Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

165results about How to "Temperature difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

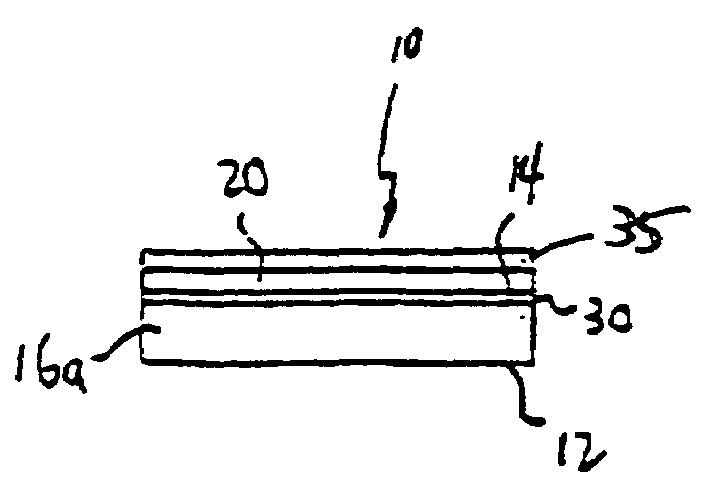

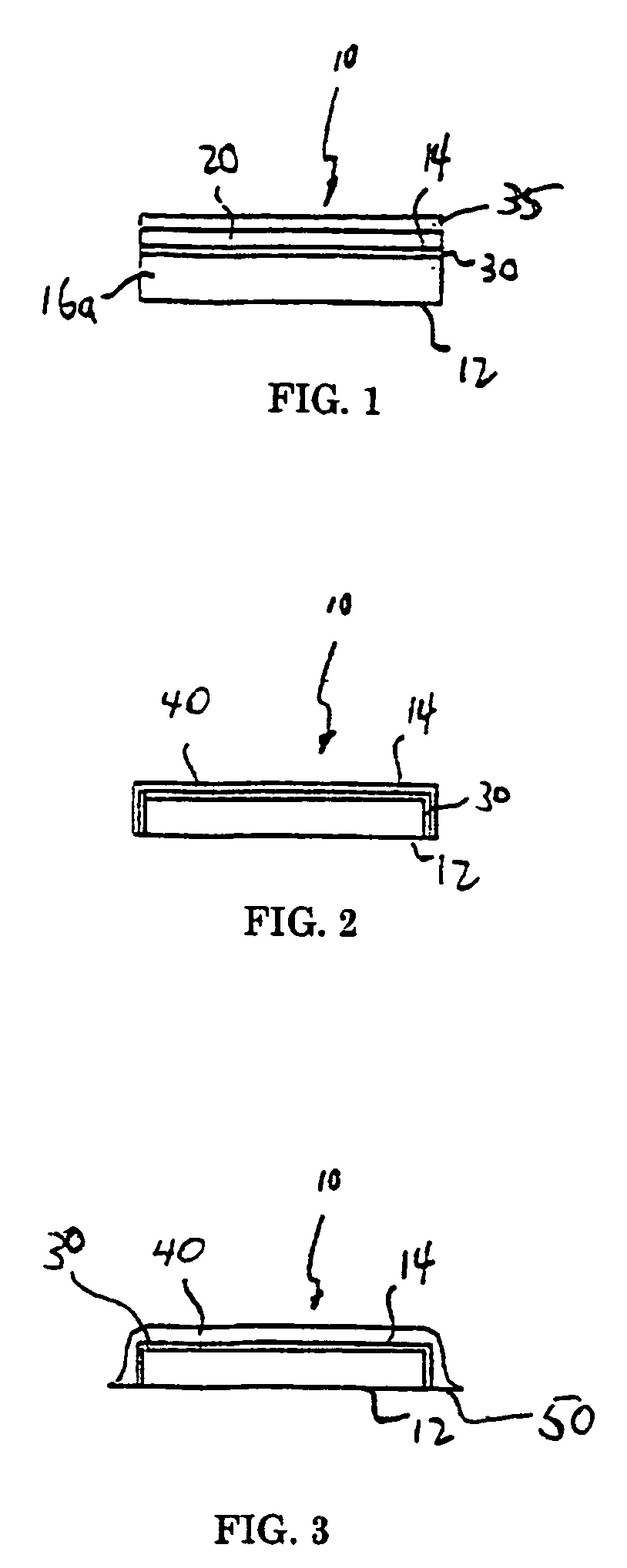

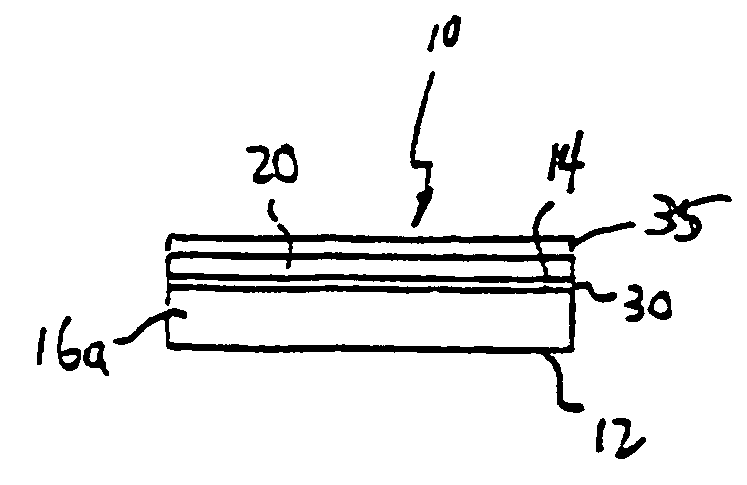

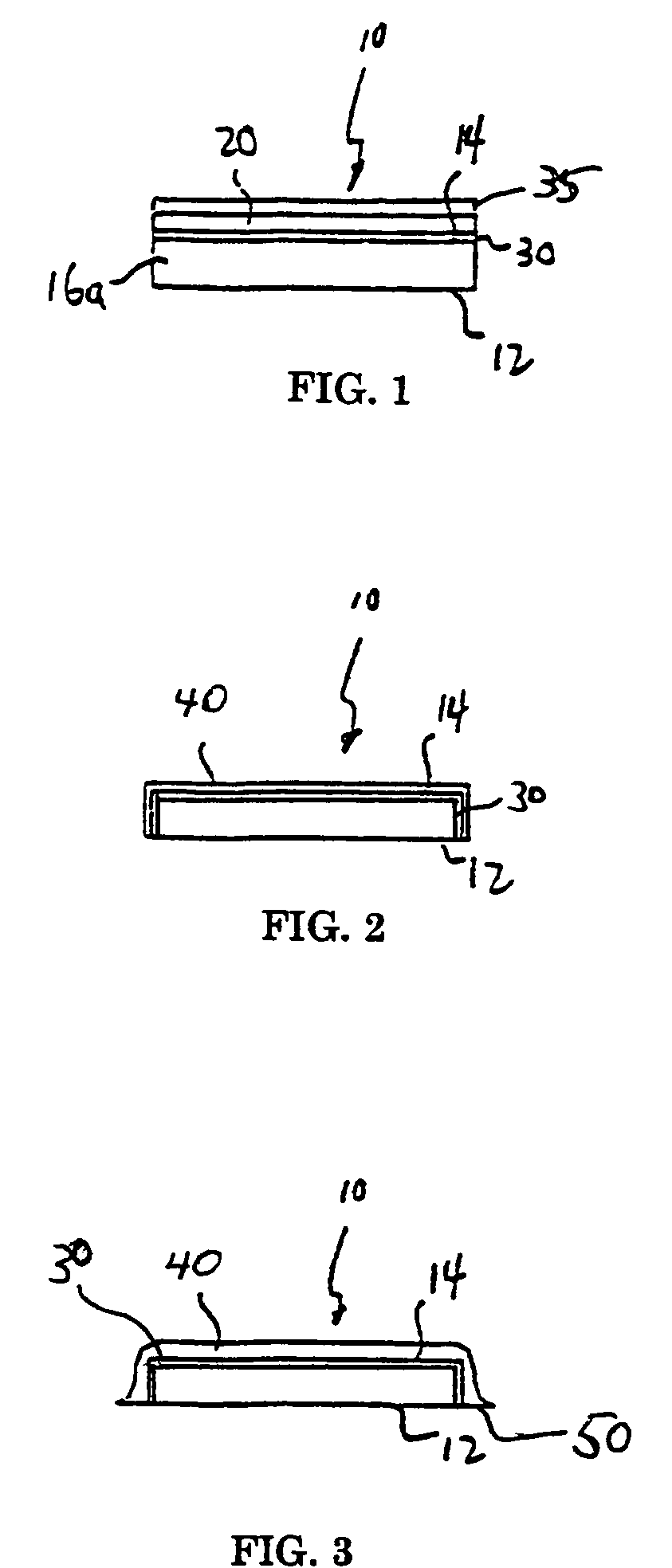

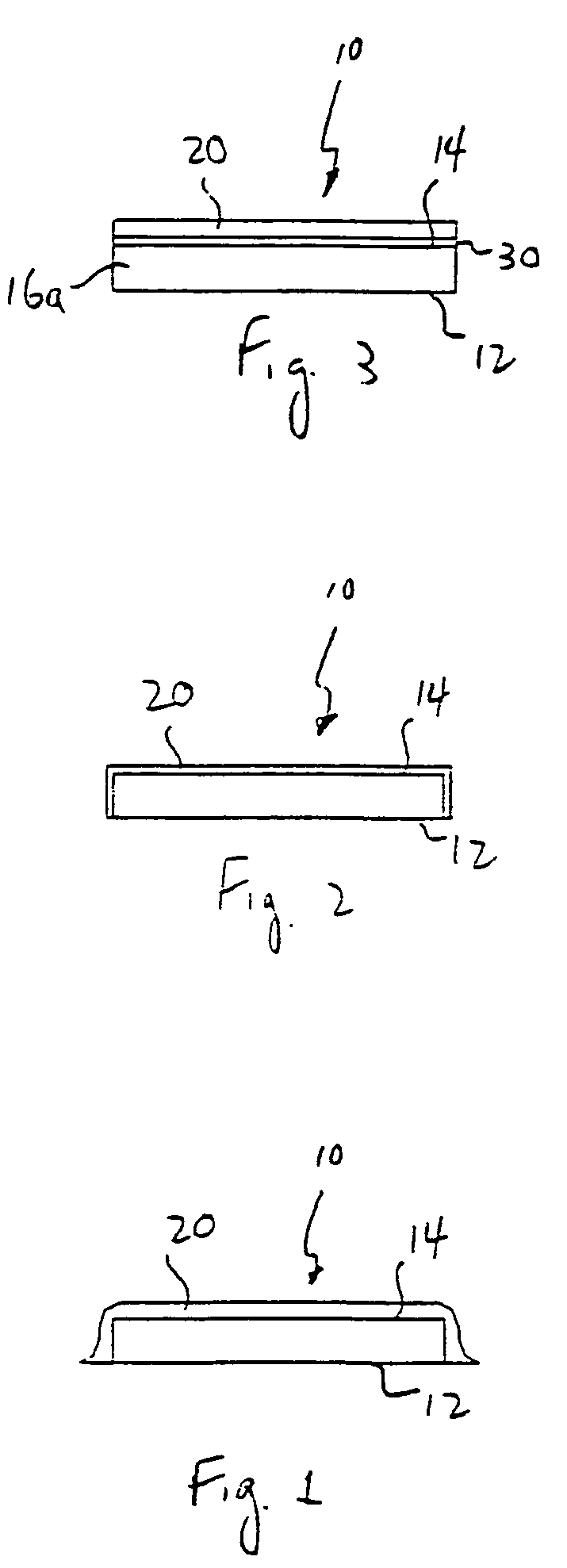

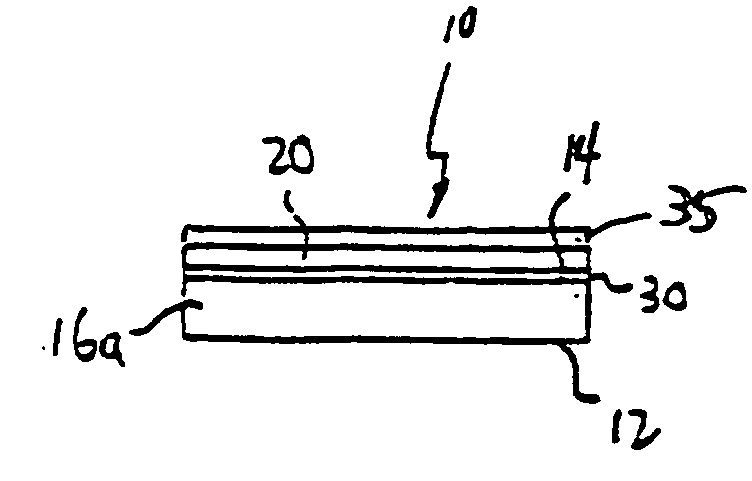

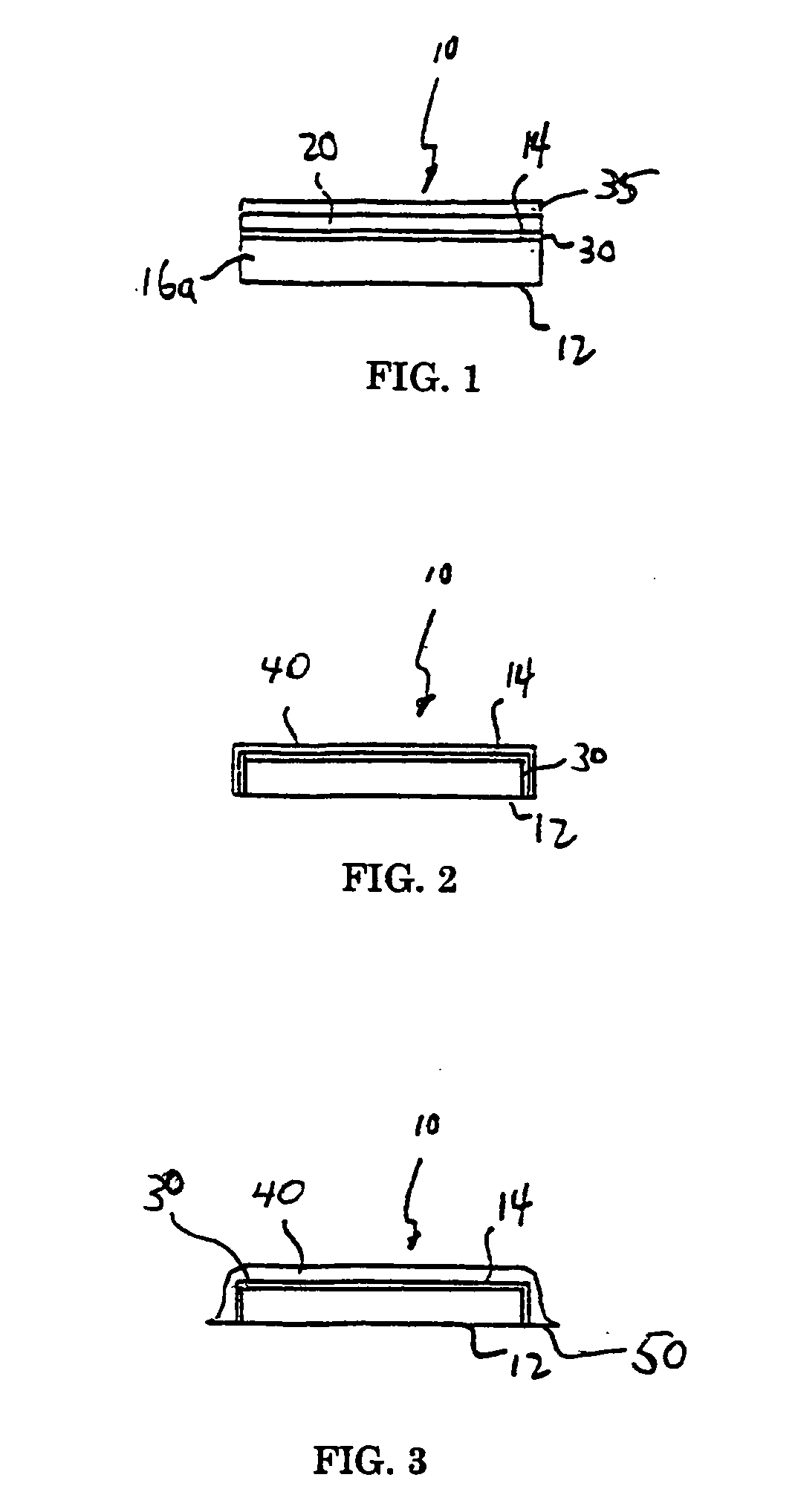

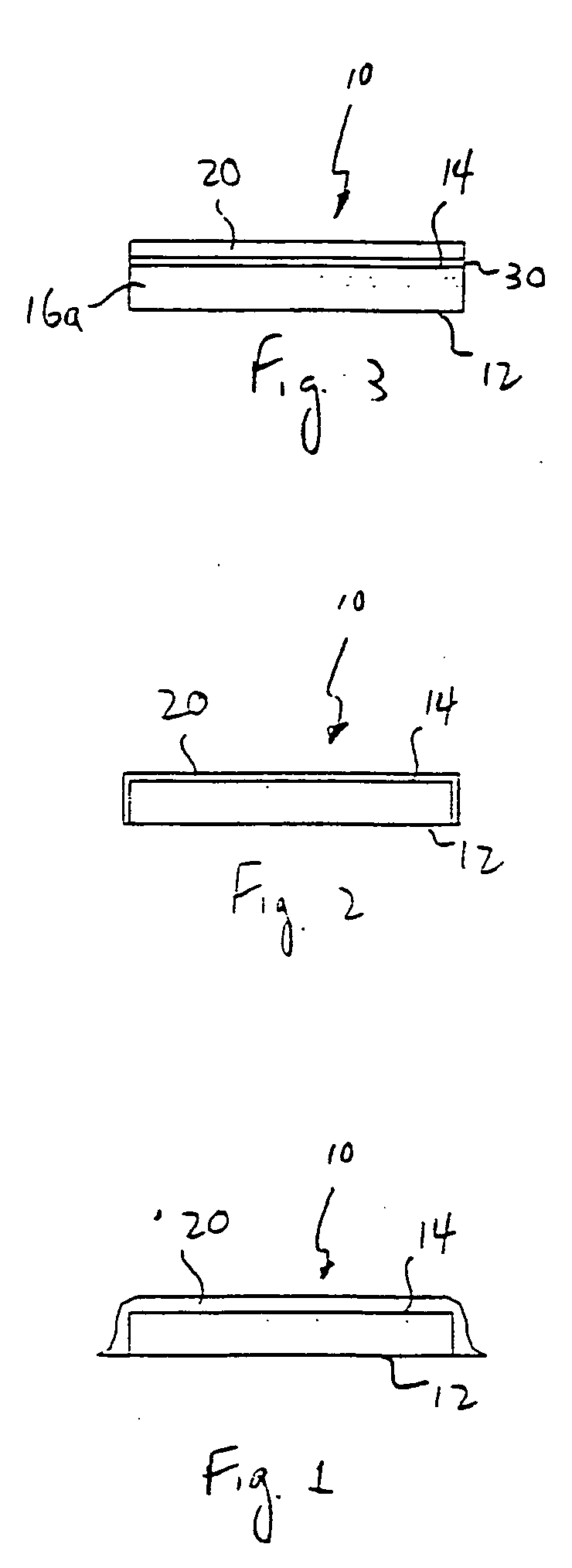

Heat spreader for display device

InactiveUS7306847B2Temperature differenceGraphiteGas discharge vessels/containersLiquid-crystal displayDisplay device

A heat spreader for a display device, such as a plasma display panel, a light emitting diode or a liquid crystal display, which includes at least one sheet of compressed particles of exfoliated graphite having two major surfaces.

Owner:NEOGRAF SOLUTIONS LLC

Heat spreader for display device

InactiveUS7303820B2Temperature differenceDigital data processing detailsLayered productsLiquid-crystal displayDisplay device

Owner:NEOGRAF SOLUTIONS LLC

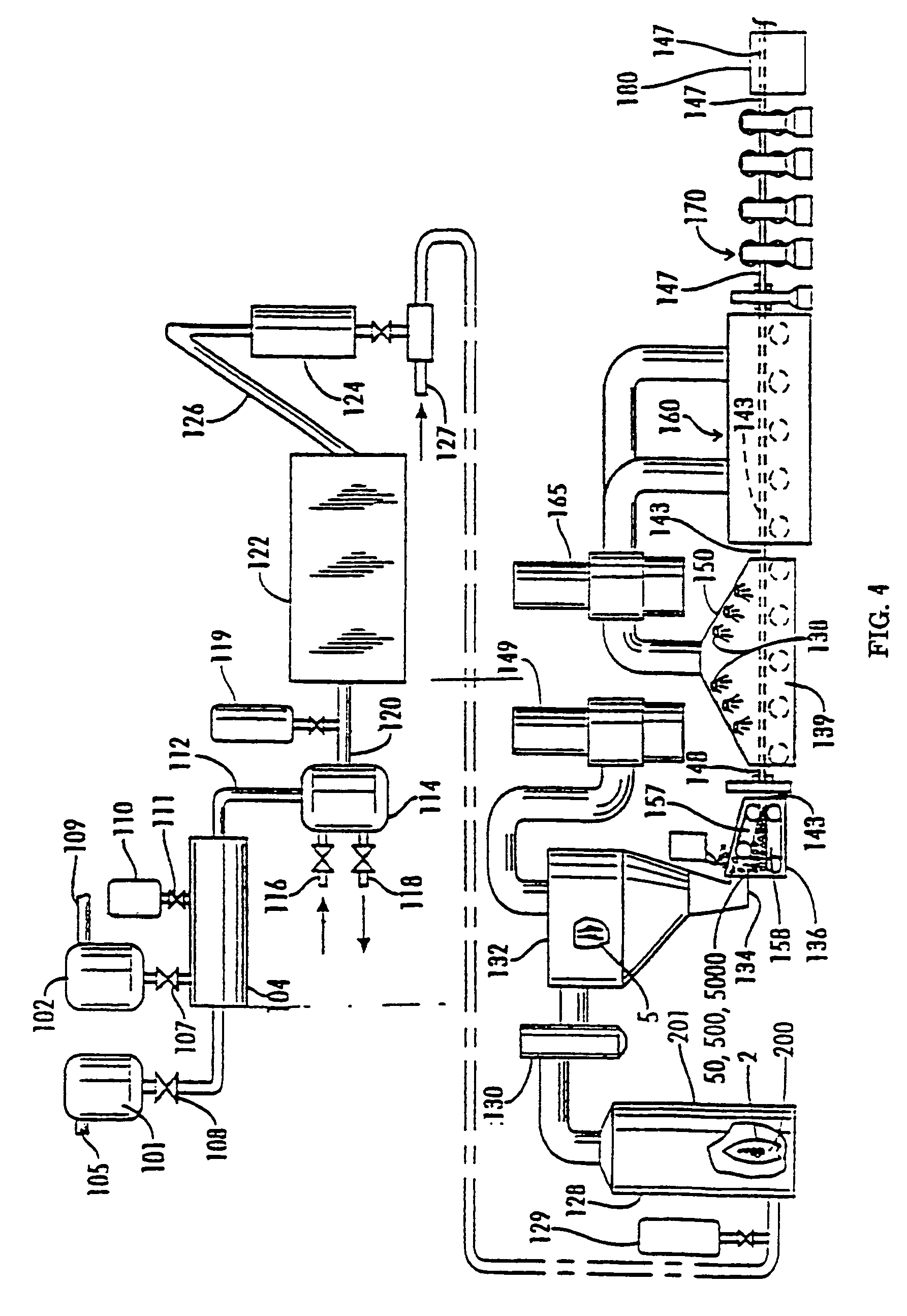

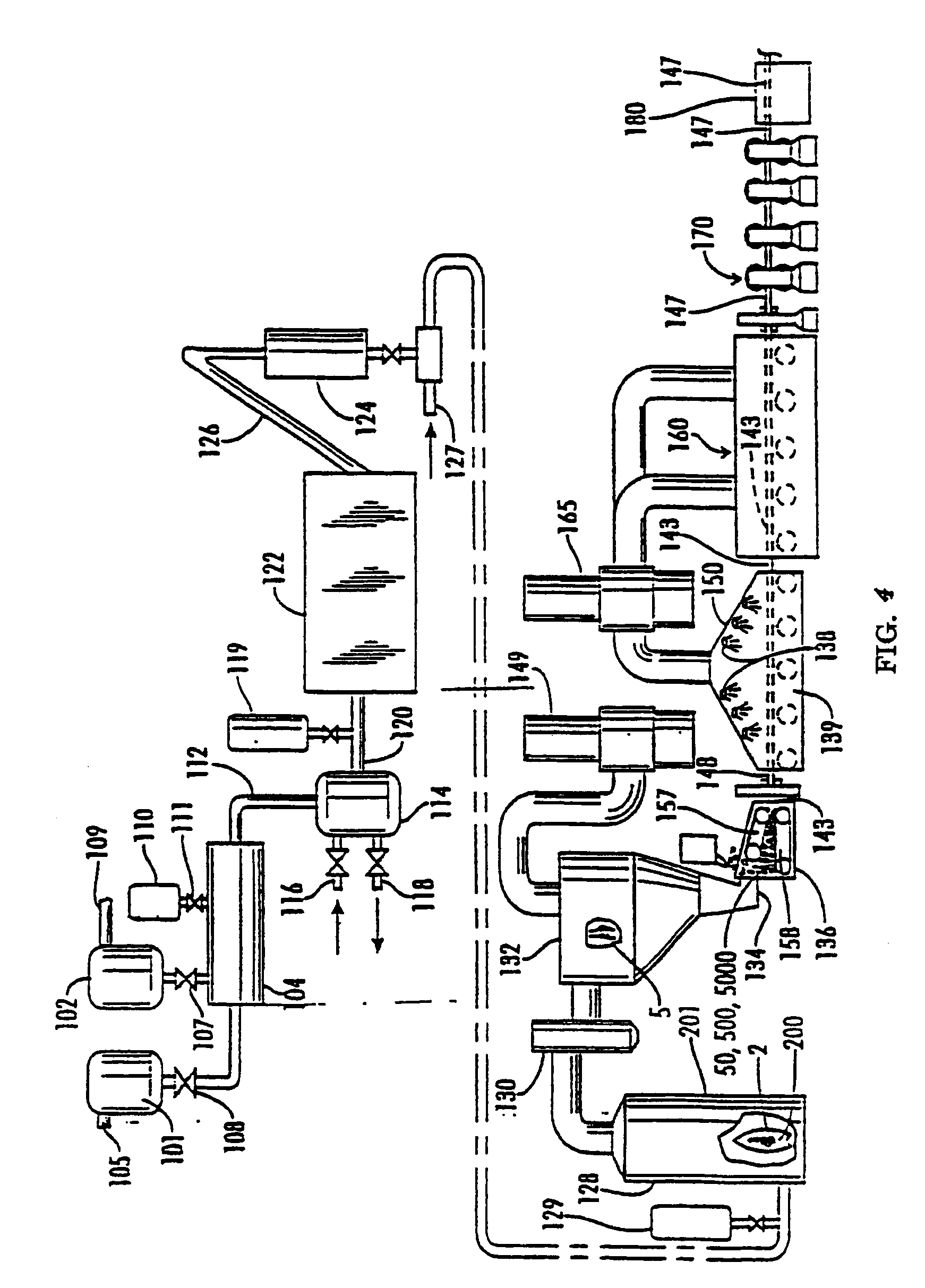

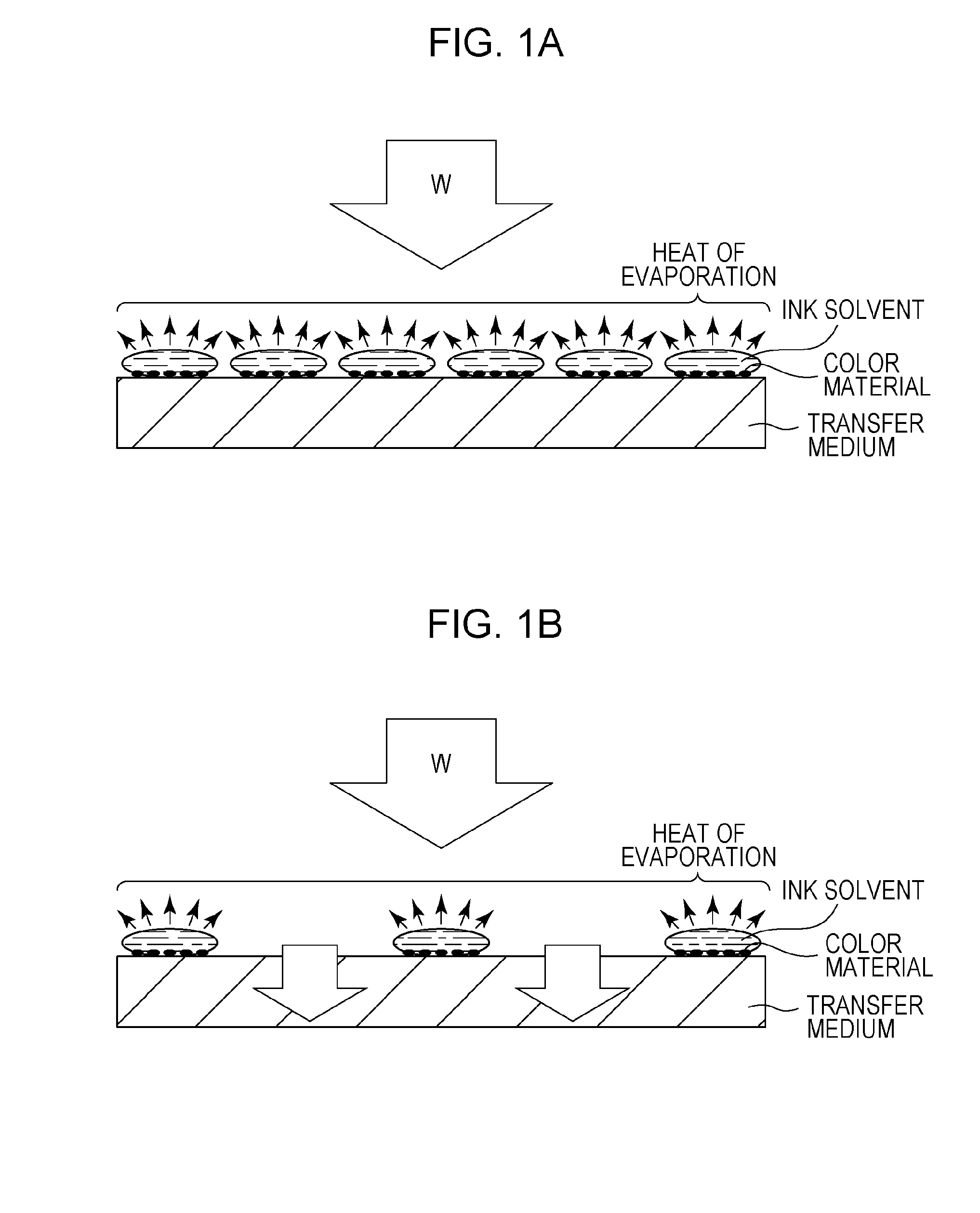

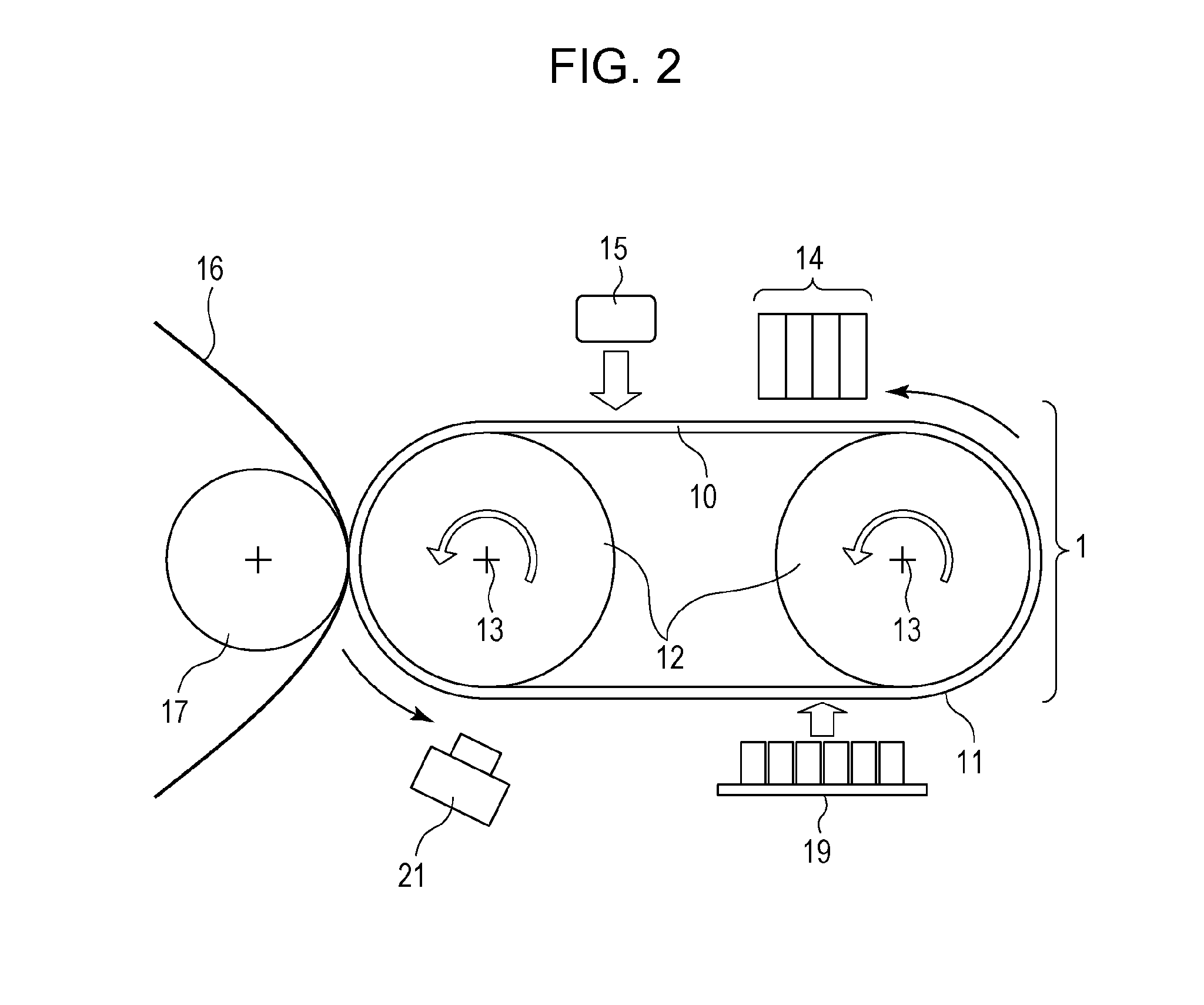

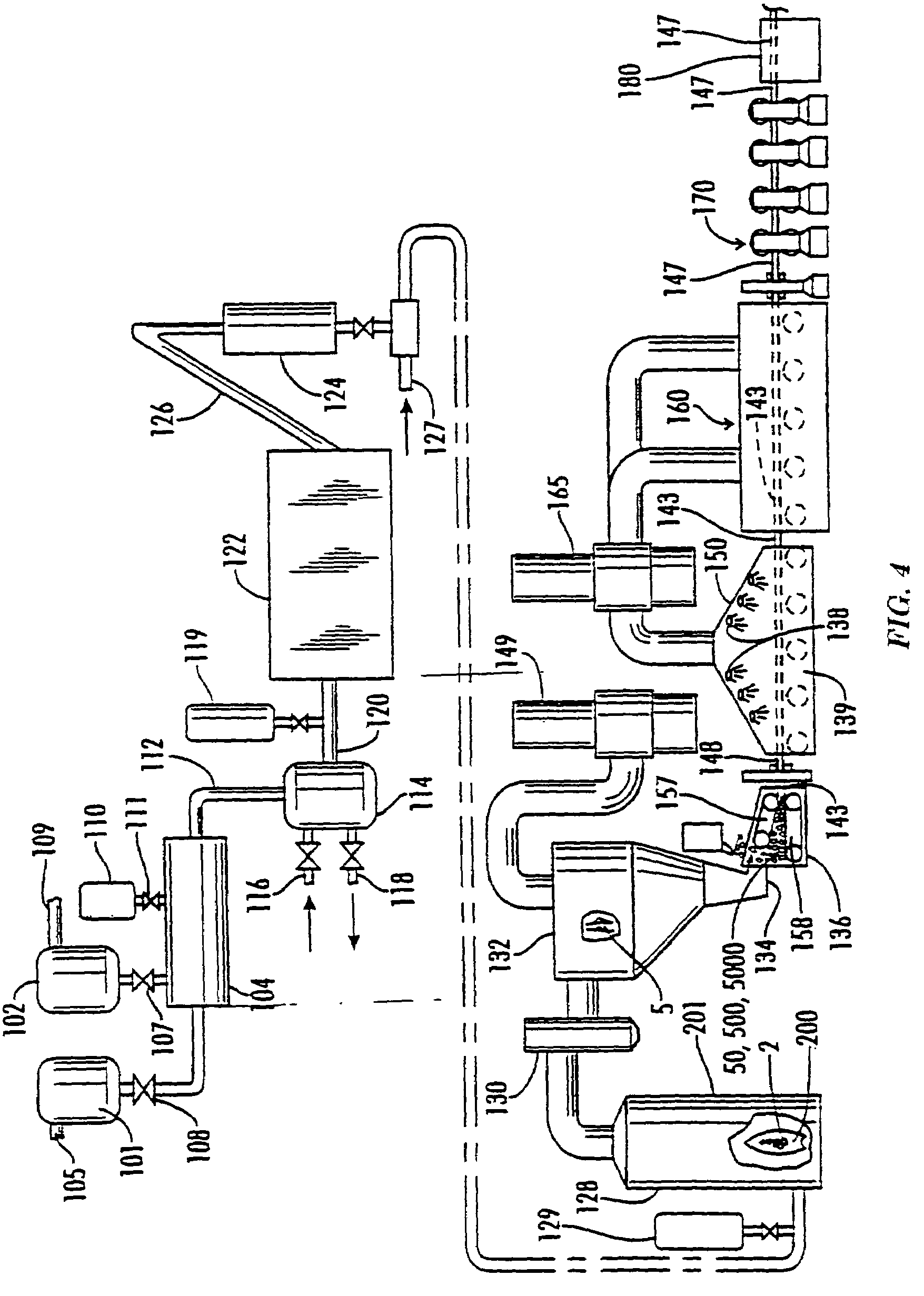

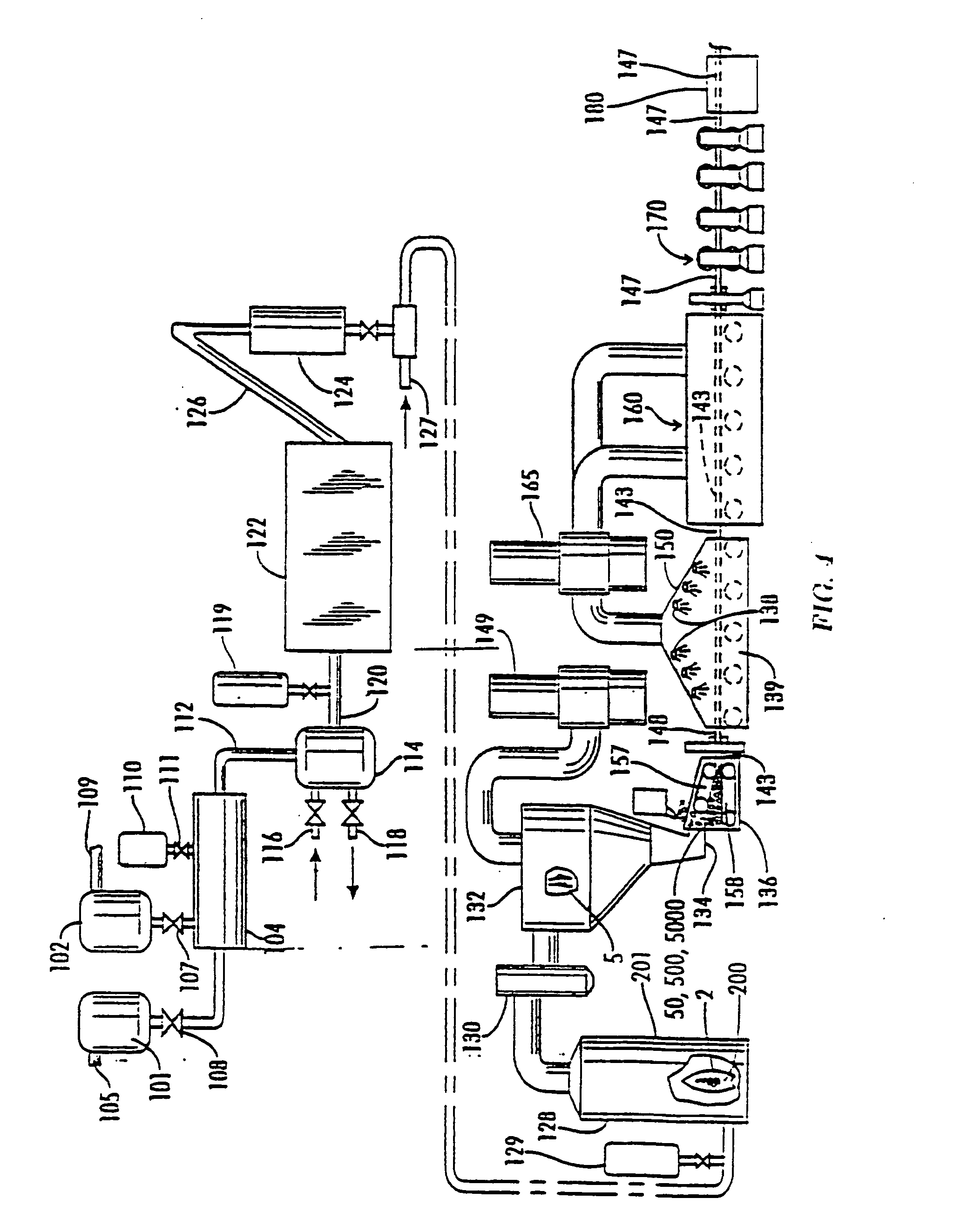

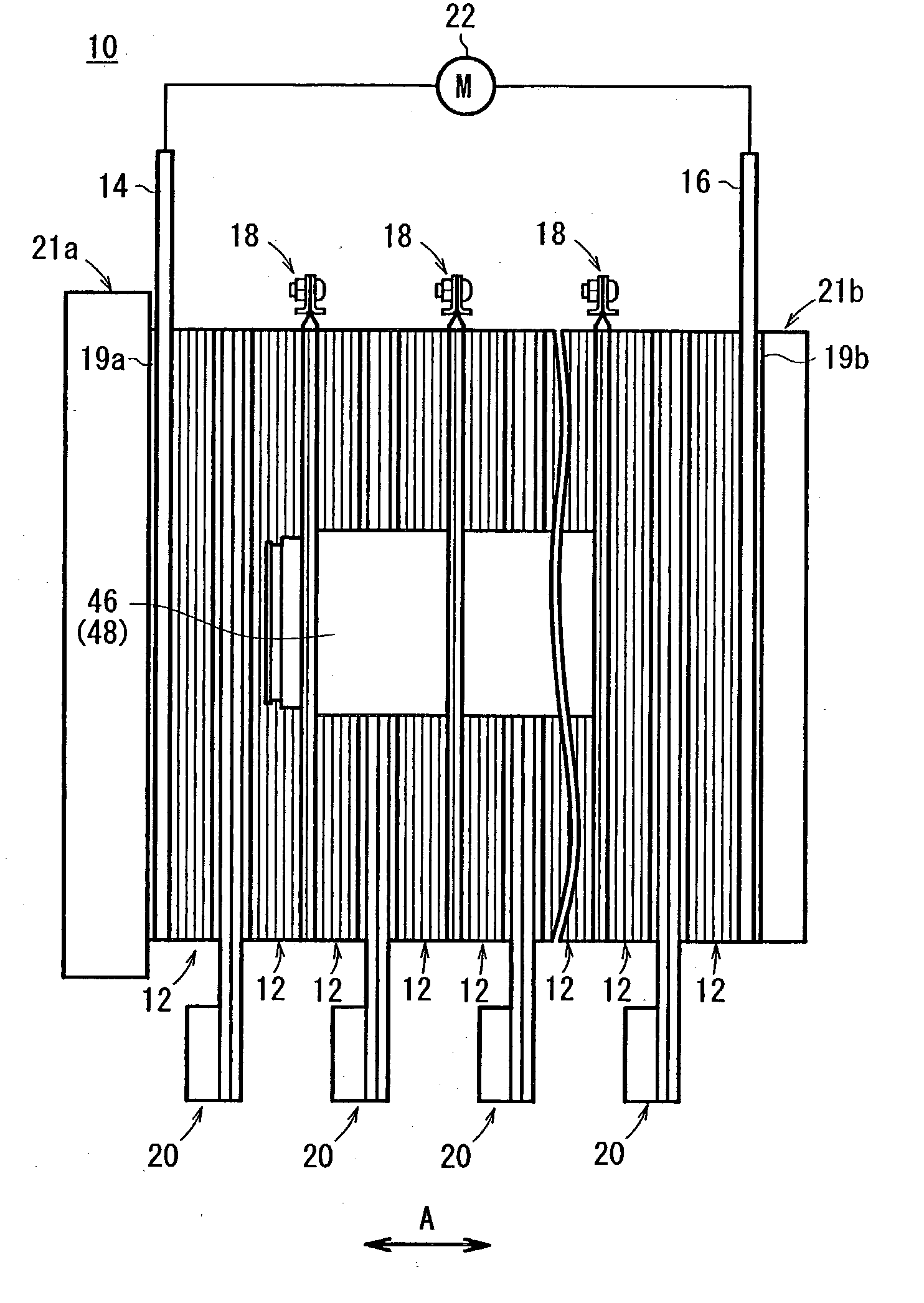

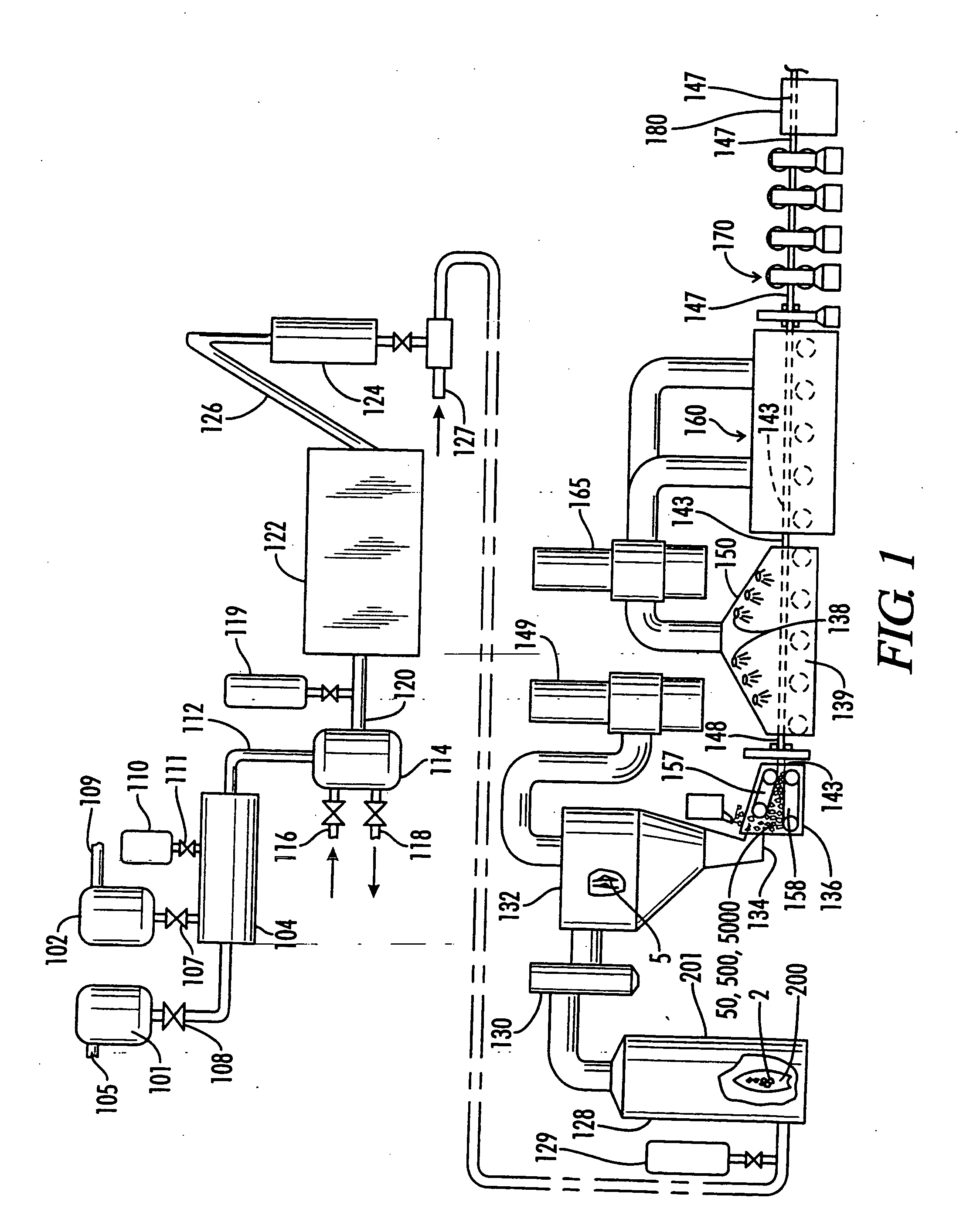

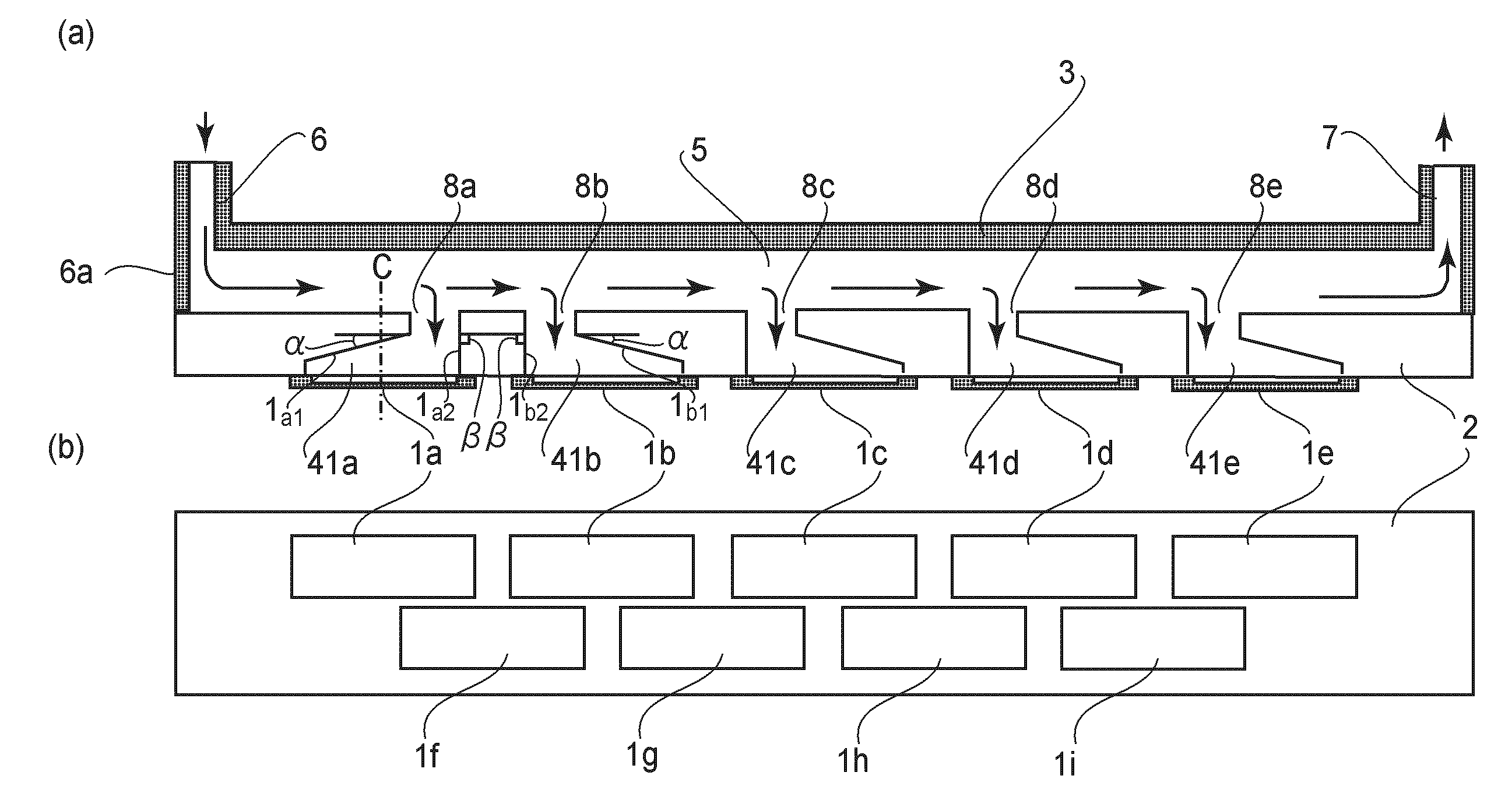

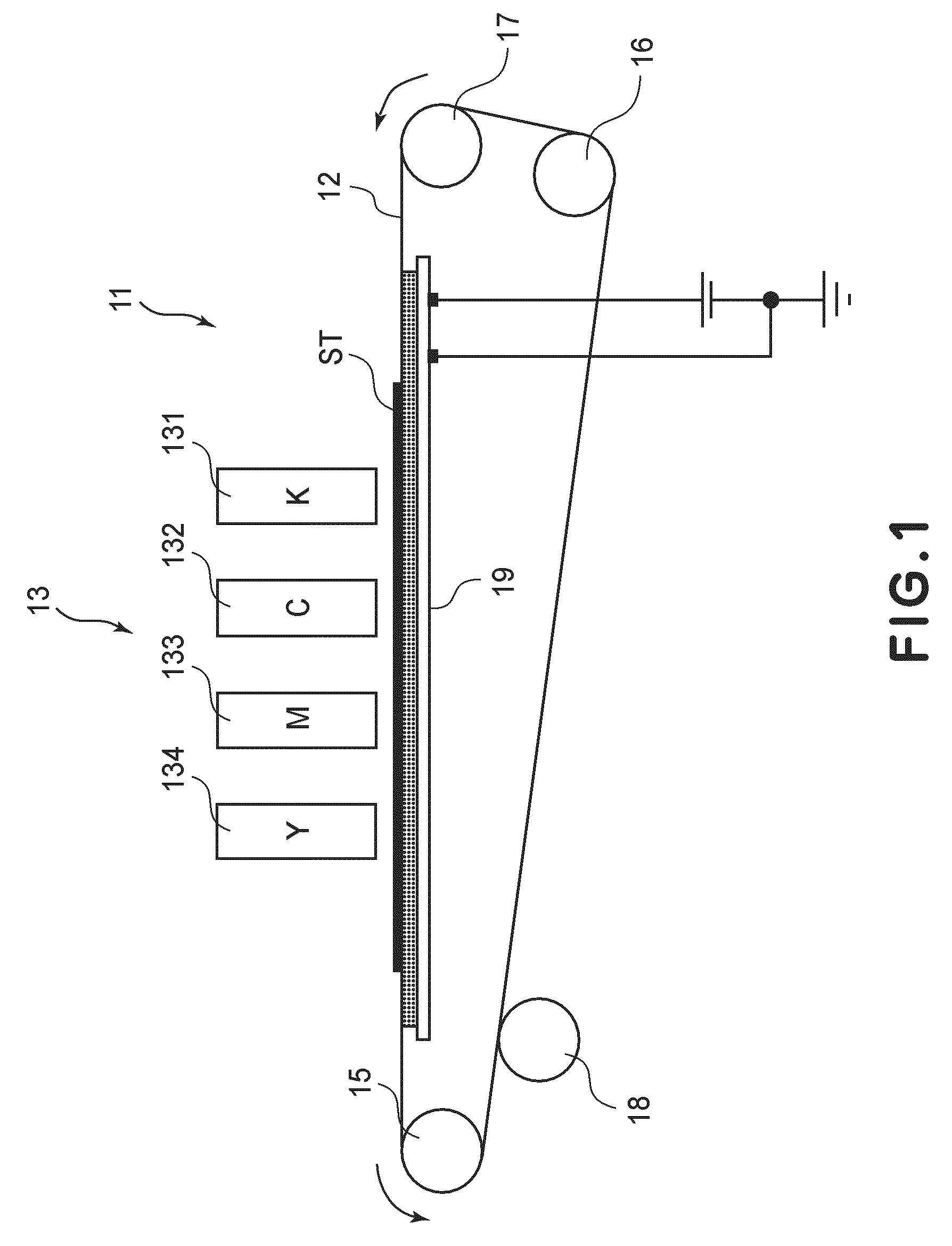

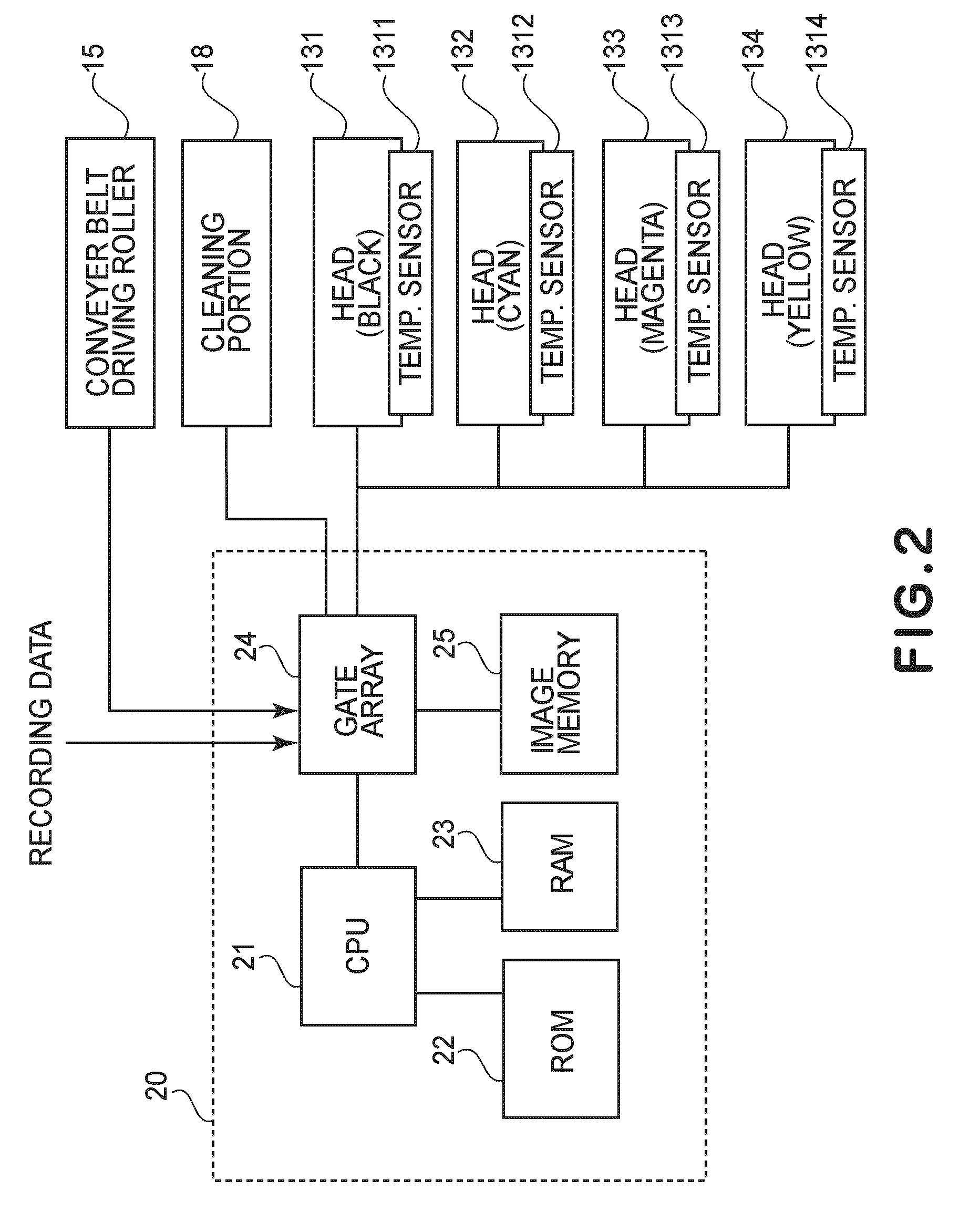

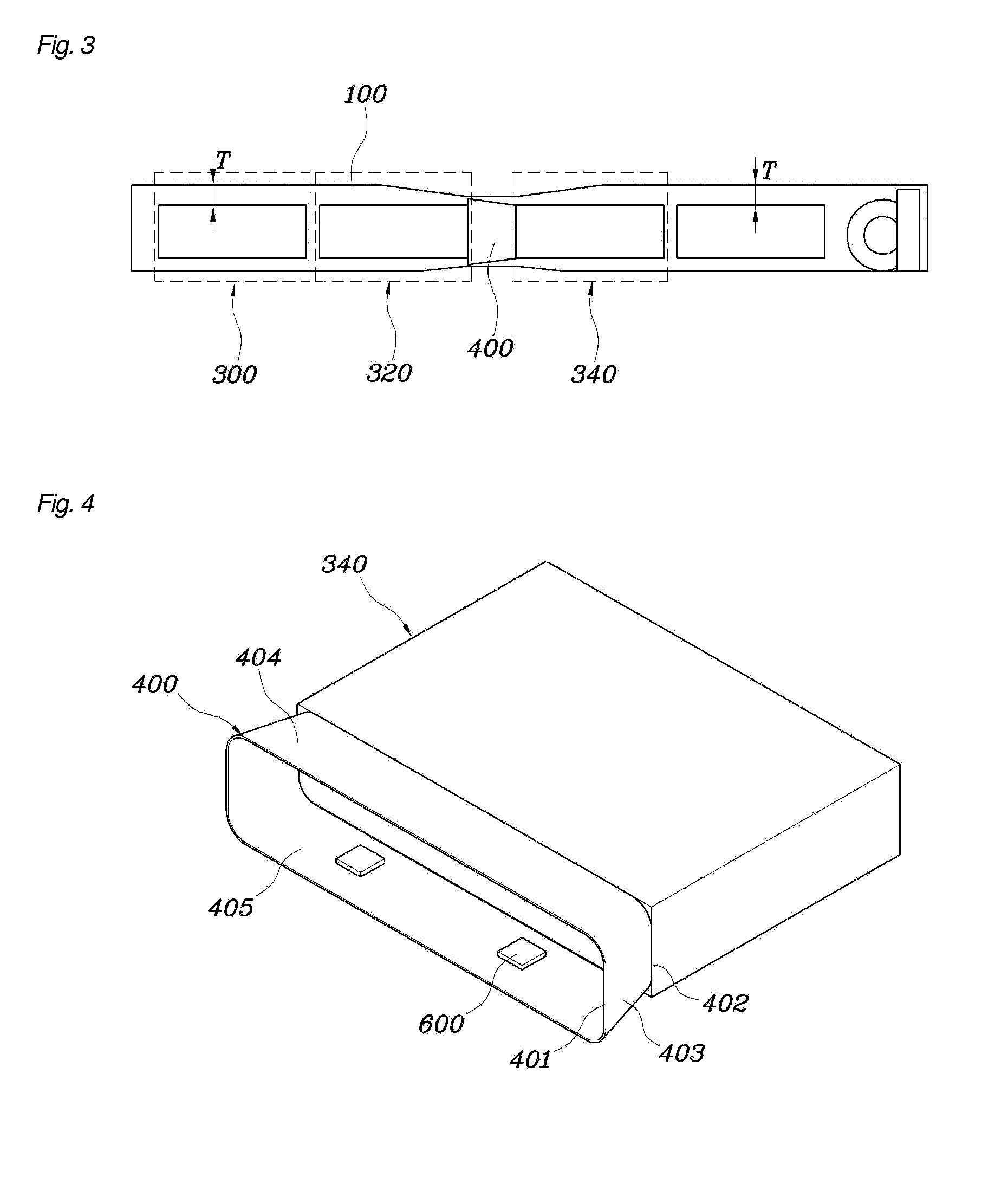

Recording apparatus

InactiveUS20120098882A1Reduce temperature differenceAvoid it happening againOther printing apparatusIntermediate imageEngineering

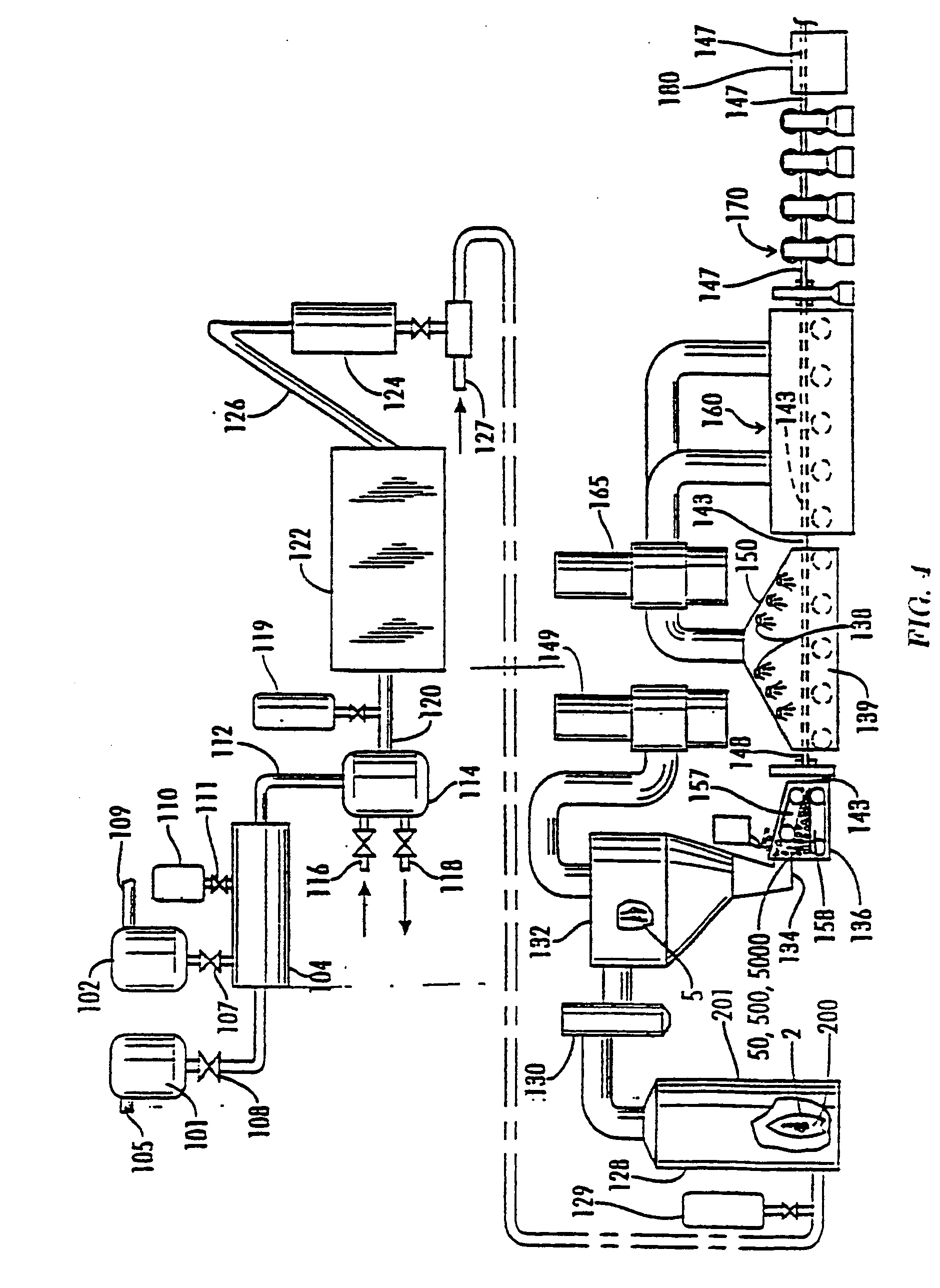

In a transfer inkjet recording system, a cooling unit is configured to independently cool multiple locations in a region in which an intermediate image of an intermediate transfer medium is formed in accordance with one of a temperature of the intermediate transfer medium after being heated by a heating unit or in accordance with image data.

Owner:CANON KK

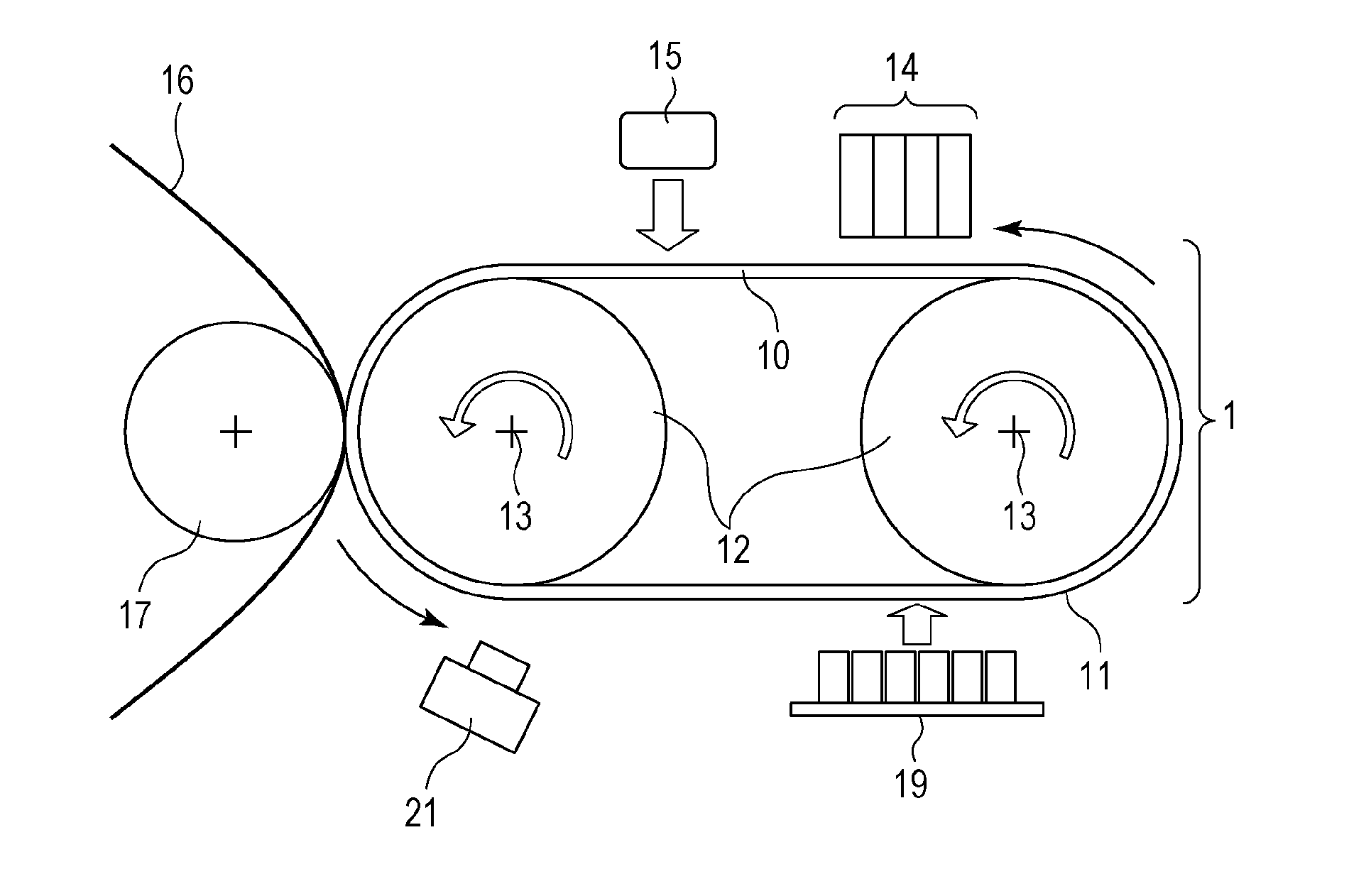

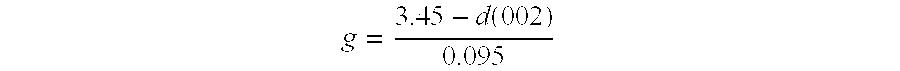

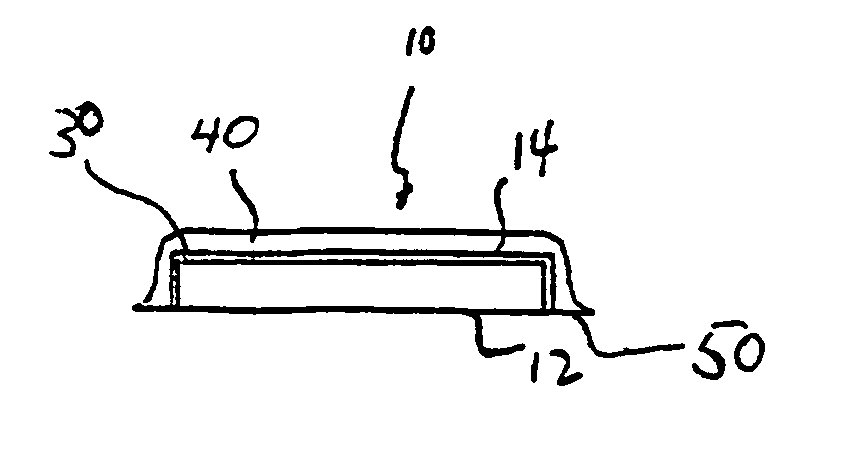

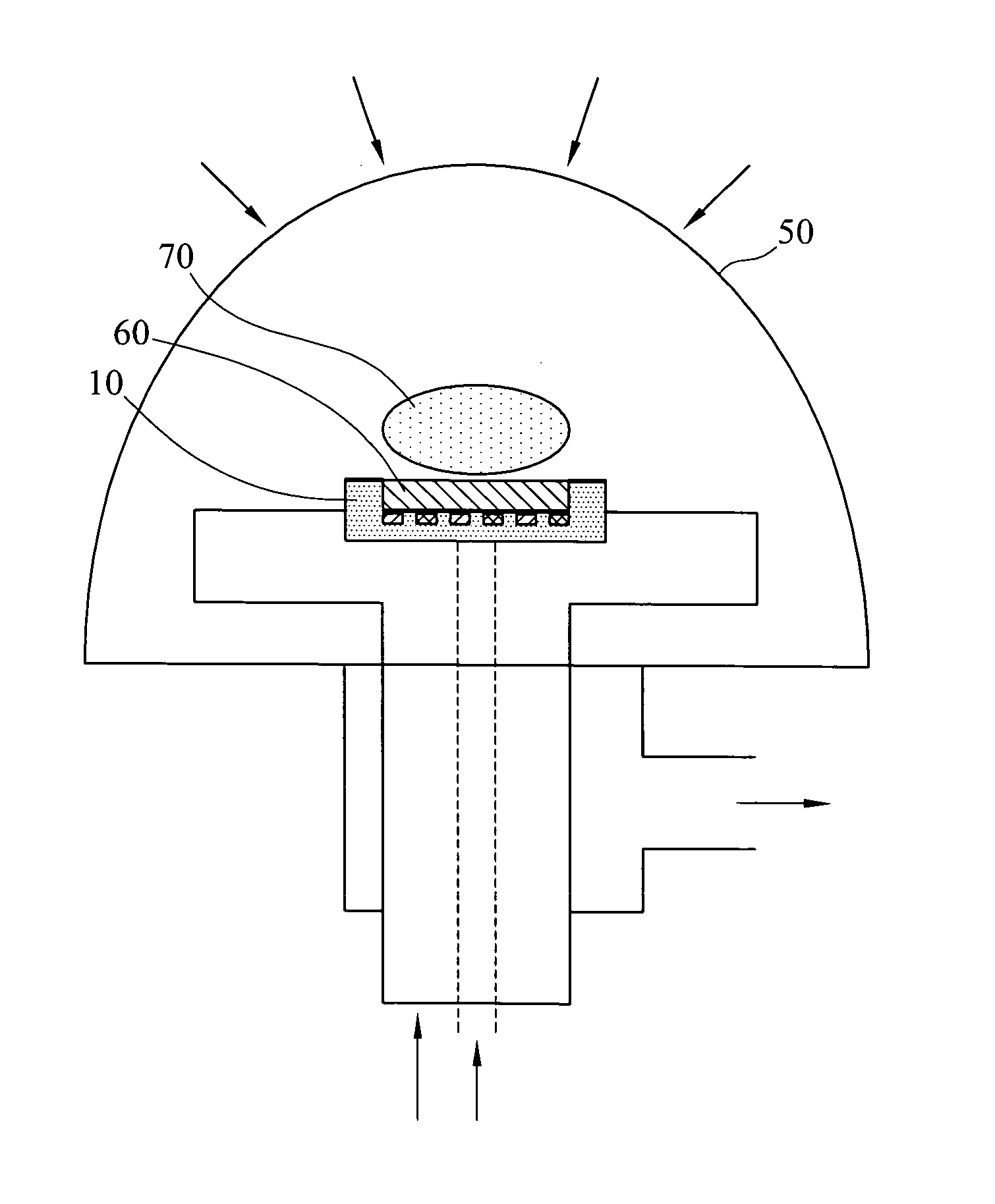

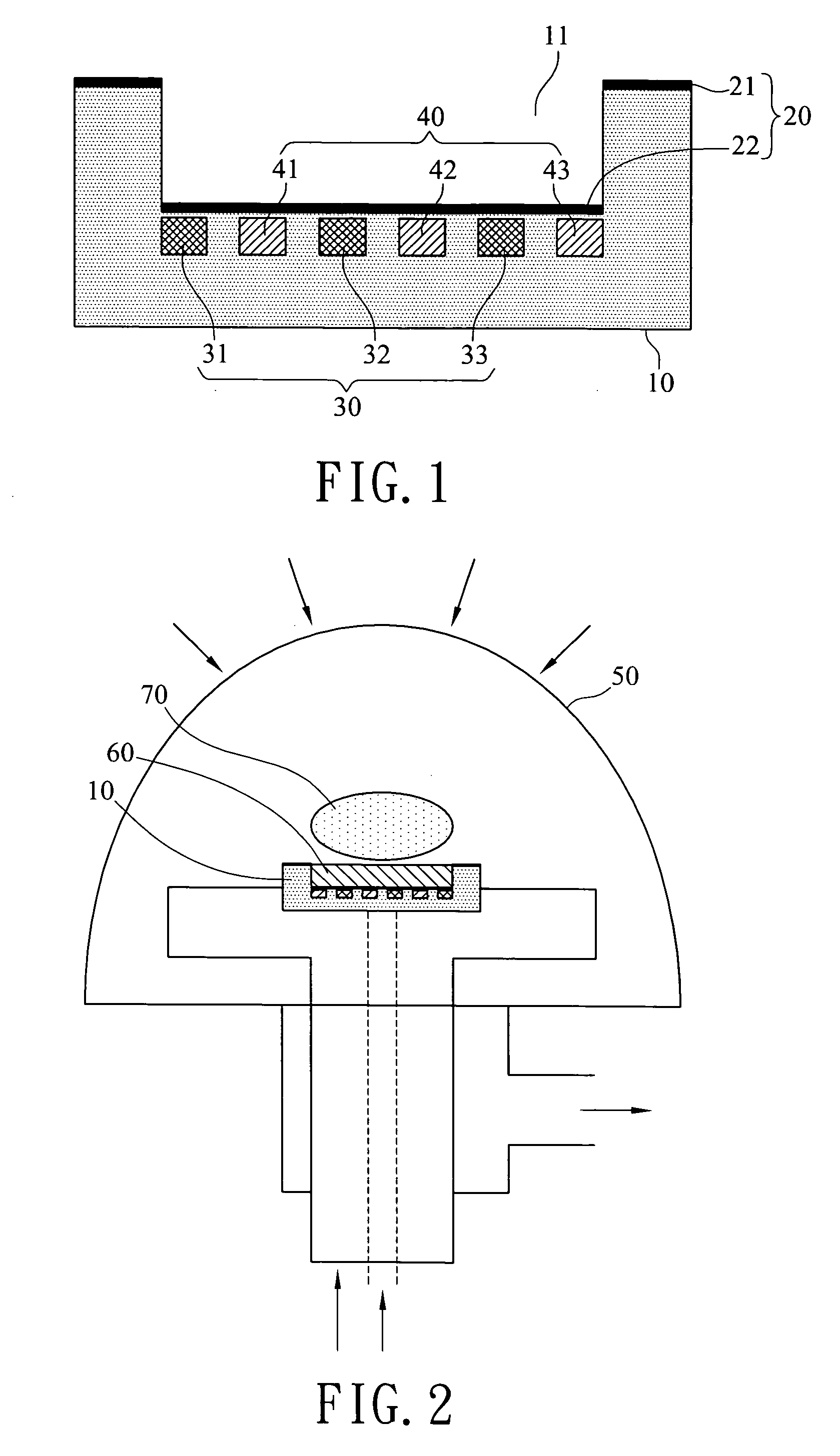

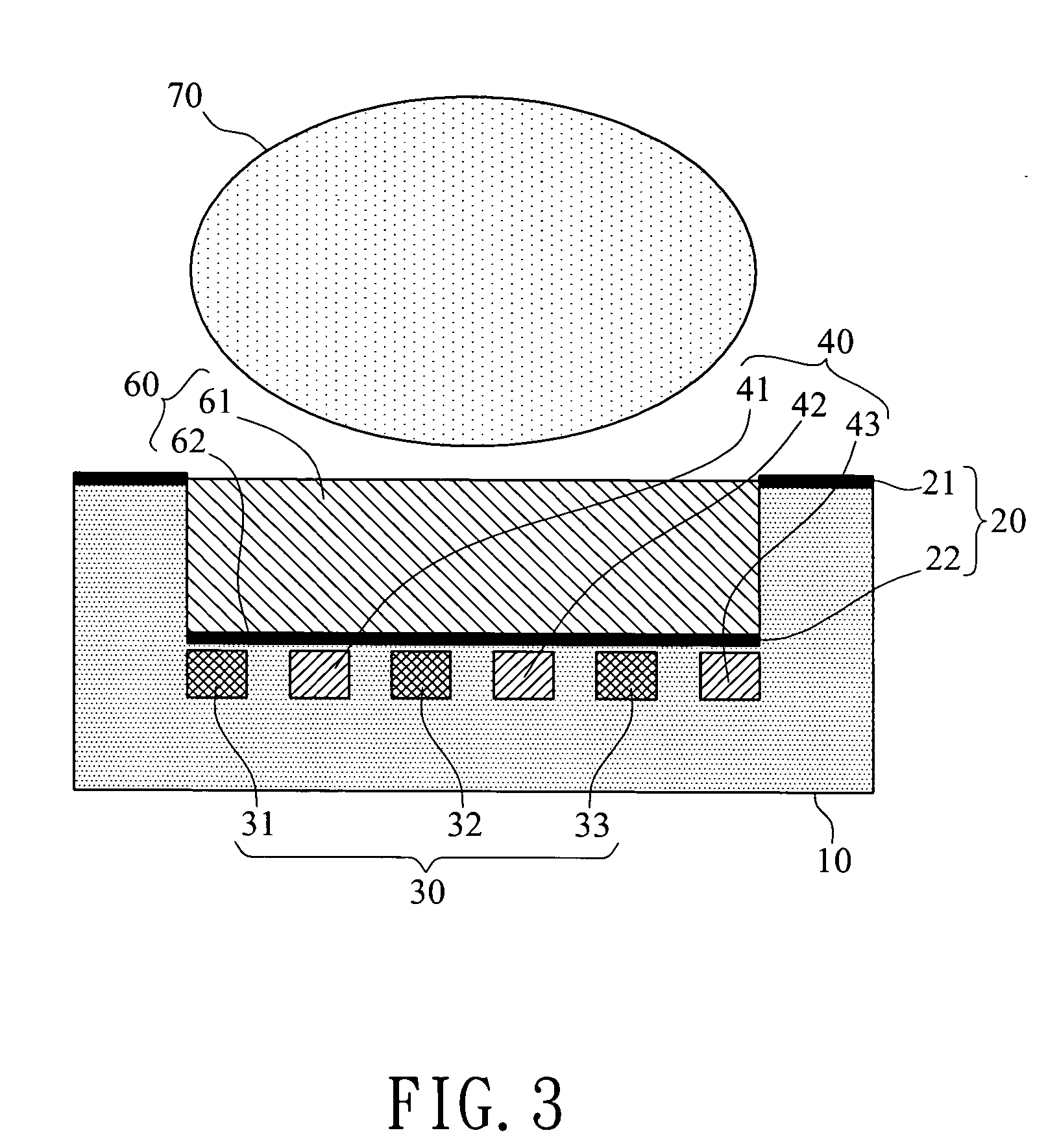

Heat spreader for emissive display device

InactiveUS7150914B2Increase temperature differenceTemperature differenceTube/lamp screens manufactureMaterial nanotechnologyDisplay deviceGraphite

A heat spreader for an emissive display device, such as a plasma display panel or a light emitting diode, comprising at least one sheet of compressed particles of exfoliated graphite having a surface area greater than the surface area of that part of a discharge cell facing the back surface of the device.

Owner:NEOGRAF SOLUTIONS LLC

Battery Set with Heat Conducting Jelly

InactiveUS20110097617A1Temperature differenceRapid temperatureCell temperature controlCell lids/coversHeat conductingBattery cell

A battery set filled with heat conducting jelly is disclosed, which comprises a shell, for housing a cooling unit; and a plurality of battery cells, each battery cell being disposed inside the shell while having a heat conducting jelly, featuring with electric insulation and heat conduction abilities, to be filled surrounding the periphery thereof and contacting with the outer surface of each battery cell.

Owner:IND TECH RES INST

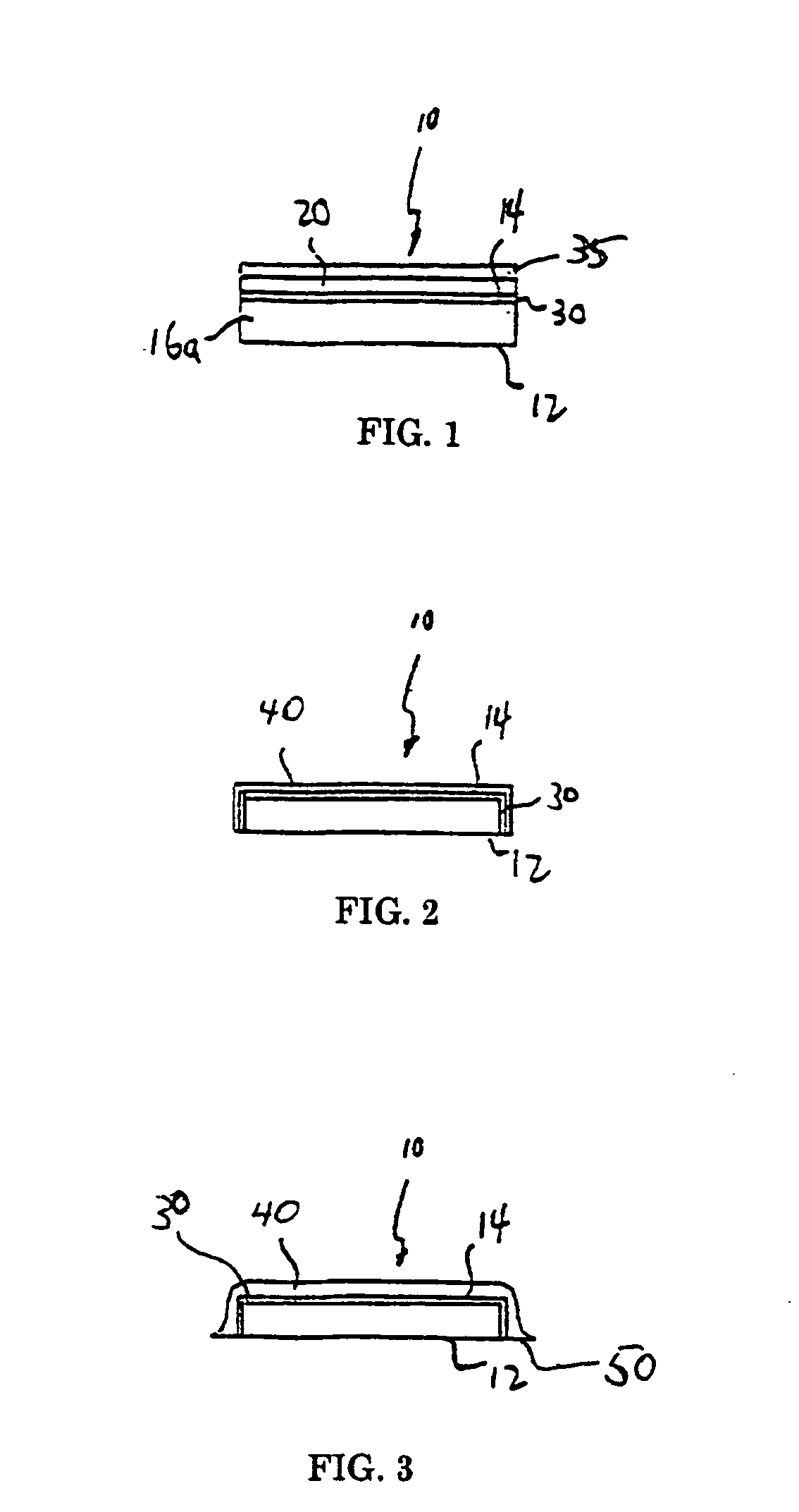

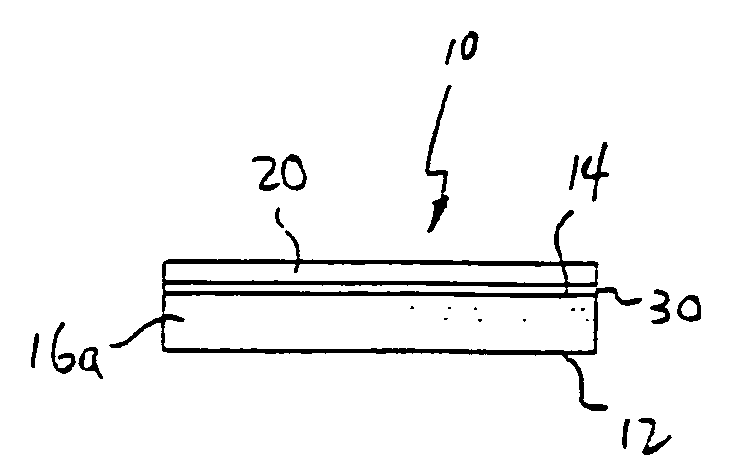

Heat spreader for display device

ActiveUS7276273B2Temperature differenceLayered productsDigital data processing detailsLiquid-crystal displayDisplay device

A heat spreader (10) for a display device, such as a plasma display panel, a light emitting diode or a liquid crystal display, comprising at least one sheet of compressed particles of exfoliated graphite having a surface area greater than the surface area of that part of the back surface of the display device where a localized region of higher temperature is generated.

Owner:NEOGRAF SOLUTIONS LLC

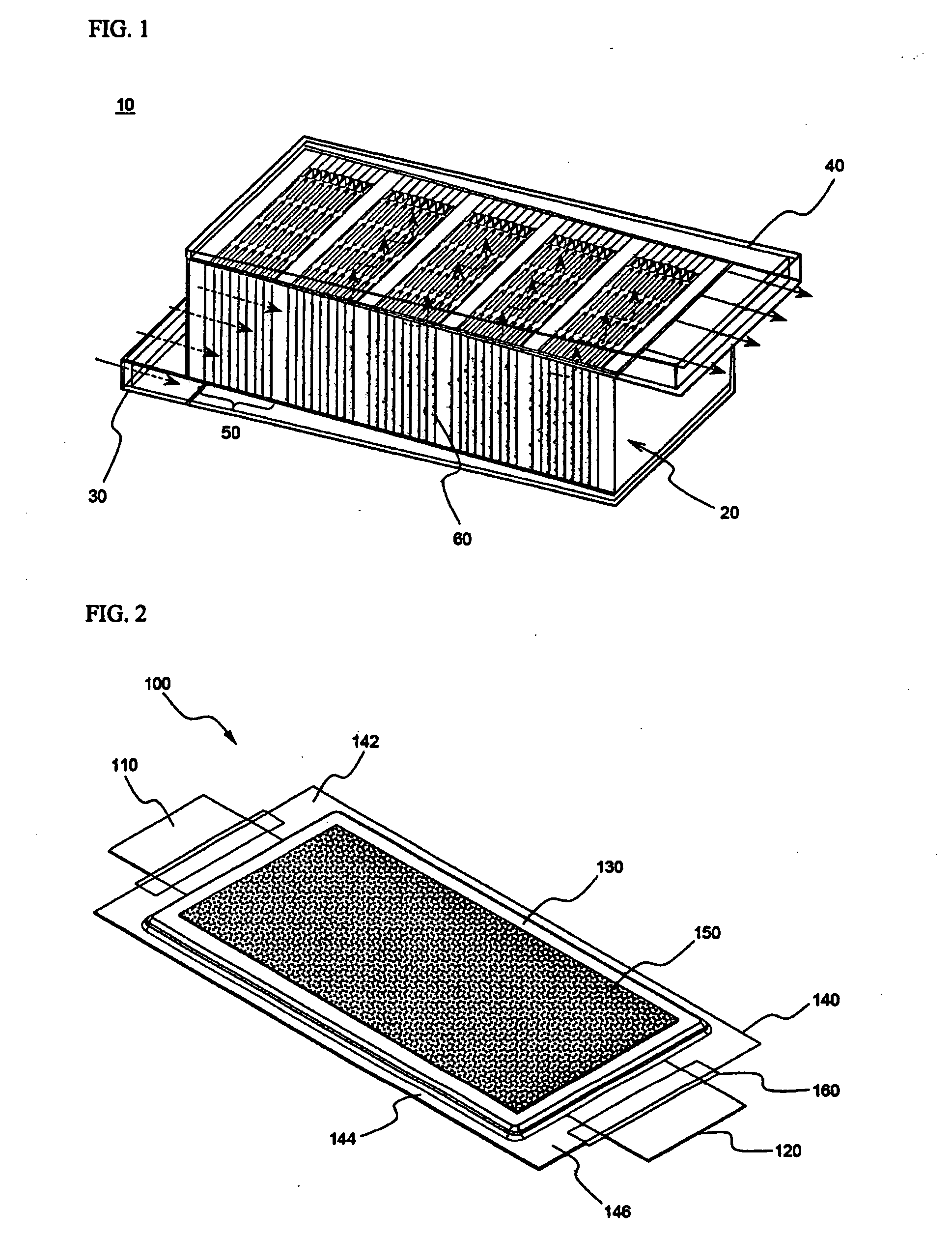

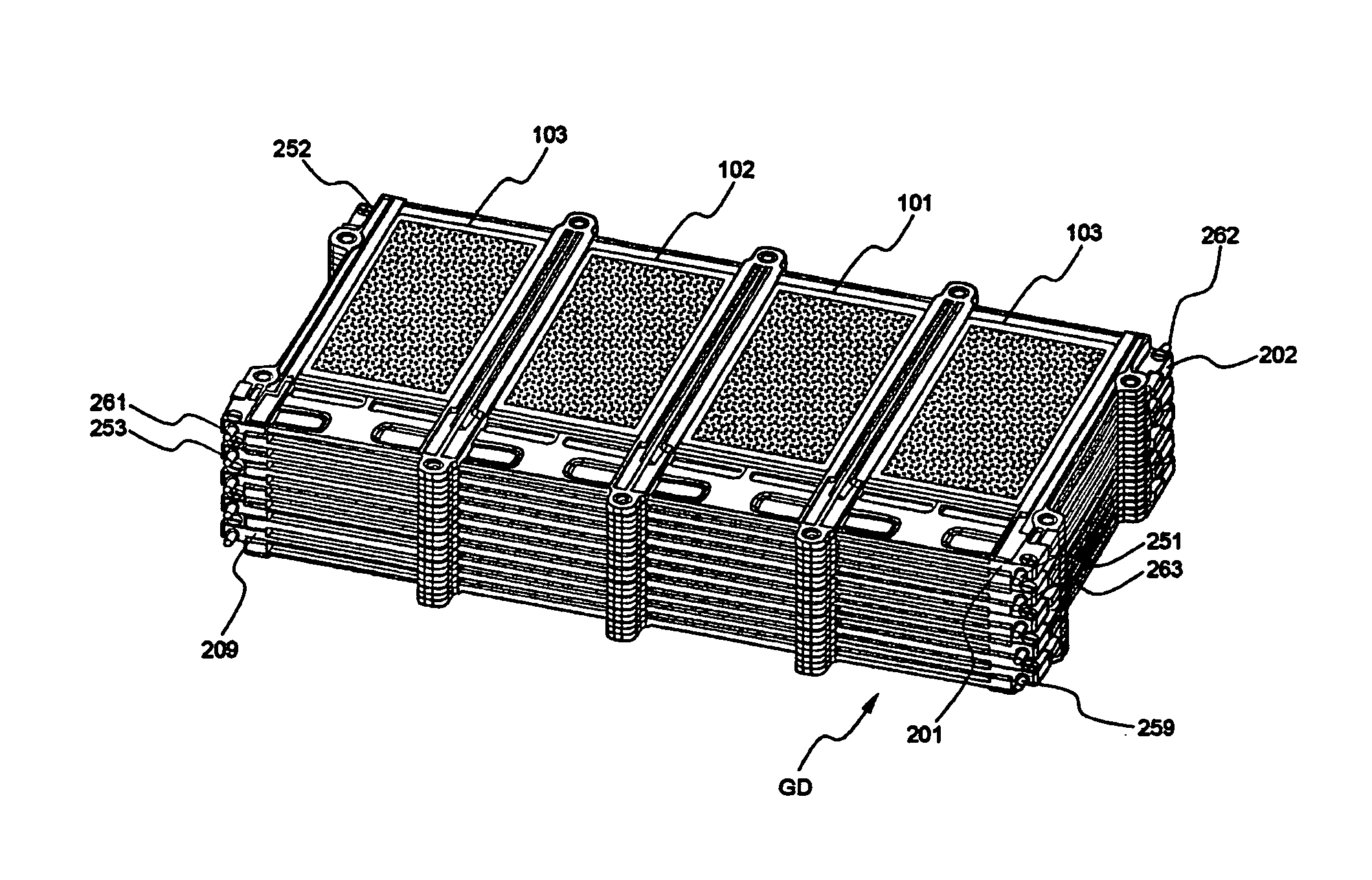

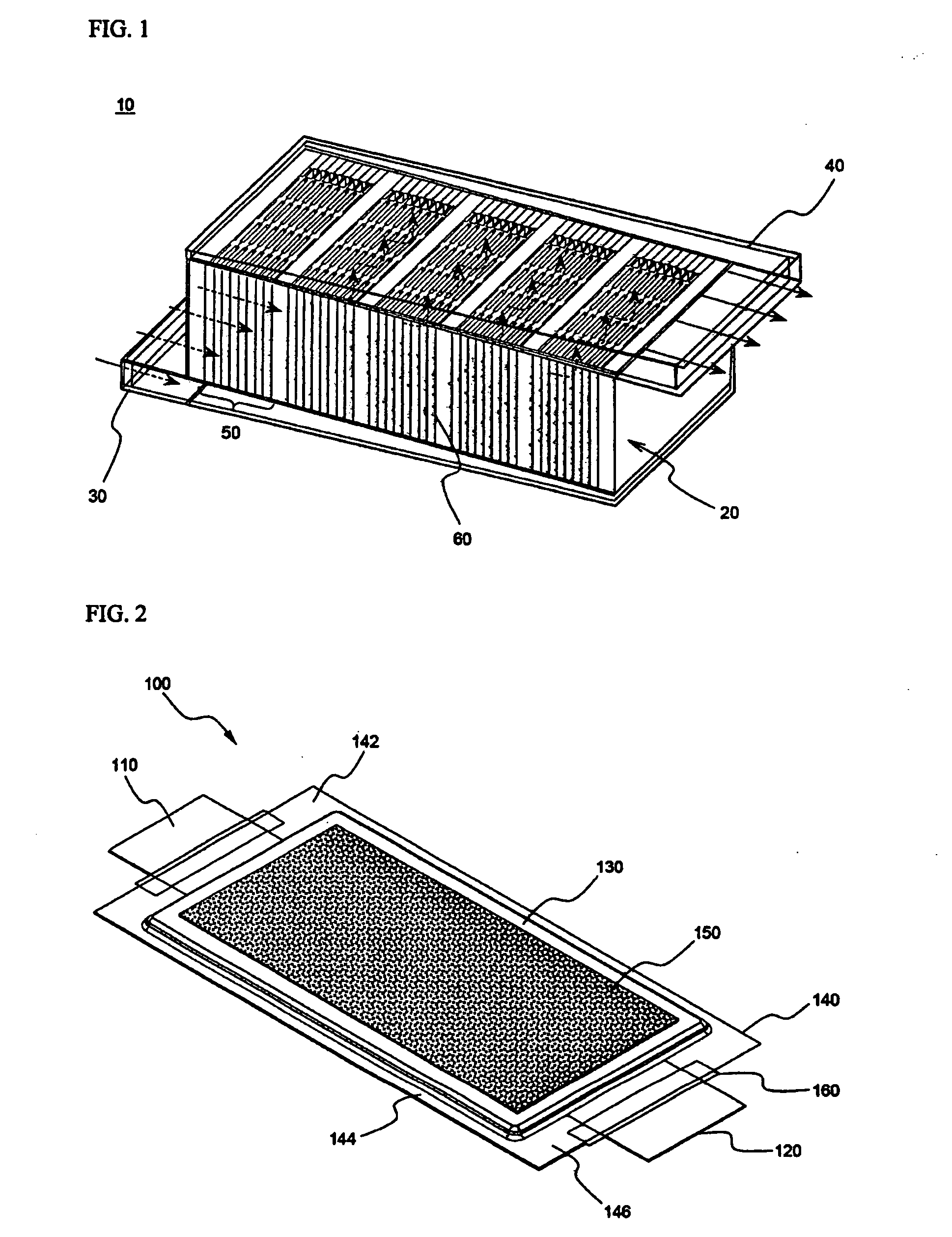

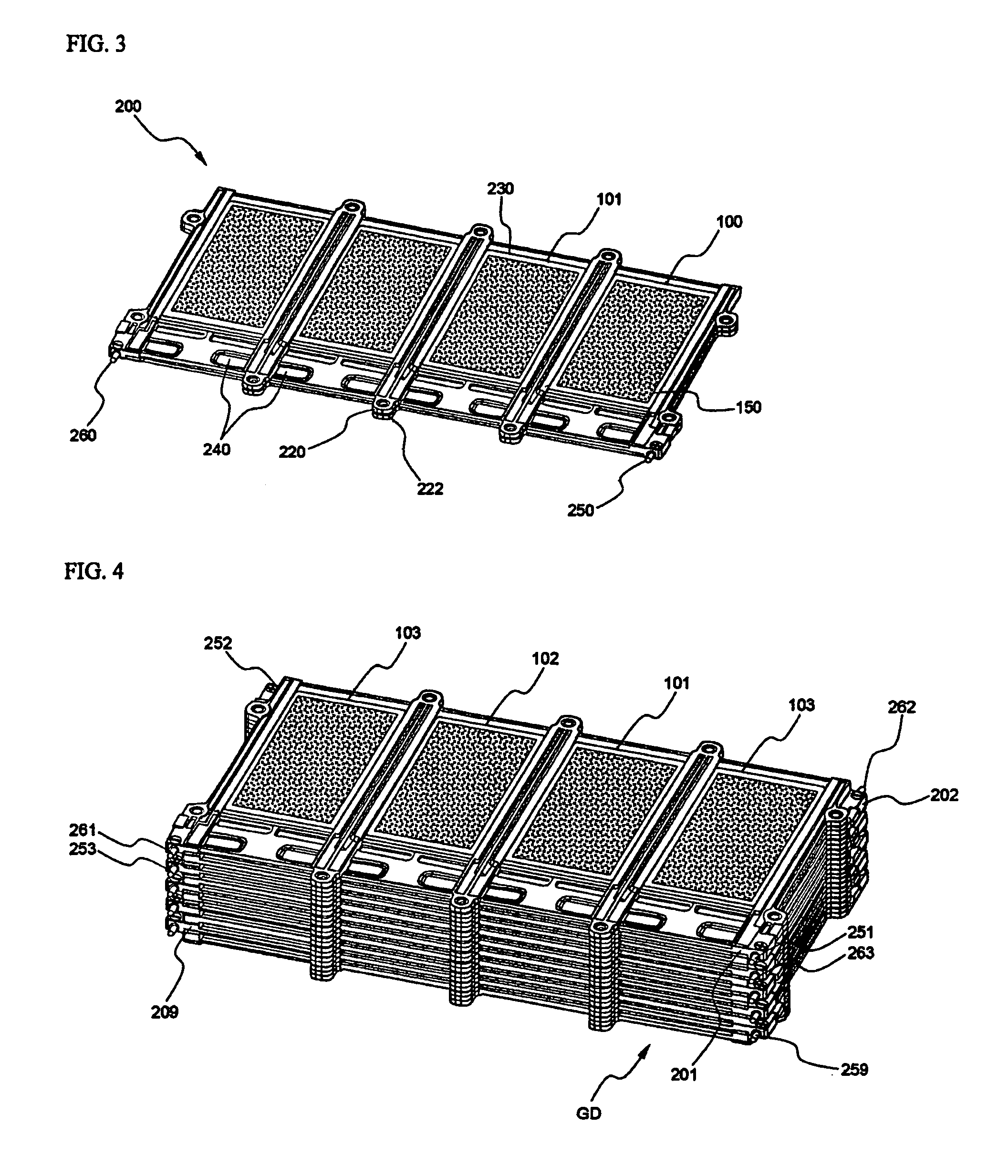

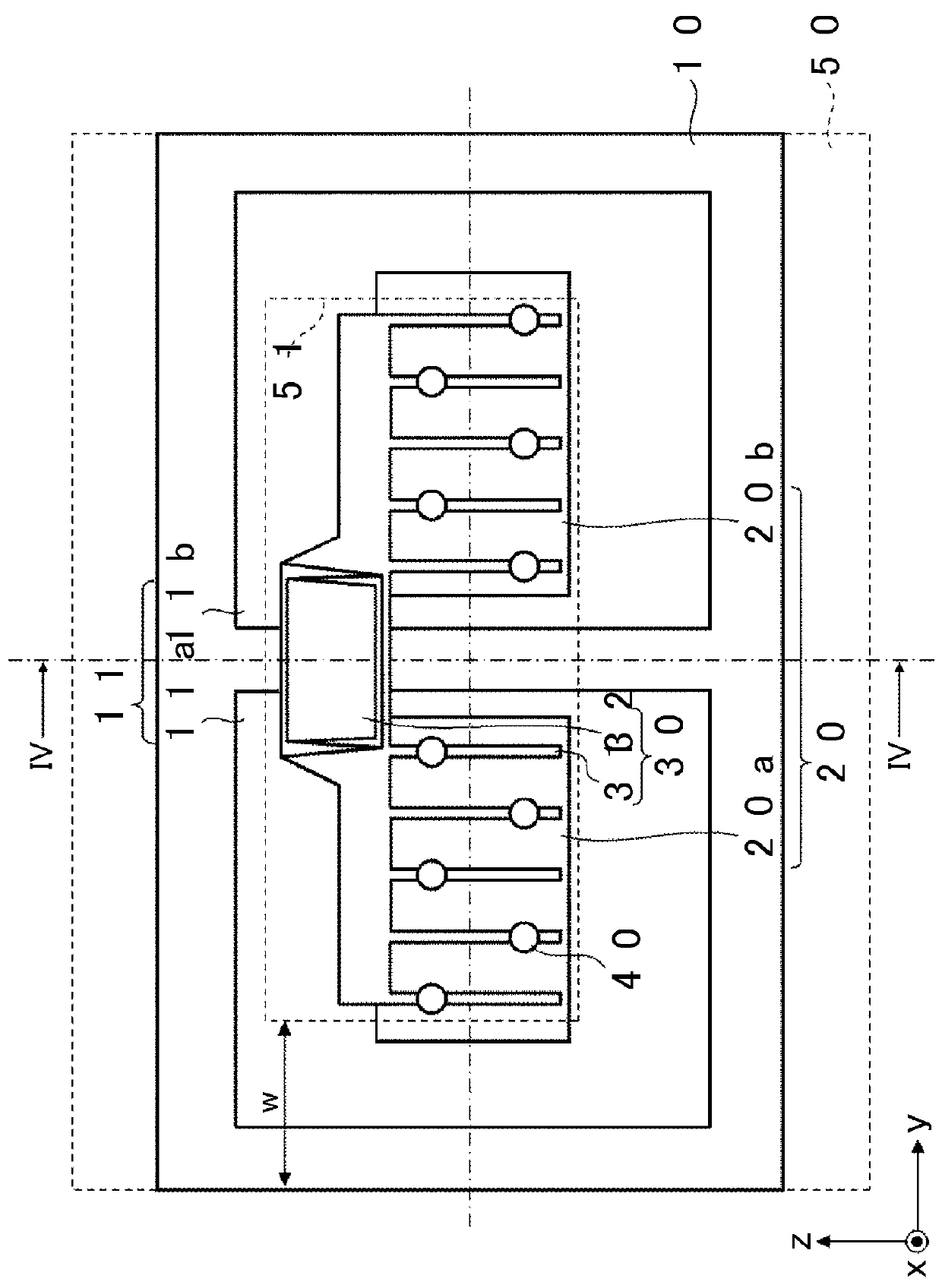

Battery Pack Comprising Combined Temperature-Controlling System

ActiveUS20090305124A1Minimize temperature differenceTemperature controlCell temperature controlBattery isolationForeign matterTemperature control

Disclosed herein is a middle- or large-sized battery pack including a plurality of unit cells electrically connected with each other, wherein the battery pack is constructed in a structure in which a heat transfer medium flows through gaps defined between the unit cells for controlling the overall temperature of the battery pack to be within a predetermined temperature range for the optimum operation of the battery pack, and each unit cell is provided at the outer surface thereof, at which the heat transfer medium is brought into contact with each unit cell, with a layer containing a phase transformation material (‘phase transformation layer’) for minimizing individual temperature difference between the unit cells. The present invention has the effect of controlling the overall temperature of the battery pack and individual controlling the temperatures of unit cells constituting the battery pack. Also, the present invention has the effect of restraining the abrupt change in temperature of the unit cells, when the battery pack is not in operation or when the external environment abruptly changes, thereby preventing the degradation of the unit cells. Furthermore, the present invention has the effect of minimizing damage to the unit cells due to foreign matter when the foreign matter is brought into contact with the unit cells. In addition, the present invention has the effect of reducing the overall temperature difference of the battery pack and manufacturing a middle- or large-sized battery pack having a compact structure.

Owner:LG ENERGY SOLUTION LTD

Heat spreader for display device

InactiveUS20060171124A1Temperature differenceGraphiteGas discharge vessels/containersLiquid-crystal displayDisplay device

A heat spreader for a display device, such as a plasma display panel, a light emitting diode or a liquid crystal display, which includes at least one sheet of compressed particles of exfoliated graphite having two major surfaces.

Owner:NEOGRAF SOLUTIONS LLC

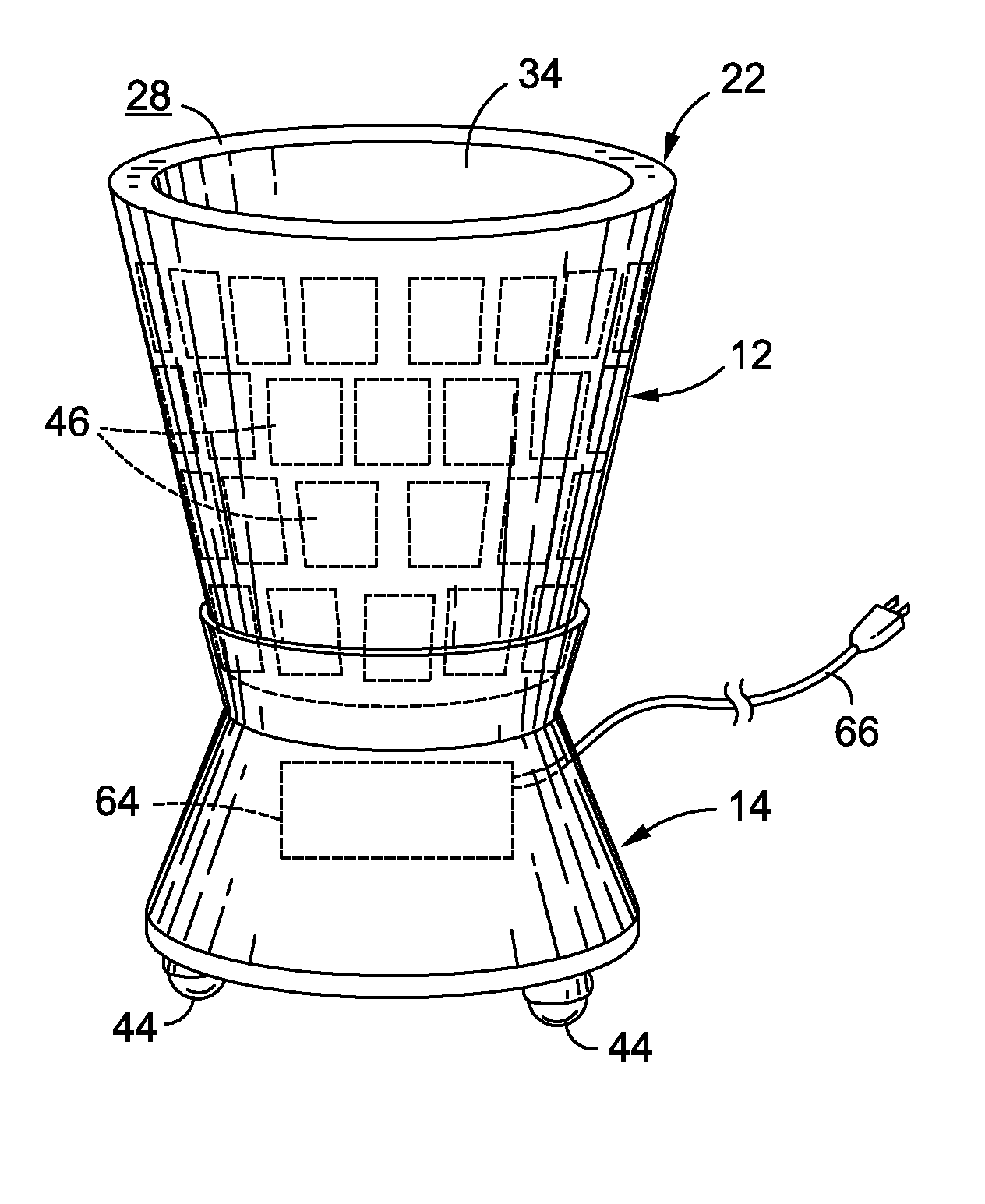

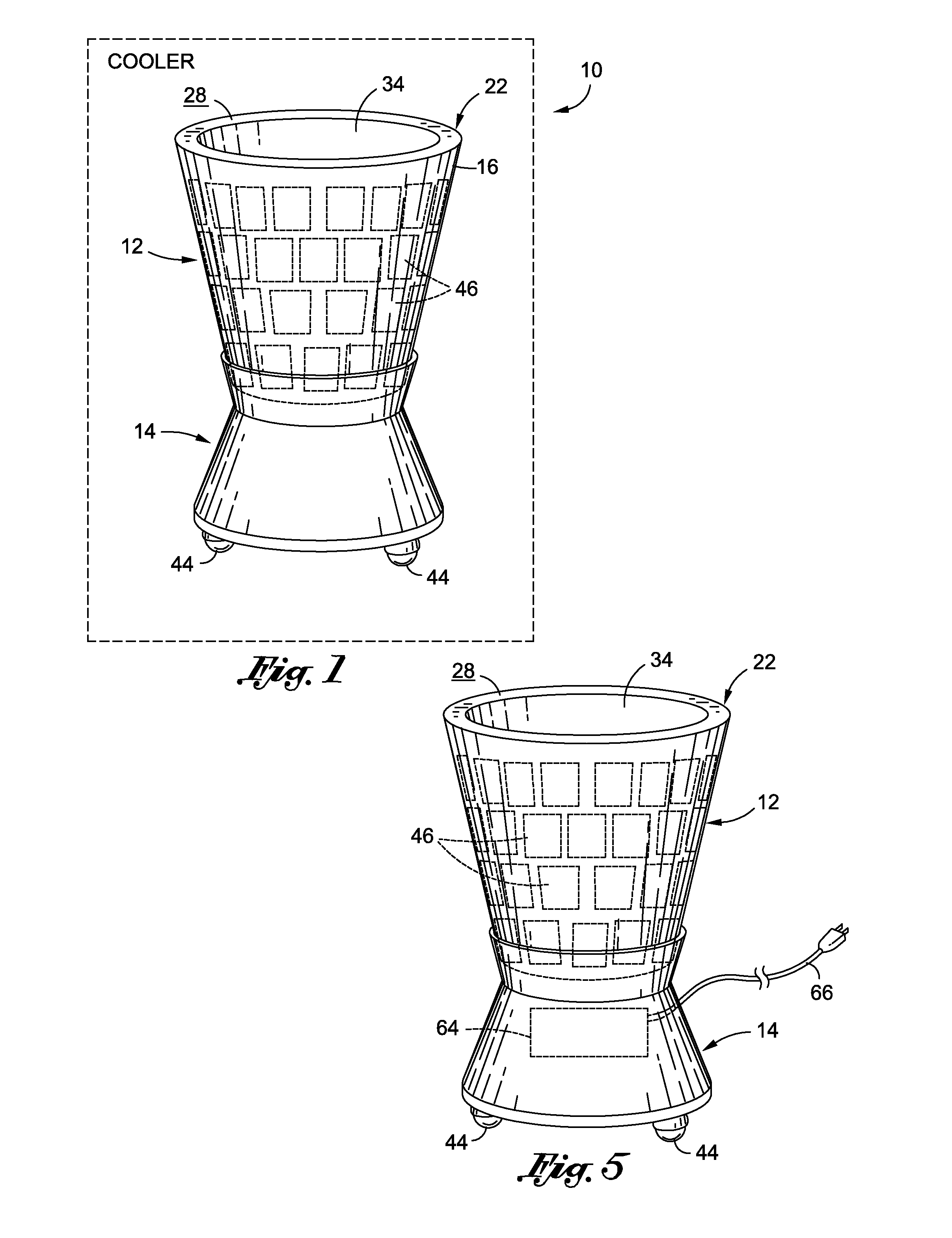

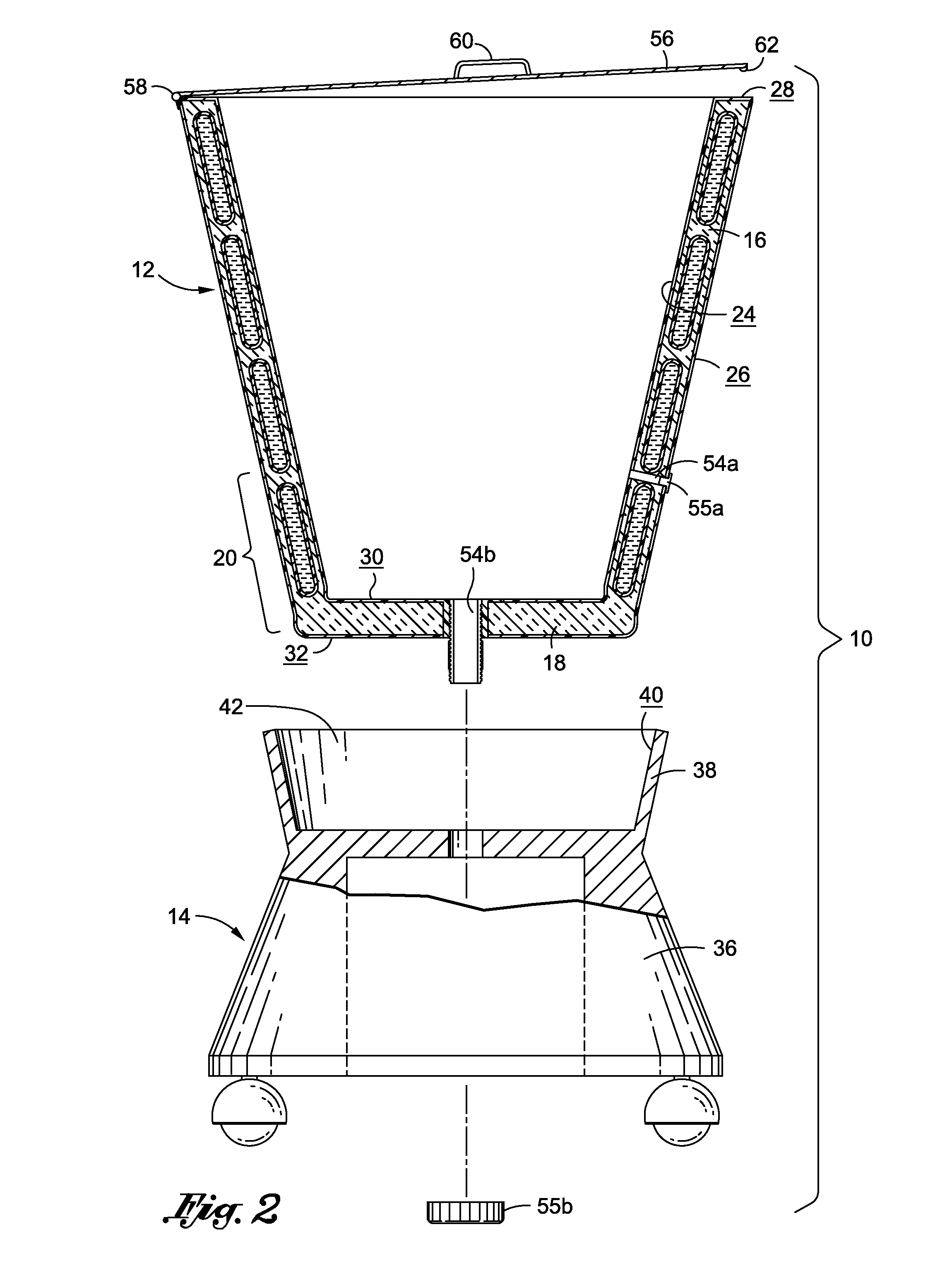

Refreezable ice barrel

ActiveUS20110041546A1Reduce the amount requiredFewer ice refillsContainer filling methodsDomestic refrigeratorsWater useEngineering

Provided is an environmentally friendly refreezable barrel for chilling a plurality of items in an energy efficient manner that also conserves water. The refreezable barrel includes a cooler body defining an open end and a closed end portion. The cooler body defines a cavity extending from the open end towards the closed end portion. The cavity is configured to receive the plurality of items. A cooling element is disposed within the cooler body and is refreezable to mitigate temperature rise within the cooler body to prolong the melting of ice within the barrel, thereby reducing the overall amount of water used by the barrel. The refreezable barrel also includes a cooler stand defining a recess configured to engage with the closed end portion of the cooler body.

Owner:INNOVATIVE DISPLAYWORKS INC

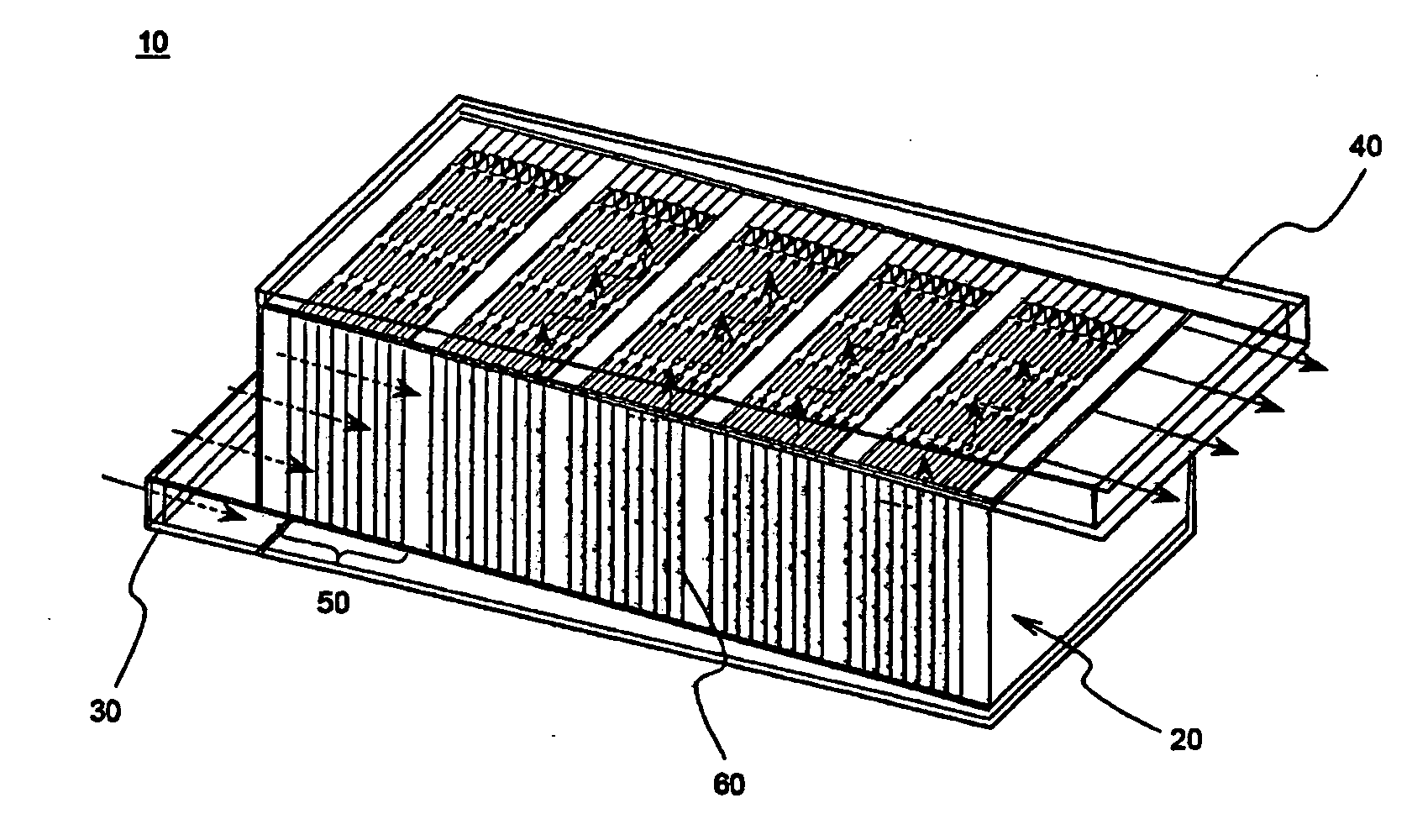

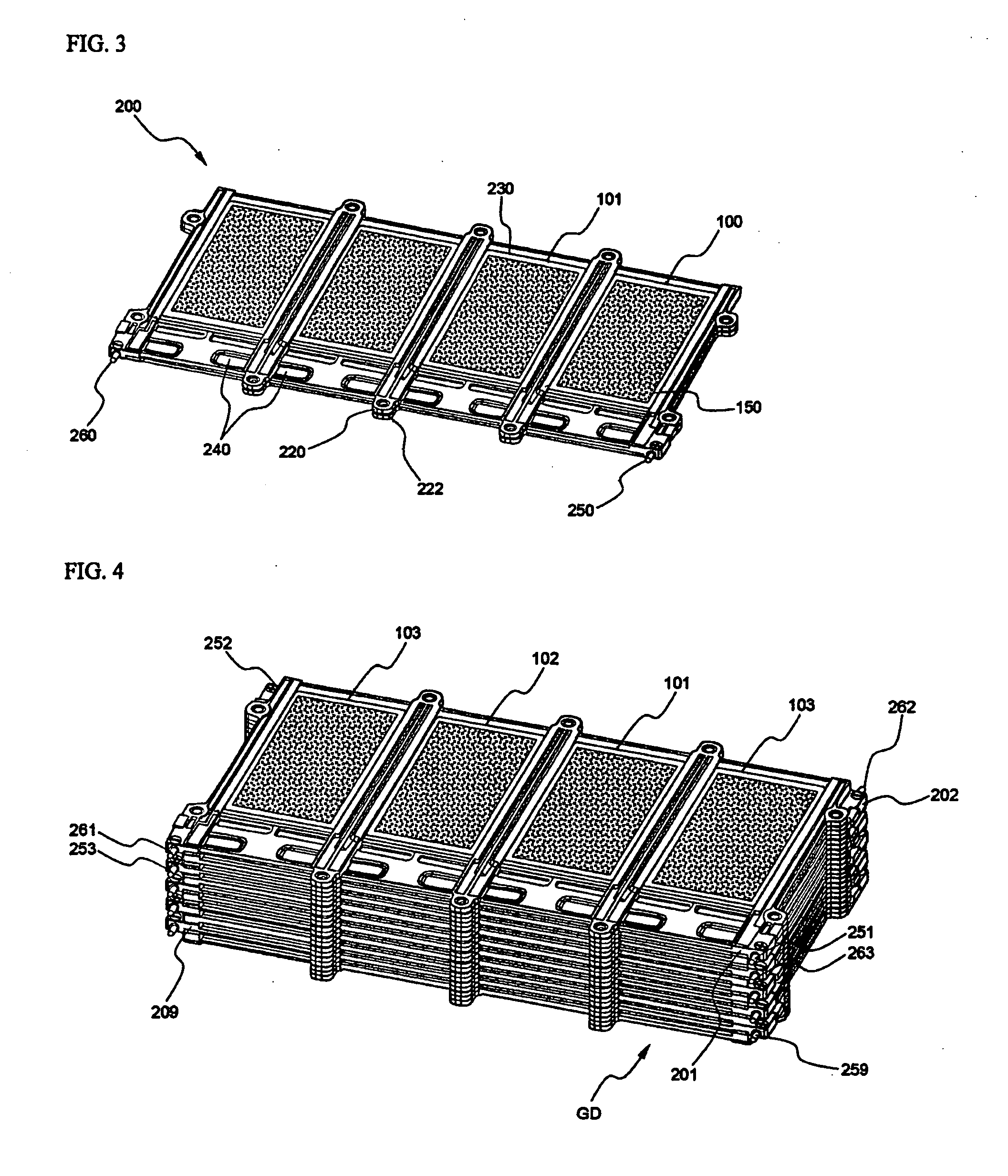

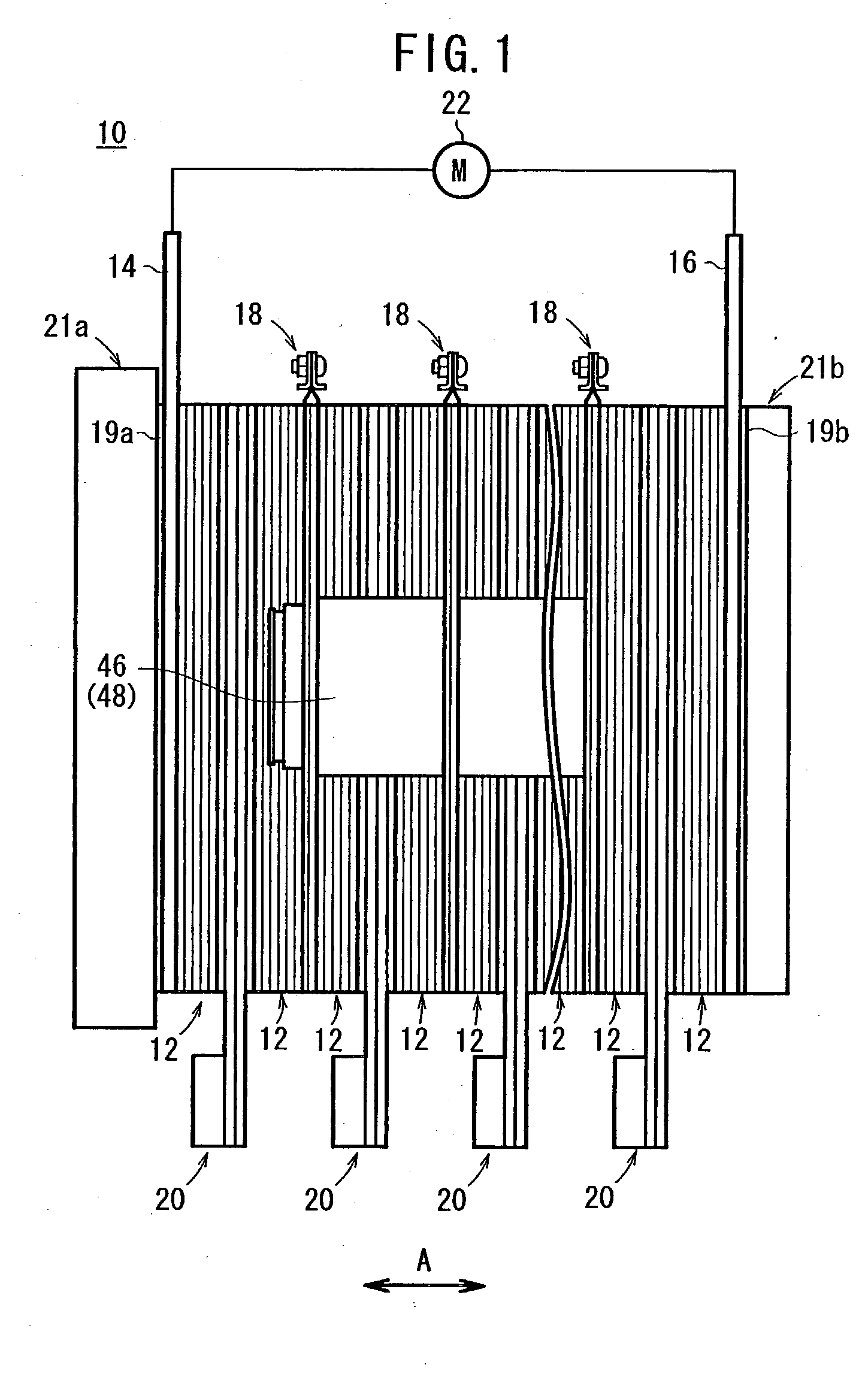

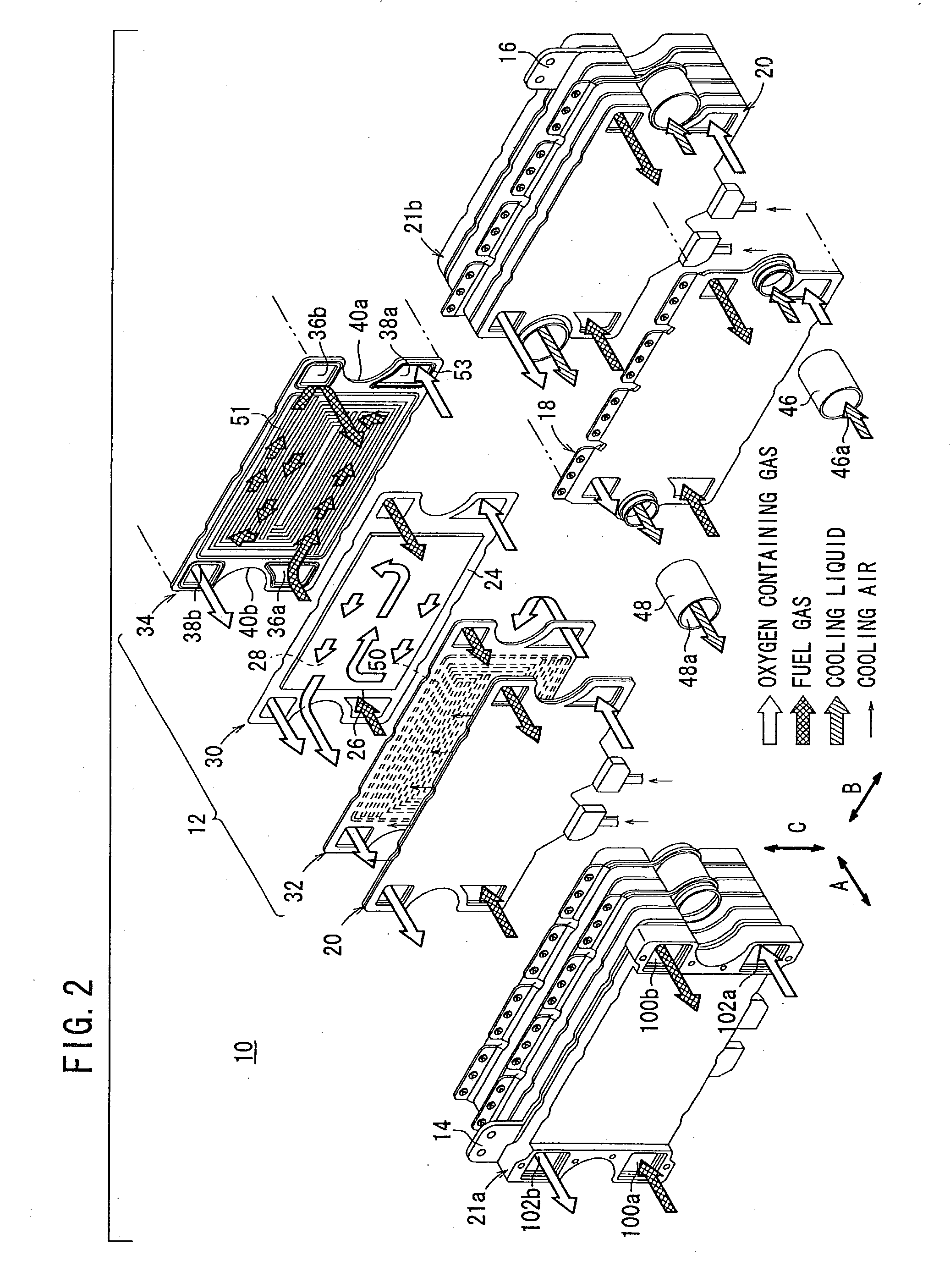

Fuel cell stack

InactiveUS20050266286A1Simple and compact structurePower generation performance is maintained desirablyFuel cell heat exchangeFuel cells groupingFuel cellsNuclear engineering

A fuel cell stack includes power generation cells, terminal plates, first cooling cells, and second cooling cells. The terminal plates are electrically connected to the power generation cells. The first cooling cells are interposed between the terminal plates, and a cooling liquid is supplied to the first cooling cells for cooling the power generation cells. The second cooling cells are interposed between the terminal plates. A predetermined number of power generation cells are interposed between the first cooling cell and the second cooling cell. A cooling air is supplied to the second cooling cell for cooing the power generation cells.

Owner:HONDA MOTOR CO LTD

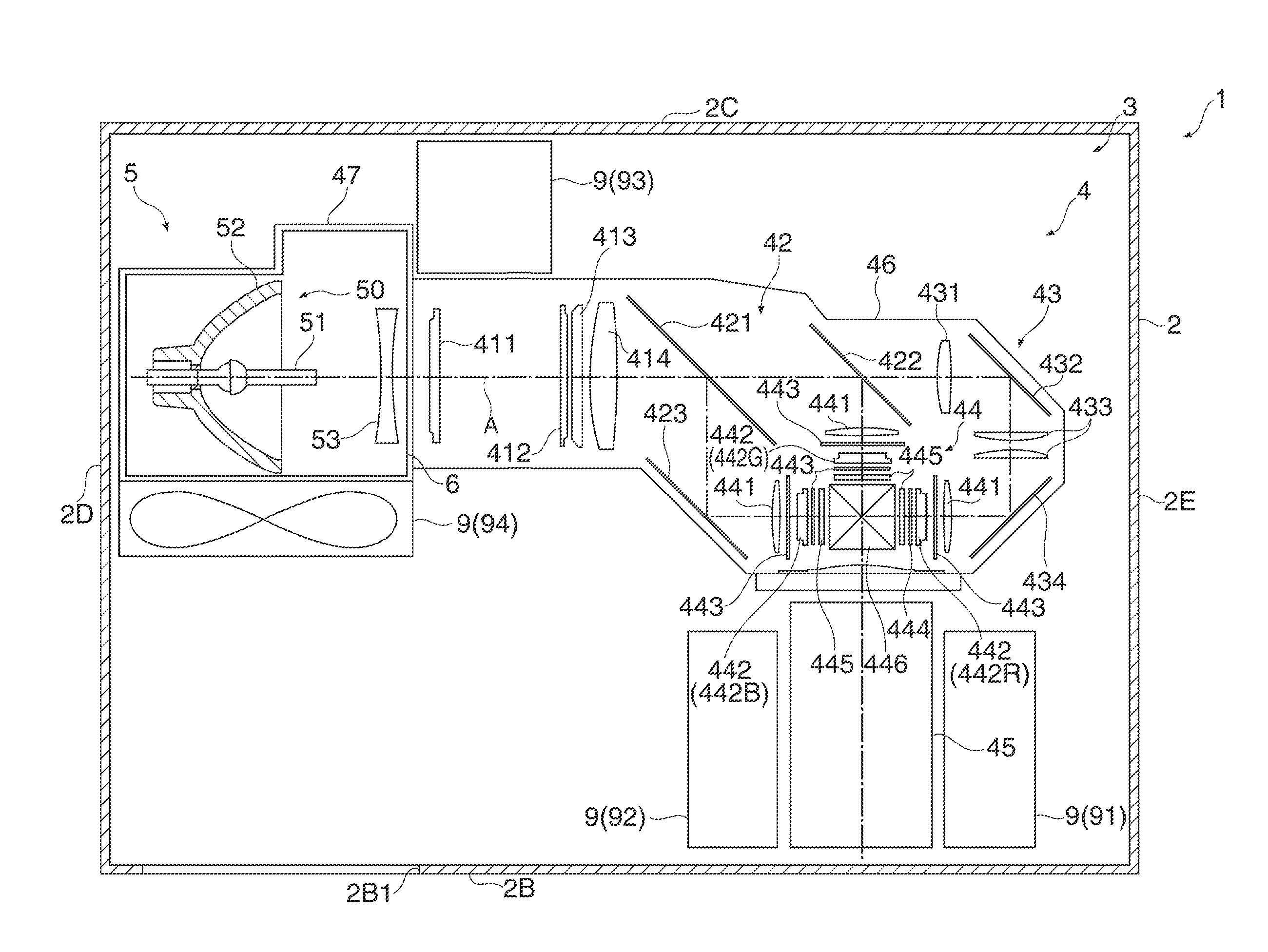

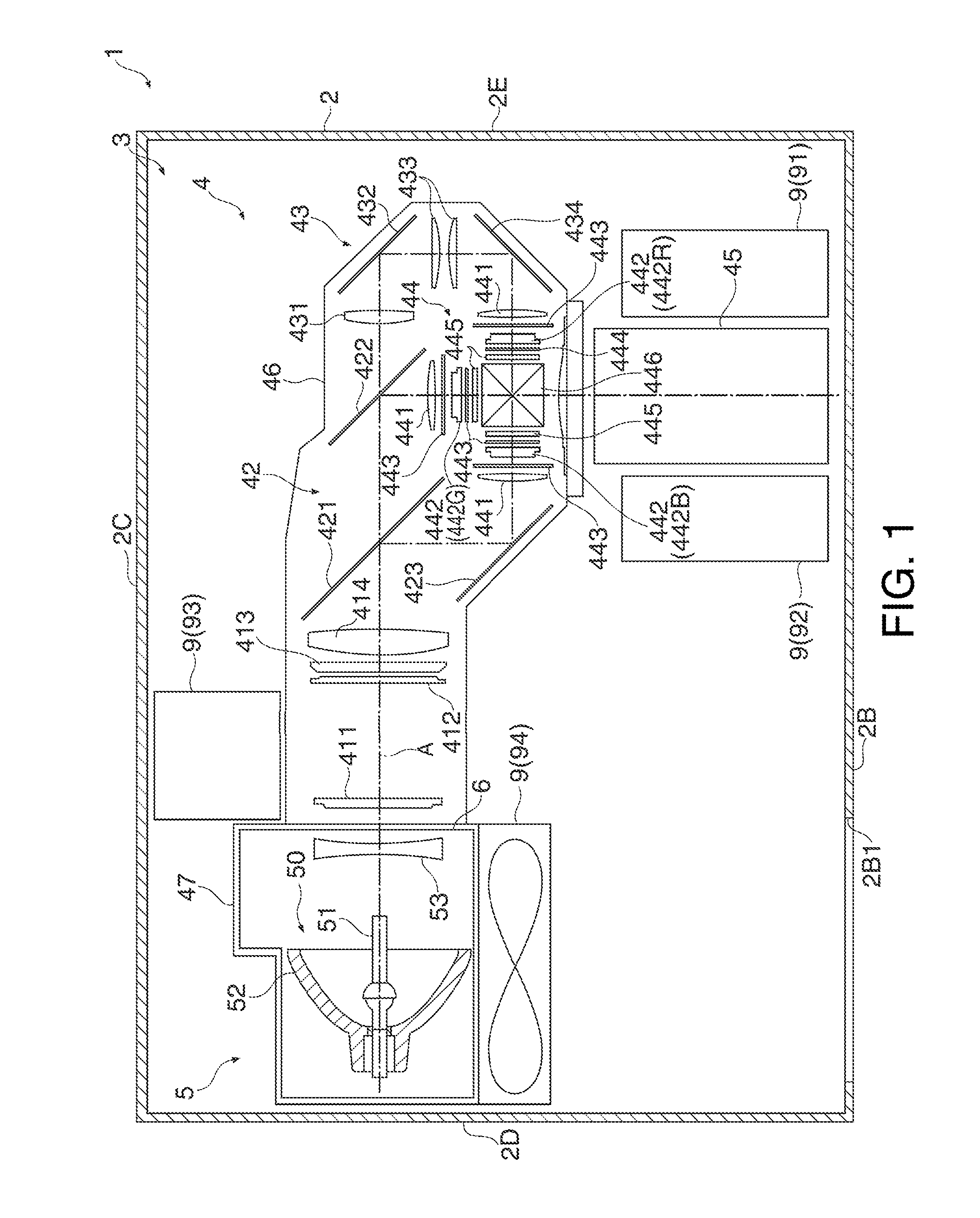

Light source device and projector

ActiveUS20100103382A1Reduce necessityReduce laborPoint-like light sourceElectric discharge tubesForamen PrimumLight emission

A light source device includes: an arc tube having a light emission portion; a first reflection mirror having a substantially concave surface for reflecting light emitted from the light emission portion; and a container which accommodates the arc tube and the first reflection mirror, wherein the container has a duct unit disposed above the arc tube. The duct unit includes a first opening open to the arc tube and disposed at a position shifted toward the traveling direction side from an opening end of the first reflection mirror, a wall portion which forms the edge of the first opening on the side opposite to the traveling direction side as a final end of the duct unit, and an inclined portion disposed in the vicinity of the edge of the first opening on the traveling direction side to bend the flowing direction of the cooling air toward the surface opposite to the surface having the first opening.

Owner:SEIKO EPSON CORP

Heat spreader for emissive display device

InactiveUS20070042188A1Increase temperature differenceTemperature differenceTube/lamp screens manufactureMaterial nanotechnologyDisplay deviceGraphite

Owner:NEOGRAF SOLUTIONS LLC

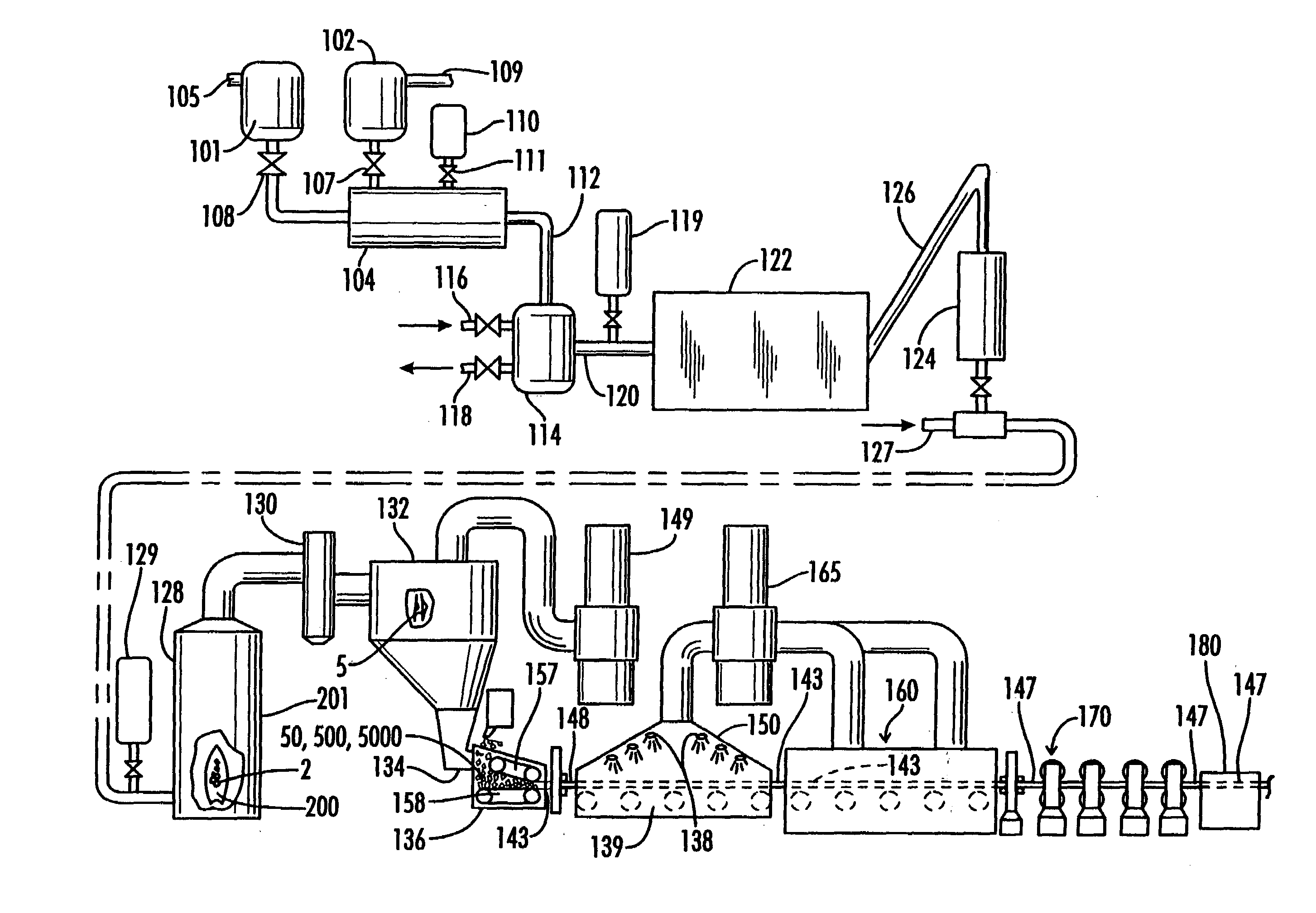

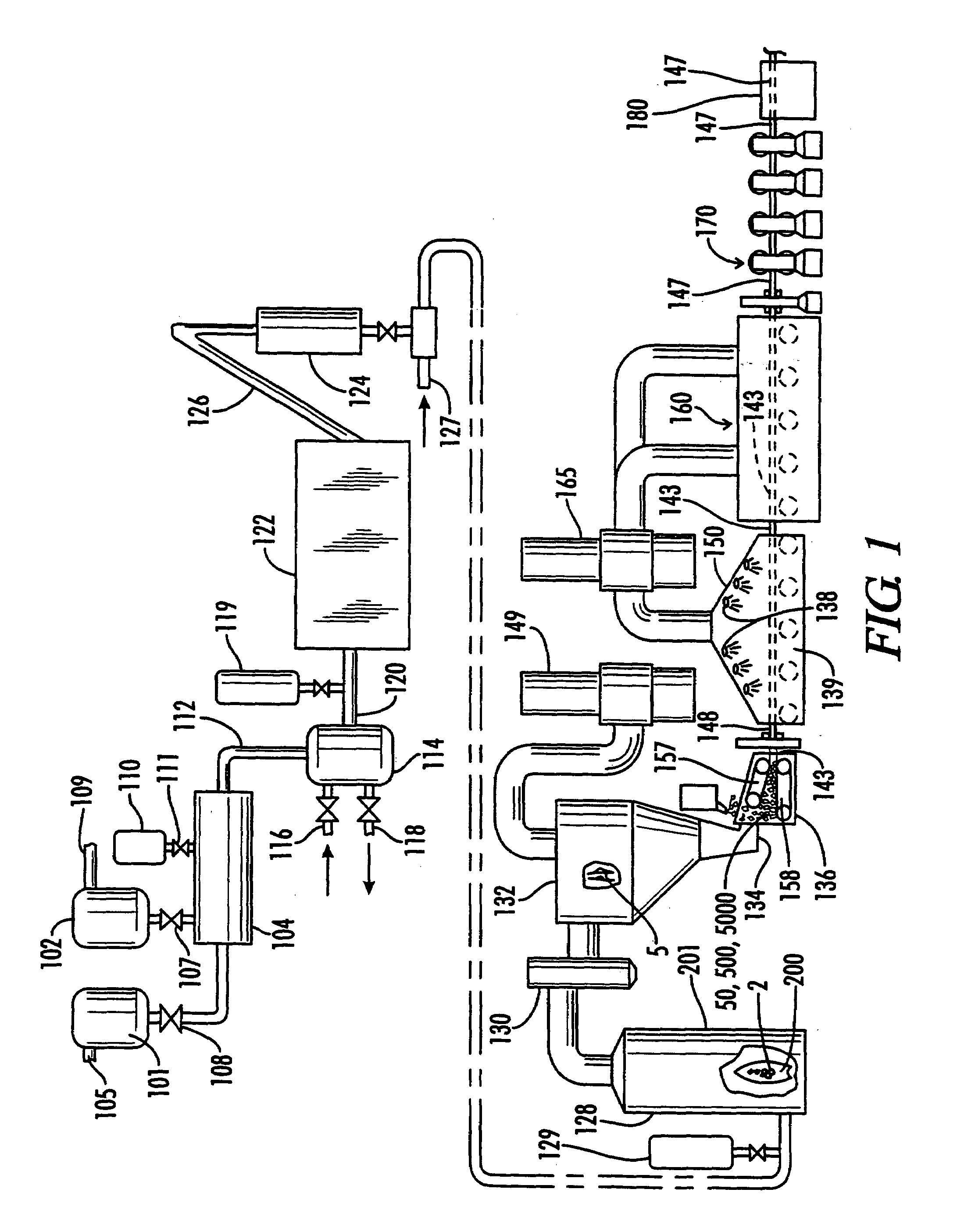

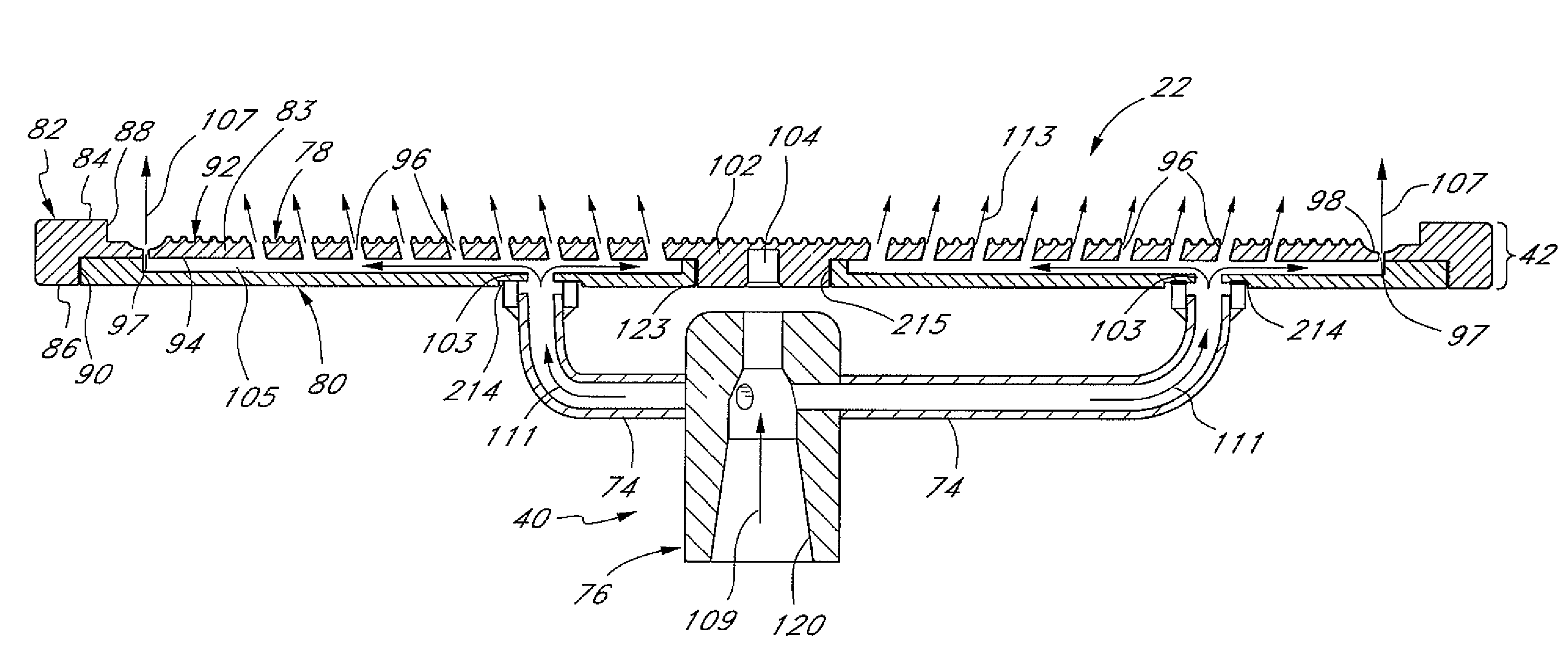

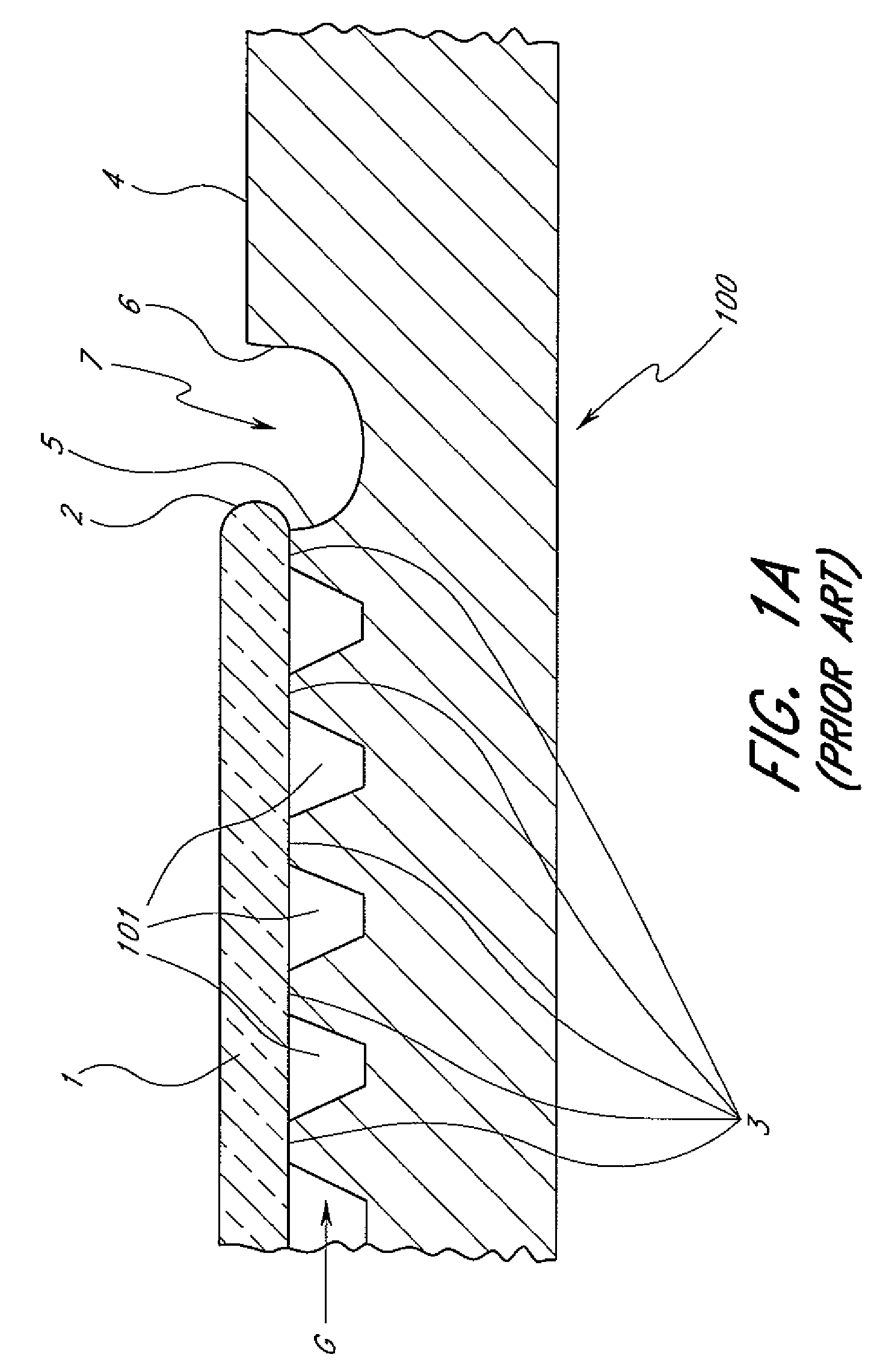

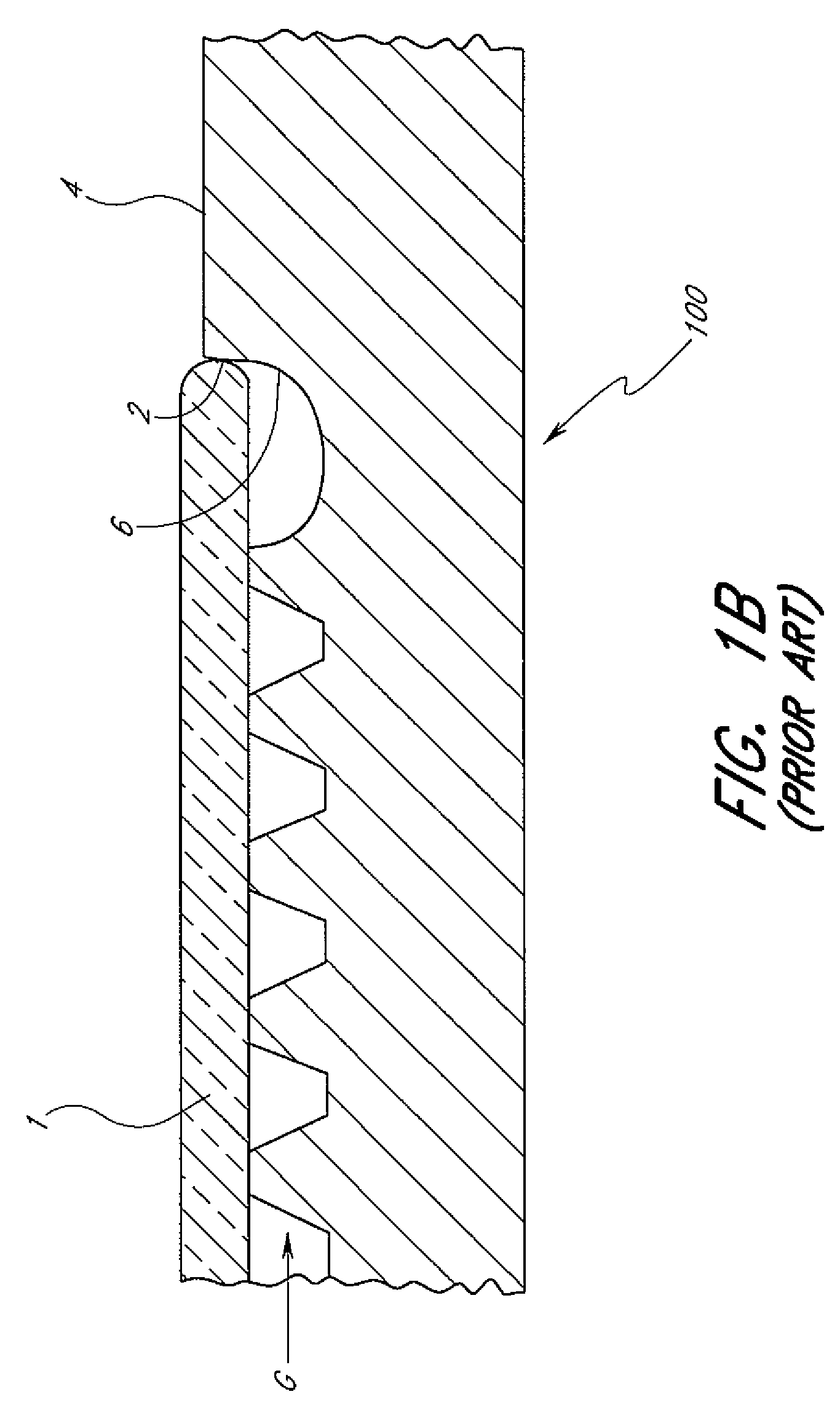

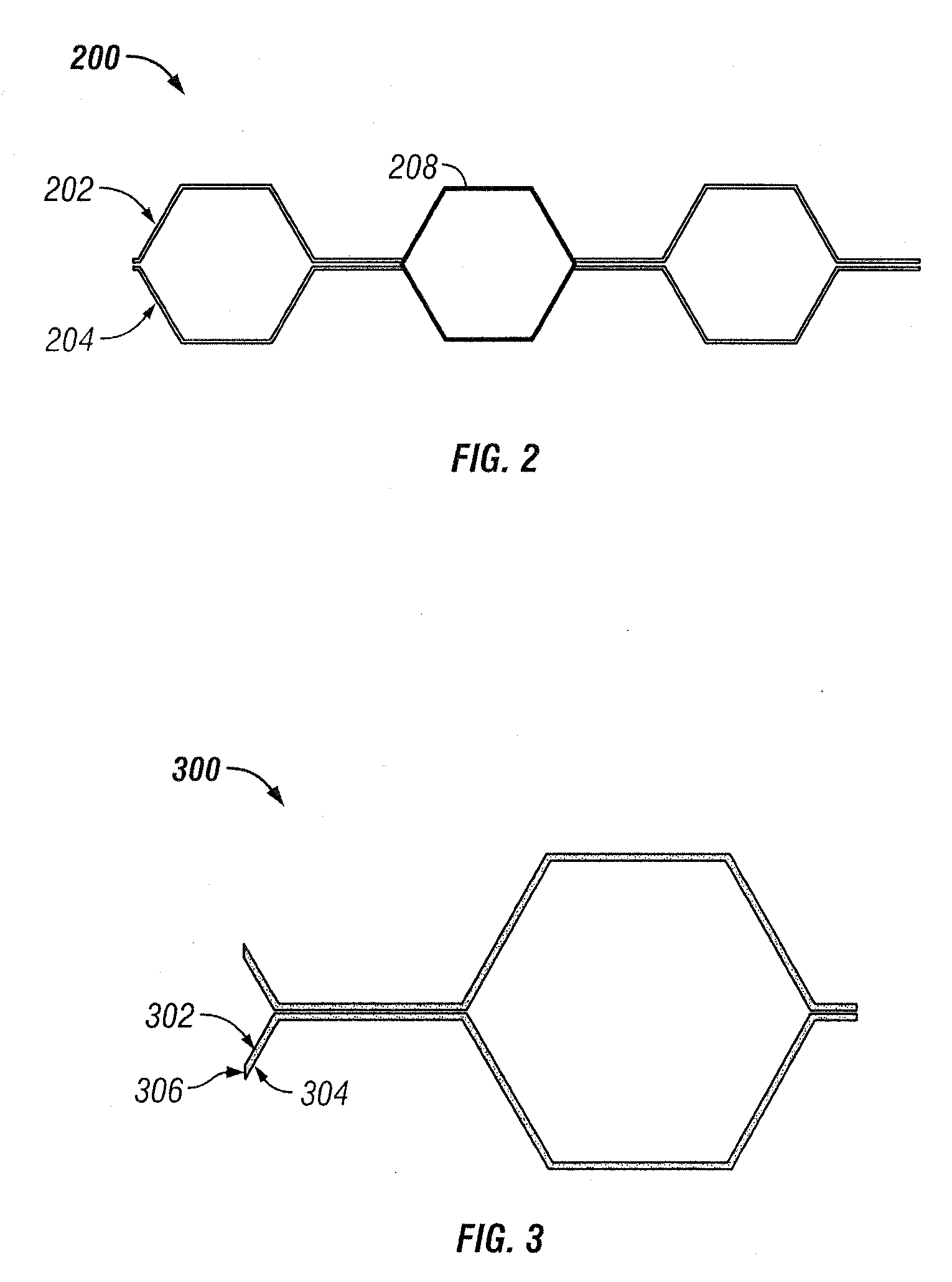

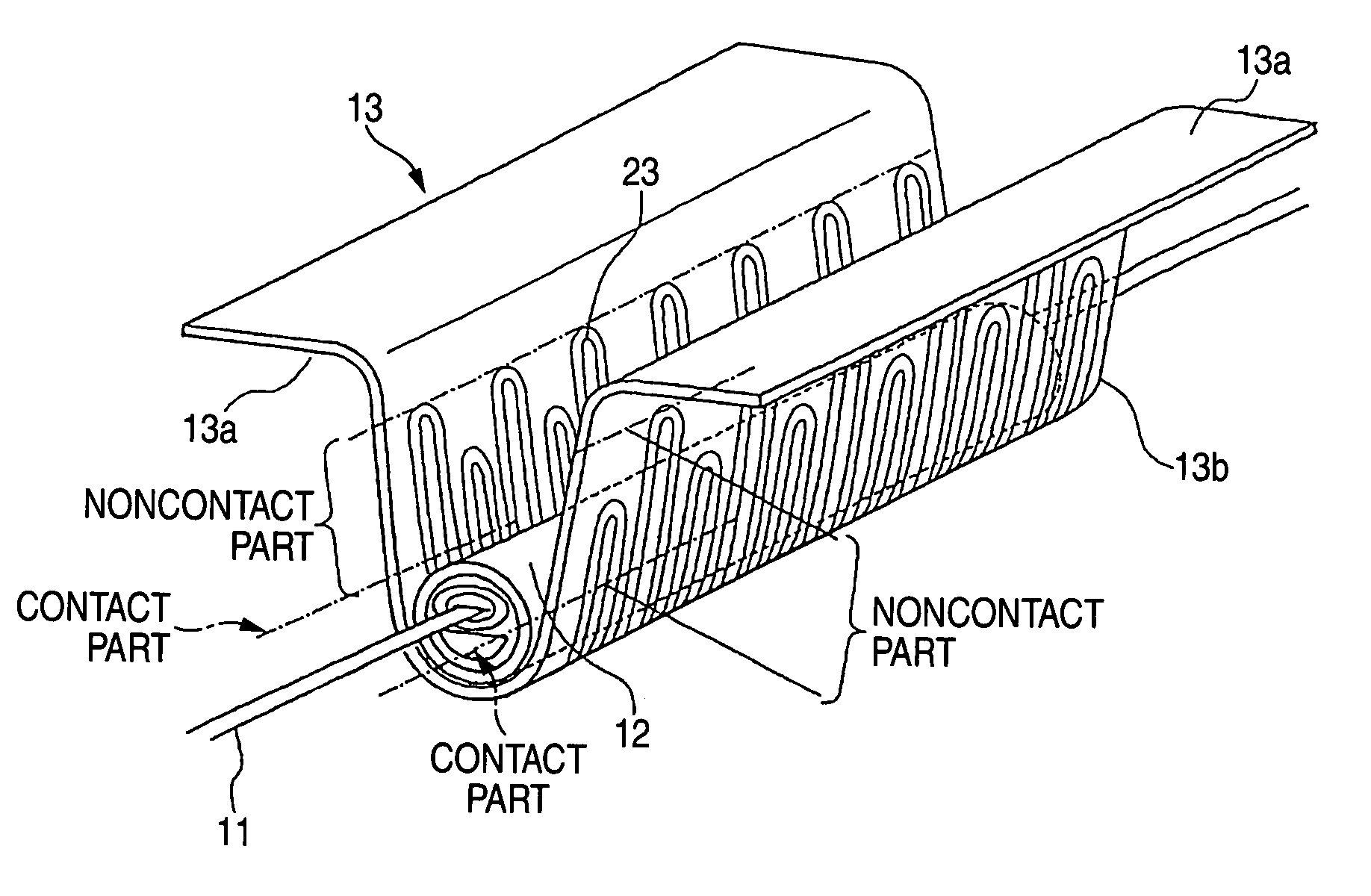

Method of supporting a substrate in a gas cushion susceptor system

InactiveUS7601224B2Slow its descentReduce temperature differenceVacuum evaporation coatingSemiconductor/solid-state device manufacturingSusceptorEngineering

An apparatus and method to position a wafer onto a wafer holder and to maintain a uniform wafer temperature is disclosed. The wafer holder or susceptor comprises a recess or pocket whose surface includes a grid containing a plurality of grid grooves that separate protrusions. A plurality of gas passages is provided in the susceptor to enable an upward flow of gas toward the bottom surface of the substrate. During drop-off of the substrate, a cushion gas flow is provided to substantially slow the rate of descent of the substrate onto the susceptor and to gradually heat the substrate before it makes contact with the susceptor. Optionally, a trickle gas flow may be provided through the aforementioned passages during processing of the substrate to prevent deposition of reactant gases onto the bottom surface of the substrate. A liftoff gas flow may then be provided through the passages to help lift the substrate off of the susceptor after processing is completed and thus aid in removing the substrate from the process chamber. These features help to achieve temperature uniformity and thus quality of deposited films onto the substrate.

Owner:ASM IP HLDG BV

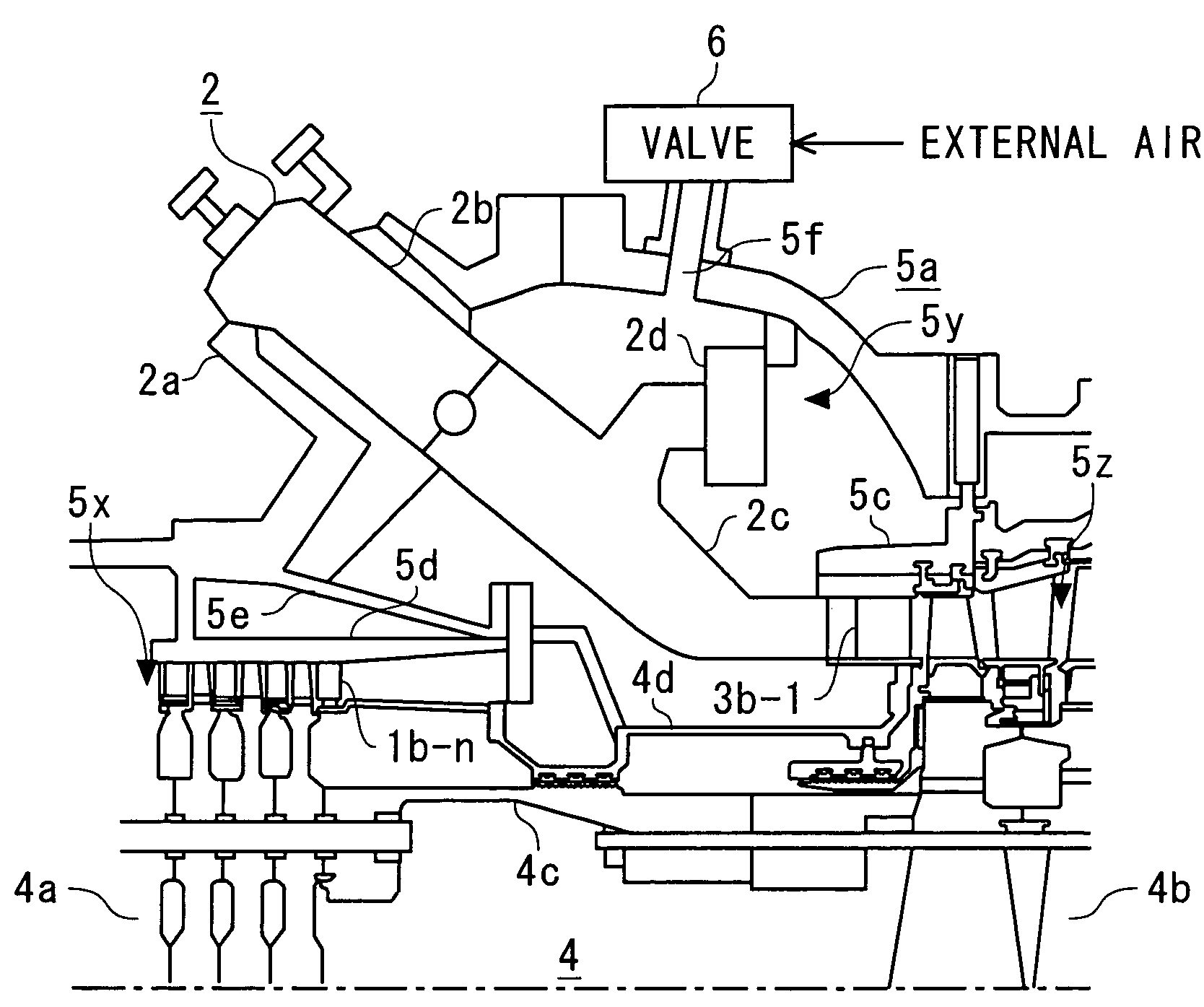

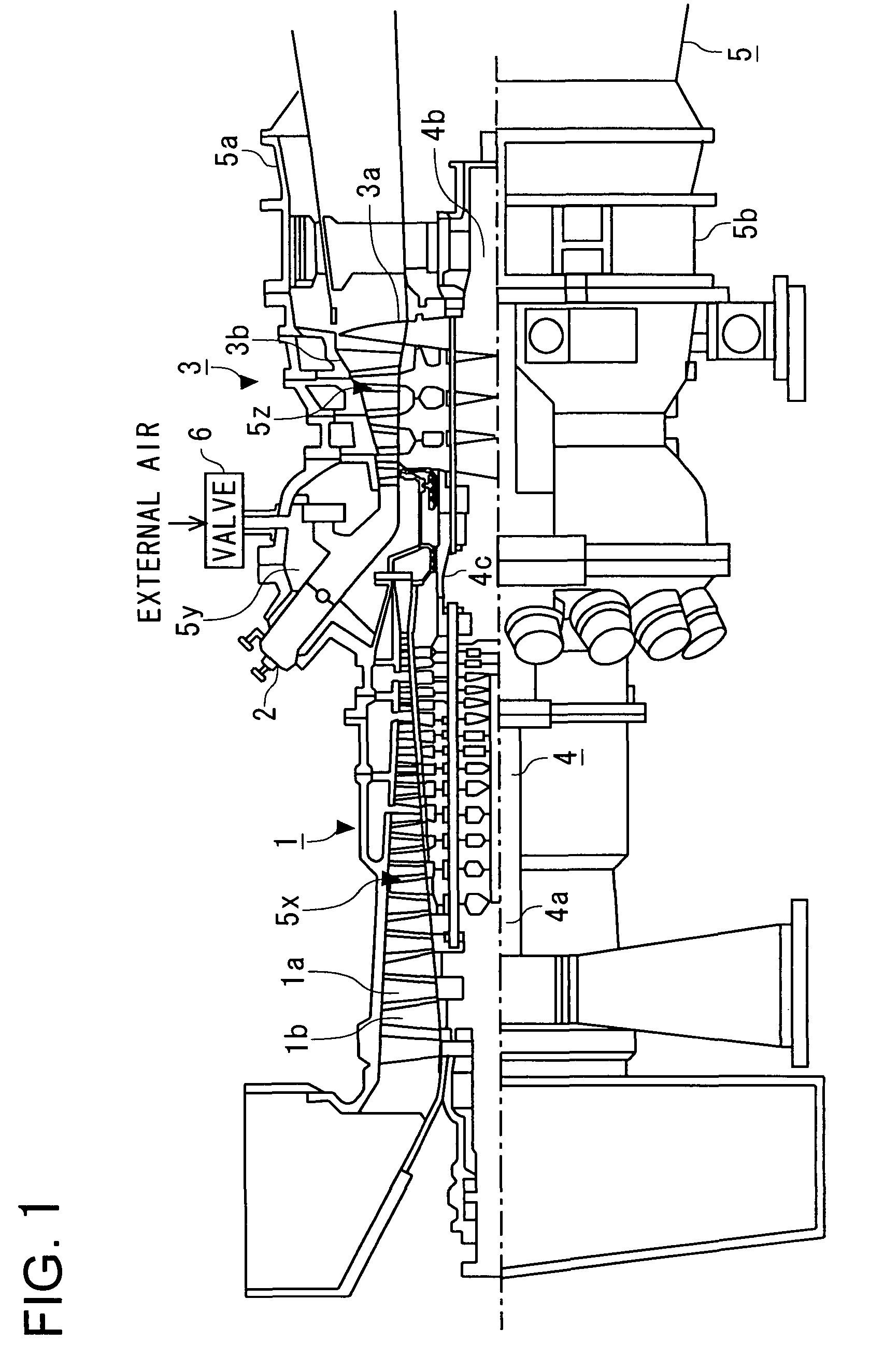

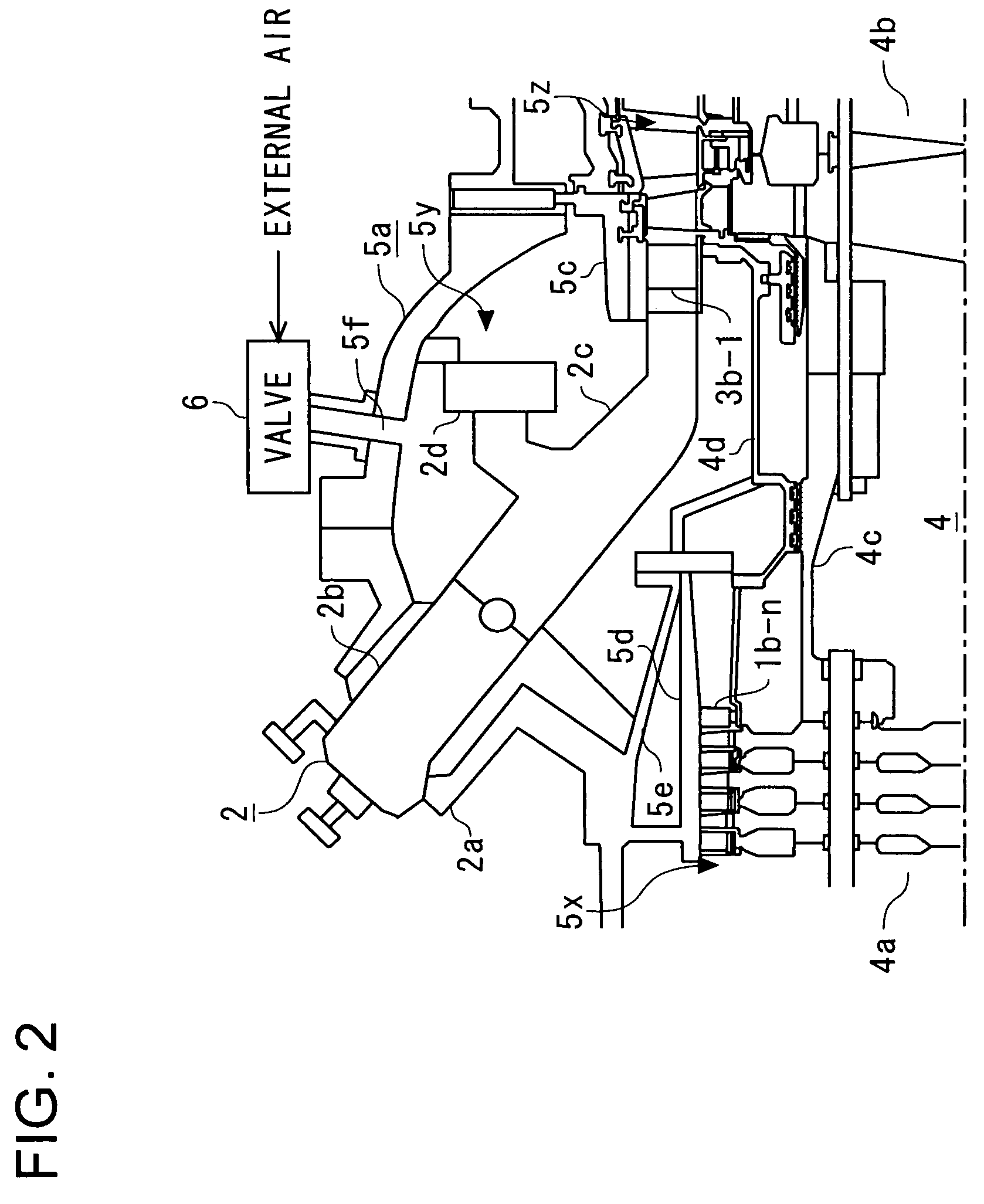

Casing and gas turbine

ActiveUS7798767B2Prevent thermal deformationAvoid temperatureWind motor controlEngine fuctionsThermal deformationGas turbines

A valve (6) for supplying the external air to the inside of an upper casing (5a) is provided to the upper casing (5a), and when the operation of a gas turbine is stopped, the external air is introduced from the upper casing (5a) to the inside of the casing (5). When the external air is introduced from the upper casing (5a), the upper casing (5a) is cooled to prevent thermal deformation of the casing (5).

Owner:MITSUBISHI POWER LTD

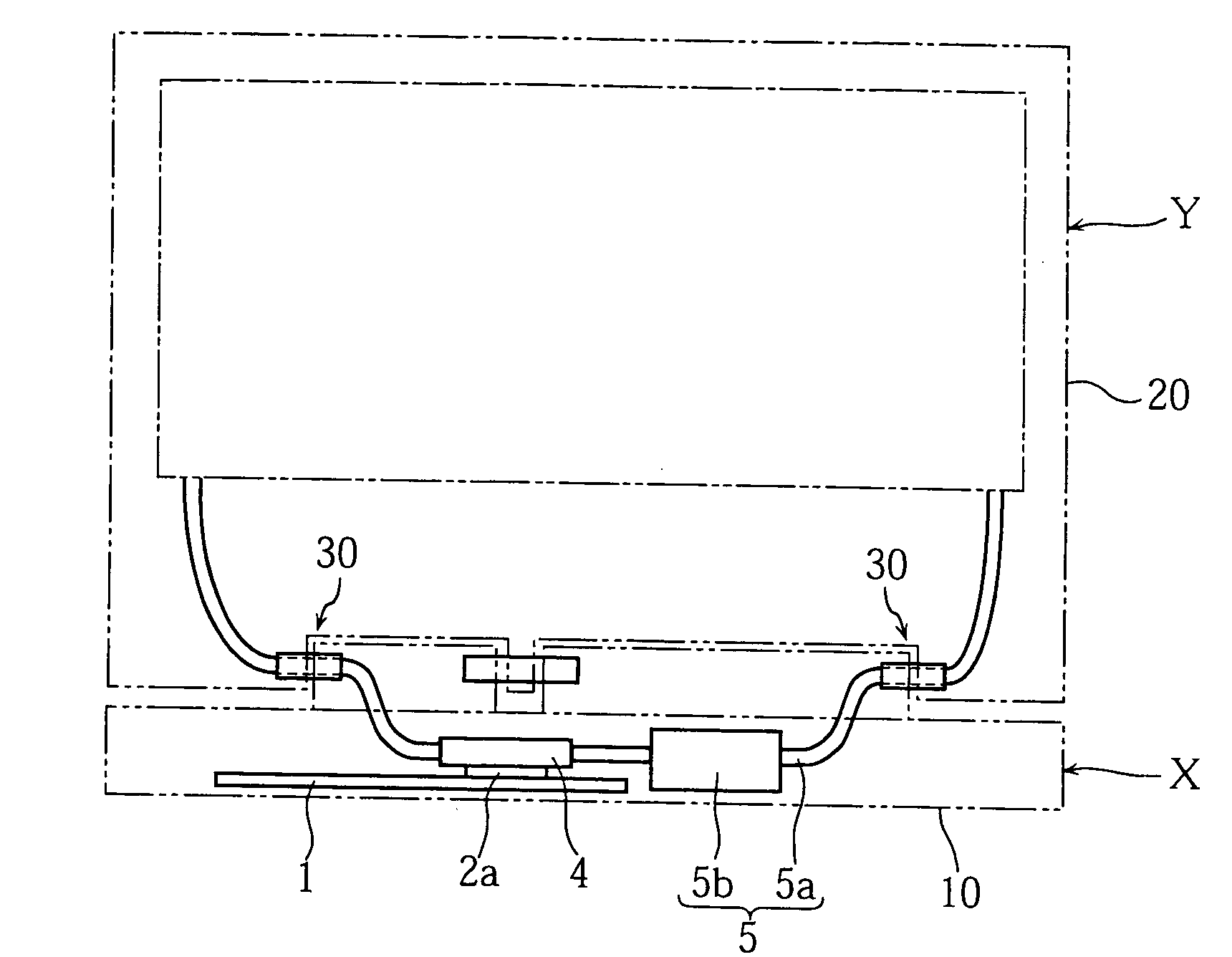

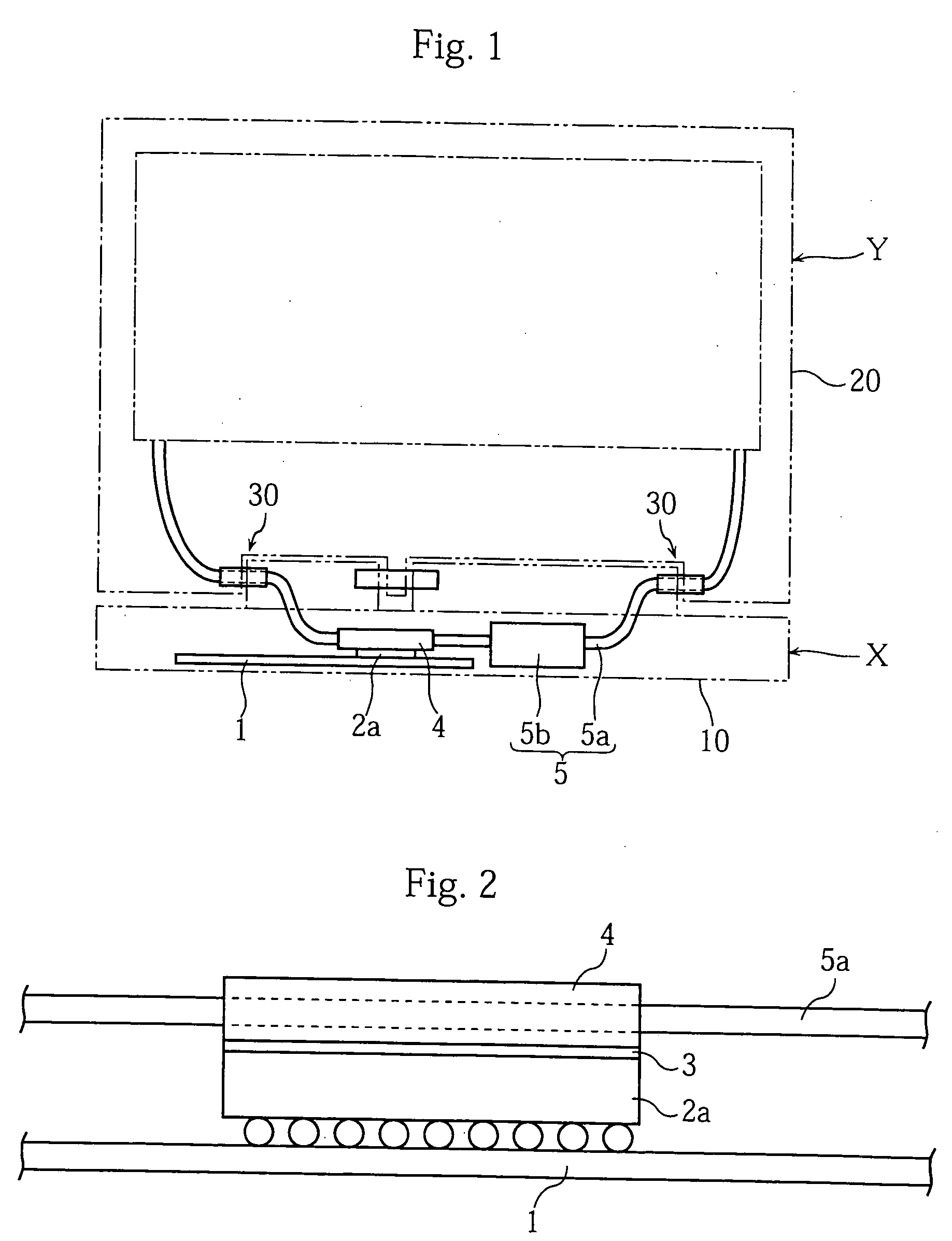

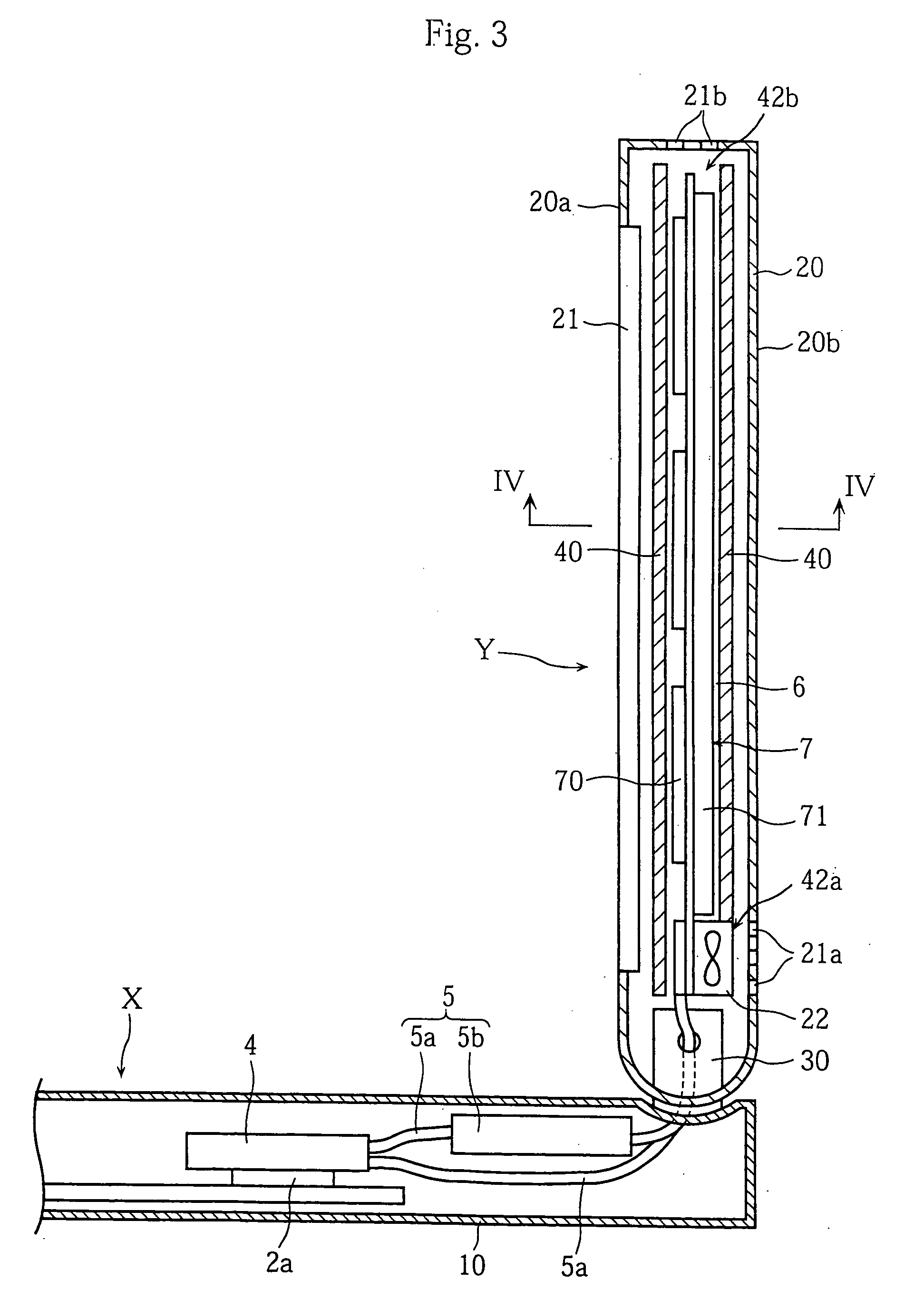

Cooling structure for electronic equipment

InactiveUS20060005549A1Improve cooling effectReduce adverse effectsDomestic cooling apparatusSemiconductor/solid-state device detailsEngineeringMechanical engineering

A cooling structure for electronic equipment is designed for cooling a heat-generating body (2a) disposed inside a case (20) by recovering heat generated by the heat-generating body (2a) and dissipating the heat to the outside of the case (20). The cooling structure includes a heat-receiving section (4) for recovering heat generated in the heat-generating body (2a), a thermally insulated space (6) provided with an air inflow orifice (42a) and an air outflow orifice (42b) and thermally insulated from the heat-generating body (2a) and heat-receiving section (4) by a thermally insulating member (40), a heat-dissipating section (7) provided inside the thermally insulated space (6), a heat transfer member (5) for transferring the heat recovered in the heat-receiving section (4) to the heat-dissipating section (7), and a fan (22) for generating forcibly an air flow in the thermally insulated space (6). The heat generated by the heat-generating body (2a) is transferred to the heat-dissipating section (7) via the heat-receiving section (4) and heat transfer member (5) and dissipated in a concentrated fashion by using the fan (22) inside the thermally insulated space (6).

Owner:FUJITSU LTD

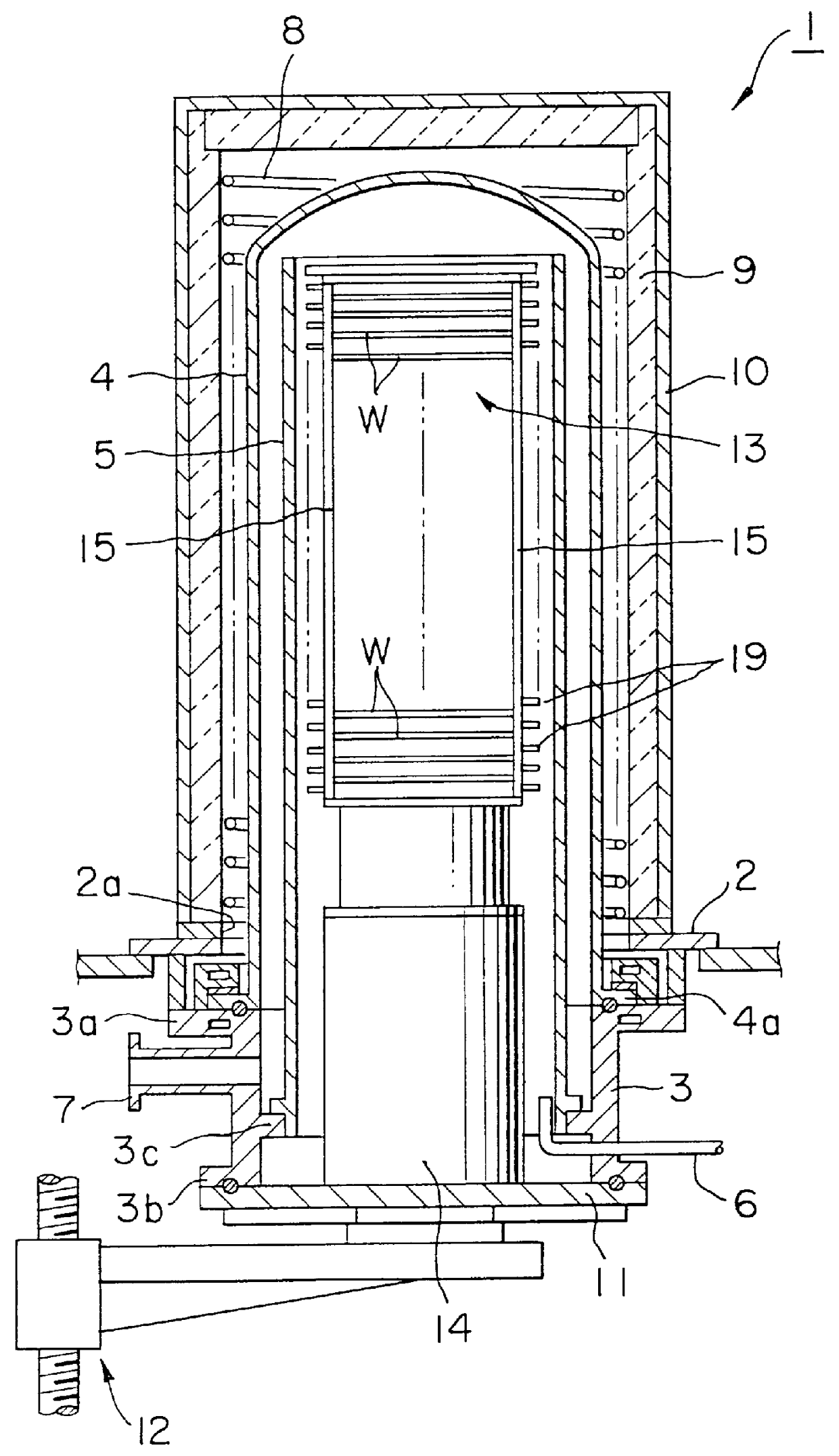

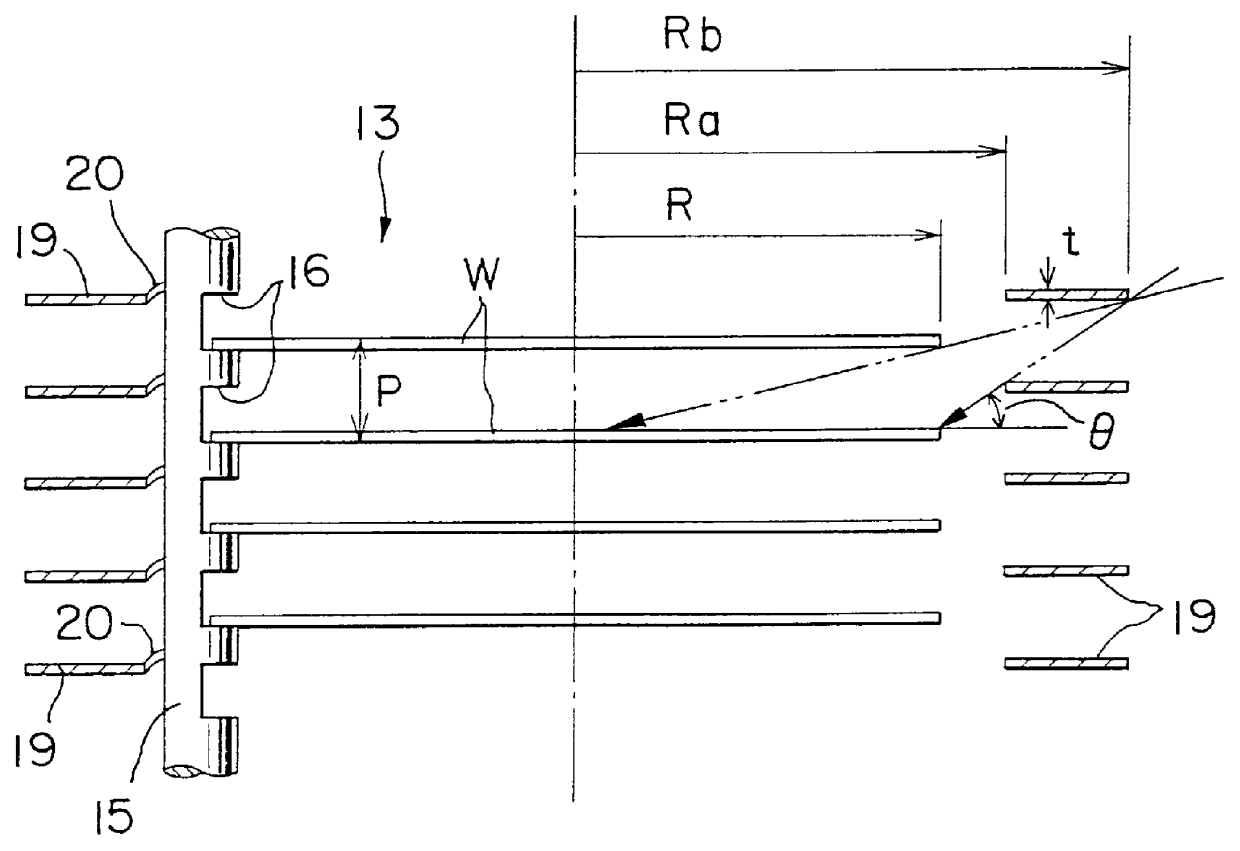

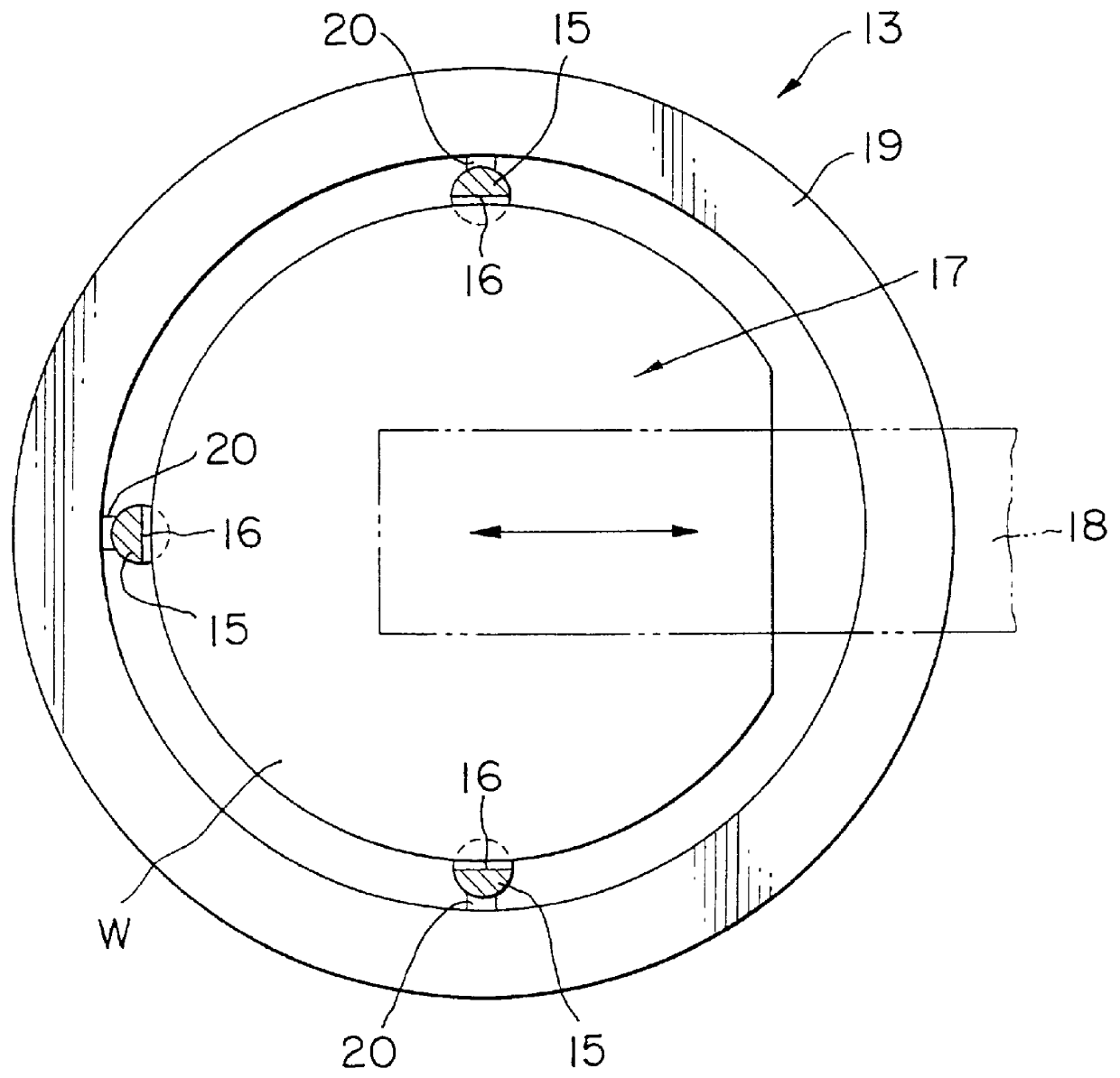

Thermal treatment apparatus with thermal protection members intercepting thermal radiation at or above a predetermined angle

InactiveUS6031205ATemperature differenceTemperature can be raised and loweredMuffle furnacesDiffusion/dopingAngle of incidenceEngineering

PCT No. PCT / JP96 / 00503 Sec. 371 Date Sep. 10, 1997 Sec. 102(e) Date Sep. 10, 1997 PCT Filed Mar. 1, 1996 PCT Pub. No. WO96 / 28843 PCT Pub. Date Sep. 19, 1996In a thermal treatment apparatus that accommodates substrates to be processed (W) in multiple stages within a reaction tube (4) and subjects them to a thermal treatment, thermal protection members (19) are provided around the peripheries of the substrates (W) to be processed to intercept thermal radiation that is incident on the peripheral edge portions thereof at a predetermined angle of incidence or greater. The peripheral edge portions of substrates (W) to be processed are generally more readily affected by thermal radiation as the angle of incidence of thermal radiation thereon increases, but, since thermal radiation from the heater at a predetermined angle of incidence ( theta ) or greater is intercepted by the thus disposed thermal protection members (19), the effects on thermal radiation on the peripheral edge portions of the substrates (W) to be processed are controlled. As a result, the temperature difference within the surface between the central portion and peripheral edge portion of each substrate to be processed (W) can be sufficiently reduced, not only under normal pressure within the reaction tube (4) but also under reduced pressures, and thus the temperature can be raised or lowered rapidly, enabling an increase in throughput.

Owner:TOKYO ELECTRON LTD

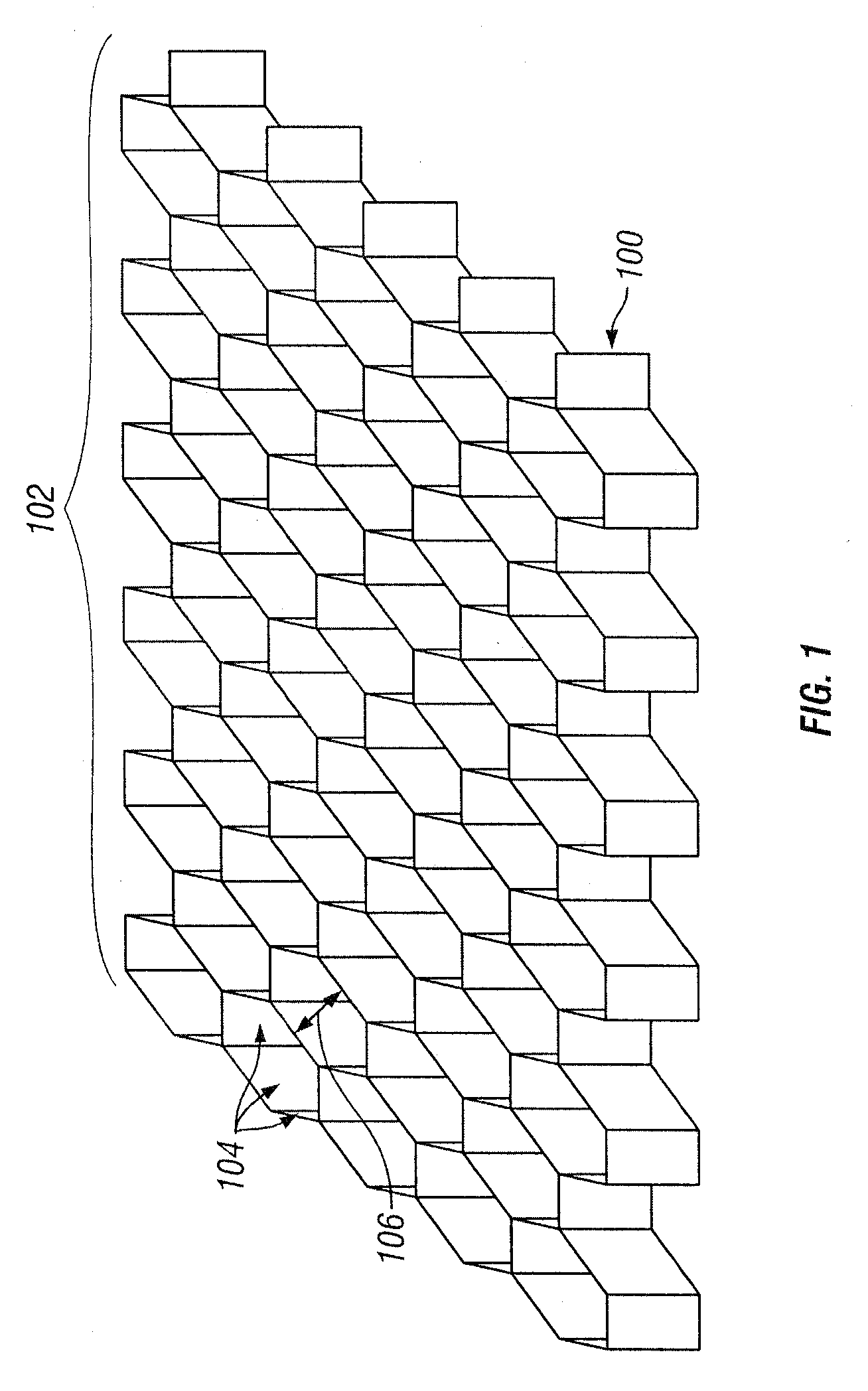

Thermally conductive structure

ActiveUS20090178410A1Reduce thermal deformationReduce and eliminate thermal deformationEngine manufacturePaper/cardboard articlesThermal deformationTemperature difference

A multi-layered honeycomb structure adapted to reduce and / or eliminate thermal deformation is disclosed herein. In some embodiments, walls of the honeycomb structure comprise a first layer, optionally, a second layer, and a core layer adjacent to the first layer or between the first and second layers. The first and second layers may be compositions of Inconel or other high strength materials. The core layer may be copper or another thermally conductive material. The core layer is adapted to transmit heat between a first region of a structure and a second region. In this manner, heat can be transferred from the heated region to an unheated region, thereby reducing the temperature difference between the regions and thus the amount of thermal deformation.

Owner:STRAZA GEORGE C P

Heat spreader for display device

InactiveUS20060098413A1Inhibit flakingEasy to reworkDigital data processing detailsLayered productsLiquid-crystal displayDisplay device

A heat spreader for a display device, such as a plasma display panel, a light emitting diode or a liquid crystal display, which includes at least one sheet of compressed particles of exfoliated graphite having two major surfaces, both of which have a layer of an adhesive thereon.

Owner:NEOGRAF SOLUTIONS LLC

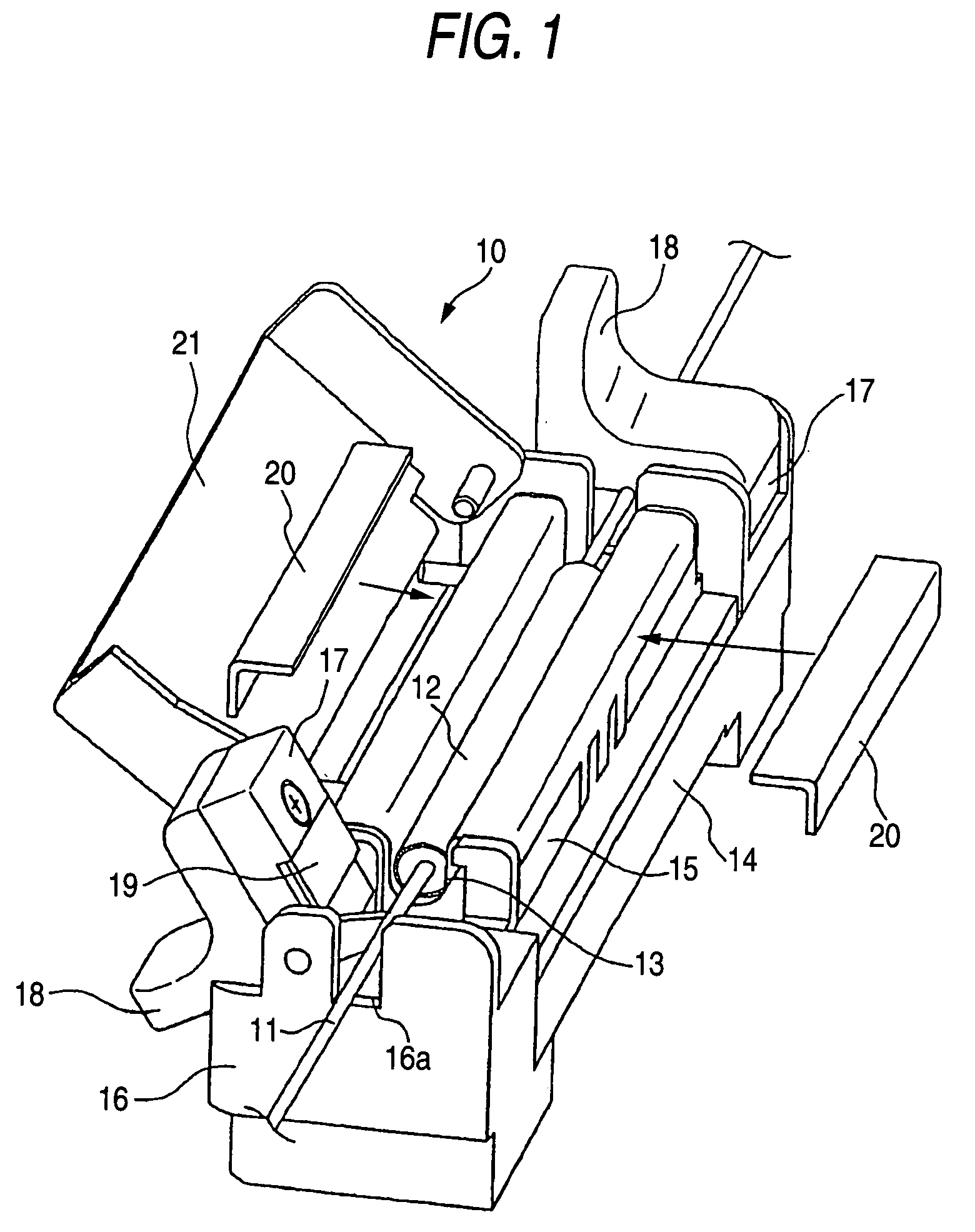

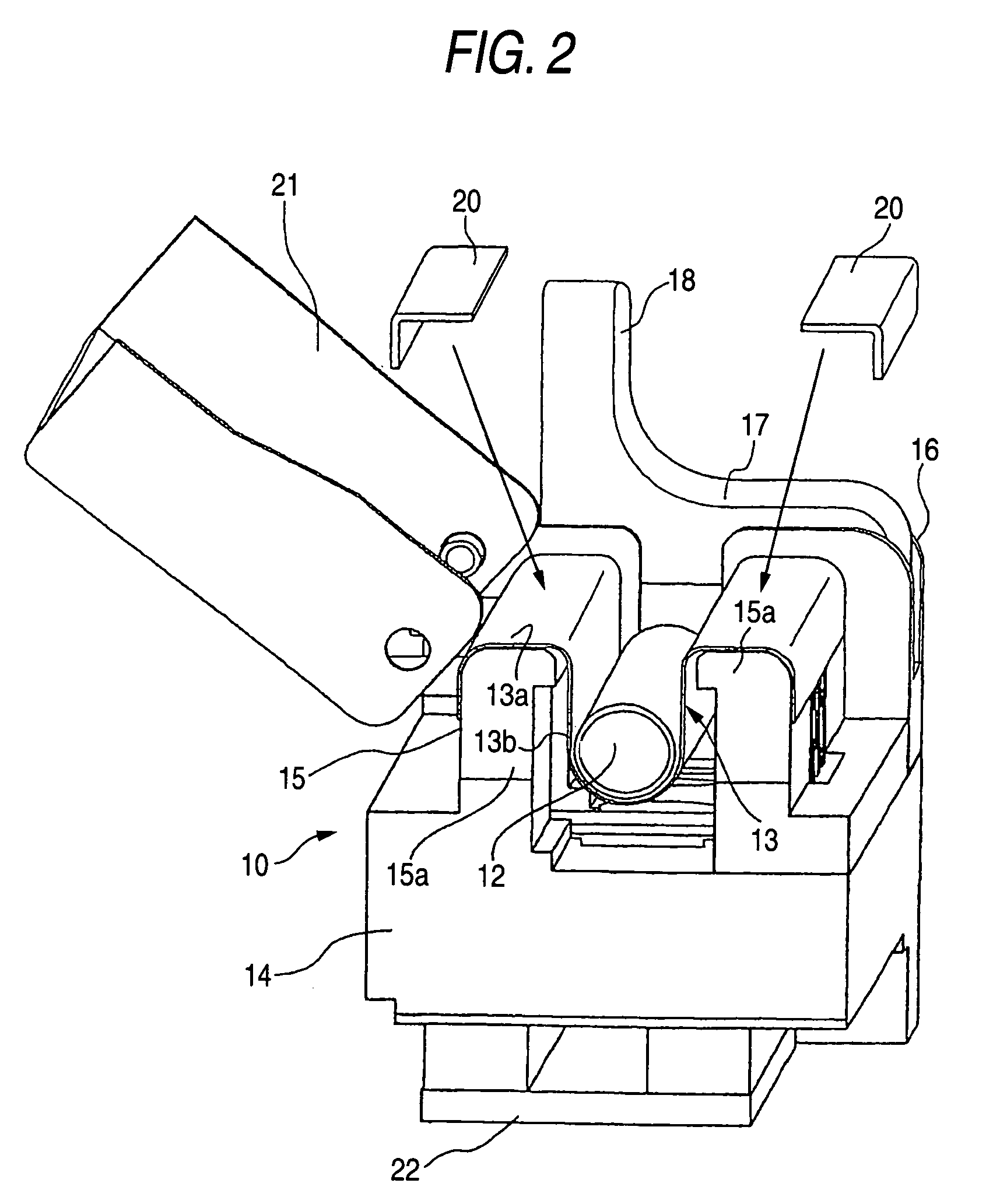

Apparatus and method for heat-treatment of optical fiber reinforcing member and optical fiber fusion splicing apparatus

ActiveUS7212718B2Curb riseEasily be wiped awayHeater elementsHeating element shapesEngineeringFusion splicing

A heat-treatment apparatus according to the present invention comprises a sheet-like heating body, which is bent like a letter “U”, and a heat equalizing plate constituted by a metal plate bonded to a heat generating part of the sheet-like heating body. The heat equalizing plate is bonded to the inner surface of the sheet-like heating body bent like a letter “U”. Alternatively, a fluorocarbon resin is coated on the surface of the heat equalizing plate.

Owner:SUMITOMO ELECTRIC IND LTD

Ink jet recording head

An ink jet recording head is constituted by a plurality of recording element substrates each including at least one nozzle array having a plurality of nozzles for ejecting ink and heat generating resistors for ejecting the ink by thermal energy, a common liquid chamber having an introducing port for supplying the ink to the nozzles and a discharging port for discharging the introduced ink outside the ink jet recording head, and a supporting member on which the recording element substrates are mounted and in which a plurality of individual liquid chambers for supplying the ink to associated ones of the recording element substrates and a plurality of ink inlet ports for supplying the ink from the common liquid chamber to associated ones of the individual liquid chambers are formed. The individual liquid chambers are arranged in a direction of flow of the ink flowing from the ink introducing port toward the discharging port. At least in an upstreammost individual liquid chamber with respect to the direction, a center line of an associated inlet port with respect to the direction is located downstream of a center line of with respect to the direction.

Owner:CANON KK

Heat spreader for display device

ActiveUS20050142317A1Good thermal contactPrevent and reduce possibilityDigital data processing detailsLayered productsLiquid-crystal displayDisplay device

A heat spreader (10) for a display device, such as a plasma display panel, a light emitting diode or a liquid crystal display, comprising at least one sheet of compressed particles of exfoliated graphite having a surface area greater than the surface area of that part of the back surface of the display device where a localized region of higher temperature is generated.

Owner:NEOGRAF SOLUTIONS LLC

Battery pack comprising combined temperature-controlling system

ActiveUS8343647B2Temperature controlMinimized in sizeCell temperature controlBattery isolationForeign matterElectricity

Disclosed herein is a middle- or large-sized battery pack including a plurality of unit cells electrically connected with each other, wherein the battery pack is constructed in a structure in which a heat transfer medium flows through gaps defined between the unit cells for controlling the overall temperature of the battery pack to be within a predetermined temperature range for the optimum operation of the battery pack, and each unit cell is provided at the outer surface thereof, at which the heat transfer medium is brought into contact with each unit cell, with a layer containing a phase transformation material (‘phase transformation layer’) for minimizing individual temperature difference between the unit cells. The present invention has the effect of controlling the overall temperature of the battery pack and individual controlling the temperatures of unit cells constituting the battery pack. Also, the present invention has the effect of restraining the abrupt change in temperature of the unit cells, when the battery pack is not in operation or when the external environment abruptly changes, thereby preventing the degradation of the unit cells. Furthermore, the present invention has the effect of minimizing damage to the unit cells due to foreign matter when the foreign matter is brought into contact with the unit cells. In addition, the present invention has the effect of reducing the overall temperature difference of the battery pack and manufacturing a middle- or large-sized battery pack having a compact structure.

Owner:LG ENERGY SOLUTION LTD

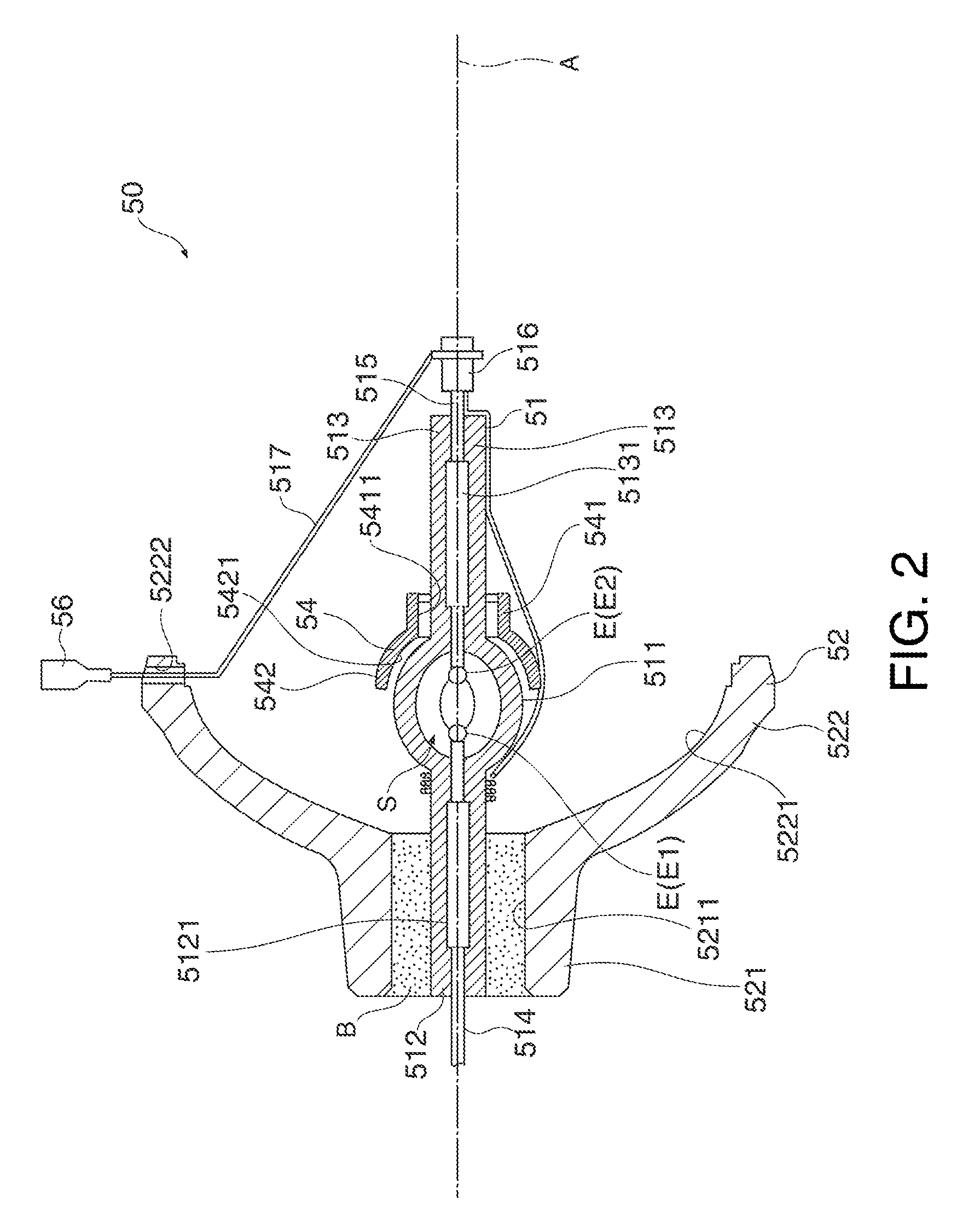

Hall effect thruster with cooling of the internal ceramic

ActiveUS20110062899A1Little and no instabilityImprove performanceTransit-time tubesMachines/enginesTemperature differenceCeramic

The invention relates to the field of Hall effect thrusters. The invention provides a Hall effect thruster having a discharge channel of annular shape extending along an axis, the discharge channel being defined by an outer wall of annular shape and an inner wall of annular shape situated inside the space defined by the outer wall, a cathode situated outside the discharge channel, and an injector system situated at the upstream end of the discharge channel and also forming an anode, the downstream end of the discharge channel being open, wherein the thruster includes a heat sink device comprising a heat sink in contact with the inner wall and of thermal conductivity that is greater than the thermal conductivity of the inner wall, the heat sink being a sleeve and the heat sink device being suitable for discharging heat from the inner wall to the outside of the thruster so as to reduce the temperature difference between the inner wall and the outer wall.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

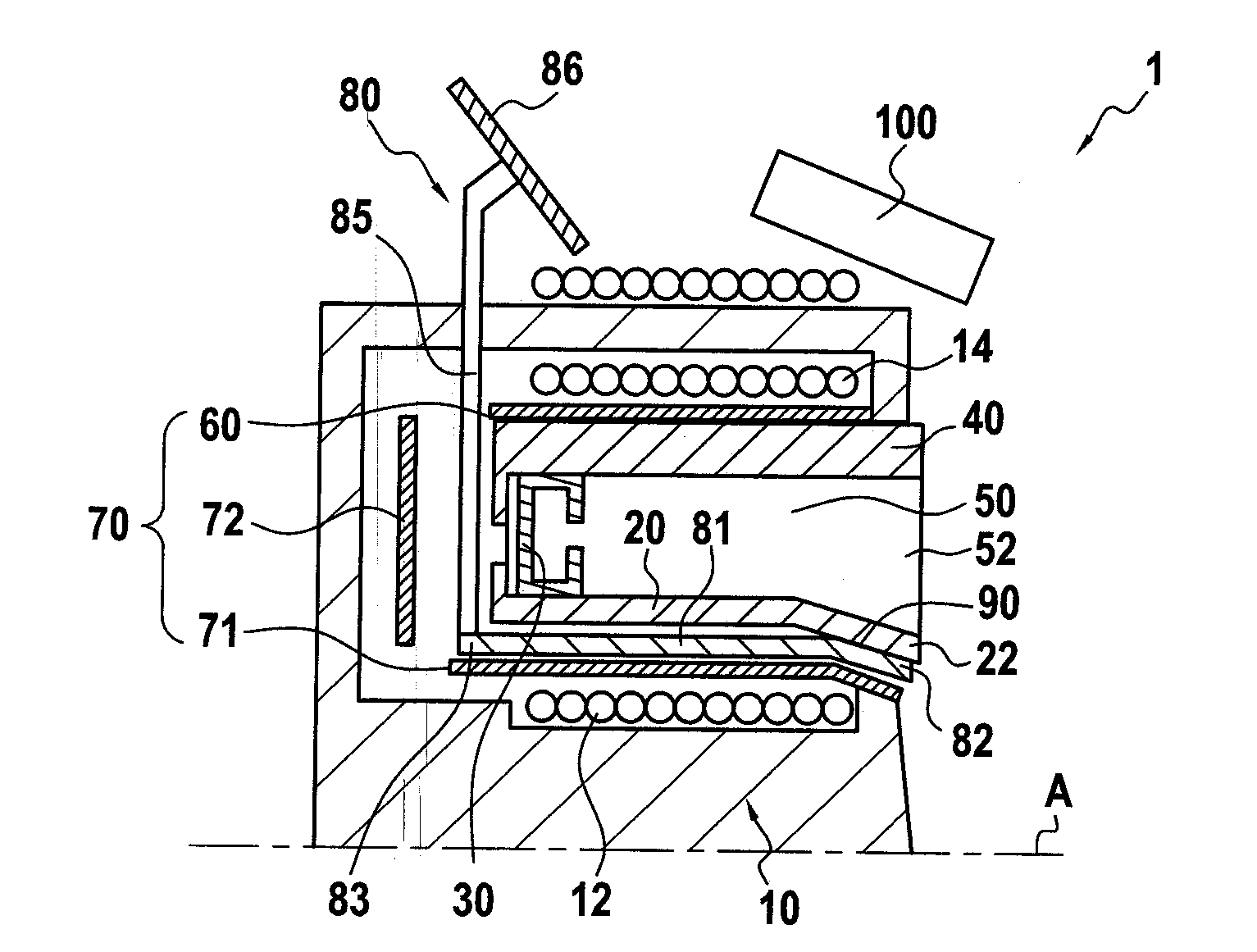

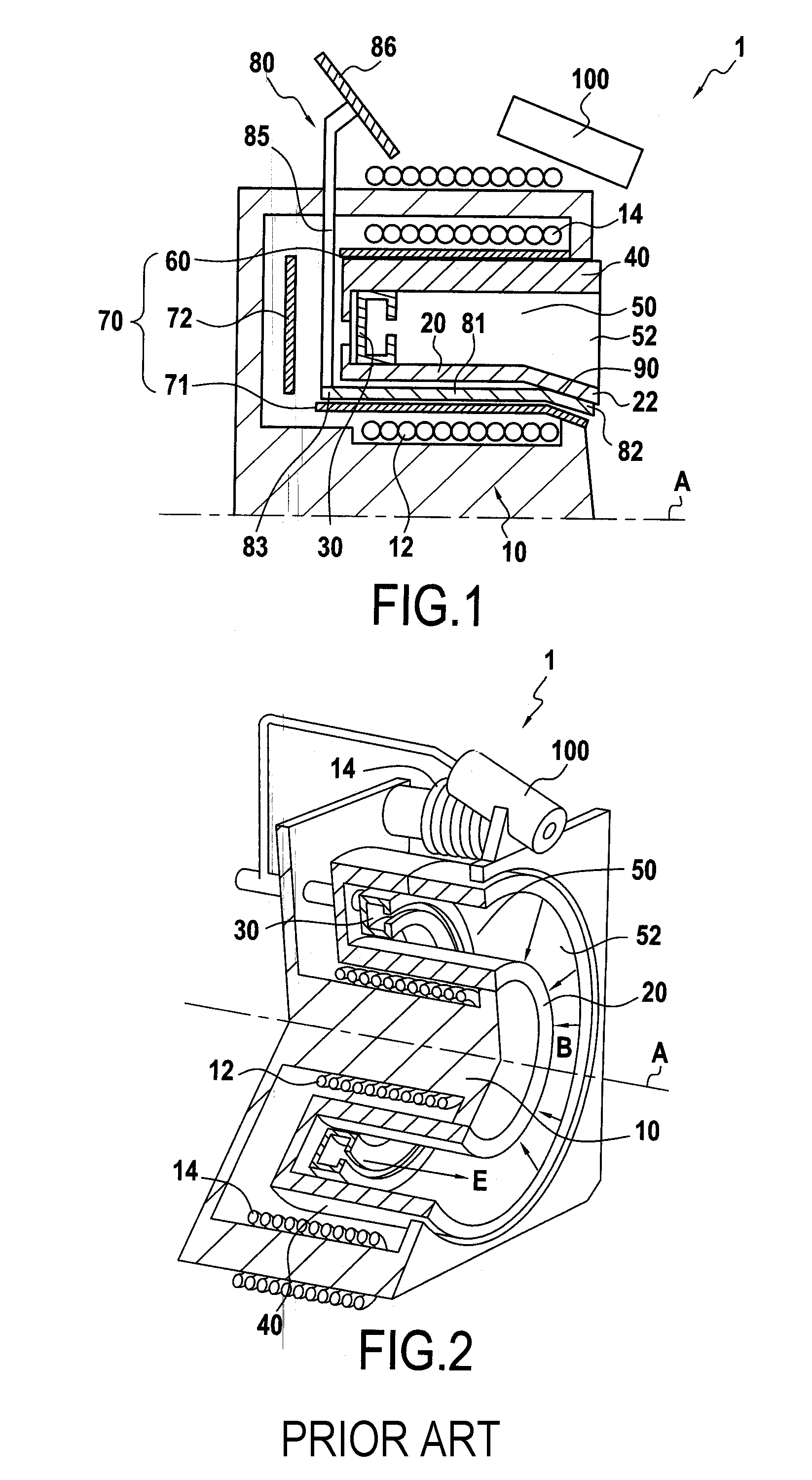

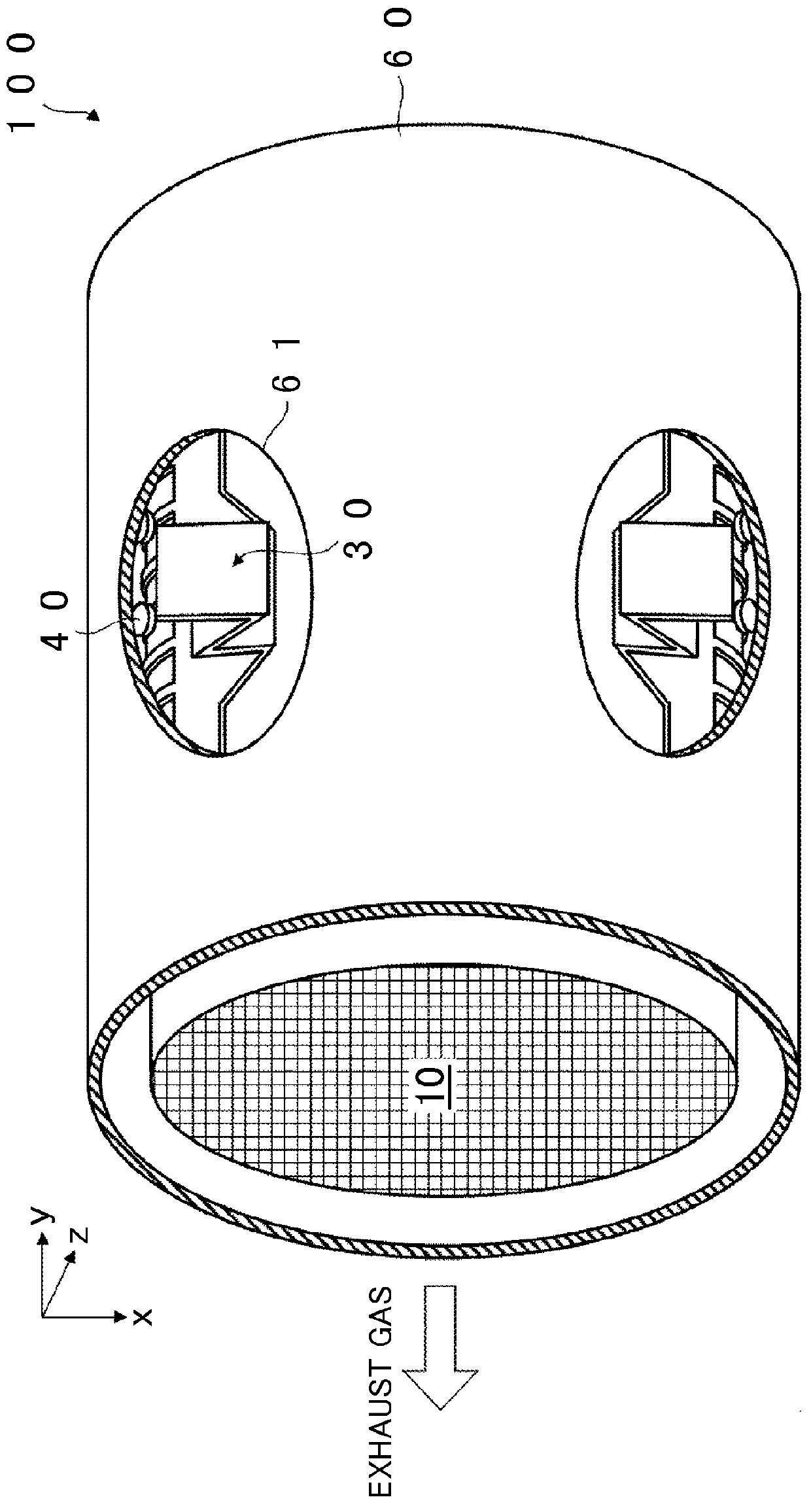

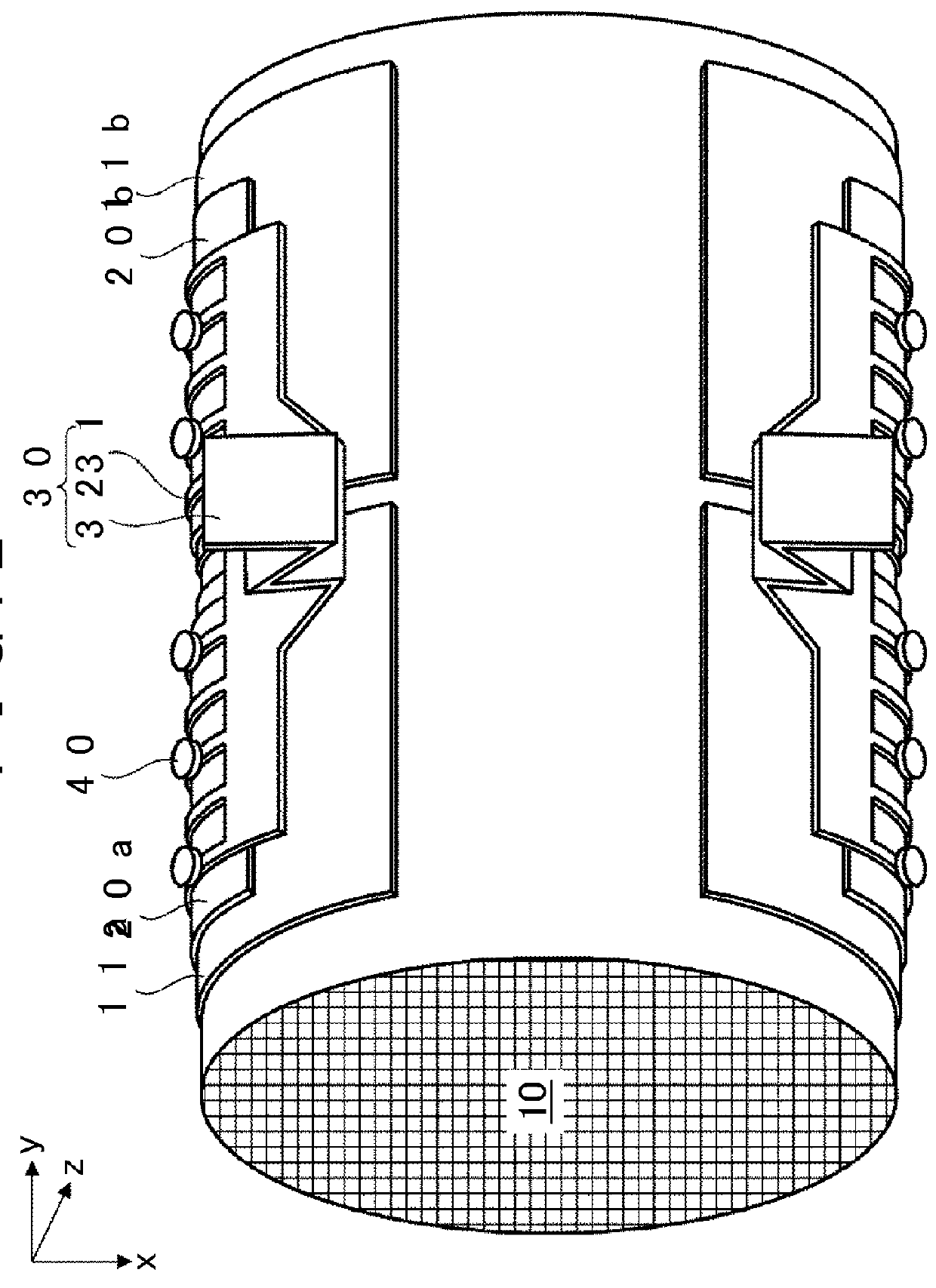

Electrically heated catalyst device

ActiveUS20160032806A1Reduce thermal stressAvoid crackingInternal combustion piston enginesExhaust apparatusElectricityEngineering

An electrically heated catalyst device includes: a carrier configured to carry a catalyst; a pair of electric diffusion layers formed on an outer peripheral surface of the carrier so as to be opposed each other; and wiring members each fixed to each of the electric diffusion layers, and the carrier is electrically heated via the wiring members. Each of the electric diffusion layers is formed so as to be divided into a plurality of regions in an axial direction of the carrier.

Owner:TOYOTA JIDOSHA KK

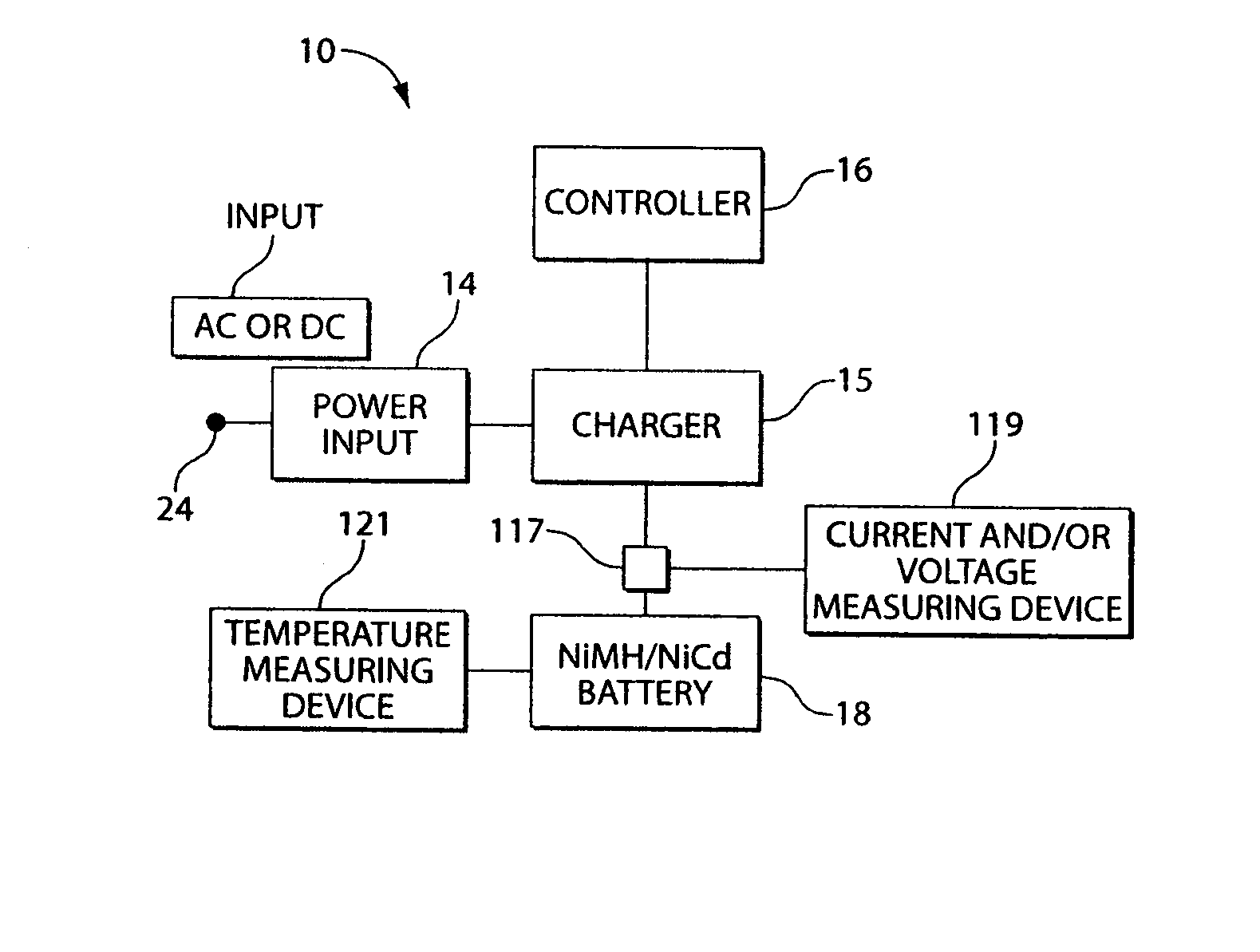

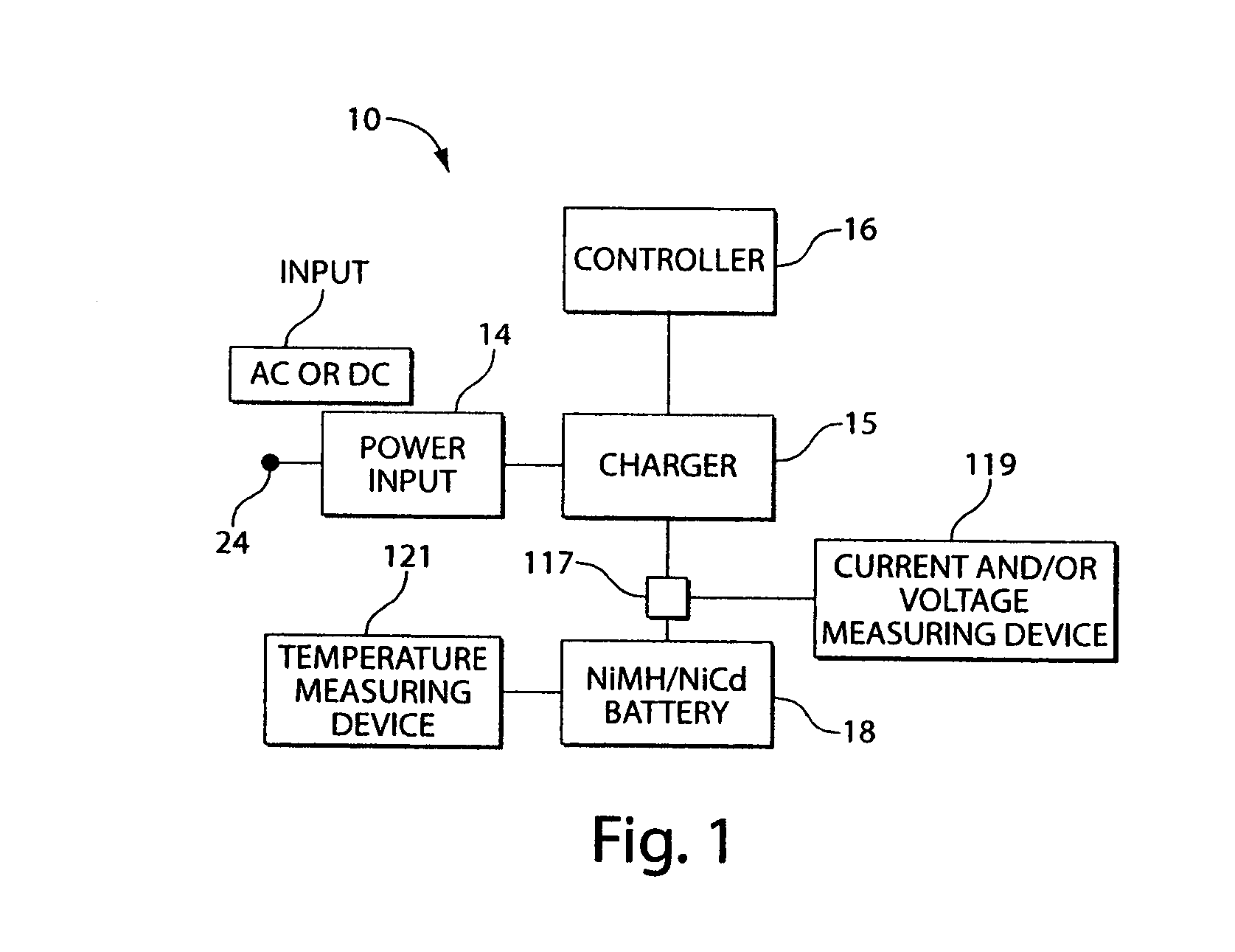

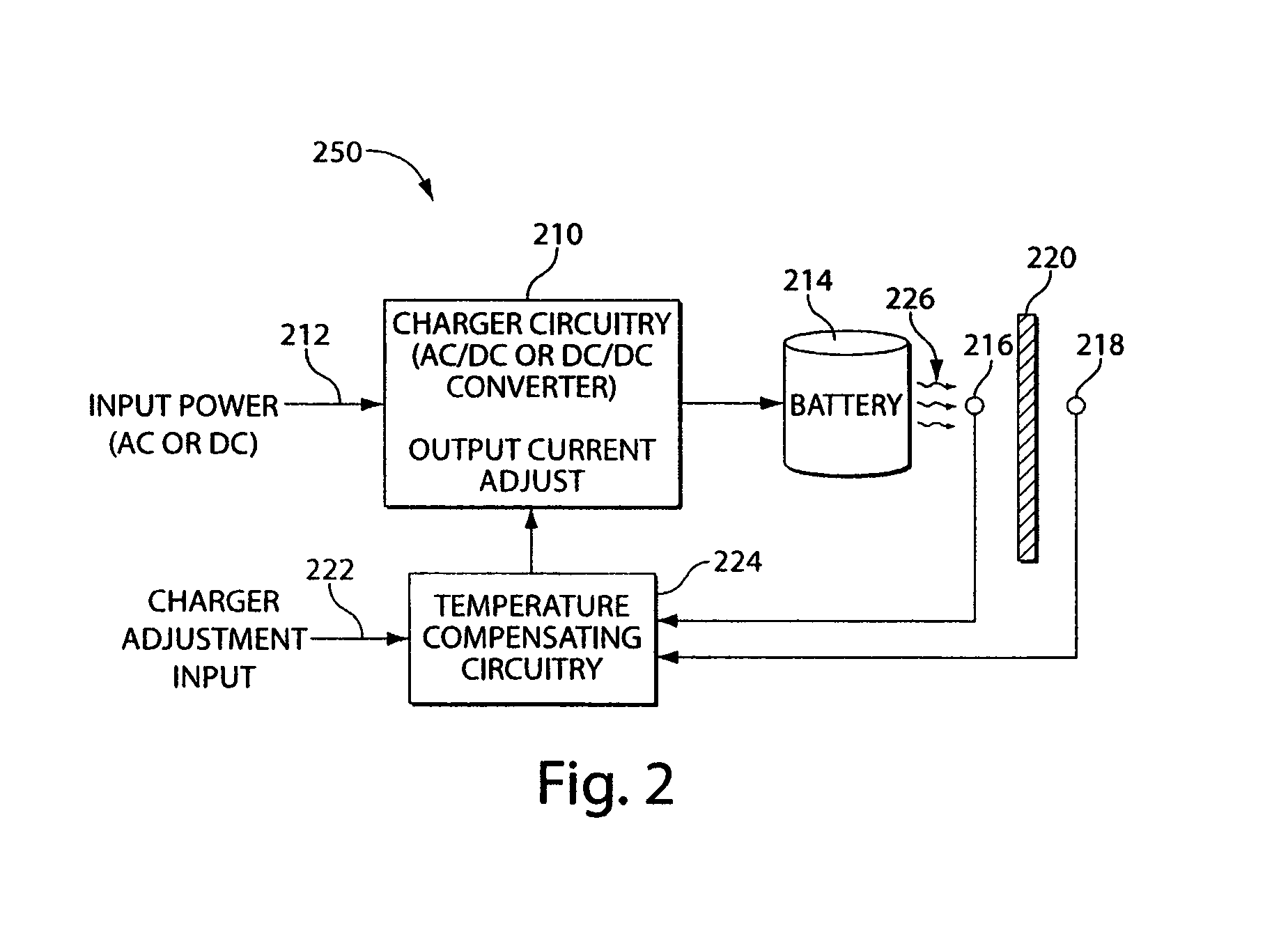

Method and system for charging a NiMH or NiCd battery

InactiveUS7405538B1Extend battery lifeTemperature differenceBatteries circuit arrangementsSecondary cells charging/dischargingOperating temperatureDifferential method

A method of charging a NiMH or NiCd battery such that charging does not occupy a substantial amount of time and such that the operating temperature of the battery is reduced during the lifetime of the battery, thereby extending the life of the battery. This invention is a method of charging that is accomplished using a temperature differential method to continuously regulate the rate of charge injected into the battery. An amplifier is used to amplify the difference in temperature between one or more cases in which the battery is contained and ambient temperature. In this method, the greater the difference in temperature, the lower the charging current is injected into the battery. The method of charging may be incorporated into uninterruptible power supply equipment.

Owner:SCHNEIDER ELECTRIC IT CORP

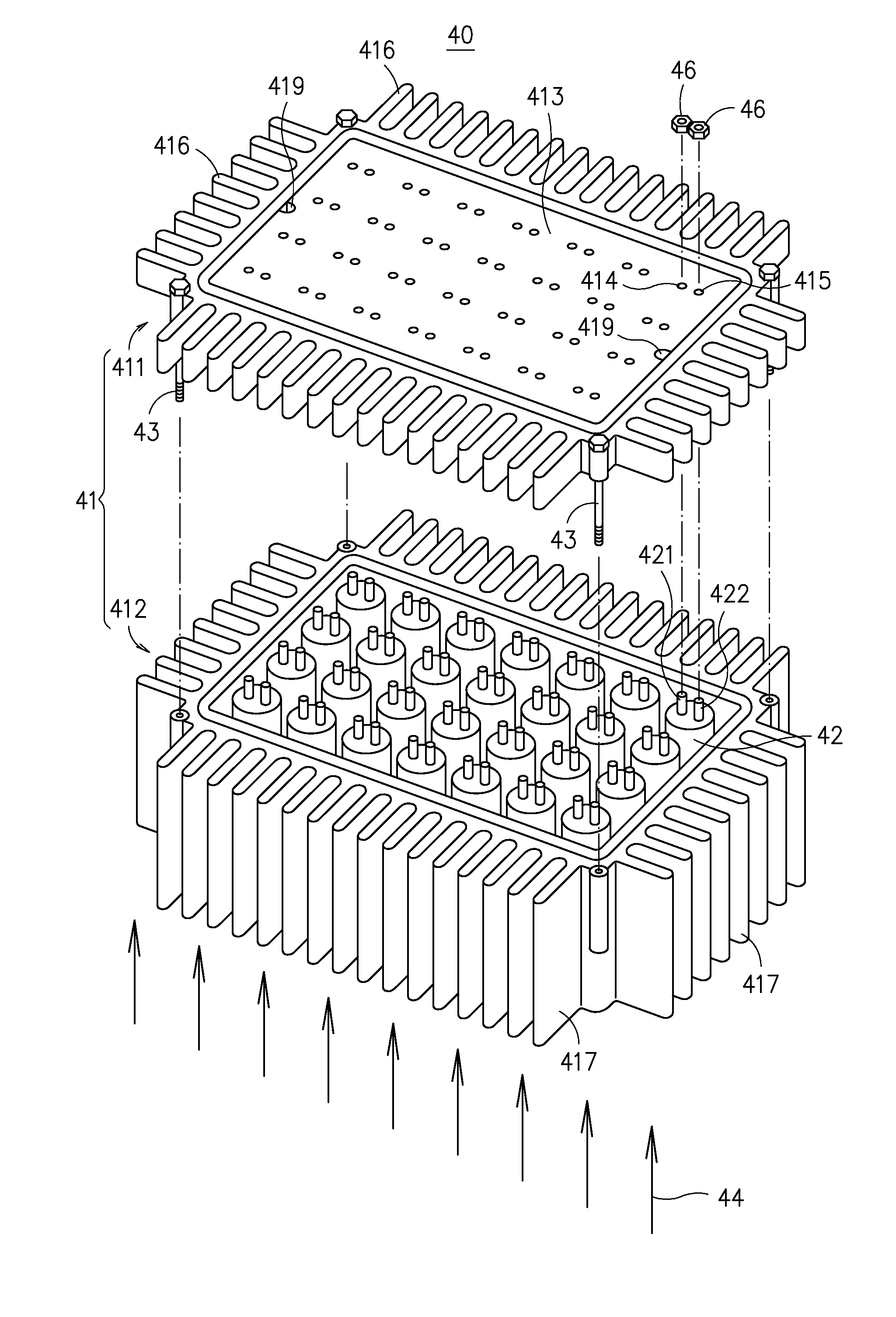

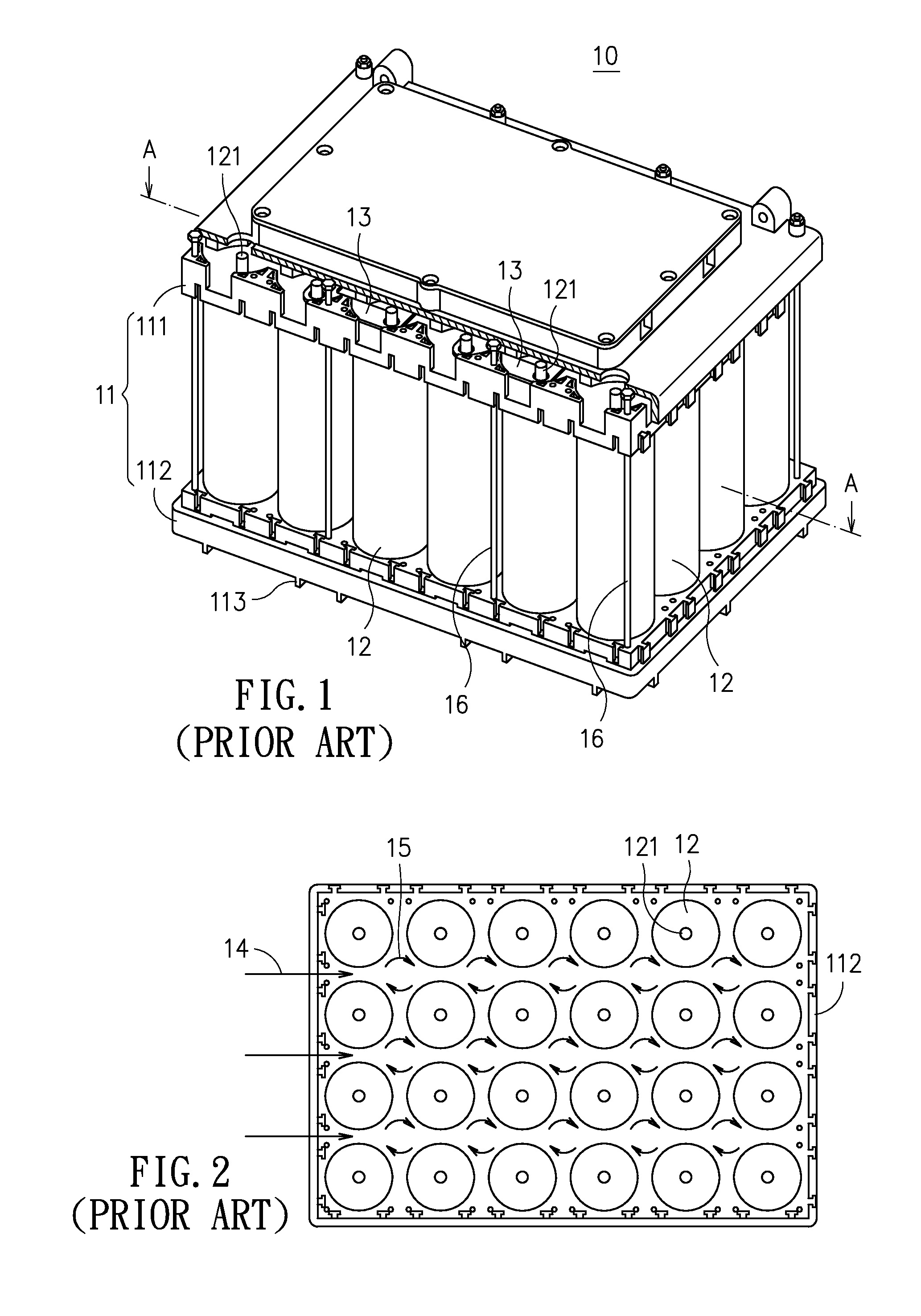

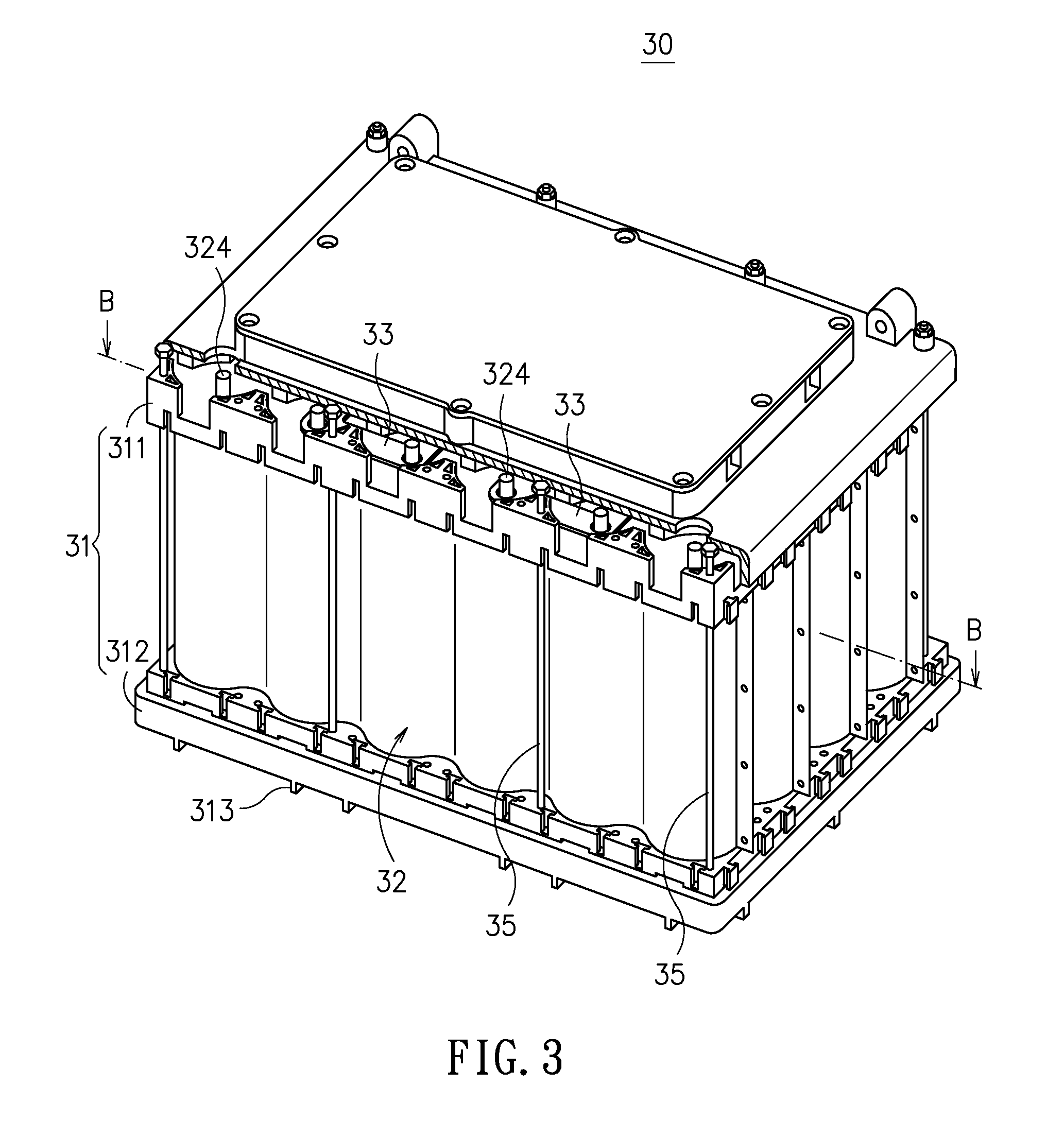

Battery assembly for vehicle and vehicle having the same

InactiveUS20140141288A1Increase cooling performance and enduranceOptimized areaCell temperature controlPropulsion by batteries/cellsEngineeringMechanical engineering

A battery assembly for a vehicle and a vehicle having the battery assembly are provided. The battery assembly includes a battery housing in which air-conditioned air is introduced into a front thereof and is discharged from a rear thereof, a plurality of battery rows that are disposed in the battery housing so as to be perpendicular to a flow of the air-conditioned air, the battery rows forming through-holes through which the air-conditioned air flows, and being disposed in parallel to each other, one after another, from the front to the rear of the battery housing, and an internal duct that is disposed between a pair of adjacent battery rows among the battery rows having open front and rear end faces so that the air-conditioned air flows into the front end face through the rear end face.

Owner:HYUNDAI MOTOR CO LTD +1

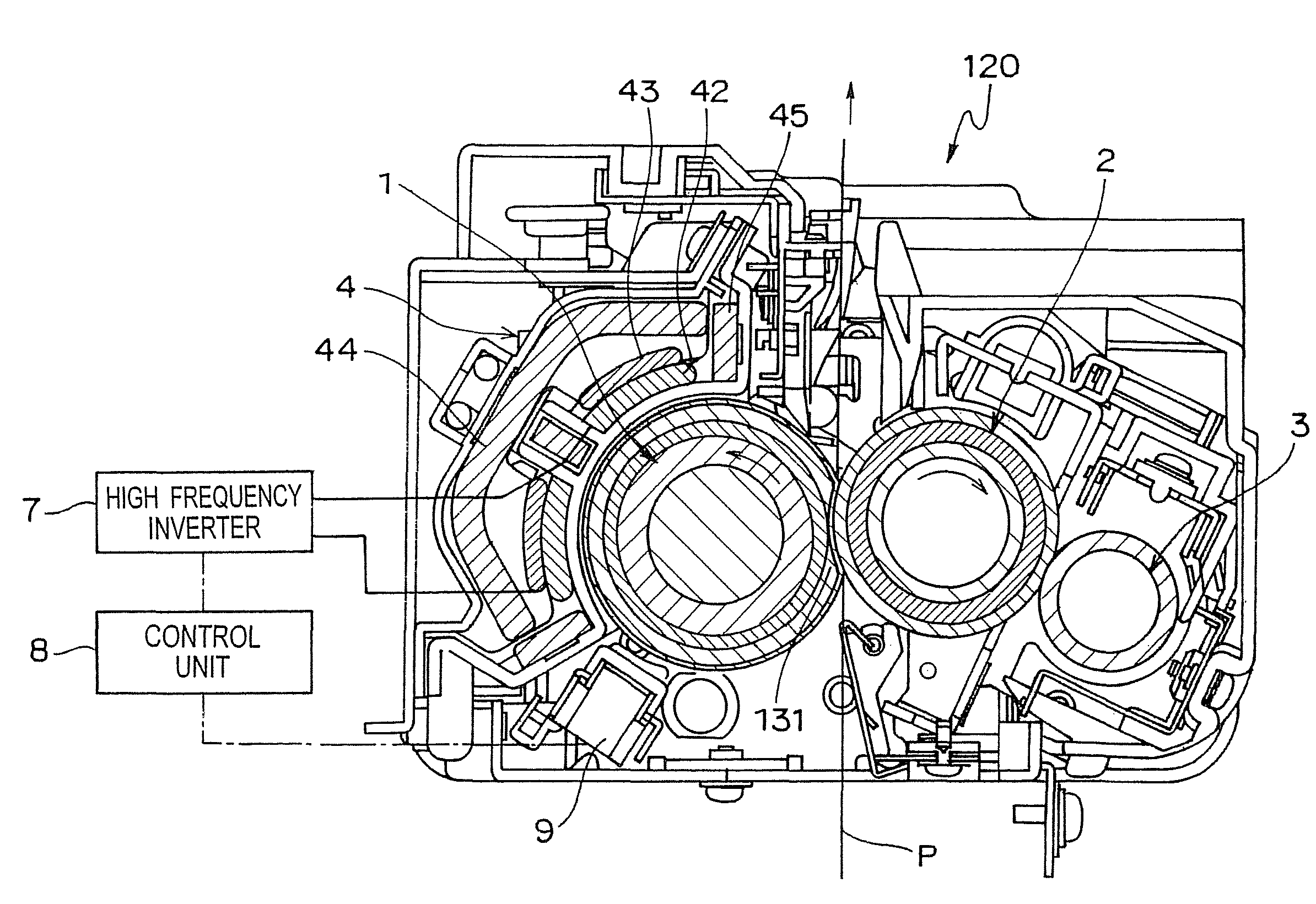

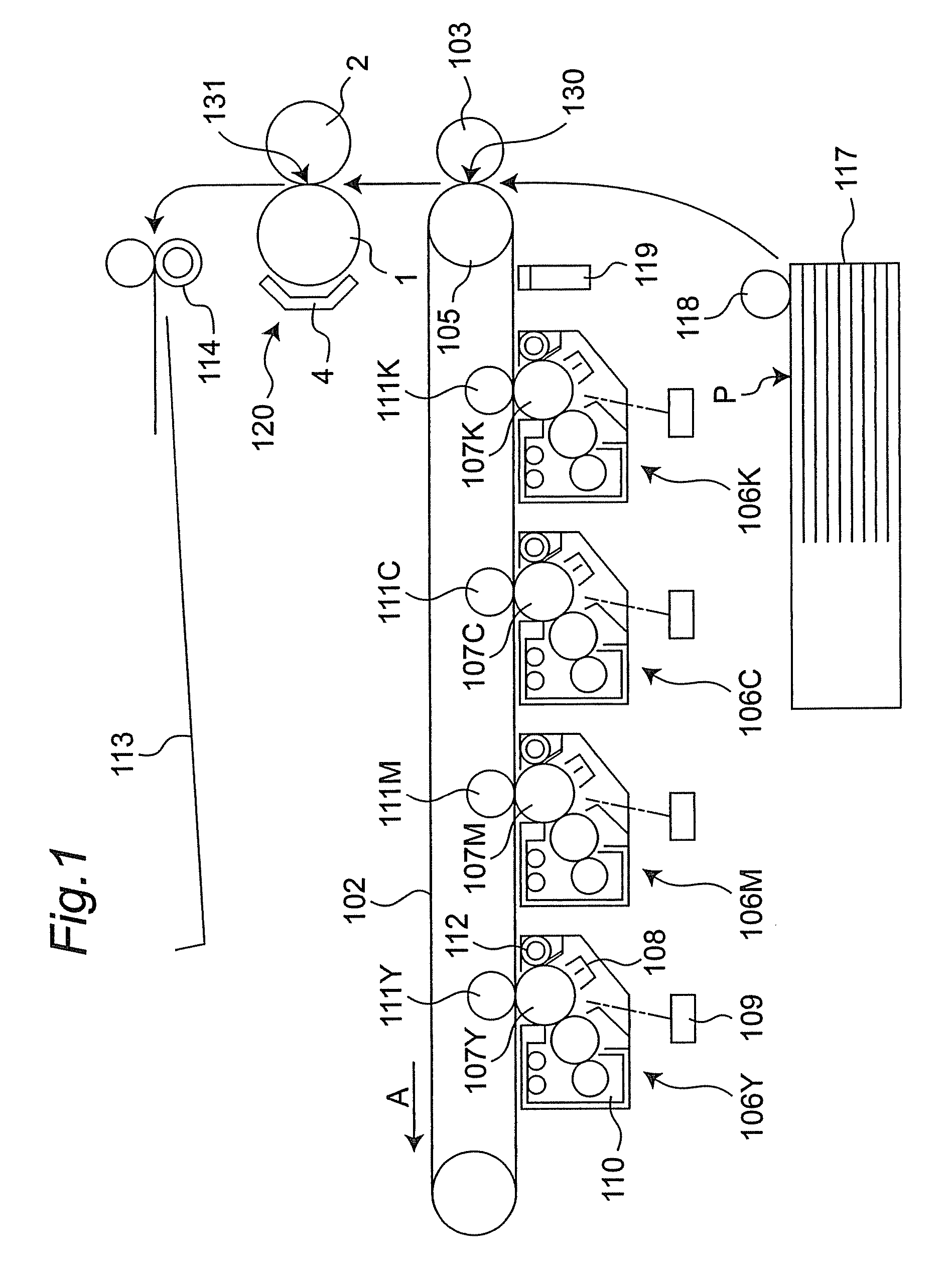

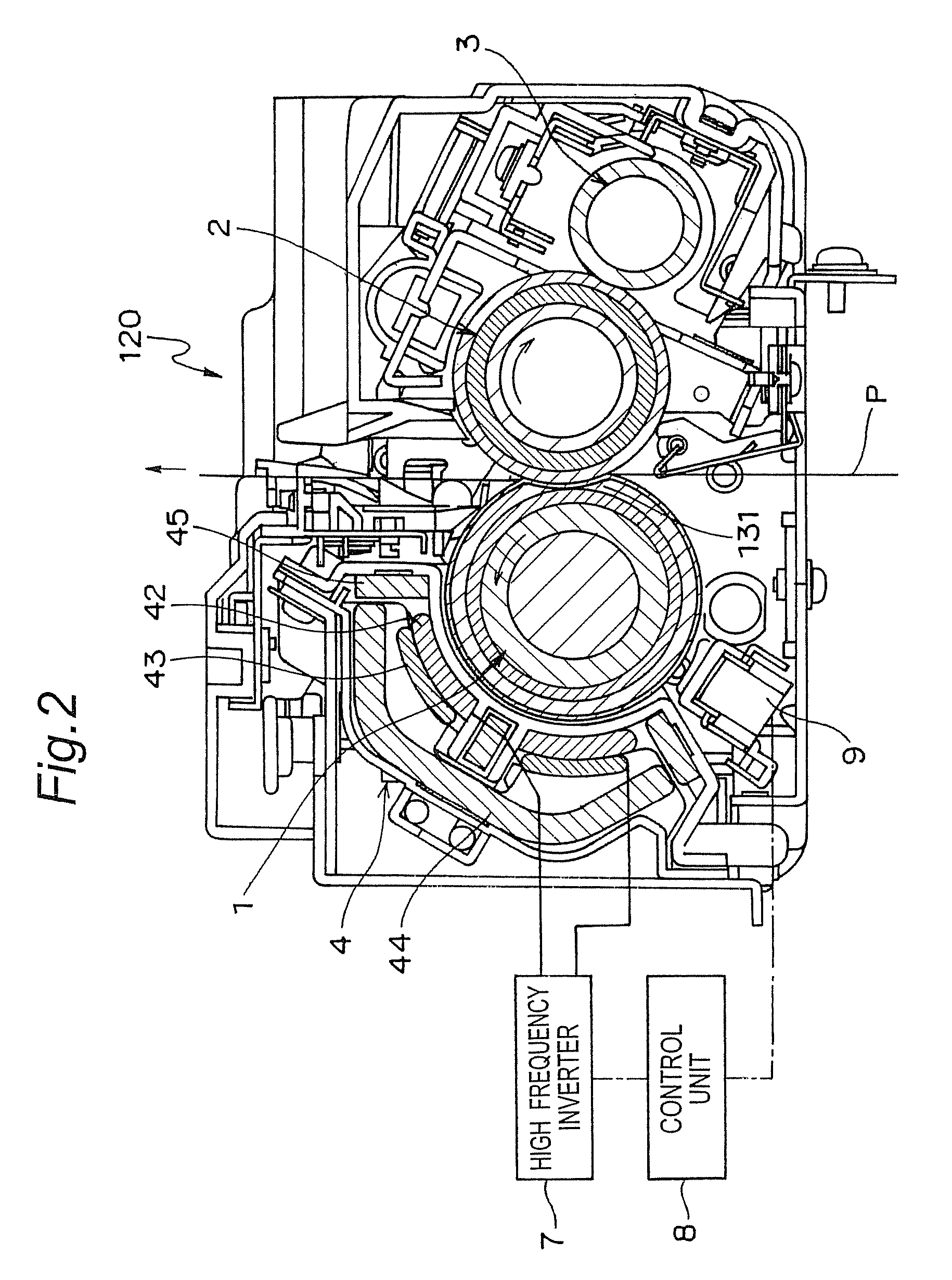

Fixing device and image forming apparatus

InactiveUS7925198B2Avoid temperature riseReduce temperature differenceElectrographic process apparatusEngineeringElectromagnetic induction

A fixing device has a fixing roller, a pressure roller, an electromagnetic-induction heating section, and a heat pipe. The pressure roller has a metal layer, so that heat transferred directly from the fixing roller to the pressure roller is thermally transported by the metal layer of the pressure roller, whereby temperature of the pressure roller in its axial direction can be equalized.

Owner:KONICA MINOLTA BUSINESS TECH INC

Substrate temperature control apparatus

InactiveUS20050126490A1Reduce excessive instantaneous temperature variationReduce thermal stressChemical vapor deposition coatingTemperature controlEngineering

A substrate temperature control apparatus adopted for use in plasma diamond coating of a substrate to reduce warping caused by excessive temperature variations includes a holding dock with a temperature sensor, a cooler and a heater installed therein. During the plasma process, if the detected temperature variation is excessive, the cooler or heater is activated to control the temperature of the upper surface and the lower surface of the substrate so that the temperature on two sides are controlled within a selected range to reduce warping.

Owner:IND TECH RES INST

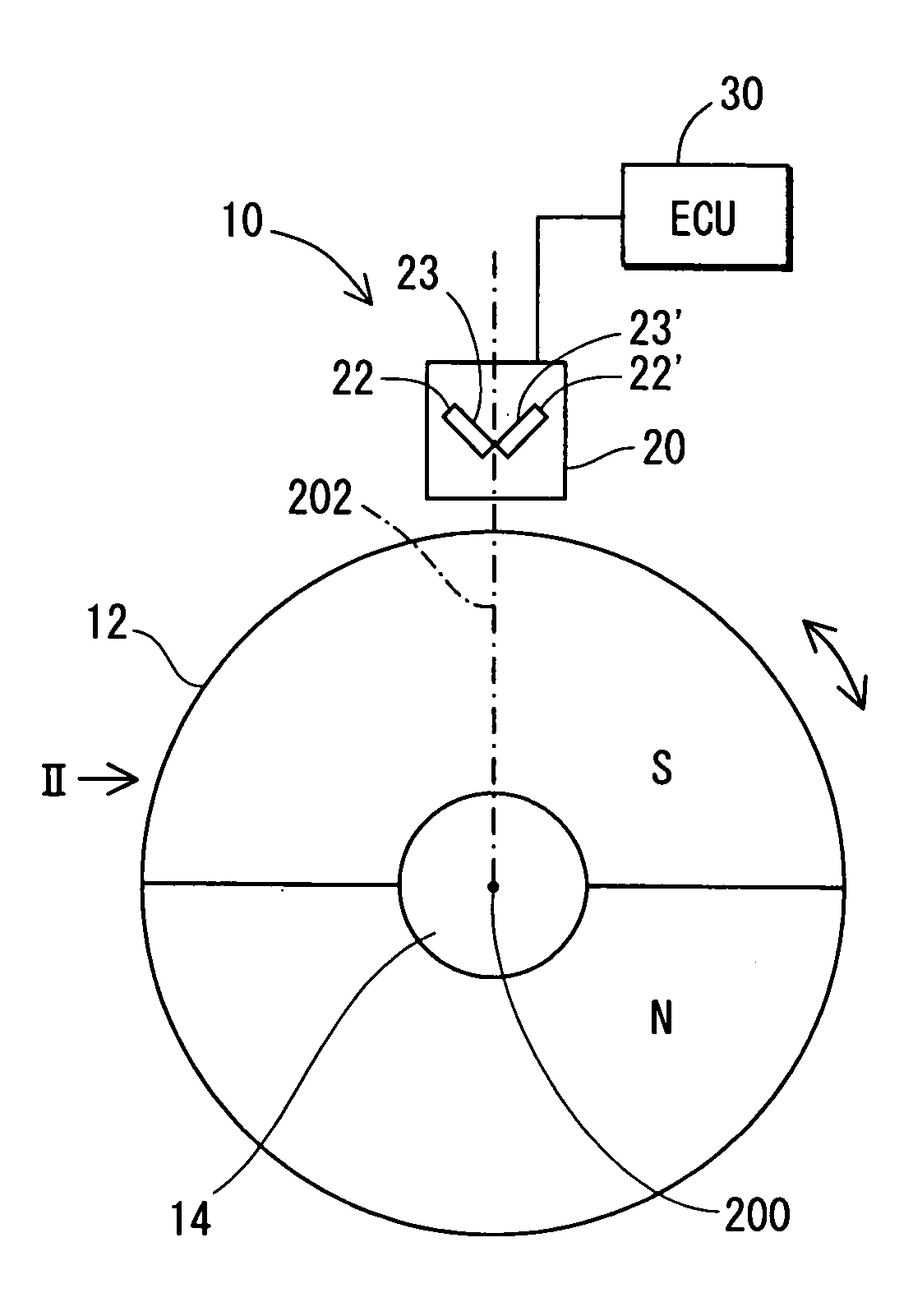

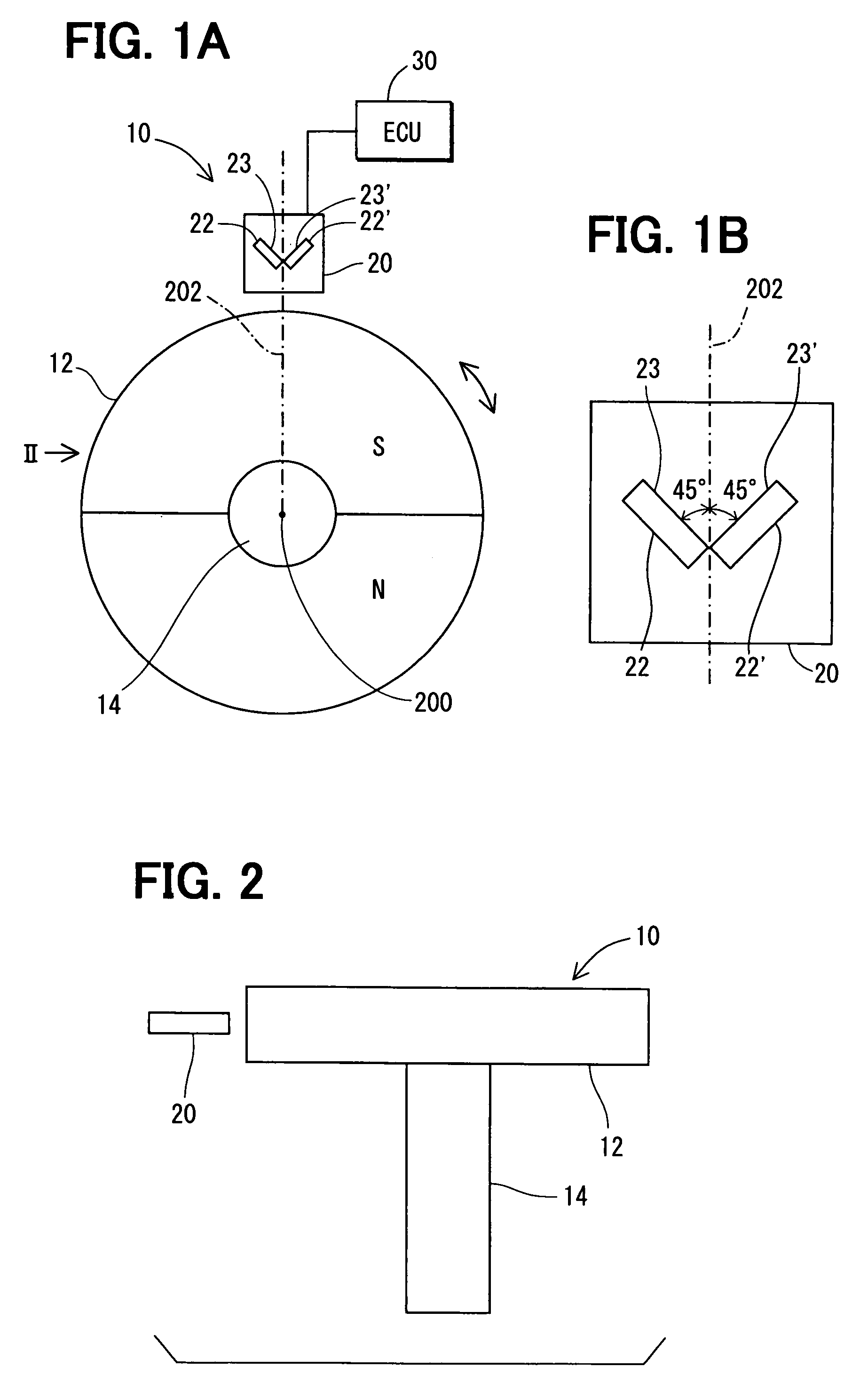

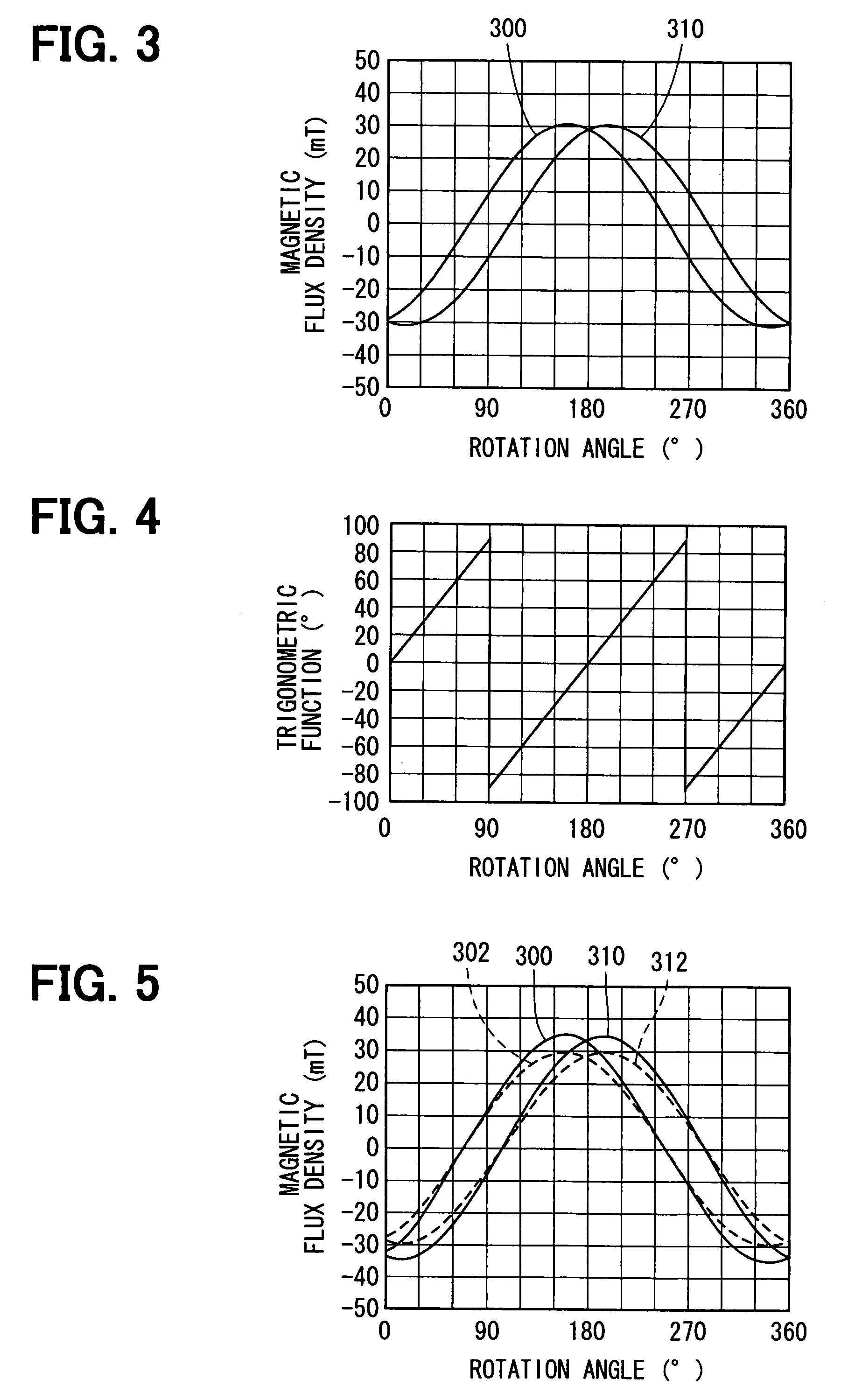

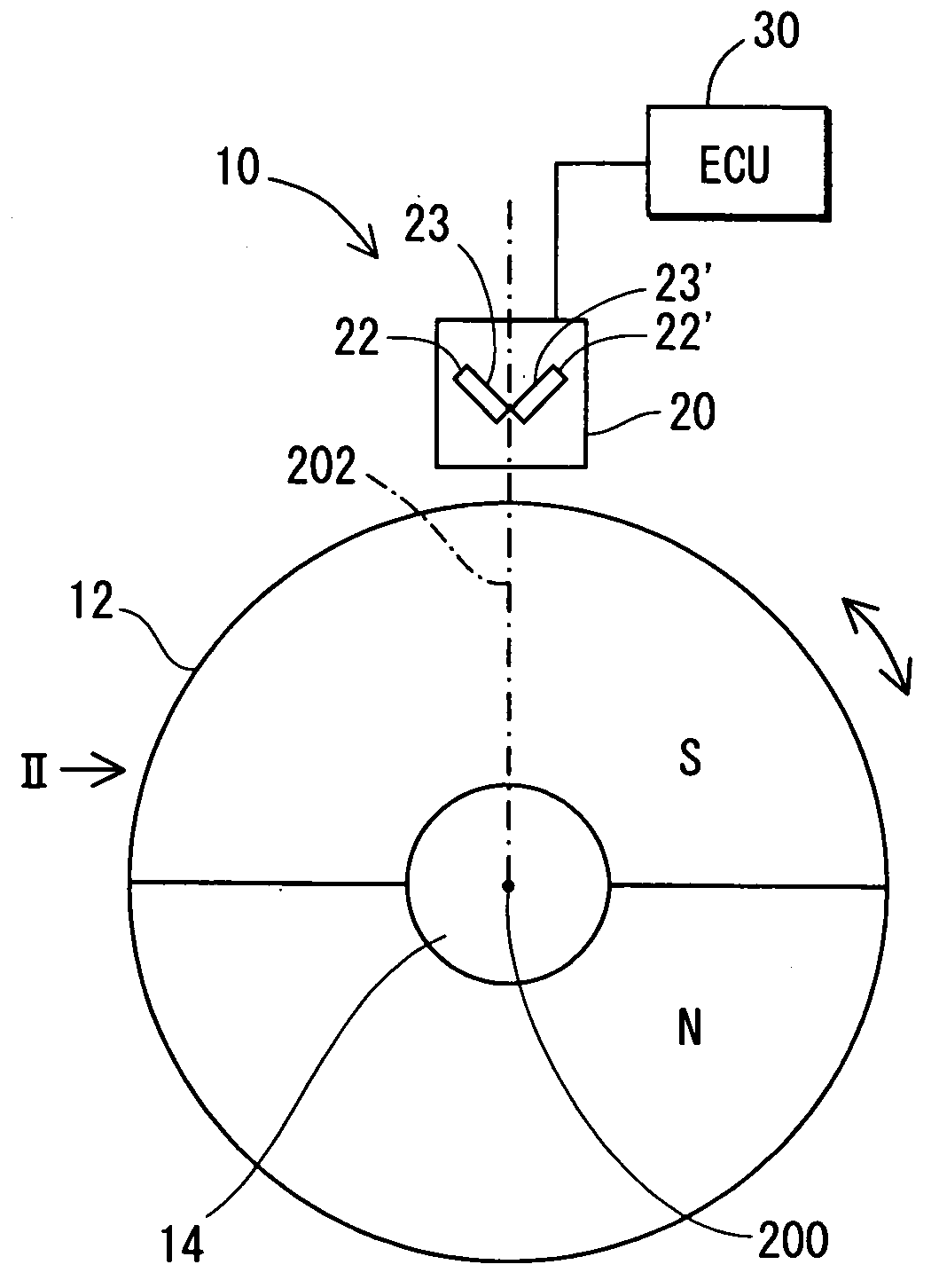

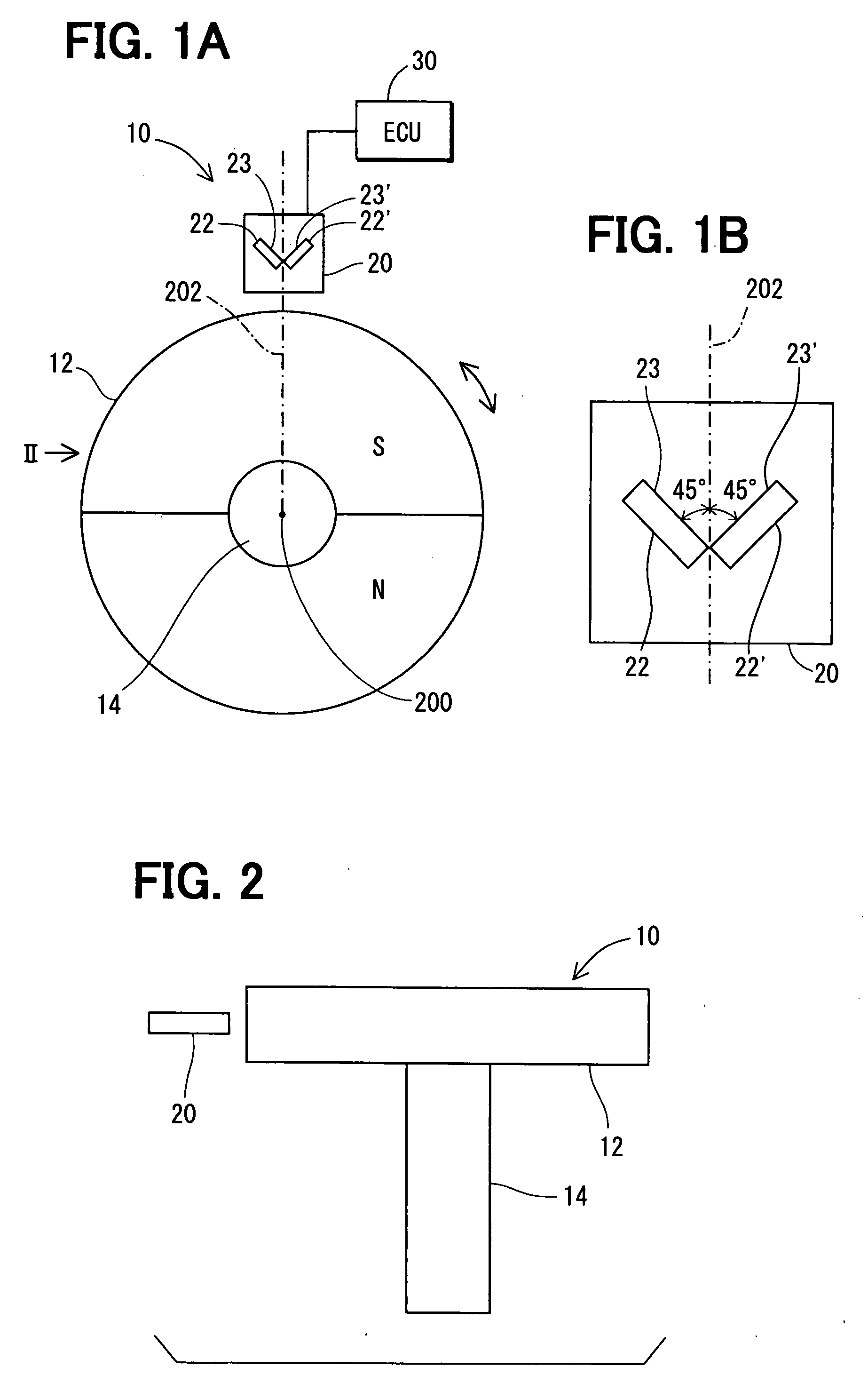

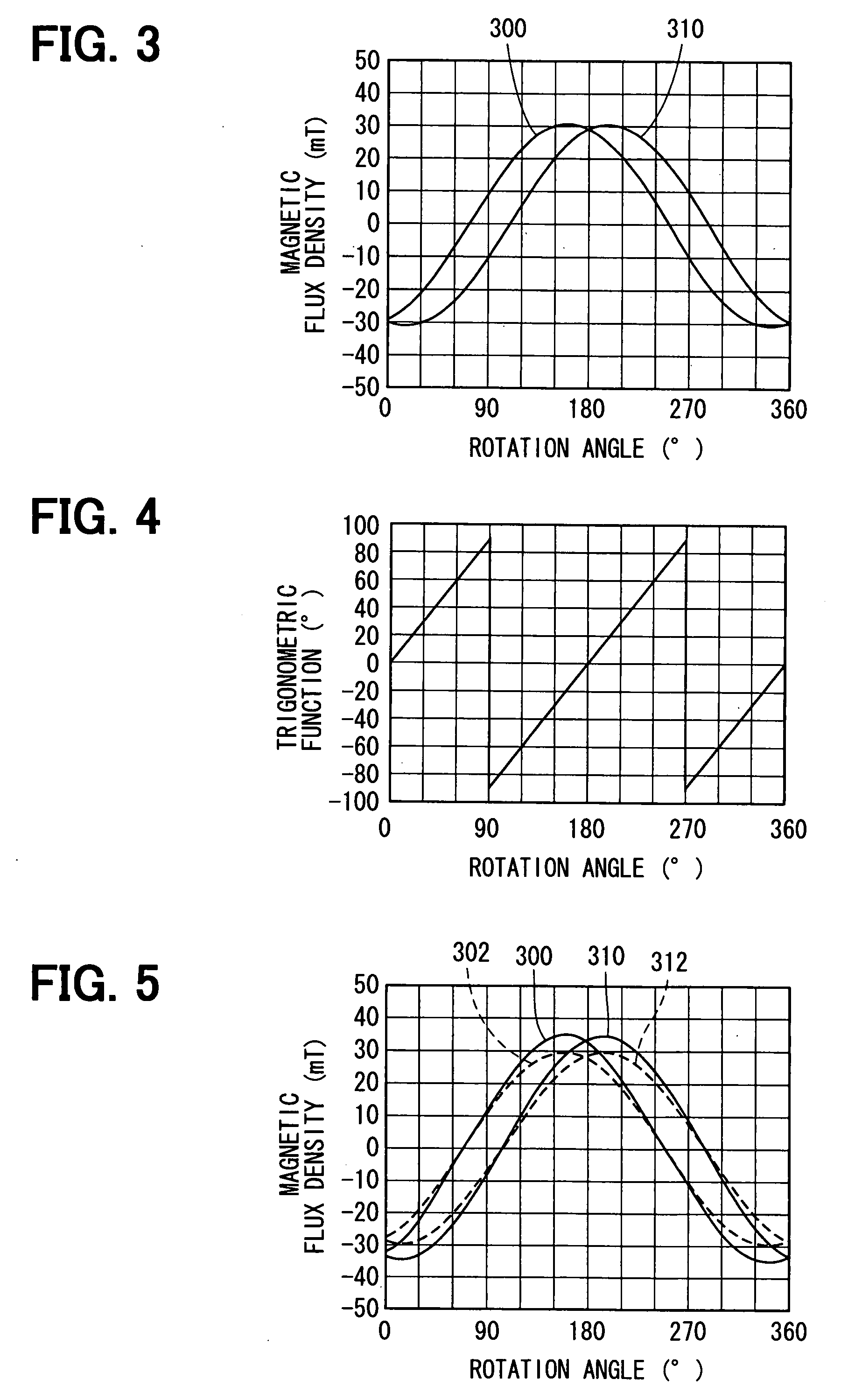

Rotation angle detecting device

InactiveUS7663360B2Compact and accurate rotation angleTemperature differenceSolid-state devicesMagnetic field measurement using galvano-magnetic devicesClassical mechanicsMagnetic field

A rotation angle detecting device includes a magnetic member for providing a magnetic field, a magnetic sensor for sensing a change in the magnetic field when the magnetic member rotates relative to the magnetic sensor about a rotation axis. The magnetic sensor is disposed at a single position and includes a pair of sensor elements. The pair of sensor elements is disposed on an imaginary plane that is perpendicular to the rotation axis so that sensing surfaces of the sensor elements have 90 degrees in angle to each other and so that each of the sensing surfaces inclines by 45 degrees in angle to a line intersecting the rotation axis at right angles.

Owner:DENSO CORP +1

Rotation angle detecting device

InactiveUS20080048651A1Compact and accurateCompact and accurate rotation angleSolid-state devicesMagnetic field measurement using galvano-magnetic devicesClassical mechanicsMagnetic field

A rotation angle detecting device includes a magnetic member for providing a magnetic field, a magnetic sensor for sensing a change in the magnetic field when the magnetic member rotates relative to the magnetic sensor about a rotation axis. The magnetic sensor is disposed at a single position and includes a pair of sensor elements. The pair of sensor elements is disposed on an imaginary plane that is perpendicular to the rotation axis so that sensing surfaces of the sensor elements have 90 degrees in angle to each other and so that each of the sensing surfaces inclines by 45 degrees in angle to a line intersecting the rotation axis at right angles.

Owner:DENSO CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com