3 is a porous structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com