Preparation method for high-intensity nickel-based high-temperature self-lubricating composite material

A high-temperature self-lubricating and composite material technology is applied in the field of preparation of high-strength nickel-based high-temperature self-lubricating composite materials to achieve the effects of good heat resistance and high oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] According to the mass percentage: Ag10%, BaF 2 with CaF 2 Eutectic 10%, Cr 2 o 3 10%, nickel-based alloy 70%, each powder material was weighed separately, wherein the nickel-based alloy composition is: 70Ni-15Cr-8Mo-5W-2Ti. Mix in a high-energy ball mill at a speed of 200 rpm for 6 hours to obtain a composite powder, put the composite powder into a graphite mold, and then place it in a vacuum hot-press sintering furnace for hot-press sintering. The sintering parameters are: vacuum 0.8×10 -1 Pa, heating rate 20°C / min, sintering temperature 1100°C, applied pressure 20MPa, holding time 30min. After sintering, the material is cooled to room temperature with the furnace and taken out.

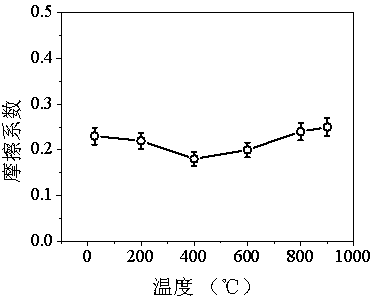

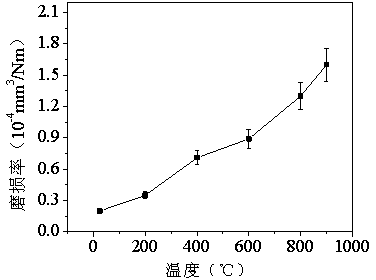

[0021] The room temperature compressive strength of the material is 1515MPa, the bending strength is 1128MPa, and the hardness is 3.48GPa. The average friction coefficient and wear rate from room temperature to 900°C are shown in Table 1 below.

[0022] Table 1: Material friction coeffic...

Embodiment 2

[0025] According to the mass percentage: Ag12%, BaF 2 with CaF 2 Eutectic 10%, Cr 2 o 3 5%, nickel-based alloy 73%, each powder material was weighed separately, wherein the nickel-based alloy composition is: 70Ni-15Cr-8Mo-5W-2Ti. Mix in a high-energy ball mill at a speed of 300 rpm for 6 hours to obtain a composite powder, put the composite powder into a graphite mold, and then place it in a vacuum hot-press sintering furnace for hot-press sintering. The sintering parameters are: vacuum 0.6×10 -1 Pa, heating rate 20°C / min, sintering temperature 1100°C, applied pressure 15MPa, holding time 30min. After sintering, the material is cooled to room temperature with the furnace and taken out.

[0026] The room temperature compressive strength of the material is 1483MPa, the bending strength is 1140MPa, and the hardness is 3.36GPa. The average friction coefficient and wear rate from room temperature to 900°C are shown in Table 2 below.

[0027] Table 2: Material friction coeffici...

Embodiment 3

[0030] According to the mass percentage: Ag12%, BaF 2 with CaF 2 Eutectic 8%, Cr 2 o 3 20%, nickel-based alloy 60%, each powder material was weighed separately, wherein the nickel-based alloy composition is: 71Ni-12Cr-10Mo-4W-3Ti. Mix in a high-energy ball mill at a speed of 300 rpm for 6 hours to obtain a composite powder, put the composite powder into a graphite mold, and then place it in a vacuum hot-press sintering furnace for hot-press sintering. The sintering parameters are: vacuum 0.6×10 -1 Pa, heating rate 20°C / min, sintering temperature 1200°C, applied pressure 15MPa, holding time 30min. After sintering, the material is cooled to room temperature with the furnace and taken out.

[0031]The room temperature compressive strength of the material is 1380MPa, the bending strength is 1062MPa, and the hardness is 3.75GPa. The average friction coefficient and wear rate from room temperature to 900°C are shown in Table 3 below.

[0032] Table 3: Material friction coeffici...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com