Fluid product service life testing device and testing method

A technology of life test equipment and fluid products, which is applied in the direction of measuring equipment, testing wear resistance, instruments, etc., can solve the problems of not testing the life of high-pressure manifolds, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

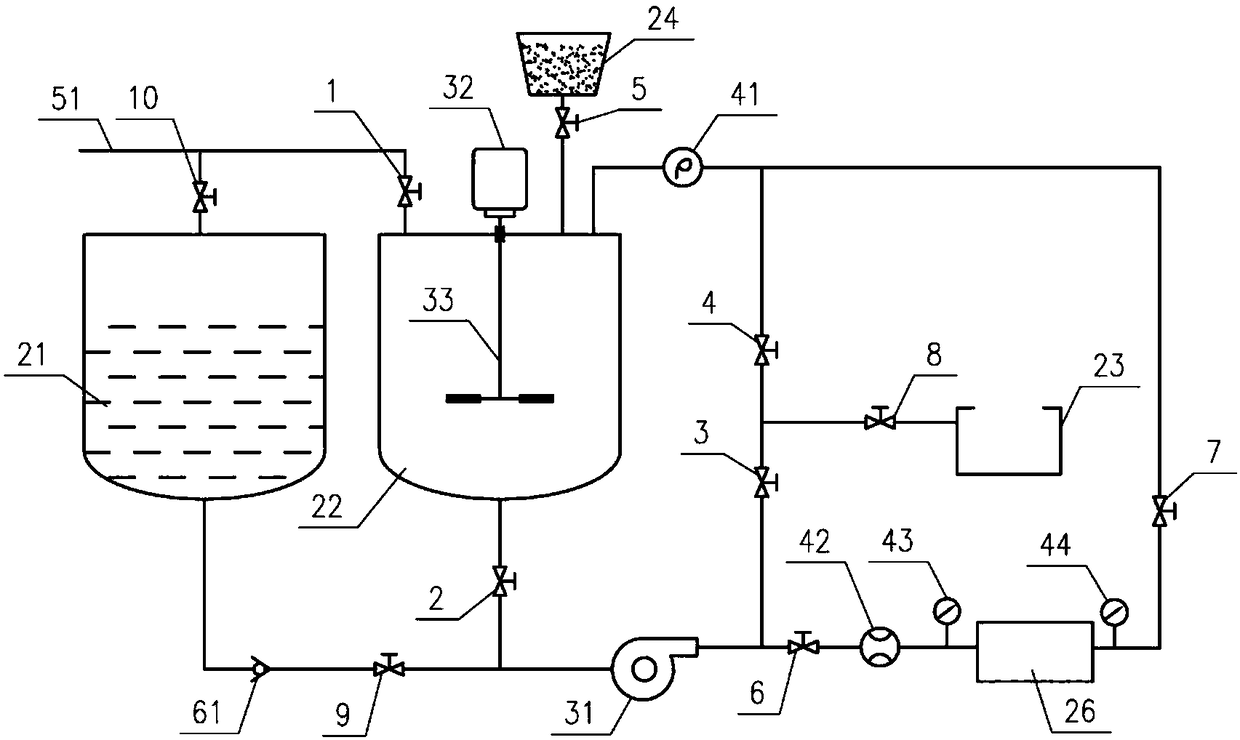

[0031] Example: as attached figure 1 As shown, a fluid product life test device includes a fluid generating device, a fluid product testing area 26 and a cleaning device, a fluid circulation pipeline is formed between the fluid generating device and the fluid product testing area 26, and the fluid flows from the fluid generating device Continue to flow back to the fluid generating device after arriving at the fluid product test area 26, the cleaning device is communicated with the fluid circulation pipeline, and after the cleaning device communicates with the fluid product test area 26, it is communicated with the fluid generating device through the fluid circulation pipeline. The device is connected with a sediment recovery device, which includes a grit chamber 23, and a sediment recovery pipeline is arranged between the sediment recovery device and the fluid generating device.

[0032] The cleaning device includes a clean water tank 21, an external water source enters the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com