Semi-conductive nylon strap for cable shielding and preparation method thereof

A cable shielding and semi-conductive technology, which is applied in the field of nylon materials, can solve the problems of insulation layer or sheath breakdown in cables, increase hundreds of yuan, and increase cable costs, etc., and achieves easy-to-master manufacturing methods, simple processes, and reduced costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

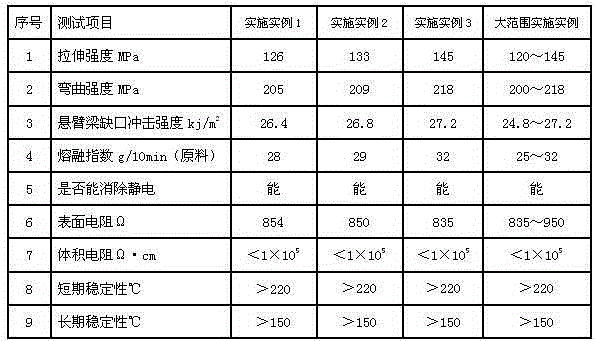

Examples

Embodiment 1

[0068] A semi-conductive nylon tape for cable shielding, characterized in that it is composed of the following raw materials in parts by weight:

[0069] Nylon 11 resin: 40 parts;

[0070] Nylon 1010 resin: 10 parts;

[0071] Nylon 6 resin: 5 parts;

[0072] Linear low density polyethylene: 10 parts;

[0073] Maleic anhydride grafted polyethylene: 8 parts;

[0074] Coupling agent: 0.6 parts;

[0075] Filling: 18 parts;

[0076] Antioxidant: 0.4 parts;

[0077] Flame retardant: 2 parts;

[0078] Conductive material: 10 parts;

[0079] Reinforcing fiber: 20 parts;

[0080] Surface modifier: 10 parts.

Embodiment 2

[0082] A semi-conductive nylon tape for cable shielding, characterized in that it is composed of the following raw materials in parts by weight:

[0083] Nylon 11 resin: 80 parts;

[0084] Nylon 1010 resin: 20 parts;

[0085] Nylon 6 resin: 10 parts;

[0086] Linear low density polyethylene: 20 parts;

[0087] Maleic anhydride grafted polyethylene: 16 parts;

[0088] Coupling agent: 0.8 parts;

[0089] Filling: 25 parts;

[0090] Antioxidant: 0.6 parts;

[0091] Flame retardant: 6 parts;

[0092] Conductor: 15 parts;

[0093] Reinforcing fiber: 25 parts;

[0094] Surface modifier: 18 parts.

Embodiment 3

[0096] A semi-conductive nylon tape for cable shielding, characterized in that it is composed of the following raw materials in parts by weight:

[0097] Nylon 11 resin: 60 parts;

[0098] Nylon 1010 resin: 15 parts;

[0099] Nylon 6 resin: 7.5 parts;

[0100] Linear low density polyethylene: 15 parts;

[0101] Maleic anhydride grafted polyethylene: 12 parts;

[0102] Coupling agent: 0.7 parts;

[0103] Filler: 21.5 parts;

[0104] Antioxidant: 0.5 part;

[0105] Flame retardant: 4 parts;

[0106] Conductive material: 12.5 parts;

[0107] Reinforcing fiber: 22.5 parts;

[0108] Surface modifier: 14 parts.

[0109] After repeated tests, the applicant found that as long as the material meets the following formula, the purpose of the invention can be achieved: a semi-conductive nylon tape for cable shielding, which is characterized in that it is composed of the following raw materials in parts by weight:

[0110] Nylon 11 resin: 40-80 parts;

[0111] Nylon 1010 resin: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com