Nano graphite composite lubricant for cold extrusion, and preparation method and application thereof

A composite lubricant, graphite lubricant technology, applied in the directions of lubricating compositions, additives, petroleum industry, etc., can solve the problem that the lubricant cannot meet the production requirements, achieve excellent diffusion and protective colloid, improve surface quality, and be difficult to decompose. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

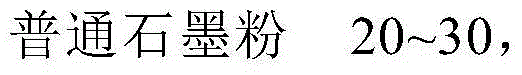

[0026] Added the nano-graphite of 0.6%% (by weight) in common cold extrusion graphite lubricant, wherein the purity of nano-graphite particle is more than 99%, particle diameter is 40nm, and adopts following preparation scheme:

[0027] (1) Take nano-graphite particles and add them to common graphite lubricants.

[0028] (2) Add chemical dispersant in the lubricant, its composition is 2.6% (by weight) sodium dioctyl sulfosuccinate and 1.5% (by weight) sodium methylenebisturide sulfonate.

[0029] (3) The lubricant was subjected to electromagnetic stirring for 25 minutes, then ultrasonically dispersed for 20 minutes, and continuously ultrasonicated 3 times to obtain a nano-graphite composite lubricant for cold extrusion.

[0030] This manufacturing technology and process is easy to implement for those skilled in the art, and those skilled in the art can implement the present invention according to the above description.

[0031] Coat the lubricant prepared in the above ratio o...

Embodiment 2

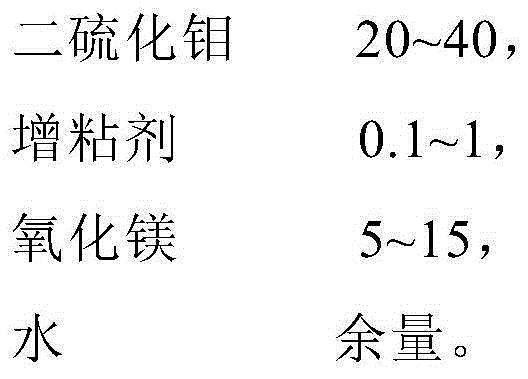

[0033] Nano-graphite composite lubricant with the following formula

[0034] Nanographite: 0.6%, graphite powder: 20%, molybdenum disulfide: 26%, tackifier: 0.4%, dispersant: 3%, magnesium oxide: 10%, water: balance.

[0035] Then prepare it in the following way:

[0036] (1) Take nano-graphite particles and add them to common graphite lubricants.

[0037] (2) Add chemical dispersant in lubricant, its composition is 1.6% (by weight) sodium dioctyl sulfosuccinate and 1.4% (by weight) sodium methylenebisturide sulfonate.

[0038] (3) The lubricant was subjected to electromagnetic stirring for 25 minutes, then ultrasonically dispersed for 20 minutes, and continuously ultrasonicated 3 times to obtain a nano-graphite composite lubricant for cold extrusion.

[0039] The lubricant prepared in the above ratio was coated on 5 actual extrusions of the flange jacket for testing, and the average forming load value obtained during the cold extrusion forming process was 145.0T (tested und...

Embodiment 3

[0041] Nano-graphite composite lubricant with the following formula

[0042] Nano graphite: 1%, ordinary graphite: 25%, molybdenum disulfide: 35%, tackifier: 0.5%, dispersant: 4.5%, magnesium oxide: 10%, water: the balance.

[0043] Then prepare it in the following way:

[0044] (1) Take nano-graphite particles and add them to common graphite lubricants.

[0045] (2) Add chemical dispersant in the lubricant, its composition is 2.6% (by weight) sodium dioctyl sulfosuccinate and 1.7% (by weight) sodium methylenebisturide sulfonate.

[0046] (3) The lubricant was subjected to electromagnetic stirring for 25 minutes, then ultrasonically dispersed for 20 minutes, and continuously ultrasonicated 3 times to obtain a nano-graphite composite lubricant for cold extrusion.

[0047] Coat the lubricant formulated in the above ratio on a ring whose material is 20 steel and whose outer diameter, inner diameter, and height ratio are 4:2:1, and use a 630T hydraulic press to upset the ring samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com