Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

112 results about "Nylon 11" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nylon 11 or Polyamide 11 (PA 11) is a polyamide, bioplastic and a member of the nylon family of polymers produced by the polymerization of 11-aminoundecanoic acid. It is produced from castor beans by Arkema under the trade name Rilsan.

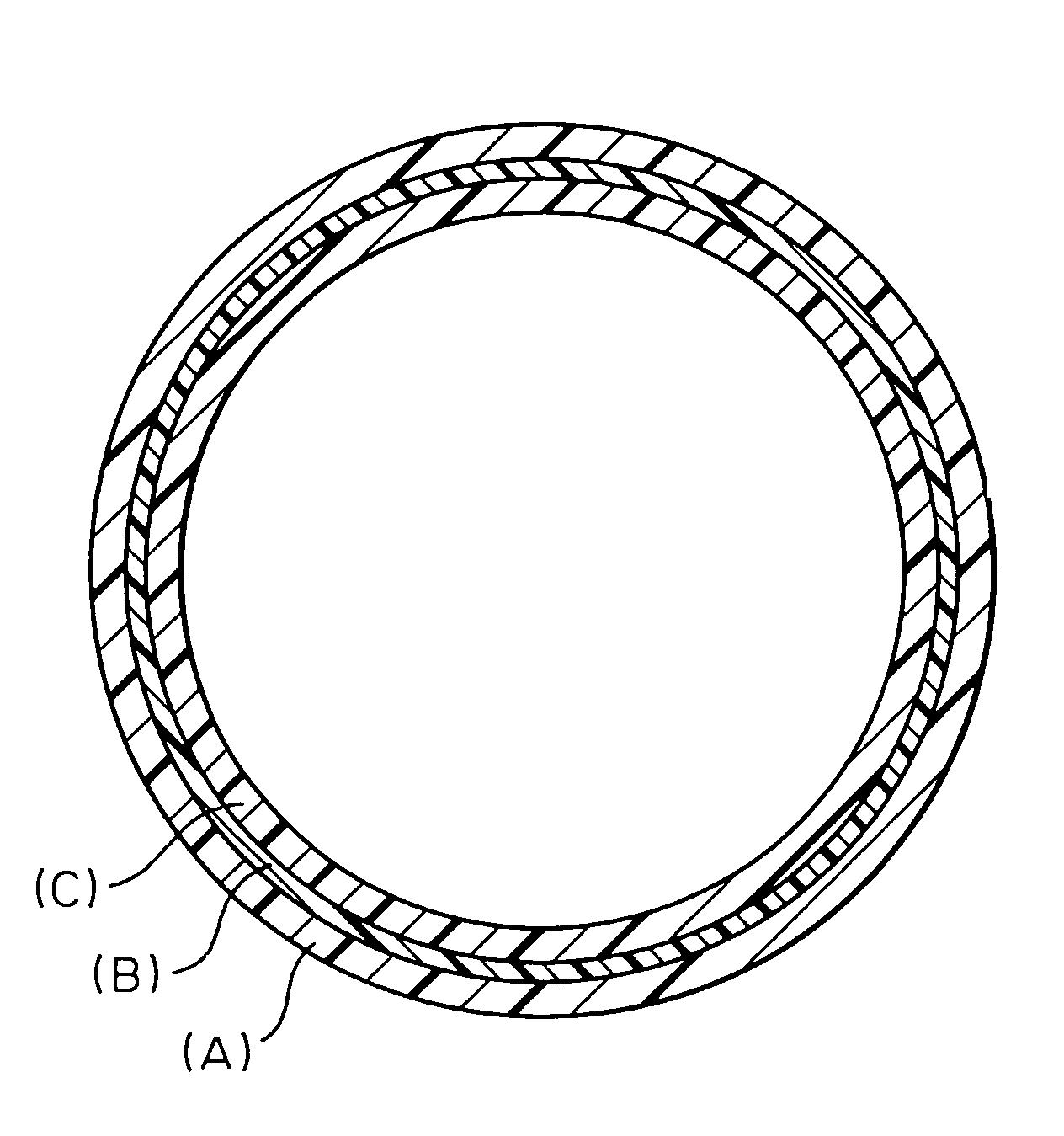

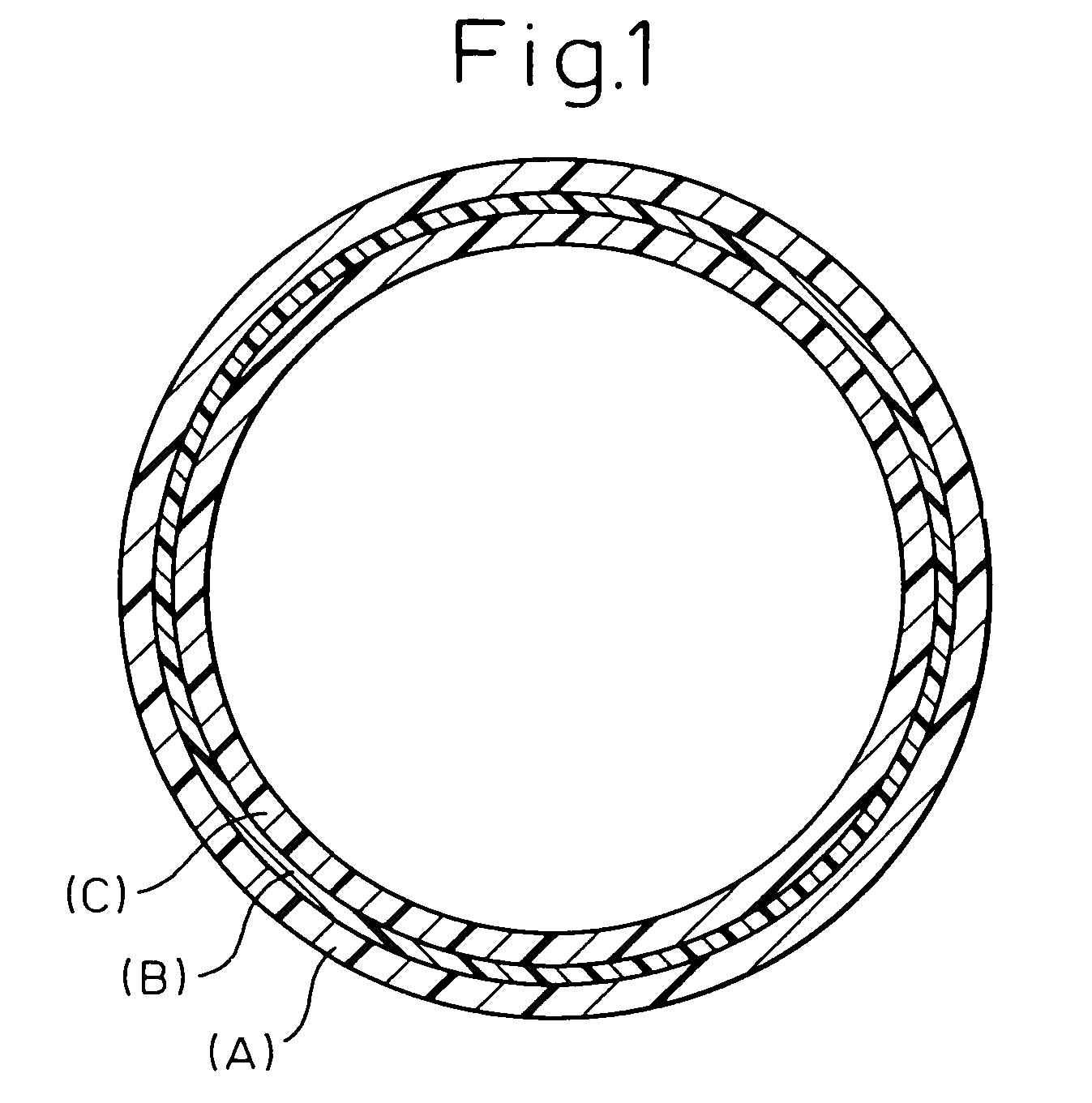

Multi-layer structure

ActiveUS6989198B2Improve penetration resistanceLarge containersRefuse receptaclesCarboxylic acidNylon 11

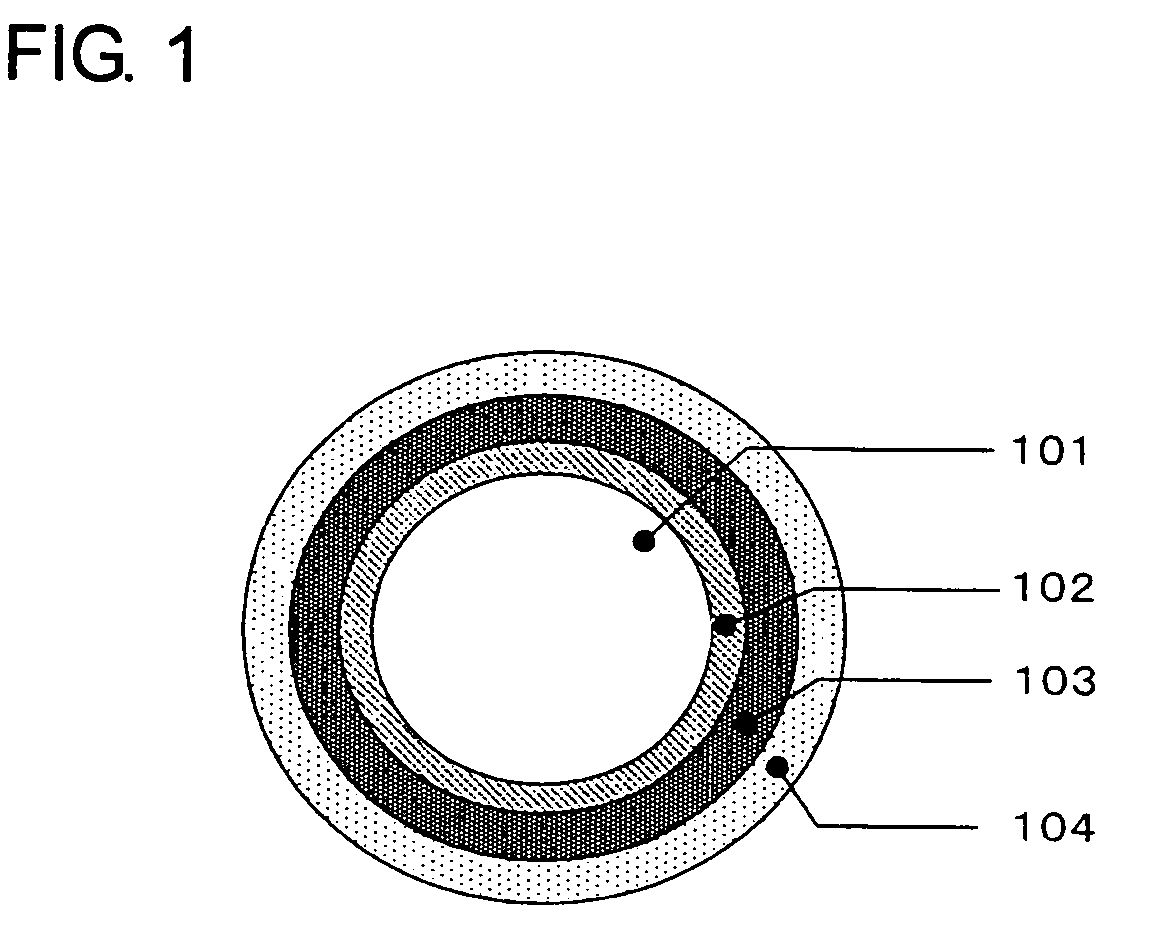

A multi-layer structure excellent in the barrier properties against alcohol gasoline, particularly hydrocarbon components, and also excellent in the interlayer adhesion, low-temperature impact resistance, heat resistance and chemical resistance is provided. The stractive is a multi-layer structure comprising two or more layers including at least a layer (a) comprising (A) nylon 11 and / or nylon 12 and a layer (b) comprising (B) a polyamide resin (nylon 9T) consisting of a dicarboxylic acid component and a-diamine component, with 60 to 100 mol % of the dicarboxylic acid component being a terephthalic acid and 60 to 100 mol % of the diamine component being a diamine component selected from 1,9-nonanediamine and 2-methyl-1,8-octanediamine, and preferably further including a layer (c) comprising (A) nylon 11 and / or nylon 12 or (C) nylon 6.

Owner:KURARAY CO LTD +1

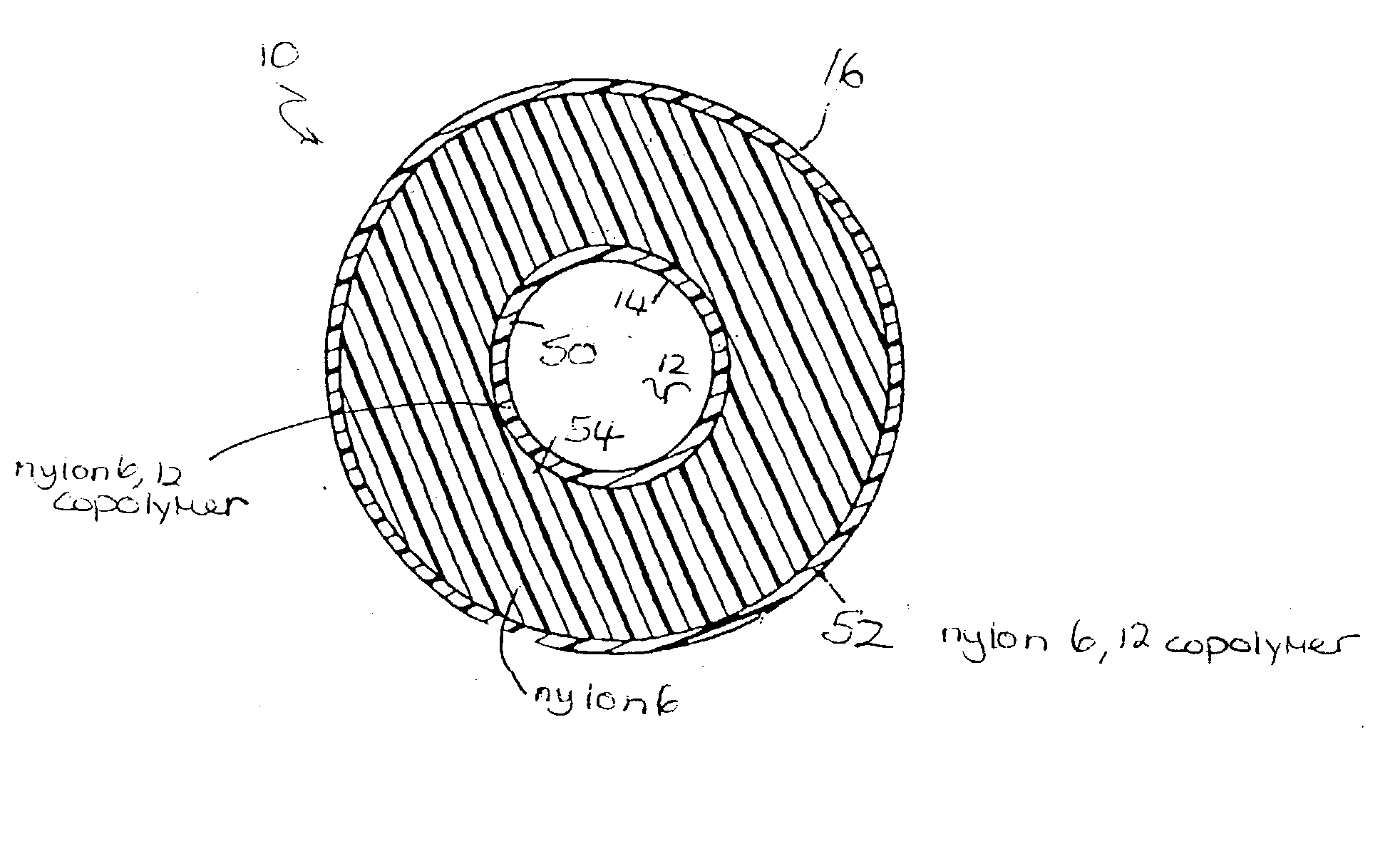

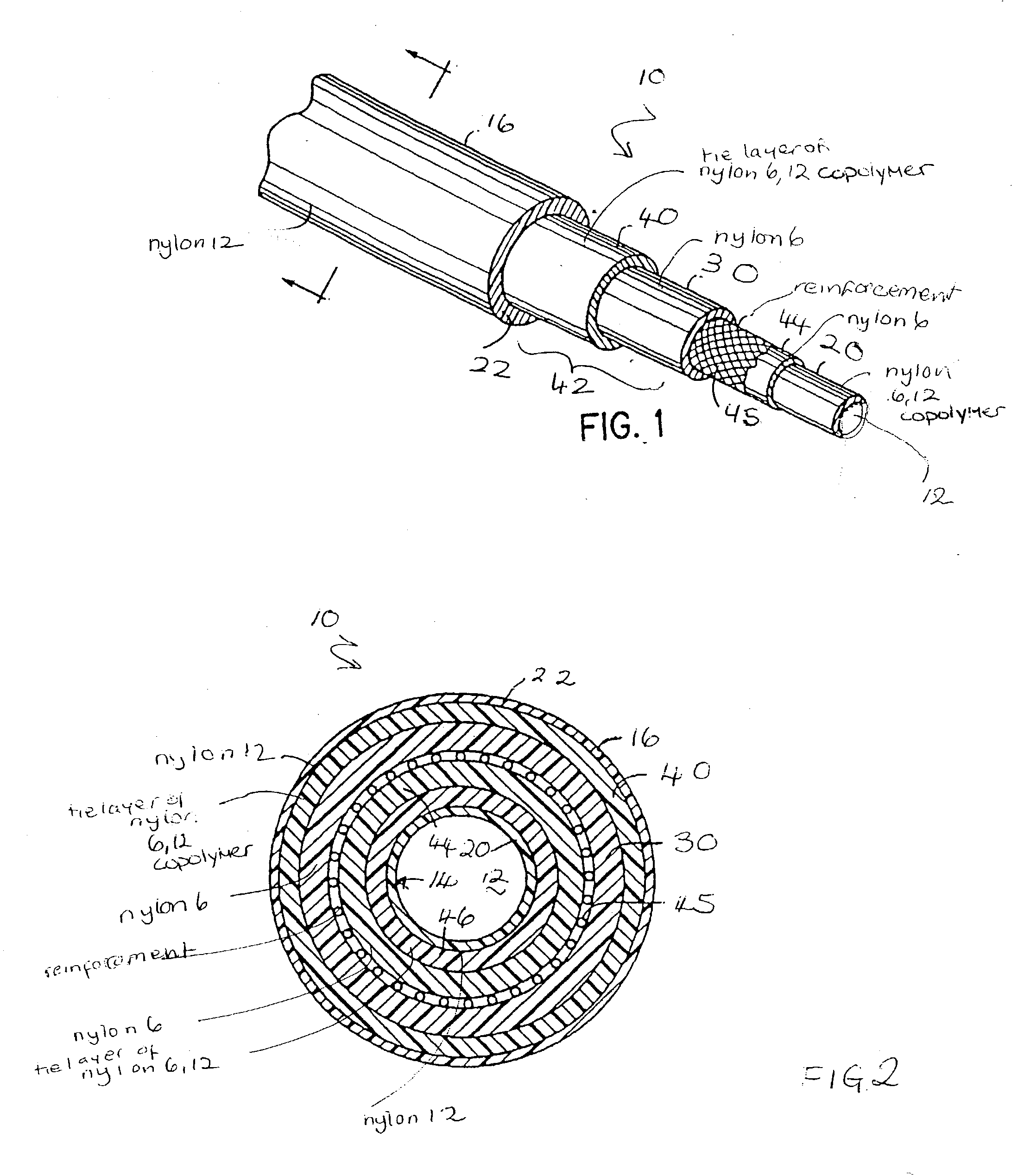

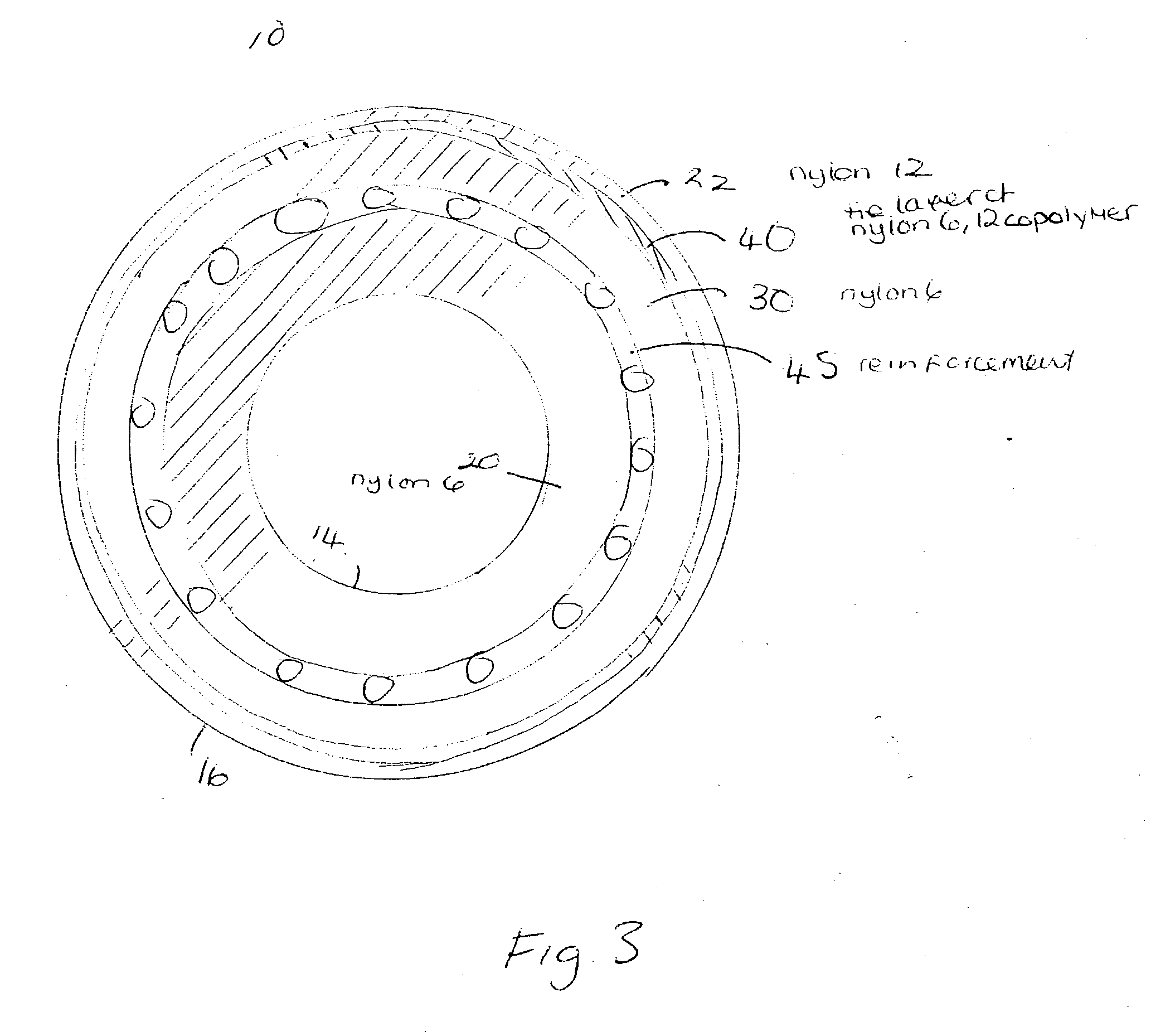

Hose comprising modified nylon 6,12 material

InactiveUS20040096615A1Improve mechanical propertiesSynthetic resin layered productsFlexible pipesPolyamideNylon 11

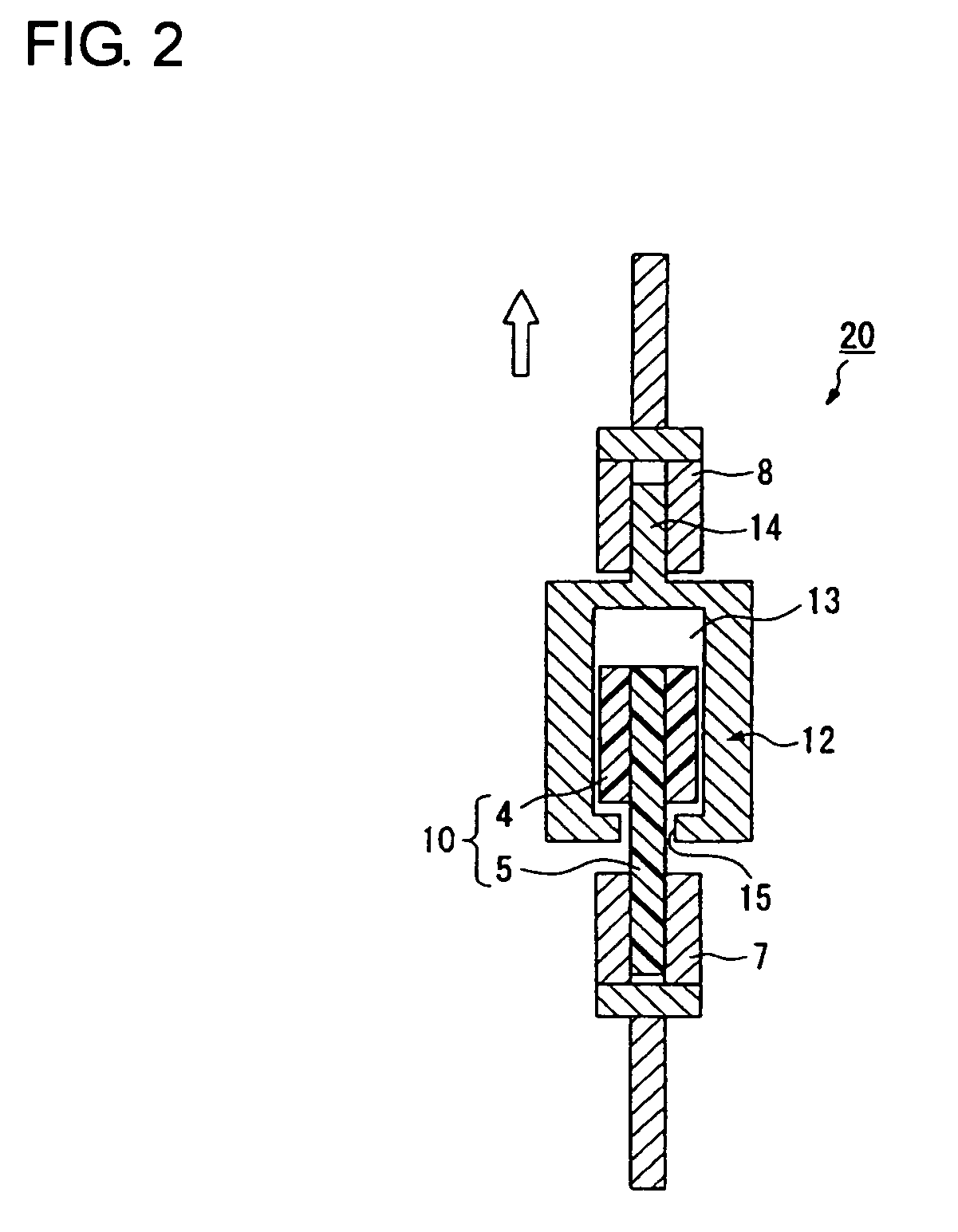

A copolymer of nylon 6 (caprolactam mer units) and nylon 12 (dodecanolactam mer units) and / or nylon 11 (undecanolactam mer units), which has been modified to provide improved physical properties, such as flex modulus, elastic modulus, and yield strength, serves as a layer of a hose suited to use in airbrake applications. The modified copolymer is resistant to degradation by zinc chloride and moisture and thus may be used as a peripheral layer of the hose in place of a conventional protective layer comprising a pure polyamide, such as nylon 11 or 12. Alternatively, the modified copolymer may be used as a tie layer for rendering a peripheral layer comprising nylon 12 or 11 compatible with a layer of nylon 6, allowing the less expensive nylon 6 material to comprise the bulk of the hose thickness. The layer includes a compatibilizer, such as a maleic anhydride grafted polyethylene, and may also include plasticizers and impact modifiers.

Owner:EATON CORP

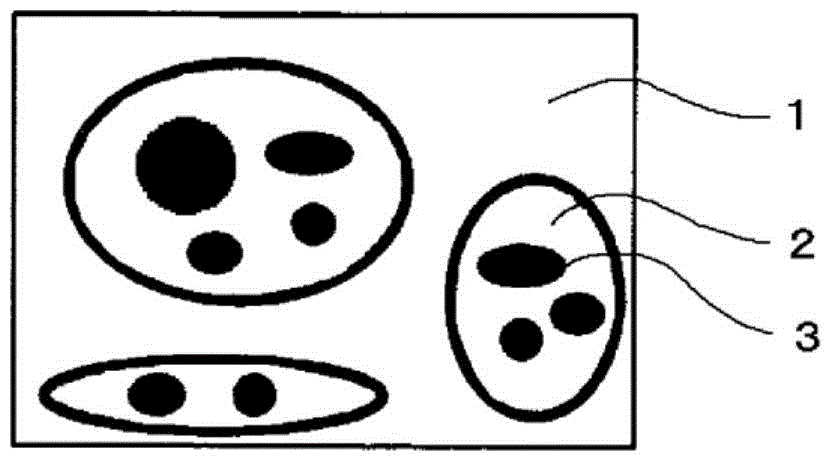

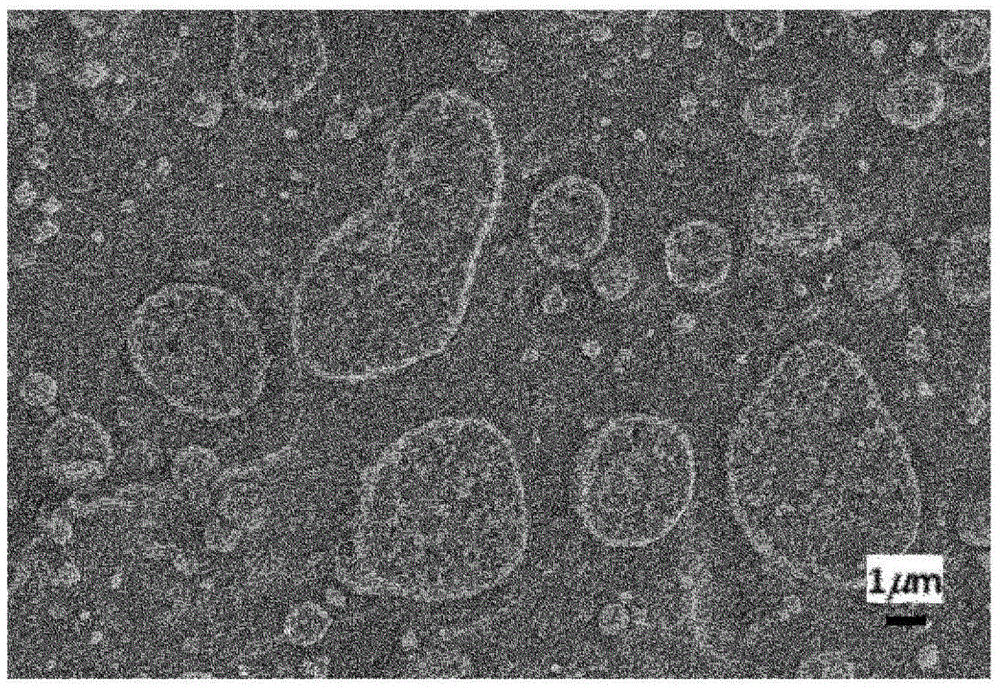

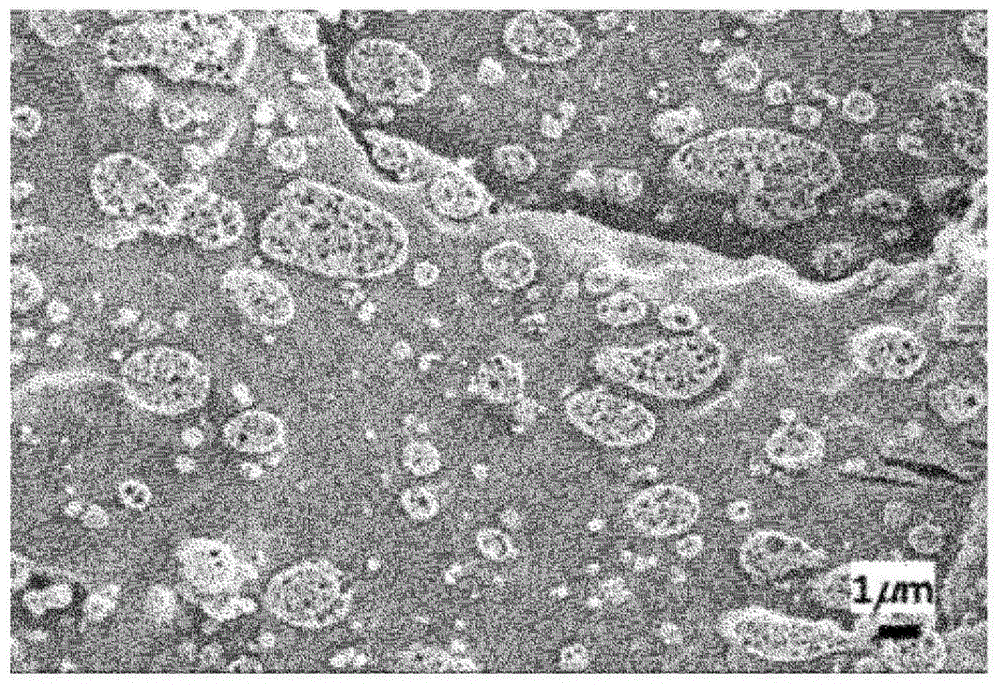

Thermoplastic resin composition and method for producing same

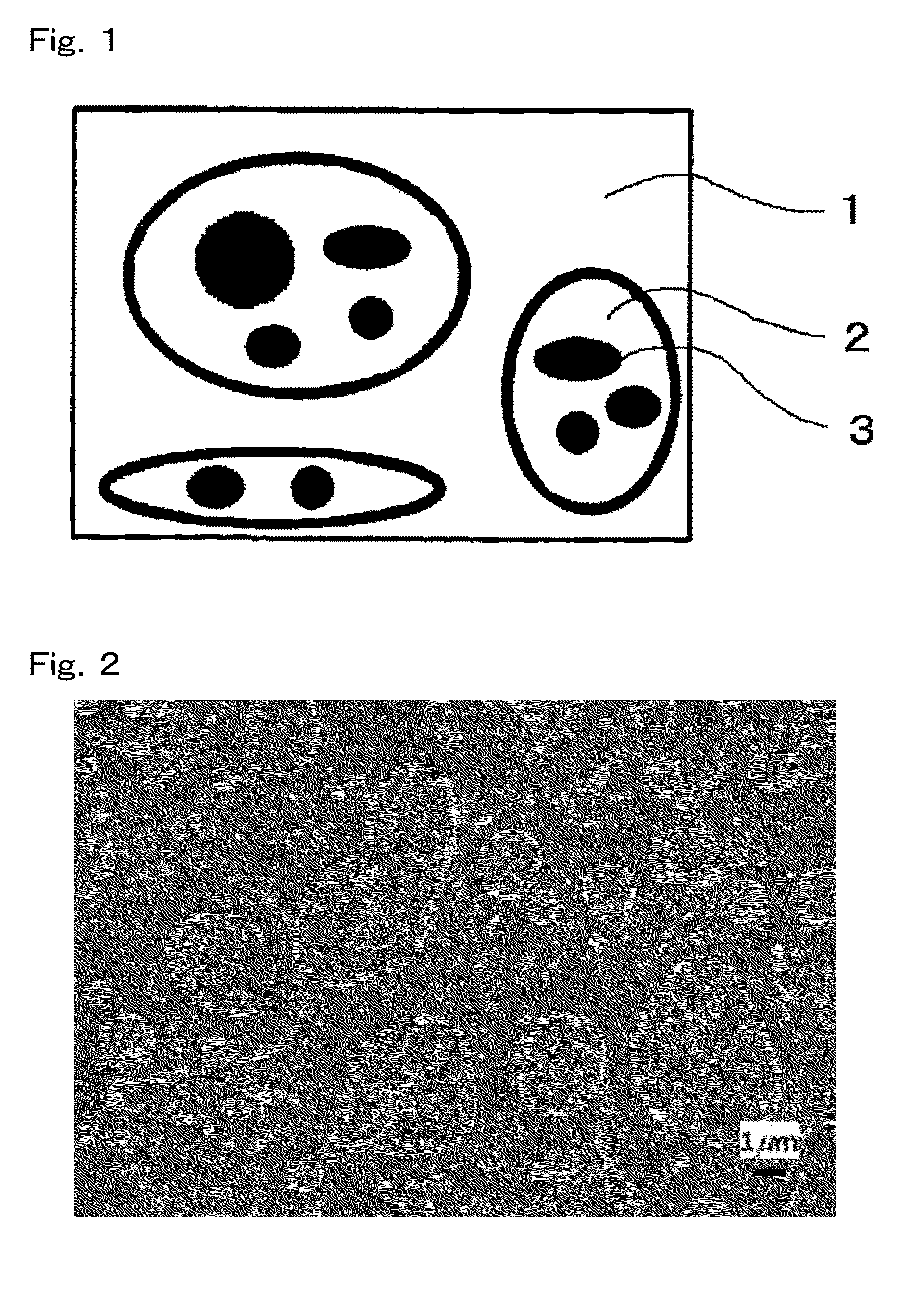

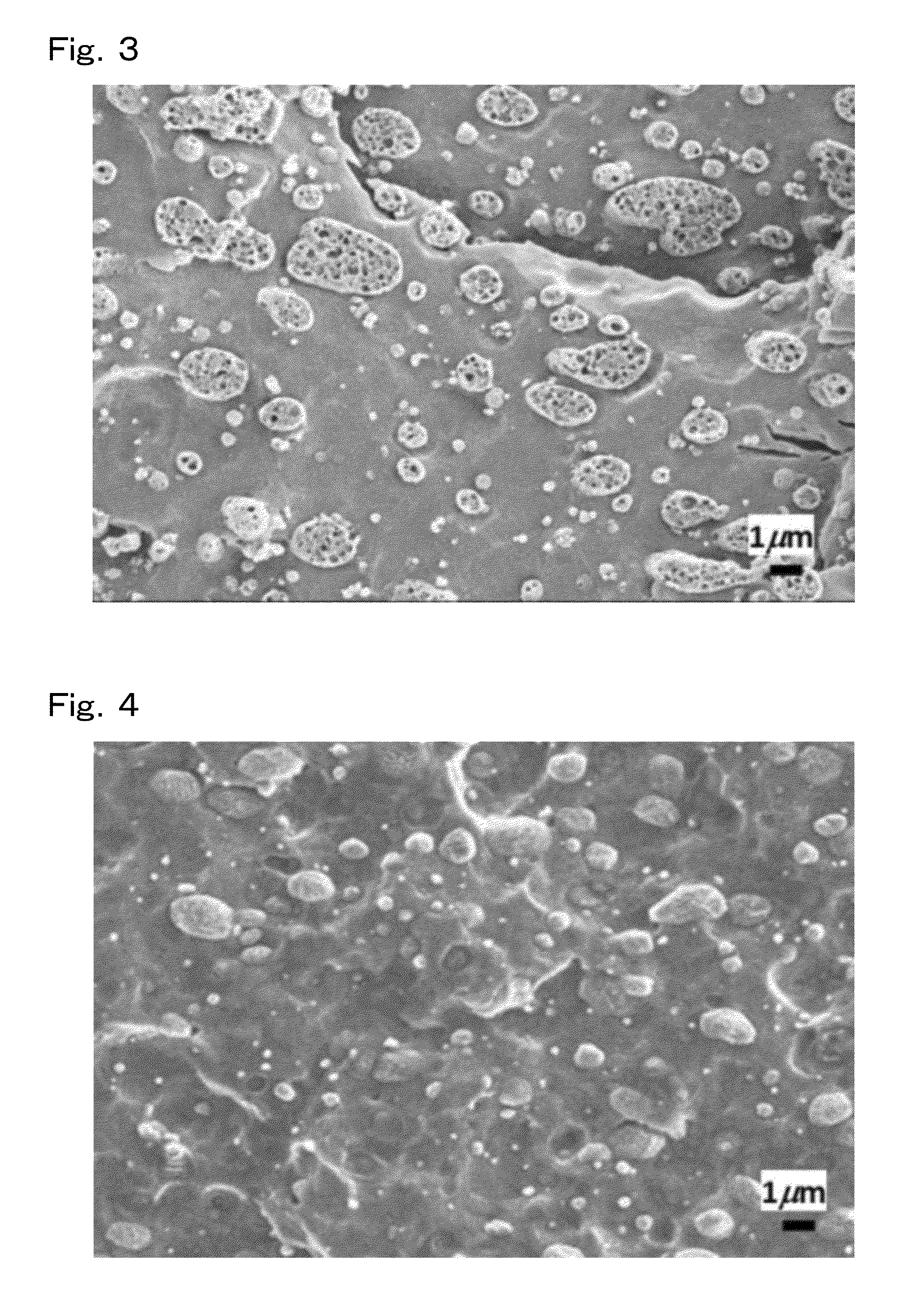

The purpose of the present invention is to provide a thermoplastic resin composition having excellent rigidity and impact resistance and a method for producing the same. The thermoplastic resin composition is obtained by mixing a polyolefin resin (such as a polypropylene resin), a polyamide resin (such as nylon 11 resin), and a compatibilizer (such as maleic anhydride-modified EPR, maleic anhydride-modified EBR). The thermoplastic resin composition is characterized in having a resin phase separate structure as observed under an electron microscope, wherein the resin phase separate structure consists of a continuous phase and a disperse phase dispersed in the continuous phase, there is a microdisperse phase in the disperse phase, and the average diameter of the microdisperse phase is 5 to 1,200 nm.

Owner:TOYOTA BOSHOKU KK

Nylon powder composition for 3D printing, and preparation method and application thereof

ActiveUS20170253702A1Improve liquidityImprove accuracyAdditive manufacturing apparatusAdditive manufacturing with solidsAntioxidantMechanical property

This invention relates to a high molecular weight nylon powder composition for 3D printing, its preparation method and use. The composition comprises: 100 parts by weight of high-viscosity nylon powder, 1-5 parts by weight of a flow agent, and 0.1-1 parts by weight of an antioxidant; the high-viscosity nylon powder is one or more selected from nylon 6, nylon 66, nylon 11, nylon 12, nylon 612 and nylon 610; or the powder composition is obtained via polymerization reaction of the raw materials comprising the following components, based on the weight parts of lactam monomers or amide monomers: 100 parts by weight of lactam monomers or amide monomers, 0.005-1 parts by weight of a catalyst, and 0.1-1 parts by weight of an antioxidant. The high molecular weight nylon powder composition prepared in the present invention has a particle diameter in the range of 20-100 micrometers, good powder spreading performance, and is suitable for the 3D printing process, and the product of the high molecular weight nylon powder composition has good mechanical properties, good dimensional stability and low manufacturing cost.

Owner:INST OF CHEM

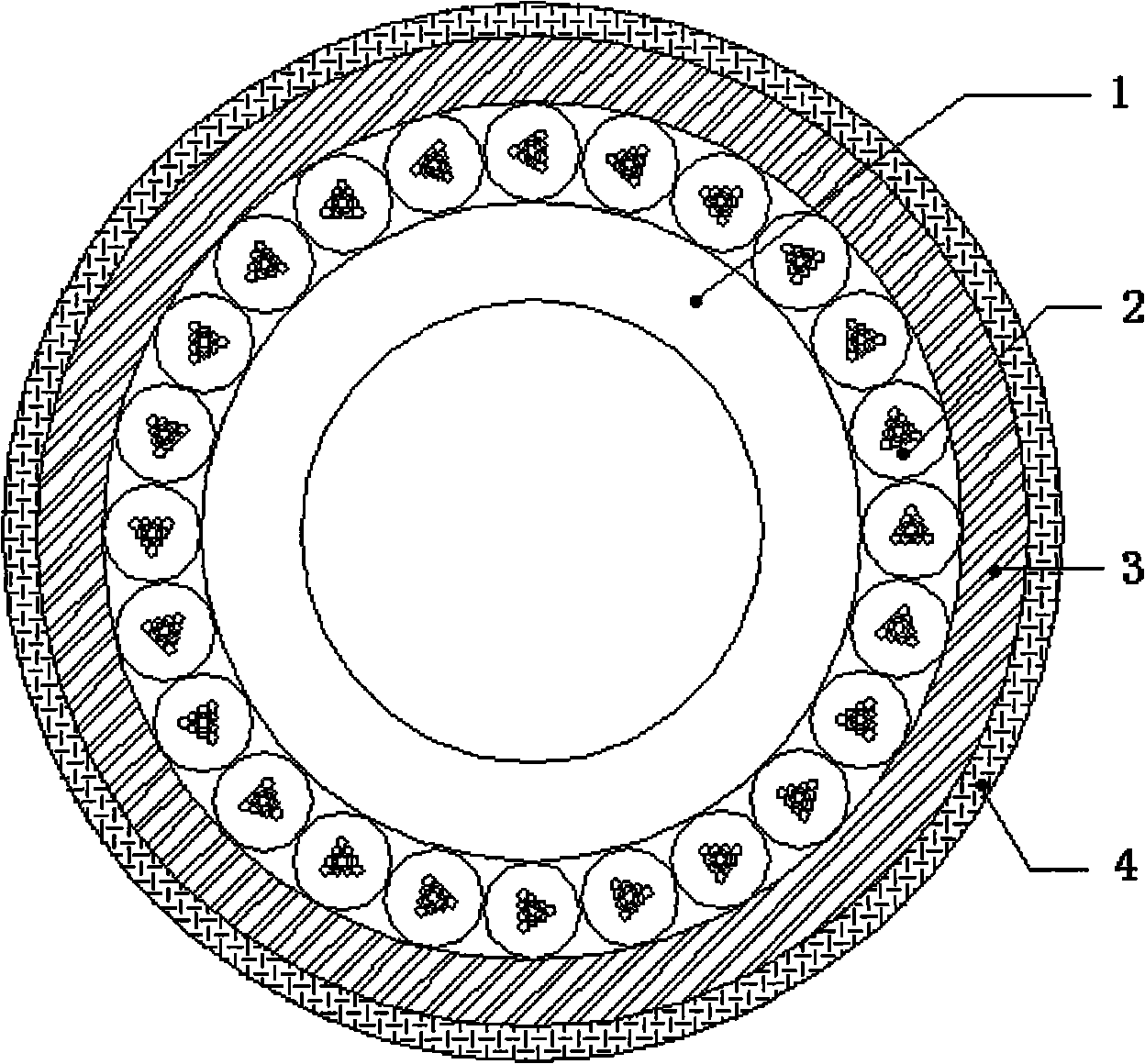

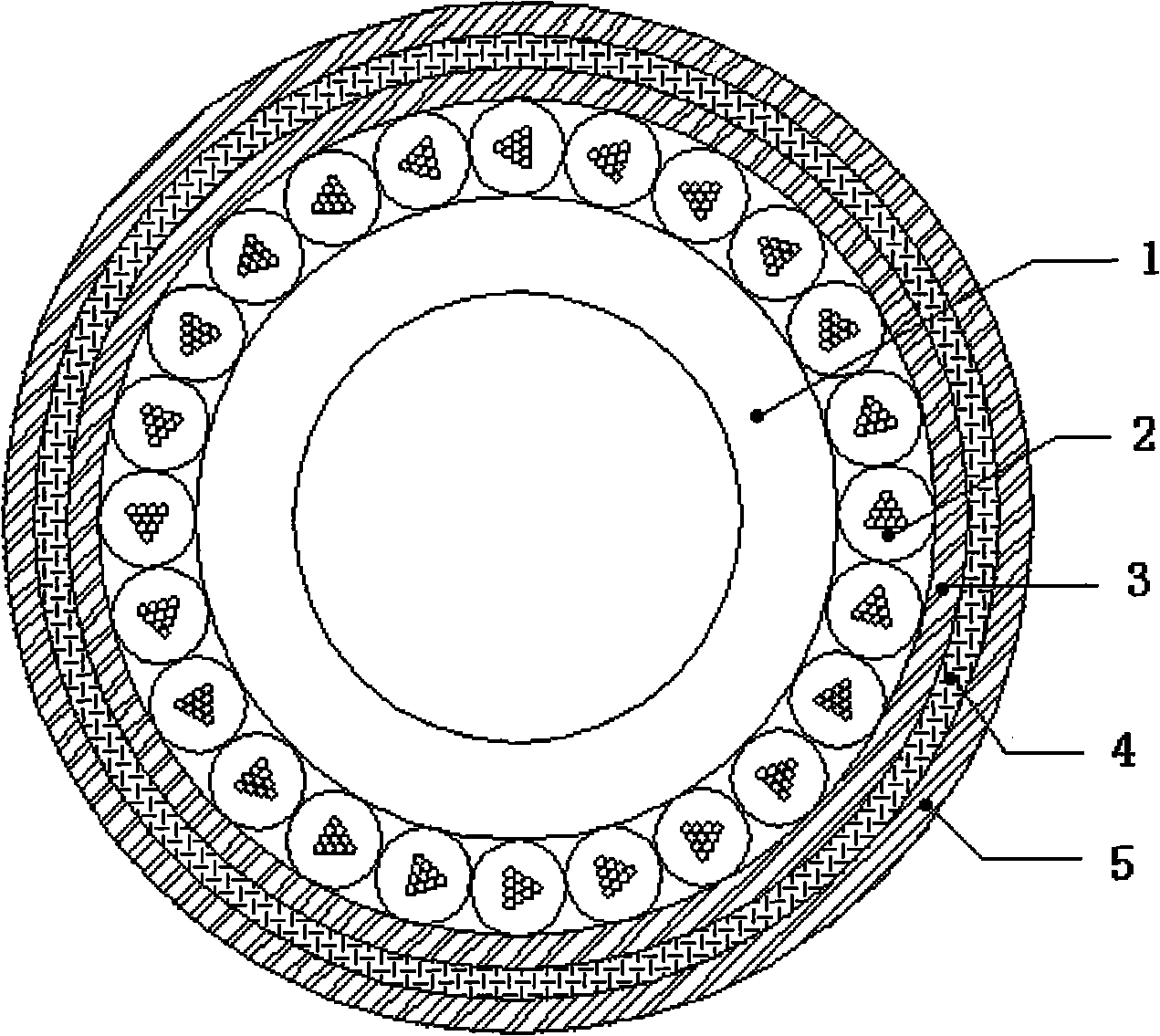

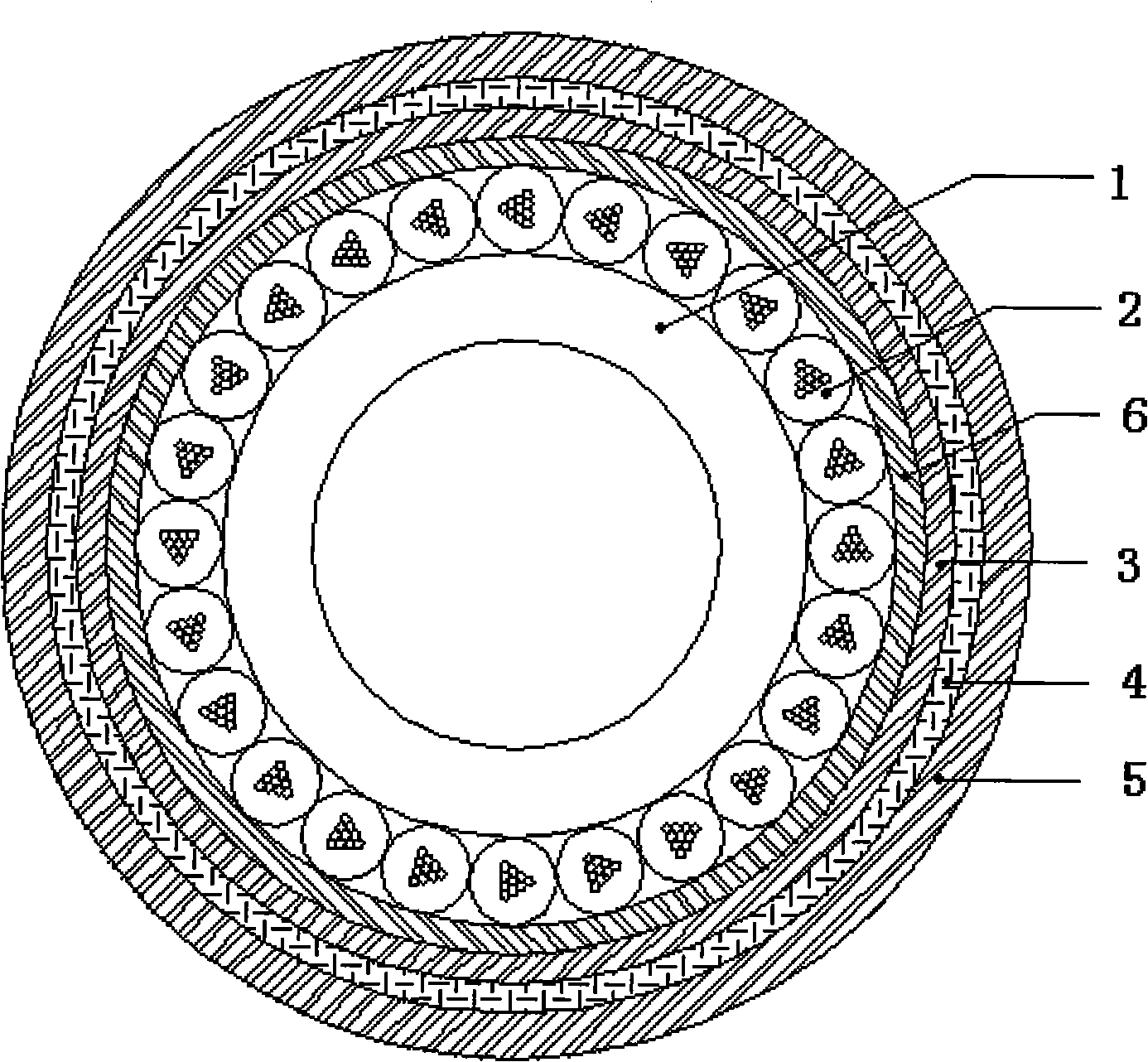

Multifunctional underwater towing line

InactiveCN101281801ASolve slidingUniform tensile forceSubmarine cablesInsulated conductorsUnderwaterEngineering

The present invention relates to a multi-functional submarine towing cable, which is characterized in: the towing cable comprises from center to exterior as follows: water transmission pipe, cables for power supply and data communication, waterproof bushing, and reinforcing rope. With consideration of leak tightness of the submarine towing cable and protection for the internal structure, an outer waterproof bushing is added outside of the reinforcing rope. A cable fixing glue layer is added outside of the cable. The water transmission pipe is made of Nylon 11 material, and the reinforcing rope is braided with Kevlar material. The present invention integrates water transmission, power transmission, and towing function to produce a towing cable that is different to steel wire cables or conventional armored cables. That is to say, the present invention provides a shipboard expendable continuous sampling system, particularly a towing cable that can be used to take water samples in real time, especially a towing cable that is loaded on a towing platform for a continuous water sampling system, with a water transmission pipe and conduction and signal transmission capability, and high tensile strength, designed to accomplish shipboard expendable continuous water sampling tasks at different predefined depths or implement shipboard expendable, quick, and online water quality monitoring.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

Polyamide-based composition for flexible pipes containing oil or gas

A composition comprising by weight:[0001]70 to 96% of at least one polyamide chosen from PA-11, PA-12, aliphatic polyamides resulting from the condensation of an aliphatic diamine having from 6 to 12 carbon atoms and an aliphatic diacid having from 9 to 12 carbon atoms, and 11 / 12 copolyamides having either more than 90% of nylon-11 units or more than 90% of nylon-12 units;[0002]4 to 10% of a plasticizer;[0003]0 to 25% of an NBR or H-NBR elastomer; and[0004]the sum of the amount of plasticizer and the amount of elastomer is between 4 and 30%;can be manufactured by melt-blending the various constituents using standard techniques for thermoplastics. The composition is particularly useful for pipes used in the operation of offshore oil and gas fields. They exhibit very good ageing resistance. They are also useful for simpler pipes in motor vehicles, these compositions withstanding the ageing caused by the temperature under the bonnet of motor vehicles and the nature of the fluids transported. Pipes which comprise at least one layer of this composition are useful for offshore uses and for simpler pipes used in motor vehicles.

Owner:ATOFINA

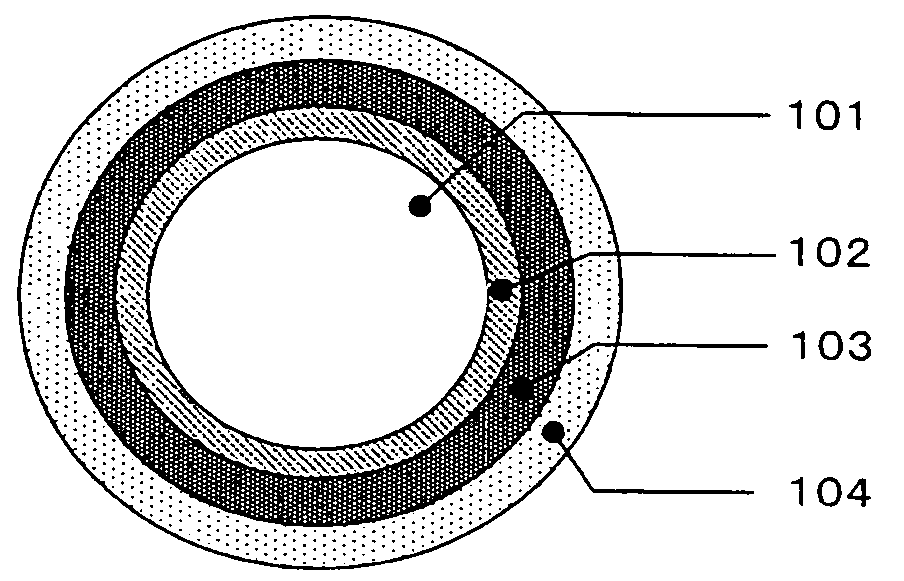

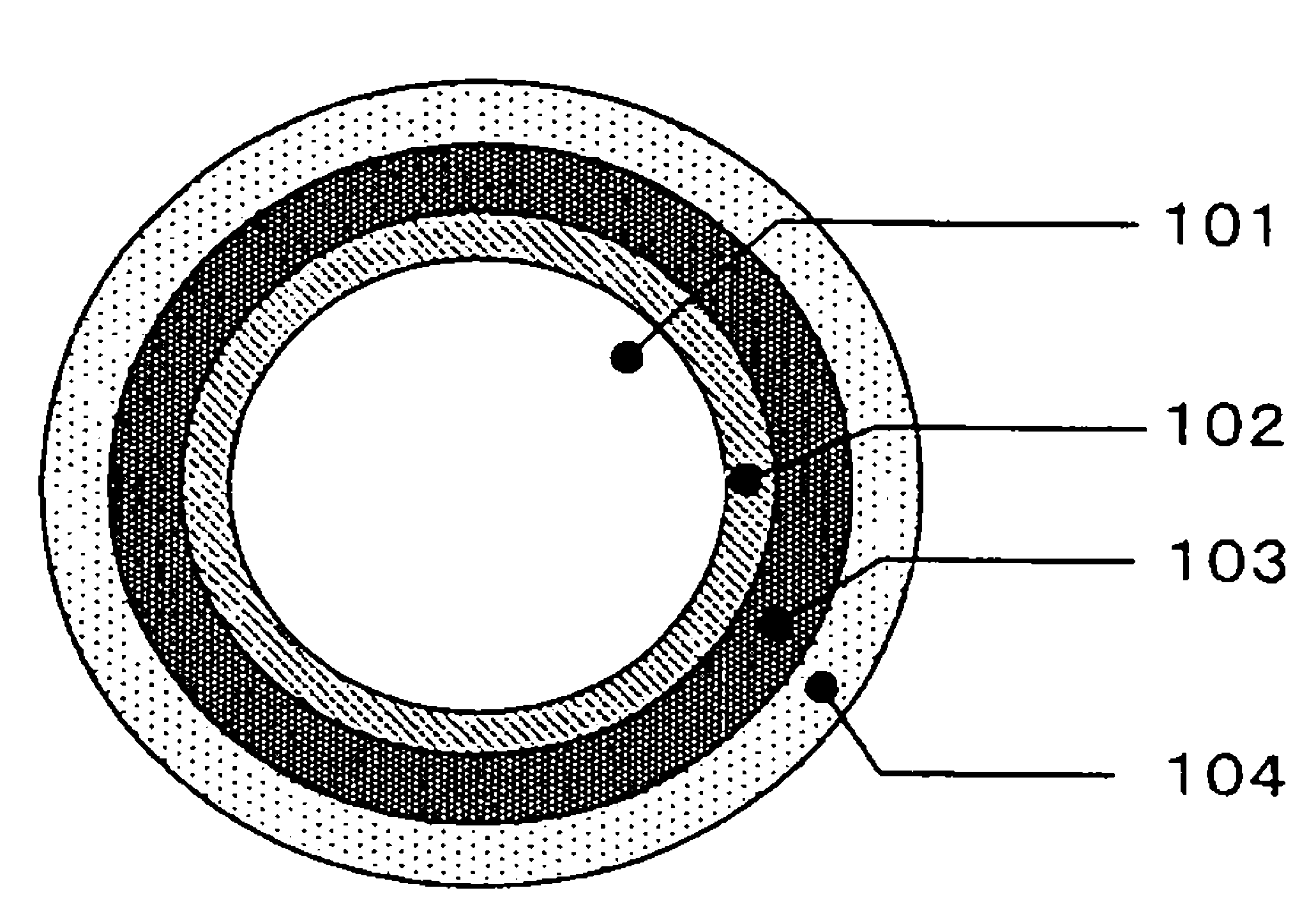

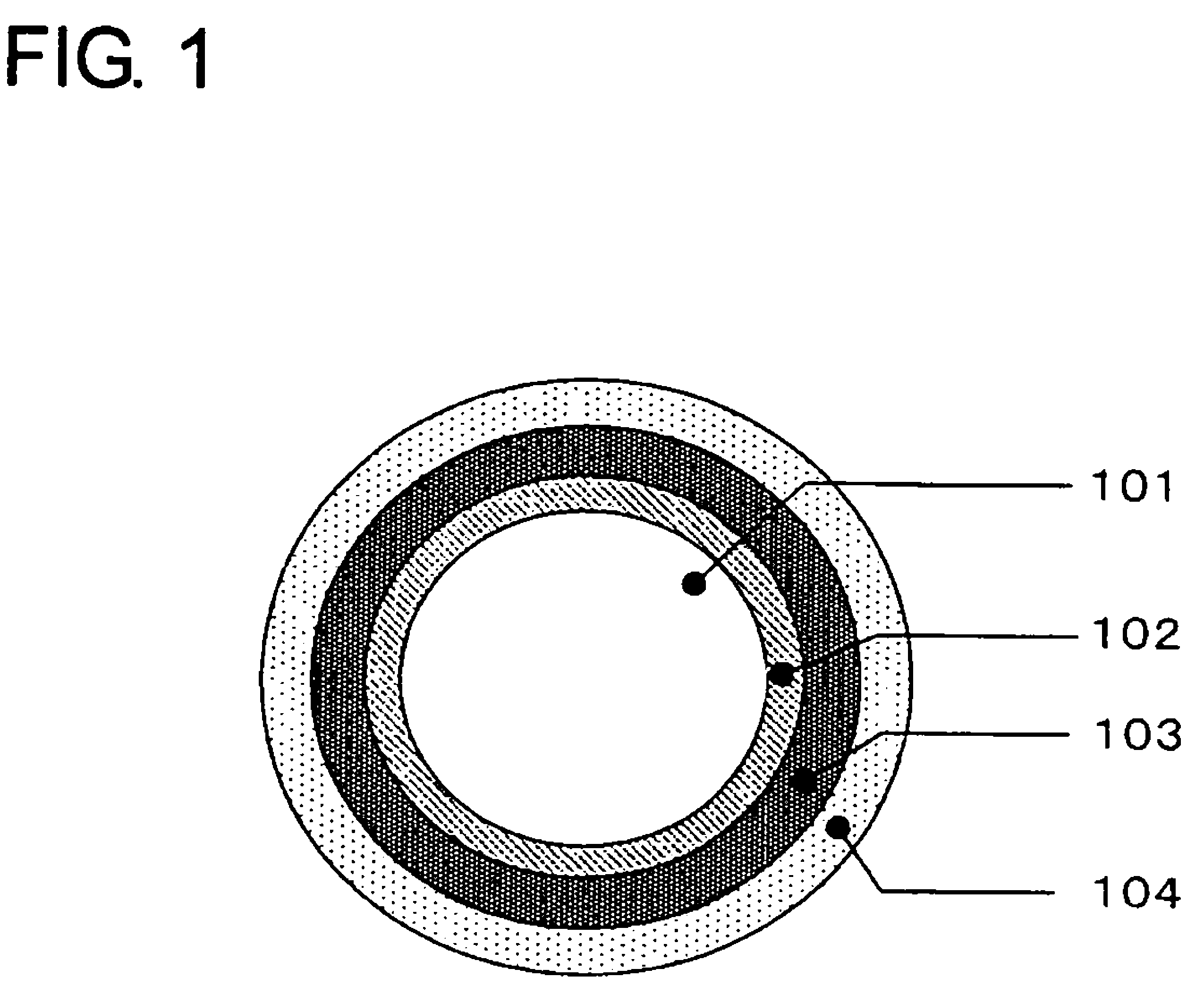

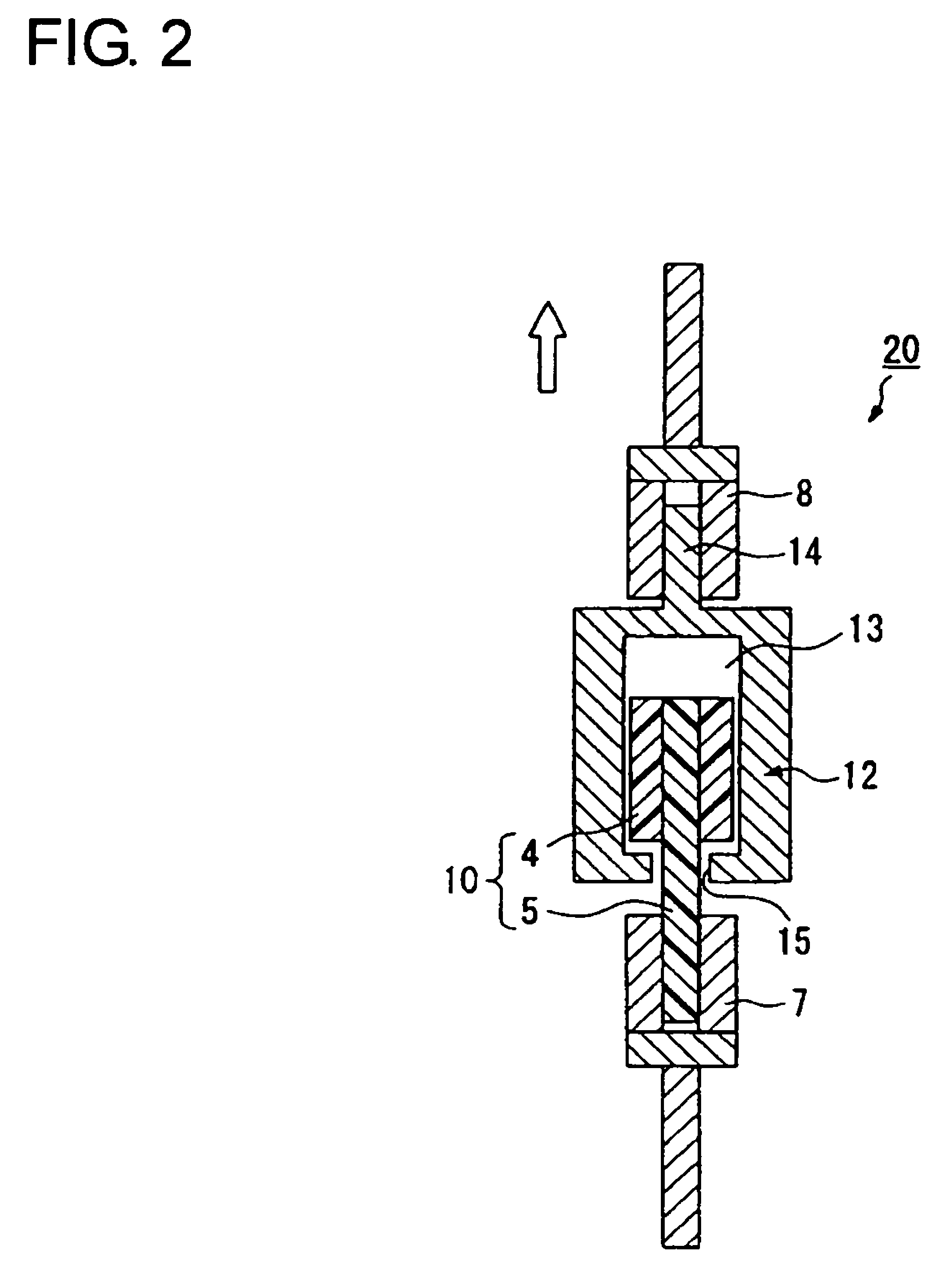

Plastic optical fiber cable and method of signal transmission using the same

ActiveUS20090279837A1Improve transmission lossExcellent long-term heat resistanceOptical fibre with multilayer core/claddingFibre mechanical structuresBare fiberPolymethyl methacrylate

A plastic optical fiber cable includes: a bare optical fiber including a core made of a poly(methyl methacrylate) or a copolymer including methyl methacrylate as a major component and a cladding layer including, at least in the outermost layer, a layer made of a certain fluorine-containing olefin-based resin; and a coating layer provided on the outer surface thereof. The coating layer includes a protective coating layer, a light blocking coating layer, and a functional coating layer, the layers being provided in the order mentioned from inner side. The protective coating layer is made of a certain resin material. The light blocking coating layer is made of a nylon-based resin including, as a major component, nylon 11 or nylon 12, the nylon-based resin containing monomer and oligomer compounds derived from the nylon-based resin in an amount of a certain range. The functional coating layer is made of a nylon-based resin composition having a crystalline melting point within a certain range, the nylon-based resin composition containing a certain amount of melamine cyanurate or bromine atoms and further containing a certain amount of inorganic chromatic pigments, or the layer is made of a nylon-based resin composition having a crystalline melting point of within a certain range and an oxygen transmission rate within a certain range.

Owner:MITSUBISHI CHEM CORP

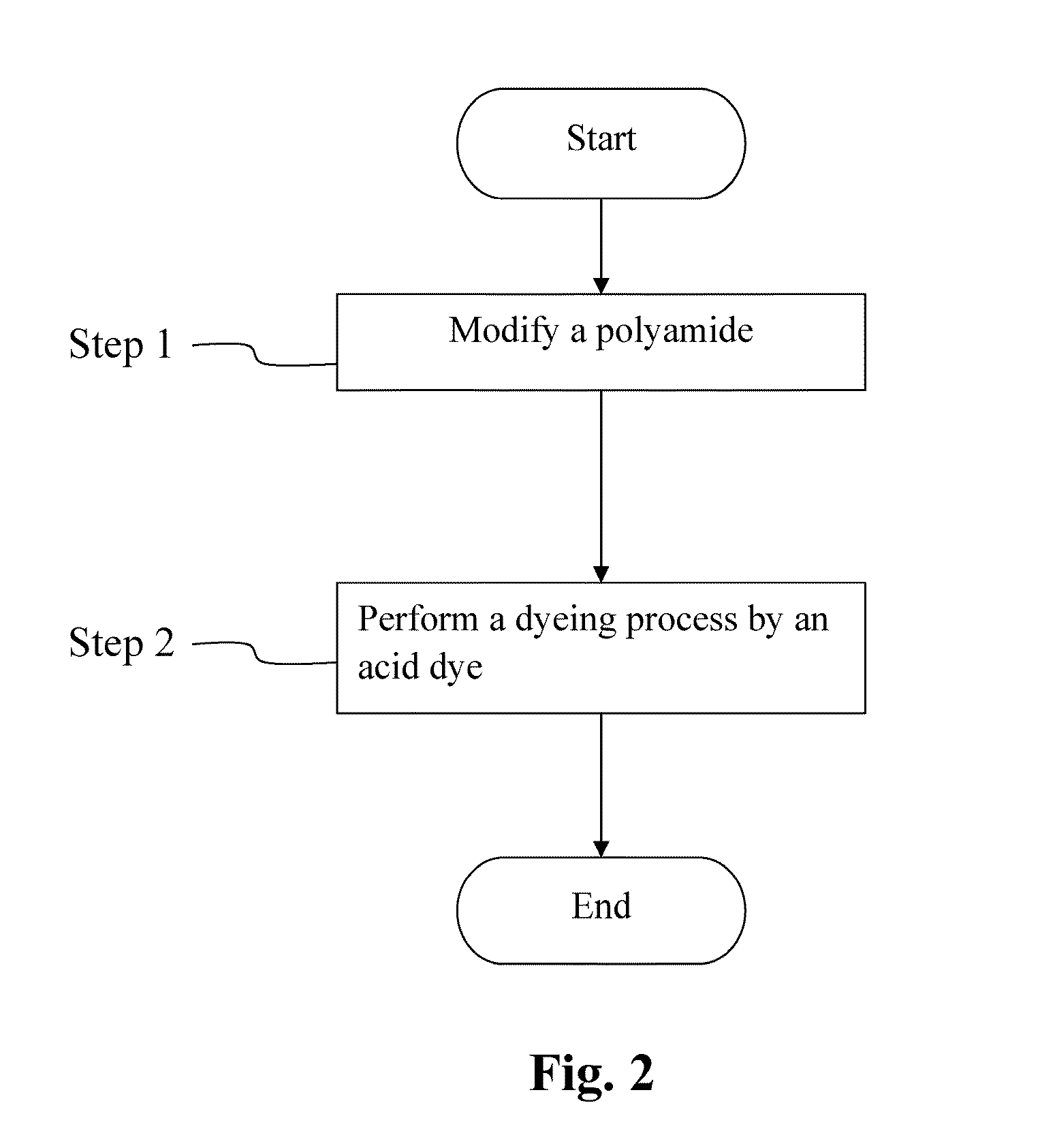

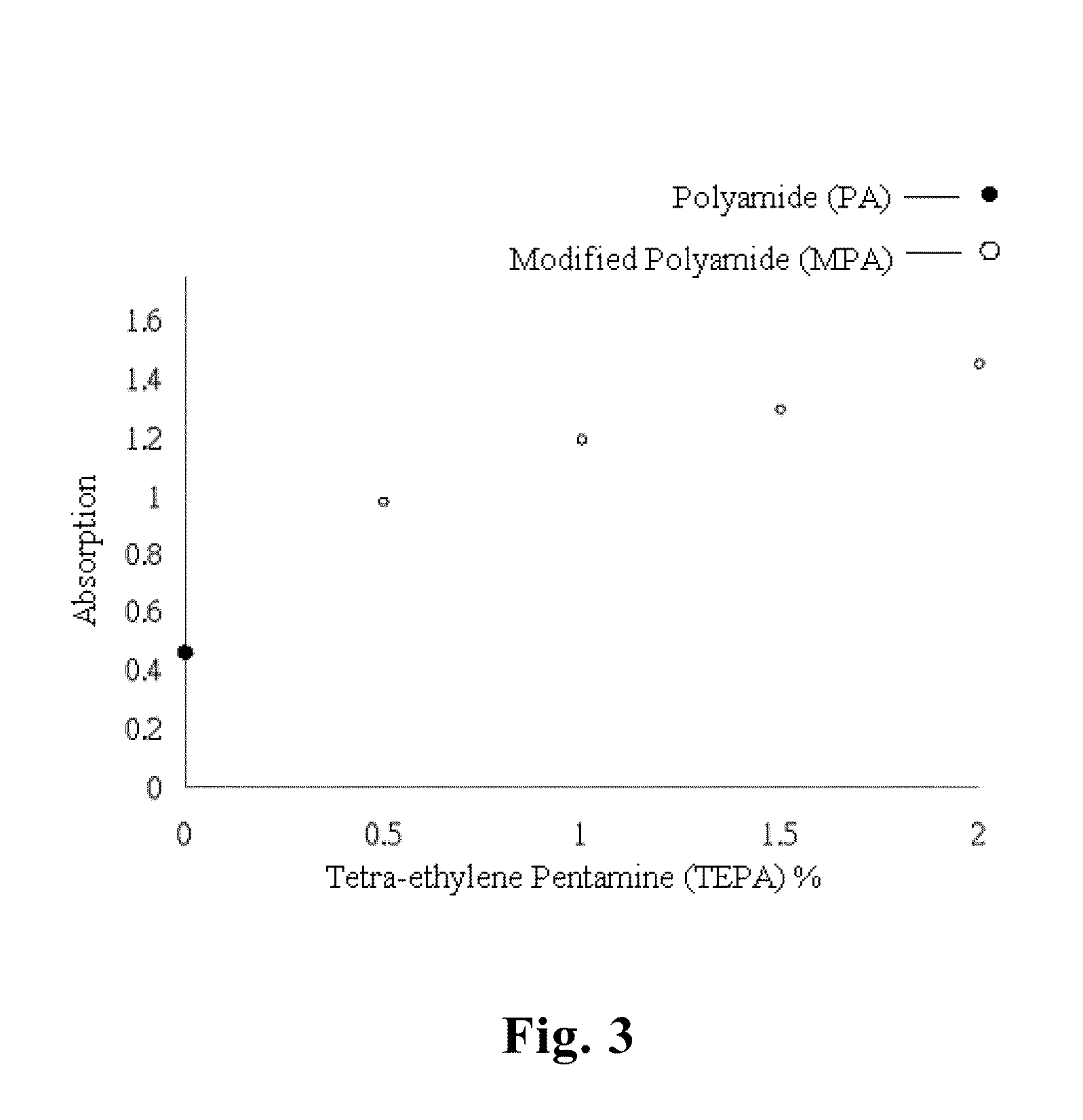

Deep Dyeing Process of Polyamide and Polyolefin

In a deep dyeing process of a polyamide (PA) including Nylon 4, Nylon 6, Nylon 46, Nylon 66, Nylon 7, Nylon 8, Nylon 9, Nylon 610, Nylon 1010, Nylon 11, Nylon 12, Nylon 13, Nylon 612, Nylon 9T, Nylon 13, MC Nylon, Nylon MXD6, and all polyamide derivatives, and a polyolefin (PO) including ethylene copolymer, propylene copolymer and their derivatives, a compatibilizer precursor is used for modifying the polyamide and polyolefin of an amino, hydroxyl or epoxy group containing chemical, and then a reactive dye and / or an acid dye is used for dyeing the polyamide and polyolefin, so that the dyed polyamide and polyolefin have excellent dye fastness, light fastness, rubbing fastness, washing fastness and low-temperature dyeability to overcome the shortcomings of conventional nylon fibers including a poor dyeing effect, a non-level dyeing quality, a high dyeing temperature (100° C. to 120° C.) and a high cost.

Owner:YEH JEN TAUT +1

Special nylon 66 composition for automobile engine hood and preparation method thereof

The invention provides a special nylon 66 composition for an automobile engine hood. The composition contains the following components by weight percent: 18-79% of nylon 66, 5-20% of copolymer nylon or long-chain nylon, 15-35% of alkali-free short glass fiber, 0-20% of mineral filler and 1.0-7% of auxiliaries, wherein the copolymer nylon is a polymer which is prepared through reaction, dehydration and polymerization of two or more monomer units, contains an amide group and is selected from one of or the mixture of more of a nylon6 / 66 copolymer, a nylon 6 / 12 copolymer and a nylon 6 / 10 copolymer; and the long-chain nylon is a polymer which is prepared through polymerization of monomers with carbon contents greater than or equal to 10 in polymer monomer units and other monomer units, contains an amide group and is selected from one of or the mixture of more of a nylon 11, a nylon 12 and a nylon 1010. The invention provides the special nylon 66 composition for the automobile engine hood and a preparation method thereof. The composition has the beneficial effects that the composition has quite high impact resistance and super strength and excellent chemical properties and dimensional stability; and products have smooth and clean surfaces and are cheap.

Owner:辰东意普万新材料(广东)有限公司

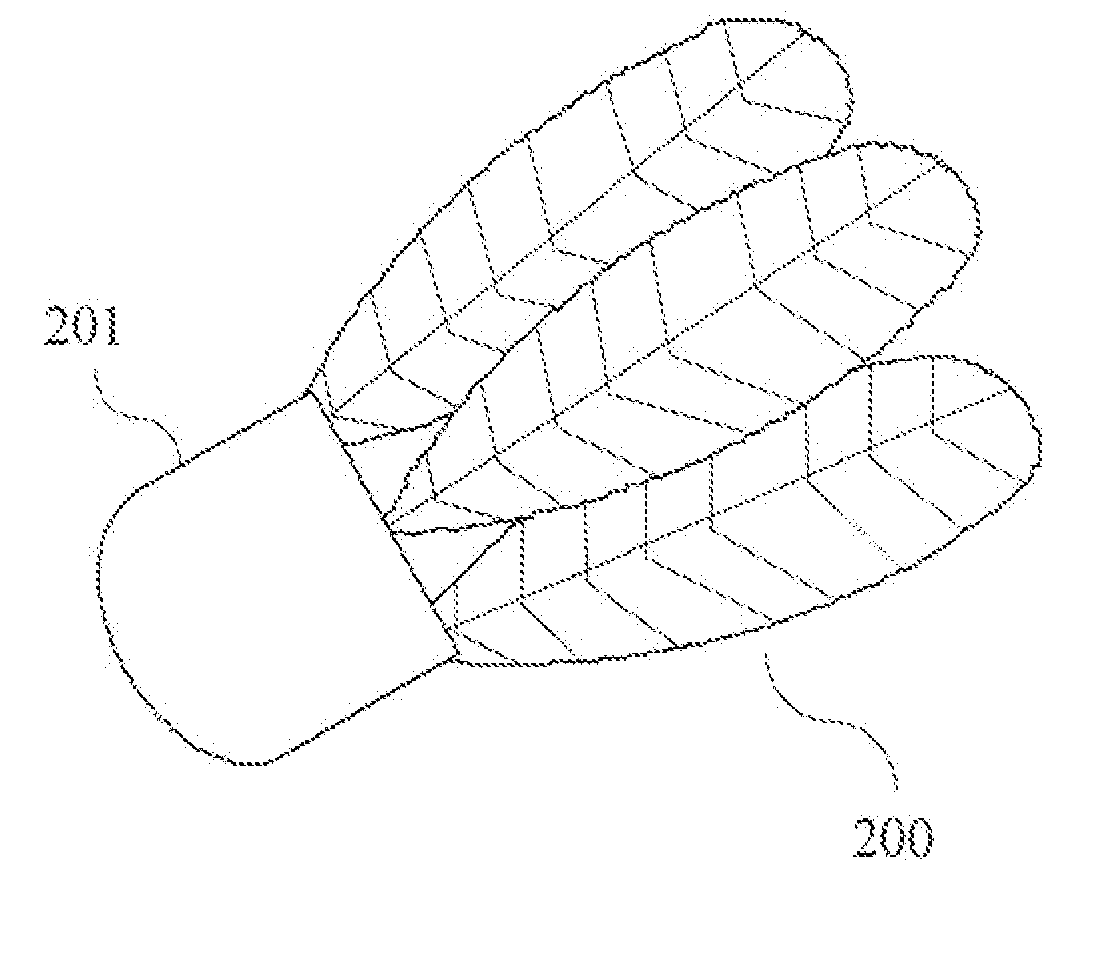

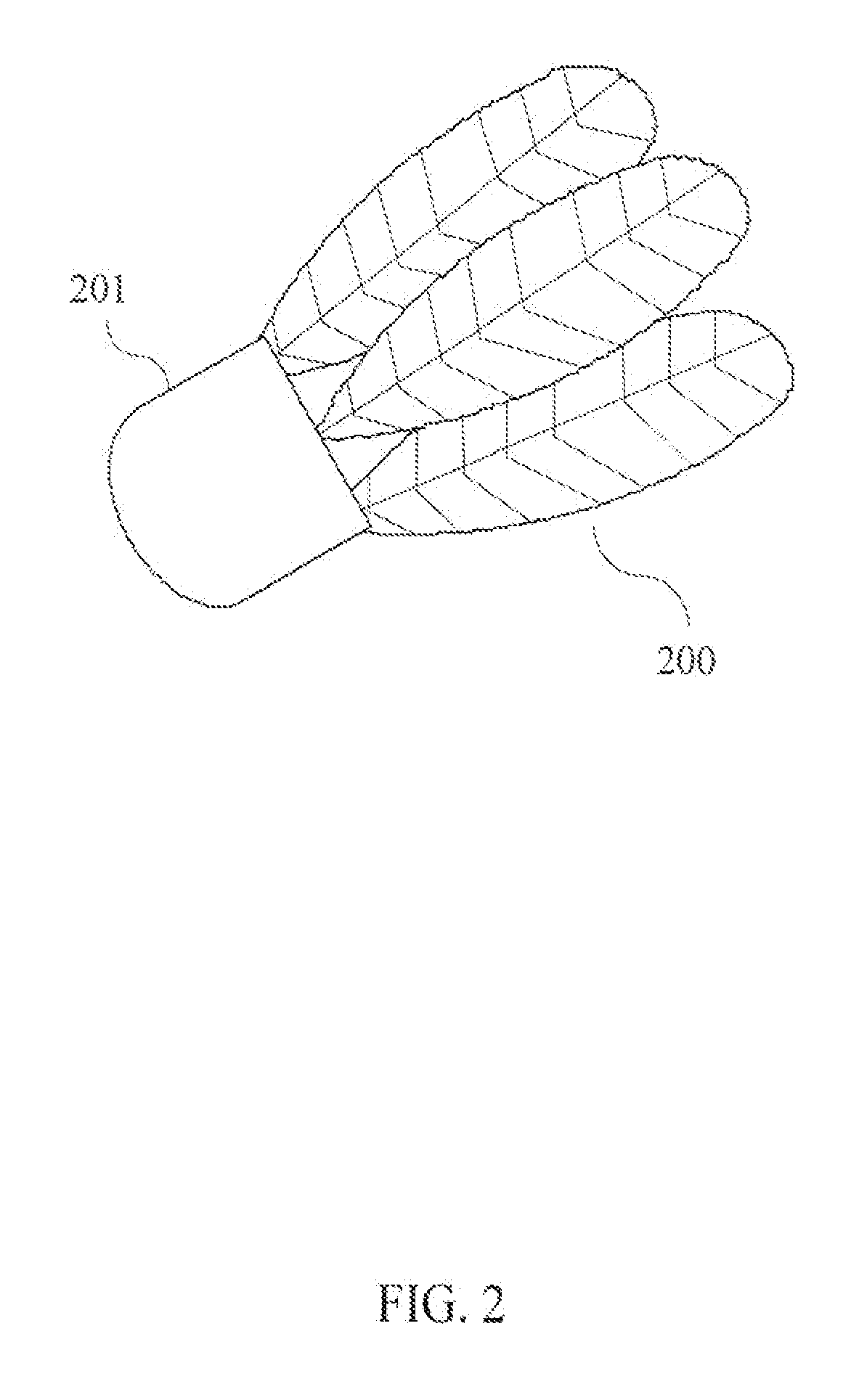

Nylon 11/Filler/Modifier Composites

A nylon 11 composite system has significantly improved flexural modulus while keeping or even increasing the impact strength. This composite system may comprise a nylon 11 / filter / modifier. The flexural modulus and impact strength increases over 150% and 80%, respectively compared with neat nylon 11. The “ball” portion of badminton shuttlecocks made by this type of composite may more closely duplicate the flight capabilities of natural duck feather shuttlecocks than nylon 11. The nylon 11 / filler / modifier ay allow for a very close duplication of the restoration effects of shuttlecocks made from feathers therefore providing a product which can be a one for one aerodynamic performance substitution for the natural product (feathers).

Owner:APPLIED NANOTECH HLDG

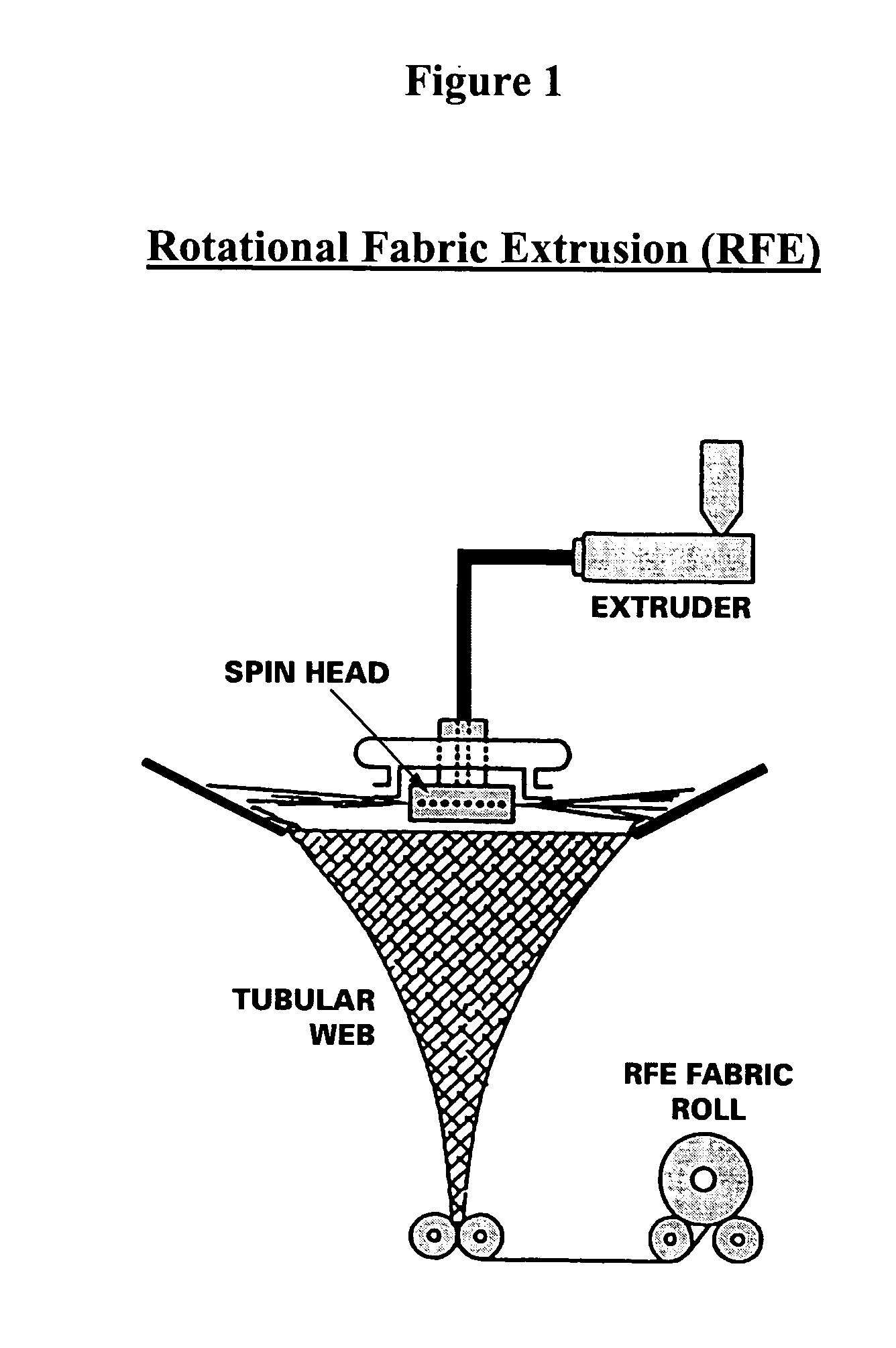

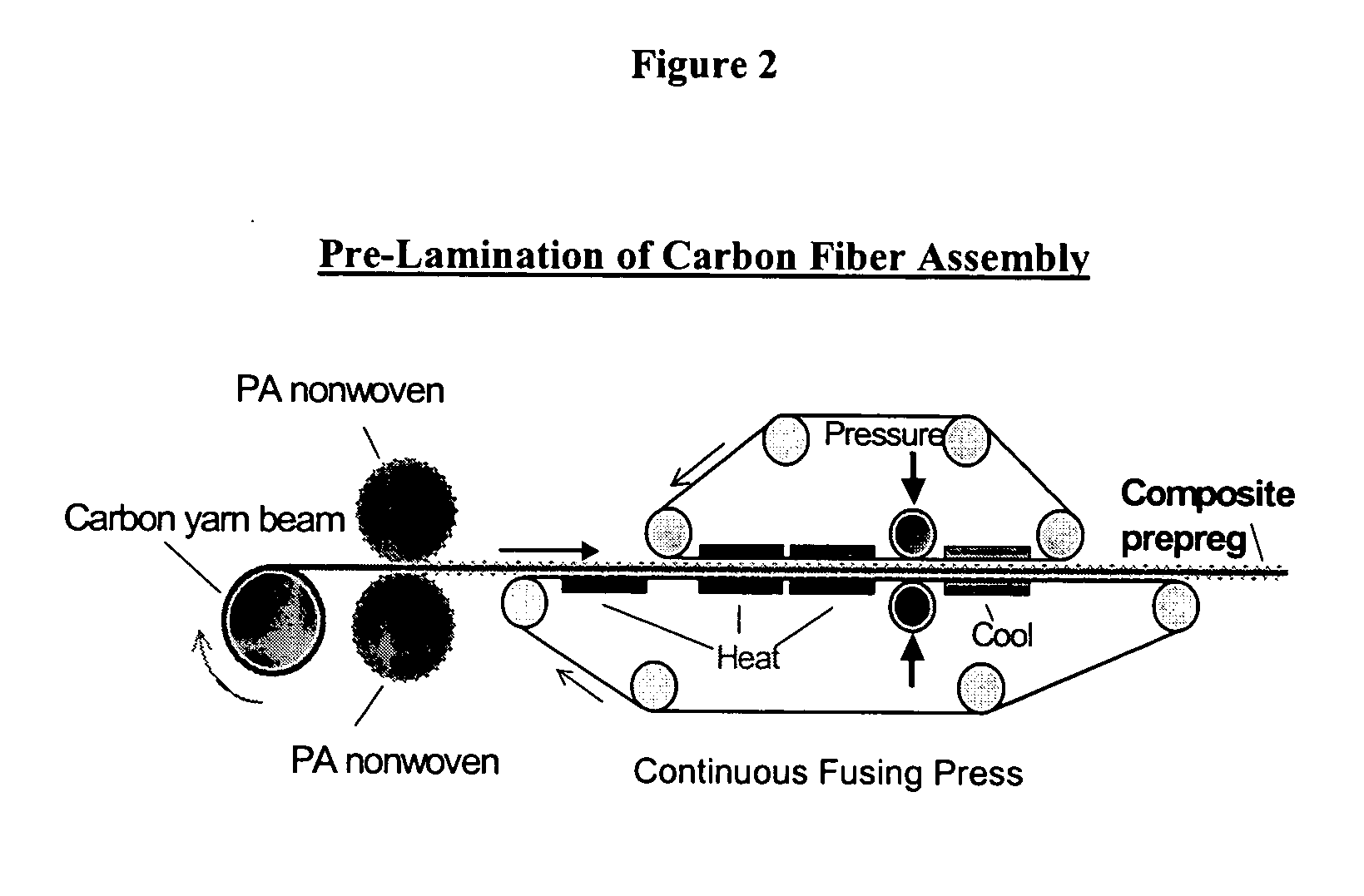

Thermoplastic nylon adhesive matrix having a uniform thickness and composite laminates formed therefrom

InactiveUS20050197026A1Enable productionSynthetic resin layered productsWoven fabricsThermoplasticAdhesive

Owner:KEUCHEL KENNETH +1

Plastic optical fiber cable and method of signal transmission using the same

ActiveUS8023789B2Improve transmission lossExcellent long-term heat resistanceOptical fibre with multilayer core/claddingFibre mechanical structuresPoly(methyl methacrylate)Engineering

Owner:MITSUBISHI CHEM CORP

Polyamide Composition Containing Ionomer

InactiveUS20130171394A1Poor salt stress crack resistanceExcellent salt stress crack resistanceLayered productsPretreated surfacesIonomerCrack resistance

Disclosed is a composition comprising polyamide comprising nylon-6 and optionally nylon-6,66, nylon-66, nylon-610, nylon-612, nylon-11, nylon-12 and an ionomer comprising an ethylene carboxylic acid copolymer, wherein 30 to 90% of the total carboxylic acid functionalities are neutralized to salts with a mixture of zinc cations and cations of a second metal selected from Group 1 of the Periodic Table of the Elements wherein the salts comprise from 20 to 90% equivalents of zinc. Articles prepared from the composition have improved salt stress crack resistance when exposed to zinc chloride solutions.

Owner:EI DU PONT DE NEMOURS & CO

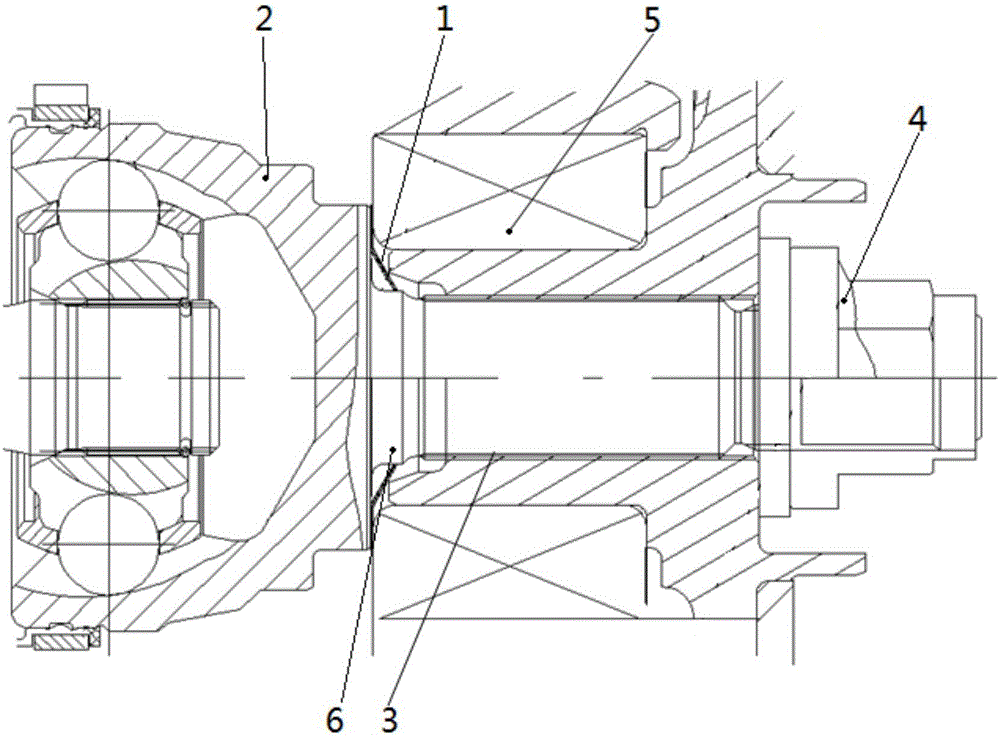

Anti-attrition spacer capable of reducing frictional abnormal sound and application of anti-attrition spacer

InactiveCN105782215AReduce friction noiseSqueak and rattle mitigationWashersSolid state diffusion coatingUniversal jointFrictional coefficient

The invention discloses an anti-attrition spacer capable of reducing frictional abnormal sound and an application of the anti-attrition spacer and belongs to the field of mechanical parts. The anti-attrition spacer takes a low-carbon alloy cold-rolled sheet as a base body, and carbonitriding thermal treatment and surface coating treatment of a polyfluorocomplex and / or a nylon 11 coating are successively performed on the low-carbon alloy cold-rolled sheet. The adhesive force between the coating and the base body in the anti-attrition spacer provided by the invention is large, and the coating has excellent anti-attrition effect and wear-resistant effect. The anti-attrition spacer is used between contact surfaces which rub with each other. With prolonging of frictional time, the coating on the anti-attrition spacer does not fall off, so that the durability of the anti-attrition spacer is ensured, the frictional coefficient between the anti-attrition spacer and the contact surfaces is effectively reduced, and the adhesive wear is reduced, and therefore, the frictional abnormal sound is further reduced. In particular, the anti-attrition spacer used in the field of automobiles can effectively relieve the frictional abnormal sound generated between the end face of a universal joint at the fixed end of a driving shaft and a contact surface of a hub bearing of an automobile.

Owner:CHERY AUTOMOBILE CO LTD

Polyamide-based multilayer tube for transferring fluids

ActiveUS20070059469A1Good resistance to fuelGood to to engine lubrication oilSynthetic resin layered productsFlexible pipesFluid transportNylon 12

The present invention relates to a multilayer tube comprising, in its radial direction from the outside inwards: an optional layer (1) made of nylon-11 or nylon-12 polyamide; an intermediate layer (2) comprising by weight, the total being 100%: 50 to 100% of at least one polyamide A1 of formula X,Y / Z or 6,Y2 / Z, in which X denotes residues of an aliphatic diamine having from 6 to 10 carbon atoms, Y denotes residues of an aliphatic dicarboxylic acid having from 10 to 14 carbon atoms, Y2 denotes residues of an aliphatic dicarboxylic acid having from 15 to 20 carbon atoms, Z denotes at least one unit chosen from residues of a lactam, residues of an α,Ω-aminocarboxylic acid, the unit X1,Y1, in which X1 denotes residues of a diamine and Y1 denotes residues of a diacid, the weight ratios Z / (X+Y+Z) and Z / (6+Y2+Z) being between 0 and 15%, and 0 to 50% of nylon-11 or nylon-12 polyamide; an optional layer (3) made of nylon-11 or nylon-12 polyamide, with the condition that at least one of the layers (1) and (3) is present; the layers being successive and adhering to one another, the inner layer being the layer in contact with the fluid transported.

Owner:ARKEMA FRANCE SA

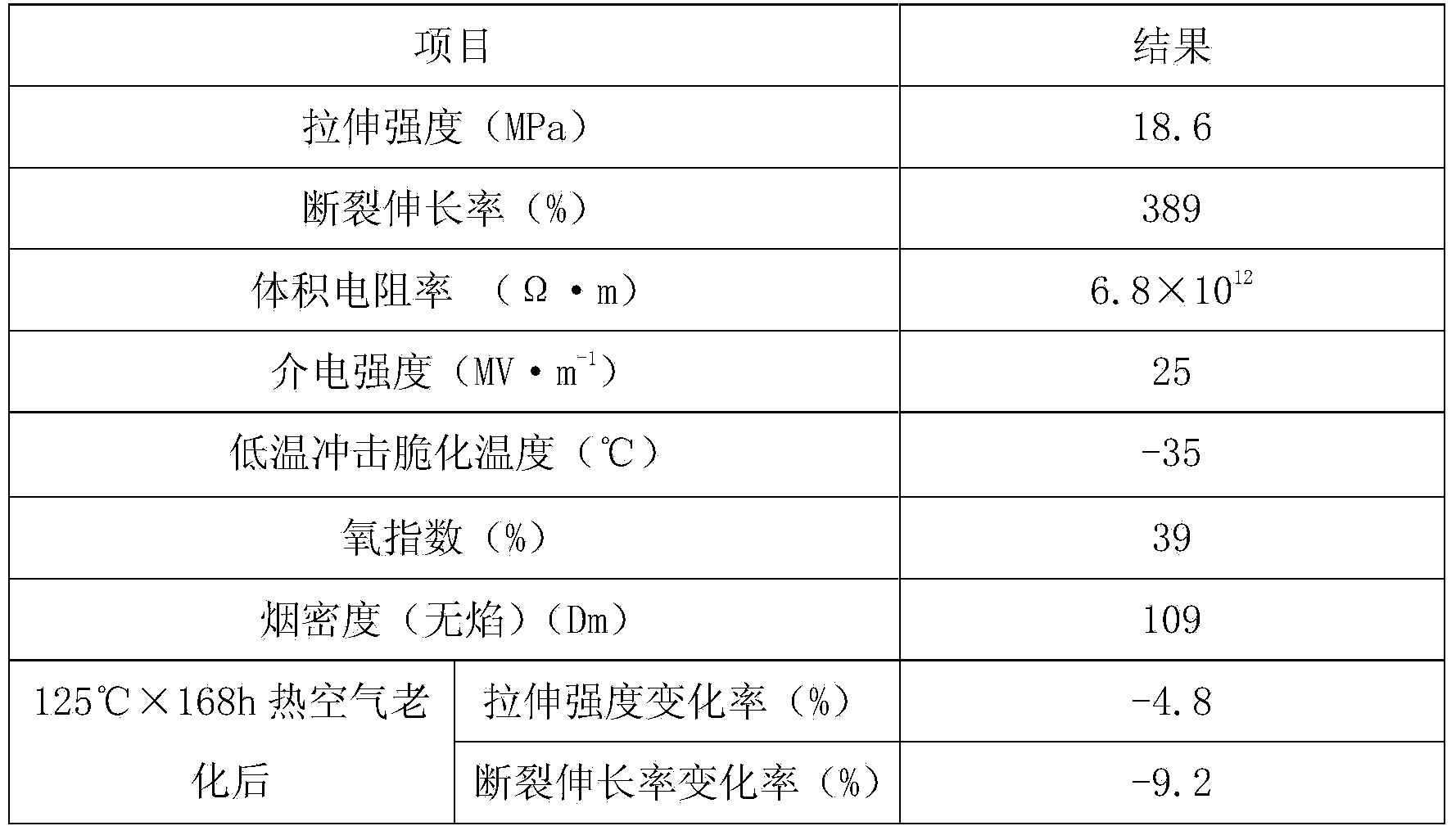

Optical fiber cable-used insulated cable material and preparation method thereof

ActiveCN104109306AHigh and low temperature flexibilityCreep resistantFibre mechanical structuresPolycarbonateNylon 11

The invention discloses an optical fiber cable-used insulated cable material and a preparation method thereof. The material is prepared by the following raw materials by weight: 70 to 90 of XS-3-type resin, 20 to 30 of PTFE, 15 to 25 of nylon-11, 10 to 15 of polycarbonate, 12 to 18 of C5 petroleum resin, 20 to 30 of precipitated white carbon black, 10 to 15 of nano sepiolite, 1 to 2 of zinc oxide, 2 to 3 of magnesium oxide, 1 to 2 of zinc stearate, 1 to 2 of barium stearate, 8 to 12 of di(2-Ethylhexyl)-4,5-epoxytetrahydrophthalate, 5 to 10 of tributyl phosphate, 2 to 3 of monostearin, 4 to 8 of hydrated zinc borate, 5 to 10 of composite filler, and 0.5 to 1 of an antioxidant 1076. The cable material is good in flexibility at high and low temperature and has excellent physical and mechanical performance of creeping resistance, wear resistance, oil resistance, tearing resistance, aging resistance and the like; the flame-retardant effects are good, and the fire tongue can be quickly extinguished after the flame disappears, other material is not burnt, the smoke amount generated in the case of burning is small, and the use demands of the insulated material of an optical fiber cable protection layer can be met.

Owner:安徽荣鹏智能装备有限公司

High barrier laminated body

ActiveUS20090269533A1Improve compatibilityIncrease flexibilitySynthetic resin layered productsFlexible pipesCarboxylic acidNylon 11

A laminated body having a thermoplastic resin layer (I) and a polyamide resin layer (II) which is made of nylon 11 and / or nylon 12. The thermoplastic resin layer (I) includes 100 parts by weight of a polyamide resin composition (A) and 0.1 to 10 parts by weight of a carbodiimide compound (B) having two or more carbodiimide groups. The polyamide resin composition (A) contains a polyamide resin (a-1) having diamine units 70 mol % or more of which are derived from m-xylylenediamine and dicarboxylic acid units 70 mol % or more of which are derived from a C4 to C20 α,ω-linear aliphatic dicarboxylic acid and a nylon 12 and / or nylon 11 component (a-2) in an amount of 5 to 95% by weight of the component (a-1) and 95 to 5% by weight of the component (a-2) each based on a total weight of the components (a-1) and (a-2). The laminated body is excellent in the barrier property, peeling resistance and mechanical properties such as strength, impact resistance and elongation, particularly in the barrier property to alcohol-containing fuels.

Owner:MITSUBISHI GAS CHEM CO INC

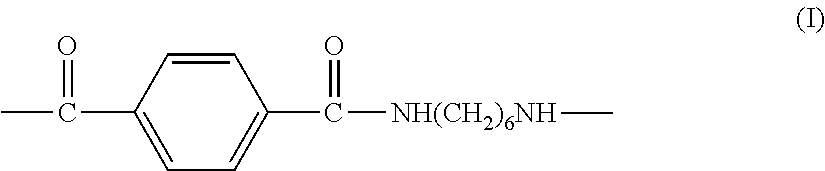

Polyamide composition containing ionomer

Disclosed is a composition comprising polyamide comprising nylon-6 / 12 or a polyamide comprising a first repeat unit of formula (I)and a second repeat unit of formula (II)—C(O)(CH2)nC(O)NH(CH2)6NH— (II);wherein n is an integer selected from 8, 10, 12, or 14, and optionally nylon-6,66, nylon-66, nylon-610, nylon-612, nylon-11, nylon-12 and an ionomer comprising an ethylene carboxylic acid copolymer, wherein 30 to 90% of the total carboxylic acid functionalities are neutralized to salts with zinc cations or a mixture of zinc cations and cations of a second metal selected from Group 1 of the Periodic Table of the Elements wherein the salts comprise from 20 to 90% equivalents of zinc. Articles prepared from the composition have improved salt stress crack resistance when exposed to zinc chloride solutions.

Owner:EI DU PONT DE NEMOURS & CO

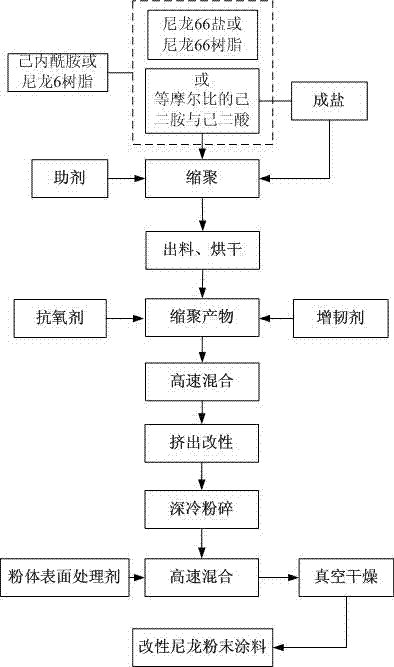

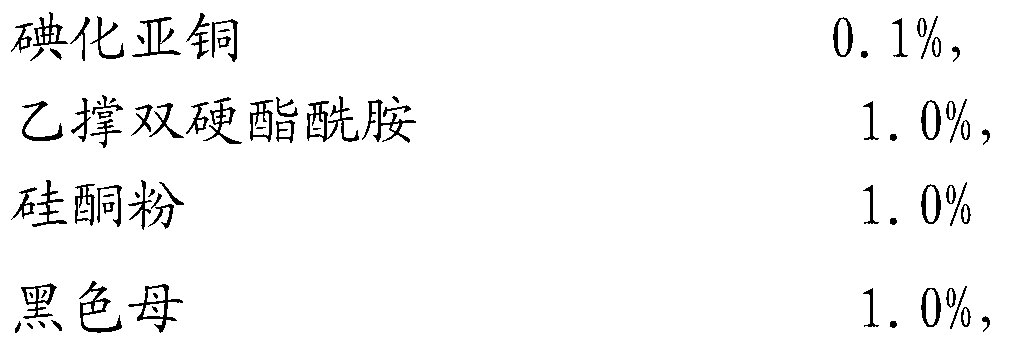

Modified nylon powder coating and preparation method thereof

InactiveCN102898941AFull play to the melting pointReduce regulationPowdery paintsPolyamide coatingsPolymer scienceNylon 12

The invention discloses a modified nylon powder coating and a preparation method thereof. The preparation method comprises the following steps of: firstly preparing a polymerization product by performing polymerization reaction on the following main synthetic materials in parts by mass: 50 to 80 parts of caprolactam or nylon 6 resin, 20 to 50 parts of nylon 66 salt, nylon 66 resin or equal mole ratio of hexamethylene diamine and hexanedioic acid, and 0.02 to 1.7 parts of an auxiliary agent; and then preparing the modified nylon powder coating through the processes of extrusion modification, deep cooling crushing and treatment with a powder surface treatment agent. The auxiliary agent comprises an antioxidant, a nucleating agent and a molecular weight adjusting agent. The modified nylon powder coating prepared by the method is lower in melting point, simple in process control and stable in product quality, can partially substitute nylon 11 and nylon 12 powder products, can effectively reduce the using cost of nylon powder, is favorable for application popularization of the nylon powder, and has a great market potential.

Owner:NANJING INST OF TECH

Process for preparing undecylenic acid by scission of castor oil

InactiveCN101289383AAvoid physical and mental harmConstant responseOrganic compound preparationCarbonyl compound preparation by oxidationBenzoyl peroxideWater vapor

The invention relates to an engineering plastic process for producing nylon-11 by caster oil and particularly relates to a method for cracking the caster oil to produce undecylenic acid, which belongs to the process flow and solves the existing problems of lead pollution and easy coking in the technology that the caster oil is cracked by the technique of cauldron-typed lead melter. The method is as follows: the caster oil and a catalyst of benzoyl peroxide solution are mixed and preheated to 150-200 DEG C, the quality proportion of which is 1000:3-7:1100-1300 with over heated water vapor of 500-600 DEG C, which enters into a loading tube from the mouth of the loading tube, enters into the top of the cracking stove body from the outlet of the loading tube, and enters into a reacting space along a screw panel; the cracking stove body at the upper part of a tower-typed cracking stove is heated to 500-600 DEG C by an electric heater to crack to produce undecylenic acid and heptaldehyde products. The engineering plastic process for producing nylon-11 by caster oil has the advantages of permanent reaction, strongly continuous operability, ,which is suitable for the production of industrialized settings and can improve the operating environment, can overcome the hurt to body and spirit of the operator by the lead pollution, and has low possibilities of coking, high yield and simple setting producing technologies.

Owner:山西宏远科技股份有限公司

Thermoplastic resin composition excellent in barrier property

InactiveUS20100004406A1Improve compatibilityIncrease flexibilityEnvelopes/bags making machinerySynthetic resin layered productsNylon 12Alcohol

A thermoplastic resin composition comprising 100 parts by mass of a polyamide resin composition (A) and 0.1 to 10 parts by mass of a carbodiimide compound (B) having two or more carbodiimide groups. The polyamide resin composition (A) contains a polyamide resin (a-1) and nylon 11 and / or nylon 12 (a-2) in an amount of 5 to 95% by mass of the component (a-1) and 95 to 5% by mass of the component (a-2) each based on a total amount of the components (a-1) and (a-2). The polyamide resin (a-1) is constituted by diamine units 70 mol % or more of which are derived from m-xylylenediamine and dicarboxylic acid units 70 mol % or more of which are derived from a C4 to C20 α,ω-linear aliphatic dicarboxylic acid. The thermoplastic resin composition is excellent in barrier property, strength and impact resistance, in particular, barrier property to alcohol-containing fuels, and suitably used as various shaped articles such as fuel containers, tubes and parts.

Owner:MITSUBISHI GAS CHEM CO INC

Low-temperature-resistant automobile nylon composite and preparation method thereof

InactiveCN104046003AImprove low temperature resistanceHigh impact strengthISOCETYL PALMITATEHydroxystearic Acid

The invention discloses a low-temperature-resistant automobile nylon composite and a preparation method thereof. The low-temperature-resistant automobile nylon composite is prepared from the following raw materials by weight: 45 to 65 parts of nylon 11, 30 to 40 parts of nylon 1010, 15 to 20 parts of polyoxymethylene, 17 to 23 parts of bis[2-(2-butoxyethoxy)ethyl] adipate, 12 to 18 parts of di-iso-butyl ester nylon acid, 10 to 15 parts of potassium hexatitanate whisker, 4 to 7 parts of zirconium silicate, 2.5 to 4.5 parts of isocetyl palmitate, 2 to 3 parts of hydroxystearic acid, 1 to 2 parts of barium laurate, 1 to 2 parts of barium myristate, 10 to 15 parts of resorcinol monobenzoate, 3 to 6 parts of vitamin E, 2 to 4 parts of distearyl alcohol pentaerythritol diphosphite, 1 to 2 parts of hydroxyl-aluminum p-tert-butyl benzoate, 1.5 to 2.5 parts of 3,4-dimethyl dibenzylidene sorbitol, 10 to 15 parts of oil shale residue, 8 to 12 parts of calcined clay, 5 to 10 parts of barite powder and 10 to 15 parts of modified kaolin. The nylon composite provided by the invention has excellent low temperature performance and can even be normally used at a low temperature of -50 DEG C; moreover, the nylon composite has high impact strength toughness, bending strength and rigidity, effectively prolongs the service life of a nylon material and broadens the application scope of the nylon material.

Owner:ANHUI ANLAN MOLD

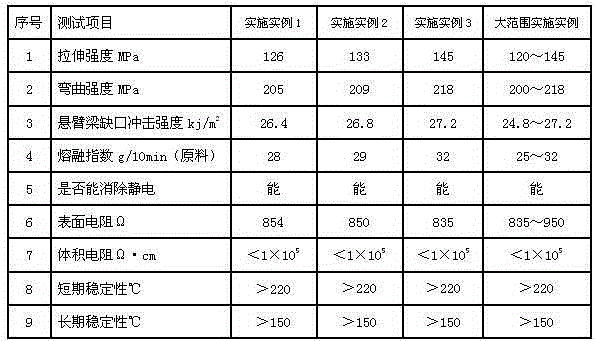

Semi-conductive nylon strap for cable shielding and preparation method thereof

The invention belongs to the technical field of materials and discloses a semi-conductive nylon strap for cable shielding. The semi-conductive nylon strap is prepared from the following raw materials in parts by weight: 40-80 parts of nylon 11 resin, 10-20 parts of nylon 1010 resin, 5-10 parts of nylon 6 resin, 10-20 parts of linear low density polyethylene, 8-16 parts of maleic anhydride grafted polyethylene, 0.6-0.8 part of a coupling agent, 18-25 parts of a filler, 0.4-0.6 parts of an antioxidant, 2-6 parts of a flame retardant, 10-15 parts of a conducting matter, 20-25 parts of reinforcing fibers and 10-18 parts of a surface modifier, wherein the ratio of the nylon 11 resin to the nylon 1010 resin to the nylon 6 resin to the linear low density polyethylene to the maleic anhydride grafted polyethylene is 8:2:1:2:1.6. The semi-conductive nylon strap disclosed by the invention has the beneficial technical effects of high tensile / bending / cantilever notch impact strength, small electric resistance, good high temperature stability, easy processing and the like, and is capable of eliminating static electricity.

Owner:青岛云塑高分子材料科技有限公司

Thermoplastic resin composition excellent in barrier property

InactiveUS7981518B2Improve compatibilityIncrease flexibilityEnvelopes/bags making machinerySynthetic resin layered productsPolymer scienceNylon 12

A thermoplastic resin composition comprising 100 parts by mass of a polyamide resin composition (A) and 0.1 to 10 parts by mass of a carbodiimide compound (B) having two or more carbodiimide groups. The polyamide resin composition (A) contains a polyamide resin (a-1) and nylon 11 and / or nylon 12 (a-2) in an amount of 5 to 95% by mass of the component (a-1) and 95 to 5% by mass of the component (a-2) each based on a total amount of the components (a-1) and (a-2). The polyamide resin (a-1) is constituted by diamine units 70 mol % or more of which are derived from m-xylylenediamine and dicarboxylic acid units 70 mol % or more of which are derived from a C4 to C20 α,ω-linear aliphatic dicarboxylic acid. The thermoplastic resin composition is excellent in barrier property, strength and impact resistance, in particular, barrier property to alcohol-containing fuels, and suitably used as various shaped articles such as fuel containers, tubes and parts.

Owner:MITSUBISHI GAS CHEM CO INC

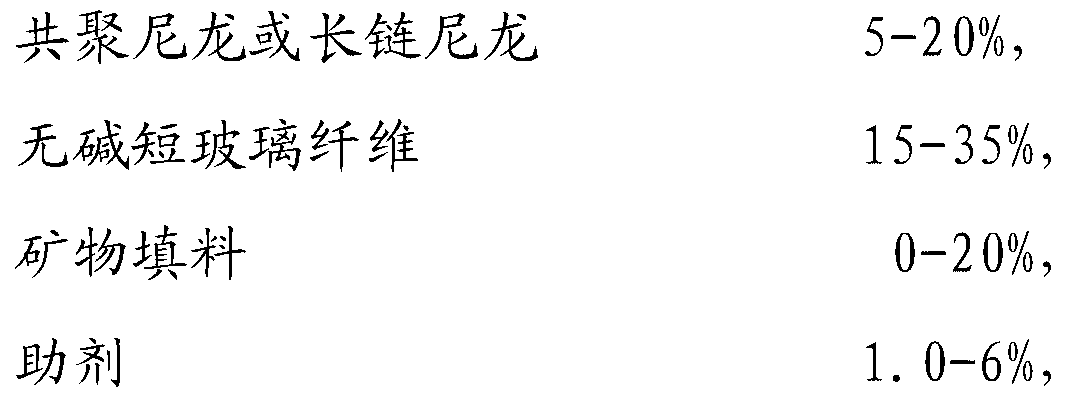

Special nylon 6 composition for automobile engine hood and preparation method thereof

InactiveCN103289372AMaterials are cheap and readily availableImprove impact resistanceAlkali freePolymer science

The invention provides a special nylon 6 composition for an automobile engine hood. The composition contains the following components by weight percent: 19-79% of nylon 6, 5-20% of copolymer nylon or long-chain nylon, 15-35% of alkali-free short glass fiber, 0-20% of mineral filler and 1.0-6% of auxiliaries, wherein the copolymer nylon is a polymer which is prepared through reaction, dehydration and polymerization of two or more monomer units, contains an amide group and is selected from one of or the mixture of more of a nylon6 / 66 copolymer, a nylon 6 / 12 copolymer and a nylon 6 / 10 copolymer; and the long-chain nylon is a polymer which is prepared through polymerization of monomers with carbon contents greater than or equal to 10 in polymer monomer units and other monomer units, contains an amide group and is selected from one of or the mixture of more of a nylon 11, a nylon 12 and a nylon 1010. The invention provides the special nylon 6 composition for the automobile engine hood and a preparation method thereof. The composition has the beneficial effects that the composition has quite high impact resistance and super strength and excellent chemical properties and dimensional stability; and products have smooth and clean surfaces and are cheap.

Owner:辰东意普万新材料(广东)有限公司

Thermoplastic resin composition and method for producing same

Owner:TOYOTA BOSHOKU KK +1

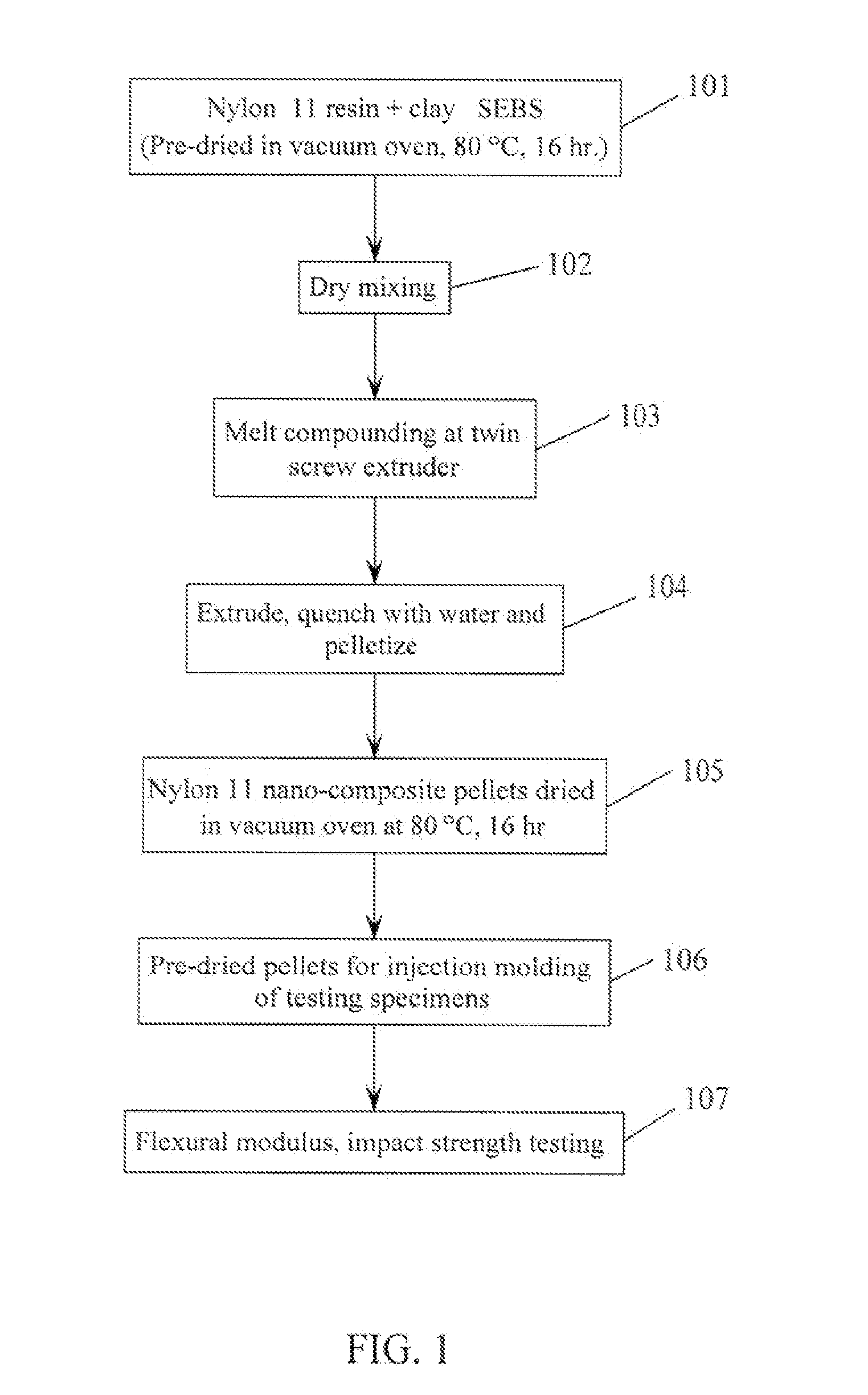

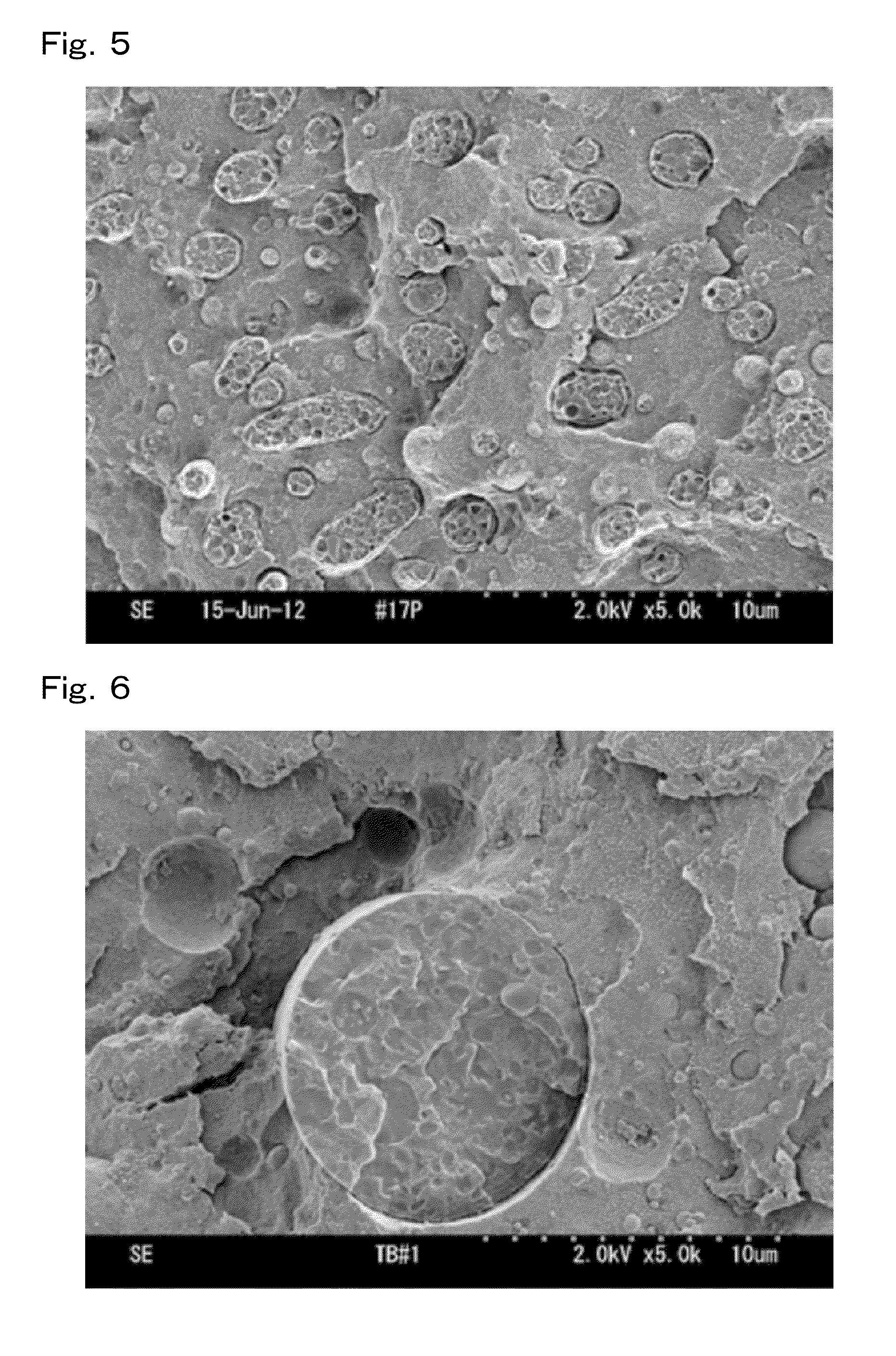

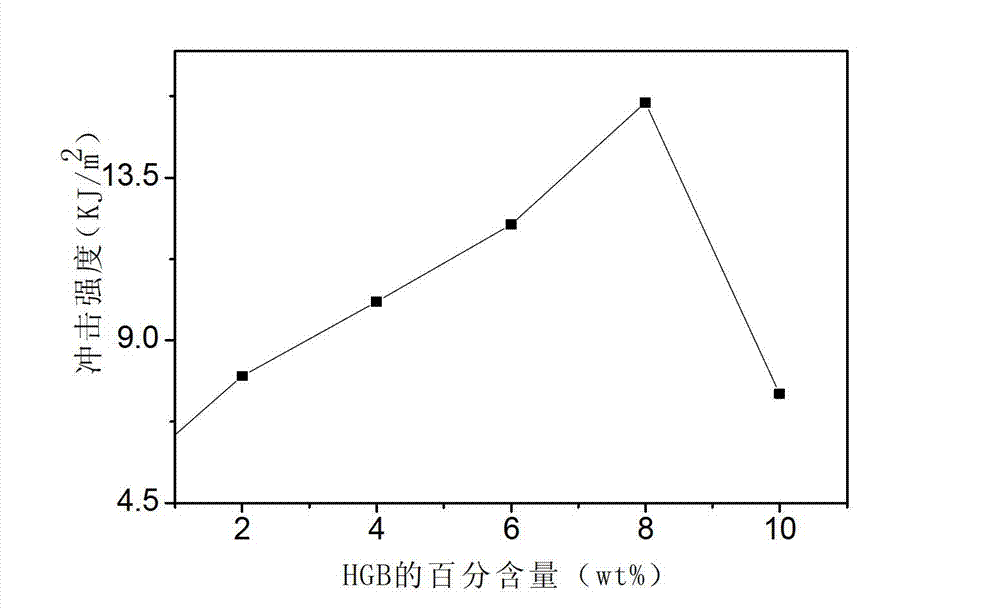

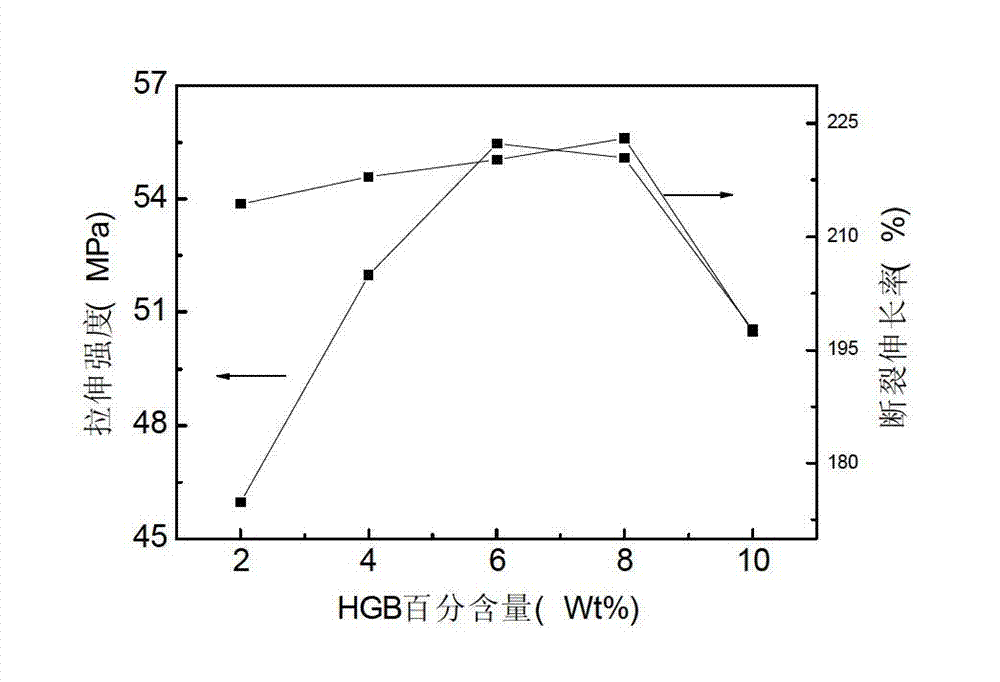

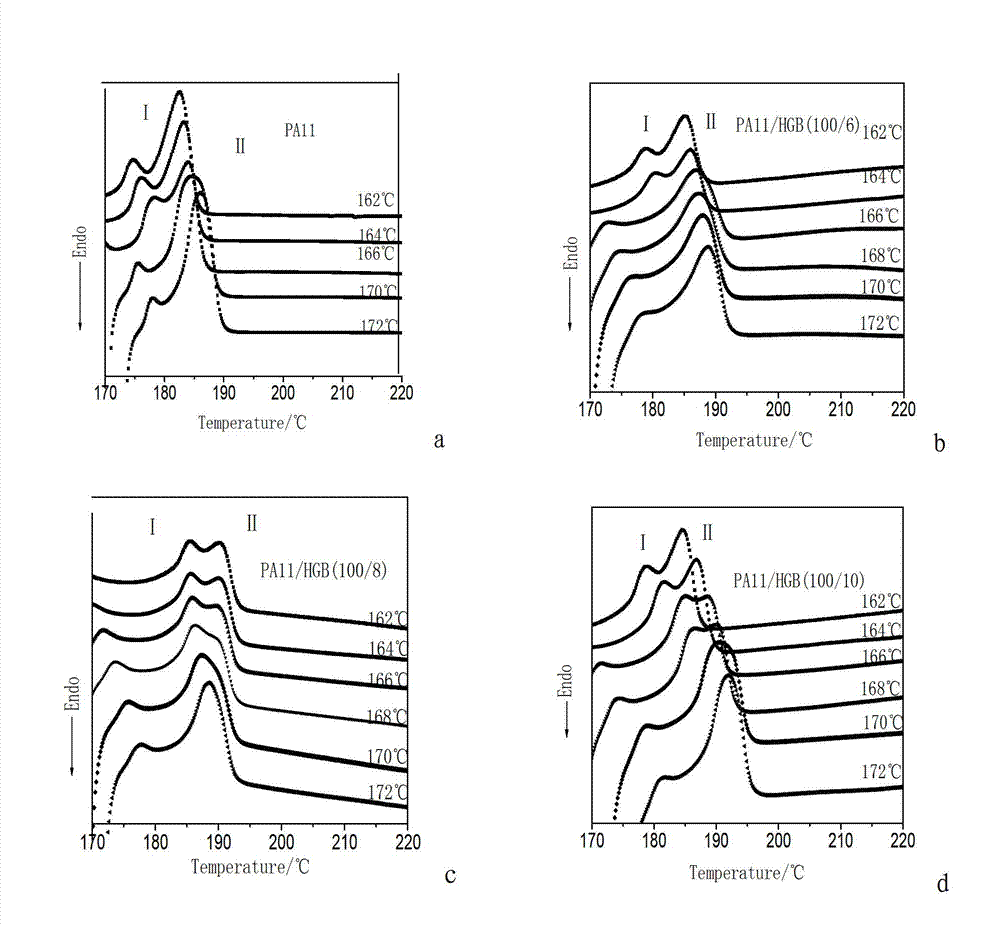

Composite material modified by nylon 11-based hollow glass bead and performance test method

InactiveCN103112097AMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesMolten stateInjection moulding

The invention discloses a preparation method and a test method of a composite material modified by nylon 11-based hollow glass bead. The preparation method comprises the steps of firstly putting nylon 11 and hollow glass beads into an oven at 80 DEG C and 0.09 MPa of the pressure of a vacuum pump to be dried for 12 hours in vacuum; respectively proportioning the nylon 11 and the hollow glass beads according to the required volume required in the formula; preparing materials by an extruder; drying the extruded materials; and injecting the materials to be formed. The test method comprises the steps of filling the nylon 11 with the hollow glass beads to be modified, extruding, pelletizing and preparing the composite material into a standard sample in a molten state by a double-screw extruder, and then testing various kinds of mechanical properties and the crystallization behavior of the sample. By analyzing the results, the influence of the glass beads of different content on the mechanical property and the crystallization behavior of the sample can be achieved, and the nylon 11-based modified composite material with better performance can be prepared.

Owner:ZHONGBEI UNIV

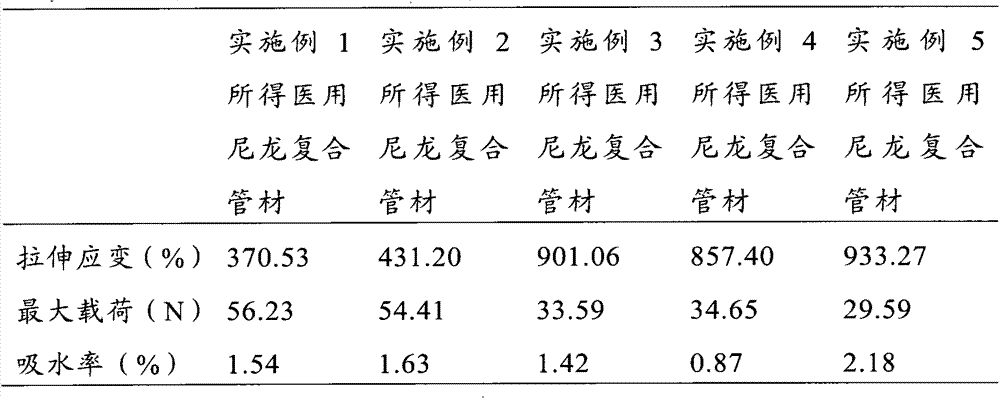

Medical nylon composite pipe and preparation method thereof

The invention discloses a medical nylon composite pipe. The medical nylon composite pipe contains at least one of nylon 6, nylon 66, nylon 610, nylon 1010, nylon 11 and aromatic nylon with a total mass percentage of less than or equal to 50%, and nylon 12 with a mass percentage of greater than or equal to 50%. The invention also discloses a preparation method of the medical nylon composite pipe. The method for preparation of the medical nylon composite pipe does not add any additive, so that the prepared medical nylon composite pipe has no harm to the human body, has good biocompatibility, and can be used in the medical field. Also the novel medical nylon composite pipe has high hardness, low water absorption and good rigidity.

Owner:ACCUPATH MEDICAL JIAXING CO LTD

Process for preparing copolymerized nylon 613 or 1013

A process for preparing copolymer nylon "613" or "1013" includes such steps as dissolving hexadiamine or decanediamine and brazilic acid in alcohol, neutralizing reaction at 40-120 deg.C while stirring for 2-6 hr, educing out salt, filtering, washing with alcohol, drying to obtain their salts, loading them along with molecular weight regulator, trigger and antiageing agent into a polymerizing reactor, reaction at 210-290 deg.C and 0.4-2.5 MPa for 2-10 hr, and vacuum reaction at 0--0.05 MPa for 0.5-2 hr. The resultant products features higher flexibility and dissolving resistance, and low cost.

Owner:BALING PETRO CHEM CO LTD SINOPEC

Polymer nano-modified nylon 11 composite material and preparation method thereof

The invention discloses a polymer nano-modified nylon 11 composite material and a preparation method thereof. The polymer nano-modified nylon 11 composite material comprises the following components in parts by weight: 50-80 parts of nylon 11, 20-30 parts of starch, 20-40 parts of polylactic acid, 5-10 parts of methyl methacrylate, 1-6 parts of maleic anhydride, 1-3 parts of oxalic acid, 1-4 parts of triphenyl phosphite, 2-8 parts of nanosilicon dioxide, 2-6 parts of nano calcium carbonate, 0.1-0.8 part of stearate, 0.1-0.6 part of borate, 1-5 parts of trimethyl chloro propane trimethyl acrylate and 1-3 parts of an antioxidant. The preparation process is simple, feasible, and easy to process; and the prepared polymer nano-modified nylon 11 composite material has the advantages of a polymer, a nano material and nylon 11, and is good in low-temperature toughness, good in barrier property, low in cost and suitable for the industries such as automobiles, aviation and electrons.

Owner:SUZHOU POLYMER NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com