Vehicle road load emulation method

A simulation method and road technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as inability to obtain road load data, inability to perform fatigue analysis, and inability to perform physical tests.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0100] Please refer to the accompanying drawings for a further description of the present invention.

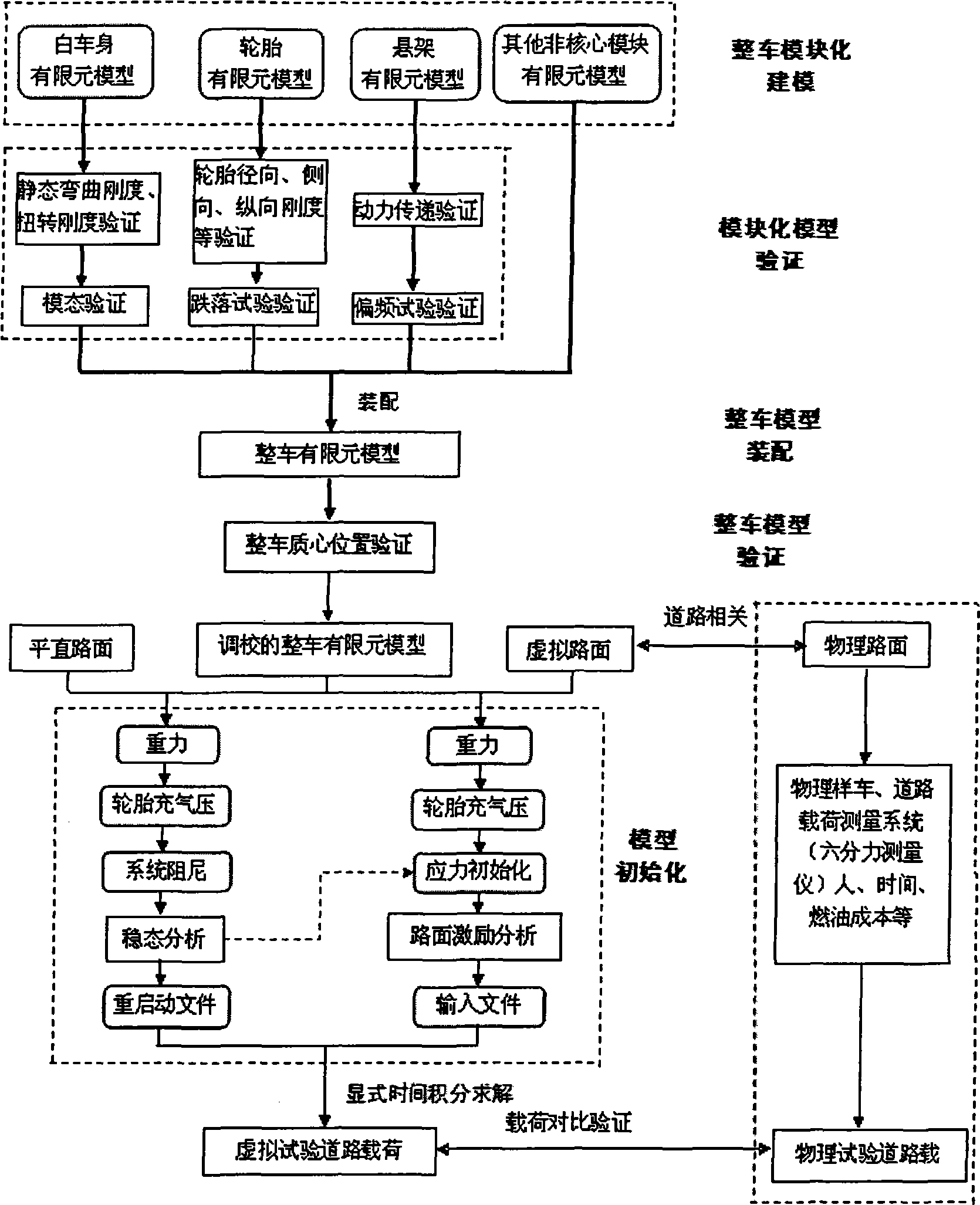

[0101] Such as figure 1 As shown, the present invention provides a kind of simulation method of vehicle road load, and this simulation method comprises the following steps:

[0102] 1) Modular modeling of the whole vehicle;

[0103] ①Establish finite element models of body-in-white and other non-core modules;

[0104] Body-in-white modules include bodyshells, doors, hoods and other body panels;

[0105] Non-core modules include steering system, transmission system, brake system, instrument panel, seat, exhaust pipe;

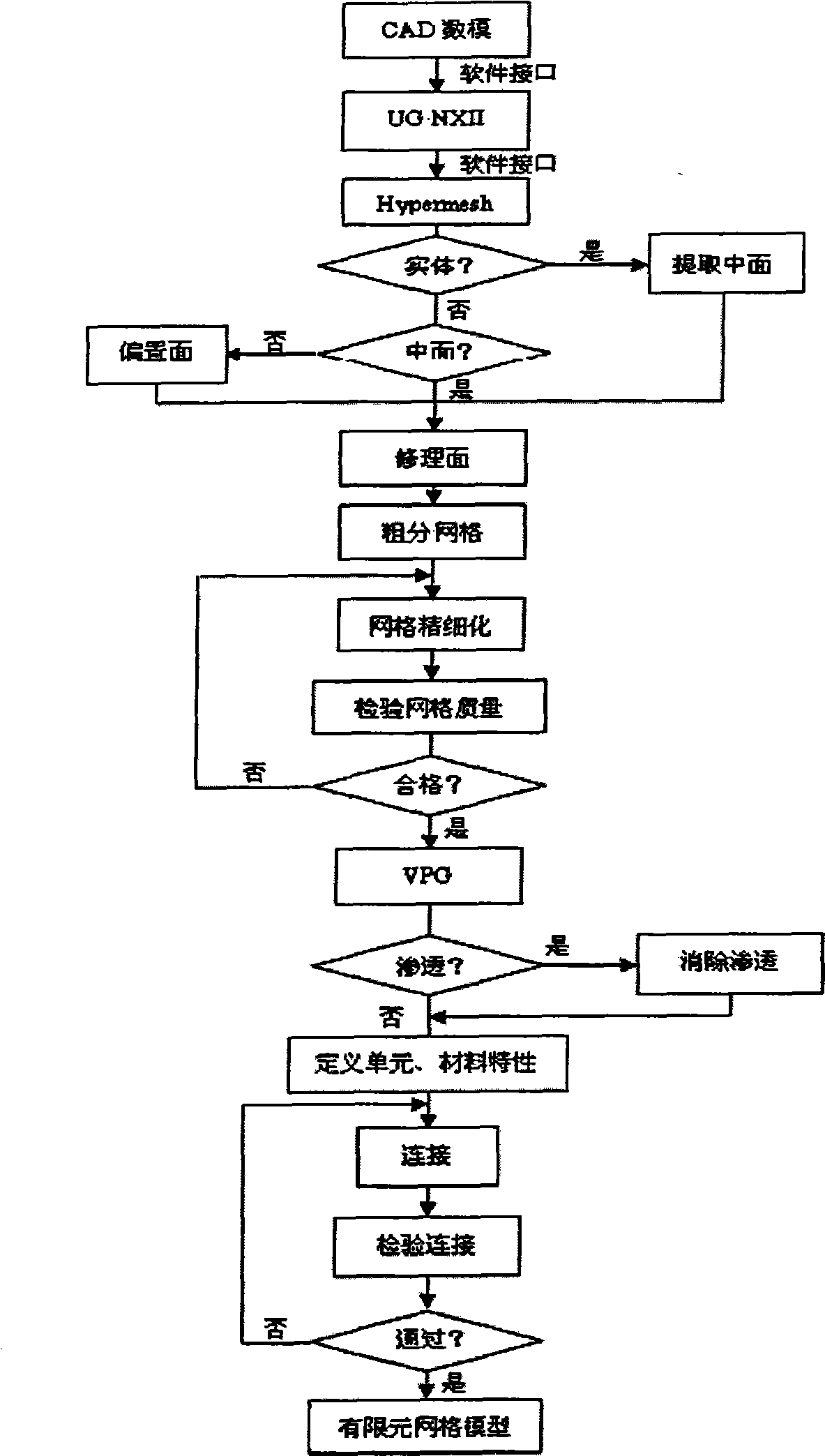

[0106] The establishment of the finite element model of the body in white and other non-core modules includes grid division, such as figure 2 As shown, element property selection and material property assignment.

[0107] After the grid division is completed, the quality of the grid division is evaluated according to the evaluation indicators of each param...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com