A pickling solid corrosion inhibitor for power plant boilers

A boiler acid and corrosion inhibitor technology, applied in the field of corrosion inhibitors, can solve the problems of corrosion, hidden dangers, pitting corrosion on the surface of carbon steel metal, etc., and achieve the effects of inhibiting penetration, slowing corrosion, and avoiding hydrogen bubbling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the embodiments of the present invention. The description of the embodiments is only to facilitate the understanding and application of the present invention, but not to limit the protection of the present invention.

[0029] Preparation of solid corrosion inhibitors for pickling of power plant boilers, including 14 parts of urotropine, 7 parts of ammonium thiocyanate, 0.8 parts of promethazine, 0.2 parts of benzotriazole, 3 parts of stannous chloride, and 3 parts of sodium thiosulfate , 2 parts of thiourea.

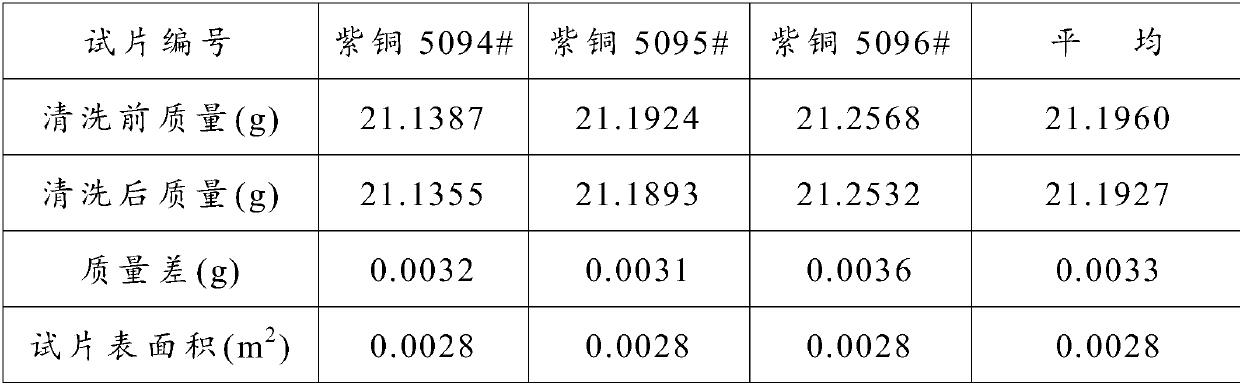

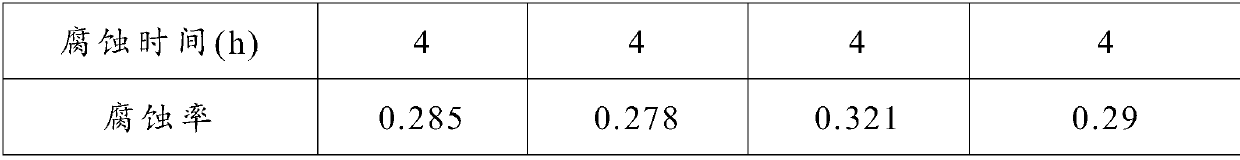

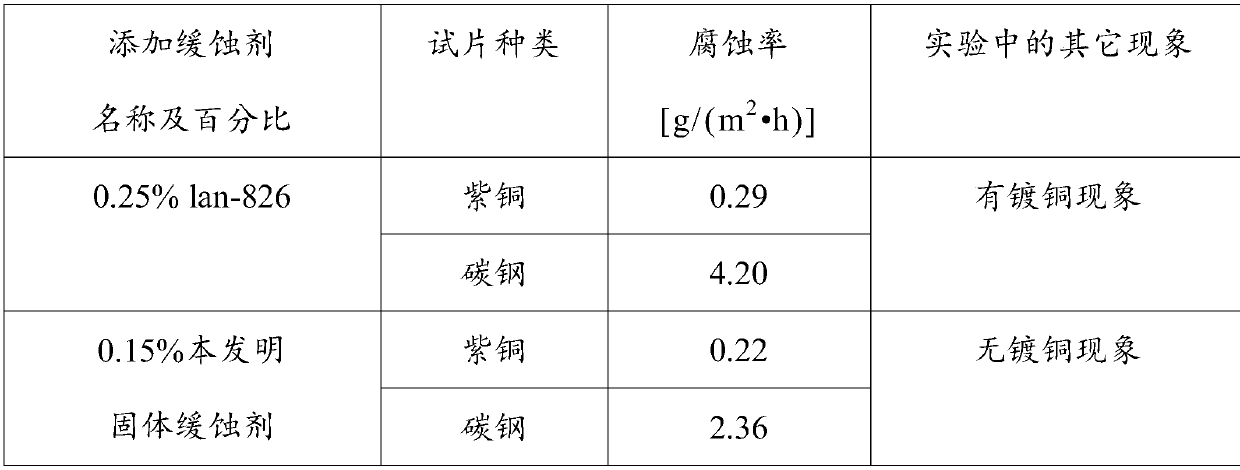

[0030] The following test experiments are all carried out by adding the above power plant boiler pickling solid corrosion inhibitor at a mass concentration of 0.15%. As a comparison, the lan-826 corrosion inhibitor with a mass fraction of 0.25% is selected as a comparative example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com