Method for detecting solid strength of grouting material for grouting connection of rebar sleeve and method for detecting grouting material construction quality

A technology of grouting connection and steel bar sleeve, applied in the direction of applying stable tension/pressure to test material strength, measuring device, strength characteristics, etc., can solve the problems that the core drilling method is not feasible and cannot be used to detect the strength of grouting materials, etc. To achieve the effect of accurate and fast detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Preferred embodiments of the present invention will be described below with reference to the drawings. It should be noted that the terms "upper", "lower", "front", "rear", "left", "right" and similar expressions used herein are for the purpose of illustration only, not limitation.

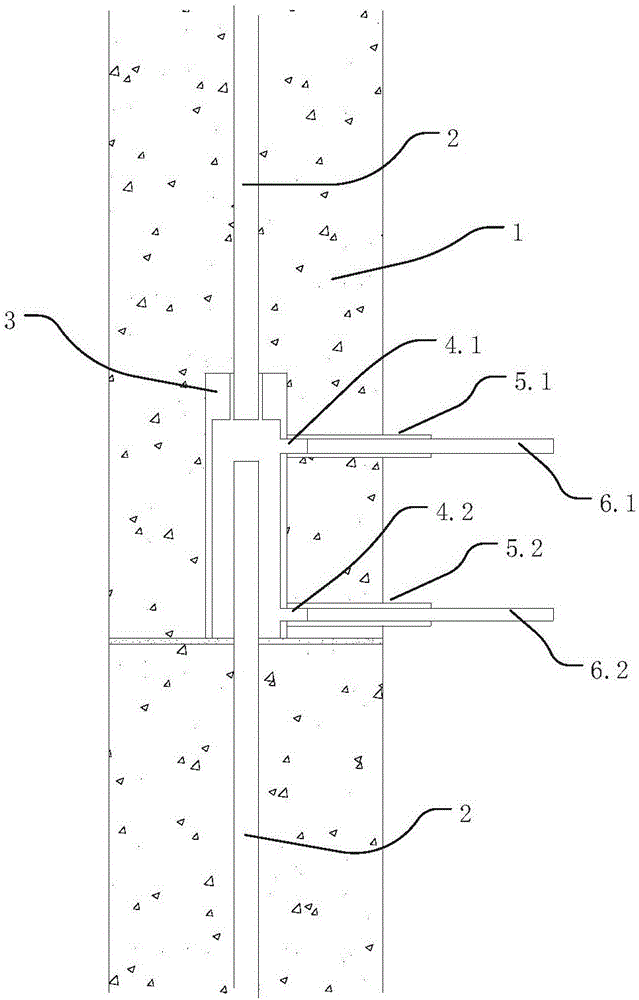

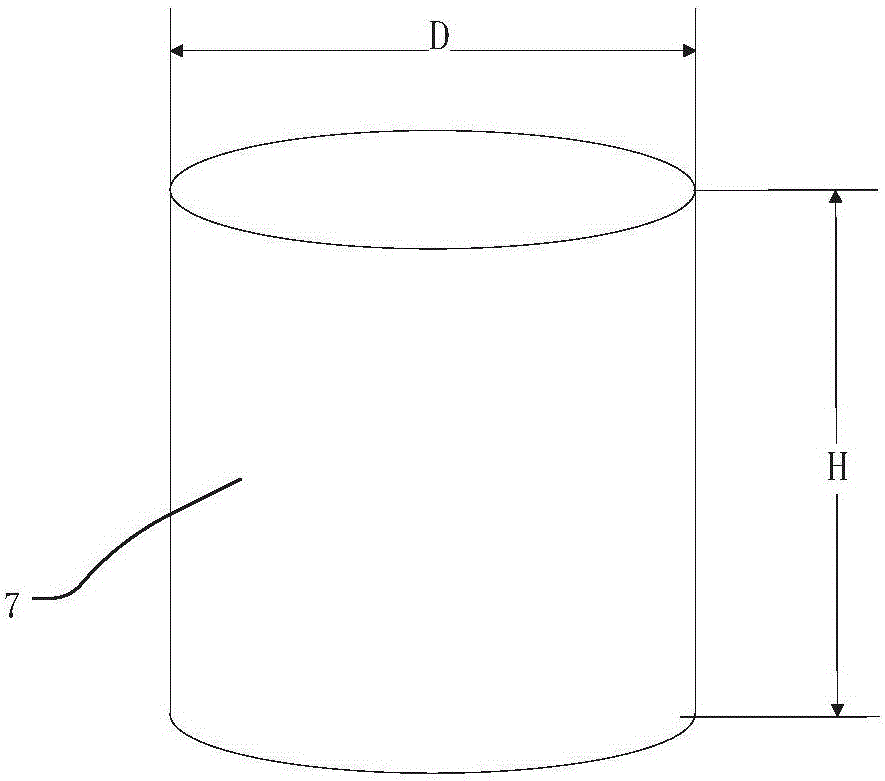

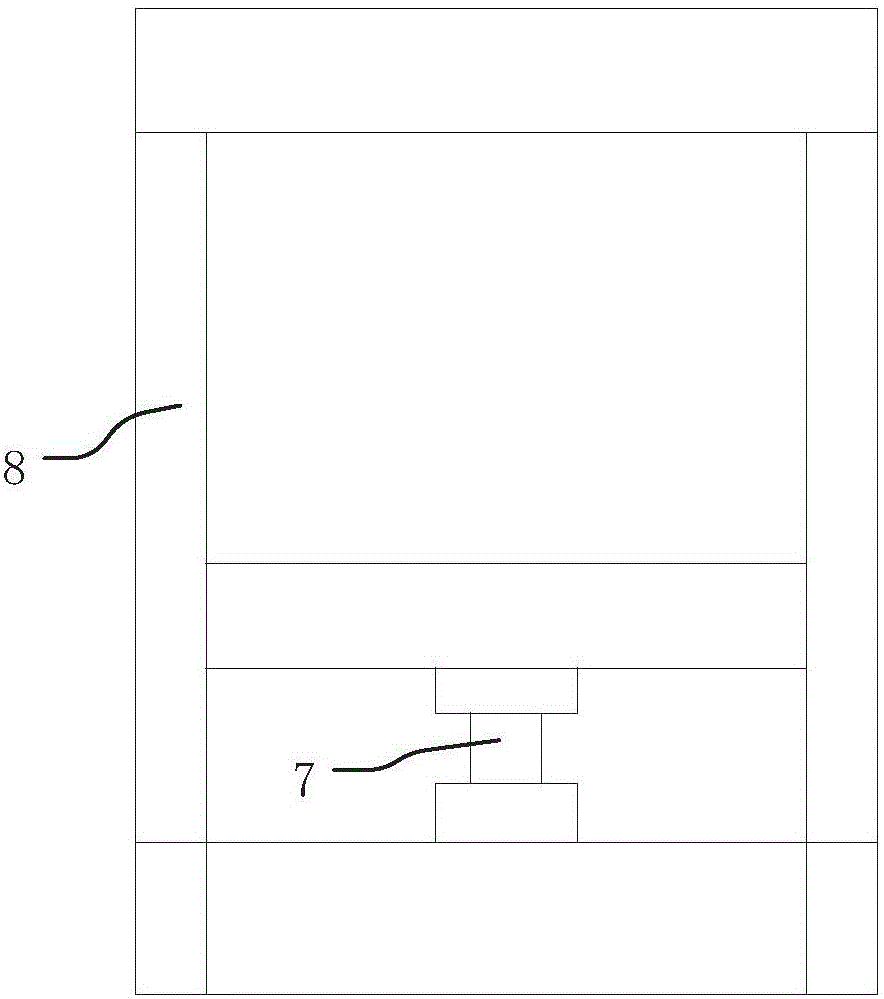

[0039] Figure 1-4 It schematically shows a method for detecting the solid strength of grouting material in a prefabricated concrete structure according to the present invention.

[0040] in the attached figure 1 A prefabricated concrete structure is shown in , wherein the concrete structure includes shaped concrete 1 and steel bars 2 wrapped in the concrete. In practice, concrete 1 includes concrete that needs to be set up and down separately. Among them in figure 1A grouting sleeve 3 is arranged in the upper concrete 1 , and the steel bar 2 in the lower concrete 1 is inserted into the inner cavity of the grouting sleeve 3 . The bottom of the grouting sleeve 3 is provided with a grouti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com