Gas appliance, gas valve and control method of gas valve

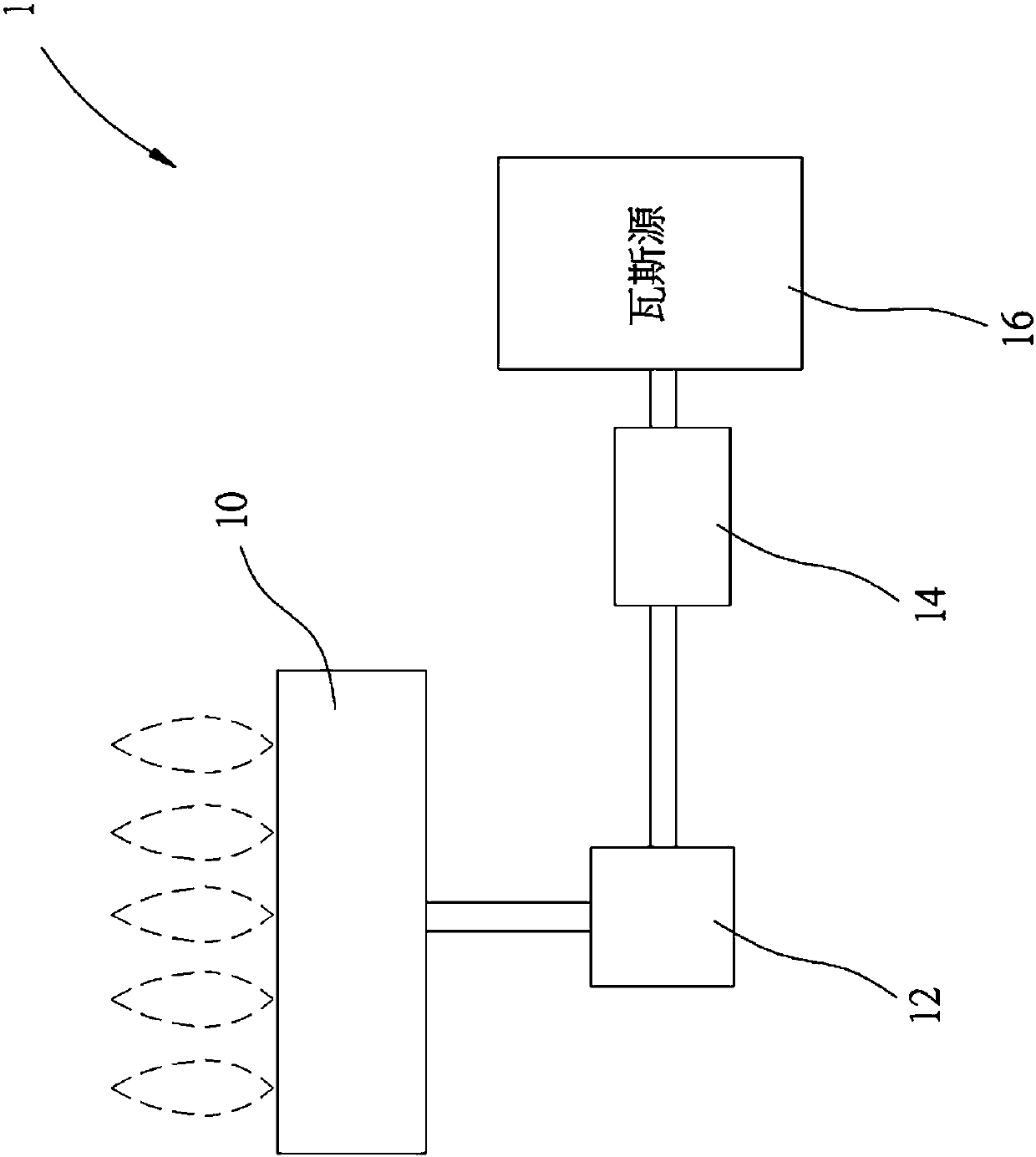

A gas and appliance technology, applied in the field of gas appliances, gas valves and their control, can solve the problems of unstable gas flow, affecting the combustion efficiency of the burner 10, unstable gas pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

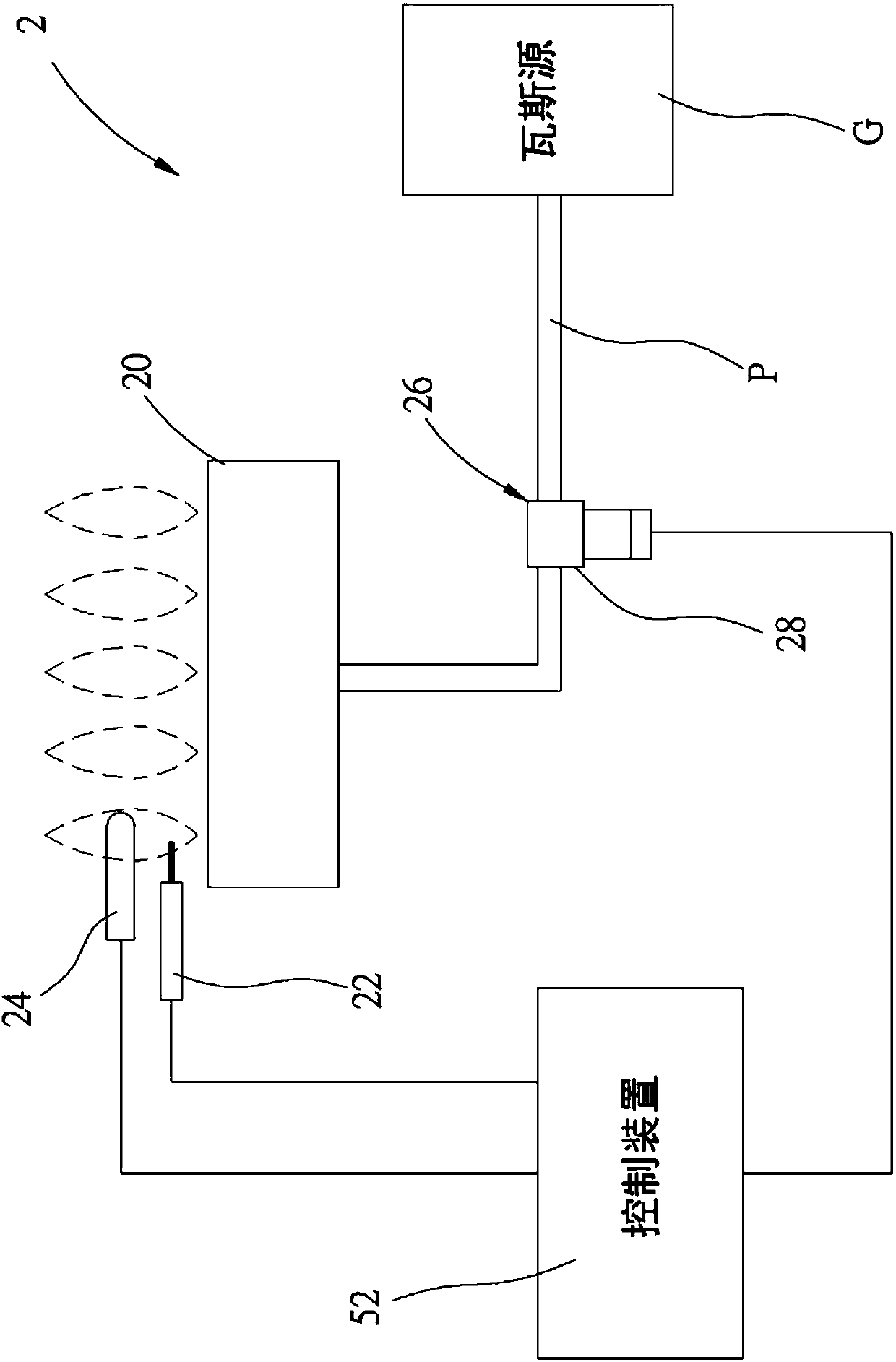

[0056] In order to illustrate the present invention more clearly, preferred embodiments are given and detailed descriptions are as follows in conjunction with the accompanying drawings. Please refer to Figure 2 to Figure 5 Shown is the gas appliance 2 of the first preferred embodiment of the present invention, including a burner 20, an igniter 22, a flame detection element 24, a gas valve 26 and a control device 52, the gas appliance 2 in this embodiment It can be any gas heating device such as gas stove, fireplace, water heater, etc.

[0057] The burner 20 is used to burn gas to generate flame. The igniter 22 is located beside the burner 20 , and the igniter 22 is controlled to generate a spark relative to the burner 20 to ignite the gas output from the burner 20 . The flame detection element 24 is located beside the burner 20 for detecting flames, and the flame detection element 24 can be a thermocouple or a flame sensing needle.

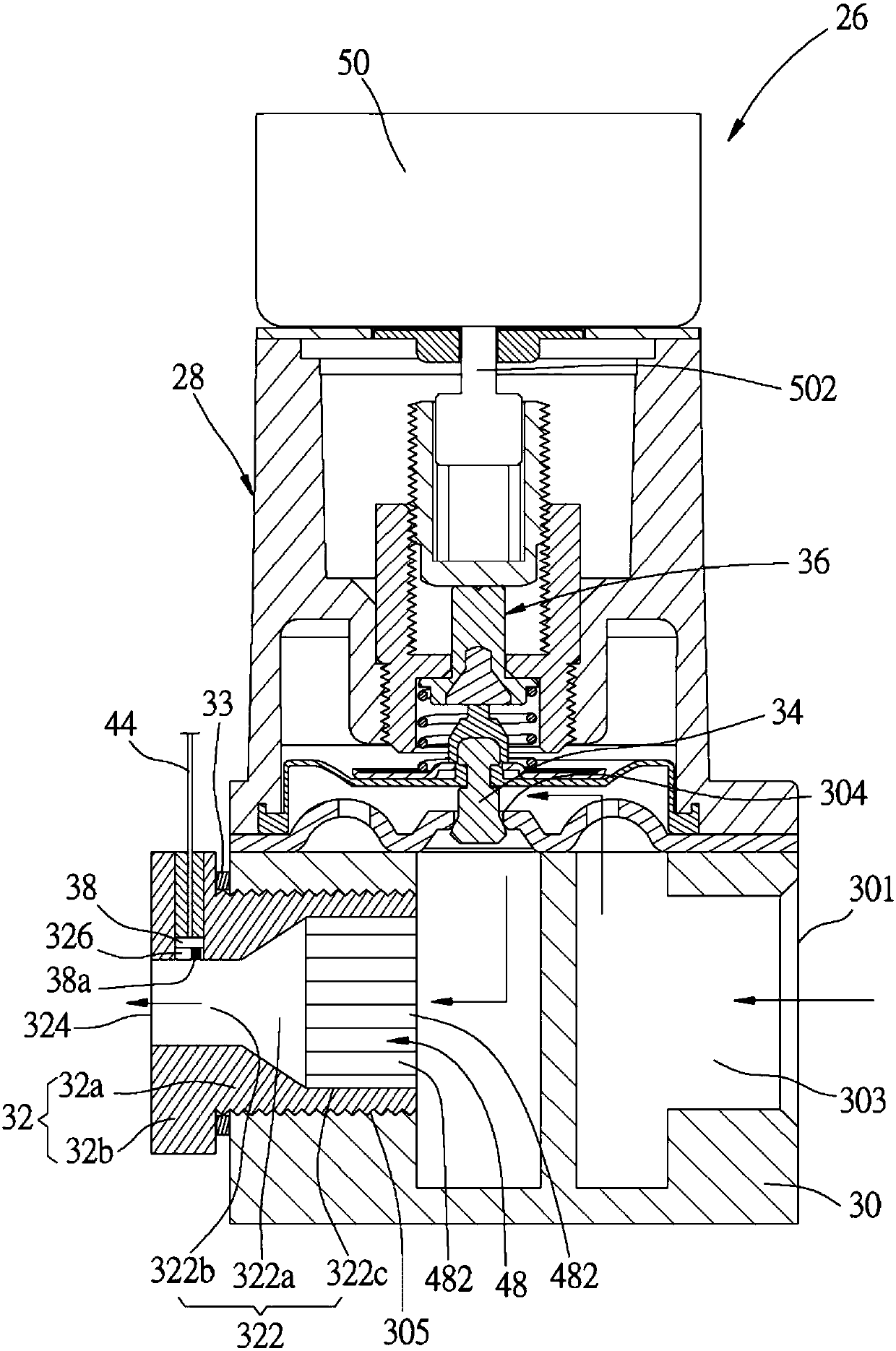

[0058]The gas valve 26 is arranged on a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com