Safety outerwear with fire resistant mesh

a technology of fire-resistant mesh and outerwear, applied in the field of safety clothing, can solve the problems of untreated natural fabrics burning for a long time, untreated natural fabrics may continue to burn until the fabric is completely consumed, and severe and/or fatal burn injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

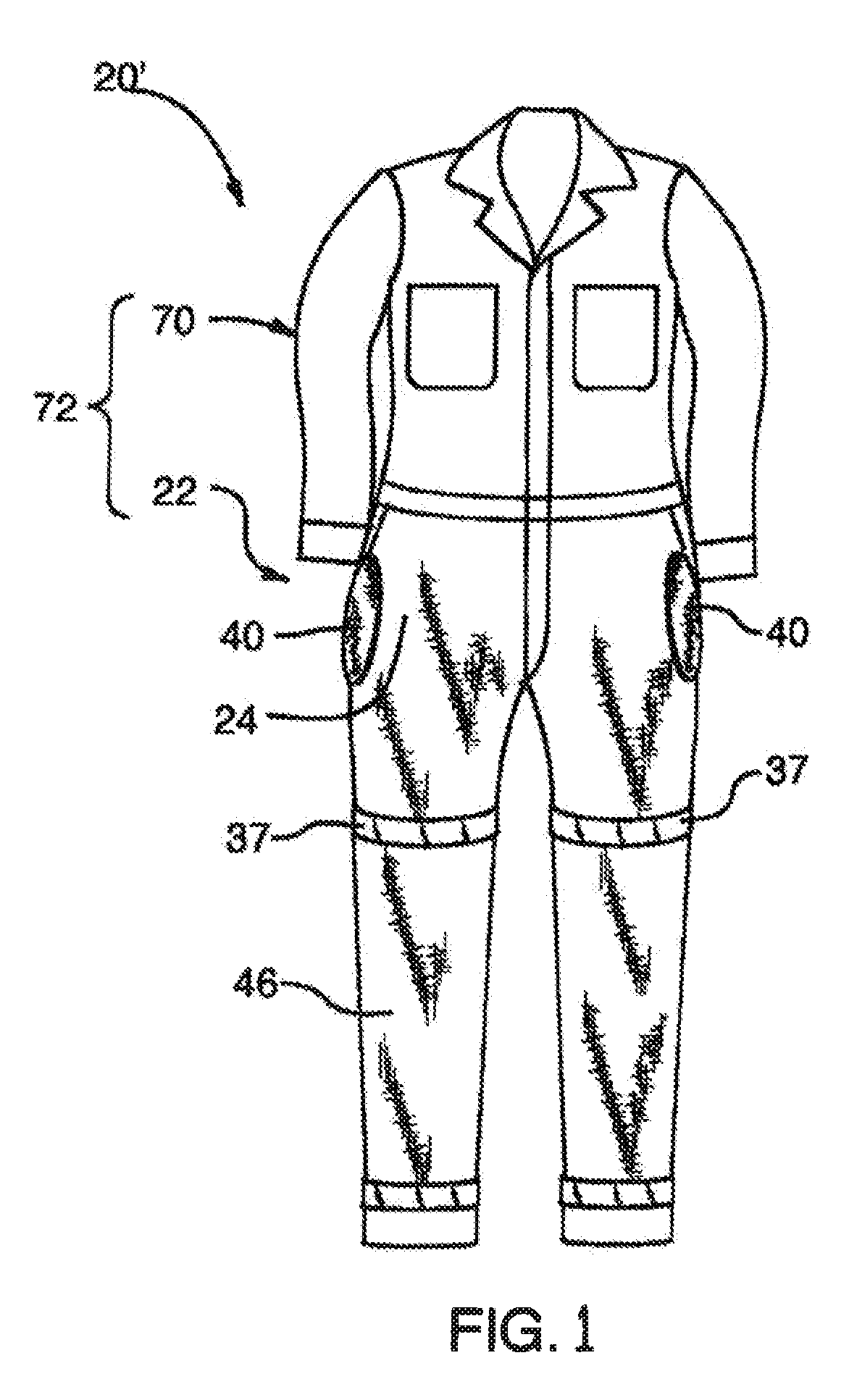

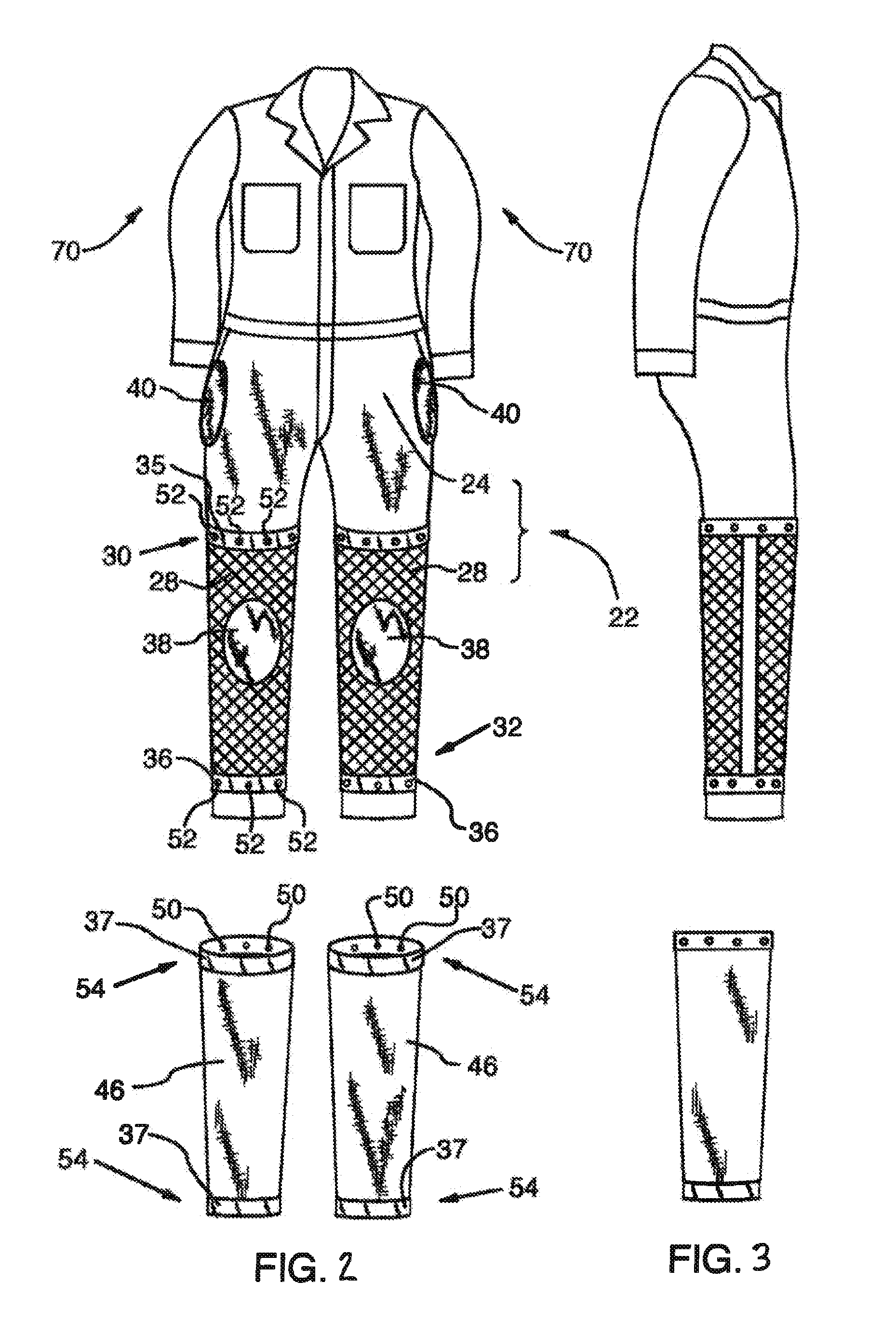

[0101] Referring now to FIG. 5 of the drawings there is shown an article of safety clothing according to a first alternate embodiment of the present invention and designated with general reference numeral 20.

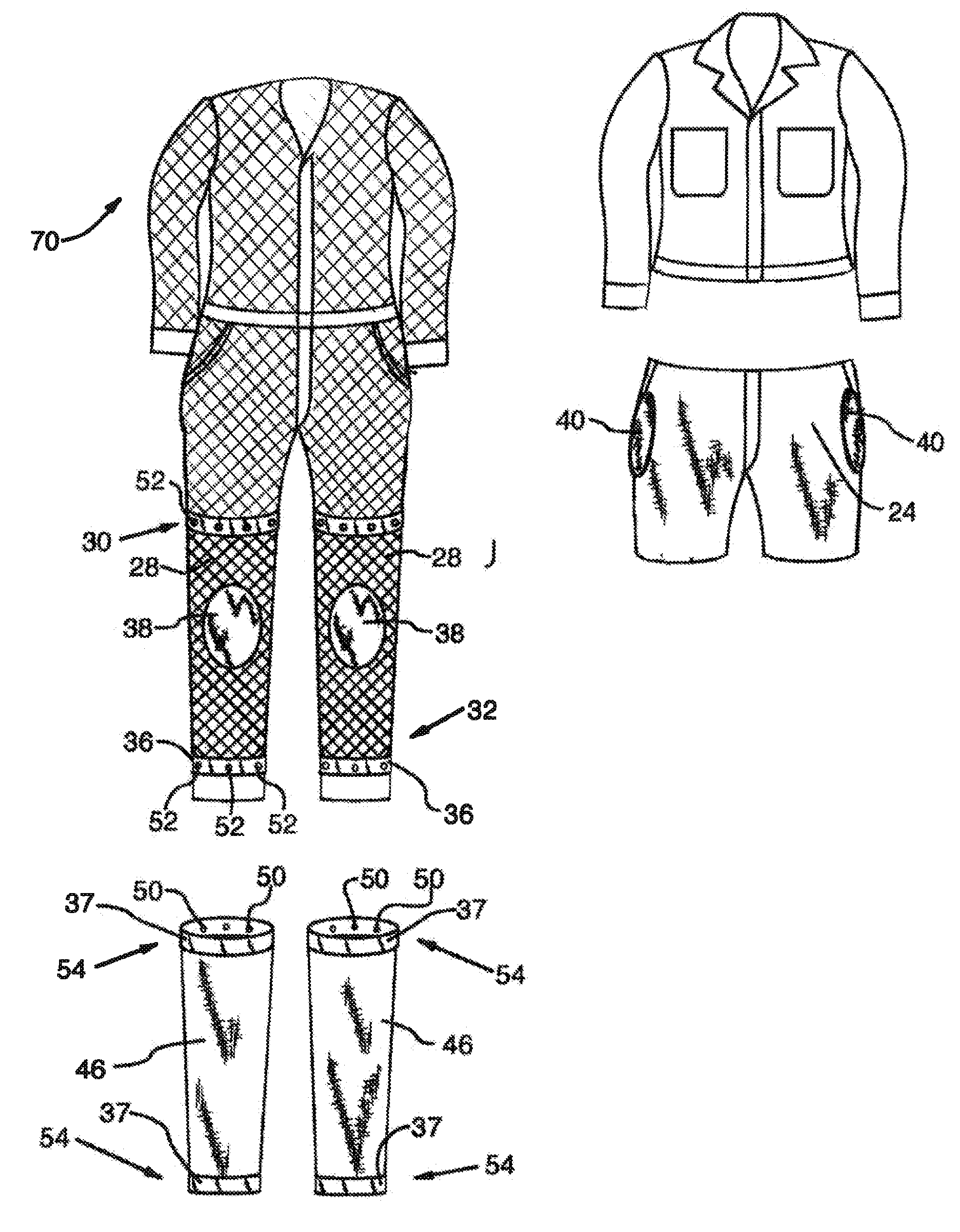

[0102] As best indicated in FIG. 7, the article 20 comprises a main body piece 22. In the preferred embodiment illustrated, the main body piece 22 takes the form of a pair of trousers adapted to be worn as an outer layer of clothing. The trousers or main body piece 22 include a trunks part 24 which is also adapted to be worn as an outer layer of clothing, and a pair of tubular leg parts 28 (hereinafter, alternately referred to as pant leg parts). The trunks part 24 is adapted to receive in encompassing relation the lower region of the torso of a wearer in use and has apertures, defined in dotted outline in FIG. 7 and designated with general reference numerals 26, trough which the legs of said wearer protrude in use. The tubular pant leg parts 28 are each adapted to receive ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com