Patents

Literature

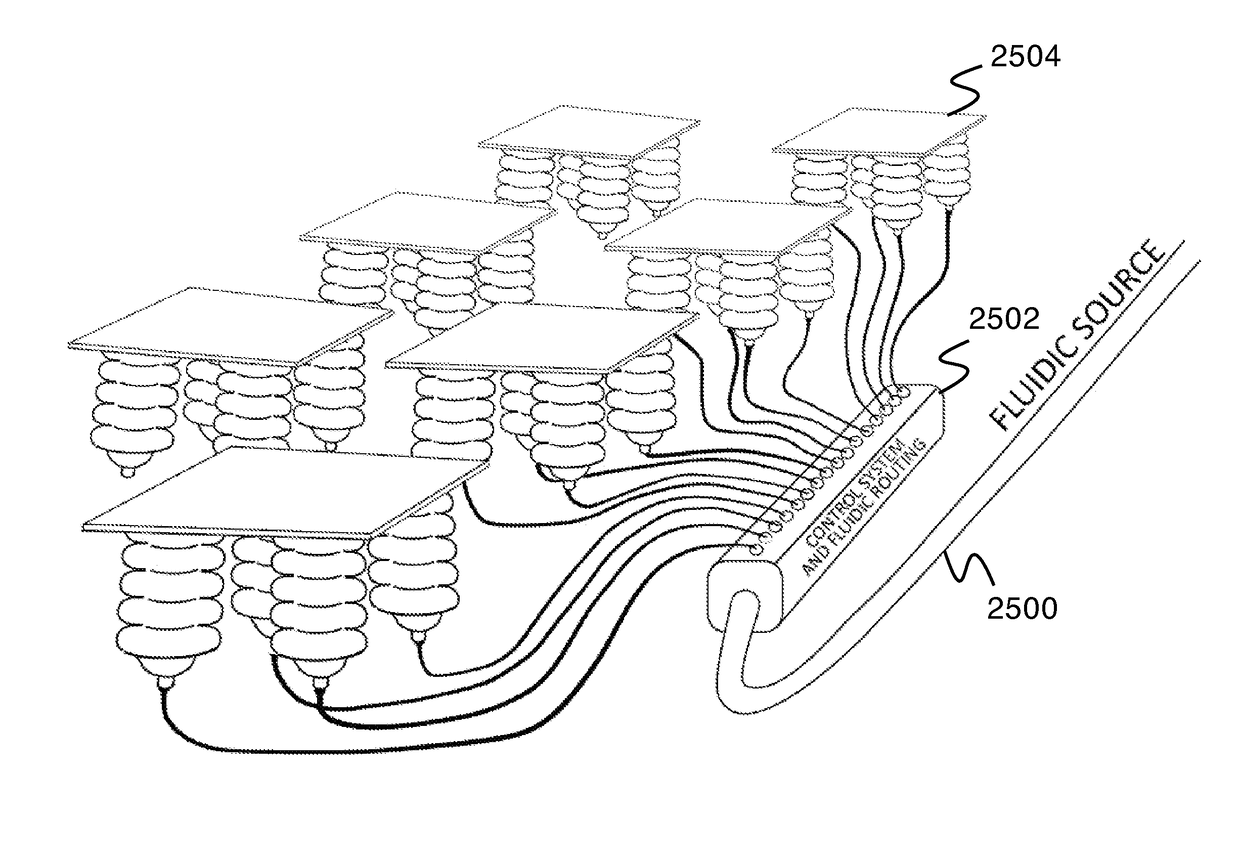

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

632results about "Bellows" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

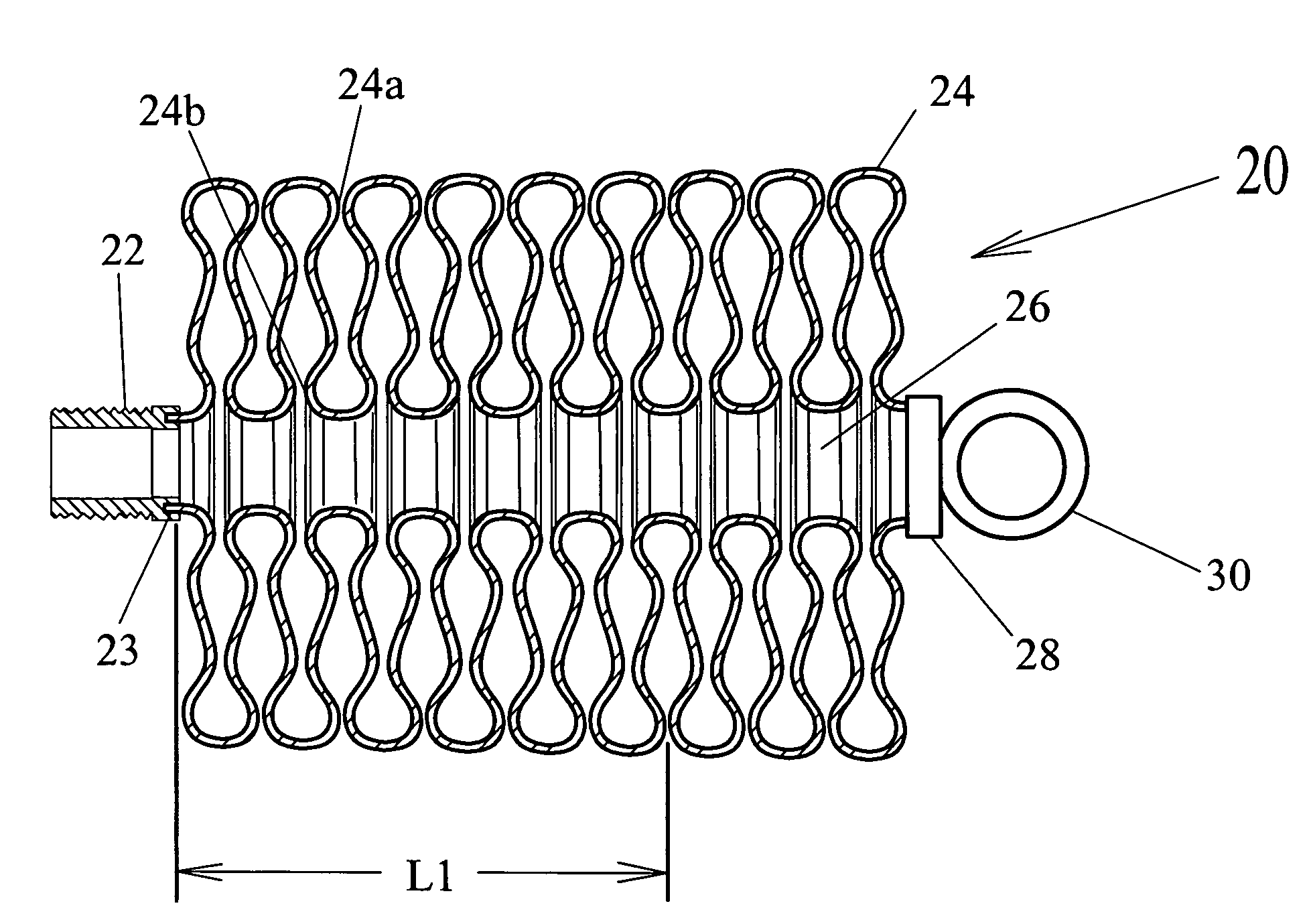

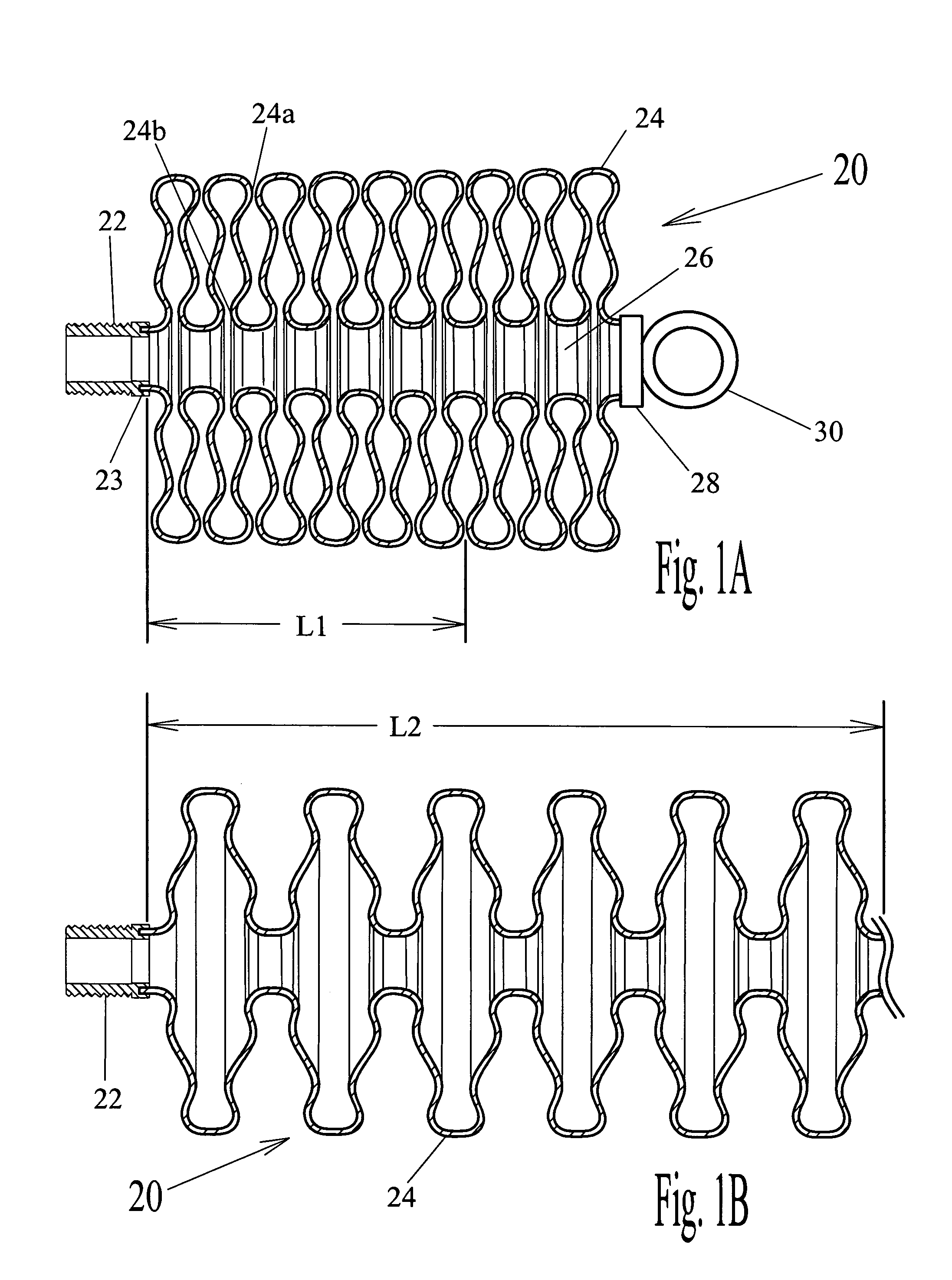

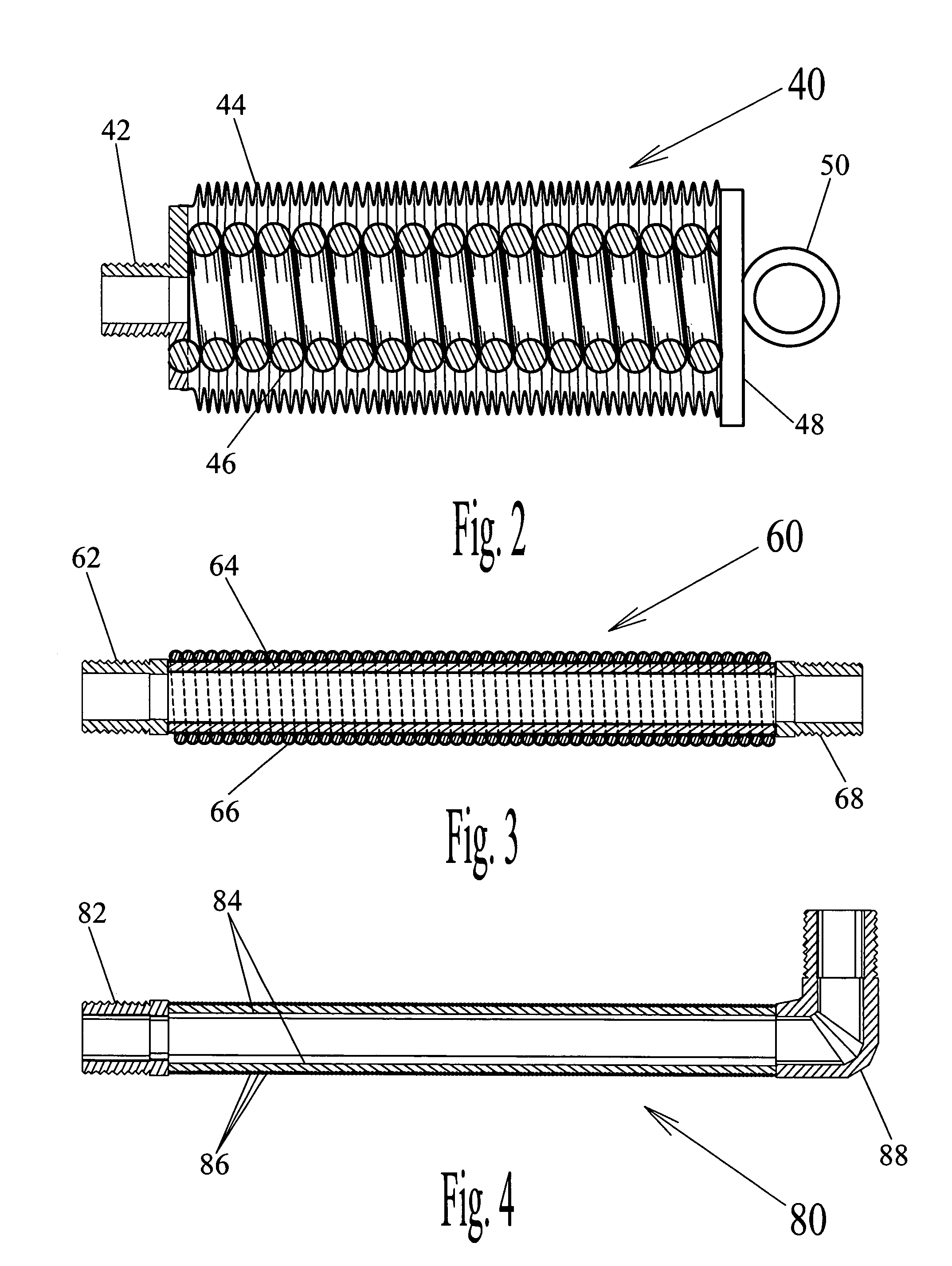

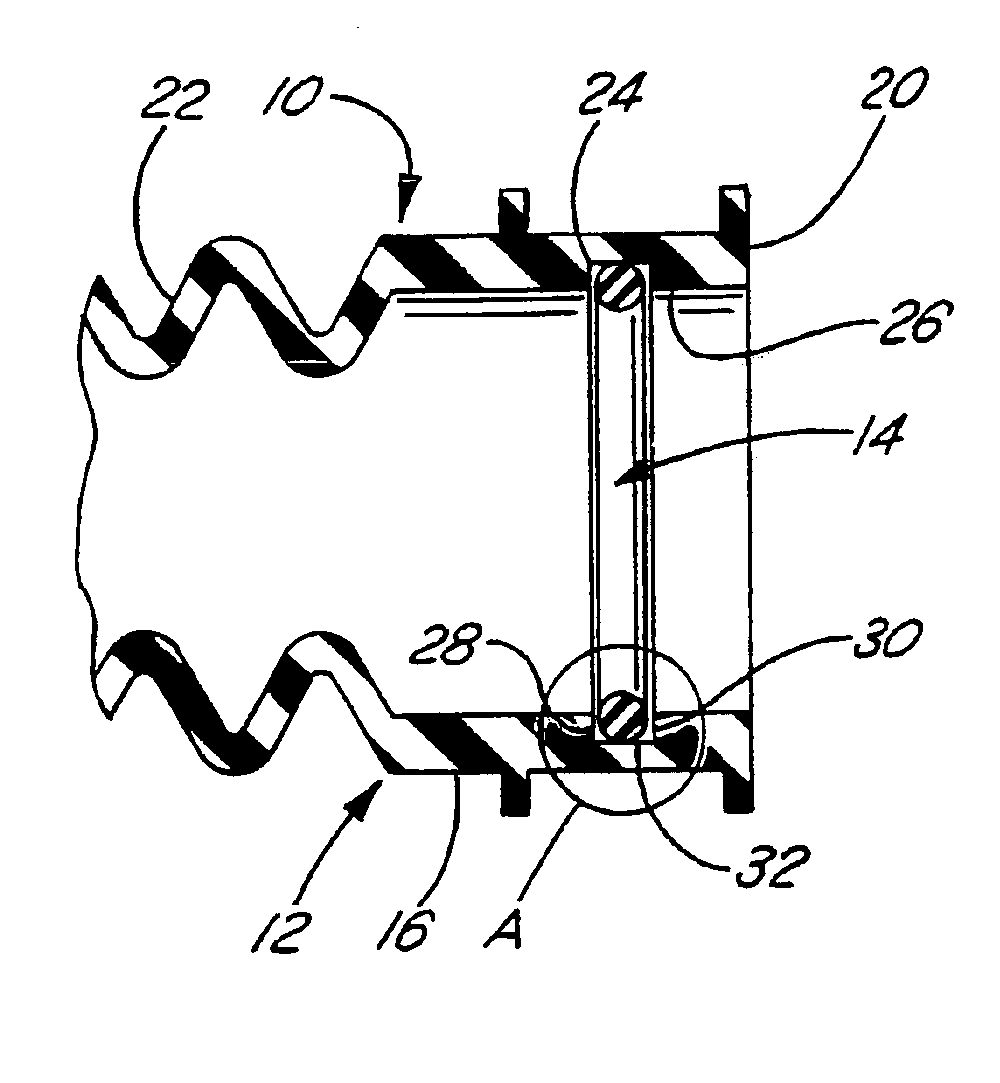

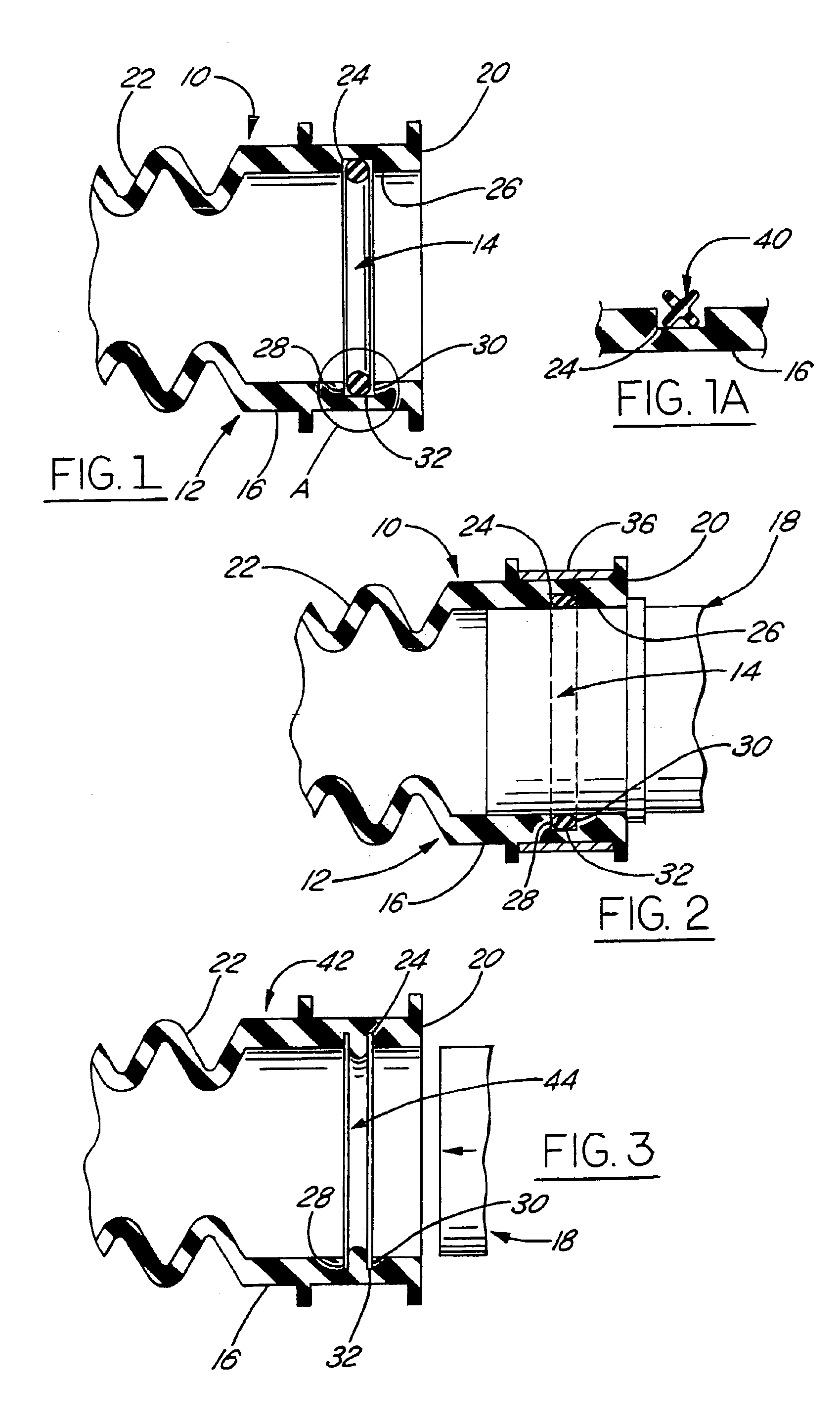

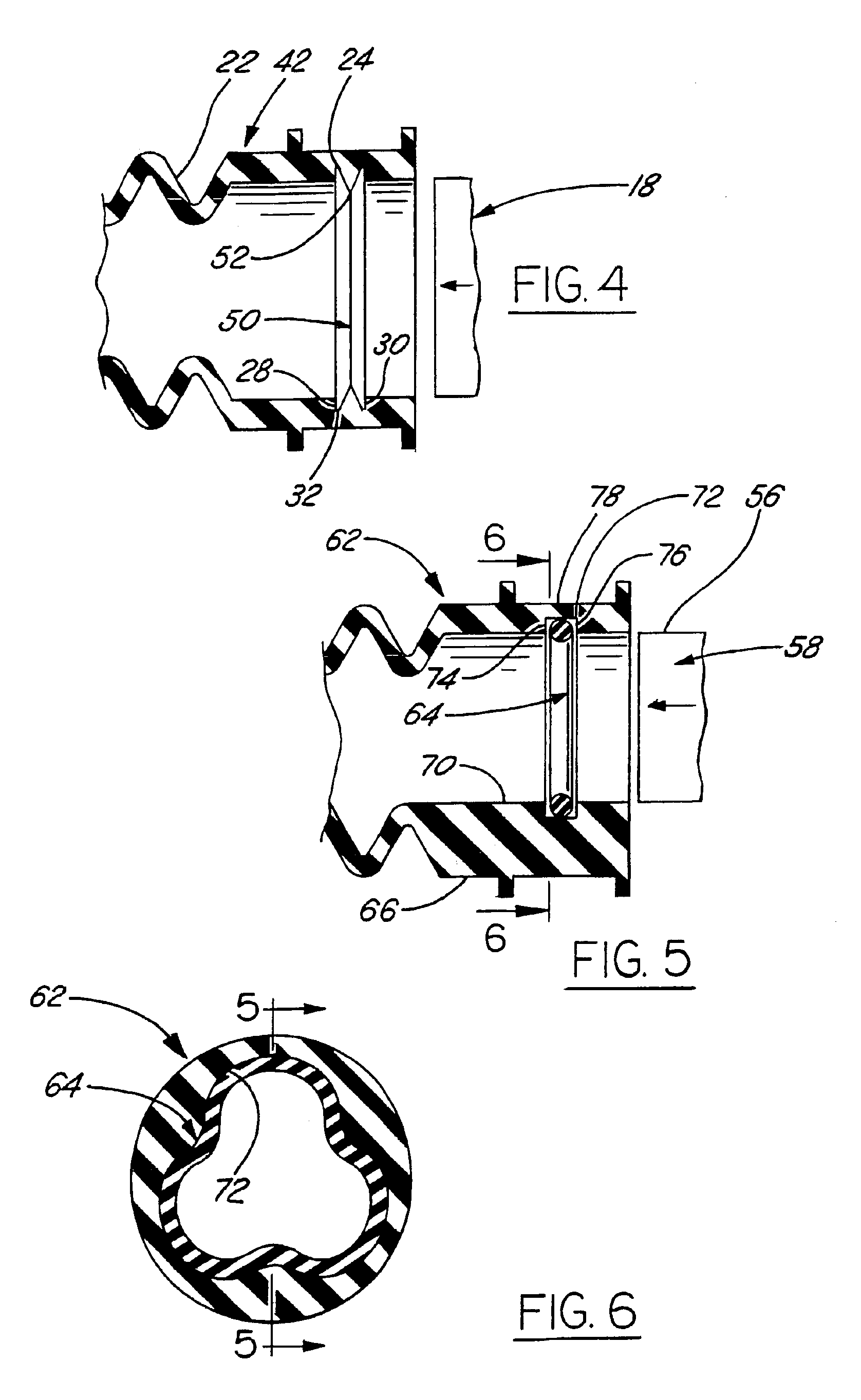

Flexible hydraulic muscle

A flexible hydraulic muscle (20) comprising a fluid port (22), bellow (24), end seal (28) and attachment ring (30). Bellow (24) also defines a retracting spring bias for generating contracting forces within muscle (20). Fluid port (22) is designed to provide an anchor point for the muscle, while at the same time, providing a means to introduce and remove hydraulic fluid from bellow (24). End seal (28) and attachment ring (30) provide the second connecting point for the muscle. These two anchor points on each end of bellow (24) provide connection points to communicate contracting force from bellow (24) into useful work. End seal (28) is securely attached or bonded to the end of bellow (24) to provide a fluid tight seal, and designed to resist longitudinal forces on the connection.

Owner:RAGNER GARY DEAN

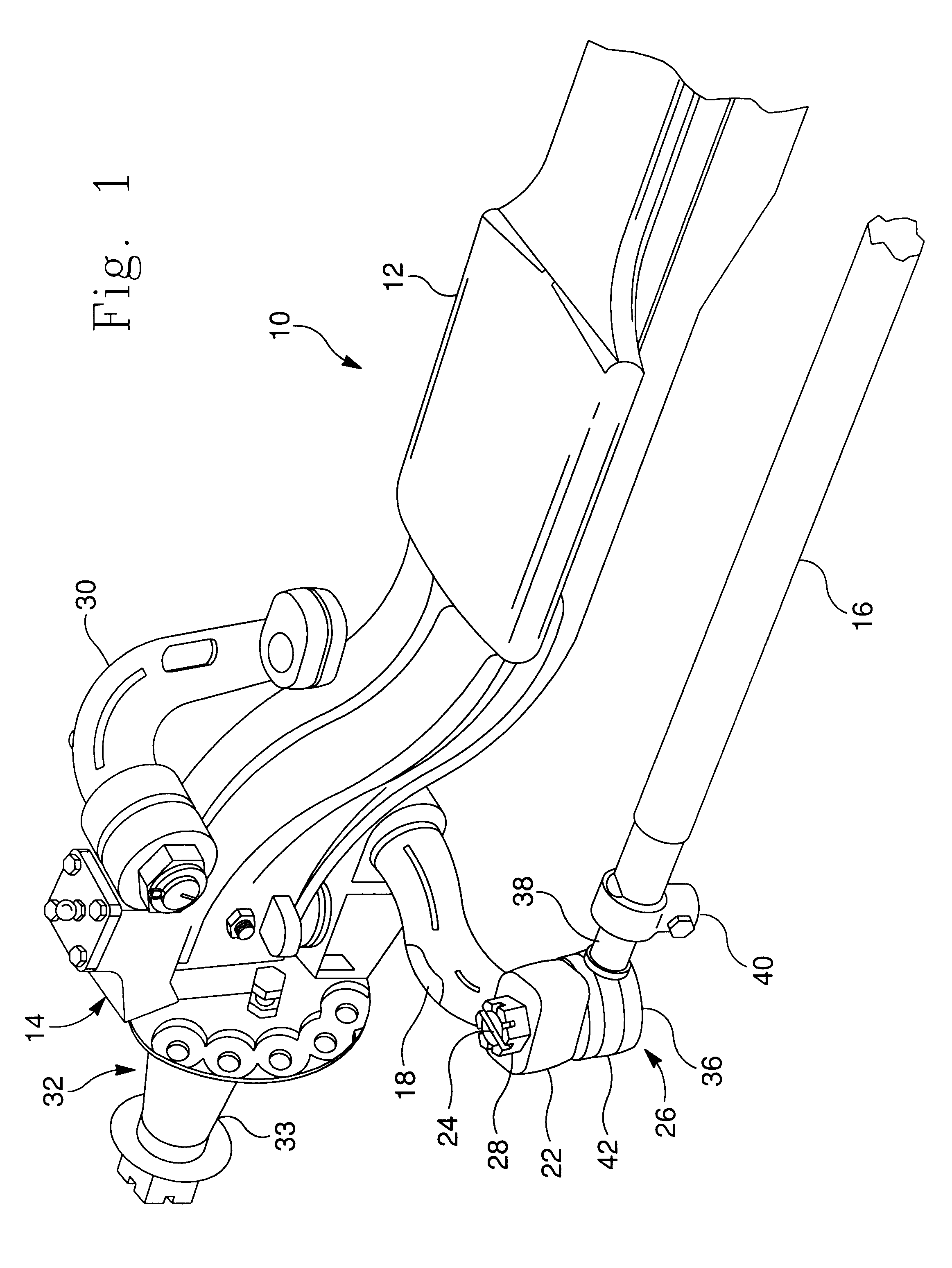

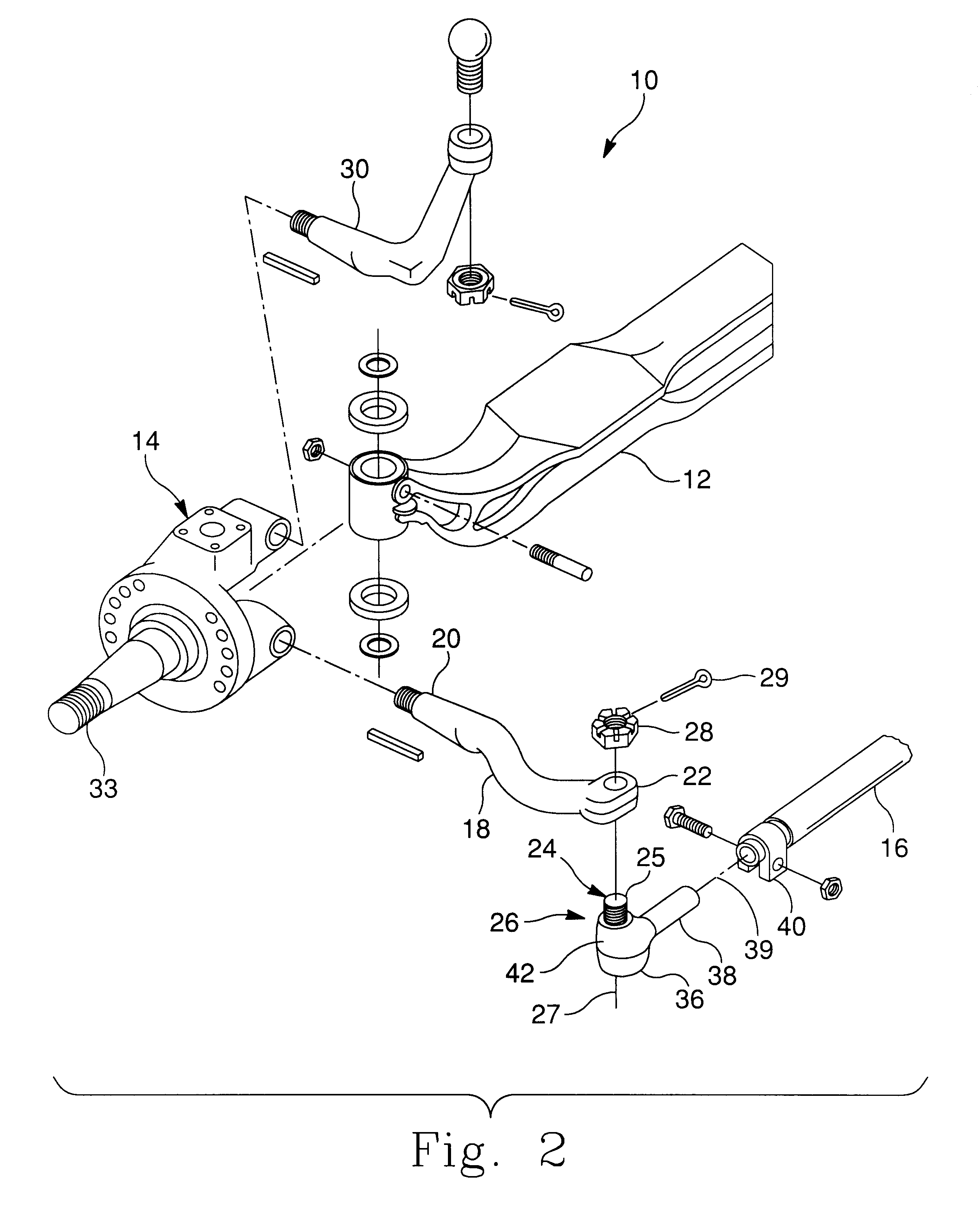

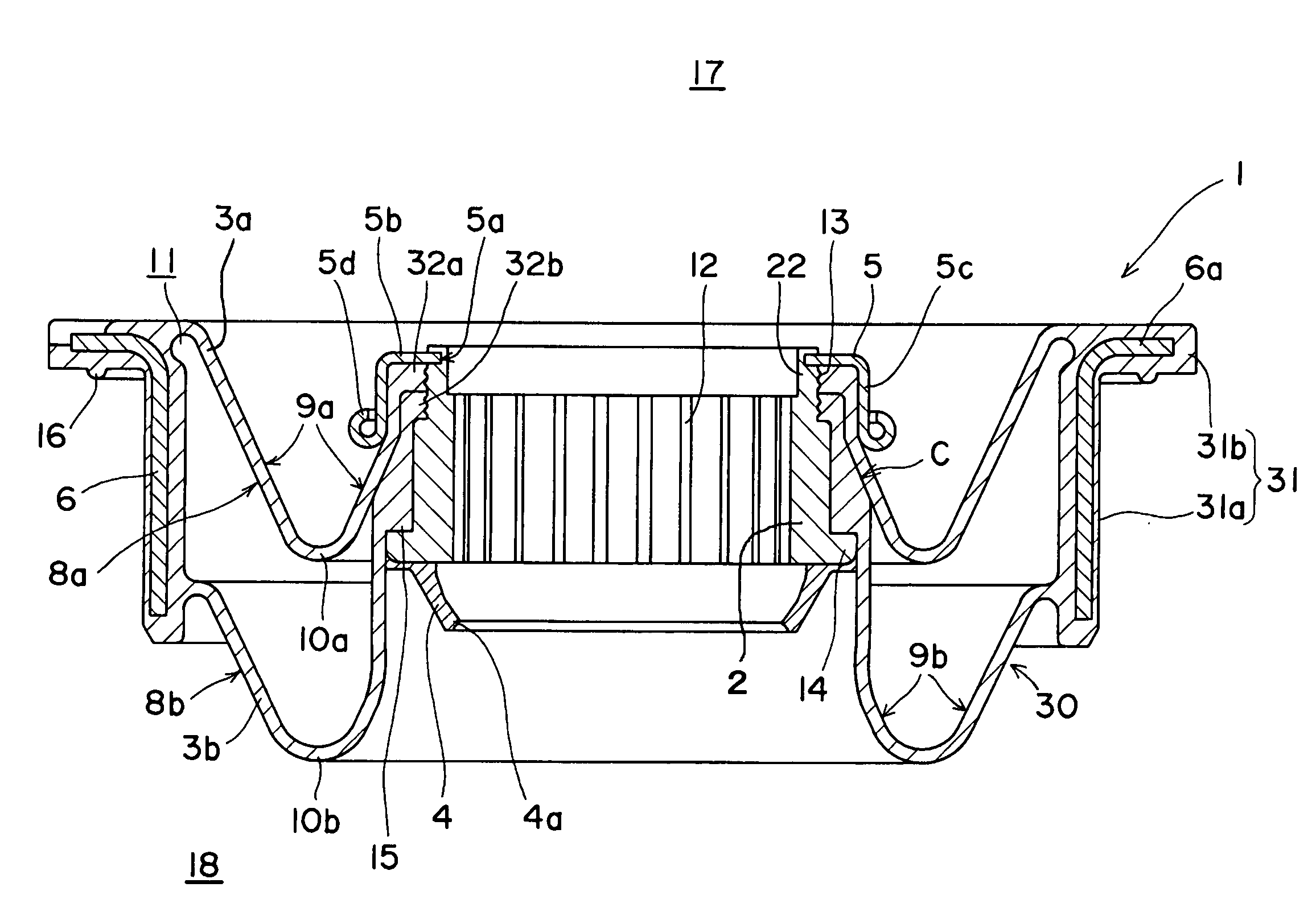

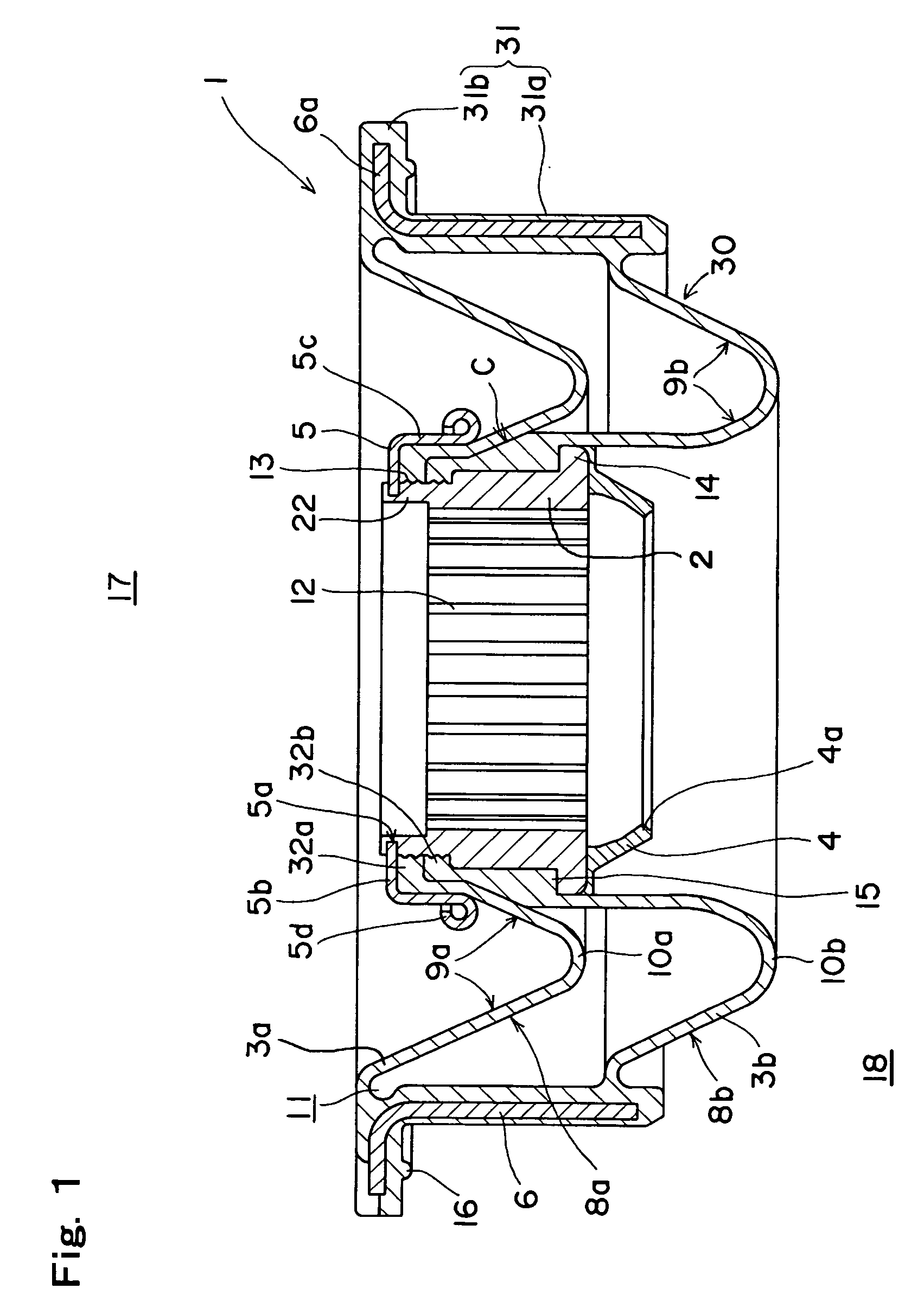

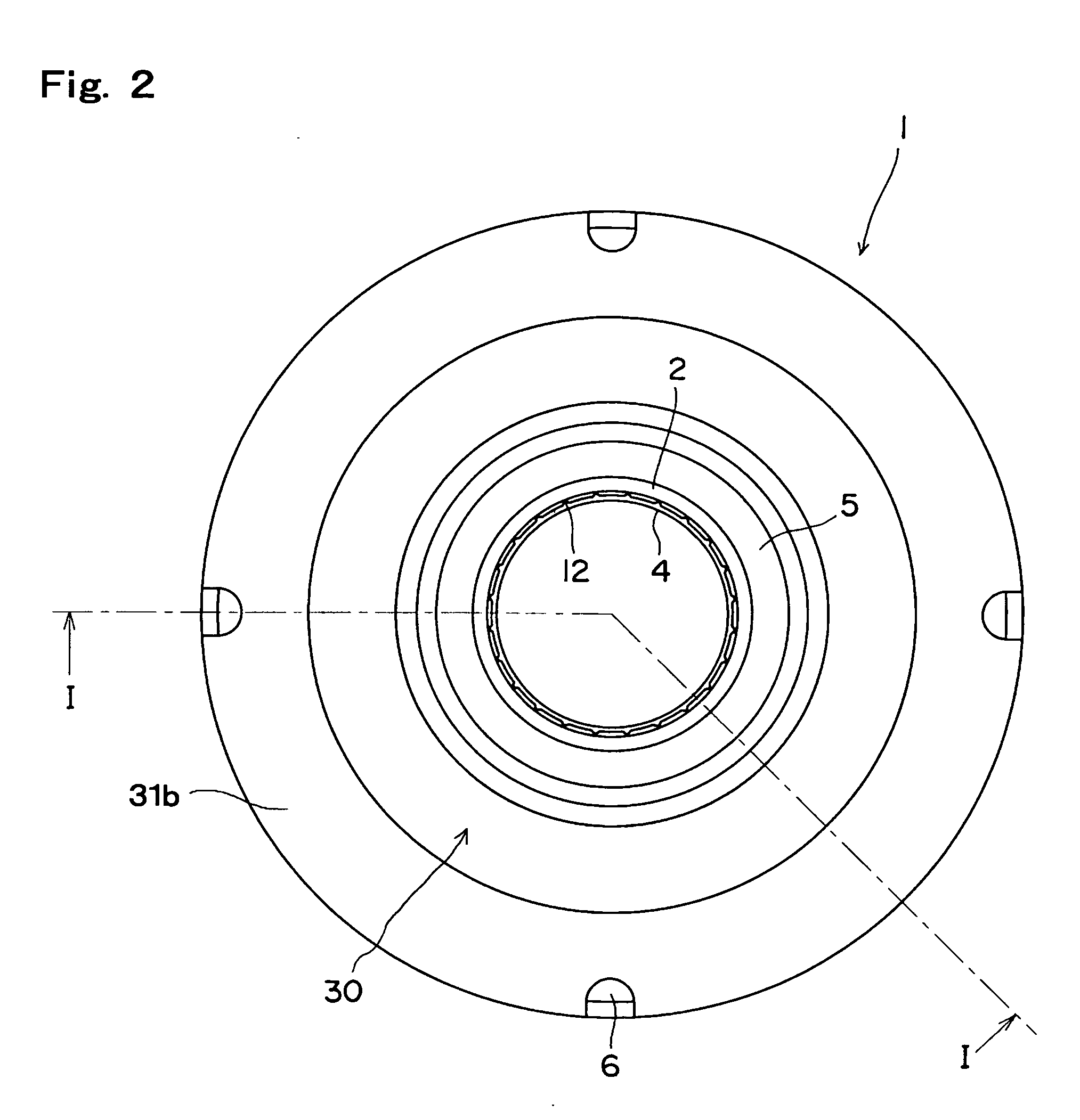

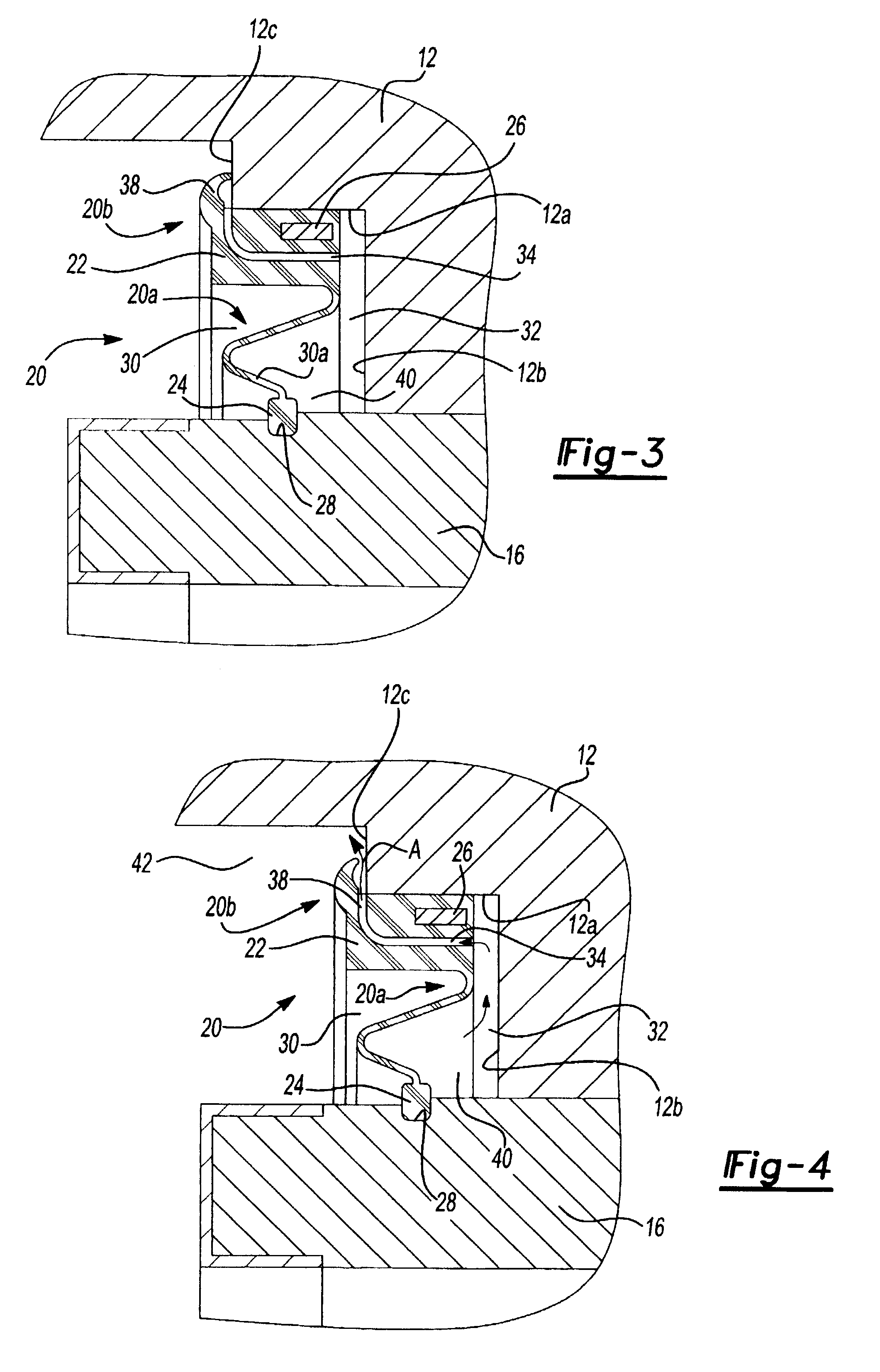

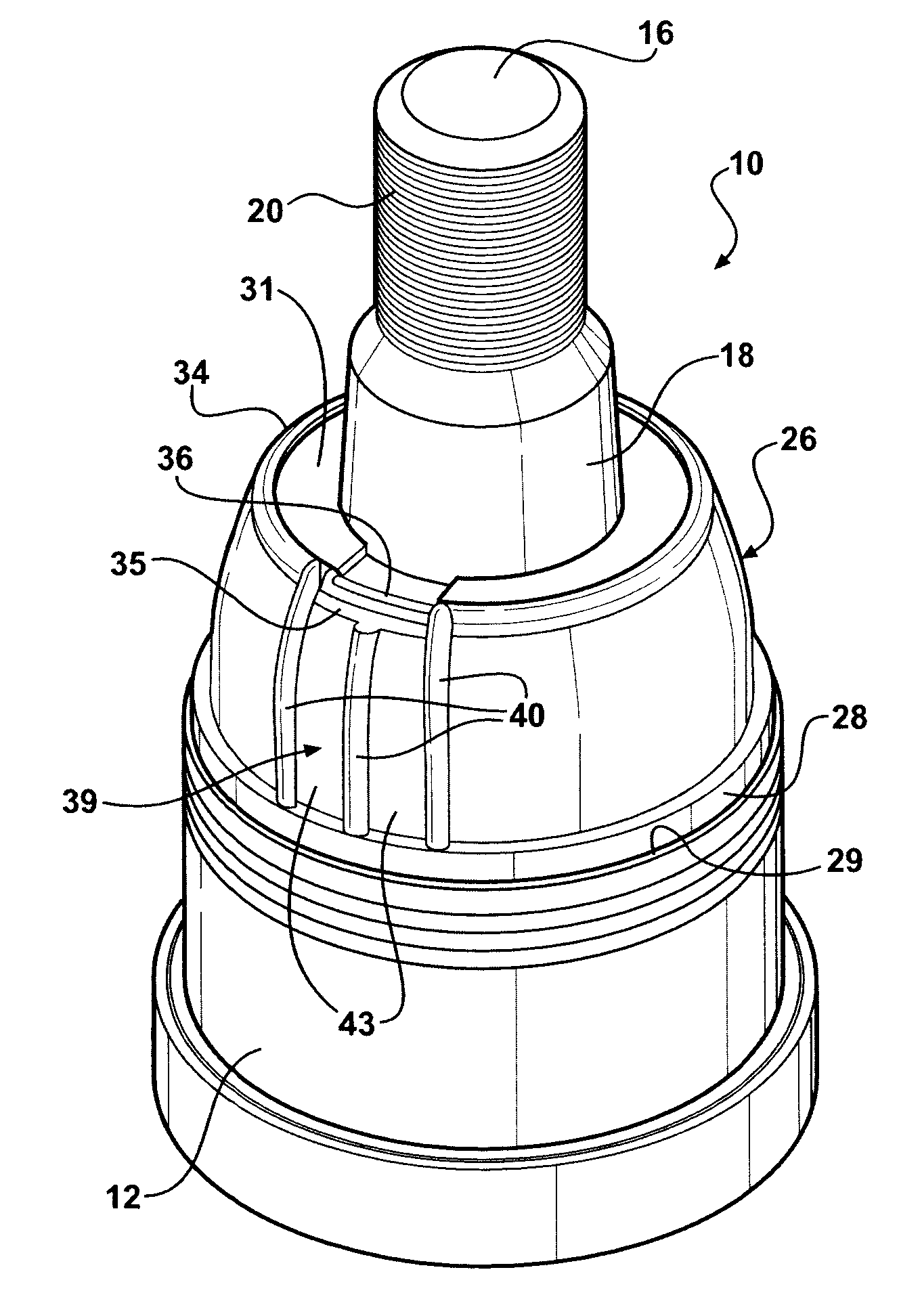

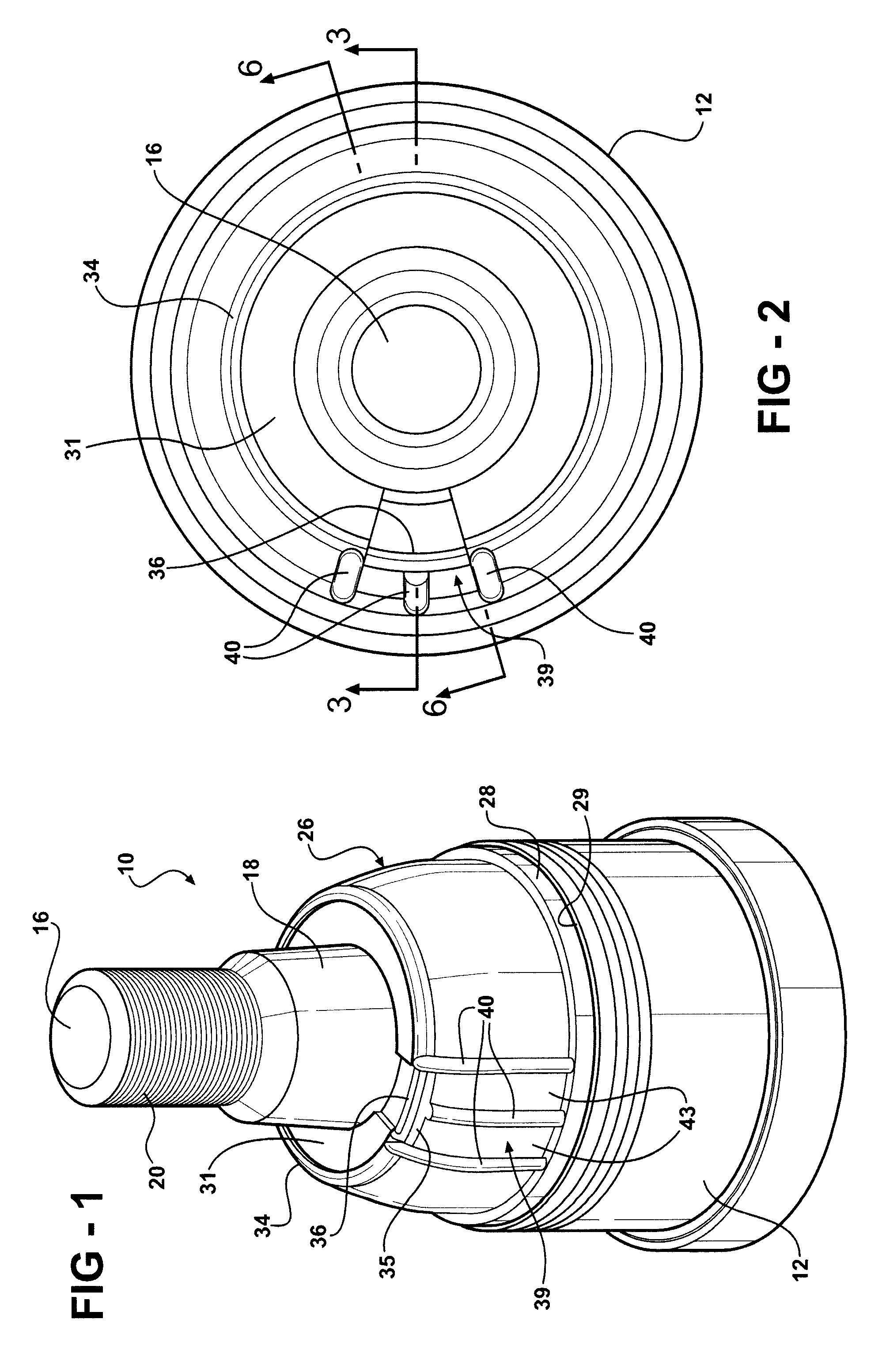

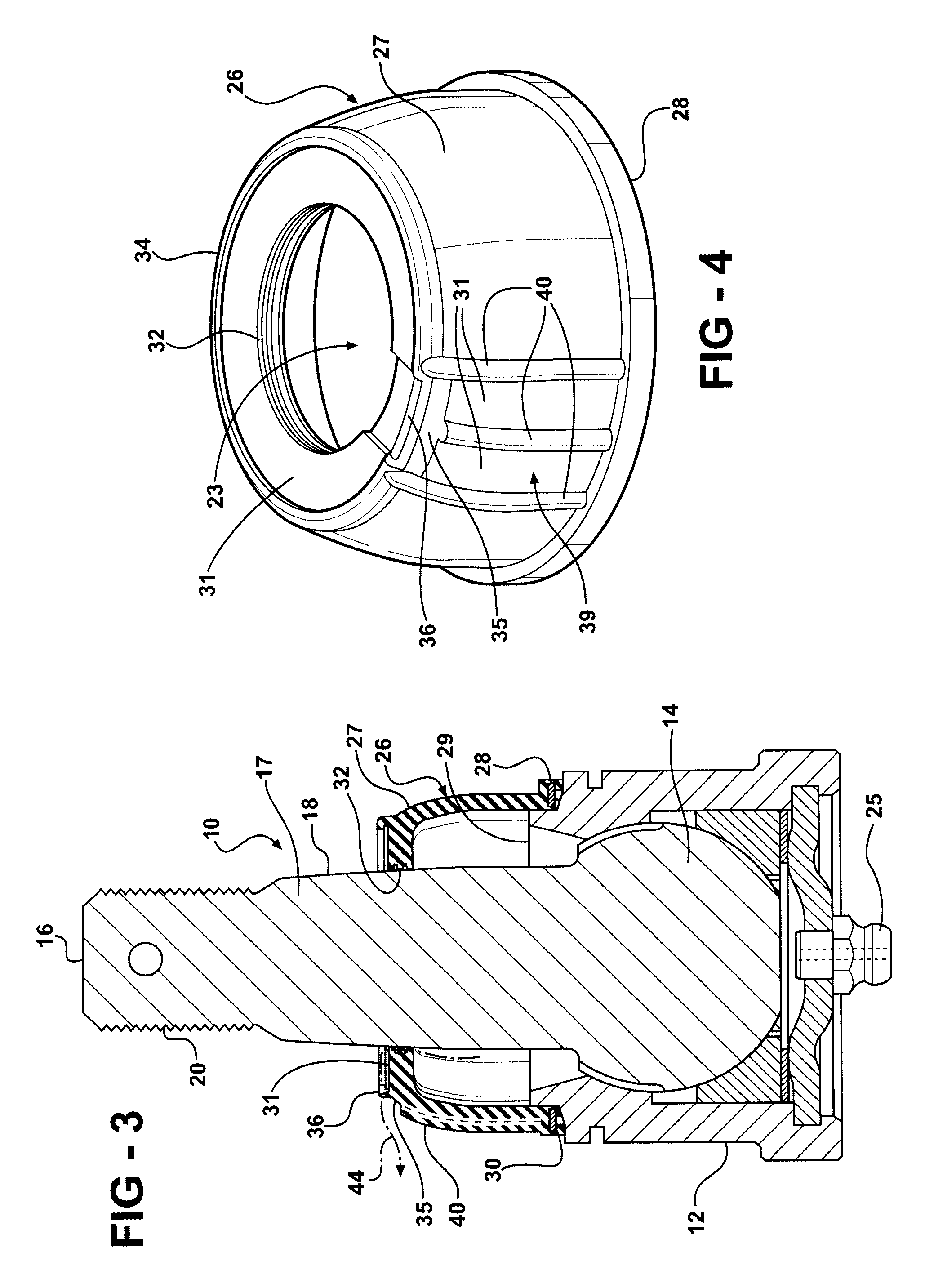

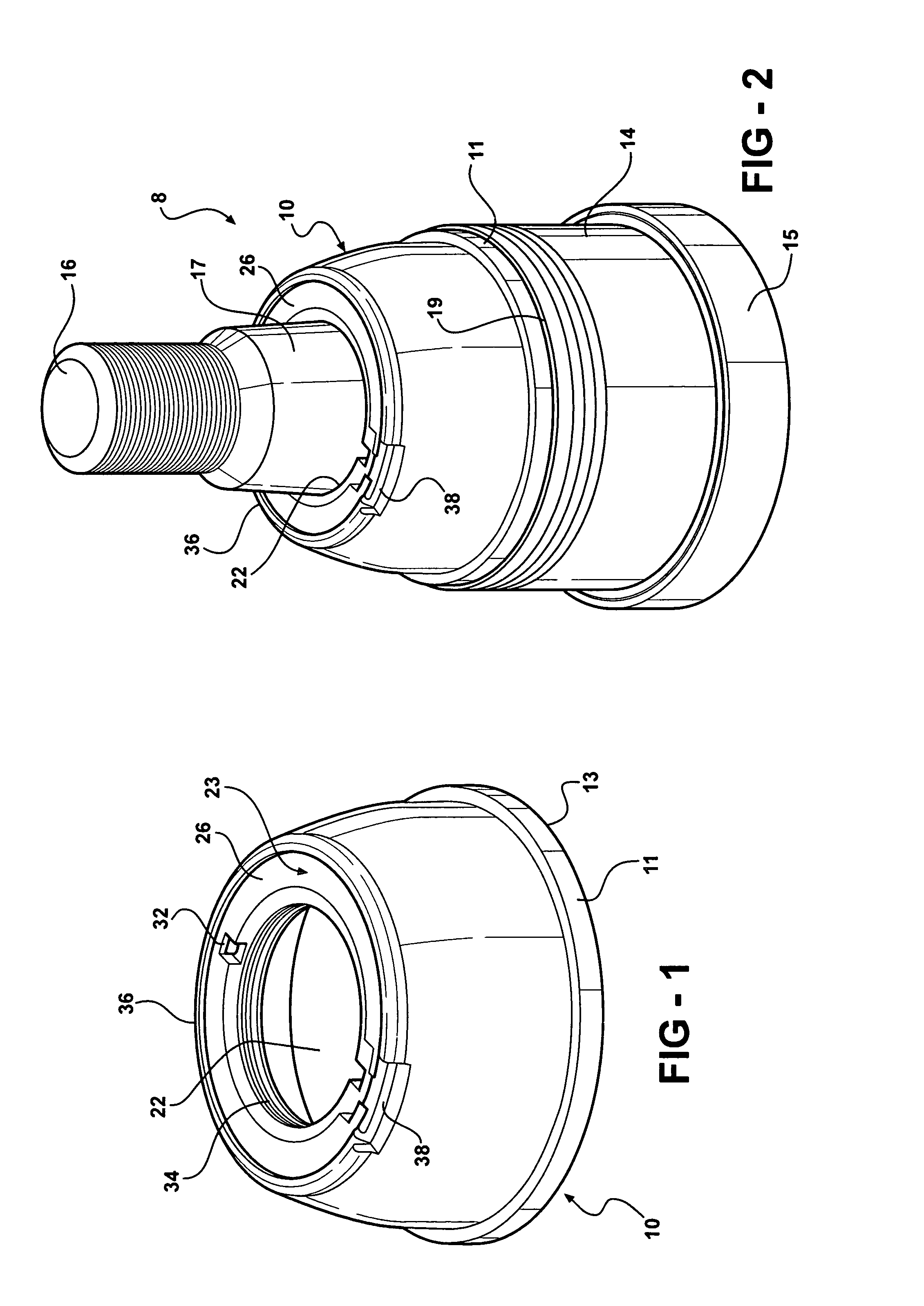

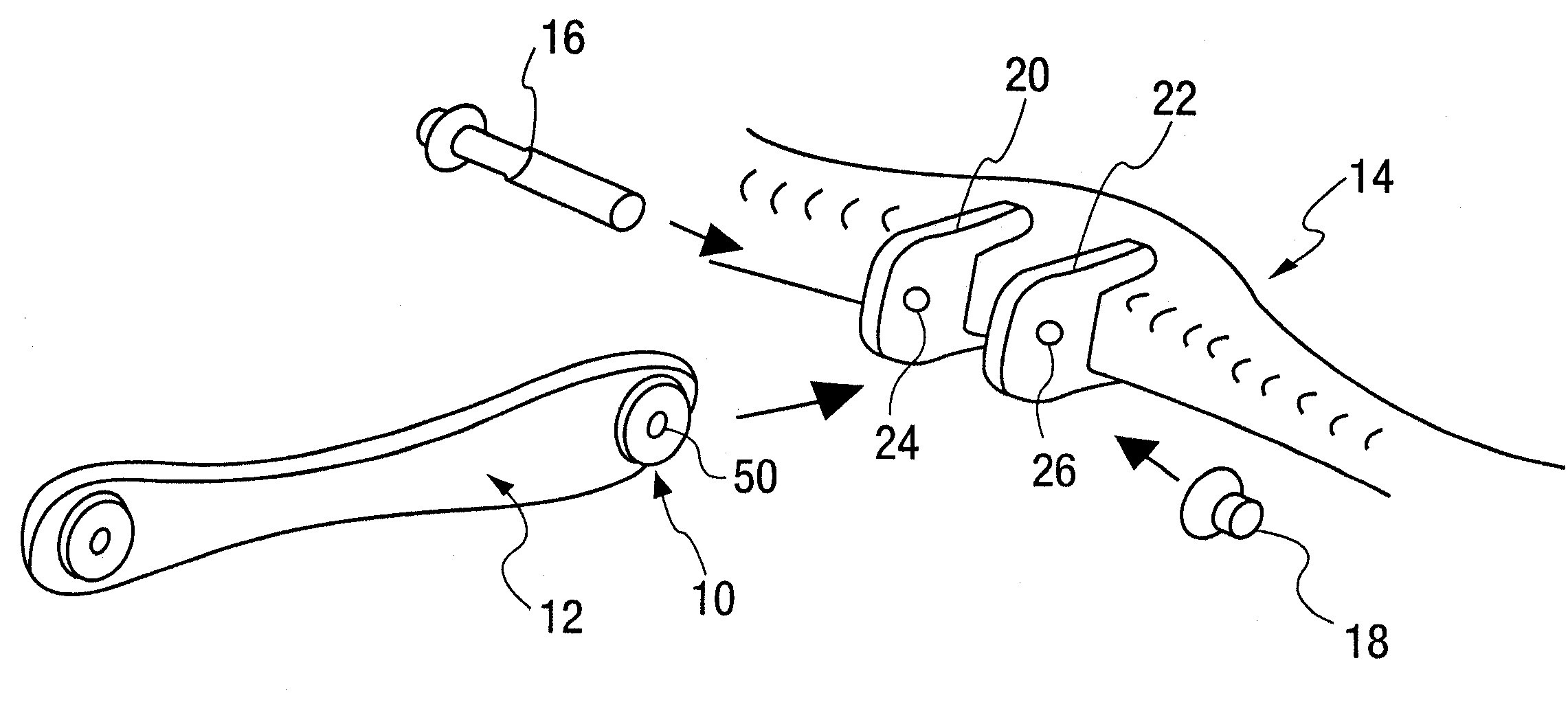

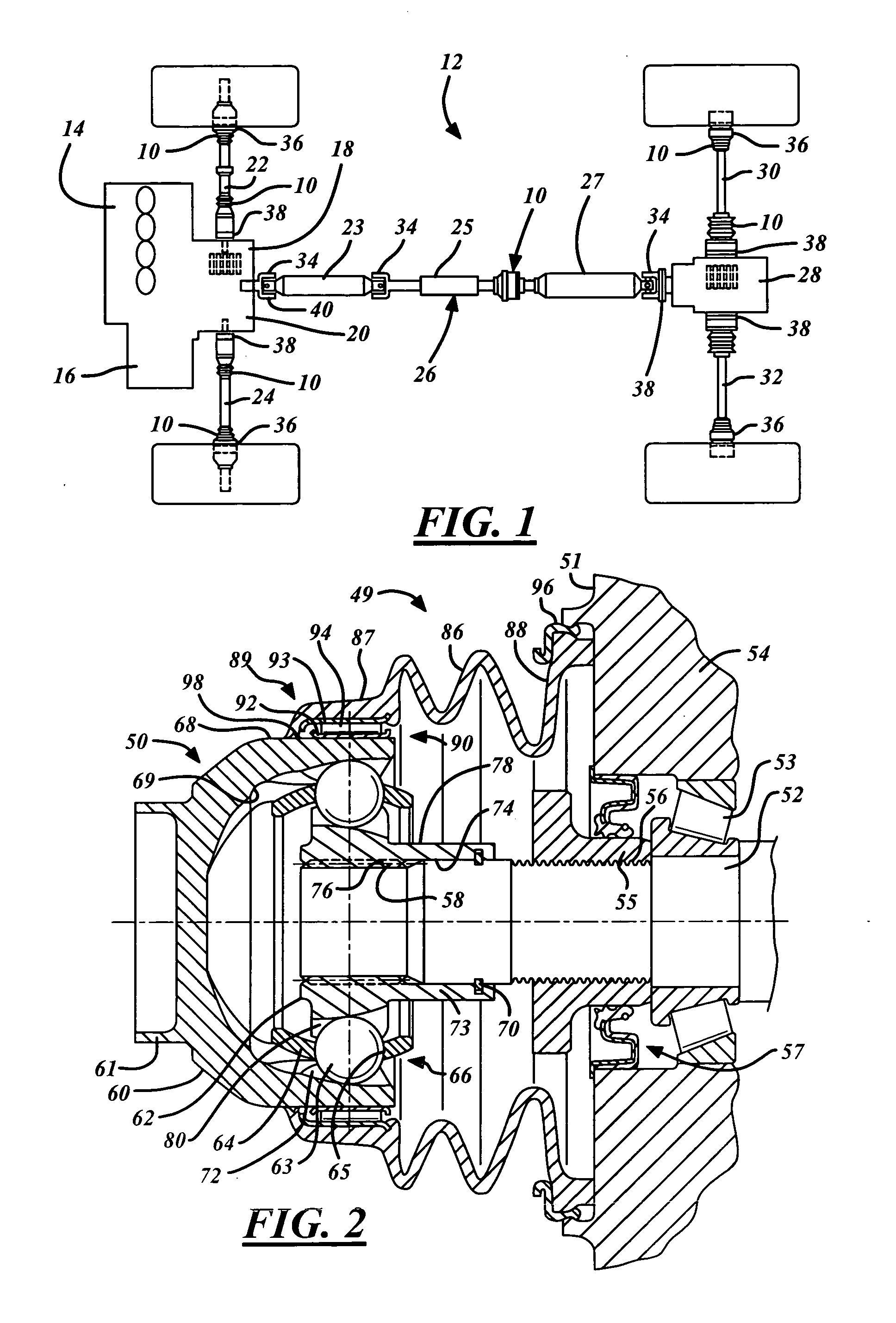

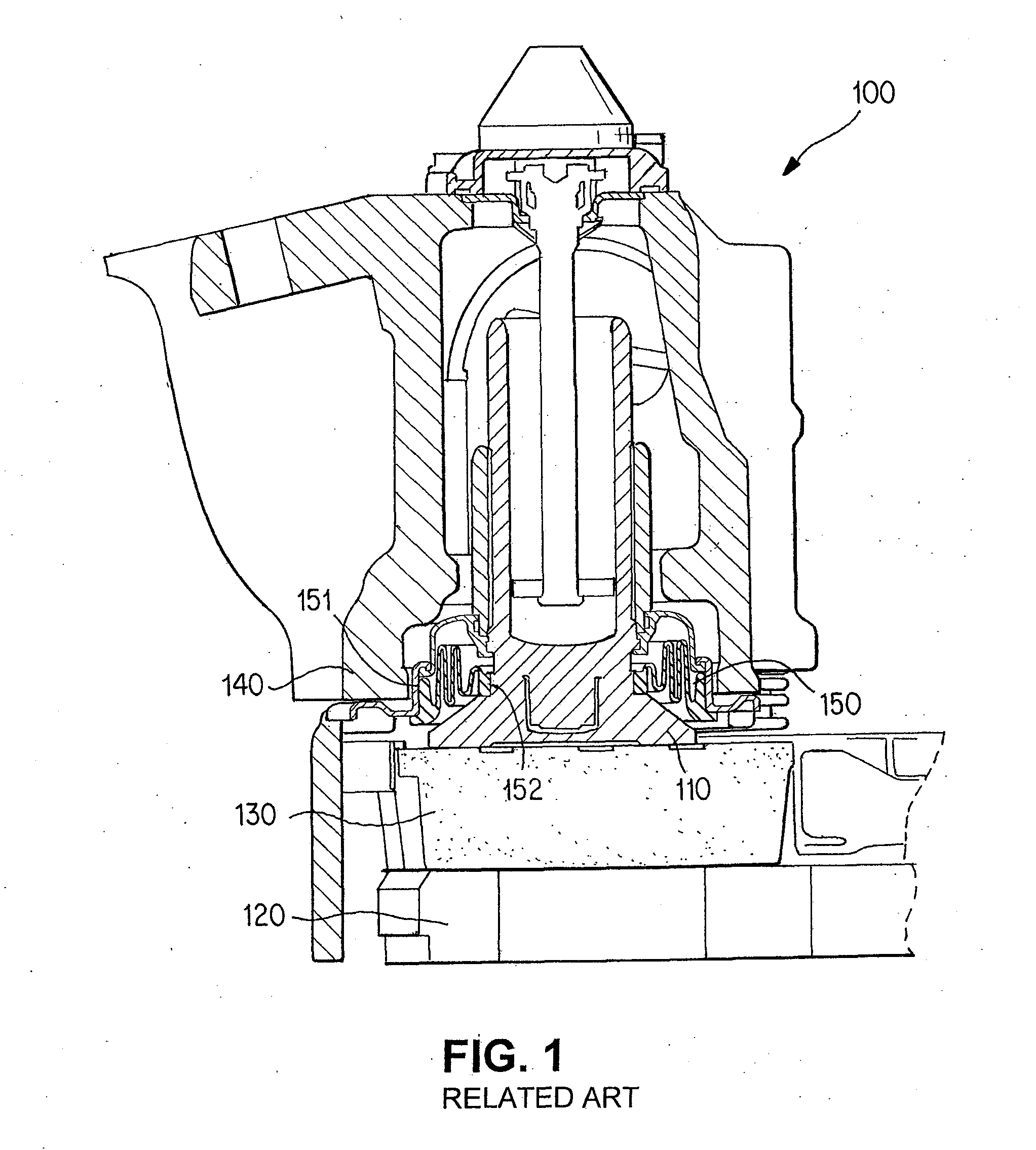

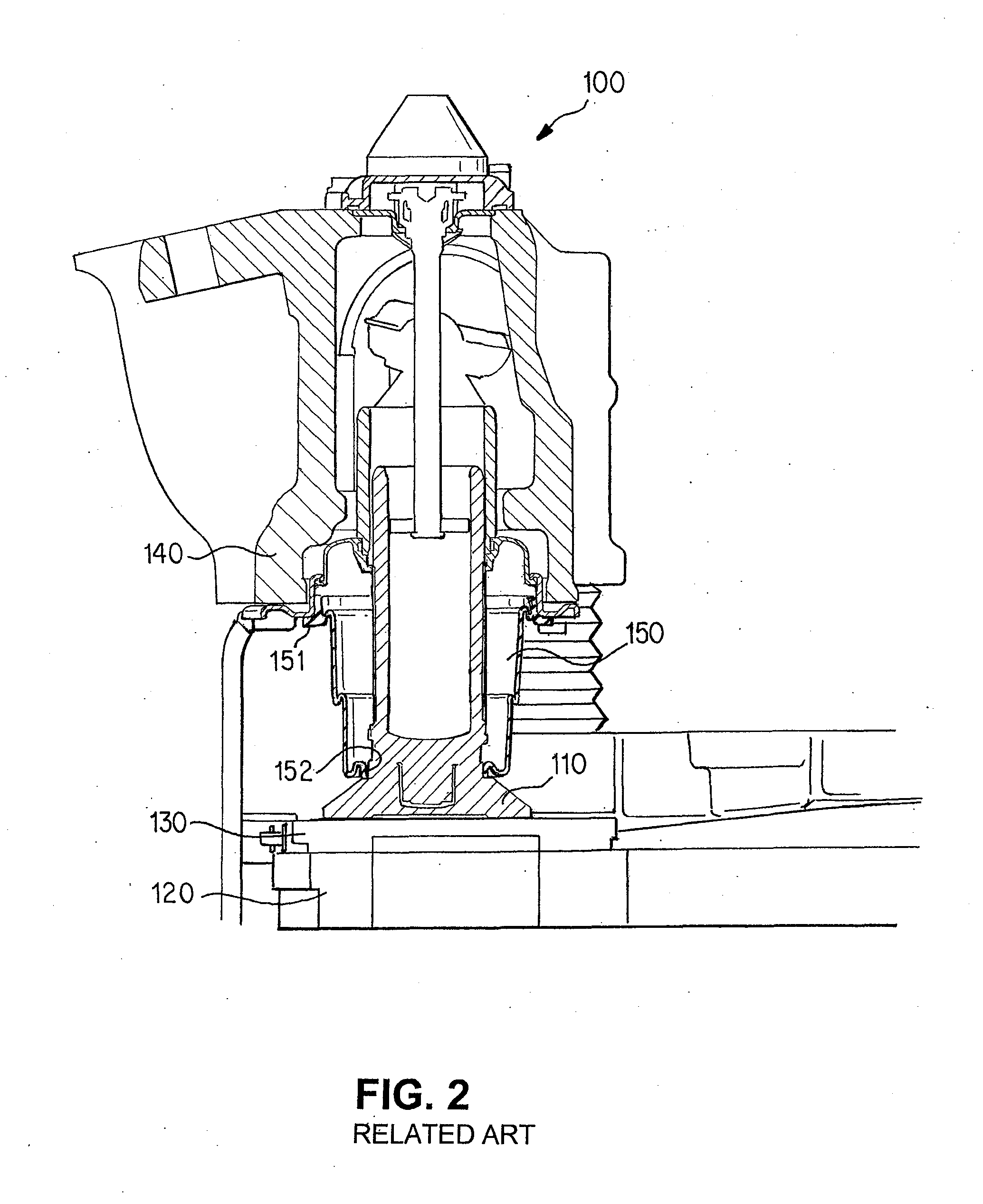

Unitized boot seal for ball joints

InactiveUS6357956B1Manufacturing friendly and cost-effectiveLow costEngine sealsSteering linkagesTransverse axisFree rotation

A pivotal ball joint assembly includes a ball joint, an input / output member, and a sealing element to provide a sealing surface abutting the boot seal and to prevent contamination of the boot seal during movement and articulation of the input / output member relative to the ball joint. The ball joint has a socket body and a ball stud pivotally mounted to the socket body. The ball stud has a shank portion that extends therefrom and is aligned along a shank axis. An elastic boot seal that extends between the ball stud and socket body is also included. The pivotal ball joint assembly also includes an input / output member affixed to the ball stud shank portion so that the socket body is able to freely rotate relative to the input / output shaft about the shank axis. The pivotal ball joint assembly is further rotatable through a limited range about a transverse axis perpendicular to the shank axis. The seal element is interposed between the boot seal, the shank portion and the input / output member to enhance the boot seal interface and thereby guard the boot seal to shank portion interface against contamination during movement and articulation of the input / output member relative to the ball joint.

Owner:DANA HEAVY VEHICLE SYSTEMS GROUP LLC

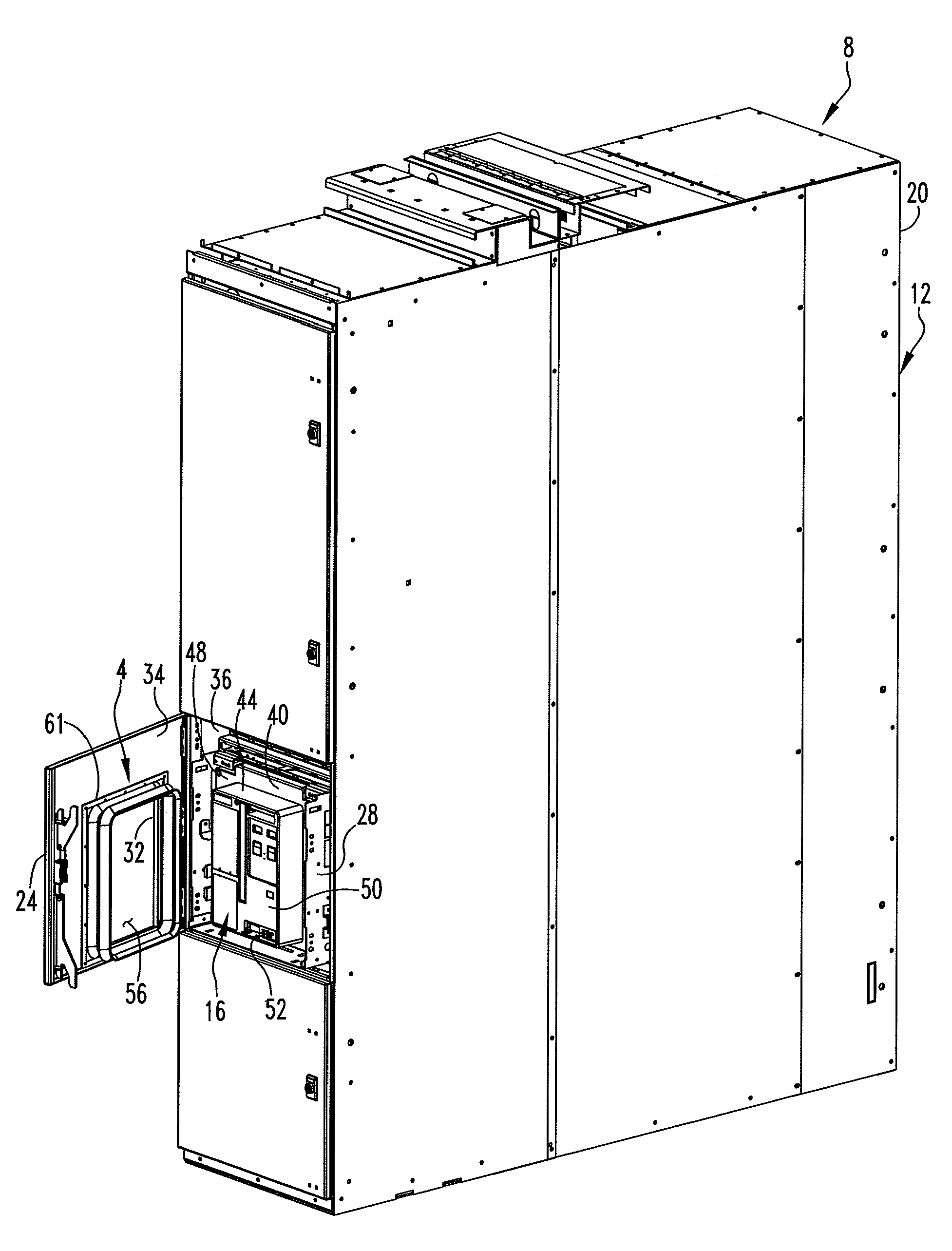

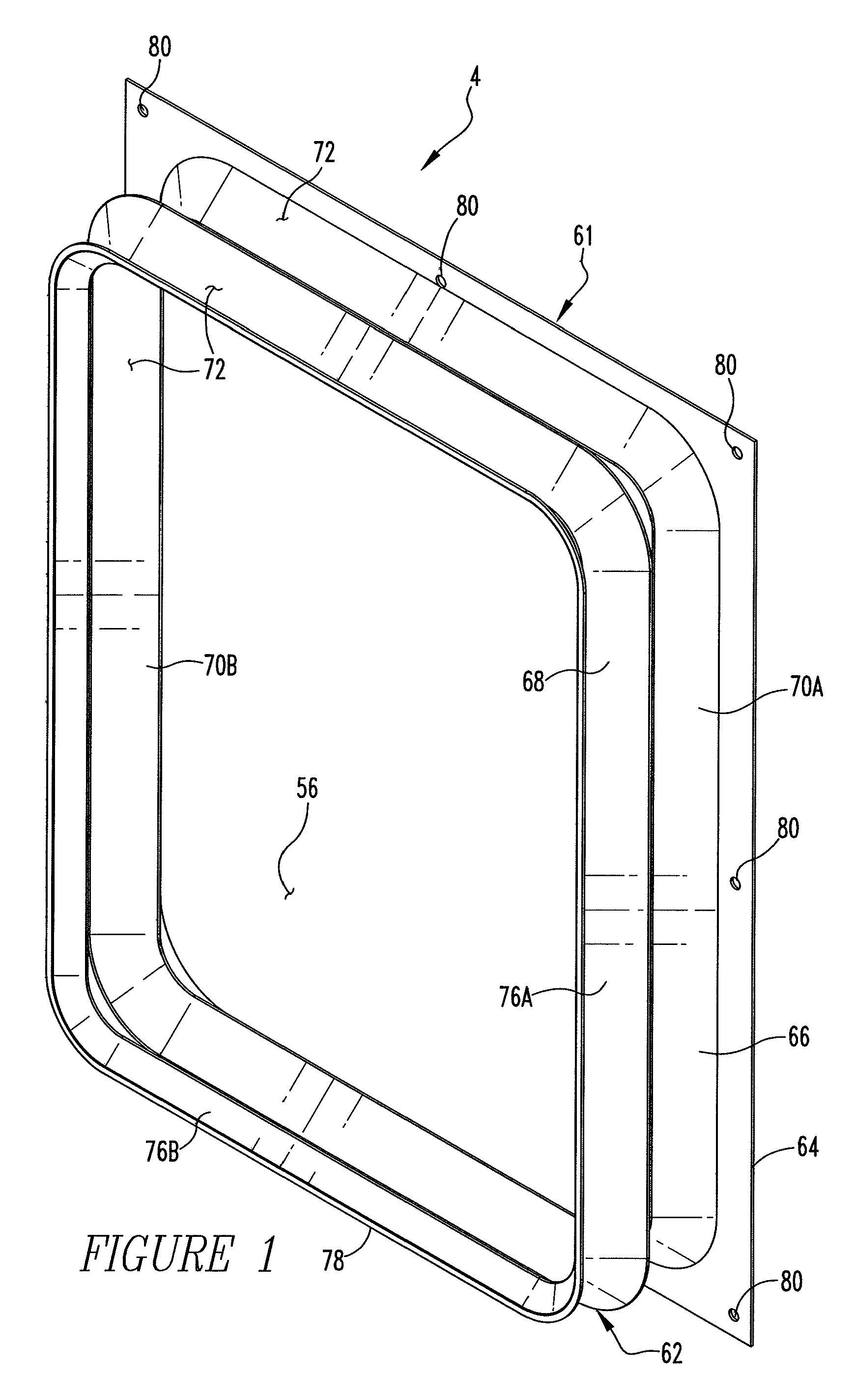

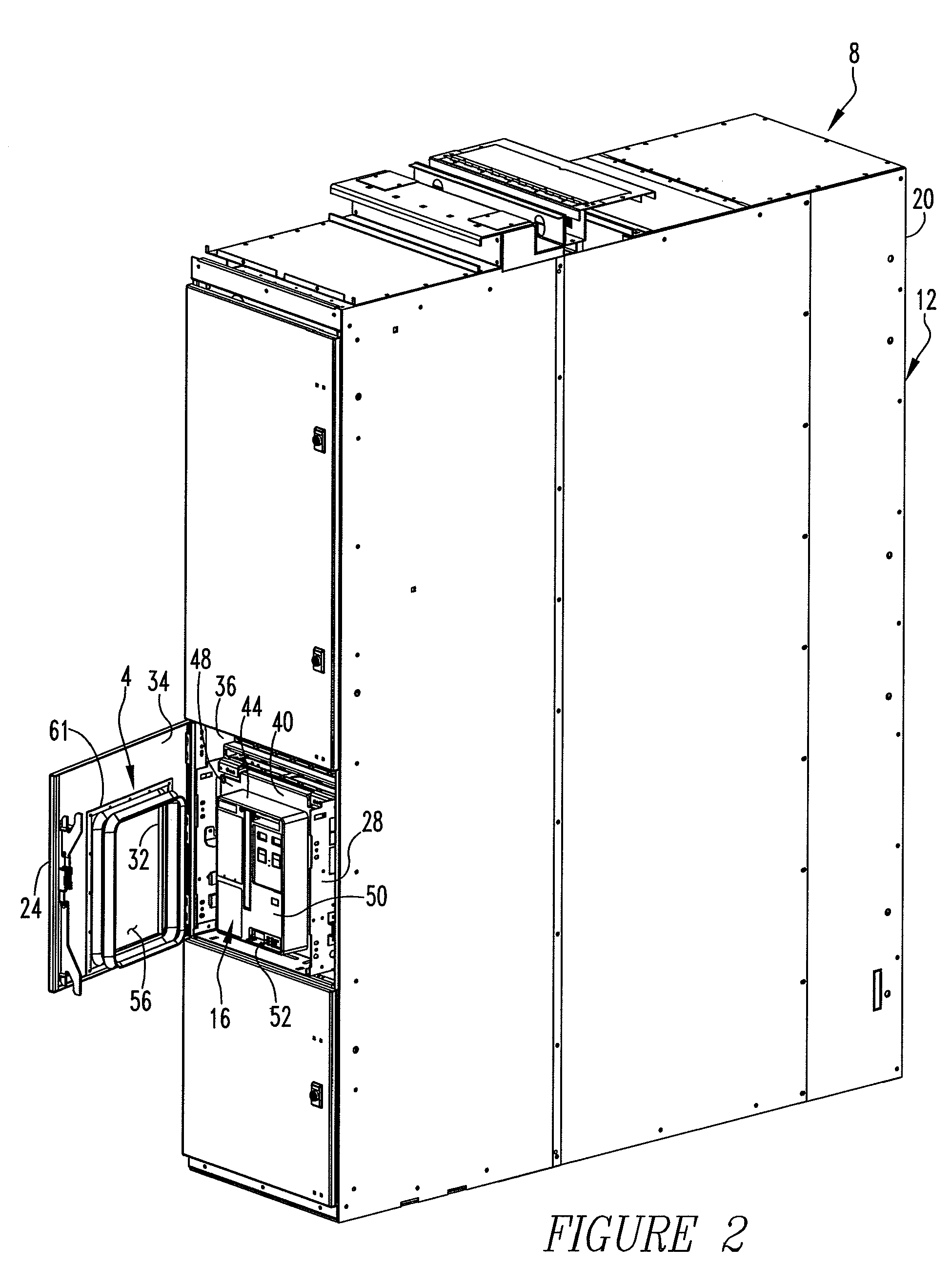

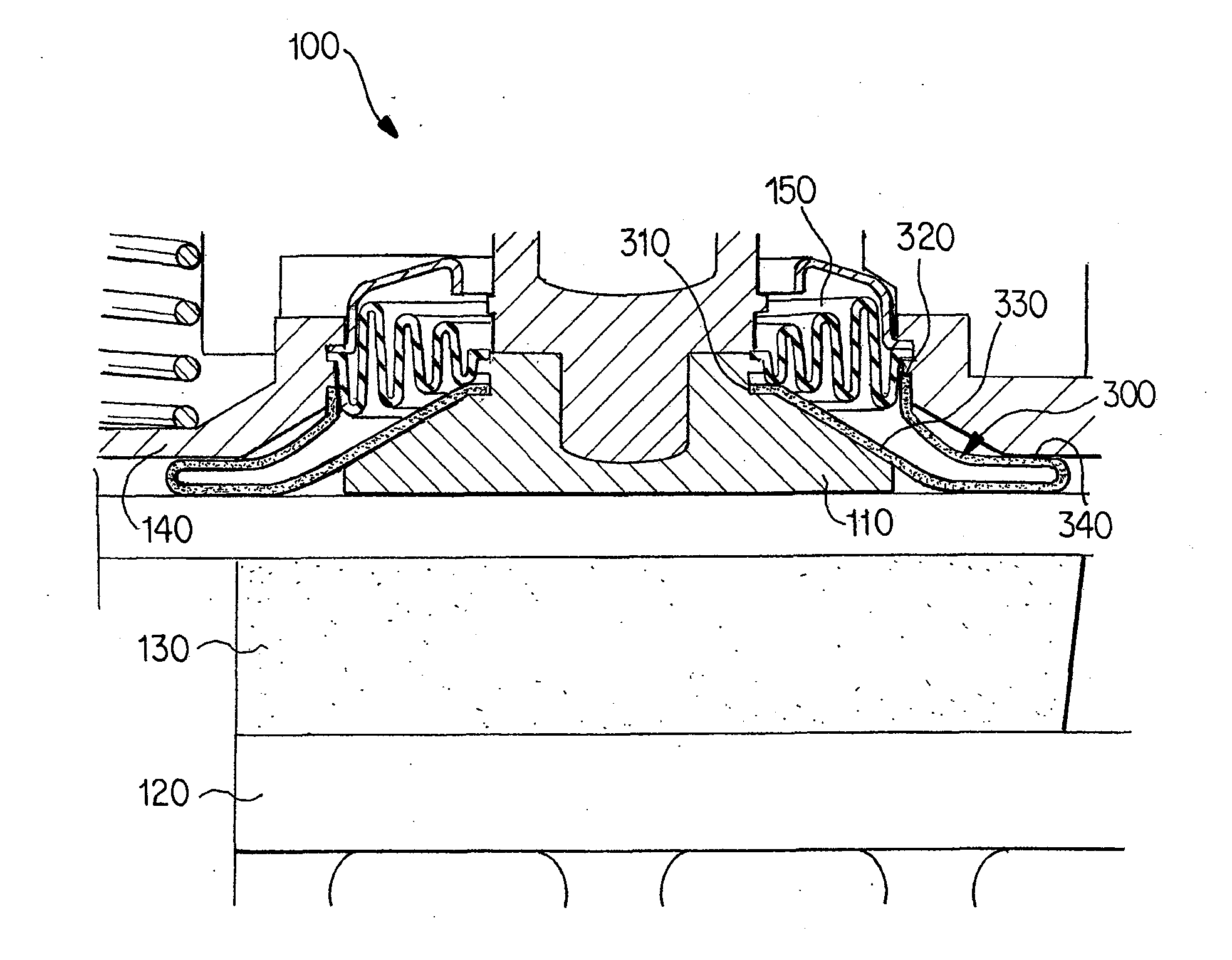

Seal apparatus for circuit breaker application

ActiveUS7952042B2High protection levelImprove the level ofNon-enclosed substationsEngine sealsEngineeringSwitchgear

A seal apparatus is disposed between a switchgear cabinet and a circuit breaker between the racked and unracked positions of the circuit breaker. The seal apparatus sealingly extends between the switchgear cabinet and the circuit breaker to resist fluid flow, such as exhaust gases and other matter, between an interior region of the switchgear cabinet and the exterior of the switchgear cabinet.

Owner:EATON INTELLIGENT POWER LTD

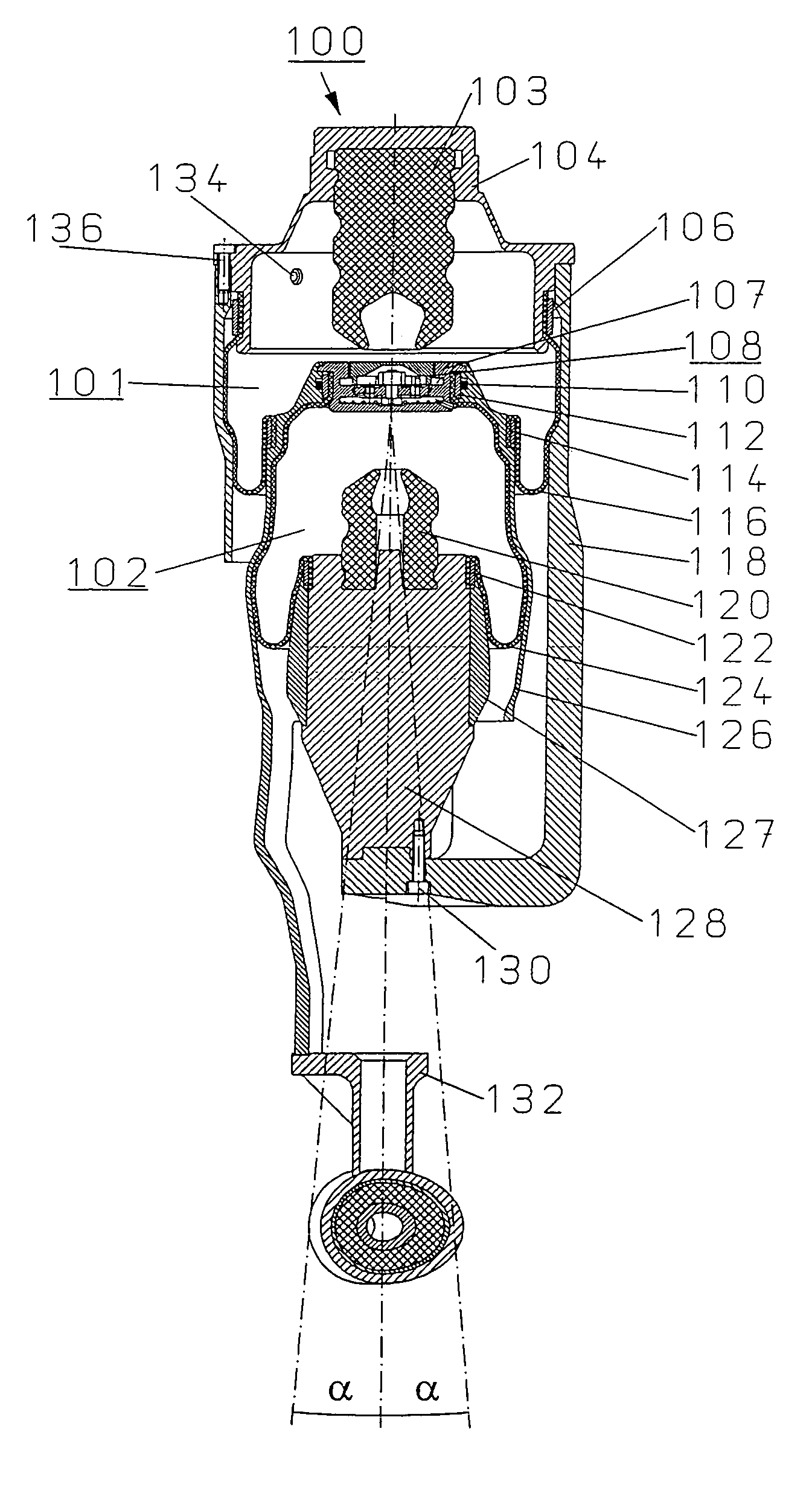

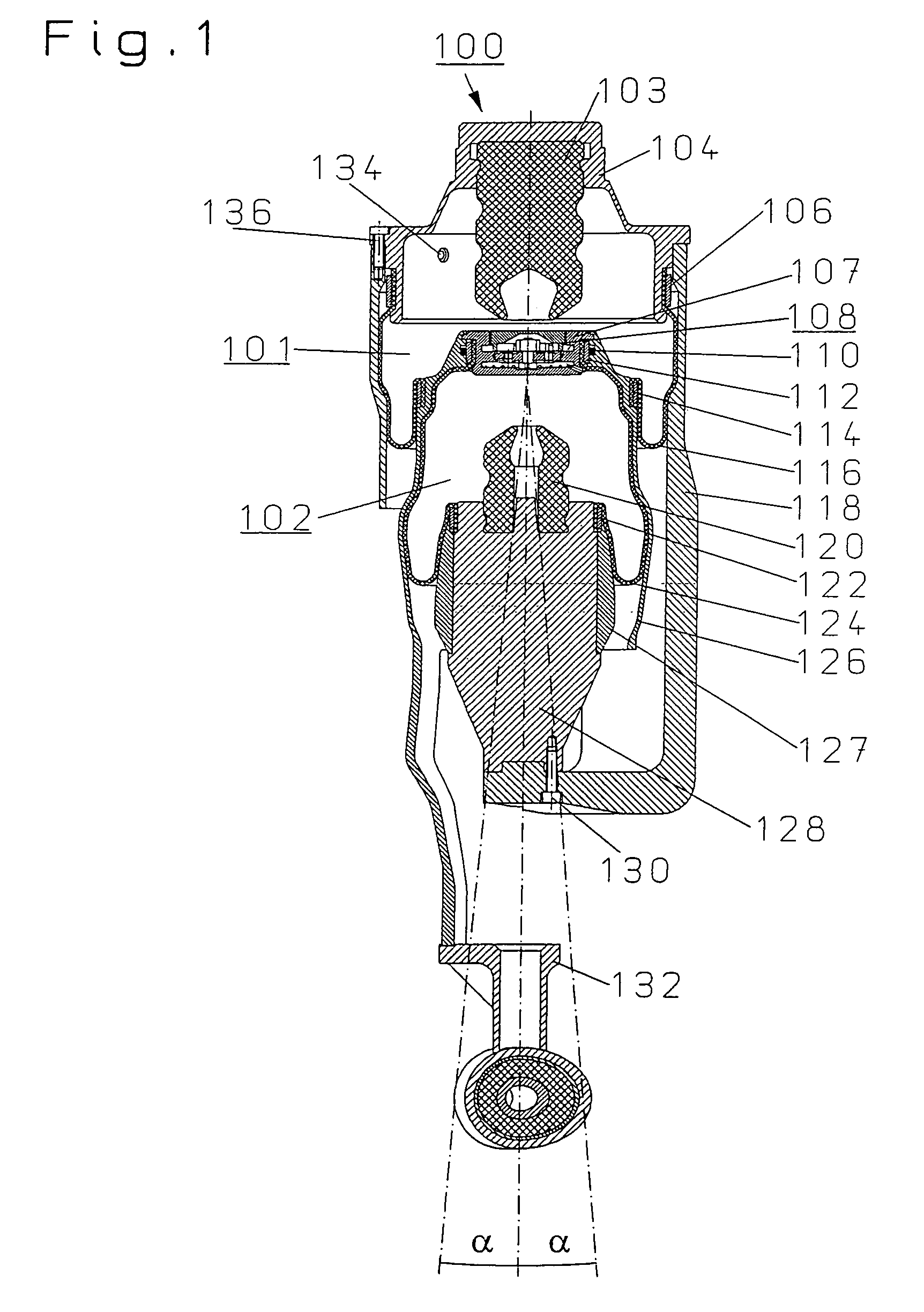

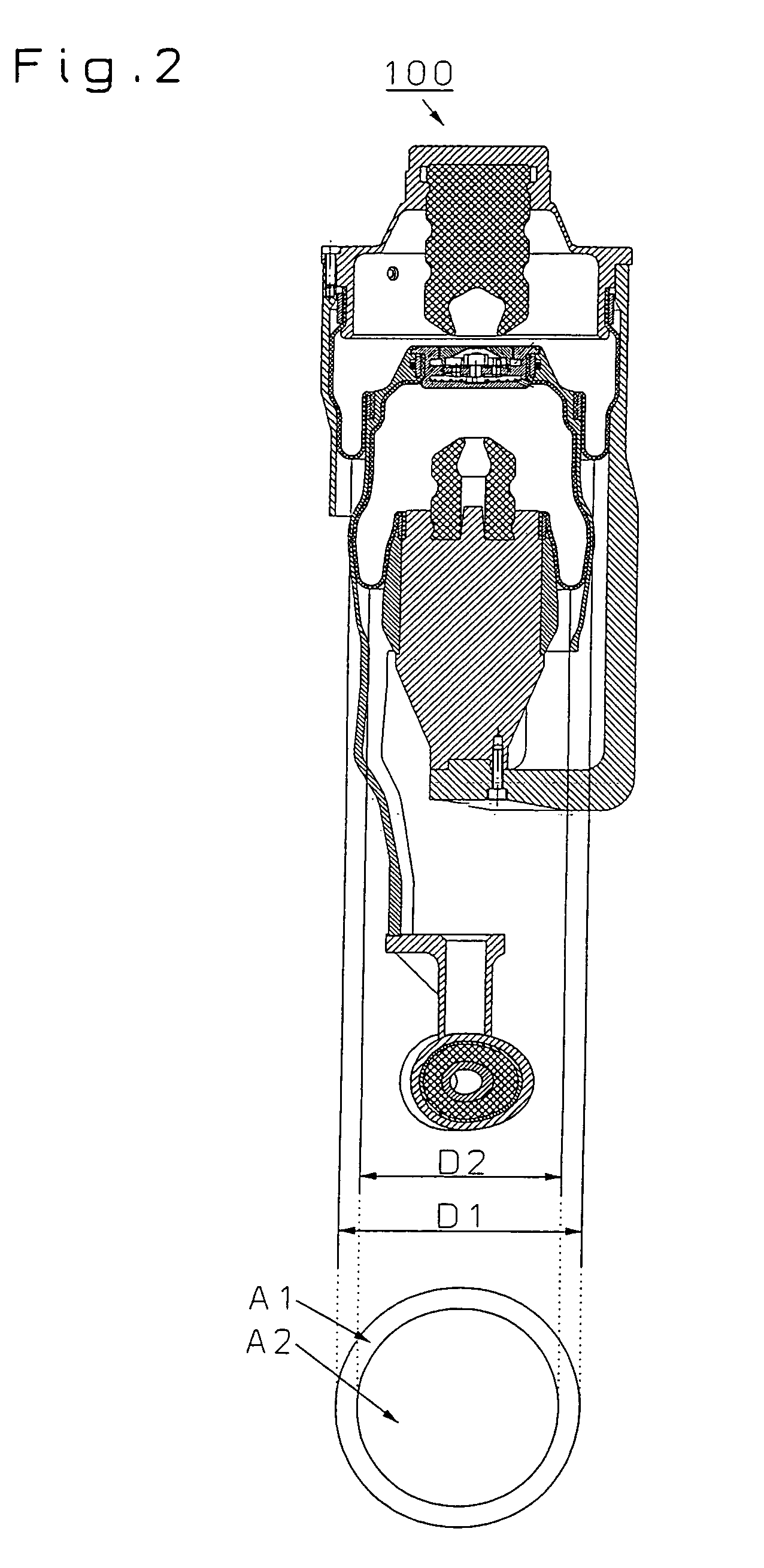

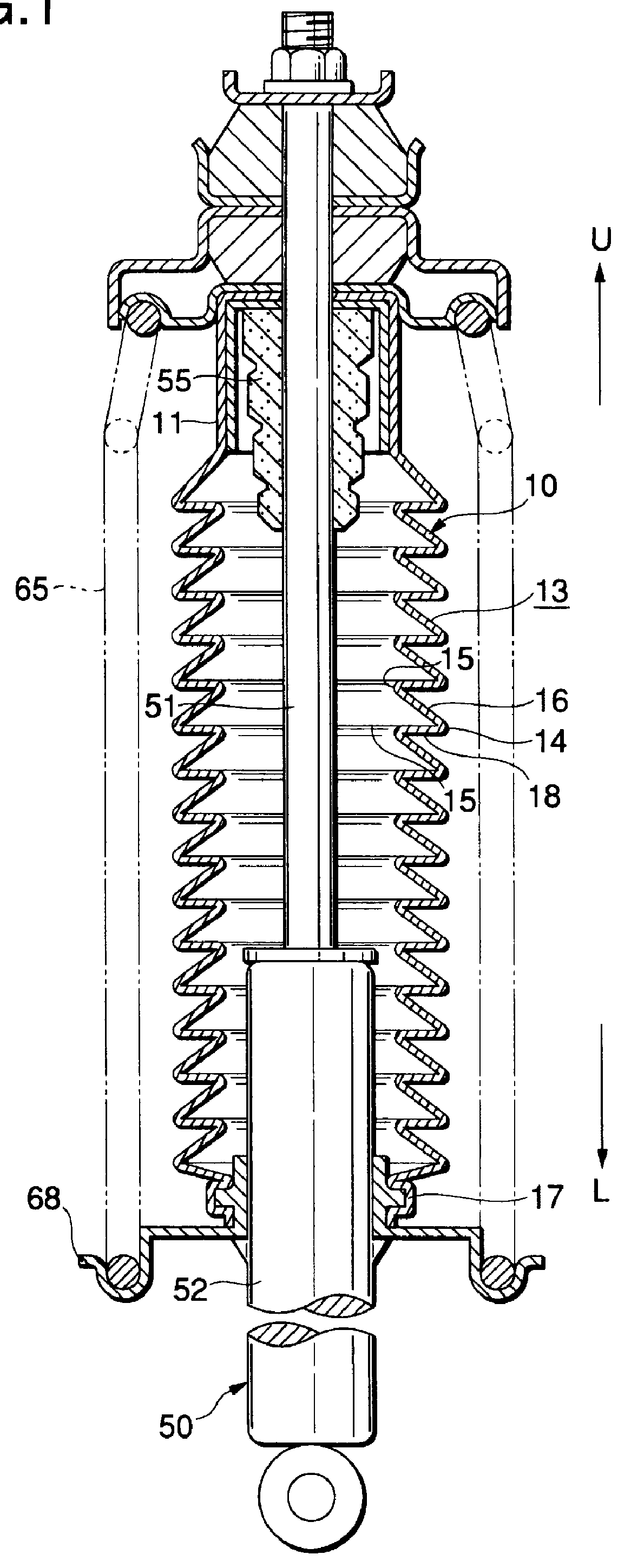

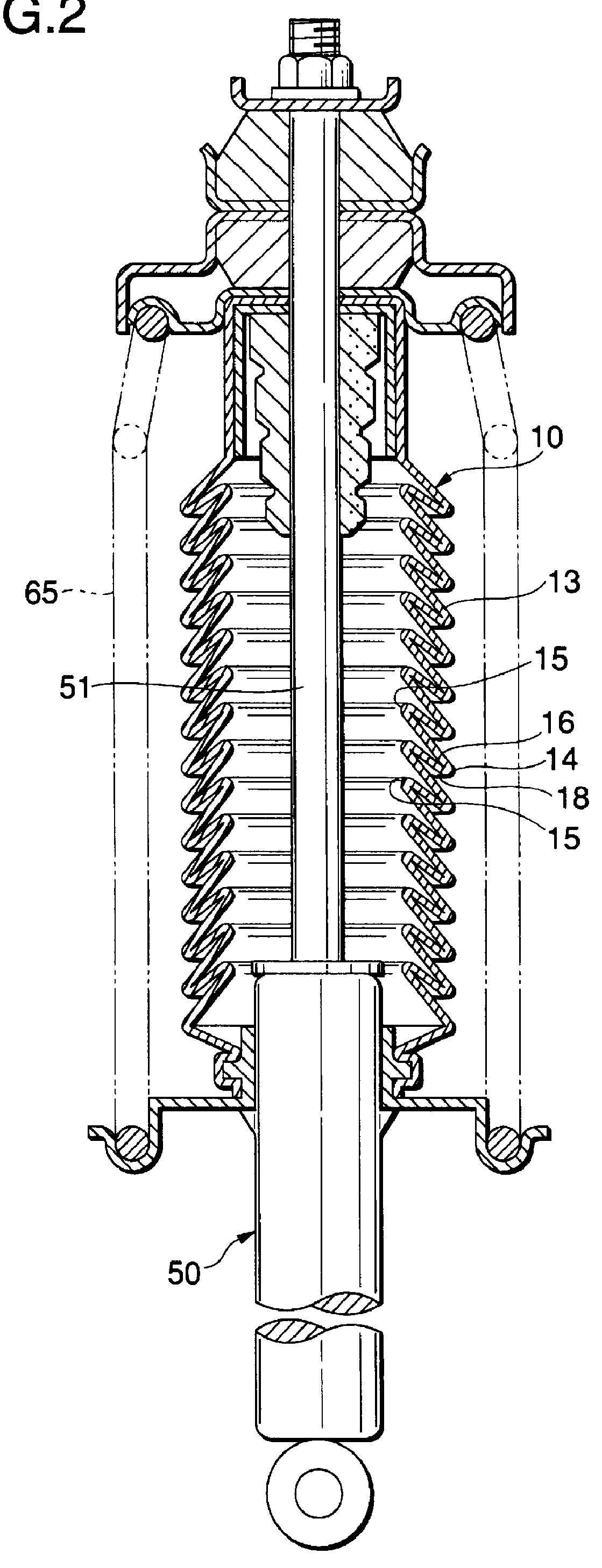

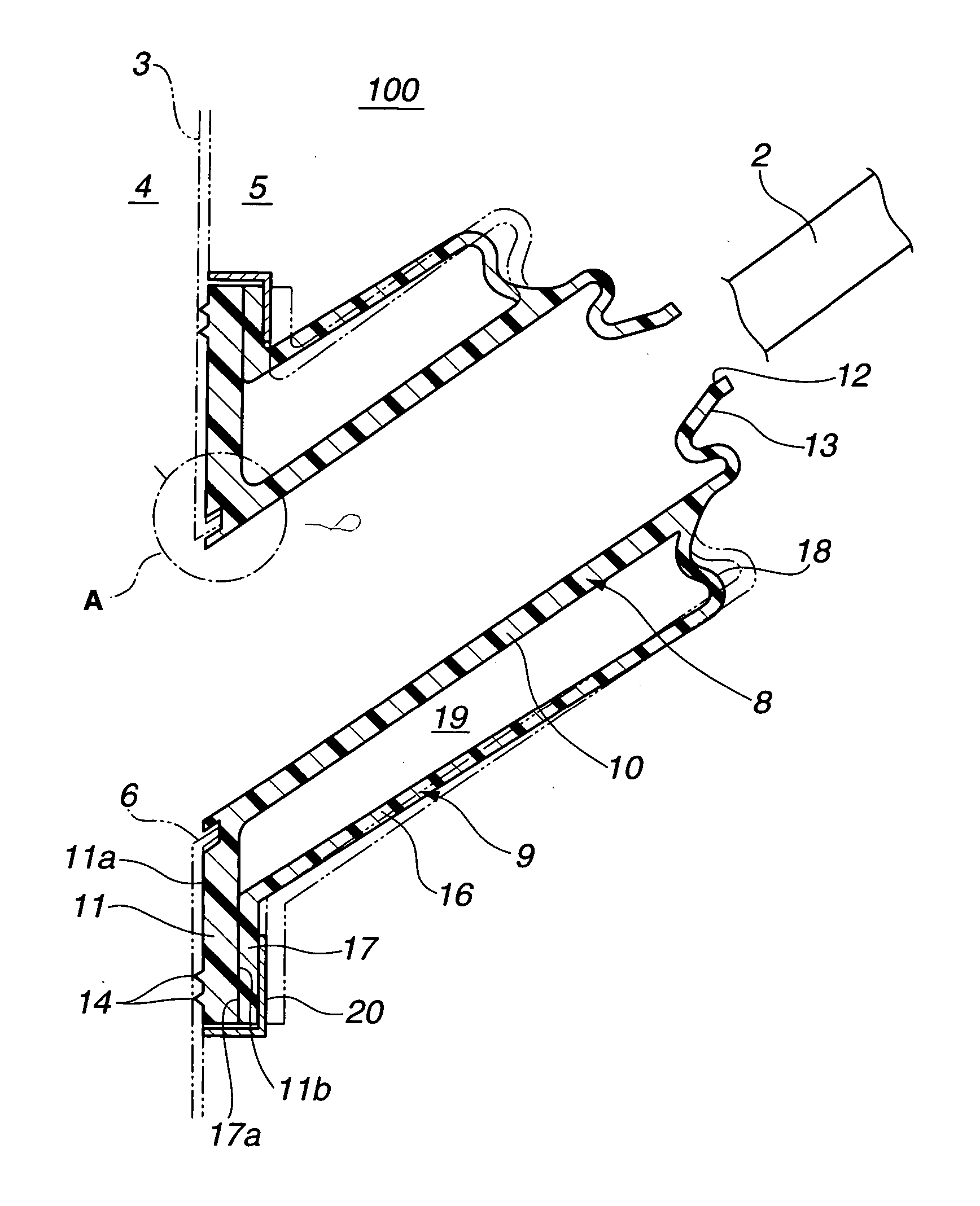

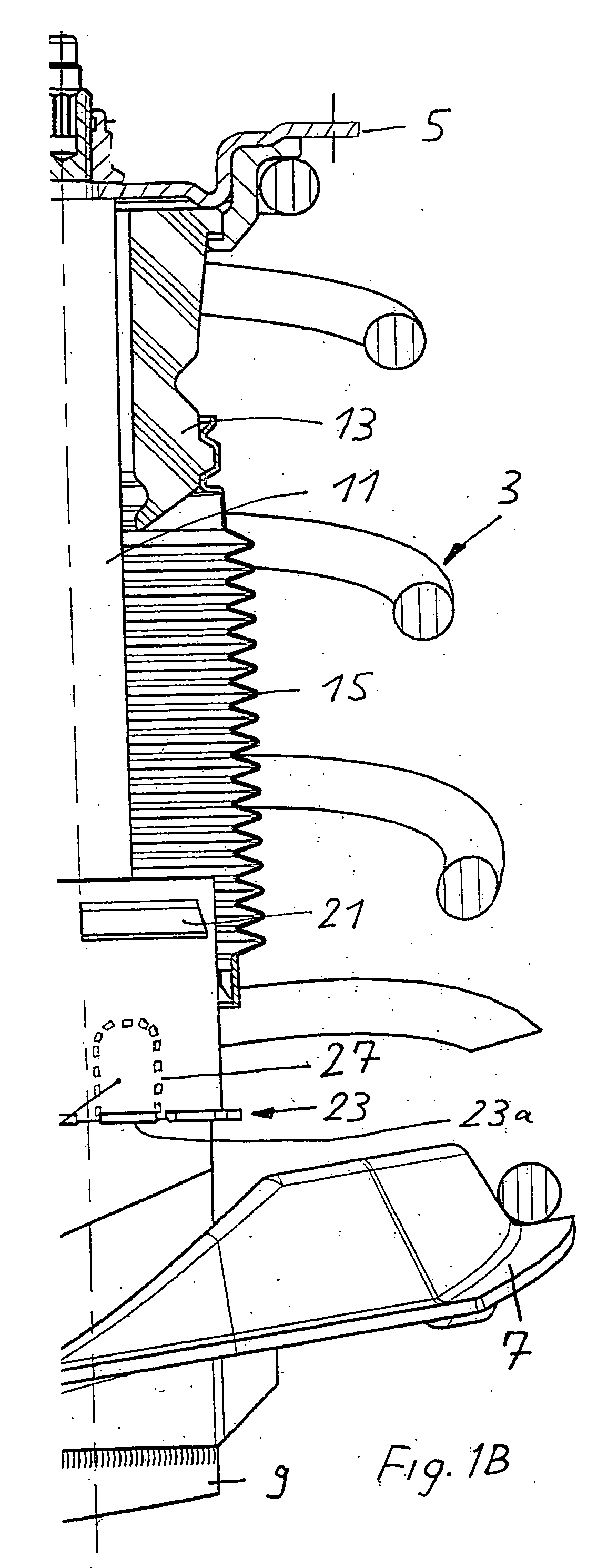

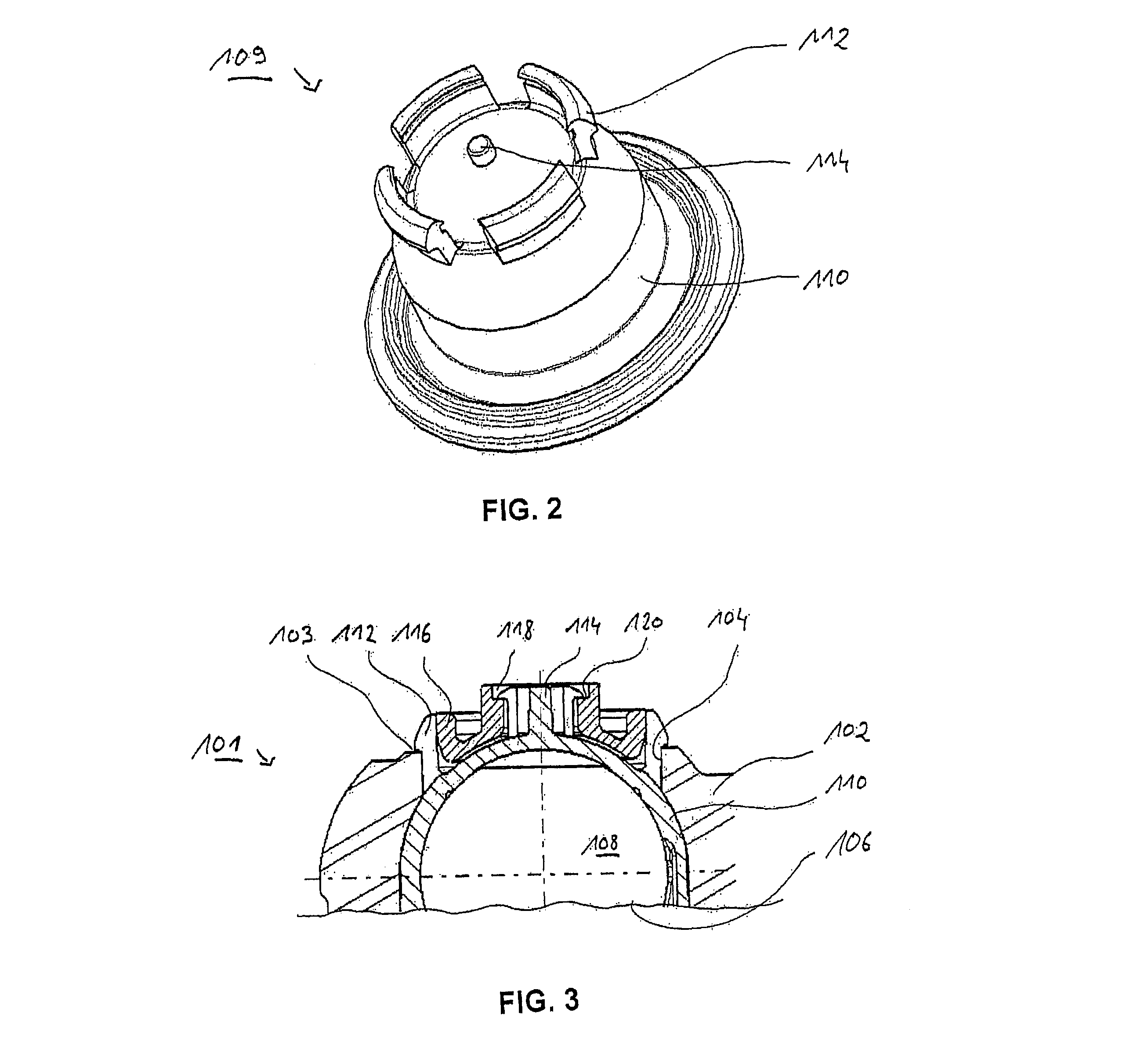

Pneumatic suspension and damping arrangement

InactiveUS7213799B2Built very short and compactNo frictionLiquid springsResilient suspensionsAir springEngineering

A pneumatic suspension and damping arrangement (100) is fixedly mounted on the chassis at the upper region and to the wheel mount at the lower region thereof. The arrangement includes two hermetically closed air springs (101, 102) filled with pressurized gas, whose volumes can be changed and which are connected via an air connection (134) to a pressurized gas source. The air springs are each enclosed by a movable wall formed by a flexible member (116, 124) and each roll off on a roll-off contour and are connected to each other via a throttle element (108) through which the gas can flow in two directions. The air springs are arranged one above the other and the roll-off contour of the first air spring (101) is defined in such a way by the second air spring (102) that the first air spring (101) rolls off on the second air spring (102). A connecting element of the upper cover (104) ) with the roll-off piston (128) of the second air spring (102) runs outside of the two air springs (101, 102).

Owner:CONTINENTAL AG

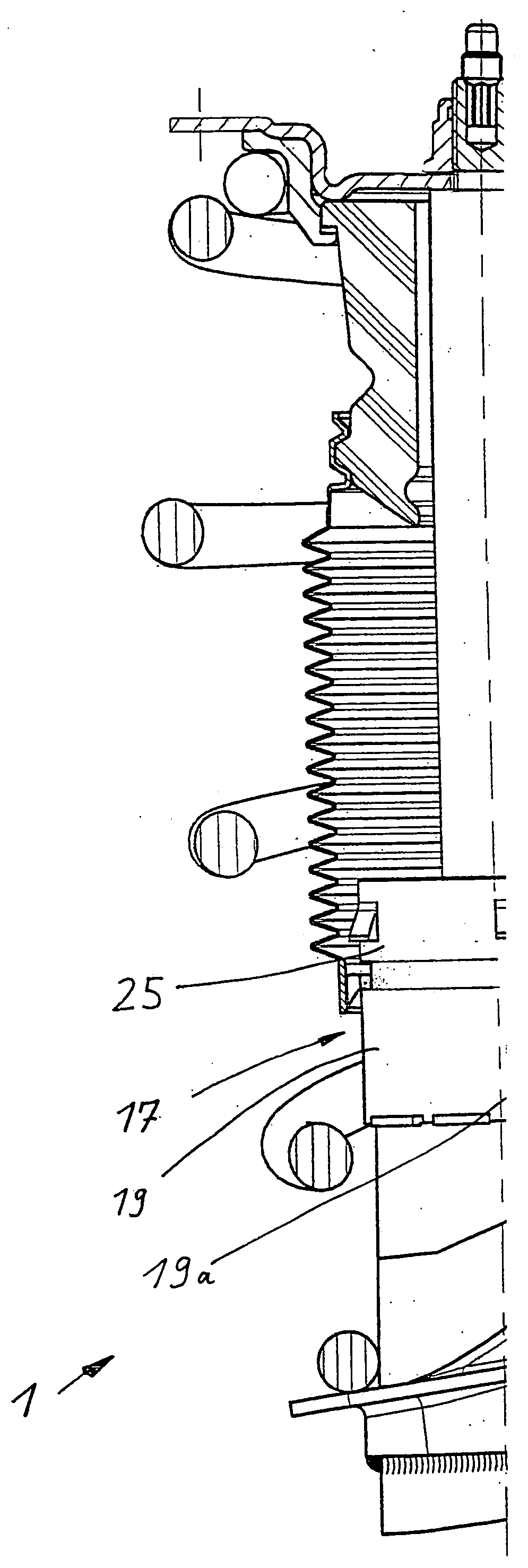

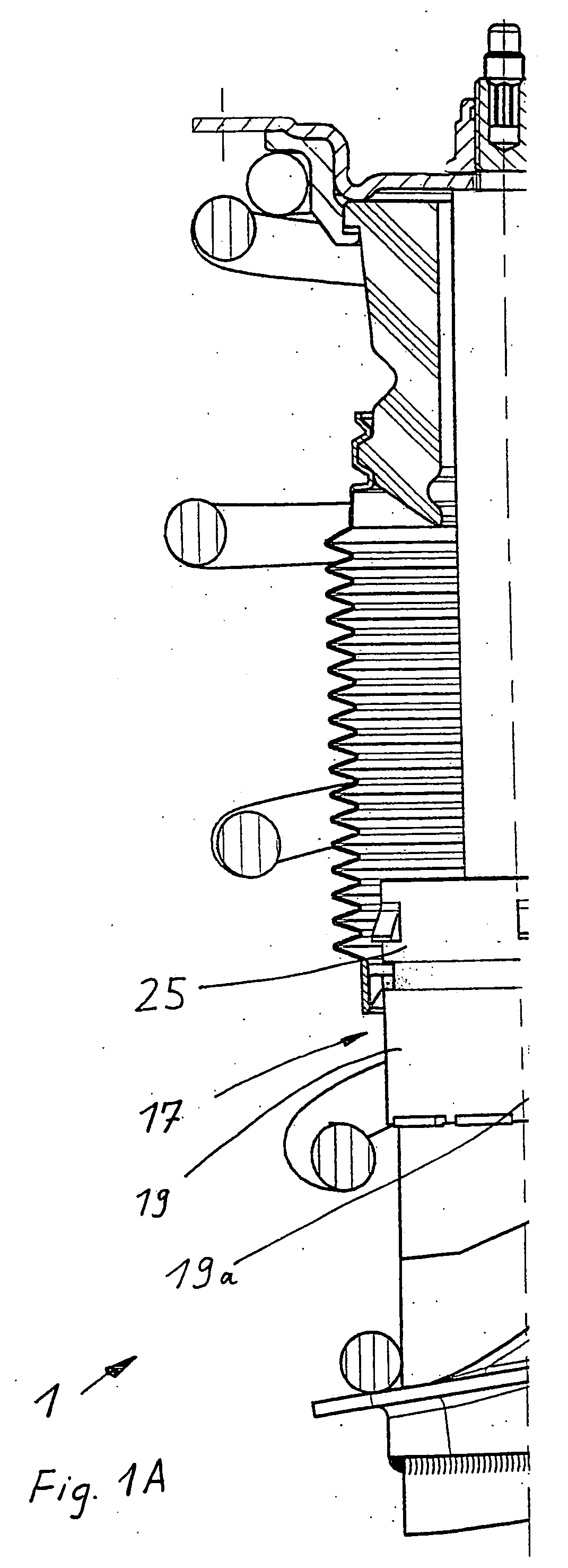

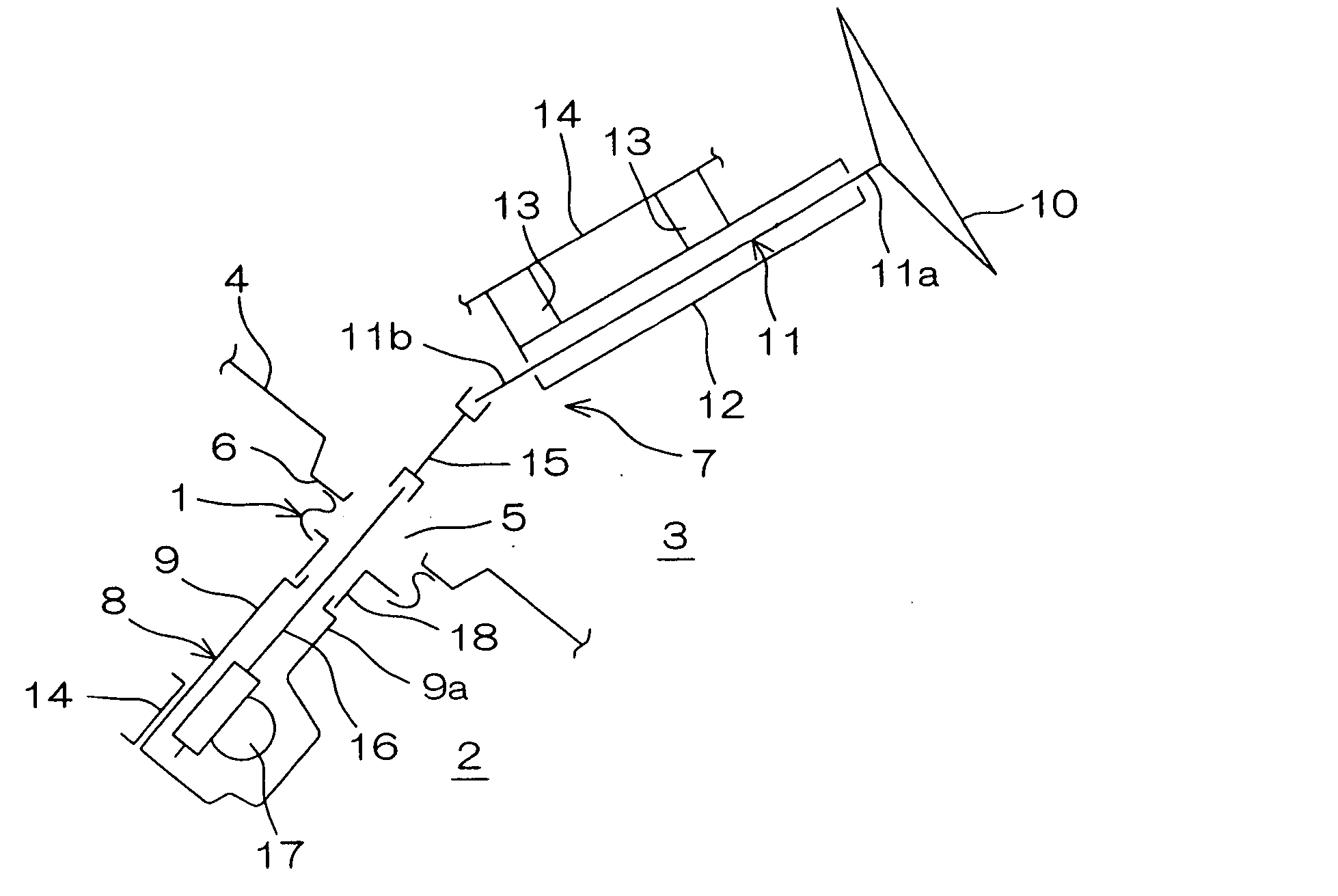

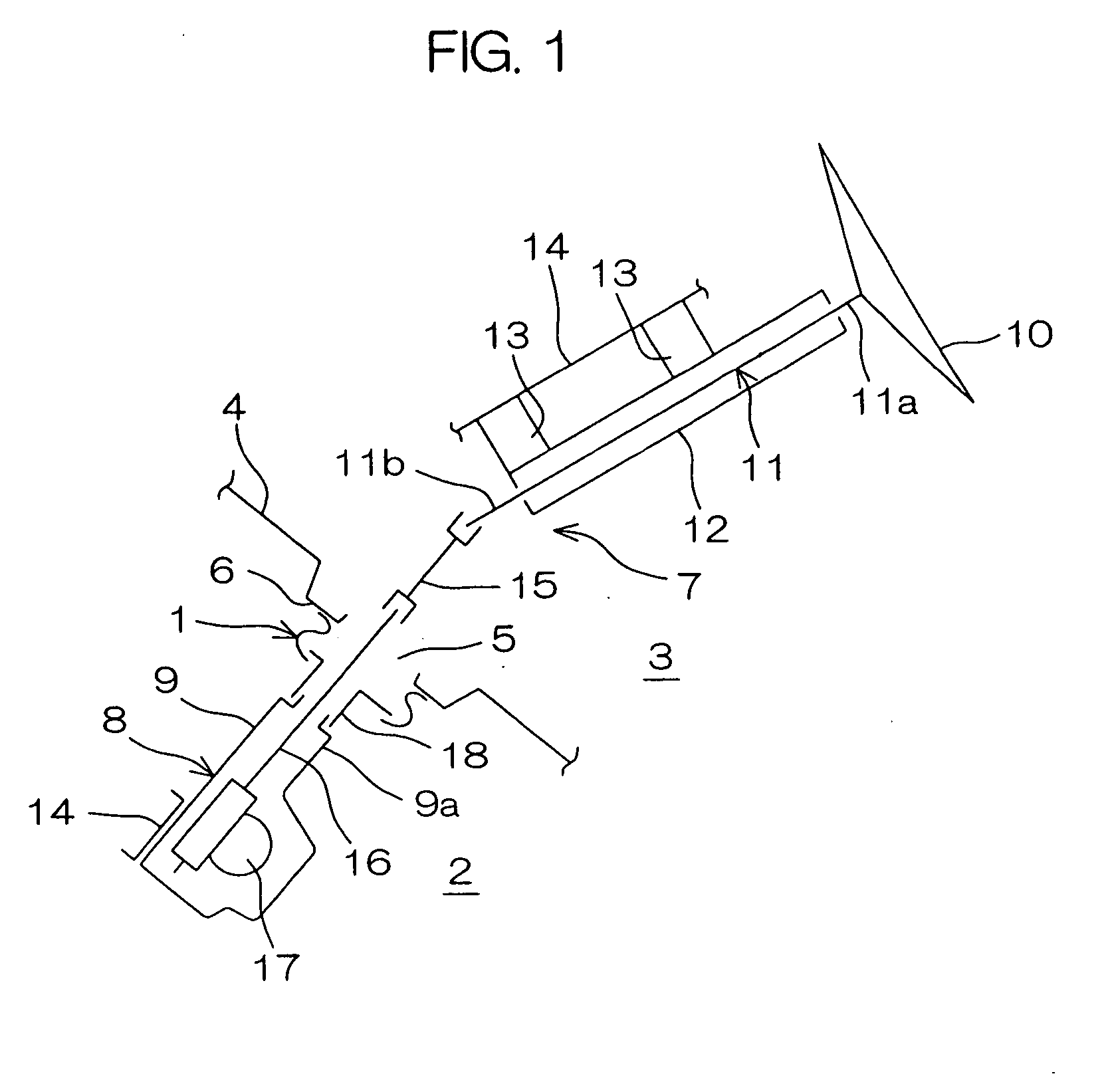

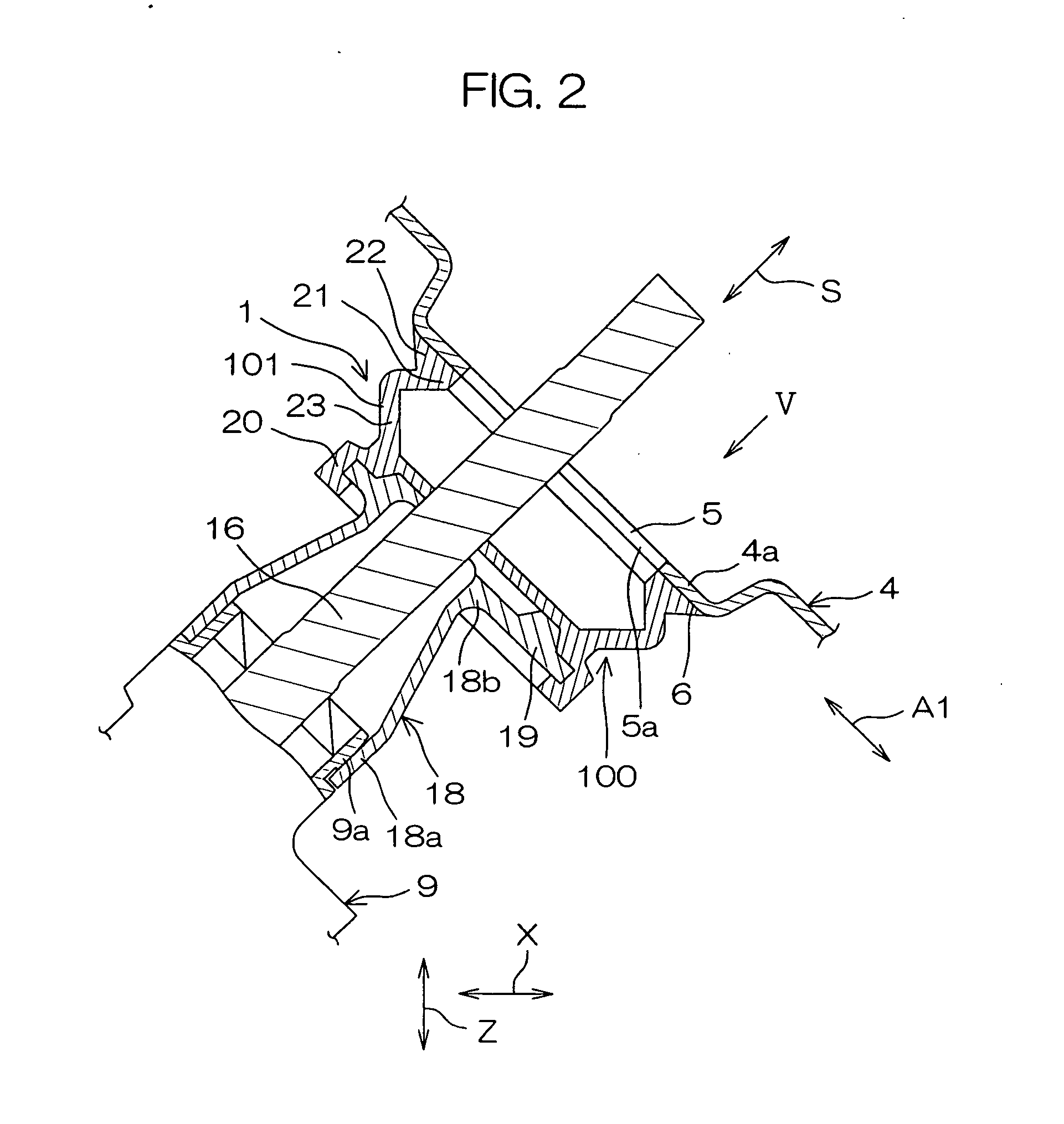

Dust Cover for a Steering Shaft

ActiveUS20080231003A1Easy to slideFlexible follow-up propertyEngine sealsYielding couplingSteering wheelControl theory

[Problem] A dust cover for a steering prevents offensive sounds from emitting during an operation of a steering wheel.[Means for Solving] A dust cover for a steering shaft according to the present invention includes: a bush 2 of low-frictional material, through which a steering shaft 20 penetrates; a plurality of bellows 3 made of rubber, provided in an axial direction of the steering shaft 20, and arranged between the bush 2 and a panel 19, for sealing the clearance; and an annular seal lip 4 in contact with the outer periphery of the steering shaft 20.

Owner:NSK LTD +2

Vibration damping coupling

InactiveUS20040226622A1Simple structureImprove shock absorptionNon-rotating vibration suppressionAdjustable jointsElastomerCoupling

A vibration damping bellows with a high vibration absorbing effect and whose a simple structure. In a vibration damping coupling, for example, the vibration damping bellows is formed by interposing viscoelastic material, material with low elasticity, or combination thereof between an inner member and an outer member, which are made of stainless steel. The stainless steel inner member and / or outer member may be omitted when occasion demands. The material of the stainless steel plate, for example, may be SUS 304 that is austenitic stainless steel. Further, flanges to perform connection with pipes may be provided in both ends of the bellows. The viscoelastic material may comprise elastomer such as silicone rubber and vibration damping alloy.

Owner:SANKAI GIKEN

Dust cover for steering shaft

InactiveUS20050250586A1Reduce frictionReduce the steering torque of the steering shaft and soundEngine sealsYielding couplingEngineeringSliding contact

A dust cover for a steering shaft attached to an vehicle body in such a way as to be in contact with the steering shaft to provide protection against dust and muddy water is provided with a cylindrical contact member that is to be in sliding contact with the steering shaft while the steering shaft is rotating and a cylindrical reinforcement member for reinforcing the cylindrical contact member provided radially outside the cylindrical contact member. A low friction material is attached, by coating or baking, to such a portion of the cylindrical contact member that is in contact with the steering shaft, or alternatively, the cylindrical contact member itself is made of a low friction member.

Owner:NSK LTD

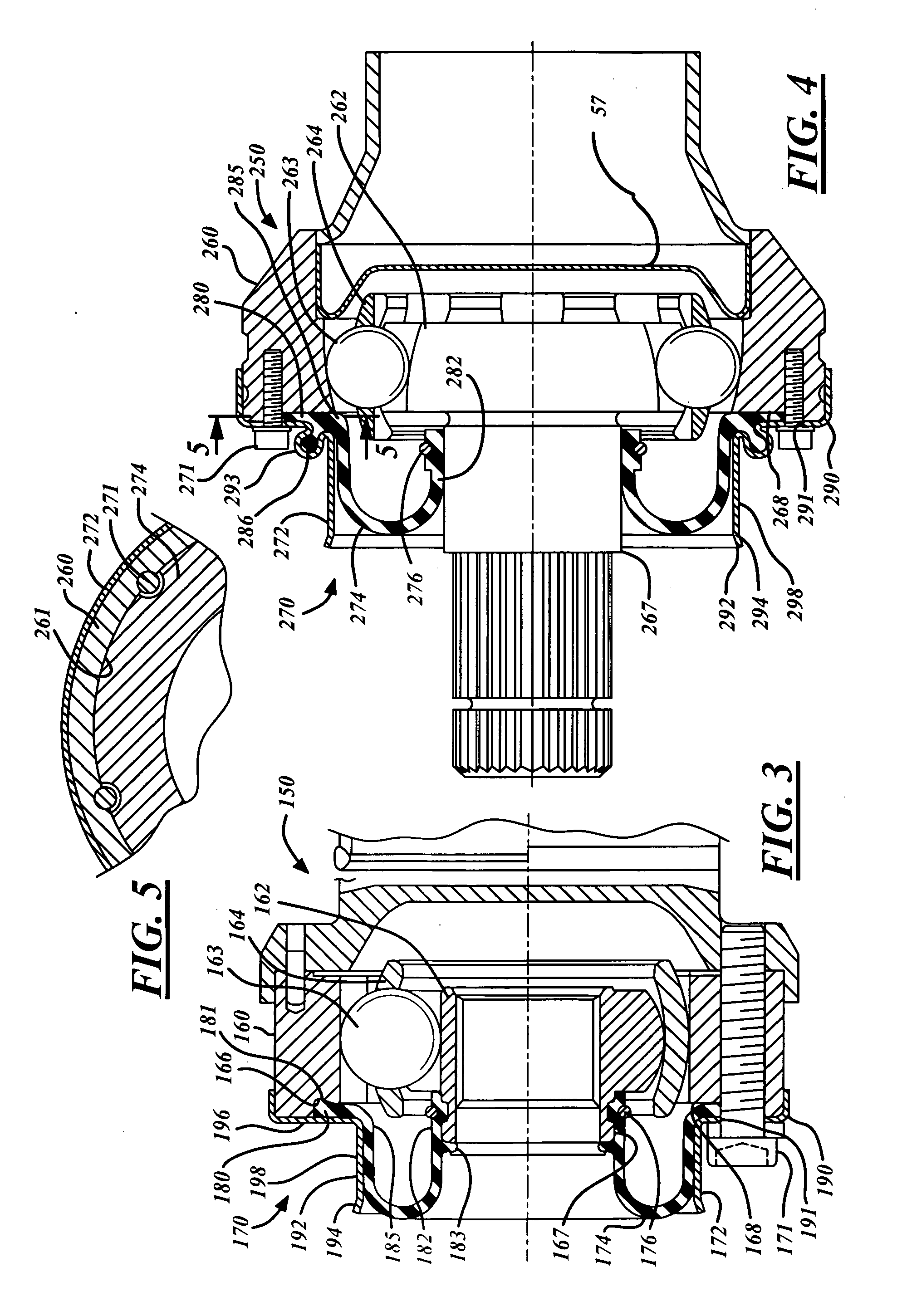

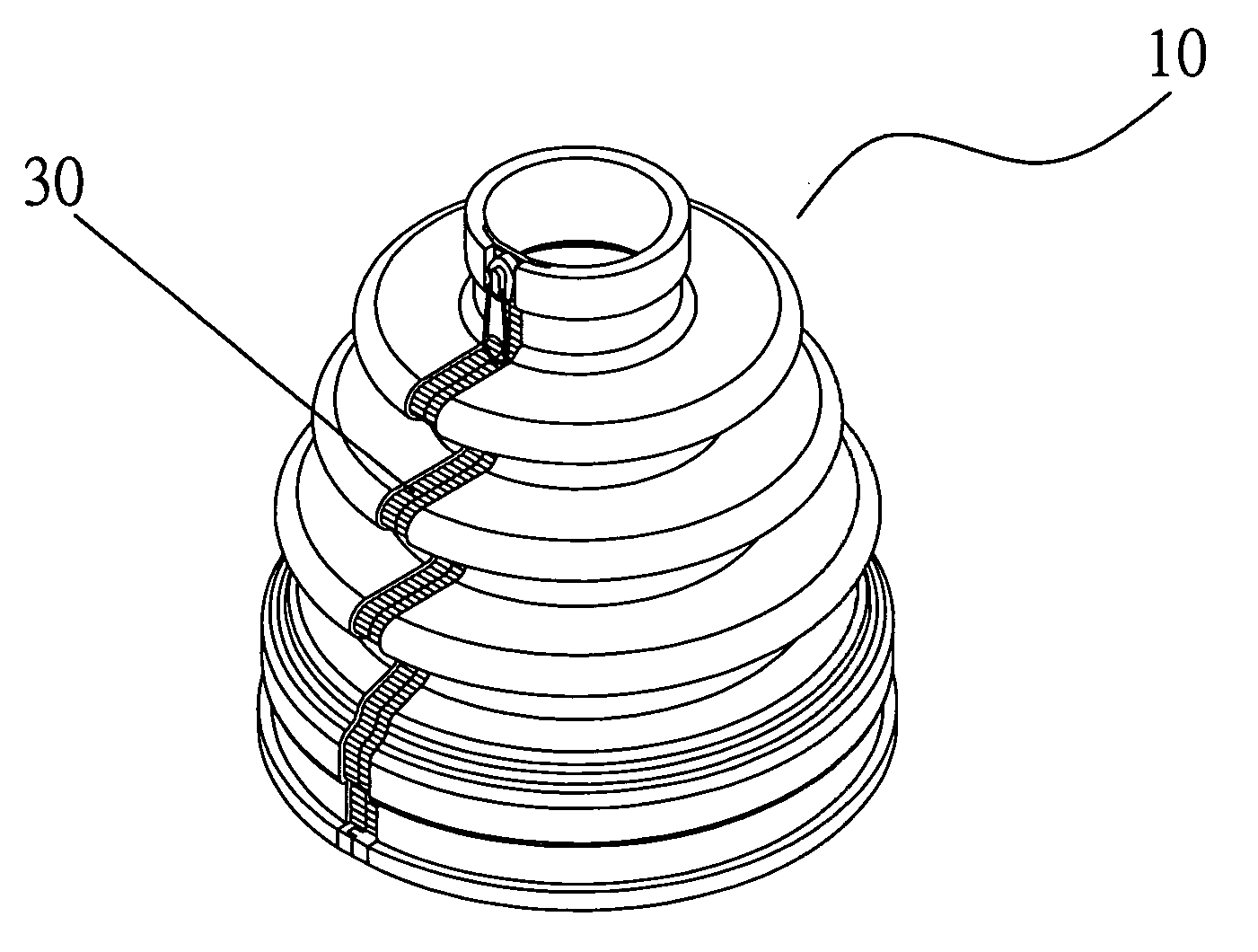

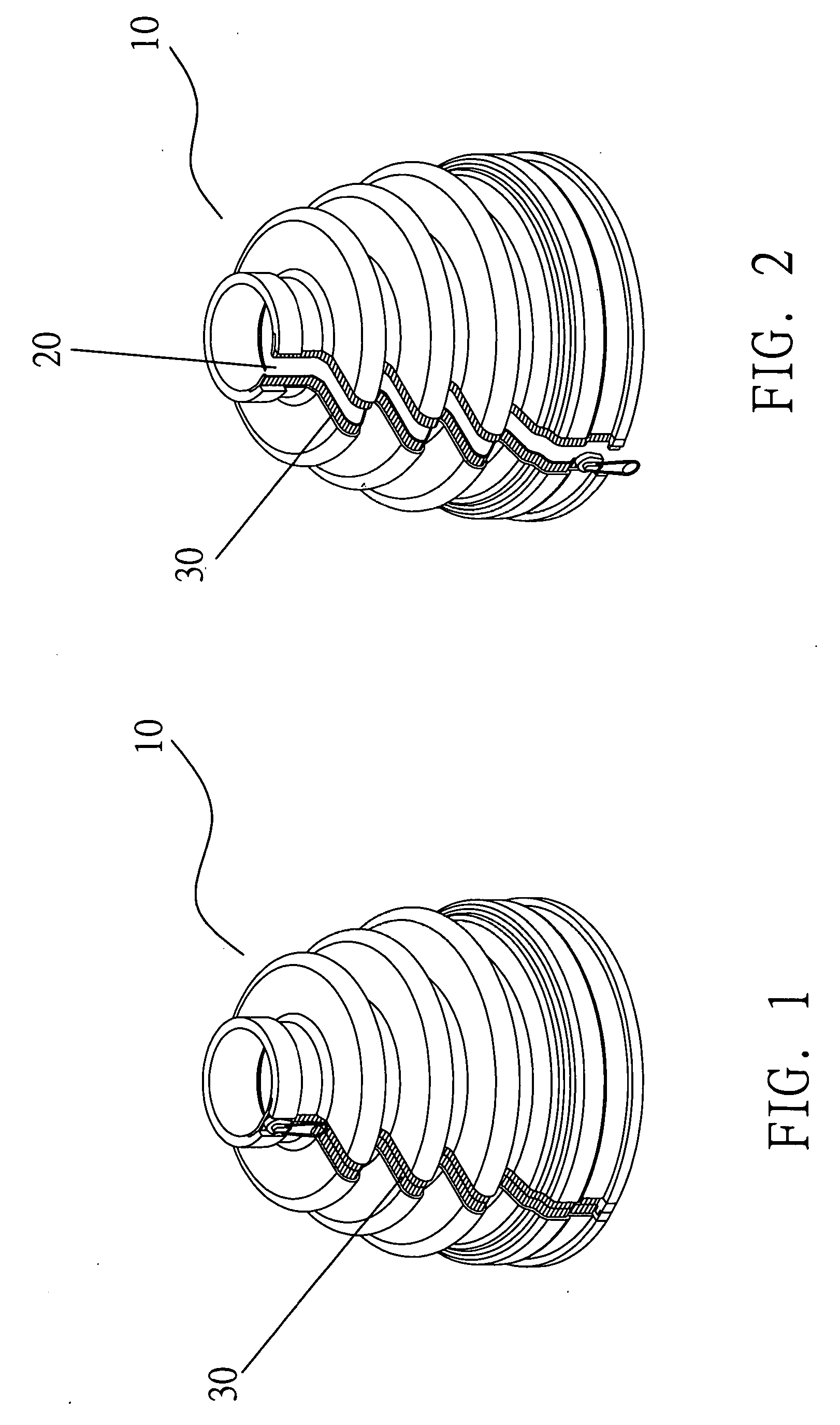

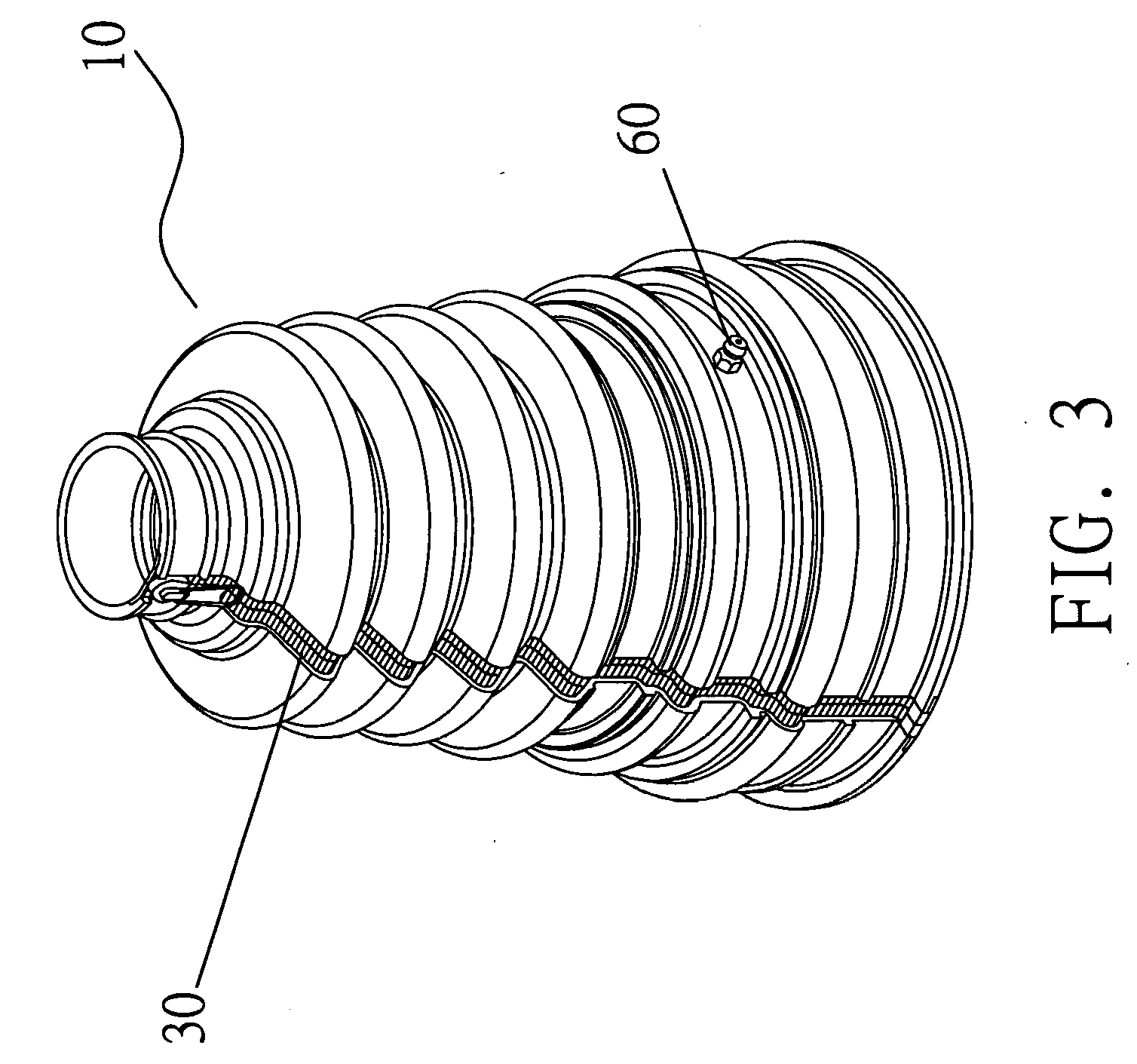

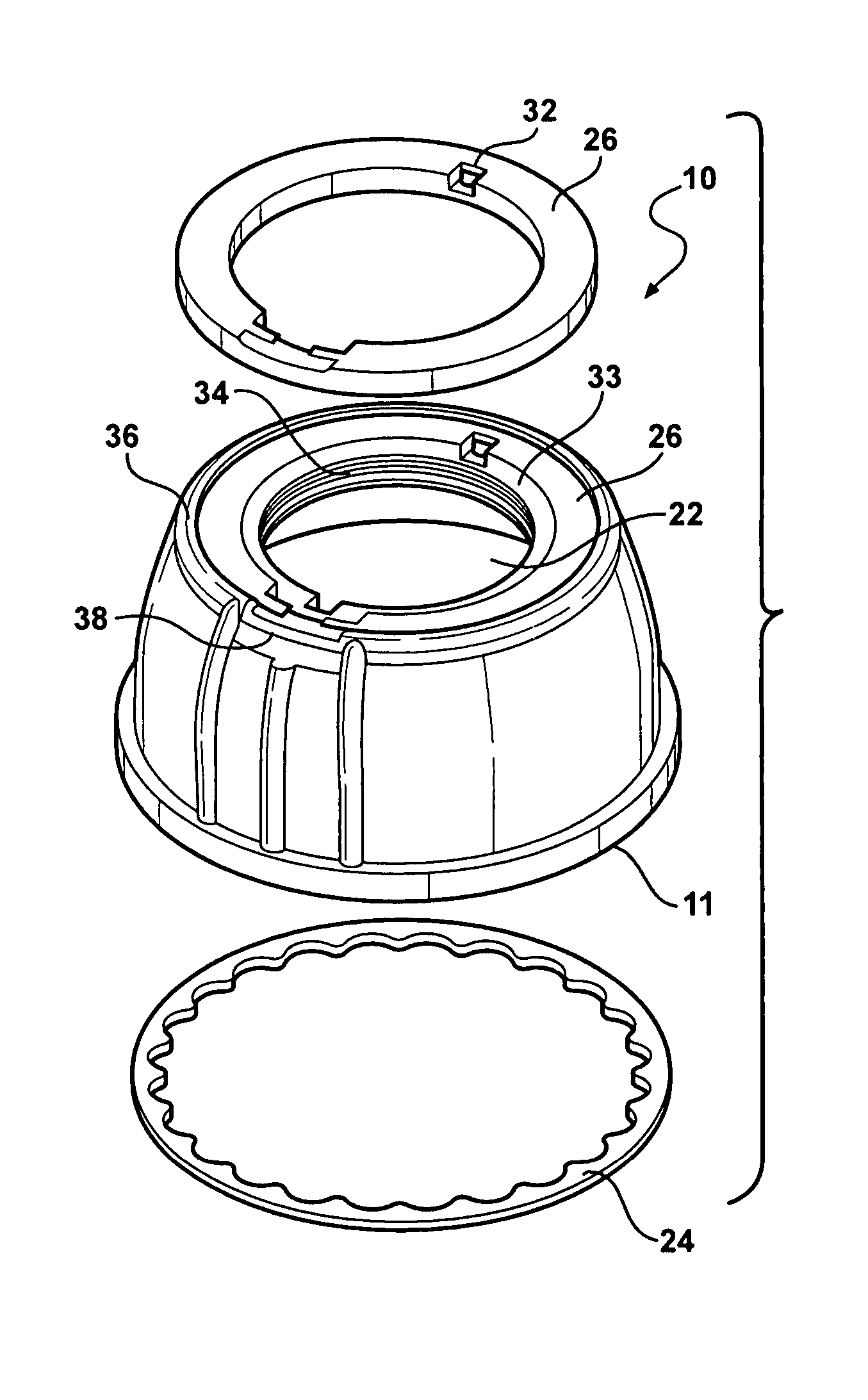

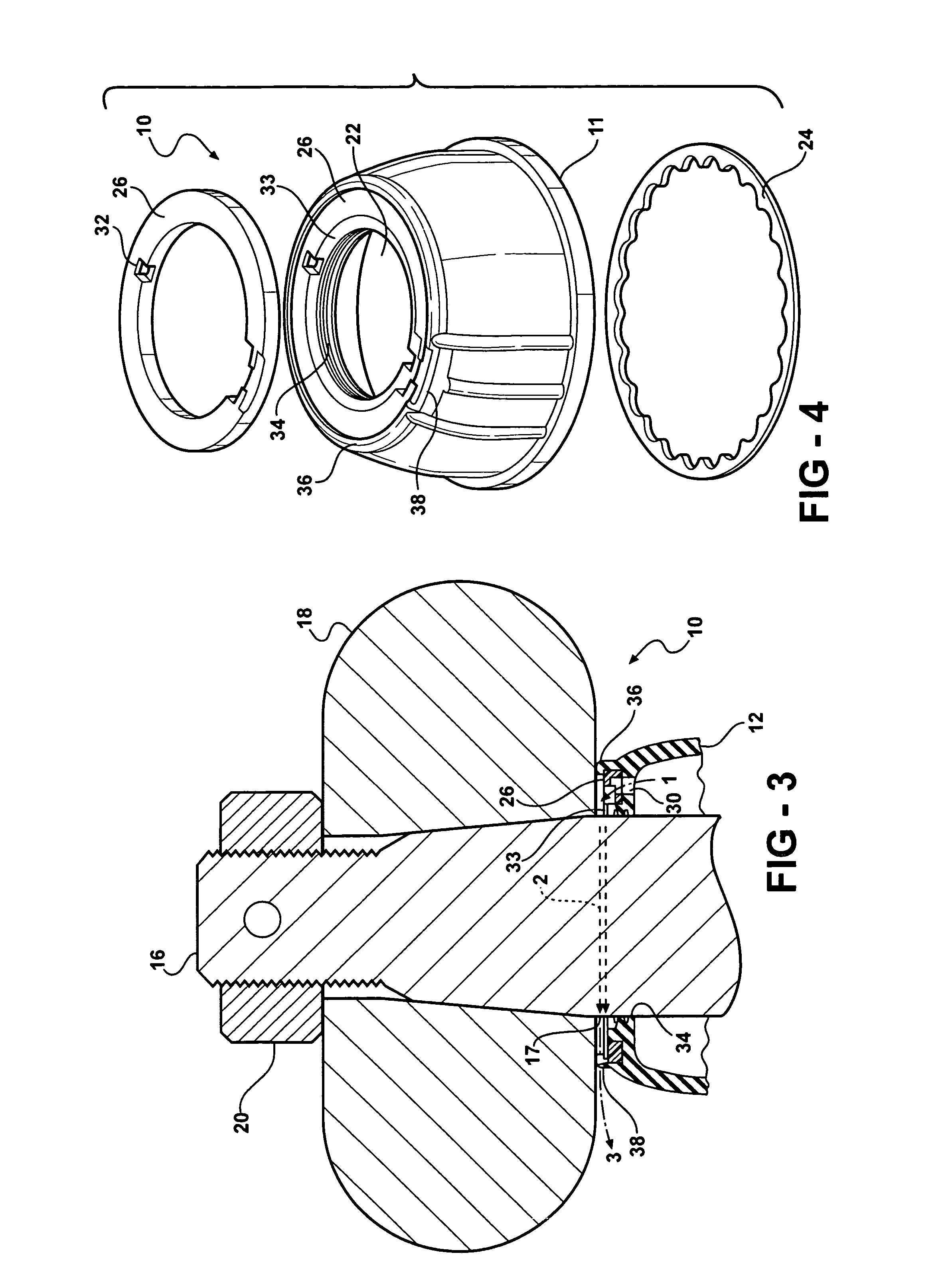

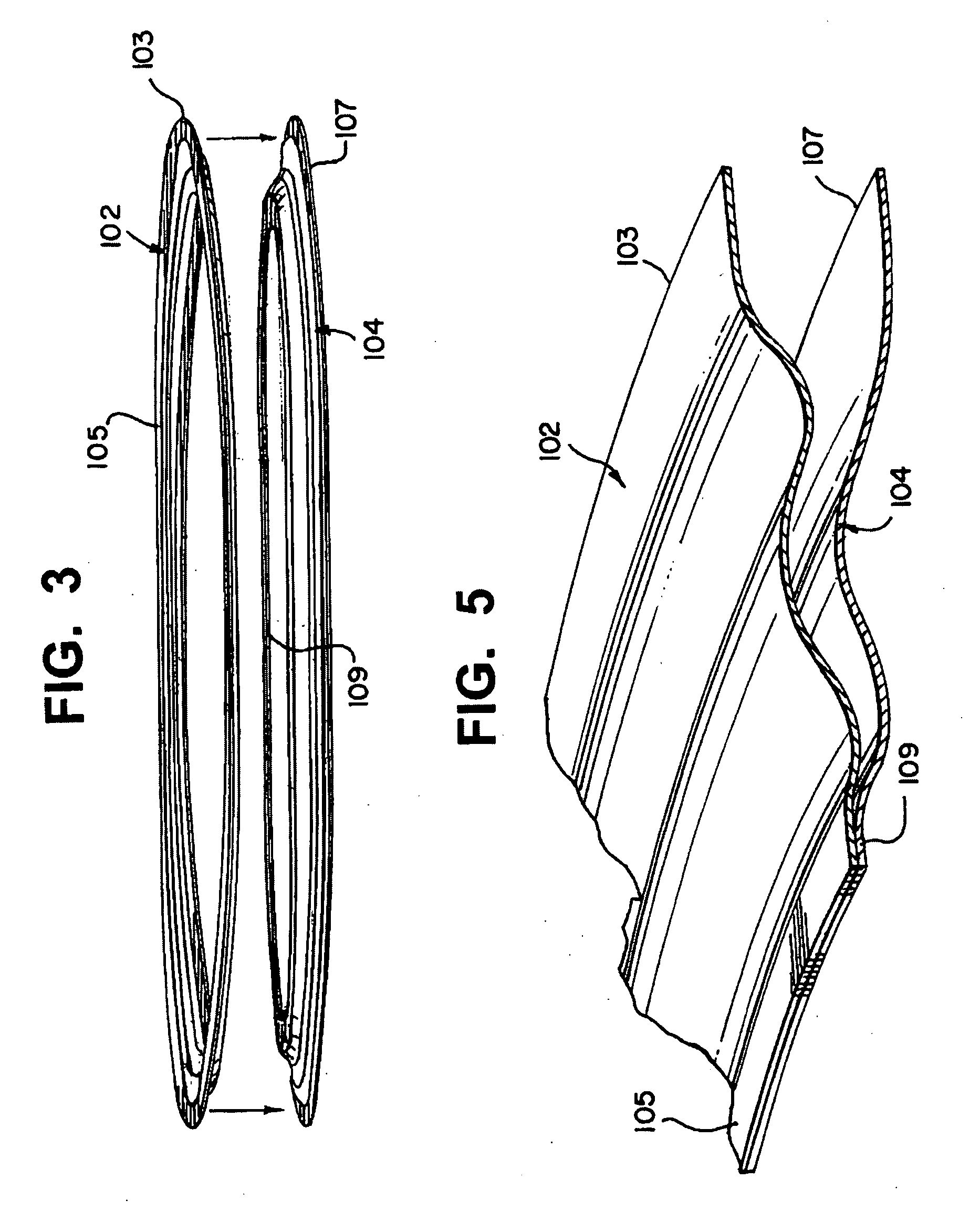

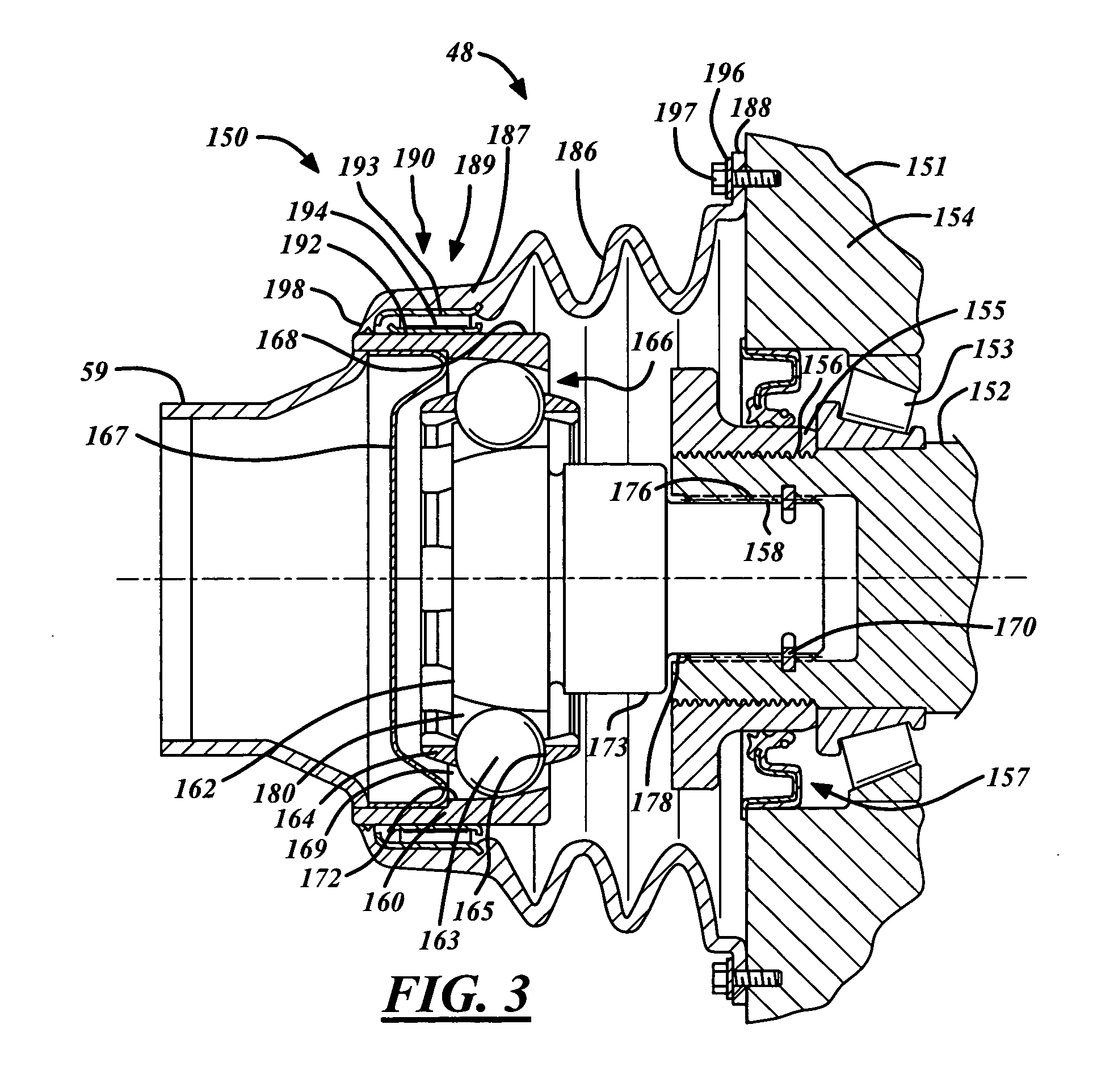

Rolling boot assembly

InactiveUS20070173337A1Minimizing sensitivityMinimizing bulging, kinking or binding of the bootYielding couplingShaftsEngineeringConstant-velocity joint

A rolling boot assembly includes a shroud having a first portion and a second portion, and a radial boot having a first section and a second section. The second portion of the shroud has a free end. The first section of the radial boot is connected to the first portion of the shroud advantageously allowing the radial boot to roll axially toward the second portion of the shroud when the second section of the radial boot is selectively attached to a shaft or an inner joint part and the first portion of the shroud is selectively connected to an outer joint part. The second portion of the shroud remains unconnected. Also provided is a constant velocity joint assembly.

Owner:GKN DRIVELINE NORTH AMERICA

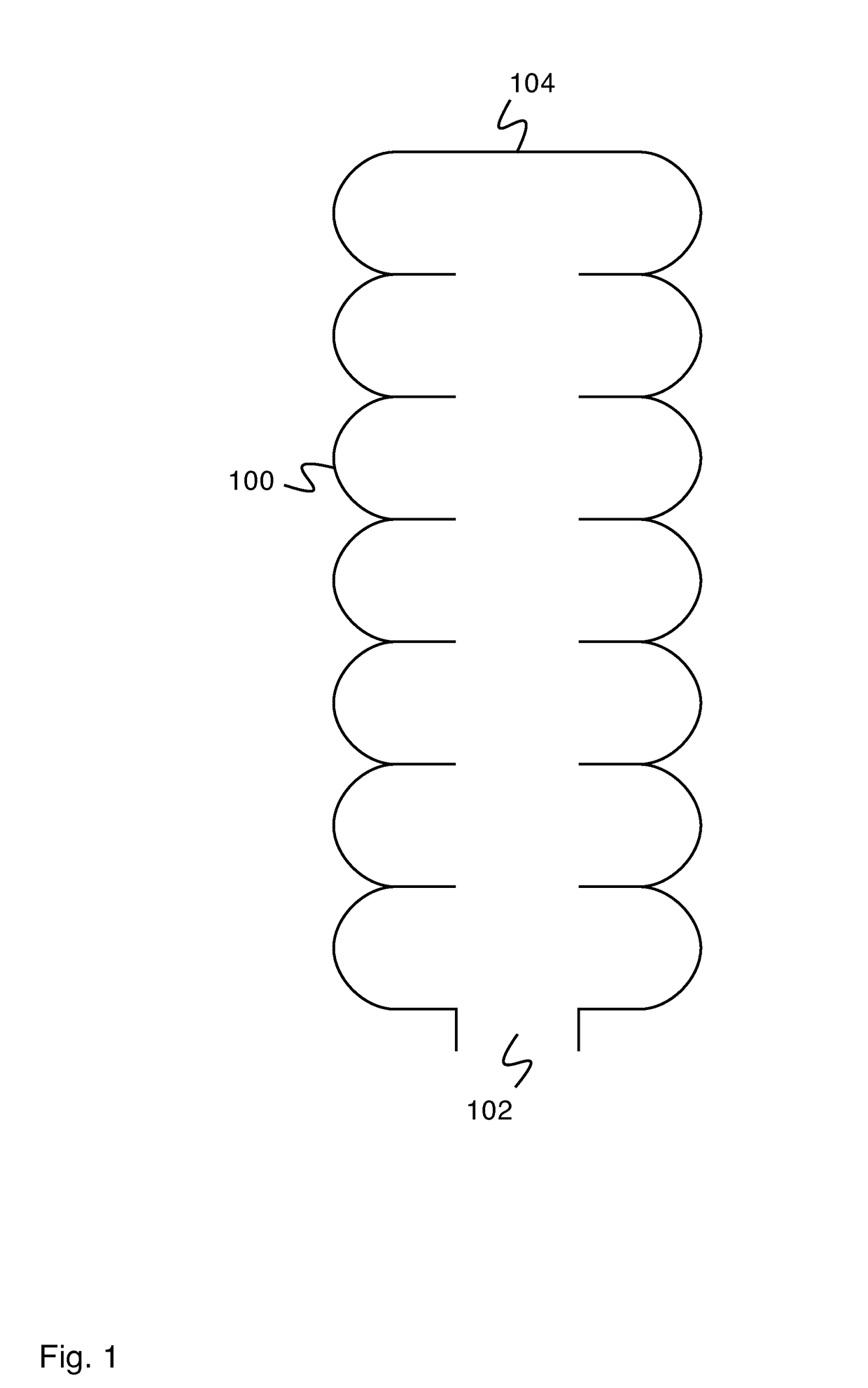

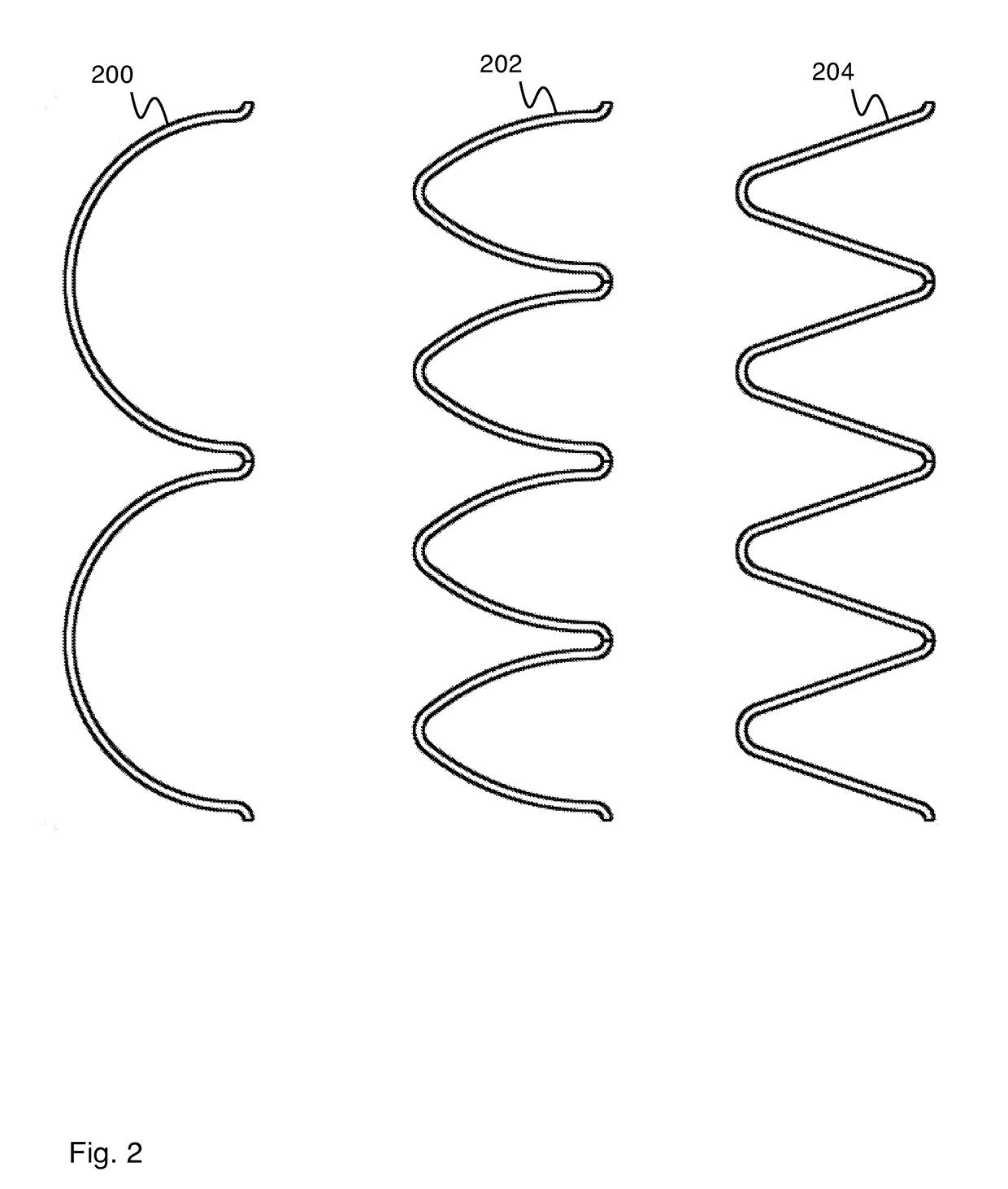

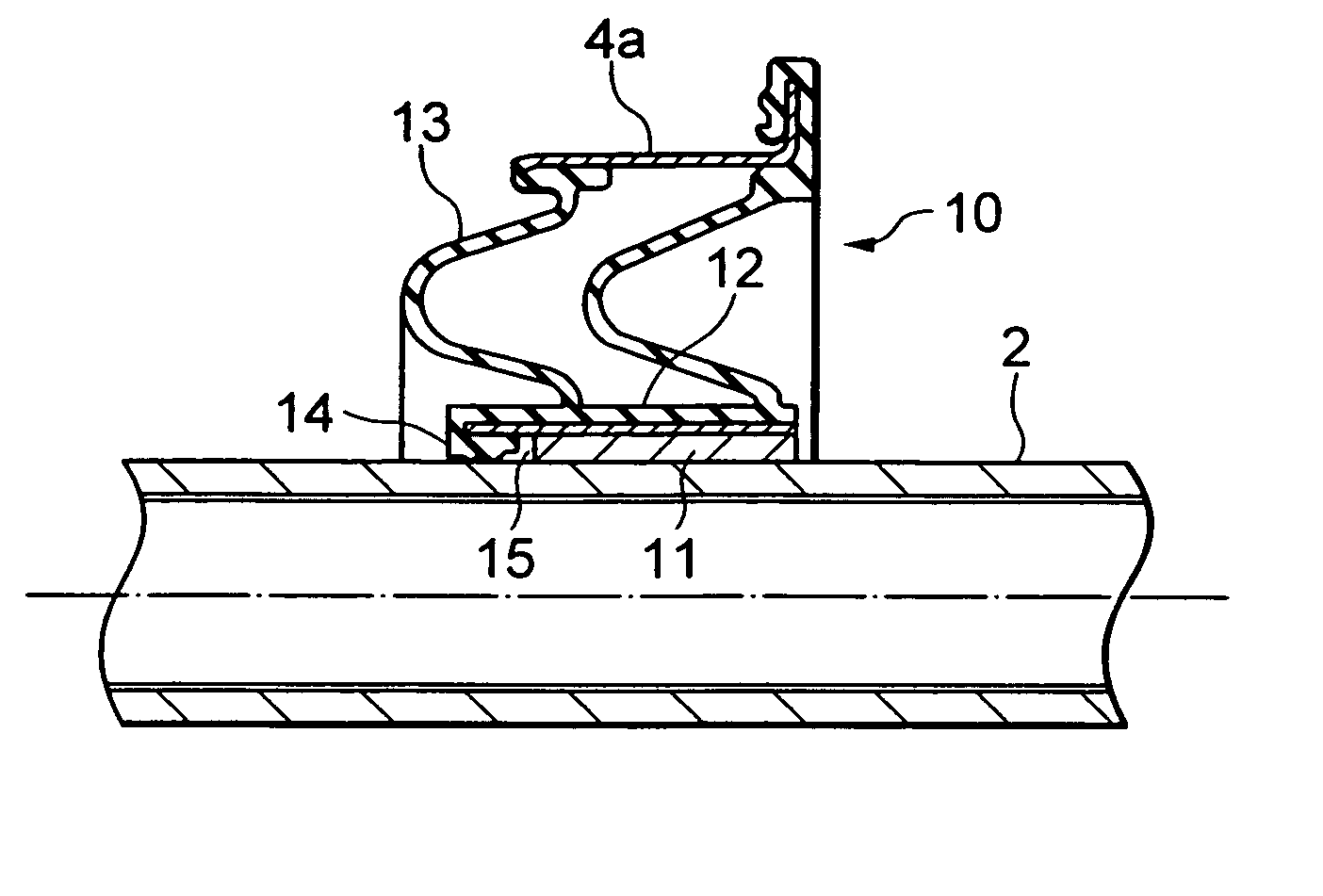

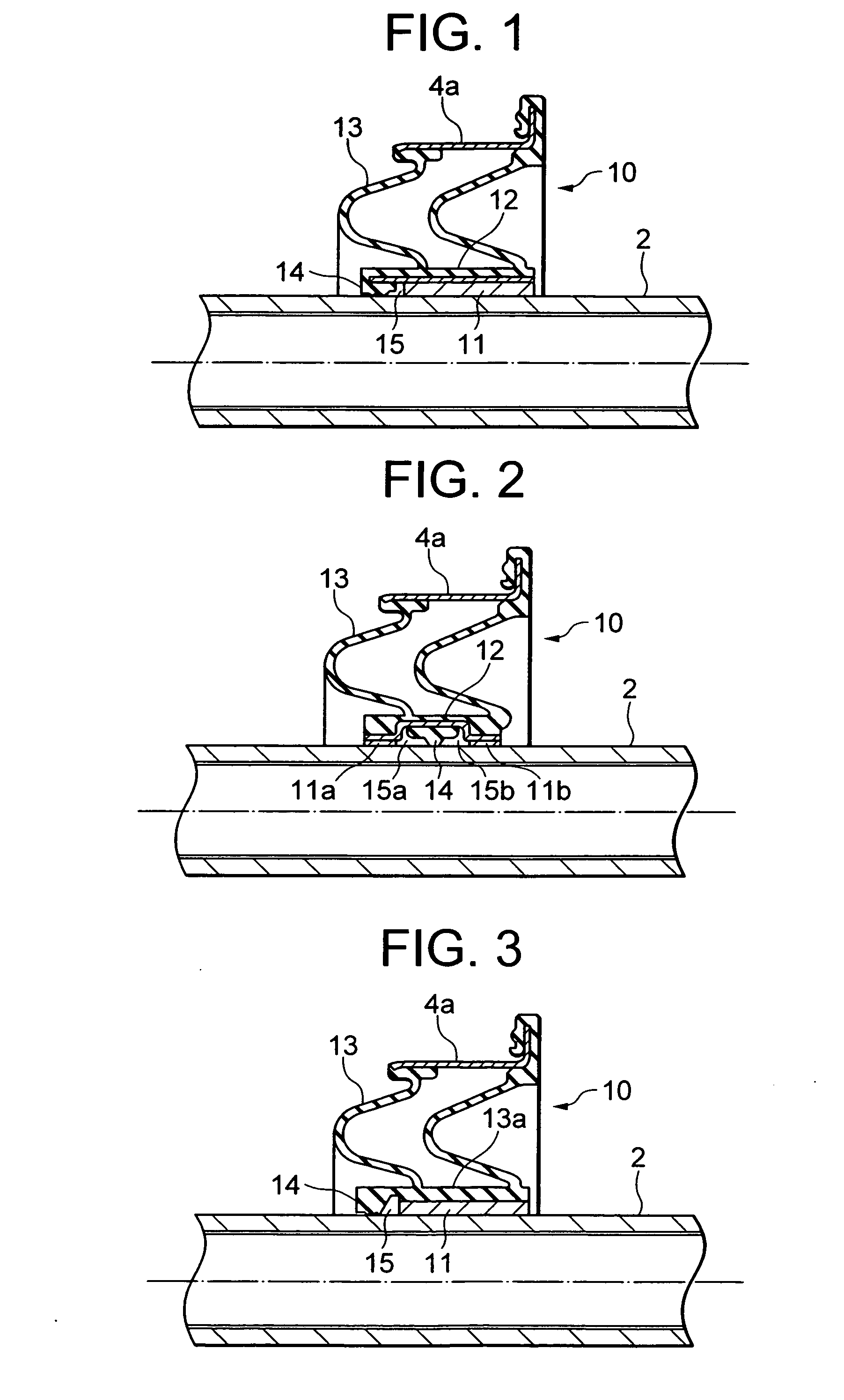

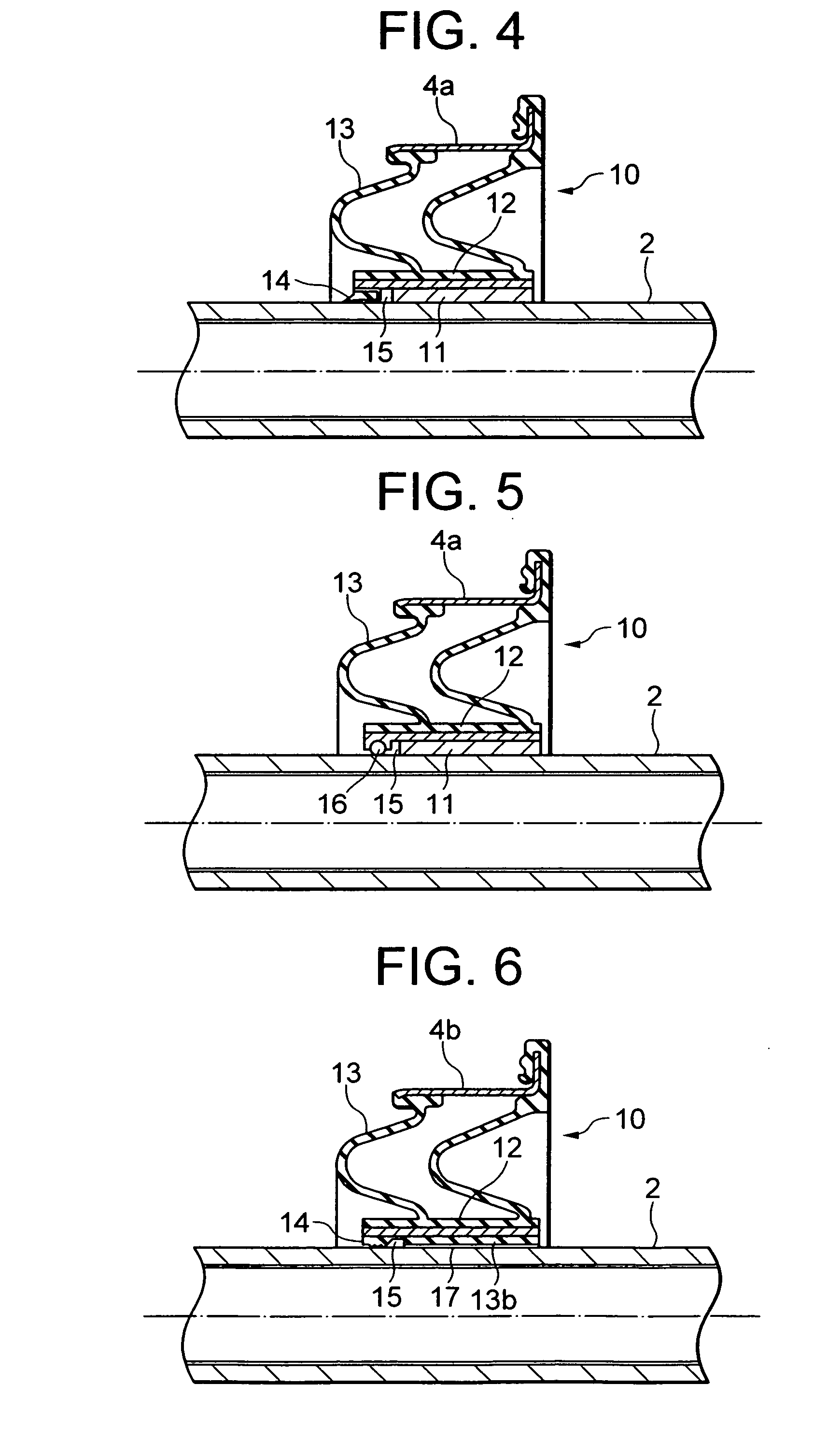

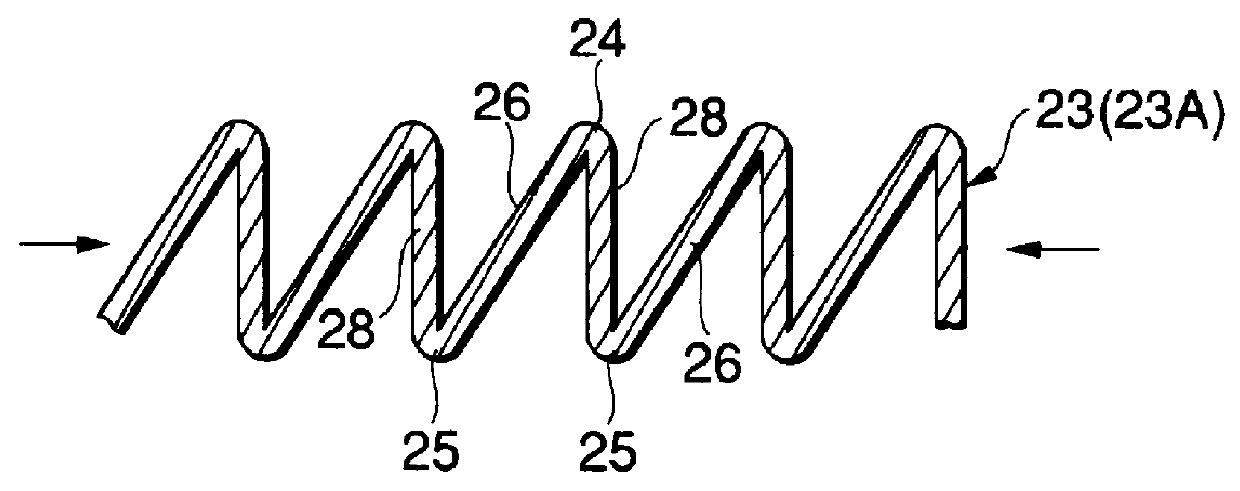

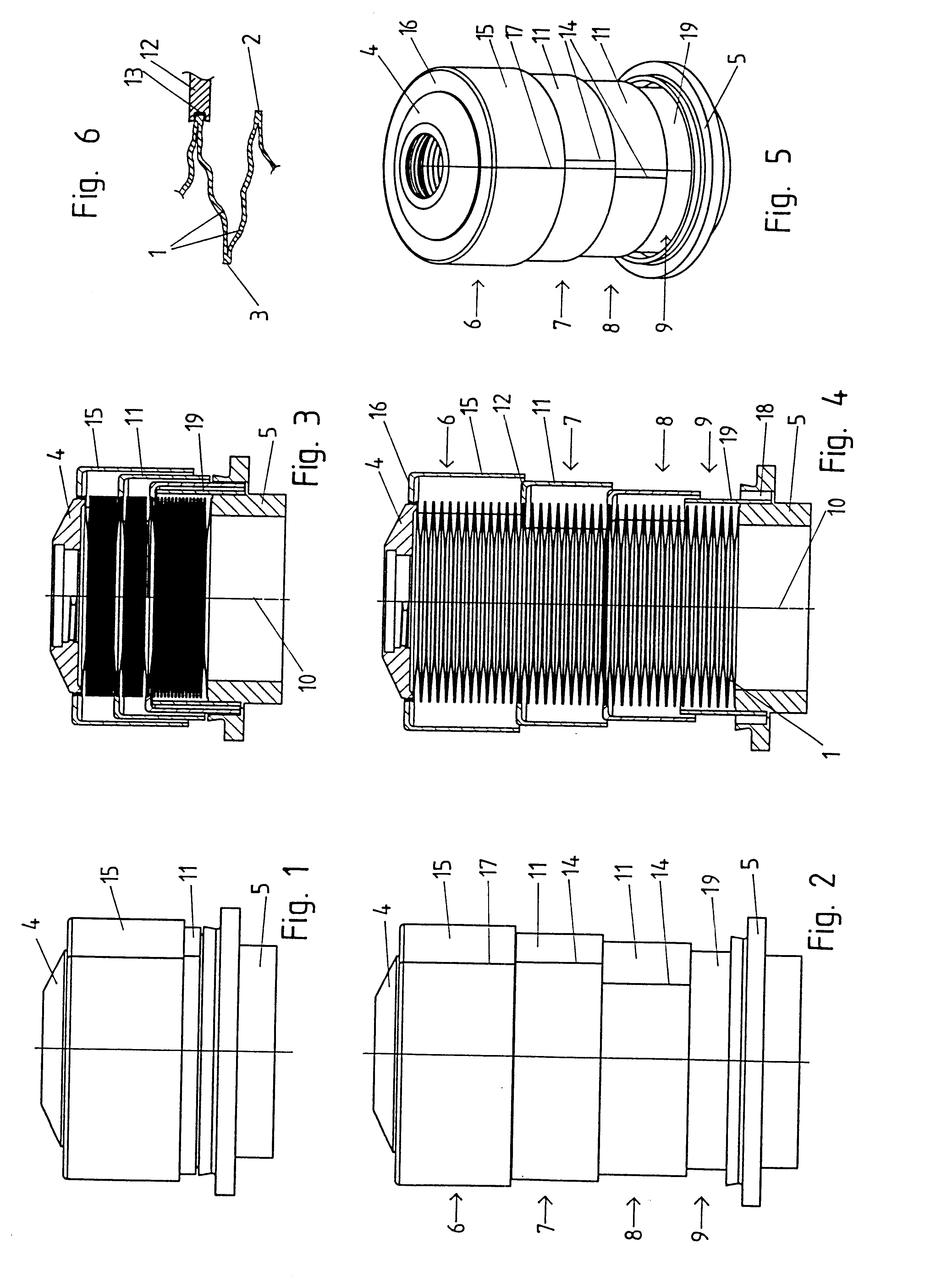

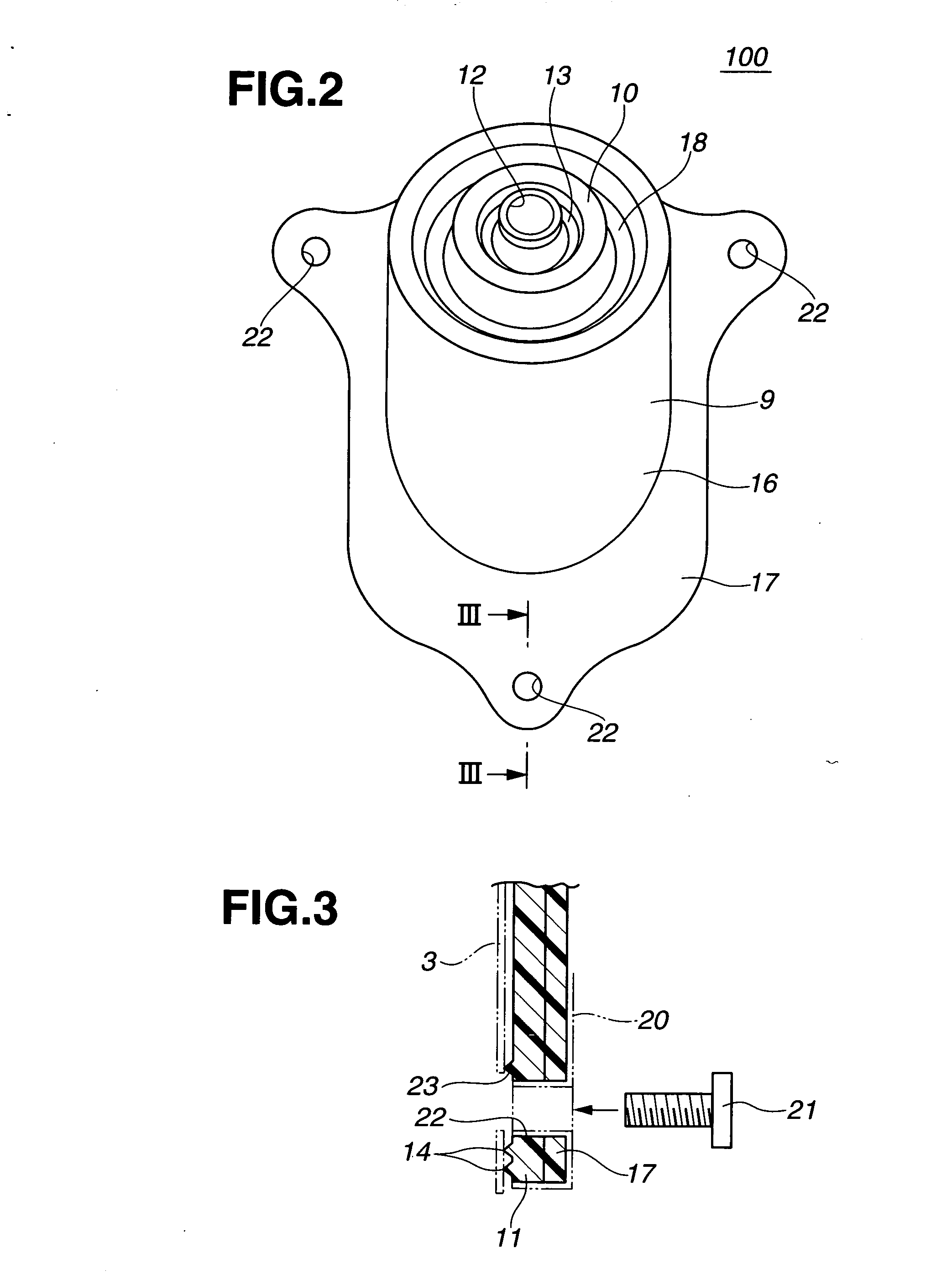

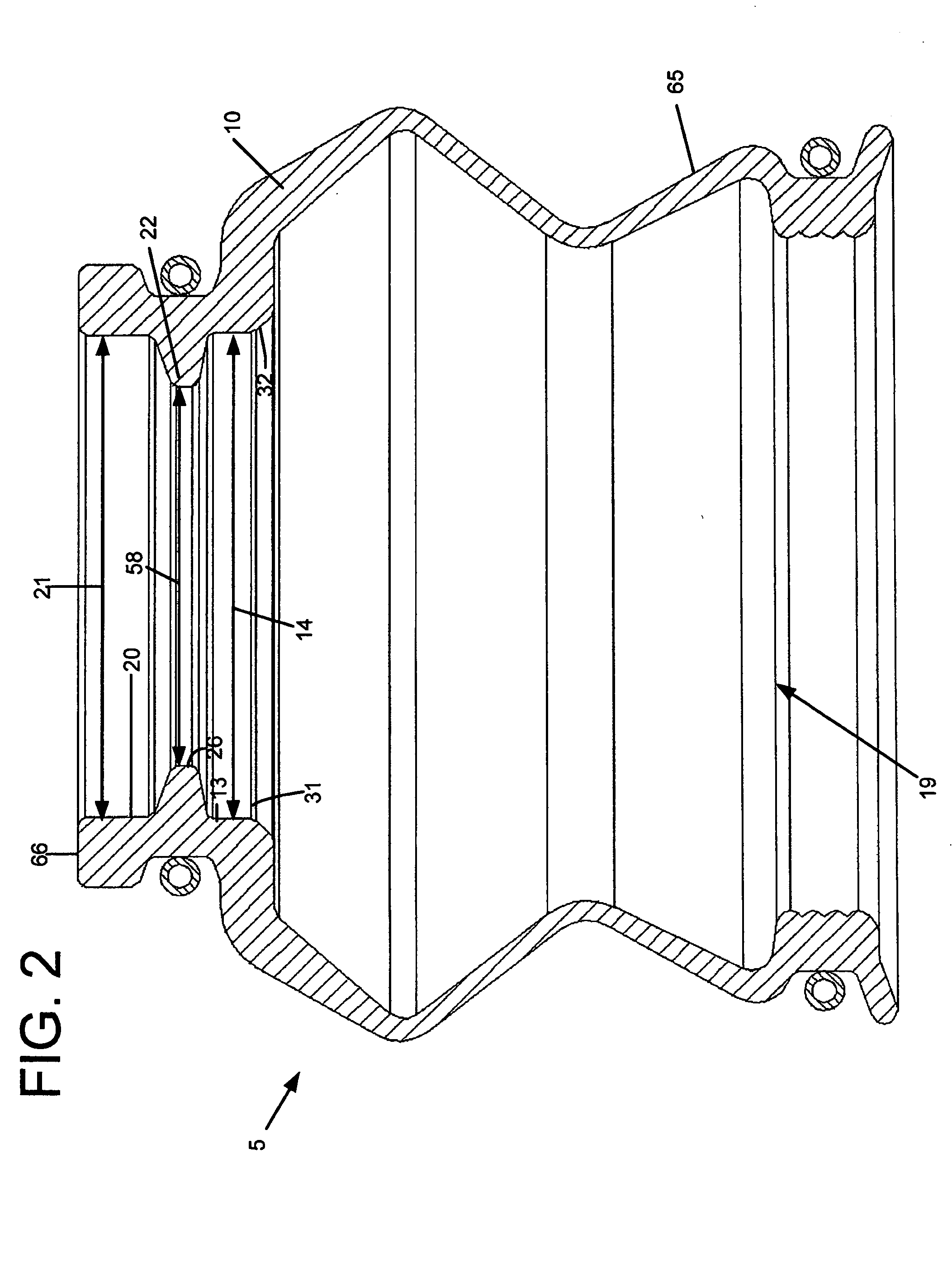

Bellows cylinder

A bellows cylinder (10) provided with a bellows part (13) at least at a part is formed so that a first surface 16 of a cylinder wall of the above bellows part is tilted to the radial direction of the bellows part and is directed to one end of the bellows part with a ridge (14) as a boundary. A second surface 18 is parallelized to the radial direction of the bellows part and is directed to the other end of the bellows part or is tilted on the side of the first surface. The second surface is pressed inside the first surface when the bellows part is compressed.

Owner:INOAC CORP

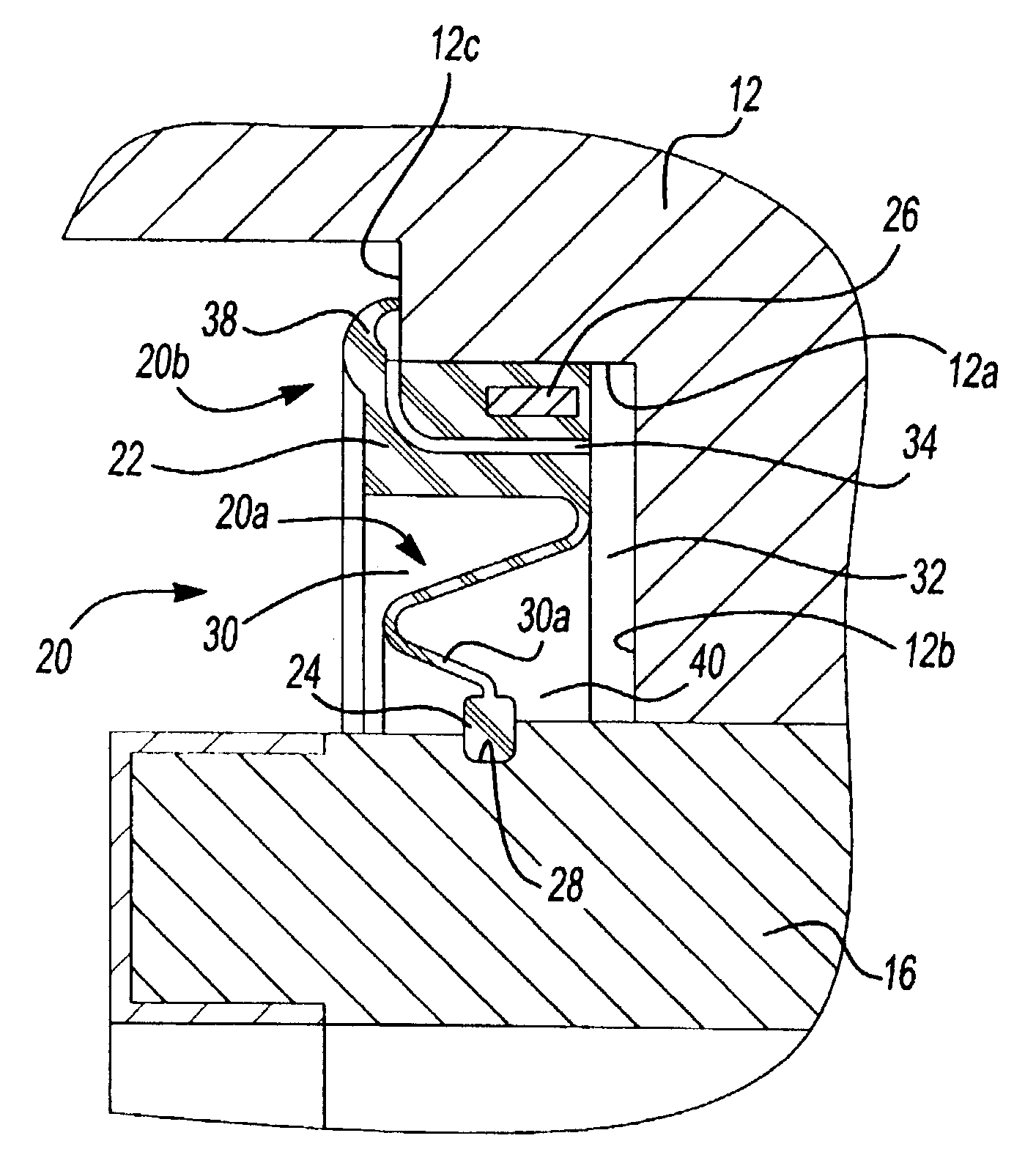

Pressure bleeding boot-type seal

A boot-type seal having a seal and a valve. The seal has a first seal member, which is configured to sealingly engage a first surface, and a second seal member, which is configured to sealingly engage a second surface. The valve is coupled to the seal and is operable in a first condition, which inhibits fluid communication therethrough, and a second condition, which permits fluid communication therethrough. The condition of the valve changes from the first condition to the second condition in response to a fluid pressure exerted on a side of the seal that exceeds a predetermined threshold pressure. A brake assembly that incorporates the boot-type seal is also provided.

Owner:AKEBONO BRAKE

Seal boot

InactiveUS20060186607A1Quick serviceFast cost reductionEngine sealsBellowsPropellerMechanical engineering

Owner:SHIH MIN FANG +1

Dust boot with grease relief passage

ActiveUS7670078B2Preventing pressurizationEngine sealsPipeline expansion-compensationEngineeringBall joint

Owner:FEDERAL MOGUL WORLD WIDE LLC

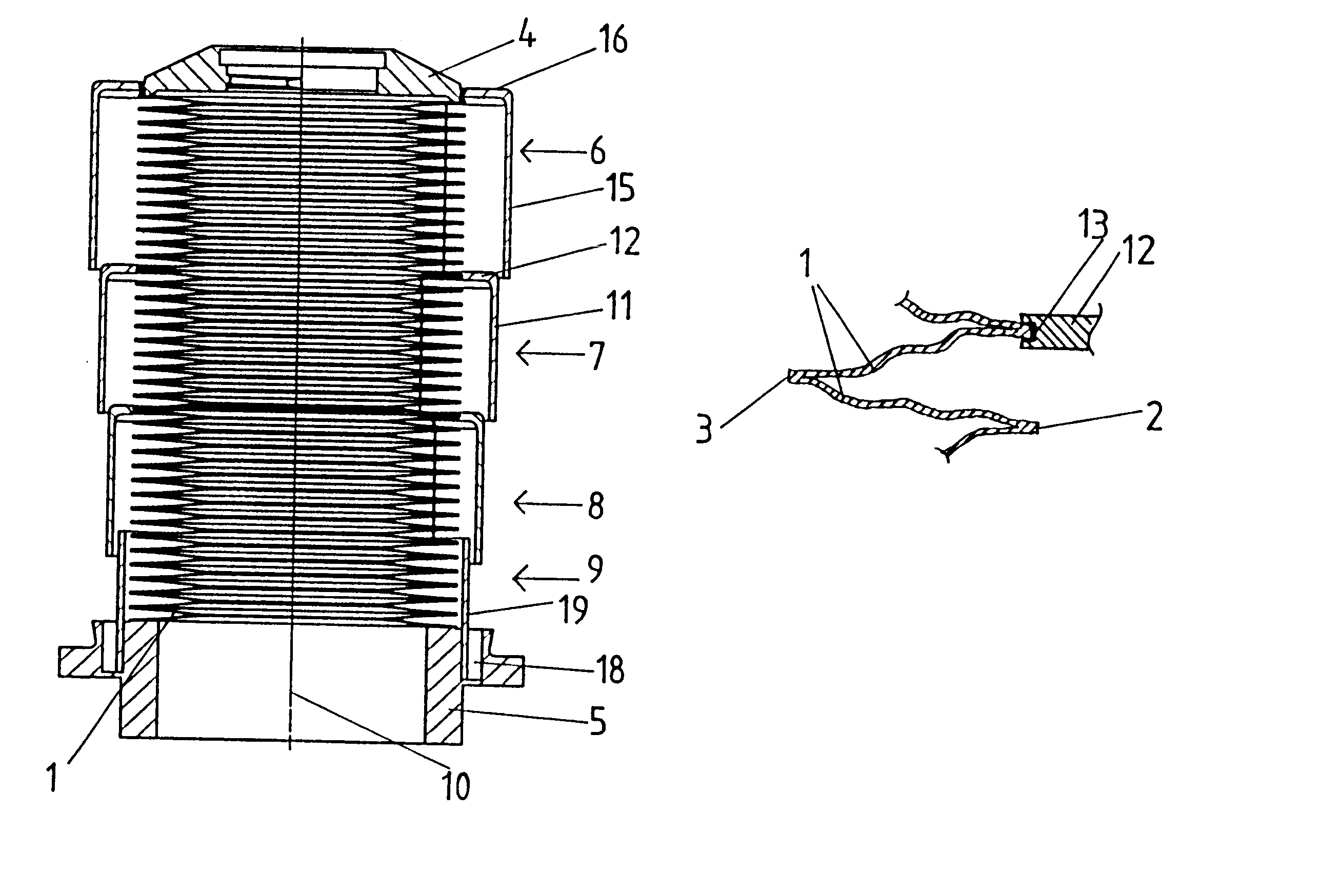

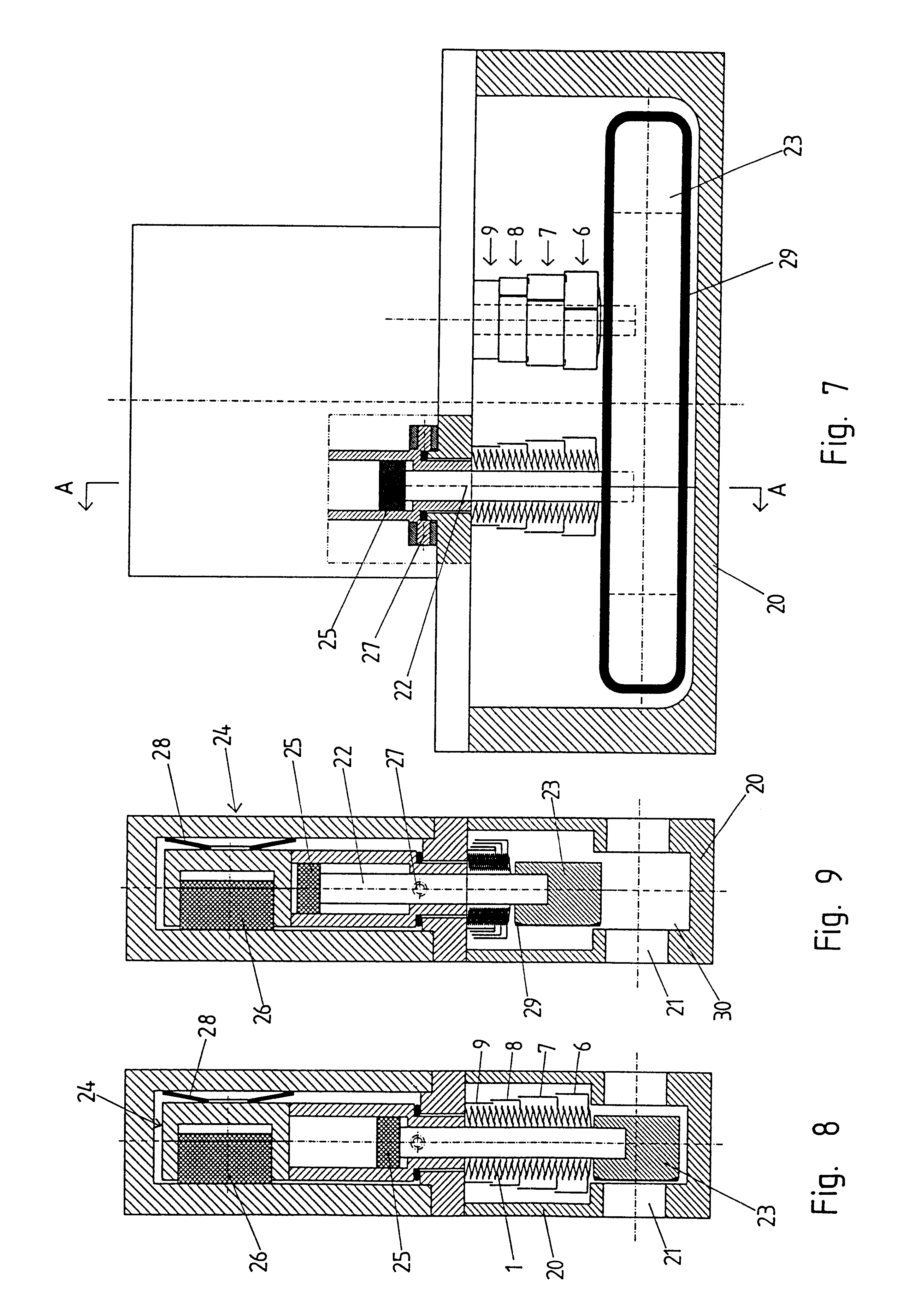

Diaphragm bellows device

A diaphragm bellows device comprises a diaphragm bellows with a plurality of successive diaphragms which are welded together alternately at the outer and inner edges, wherein the length of the diaphragm bellows can be adjusted between an expanded state and a contracted state, and a plurality of sleeve parts which surround the successive diaphragms and which, together, enclose the successive diaphragms also in the expanded state of the diaphragm bellows over its entire longitudinal extension and overlap to a greater or lesser extent in axial direction of the diaphragm bellows depending on the adjusted length of the diaphragm bellows, wherein at least one of the sleeve parts is held on the welded outer edges of two adjoining diaphragms by a snap connection.

Owner:VAT HLDG AG

Dust boot with grease channel

ActiveUS7704007B2Improve protectionImprove the lubrication effectEngine sealsYielding couplingEngineeringLubrication

A dust boot with enhanced protection from contaminants and improved lubrication characteristic includes a dust boot body having a housing opening on one end and on an opposing end a stud opening in an upper boot wall. The boot also includes a wiping lip located on an inner face of the upper boot wall in the stud opening, a grease channel on an outer surface of the upper boot wall bounded circumferentially by a rim seal, an offset opening hole through the upper boot wall into the grease channel which is offset from the wiping lip, and a flexible flap portion of said rim seal which is spaced away from said offset opening hole. The dust boot may also include an insert made from a plastic such as nylon housed in the upper boot wall such that the offset opening hole extends through the insert. The insert may also form a portion of the grease channel. The offset opening is preferably spaced opposite the flexible flap to promote the flow of grease around the outer surface of the stud. The dust boot may be incorporated into a joint assembly by placing it in sealing engagement with a housing which holds a stud in articulating engagement.

Owner:FEDERAL MOGUL WORLD WIDE LLC

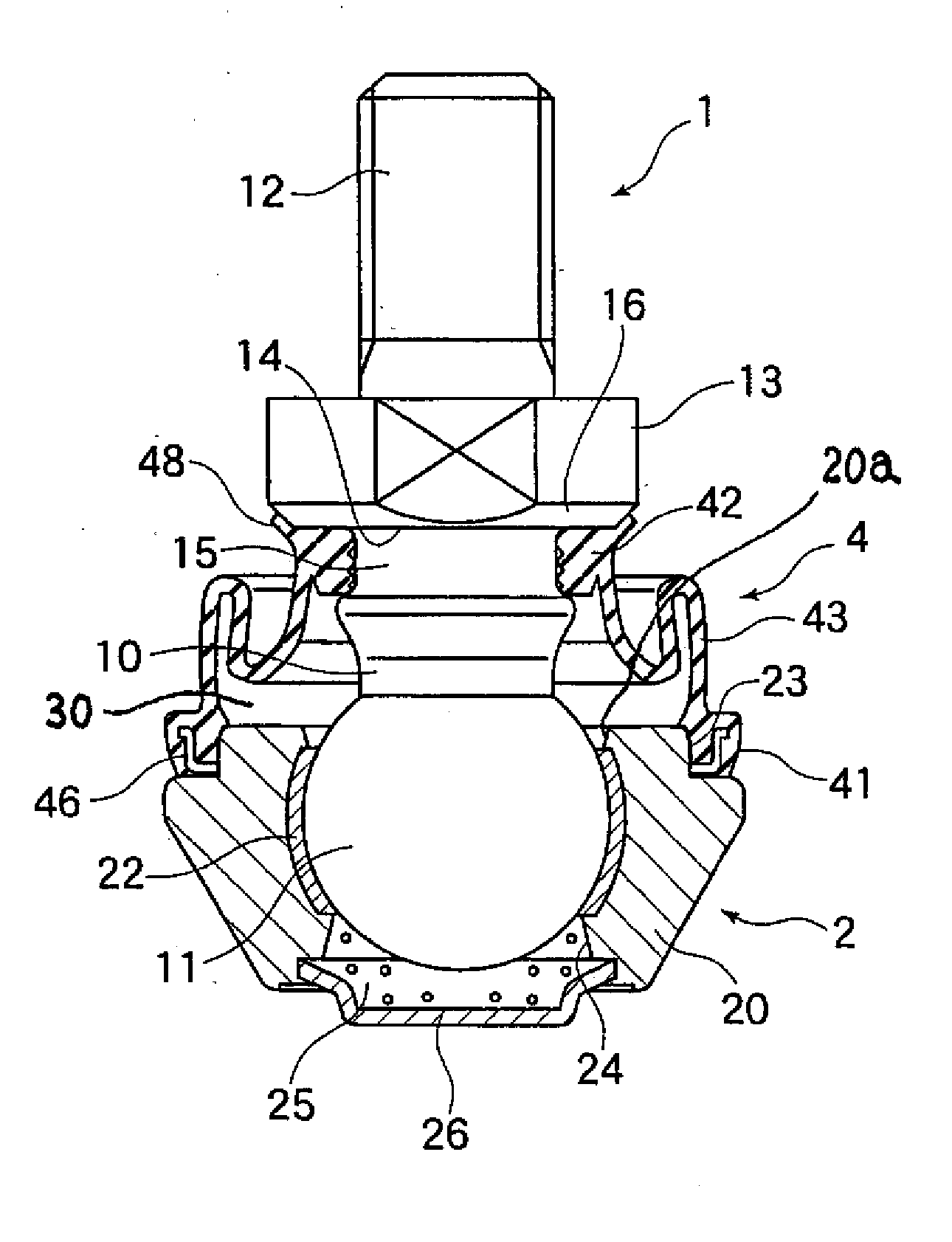

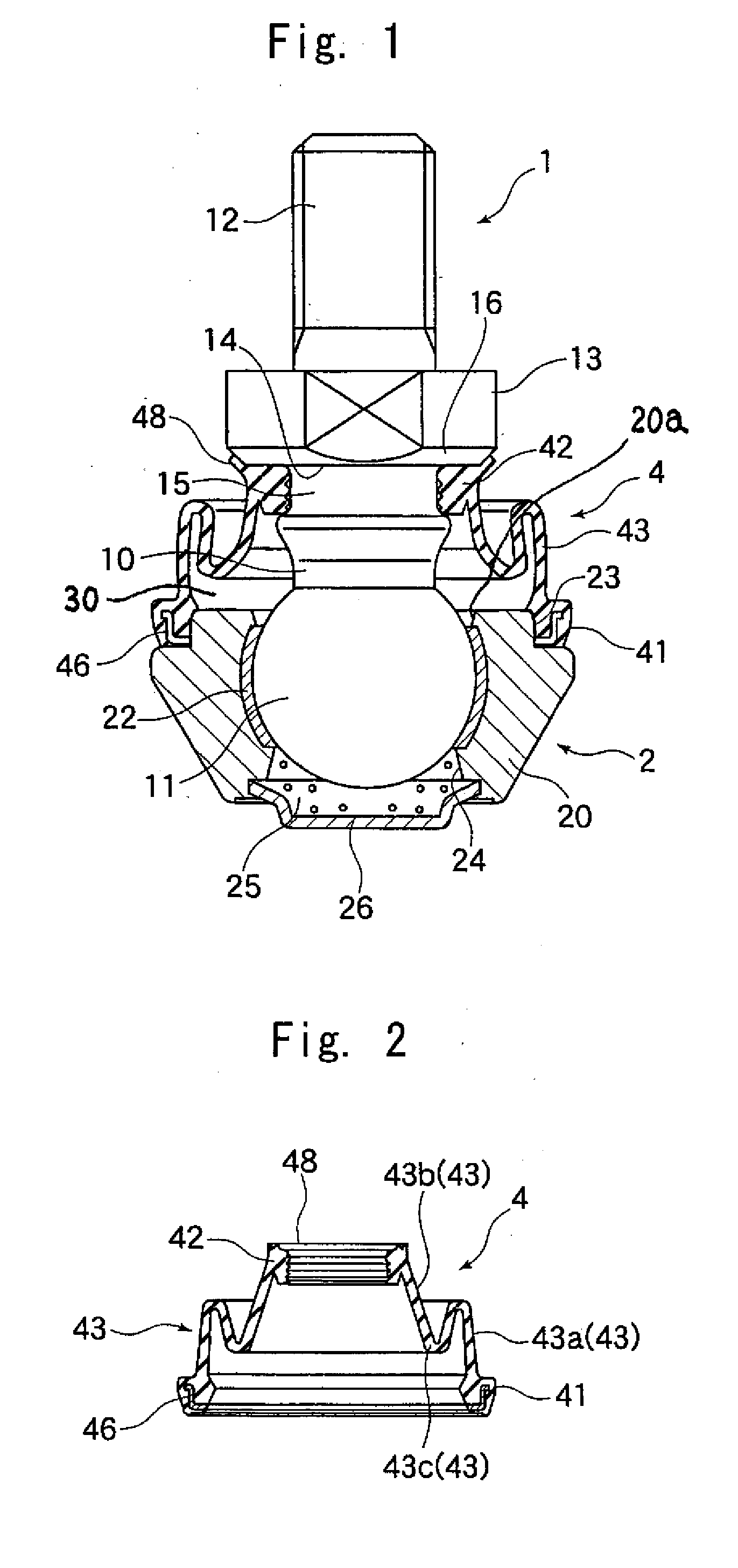

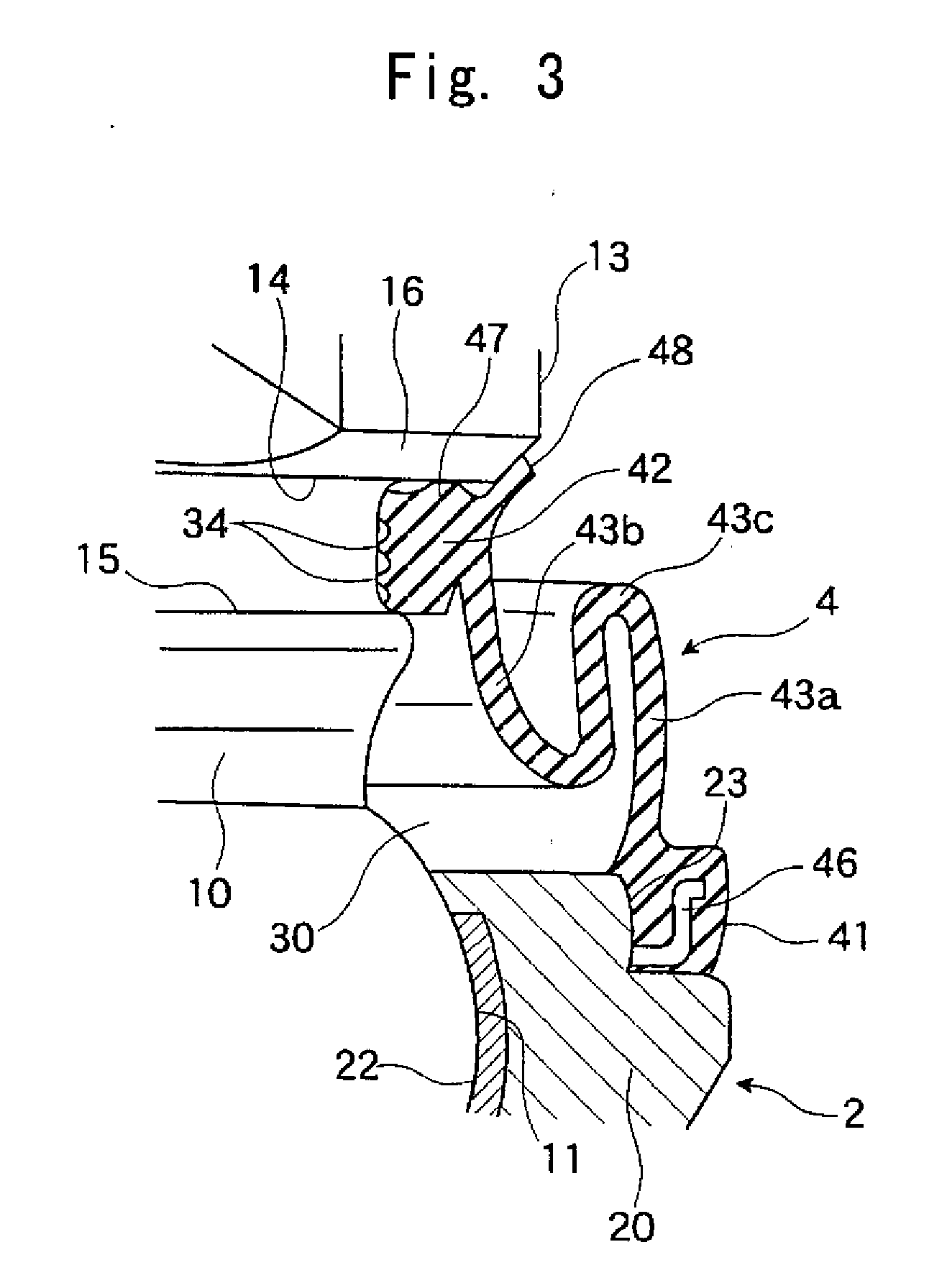

Ball joint

InactiveUS20090047063A1Prevent surfaceReliably sealed stateCouplings for rigid shaftsPivotal connectionsBall jointSpherical form

Provided is a ball joint which enhances a sealing performance between a boot seal (4) and a ball shank (1) and which can maintain this sealing performance even during swinging motion of the ball shank (1) with respect to a holder (2), making it possible to completely prevent intrusion of dust and muddy water into a ball reception portion (20) of the holder (2) The ball shank (1) is provided with a flange portion (13), with a tapered surface (16) inclined with respect to an axial direction of the ball shank (1) being formed on the flange portion (13). The boot seal (4) is constructed of an annular fixation portion fixed to the holder (2), an annular seal portion (42) tightening a shaft portion (10) of the ball shank (1) and held in press contact with the flange portion (13). The seal portion (42) has a side lip portion (48) corresponding to the tapered surface (16) of the flange portion (13) and protruding so as to diverge obliquely, the side lip portion (48) being held in press contact with the tapered surface (16) when the seal portion (42) is attached to the shaft portion (10) of the ball shank (1).

Owner:THK CO LTD

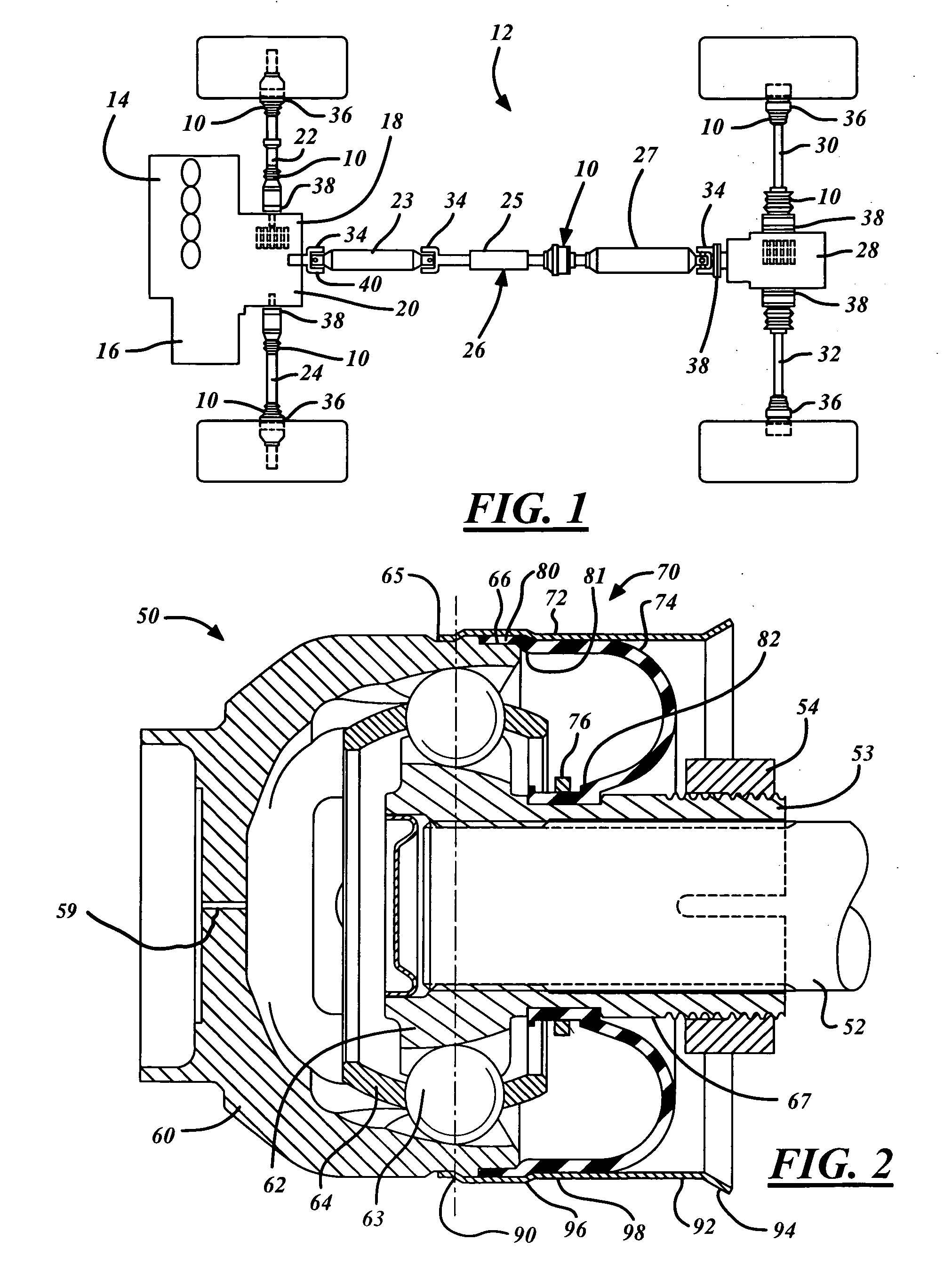

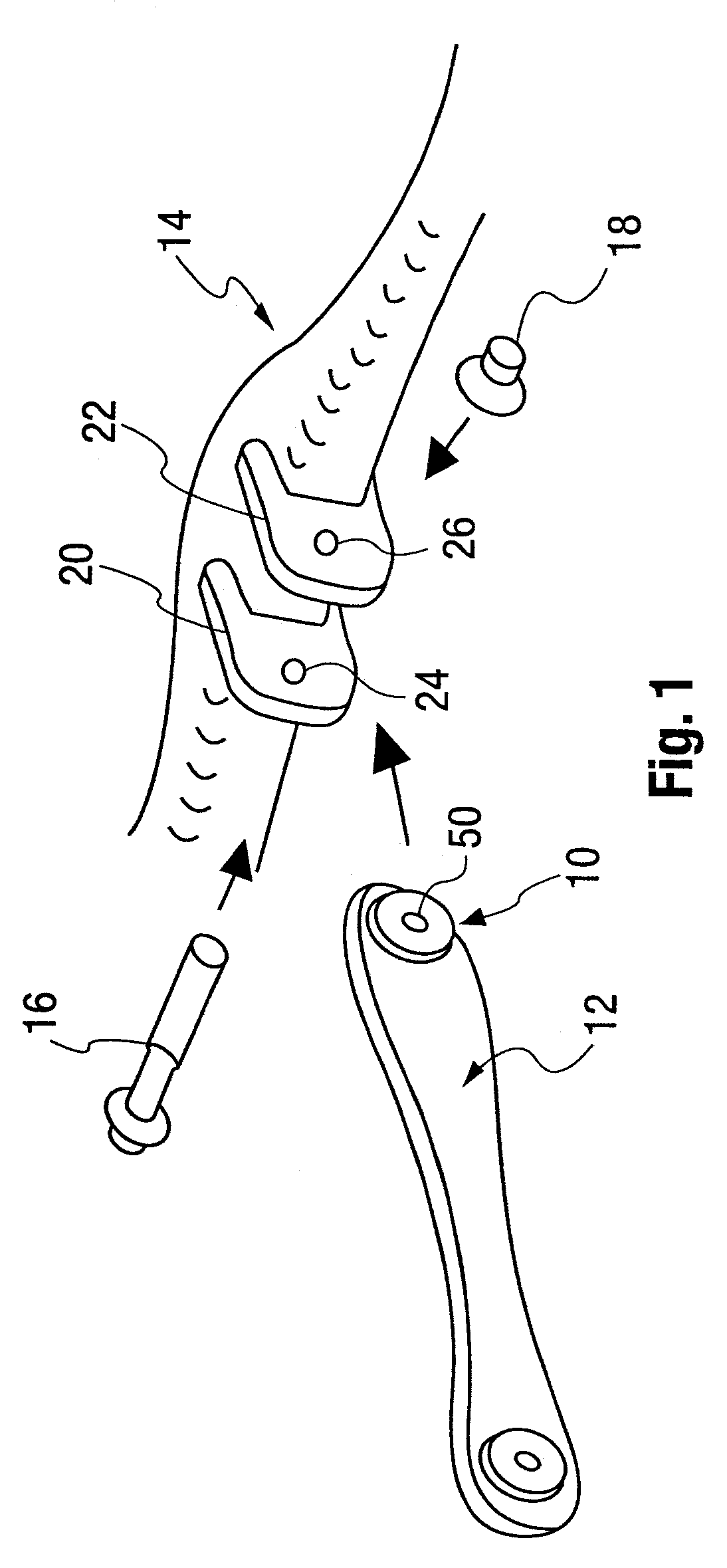

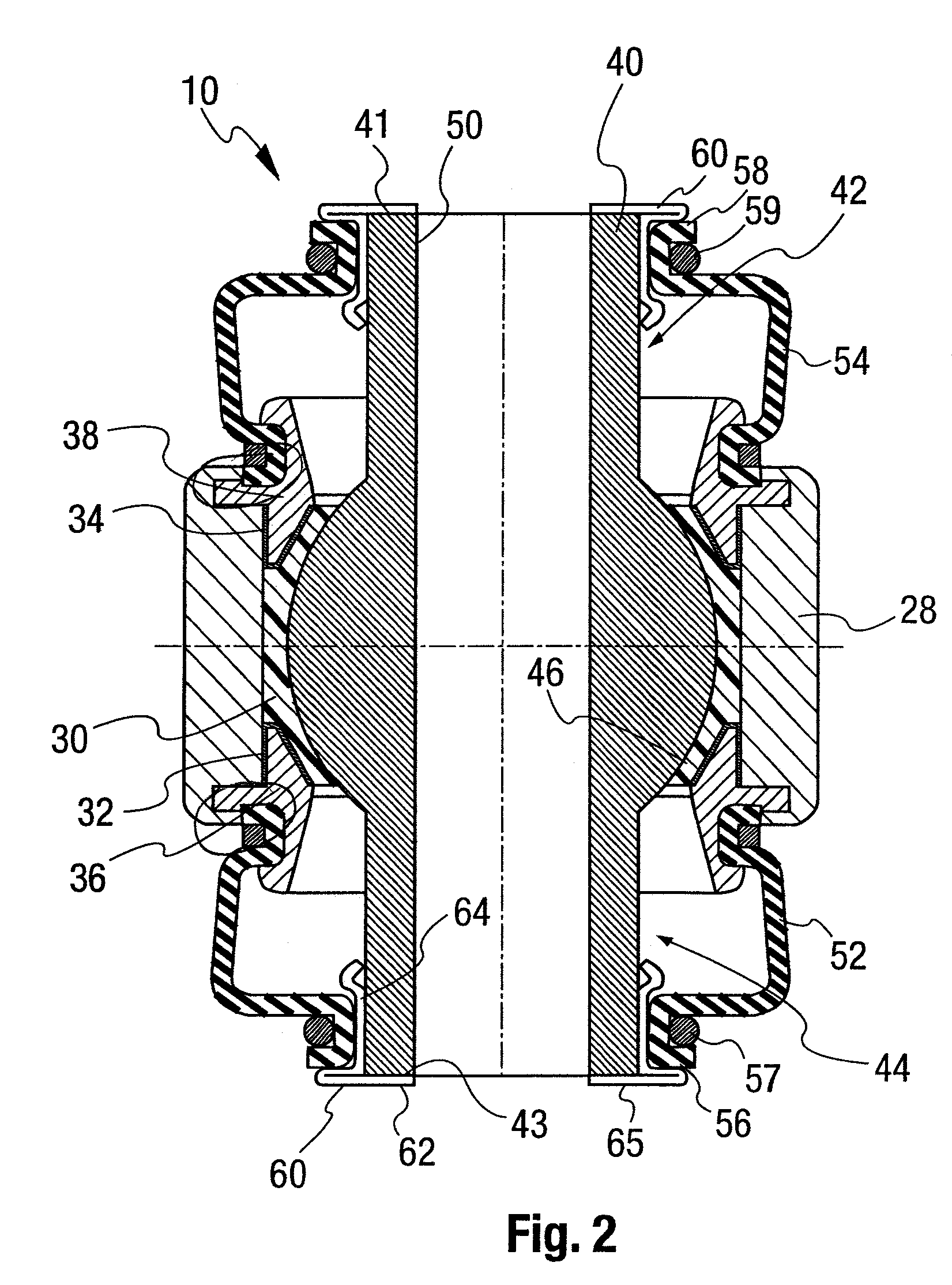

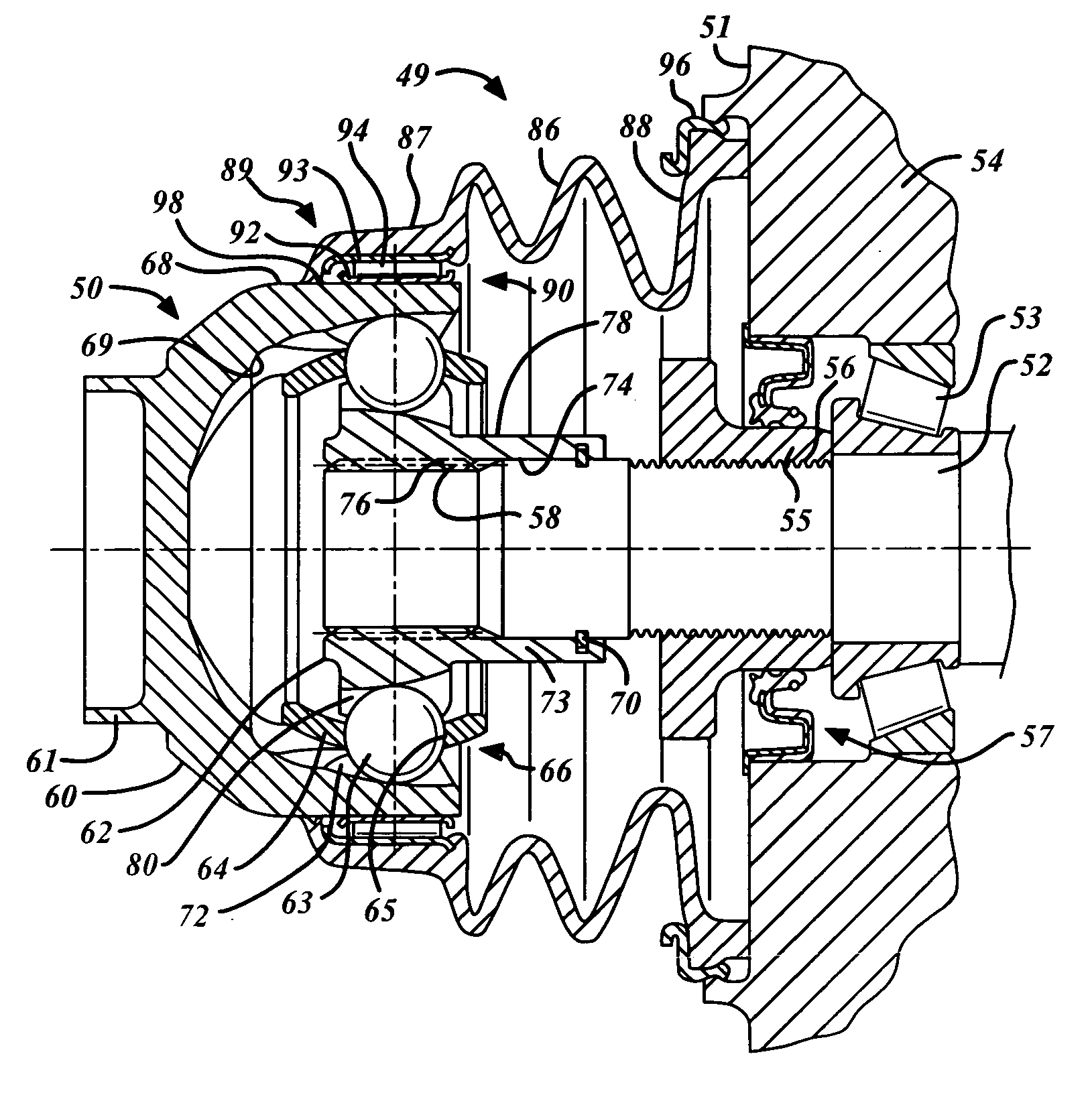

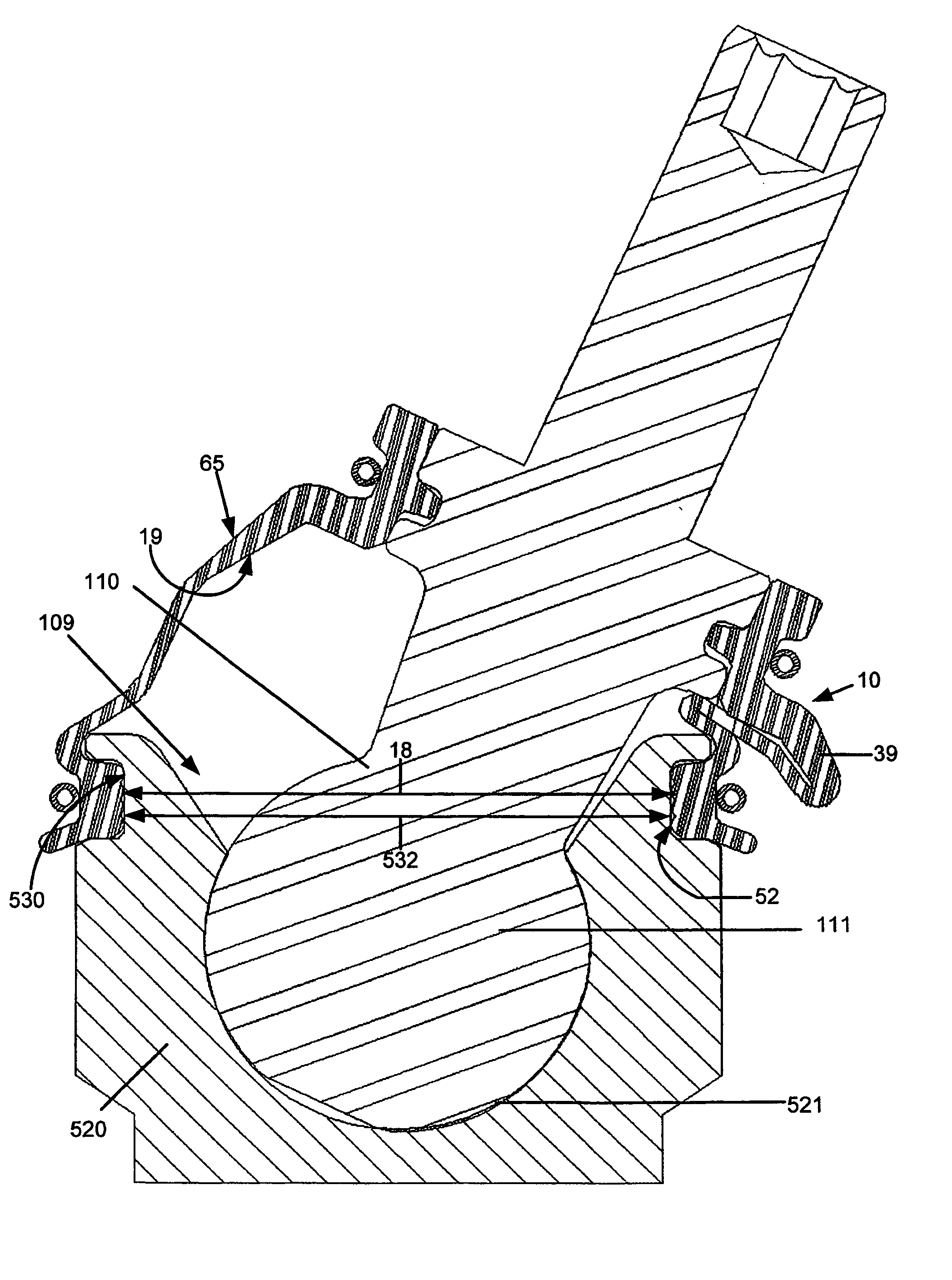

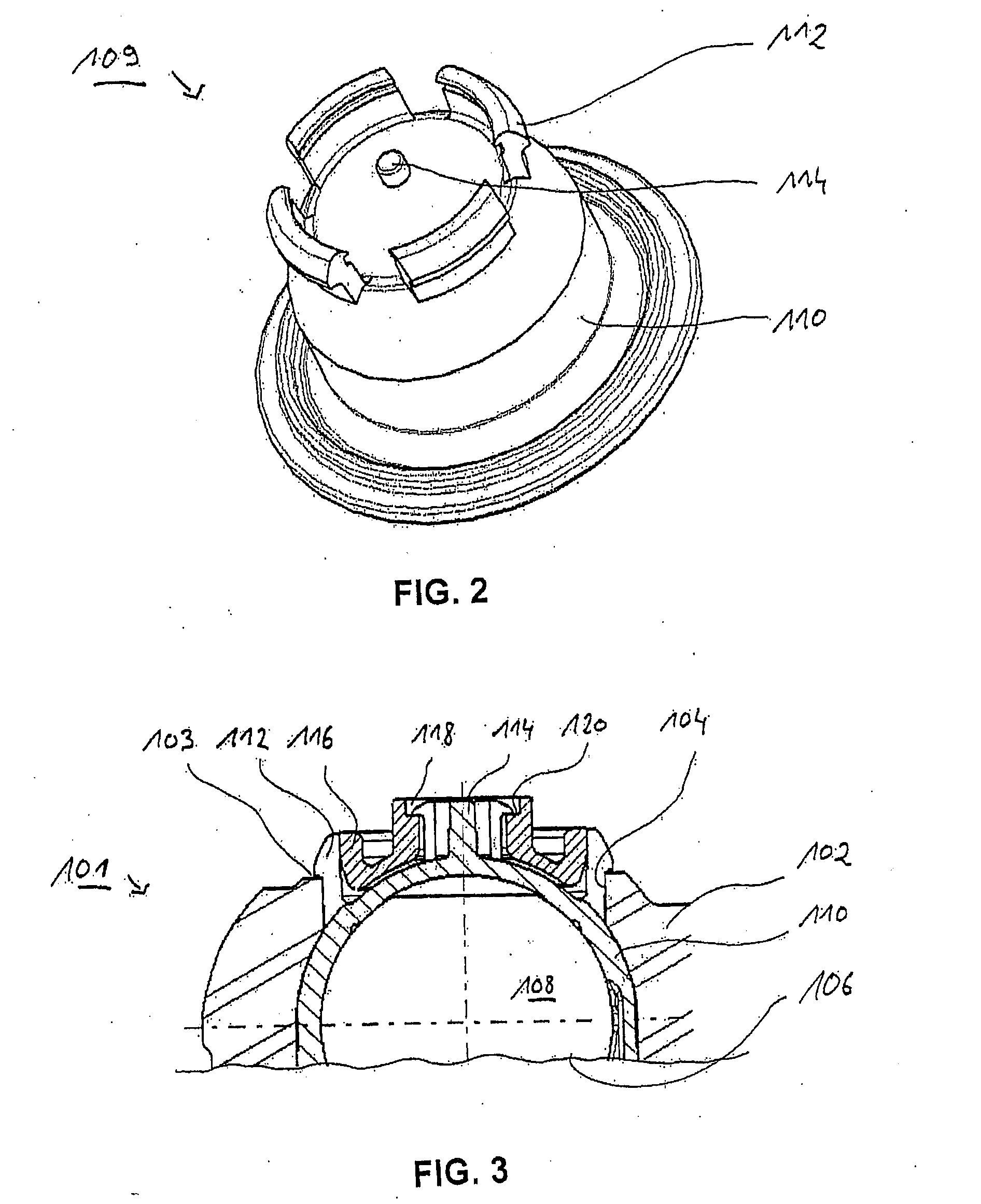

Cross axis ball and socket joint with sealing ring for cross axis sleeve ends

InactiveUS7438493B2Simple designRugged in constructionEngine sealsPipeline expansion-compensationTransverse axisBearing surface

A ball joint, is provided in the form of a cross axis joint with a housing, a bearing shell in the housing and a ball sleeve. The ball sleeve includes a ball portion with a bearing surface cooperating with the bearing shell and a first pivot pin and a second pivot pin extending from said ball portion in an axial direction. The ball sleeve has an inner surface defining a through hole (50) for receipt of a connection bolt. The first pivot pin has a first end with a first outer surface (42) and a first annular end face (41) and the second pivot pin has a second end with a second outer surface (44) and a second annular end face (43). Sealing rings (60, 60′, 60″, 90, 95) are provided, each having a first axially extending portion extending along the first outer surface and having a sealing area outer surface defining a bellows seal seat (64, 98) and a radially extending portion extending along the end face. Each bellows seal (52, 54) is connected to the housing at one end and connected to said bellows seal seat (64, 98) at another end.

Owner:ZF FRIEDRICHSHAFEN AG

Steering shaft boot

A steering shaft boot of a molded elastic material comprises an inner boot portion including a first cylindrical portion that is adapted to cover a steering shaft, a first flange portion that extend radially outward from one axial end of the first cylindrical portion and is adapted to be secured to a panel member and a first upper wall portion that extends radially inward from the other axial end of the first cylindrical portion and is adapted to be put on an outer surface of the steering shaft; and an outer boot portion including a second cylindrical portion that covers the first cylindrical portion while keeping a certain clearance therebetween, a second flange portion that extends radially outward from one axis end of the second cylindrical portion and is adapted to be secured to the panel member and a second upper wall that extends radially inward from the other axial end of the second cylindrical portion to the other axial end of the first cylindrical portion. The first and second flange portions are separate members but engageable when in use.

Owner:KINUGAWA RUBBER IND CO LTD

Retaining cap for a protective bellows

InactiveUS20040168871A1Solving the Insufficiency of ElasticitySolid configurationSpringsResilient suspensionsEngineeringMoving parts

A retaining cap includes a sleeve-shaped basic body which has at least one protective bellows retaining segment on which a protective bellows can be supported. A component which is movable with respect to the retaining cap can penetrate into the installation space of the retaining cap, the retaining cap having a plurality of deformation regions which are arranged in the circumferential direction. When in contact with the movable component, these regions make possible a free passage for the movable component.

Owner:ZF FRIEDRICHSHAFEN AG

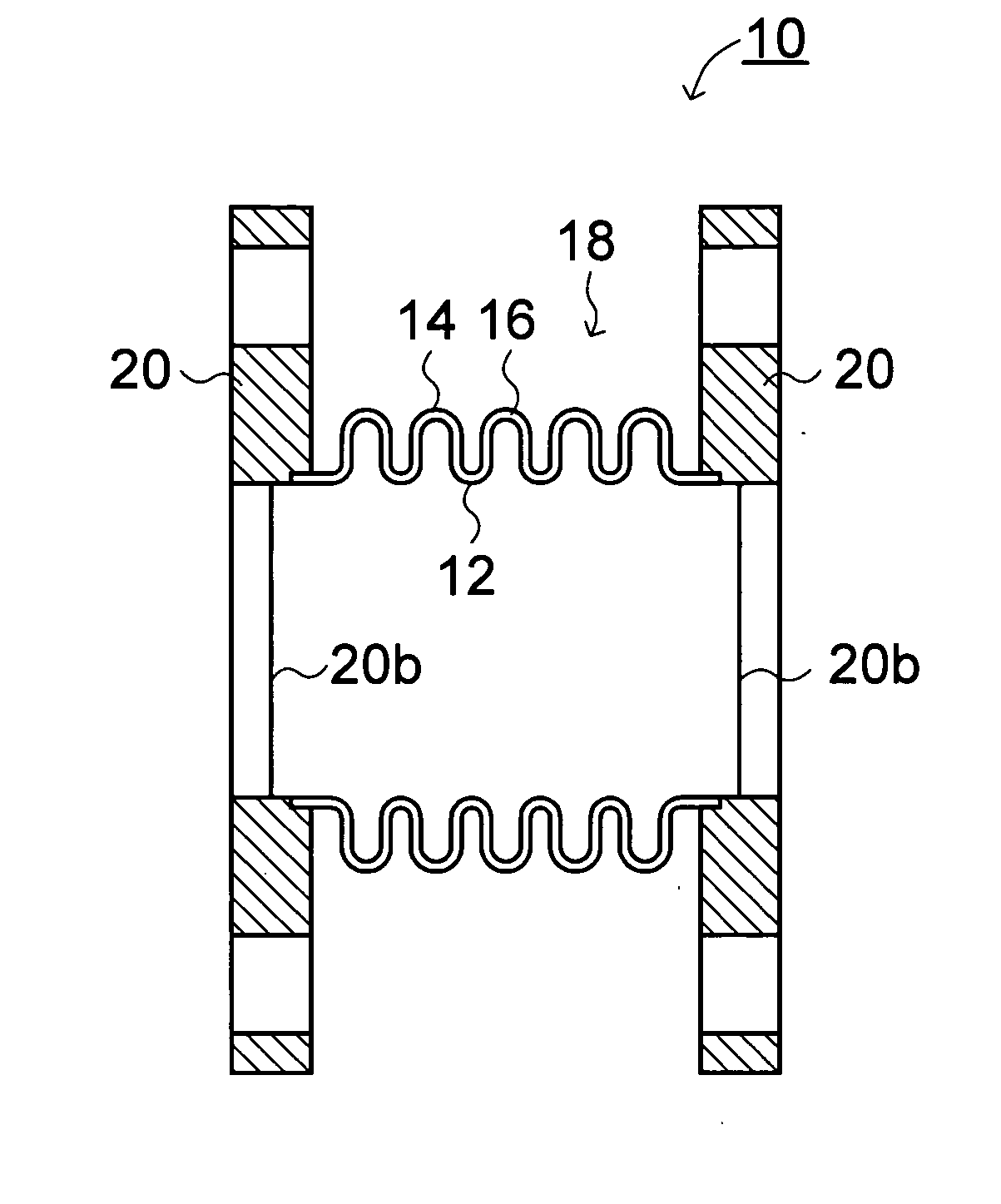

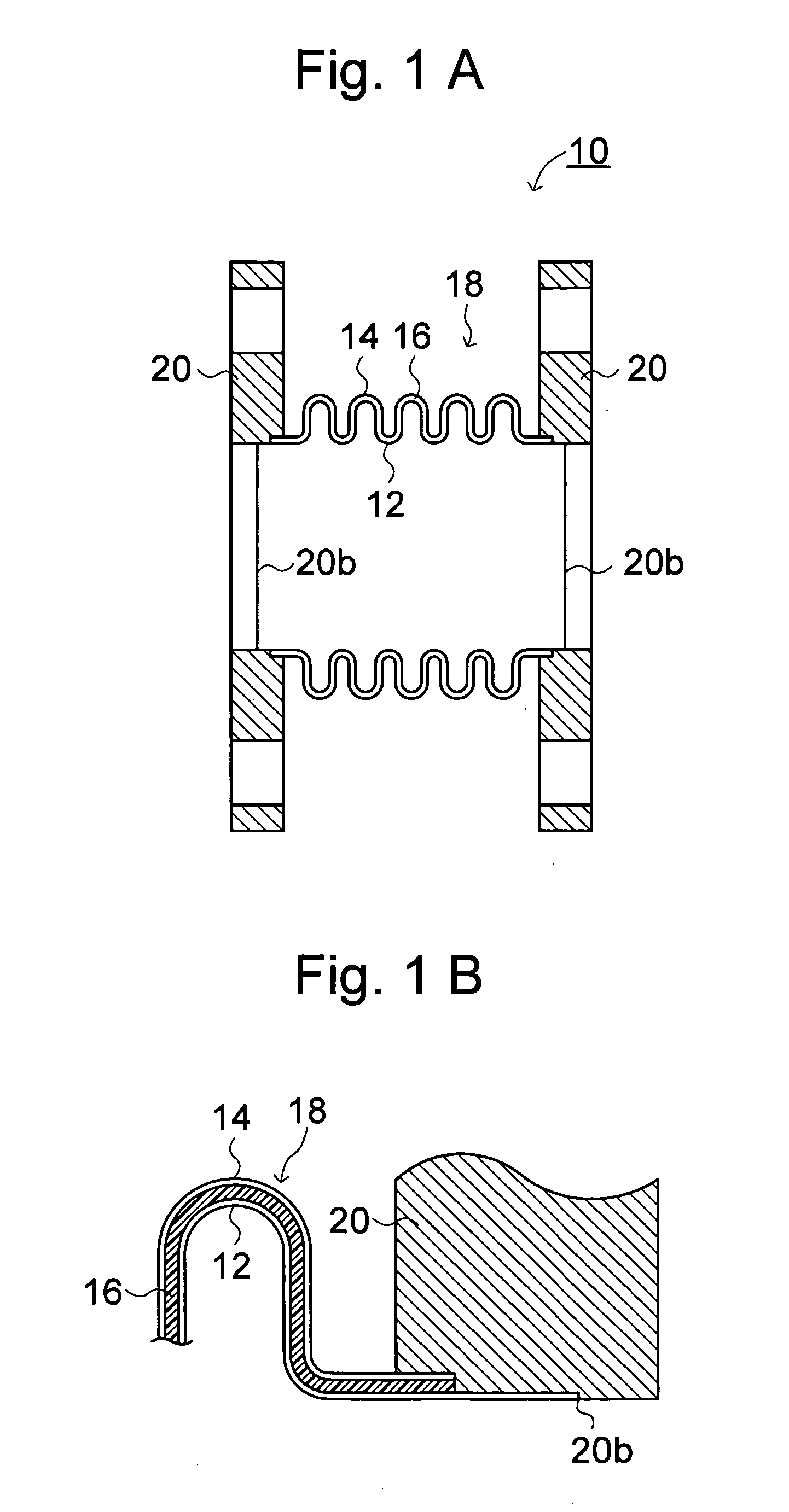

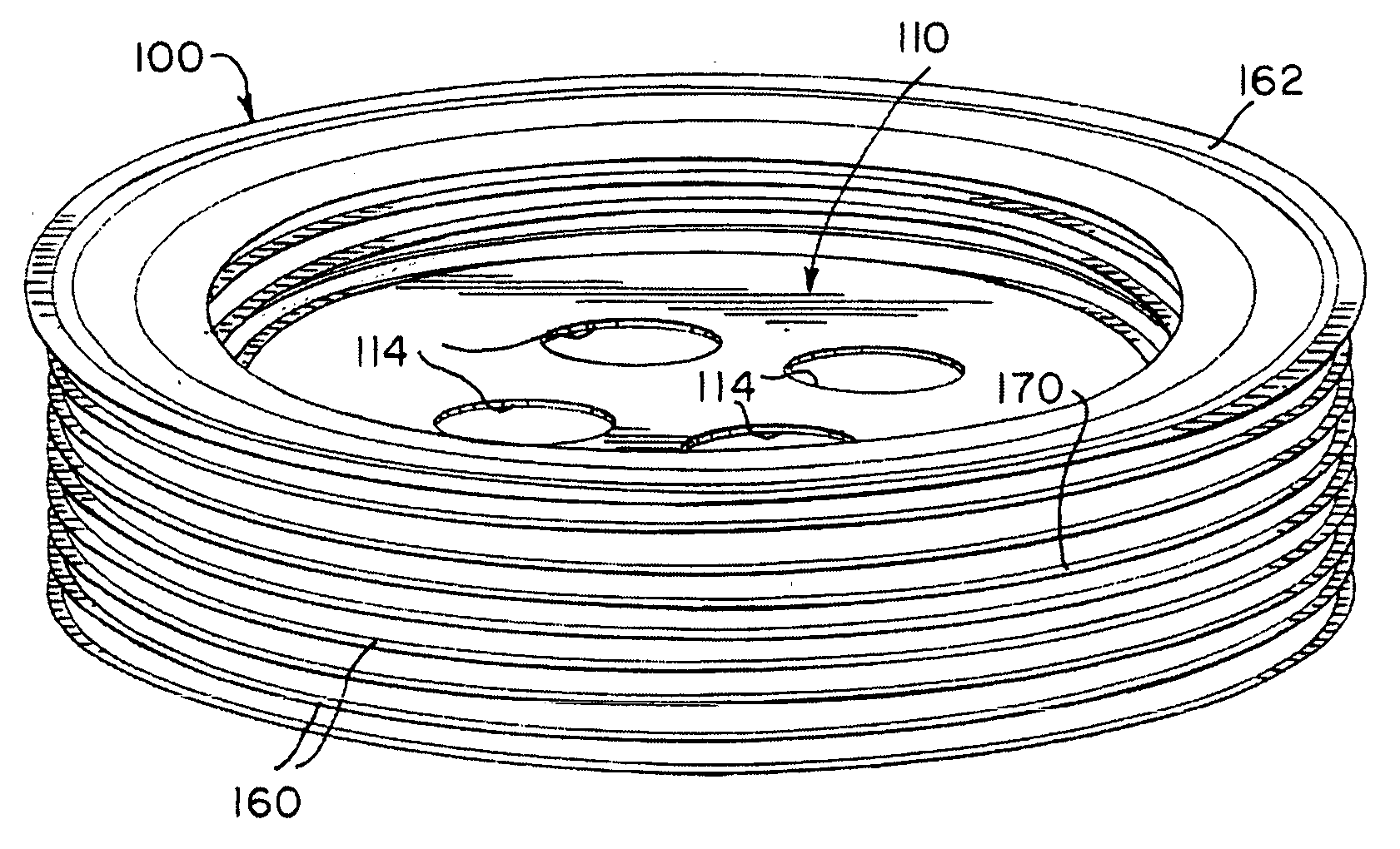

Method of Making a Metal Bellows Assembly Having an Intermediate Plate

InactiveUS20090188897A1Easy to moveIntravenous devicesWelding/cutting media/materialsThin metalSized small

The formation of a bellows made up of a stack of a predetermined number of ring-convolutions and having an intermediate plate supported within said stack is achieved by supplying several thin metal rings, each having inner and outer edges. A pair of these metal rings are positioned in contiguous relationship and their adjacent inside edges are welded together to form a ring-convolution. This process is repeated until a sufficient number of ring-convolutions are made to eventually make the desired bellows. Before these separate ring-convolutions are fused to each other, an intermediate plate and a support ring are made. The intermediate plate is a disc of metal that is sized smaller than the inside diameter of the rings and is secured to the support ring. The support ring is then positioned between two formed ring-convolutions in contiguous relationship and the three abutting outside edges are welded to each other to form a support plate convolution. The already made ring-convolutions and the support plate convolution are then stacked in the desired order and in contiguous relationship. All not-yet welded adjacent outside edges of said ring-convolutions and said support plate convolution are then welded to form the bellows. A bottom plate is formed and welded to the outside edge of the bottommost ring-convolution and a top ring is finally welded to the uppermost convolution to complete the bellows. The top ring is meant to be welded to a base plate of an infusion pump.

Owner:MEDOS INT SARL

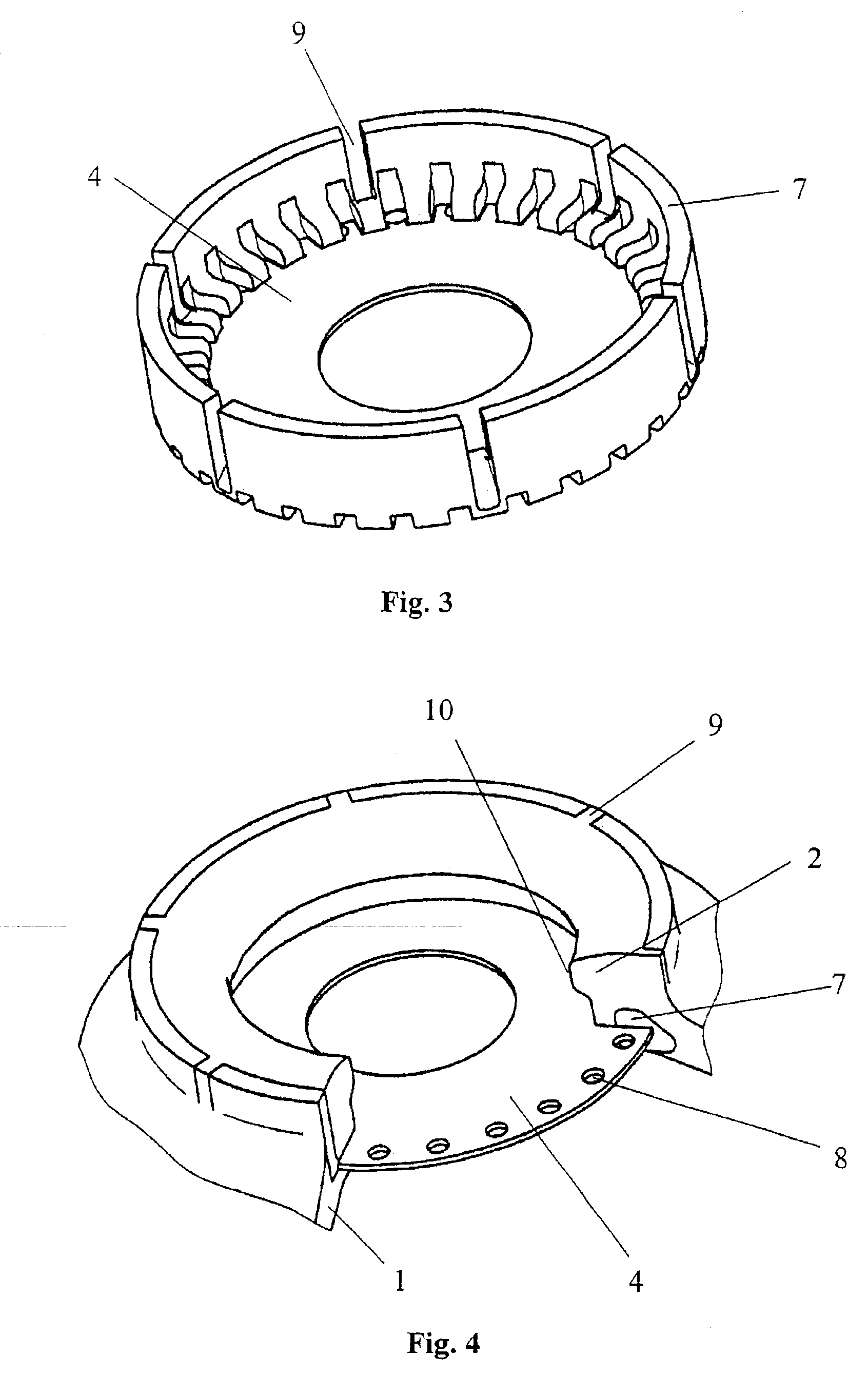

Column hole cover

Owner:MARUGO RUBBER IND +1

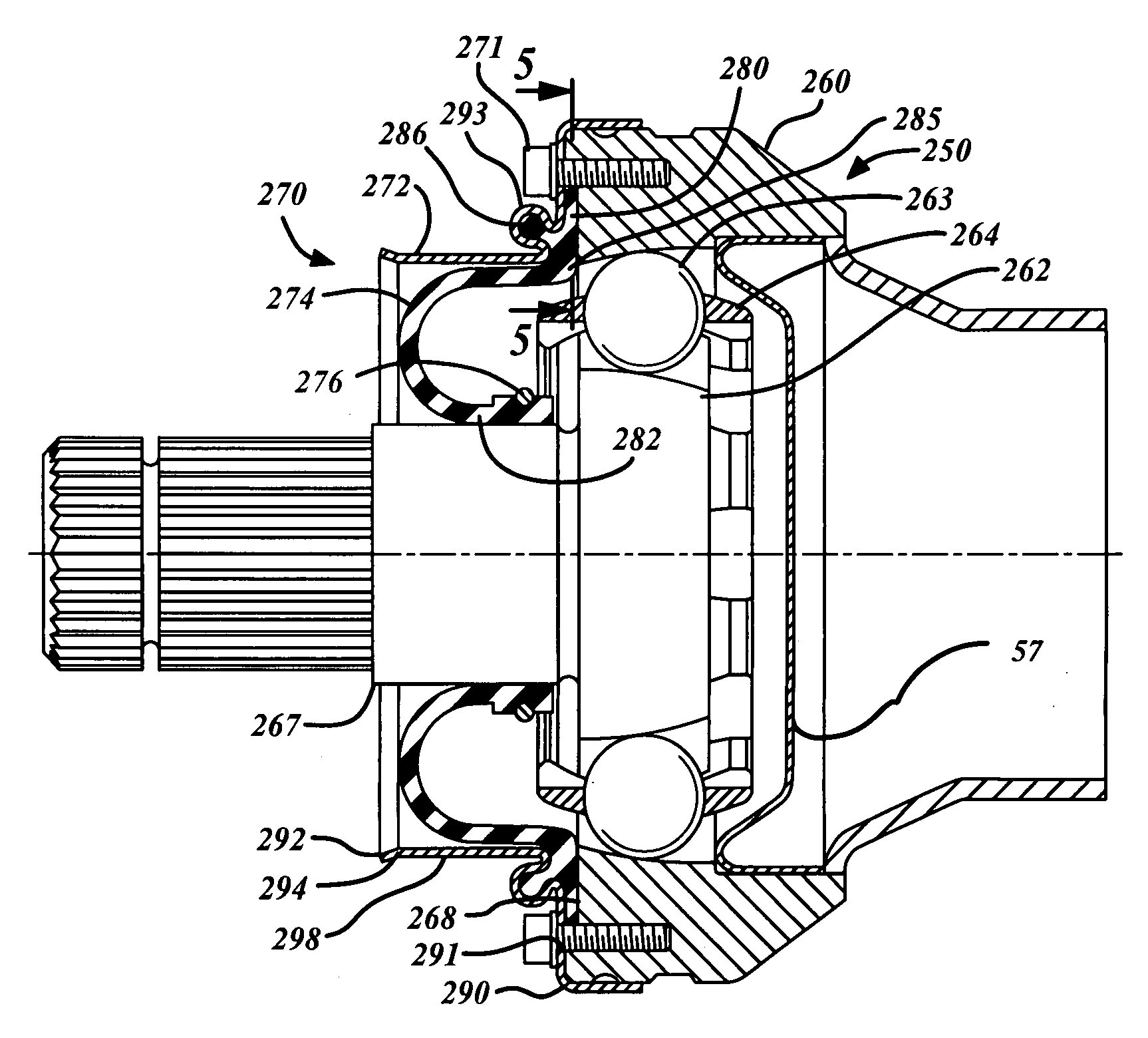

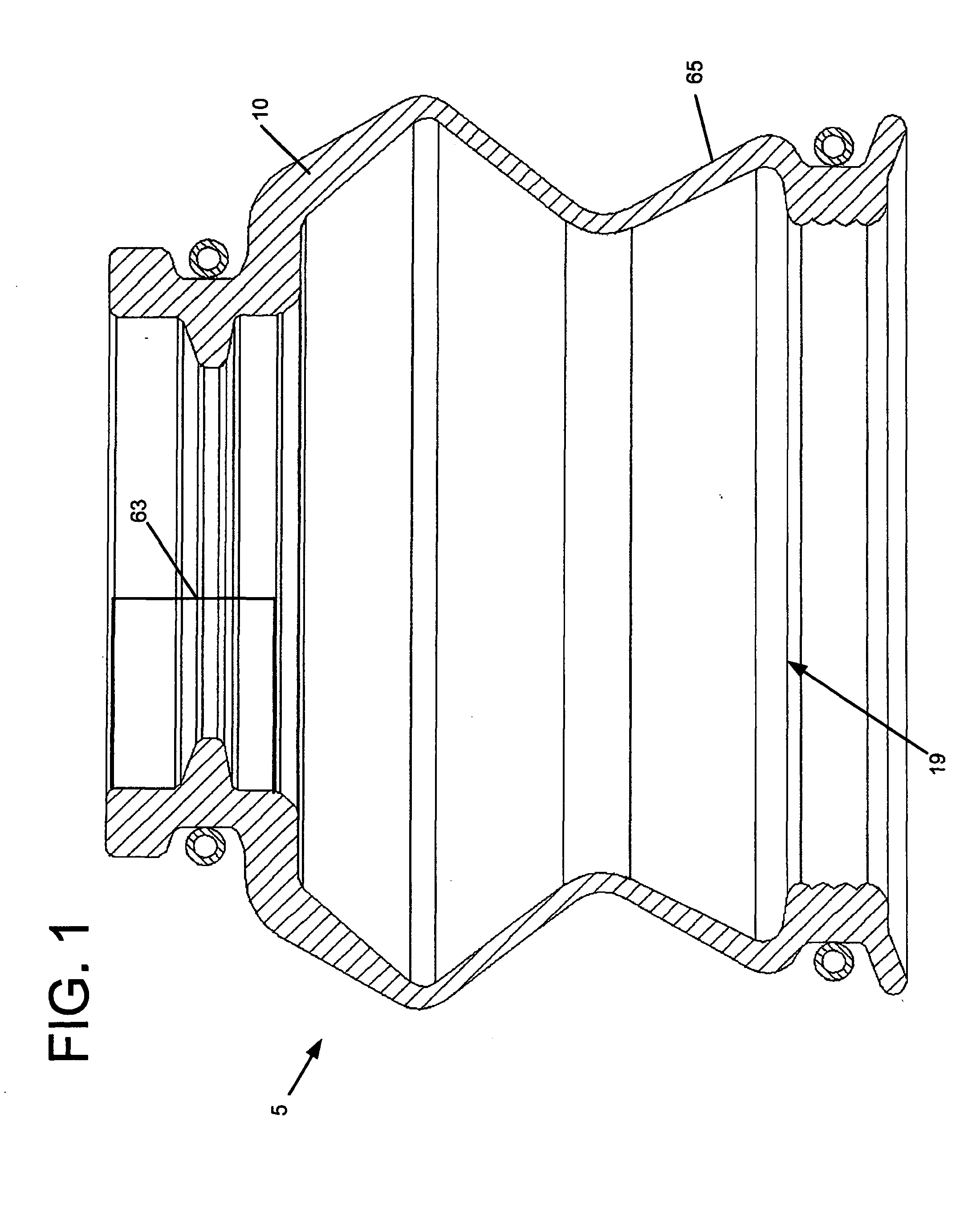

Direct torque flow constant velocity joint having a non-rotating boot

InactiveUS20070149298A1Increase flexibilityReduce gapYielding couplingRotary machine partsRotational freedomEngineering

A direct torque flow constant velocity joint connector includes an outer joint part having outer ball tracks and an outer surface, an inner joint part with inner ball tracks, a cage, a plurality of balls held in the cage and engaging the inner and outer ball tracks, and a boot. The boot includes a first end and a second end, wherein the first end is axially secured to the outer surface of the outer joint part while providing rotational freedom between the boot and the outer joint part, and the second end is selectively attachable to a supplied drive unit.

Owner:GKN DRIVELINE NORTH AMERICA

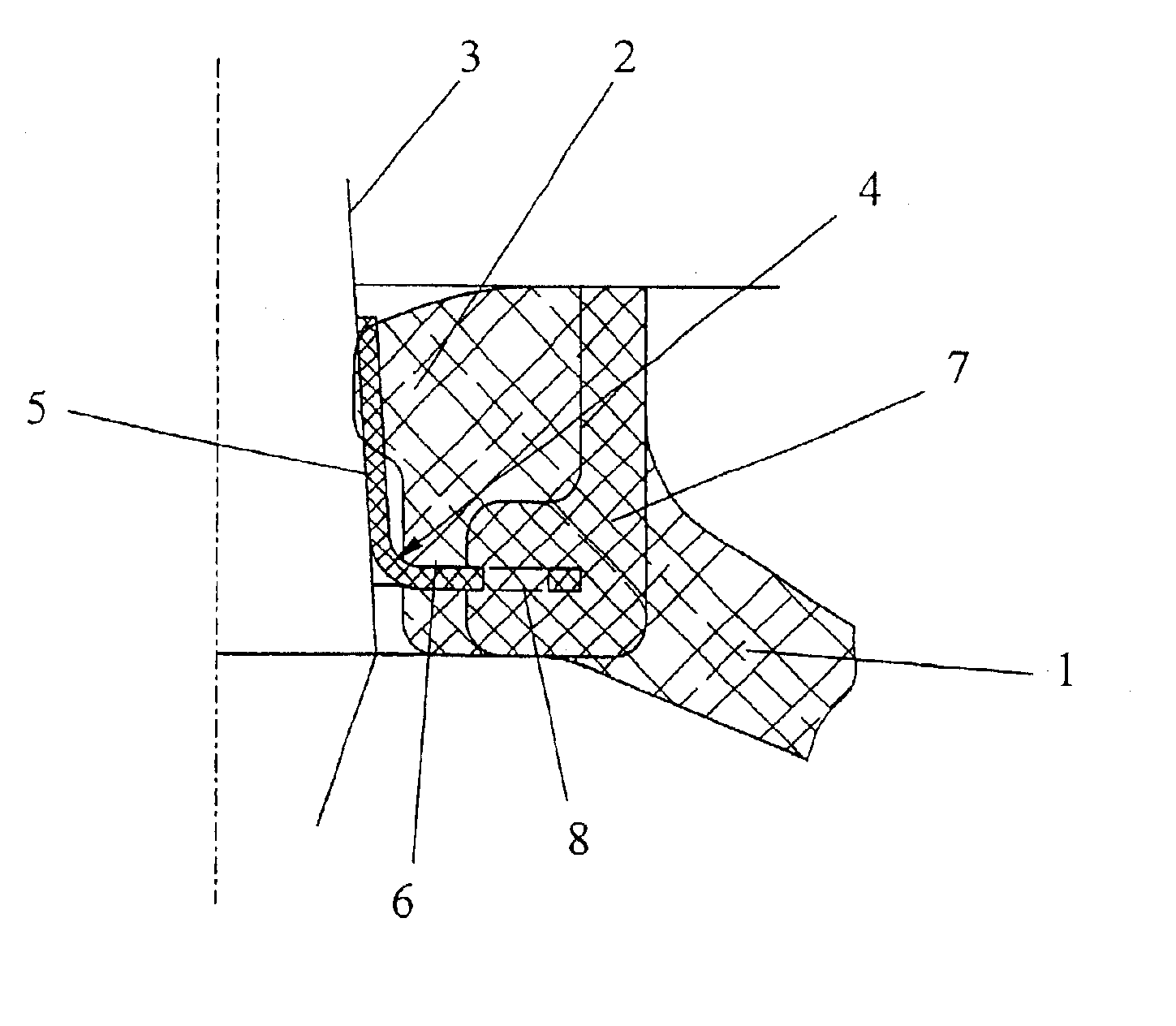

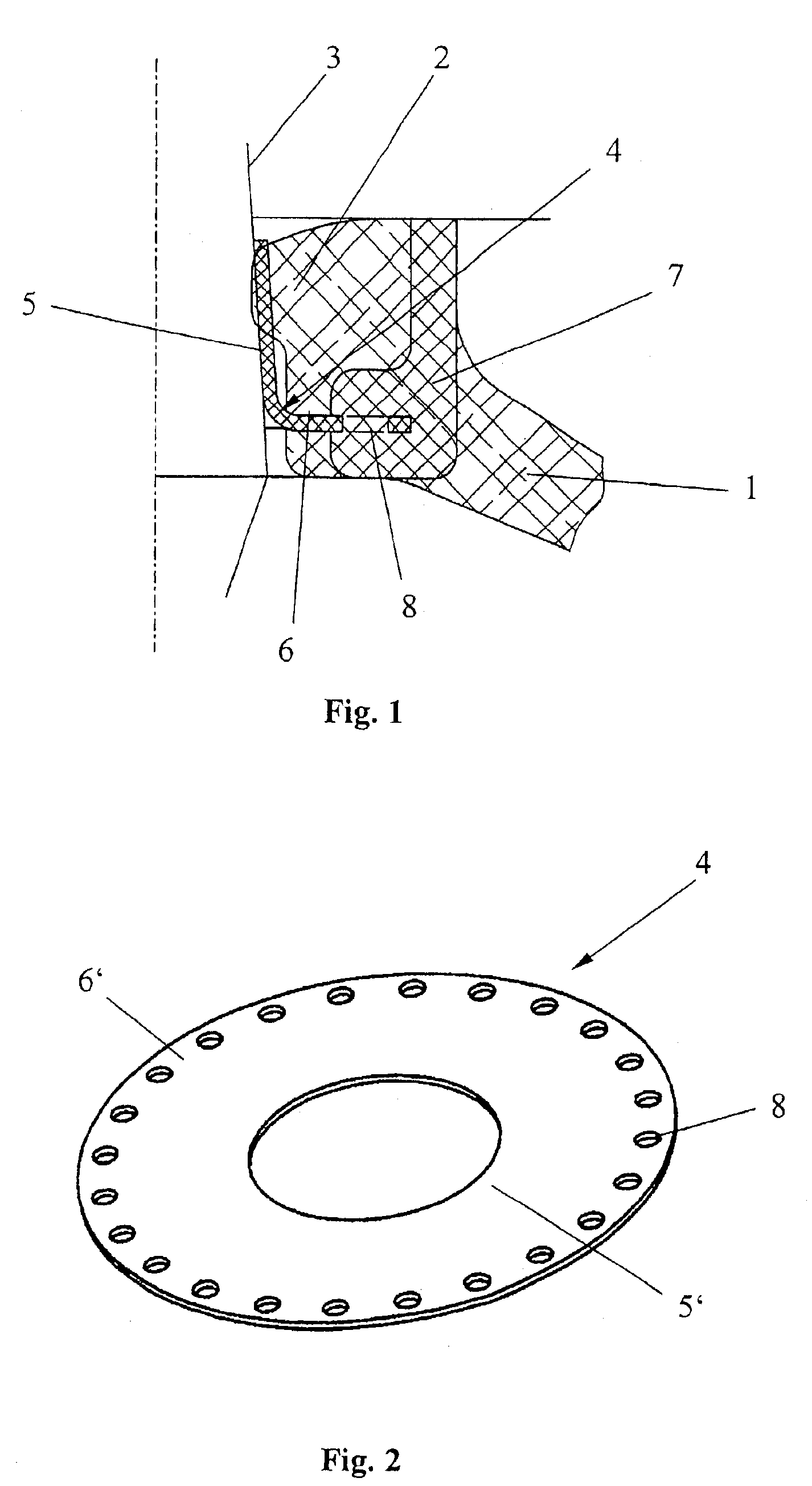

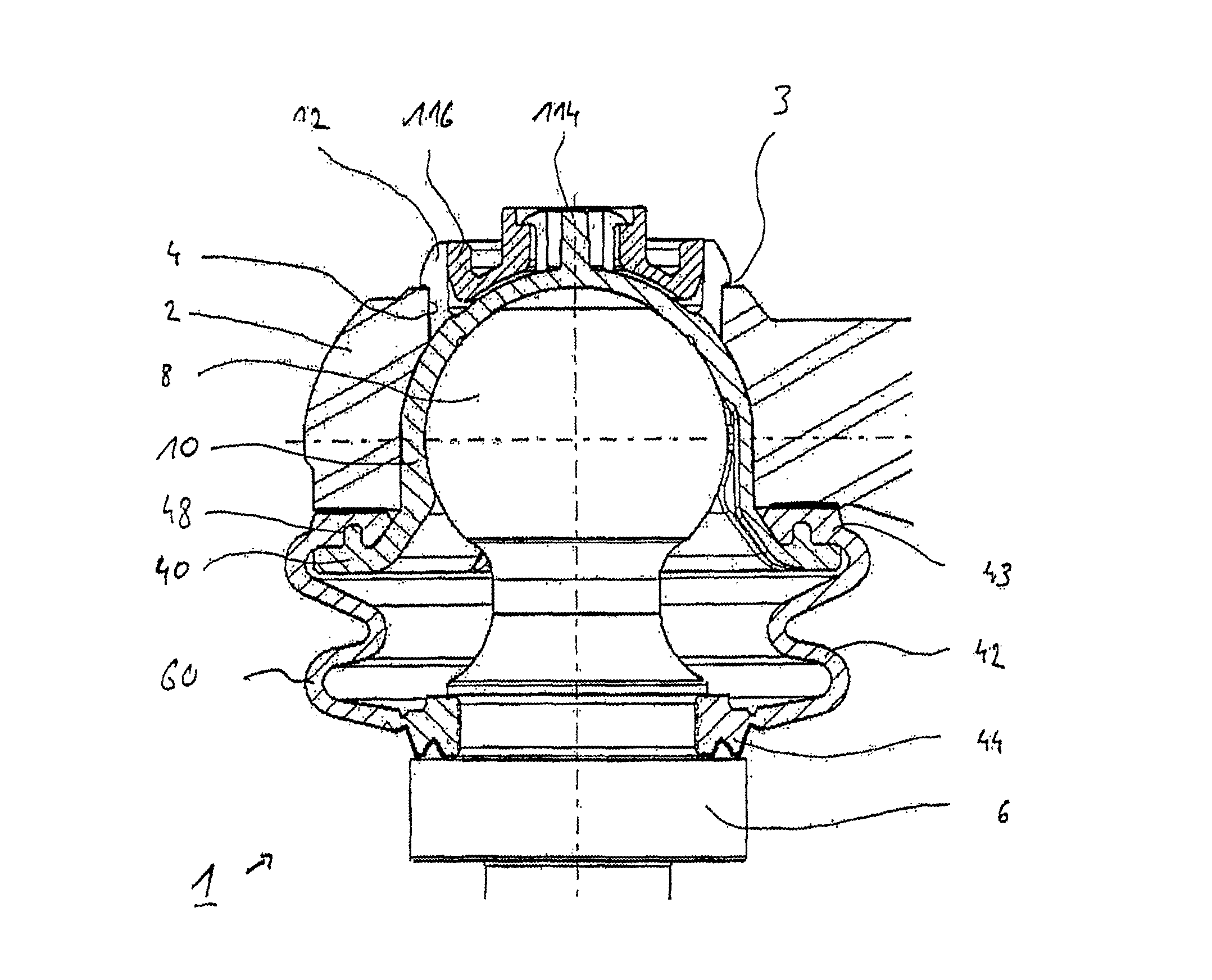

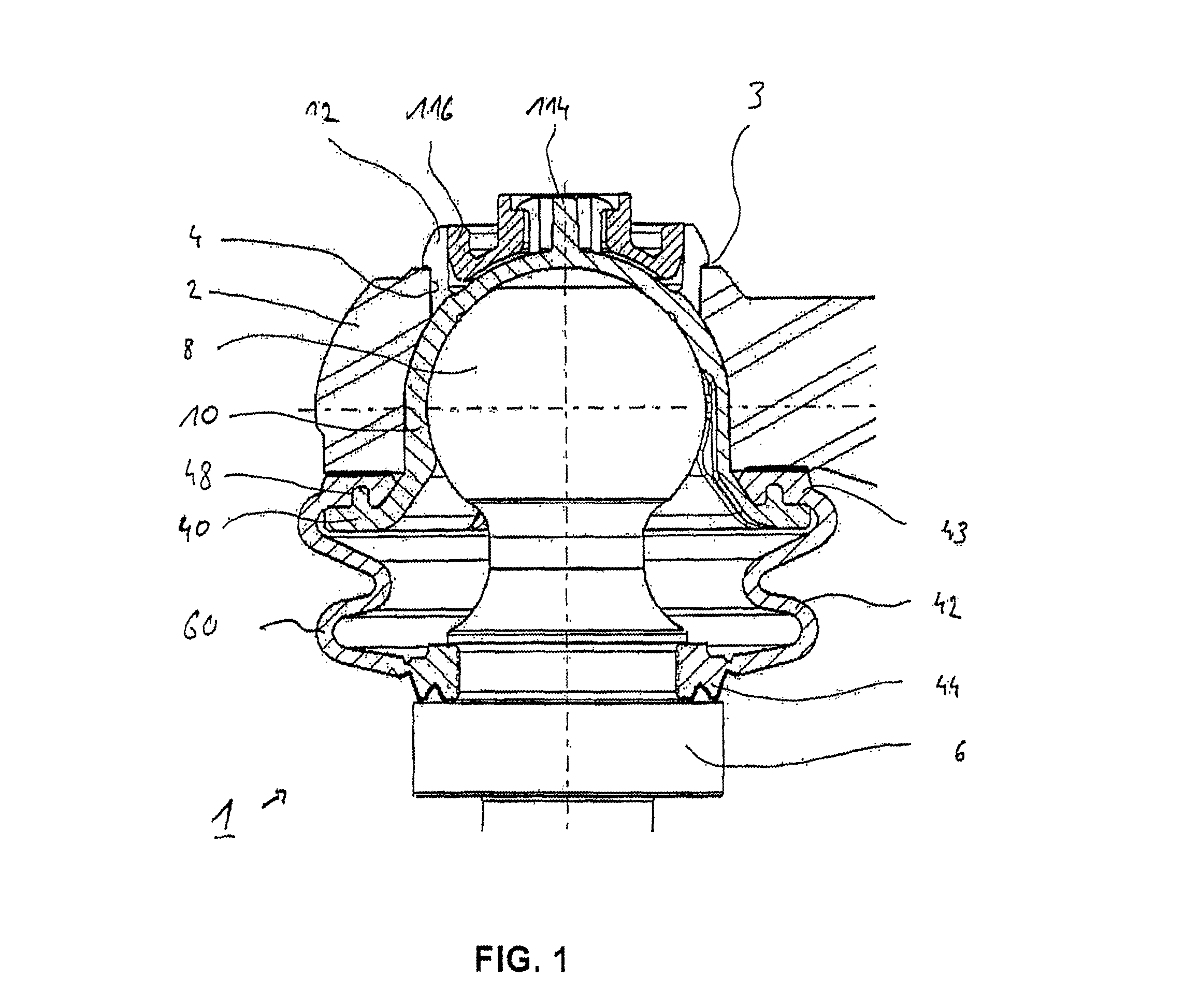

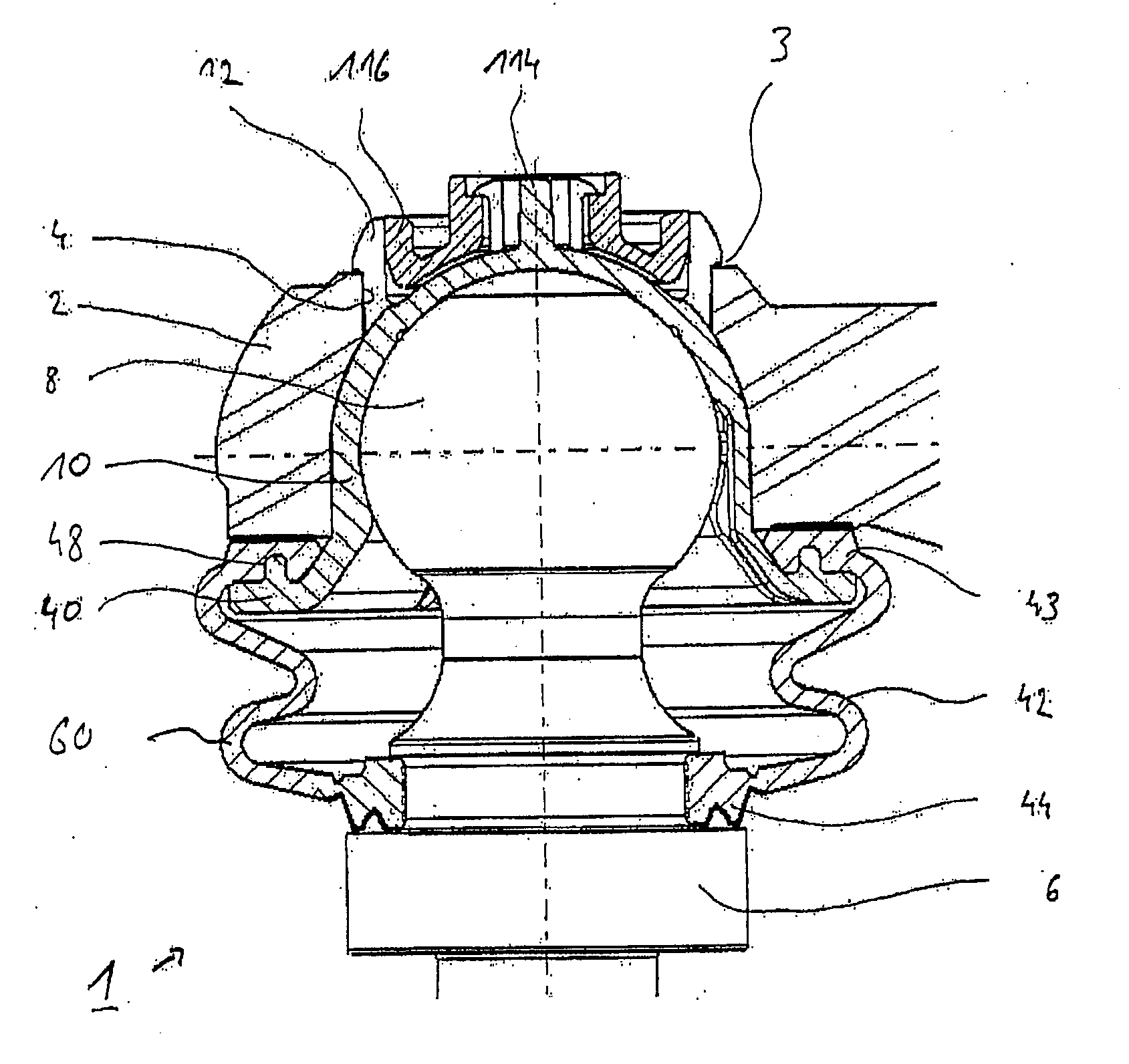

Ball- and -socket joint

InactiveUS7070355B2Add seatsUniform tension distributionEngine sealsPipeline expansion-compensationSpherical formBall and socket joint

A ball-and-socket joint has a housing, a ball pivot (3) mounted pivotably in the housing, and a sealing bellows (1), which is fastened to the housing and is mounted on the ball pivot (3) slidably via a sealing ring (4) provided with two legs (5, 6). A first leg (5) of the two legs (5, 6) is in contact with the ball pivot (3) under tension and the second leg (6) meshes with the wall of the sealing bellows (1). The second leg (6) is, furthermore, fastened in an anchoring ring (7) arranged at least partially in the wall of the sealing bellows (1).

Owner:ZF LEMFOERDER METALLWAREN AG

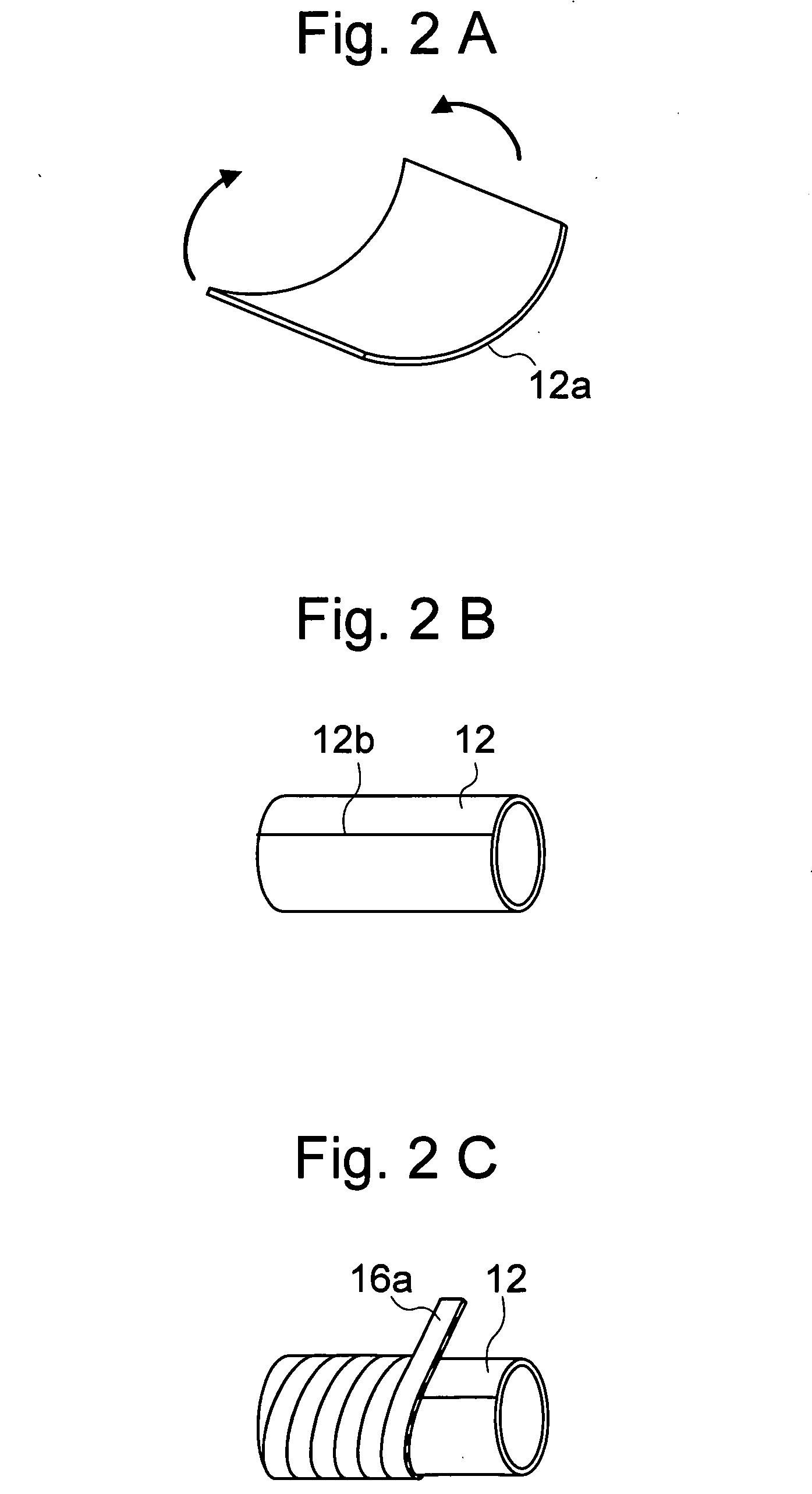

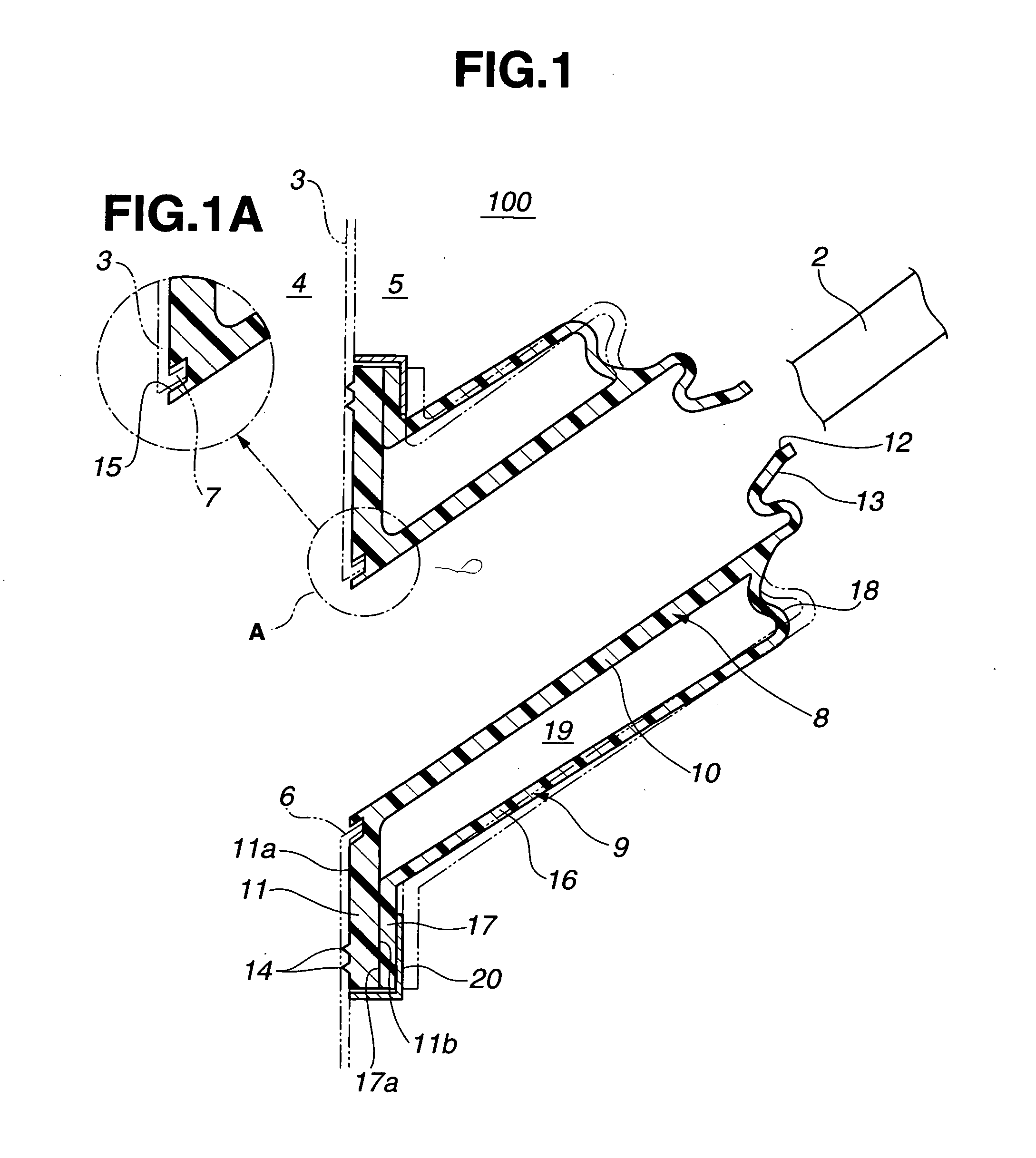

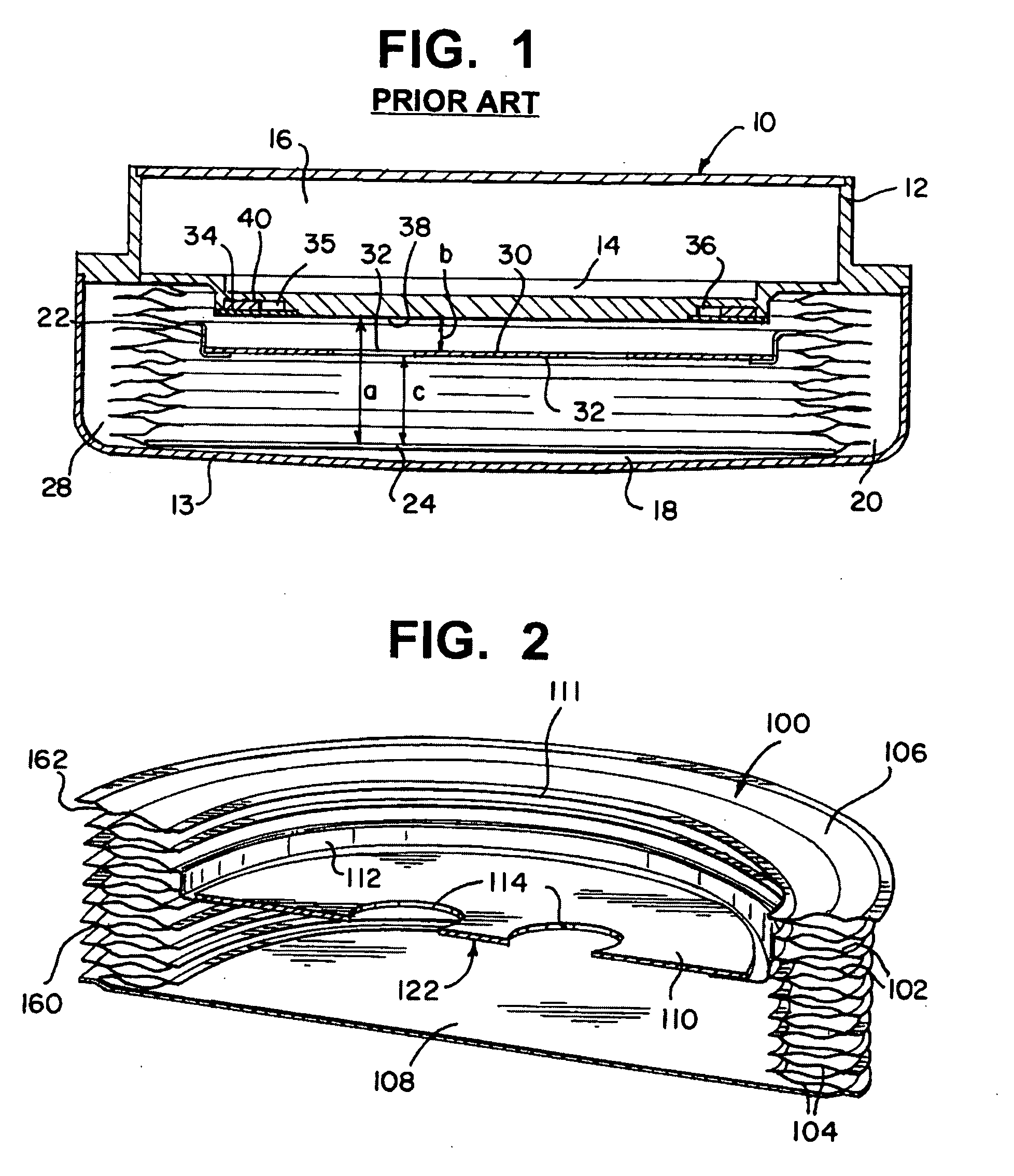

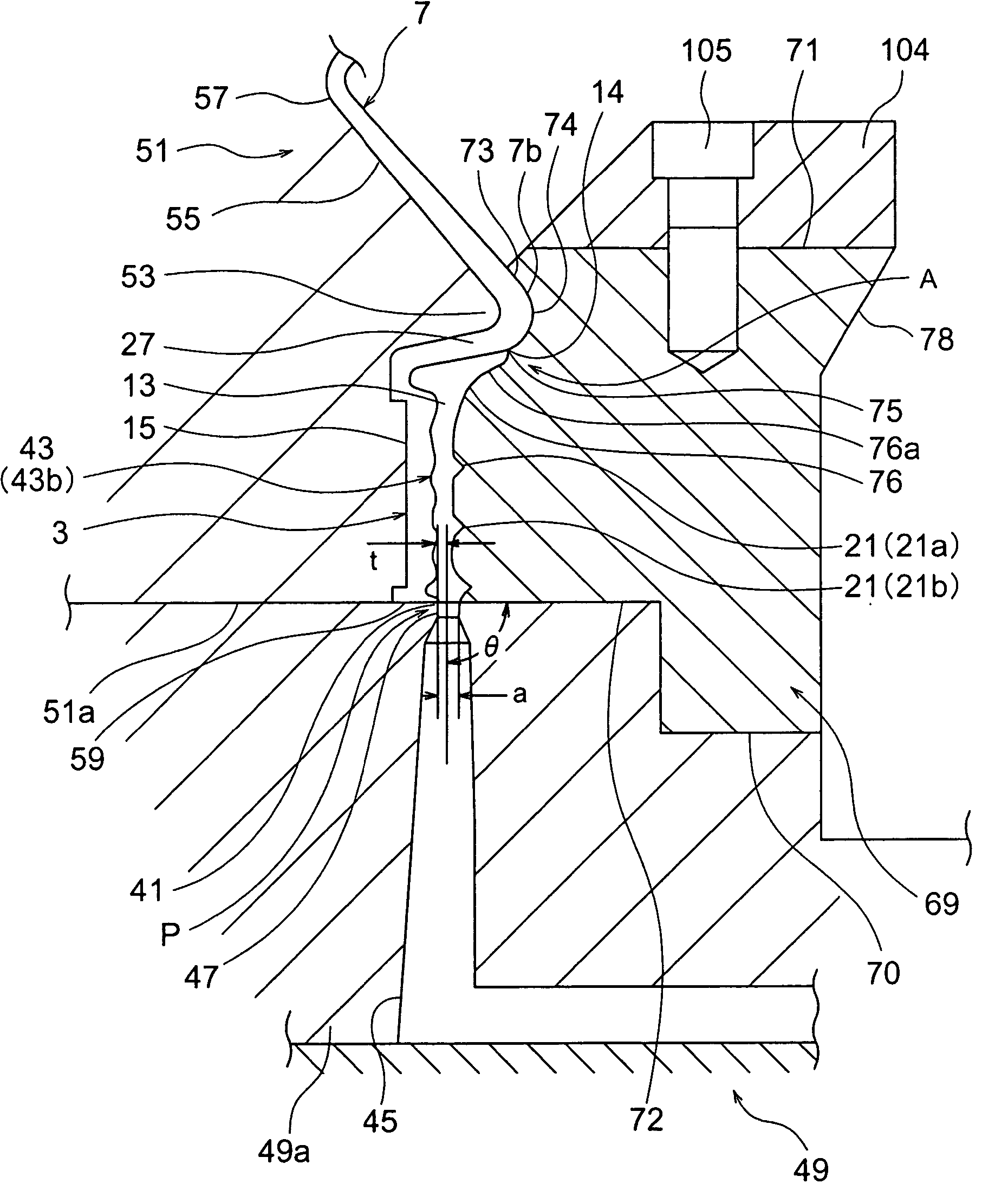

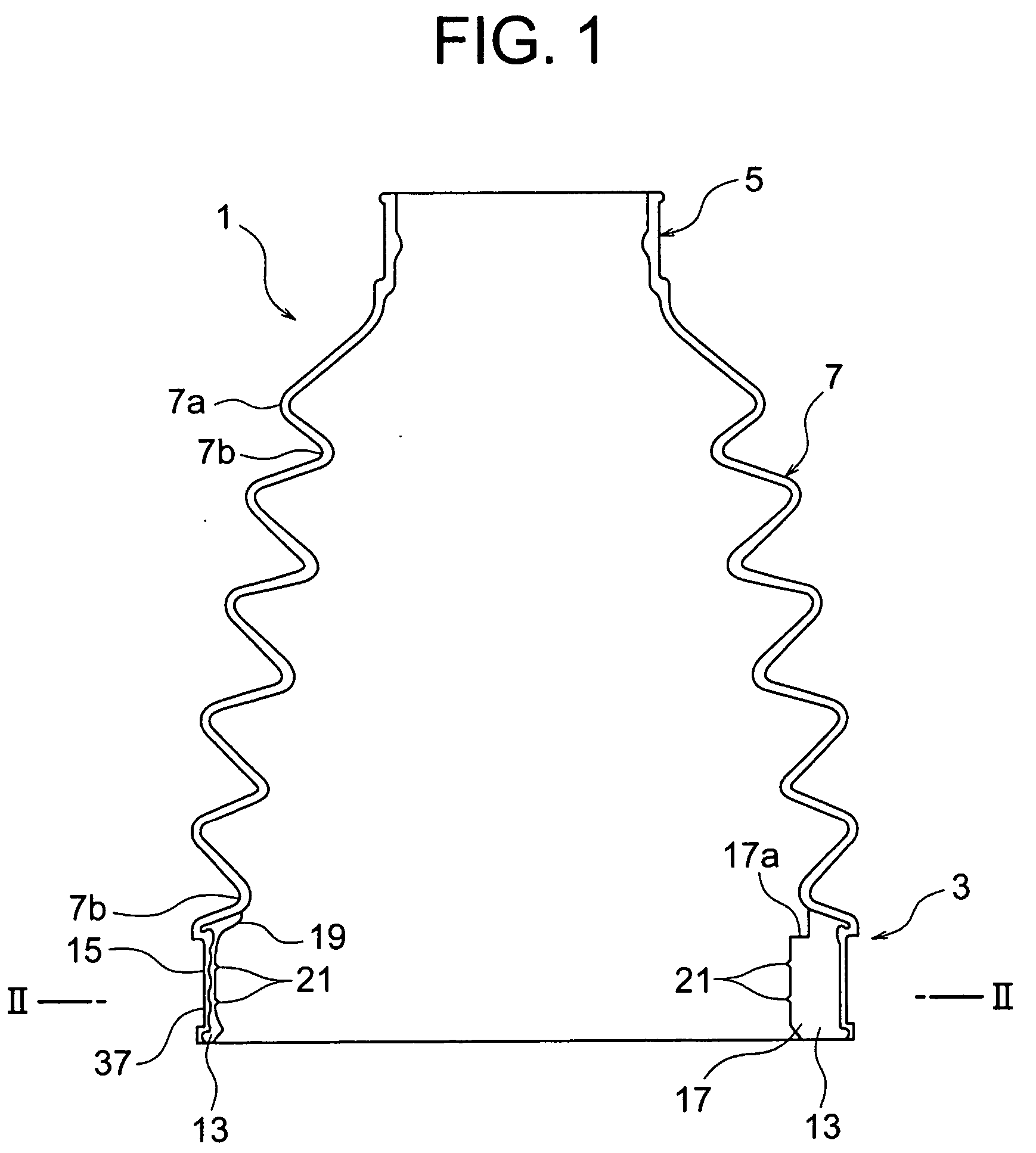

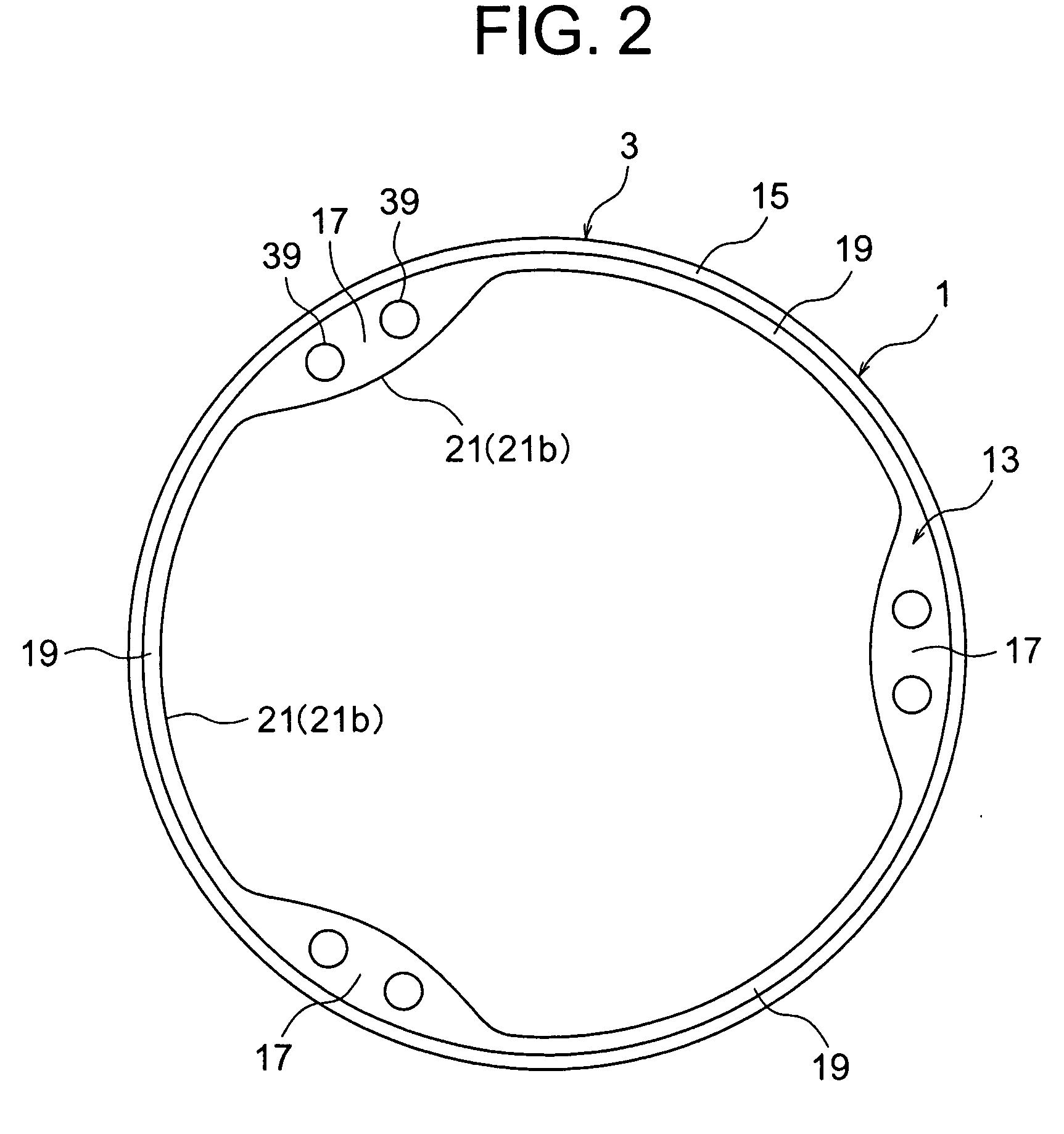

Method of manufacturing boot for constant-velocity universal joint and manufacturing apparatus for use in the method, and boot for constant velocity universal joint

InactiveUS20050046077A1Easy to pullLarge rocking angleMouldsConfectioneryUniversal jointConstant velocity

There is disclosed a boot for a constant-velocity universal joint, in which a secondary molded portion including a thick portion is formed in a large-diameter side end portion of a primary molded member, and the boot is easily pulled out of a core mold. The boot is downsized and lightened to reduce costs. A manufacturing method includes: a step of forming a secondary molding space 43 between an inner peripheral surface of a large-diameter side end portion 3 of the primary molded member and an outer peripheral surface of a core mold 69; a step of injecting a molten material into the secondary molding space to mold the secondary molded portion; and a step of integrally molding a secondary molded member on the inner peripheral surface of the large-diameter side end portion of the primary molded member to form a boot 1, moving a removable portion 83 of a second mold section 79 of the core mold 69 which abuts on at least the end portion of the thick portion in the vicinity of the bellows portion in a central axial direction of the core mold to remove the removable portion from an undercut portion 17a of a thick portion 17 just before separating the boot from the core mold, and separating the core mold 69 from the boot 1 in this state.

Owner:FUKOKU CO LTD

Boot with O-ring seal

InactiveUS6938902B2Easy constructionIncrease success rateEngine sealsYielding couplingUniversal jointFree state

A boot with O-ring seal for sealing around an article such as a universal joint housing includes a boot having a hollow body adapted to tightly receive the article. An O-ring extends lengthwise within an internal annular groove in the body. The O-ring, in its natural free state condition, has a radial dimension which is greater than the depth of the groove so that when the article is received in the body the O-ring is deformed and makes sealing contact with the article. The O-ring, in its natural free state condition, has an axial dimension which is less than the width of the groove by an amount such that when the article is received in the body and the O-ring makes sealing contact with the article, the O-ring is deformed into the space between the side walls of the groove.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

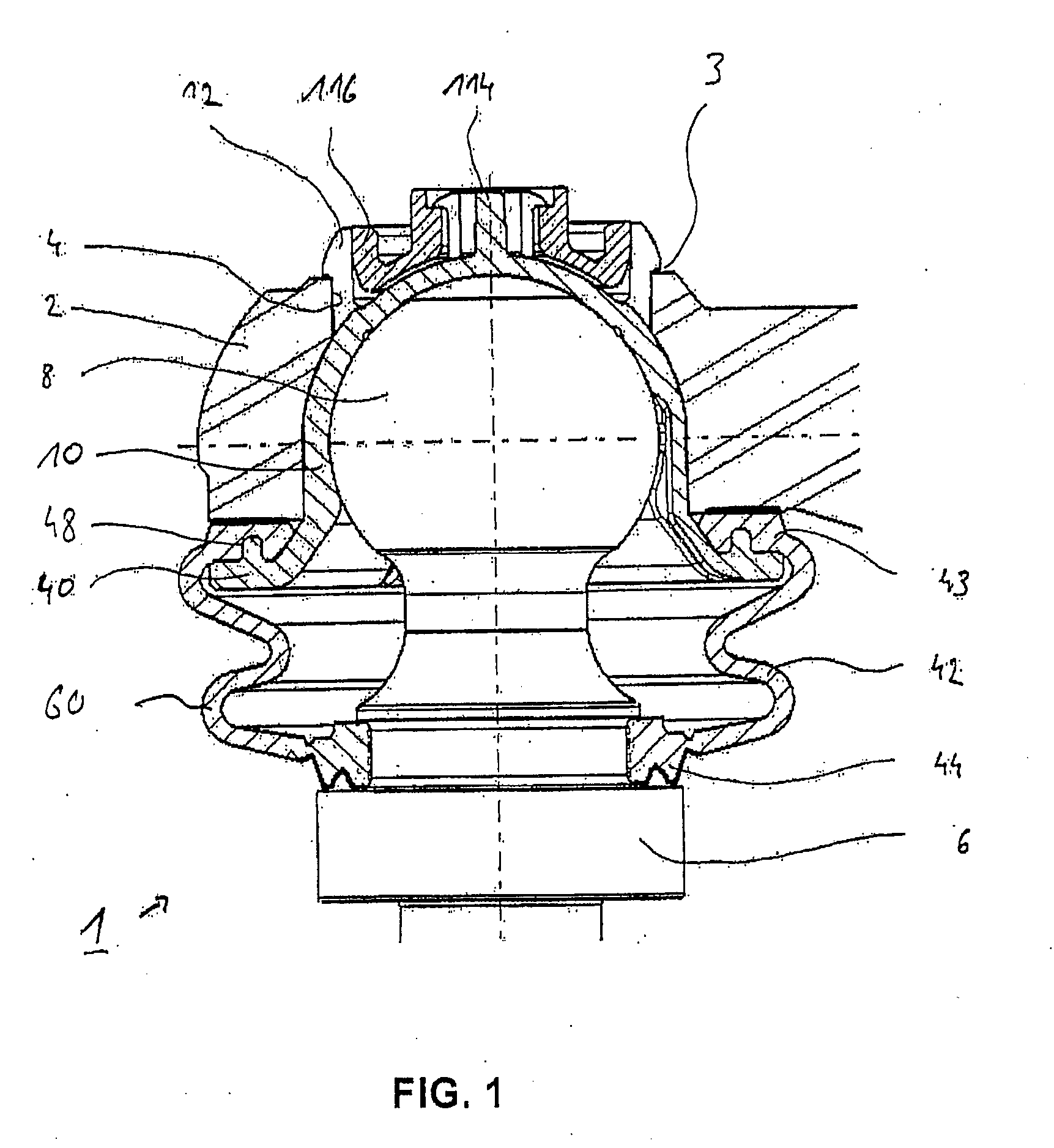

Ball joint

ActiveUS8684621B2Reduce manufacturing costHigh operating requirementsSuspensionsConnecting rodsEngineeringBall joint

A ball joint includes a joint housing having a recess, a ball stud having a ball head, a sealing bellows having a sealing seat on the housing side and a sealing seat on the stud side in the form of a bellows mouth which is adapted to be brought into contact with the ball stud, a bellows body of the sealing bellows extending between the sealing seat on the housing side and the bellows mouth, and further includes a joint socket, the ball head being accommodated for swiveling motion within the joint socket, and the joint socket being inserted in the recess of the joint housing.

Owner:THK RHYTHM AUTOMOTIVE GMBH

Joint assembly

InactiveUS20070166096A1Not affectEngine sealsPipeline expansion-compensationEngineeringMechanical engineering

A joint assembly comprising a seal provided with a first retaining surface and a second retaining surface, a ball stud provided with a ball portion and a socket, wherein the socket is provided with a seal acceptor and a ball cooperating surface, wherein the ball portion of the ball stud is within the ball cooperating surface and a portion of the seal is within the seal acceptor, and a first and a second constricting element, wherein the first constricting element is held in place by the first retaining surface on the seal and the second constricting element is held in place by the second retaining surface on the seal.

Owner:LIM CHONG KHENG +3

Ball Joint

ActiveUS20120170969A1Reduce manufacturing costOperating reliability can be highConnecting rodsPipeline expansion-compensationEngineeringBall joint

The invention relates to a ball joint, including a joint housing having a recess, a ball stud having a ball head, a sealing bellows having a sealing seat on the housing side and a sealing seat on the stud side in the form of a bellows mouth which is adapted to be brought into contact with the ball stud, a bellows body of the sealing bellows extending between the sealing seat on the housing side and the bellows mouth, and further including a joint socket, the ball head being accommodated for swiveling motion within the joint socket, and the joint socket being inserted in the recess of the joint housing.

Owner:THK RHYTHM AUTOMOTIVE GMBH

Technique for producing metal corrugated pipe

The invention discloses a production process of a metal corrugated pipe. The process comprises the steps of (1), wave plate punching and rolling press deforming; (2), shotblasting; (3), welding; (5), heat treating; (6), graphite annulus embedding (7), graphite annulus picking; (8), trimming; and (9), polishing. The process of the present invention is suitable for the metal welding corrugated pipe of single layer or multi layer wave plate, and is mainly characterized in that after the shotblasting is adopted, the wave plate produces a certain micro deforming, the fatigue lifetime is increased, and the breakage and the fracture damage of the corrugated pipe during the operation process can be reduced; simultaneously the welding process method of the invention improves the weld strength of the corrugated pipe, and reduces the oxidation of the corrugated pipe when being welded; the heat treating process method of the invention reduces the oxidation of the corrugated pipe when the heat treating is performed, and makes the elastic property be steady. The welding and the heat treating process methods of the invention reduce the elasticity losing, the breakage and fracture damage of the corrugated pipe during the operation process.

Owner:成都赛乐化新机电有限公司 +1

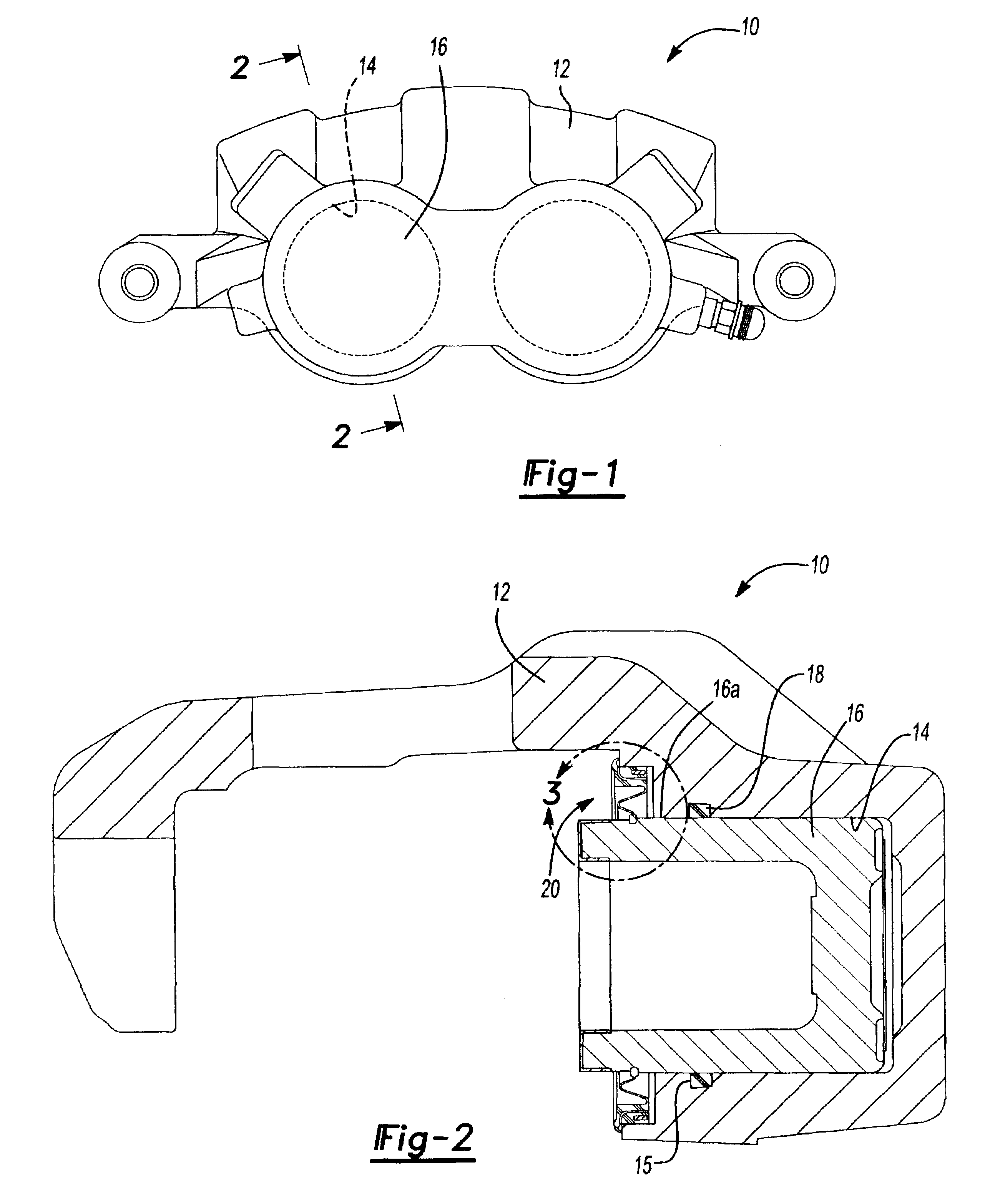

Thermal Protection for Disc Brake Components

A disc brake for a motor vehicle is provided. The disc brake includes a brake disc, a brake caliper configured to straddle the brake disc, a tappet carried by the brake caliper and arranged to push a brake pad against the brake disc, and a bellows provided between the brake caliper and the tappet to seal a gap between the brake caliper and the tappet. A layer of flexible thermal insulation material may be provided between the bellows and the tappet. The layer of flexible thermal insulation material is configured to protect an outer surface of the bellows facing the brake pad from exposure to heat. Alternatively, the bellows may include a layer of flexible thermal insulation material on which an elastomer layer is formed. The layer of flexible thermal insulation material is configured to face the brake pad.

Owner:BENDIKS SPAJSER FAUNDEJSHN BREJK LLK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com