Rotation-type compressor with housing low pressure, control mode of coolant and oil return and applications thereof

A rotary compressor, compressor technology, applied in the direction of rotary piston machinery, irreversible cycle compressors, compressors, etc., can solve problems such as non-compliance with high-pressure safety standards, and achieve the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

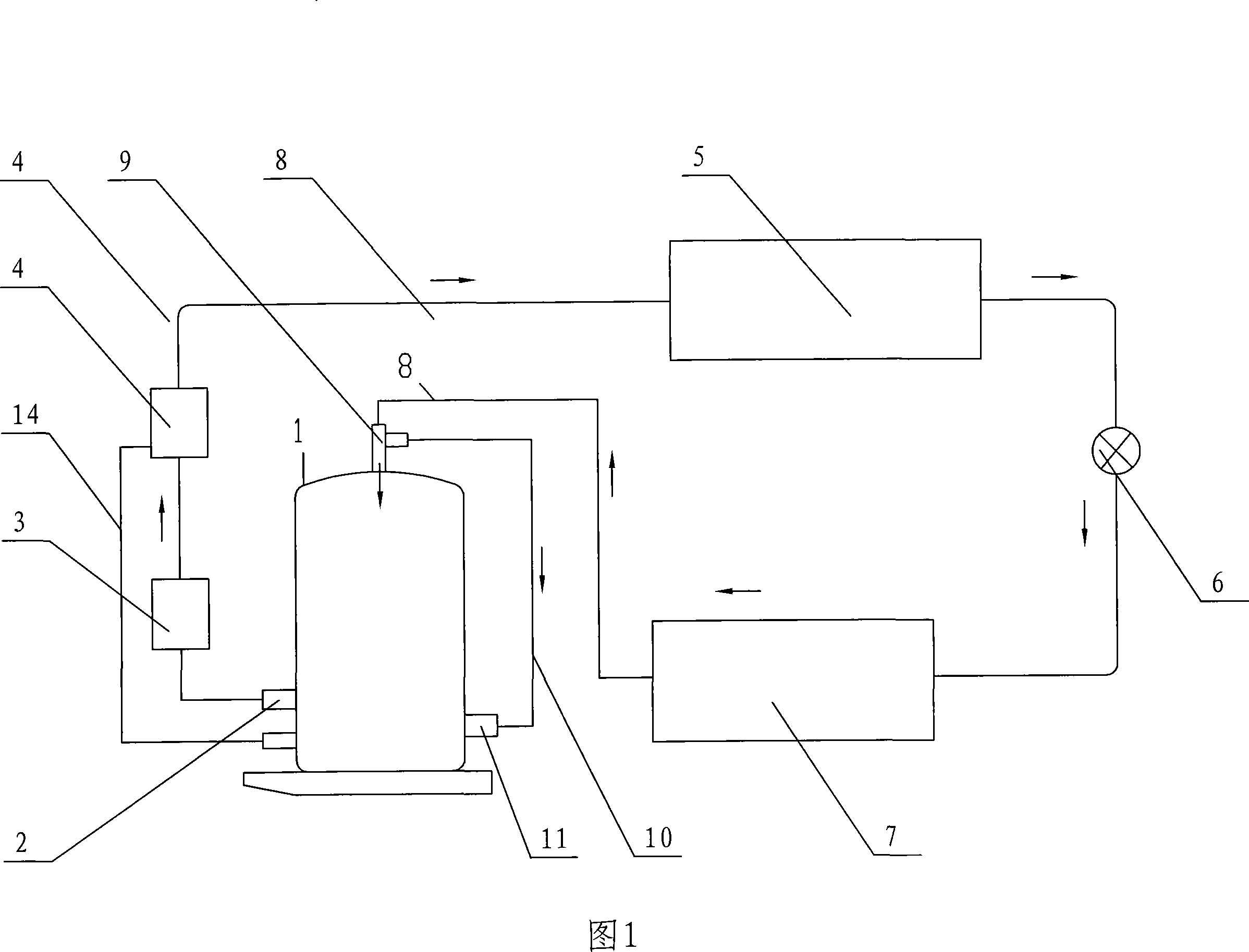

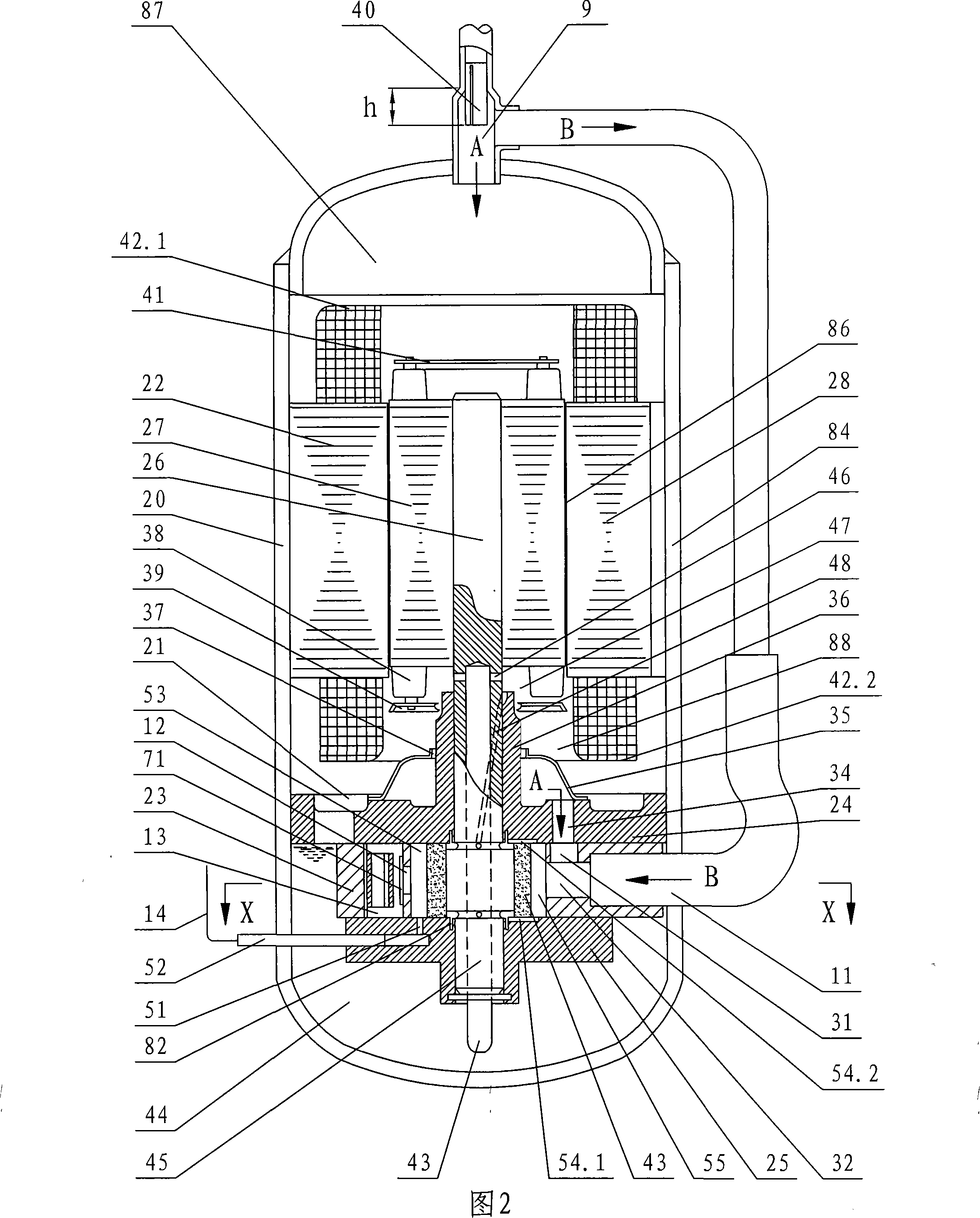

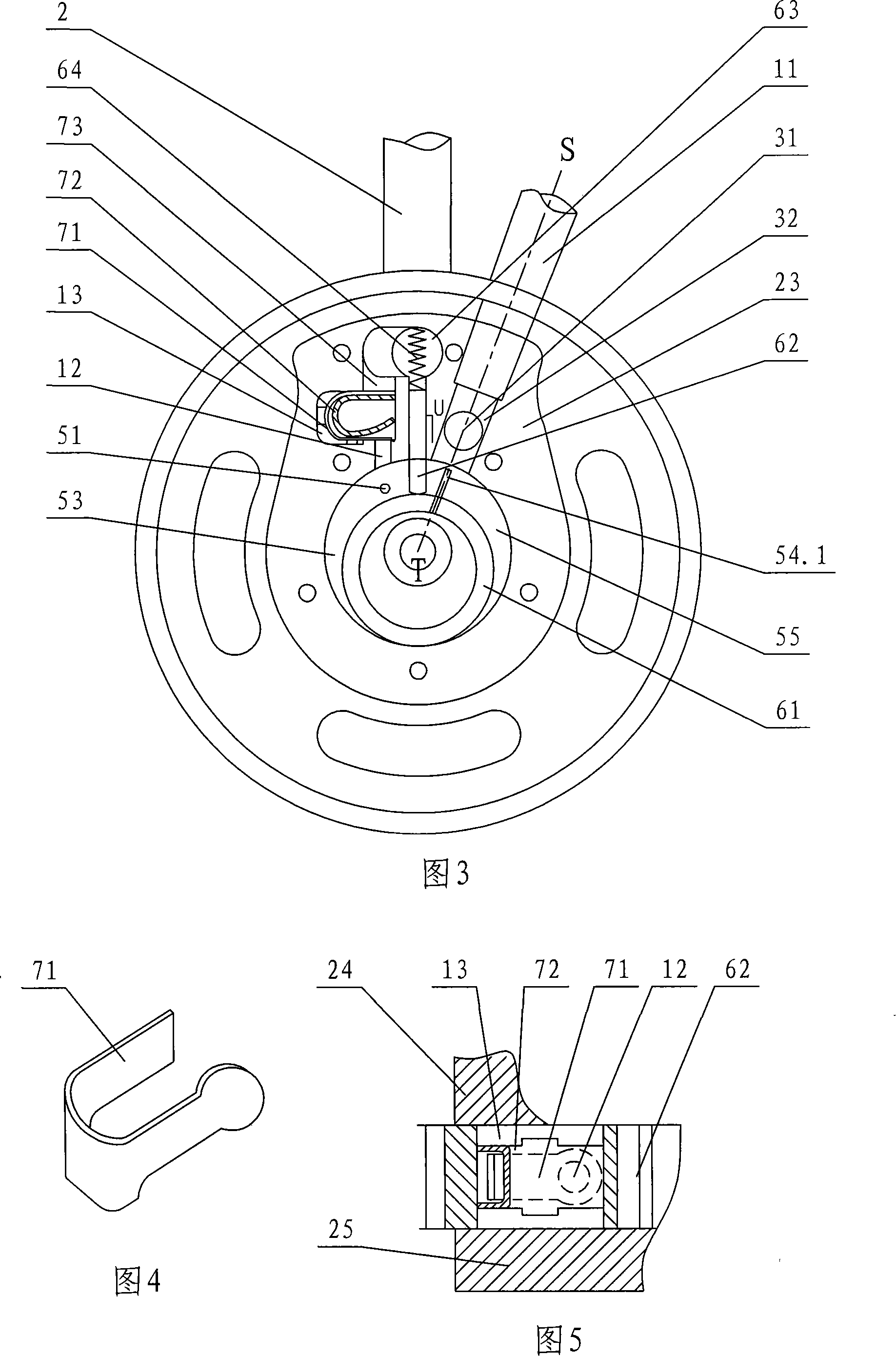

[0032] In the figure: 1 is the compressor, 2 is the exhaust pipe, 3 is the exhaust muffler, 4 is the oil separator, 5 is the condenser, 6 is the expansion valve, 7 is the evaporator, 8 is the low pressure circuit, and 9 is the shunt pipe , 10 is a bifurcated circuit, 11 is a suction pipe, 12 is an exhaust hole, 13 is an exhaust muffler chamber, 14 is an oil injection pipe, 20 is a shell, 21 is a compression assembly, 22 is a motor, 23 is a cylinder, 24 is 25 is the lower bearing, 26 is the eccentric crankshaft, 27 is the motor rotor, 28 is the motor stator, 31 is the first suction hole, 32 is the second suction hole, 34 is the third suction hole, 35 is the suction muffler, 36 is the main bearing, 37 is the ring gap, 38 is the end ring, 39 is the lower circular plate, 40 is the spring tube, 41 is the upper circular plate, 42.1 is the upper motor coil, 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com