Super-high lubricating property cutting oil and preparation method thereof

A technology of lubricating performance and cutting oil, applied in the field of ultra-high lubricating performance cutting oil and its preparation, can solve problems such as no cutting oil, and achieve the effect of improving lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

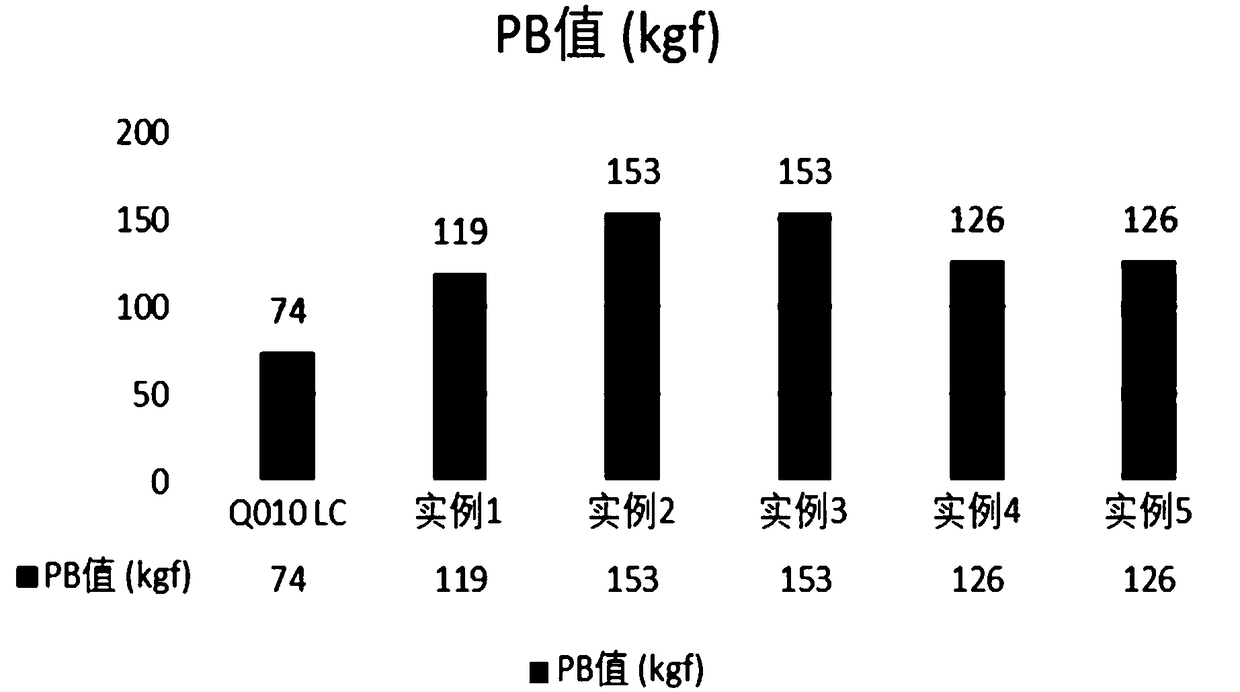

Embodiment 1

[0038] A kind of super high lubricity cutting oil, according to the formula composition of table 1:

[0039] components

[0040] Table 1

Embodiment 2

[0042] A kind of super high lubricity cutting oil, according to the formula composition of table 2:

[0043] components

[0044] Table 2

Embodiment 3

[0046] A kind of super high lubricity cutting oil, according to the formula composition of table 3:

[0047] components

[0048] table 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| Base value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com