Method for preparing modified graphene oxide anti-wear agent

A technology of oxide stone and anti-wear agent, used in additives, petroleum industry, lubricating compositions, etc., can solve the problems of high addition amount, poor mixing uniformity, low utilization rate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

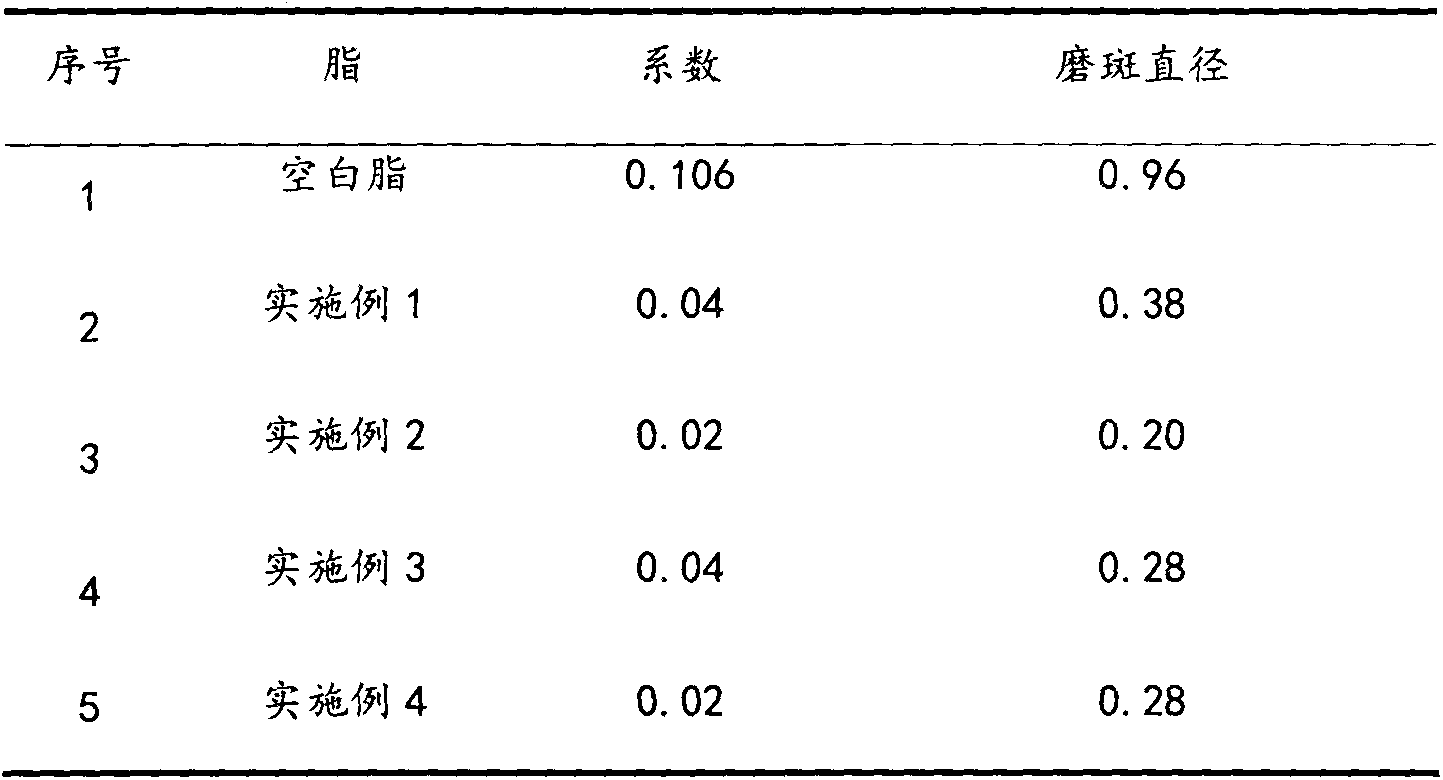

Embodiment 1

[0019] Add 1.2g of graphene oxide and 3.6g of boric acid into a 250mL three-necked flask, then add 30ml of petroleum ether, stir and add 0.024g of concentrated sulfuric acid, heat up to 60°C for reflux for 8h, and then distill off the solvent. The product was dried in a vacuum oven at 80°C to obtain an off-white solid, which was boric acid-modified graphene oxide. Adding it to ordinary lubricating grease at a ratio of 0.05%, the wear spot diameter is reduced from 0.96 of the blank grease to 0.38, the wear rate is reduced by 60%, the friction coefficient is reduced from 0.106 of the blank grease to 0.04, and the friction coefficient is reduced by 60%.

[0020] Graphene oxide is prepared by the Hummers method, which belongs to the prior art, so the specific preparation method is omitted.

Embodiment 2

[0022] Add 1g of graphene oxide and 0.5g of calcium borate into a 250mL three-neck flask, then add 70ml of n-hexane, stir and heat to 60°C, add 0.005g of concentrated sulfuric acid dropwise, continue to heat up to 150°C, condense and reflux for 2h, and then distill off the solvent. The product was dried in a vacuum oven at 20°C to obtain an off-white solid, which was calcium borate-modified graphene oxide. Adding 0.5% to ordinary grease, the wear spot diameter is reduced from 0.96 of blank grease to 0.20, the wear rate is reduced by 80%, the friction coefficient is reduced from 0.106 of blank grease to 0.02, and the friction coefficient is reduced by 80%.

Embodiment 3

[0024] Add 1g of graphene oxide and 1.5g of lanthanum borate into a 250mL three-neck flask, then add 50ml of ethanol, stir and heat to 80°C, add 0.020g of concentrated sulfuric acid, continue to heat up to 130°C, condense and reflux for 5h, and then distill off the solvent. The product was dried in a vacuum oven at 60°C to obtain an off-white solid which was lanthanum borate graphene oxide. Adding it to ordinary lubricating grease at a ratio of 0.1%, the wear scar diameter is reduced from 0.96 of the blank grease to 0.28, the wear rate is reduced by about 70%, the friction coefficient is reduced from 0.106 of the blank grease to 0.04, and the friction coefficient is reduced by about 60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com