No-phosphate corrosion and scale inhibitor and its application

A phosphorus-free corrosion and scale inhibitor technology, applied in descaling and water softening, water/sludge/sewage treatment, chemical instruments and methods, etc. Achieve the effect of avoiding eutrophication, inhibiting anode corrosion, and enhancing polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A non-phosphorus corrosion and scale inhibitor, which is mixed from the following raw materials: 1) polyaspartic acid, 2) polymaleic anhydride, 3) acrylic acid / 2-acrylamide-2-methylpropenesulfonic acid Copolymer (being the existing raw material), 3) zinc salt, 4) natural organic macromolecule, 5) molybdate, 6) other components, the mass percentages of each raw material are:

[0035] Polyaspartic Acid 10%,

[0036] Polymaleic anhydride 30%,

[0037] Acrylic acid / 2-acrylamide-2-methylpropenesulfonic acid copolymer 15%,

[0038] Zinc salt 5%,

[0039] Natural organic polymer 12%,

[0040] Molybdate 8%,

[0041] Other ingredients 20%;

[0042] The other ingredients are sodium polyacrylate; the zinc salt is zinc chloride; the natural organic polymer is sodium gluconate; and the molybdate is potassium molybdate.

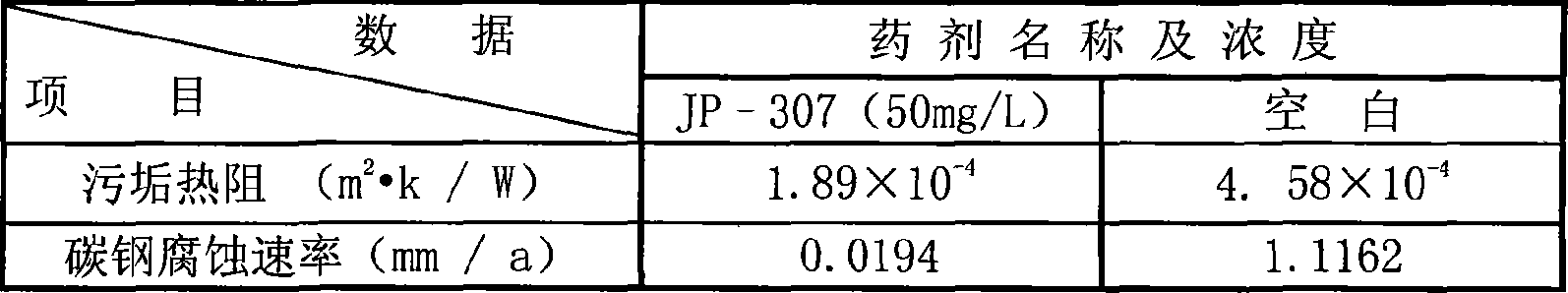

[0043]The above-mentioned non-phosphorus corrosion and scale inhibitor is applied to the circulating cooling water, and 30 mg of the non-phosphorus corrosion ...

Embodiment 2

[0045] A non-phosphorus corrosion and scale inhibitor, which is mixed from the following raw materials: 1) polyaspartic acid, 2) polymaleic anhydride, 3) acrylic acid / 2-acrylamide-2-methylpropenesulfonic acid Copolymer, 3) zinc salt, 4) natural organic polymer, 5) molybdate, 6) other components, the mass percentage of each raw material is:

[0046] Polyaspartic Acid 20%,

[0047] Polymaleic anhydride 20%,

[0048] Acrylic acid / 2-acrylamide-2-methylpropenesulfonic acid copolymer 20%,

[0049] Zinc salt 5%,

[0050] Natural organic polymer 10%,

[0051] Molybdate 5%,

[0052] Other ingredients 20%;

[0053] The other components are acrylic acid-hydroxypropyl acrylate copolymer; the zinc salt is zinc chloride; the natural organic polymer is sodium gluconate; and the molybdate is potassium molybdate.

[0054] The above-mentioned non-phosphorus corrosion and scale inhibitor is applied to the circulating cooling water, and 35 mg of the non-phosphorus corrosion and scale inhibi...

Embodiment 3

[0056] A non-phosphorus corrosion and scale inhibitor, which is mixed from the following raw materials: 1) polyaspartic acid, 2) polymaleic anhydride, 3) acrylic acid / 2-acrylamide-2-methylpropenesulfonic acid Copolymer, 3) zinc salt, 4) natural organic polymer, 5) molybdate, 6) other components, the mass percentage of each raw material is:

[0057] Polyaspartic Acid 20%,

[0058] Polymaleic anhydride 30%,

[0059] Acrylic acid / 2-acrylamide-2-methylpropenesulfonic acid copolymer 20%,

[0060] Zinc salt 4%,

[0061] Natural organic polymer 7%,

[0062] Molybdate 6%,

[0063] other ingredients 13%;

[0064] The other components are borates, and the borates are potassium borates; the zinc salts are zinc sulfate; the natural organic polymers are lignin derivatives; the molybdates are molybdenum Sodium acid.

[0065] The above-mentioned non-phosphorus corrosion and scale inhibitor is applied to the circulating cooling water, and 40 mg of the non-phosphorus corrosion and scale...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com